Page 1

LPX200

Page 2

CAUTION: THIS EQUIPMENT PRODUCES

DO NOT OPERATE THIS EQUIPMENT WITHOUT

ASNT LEVEL 3 RADIOGRAPHIC CERTIFICATION

WWW.SPELLMANHV.COM

X-RAYS WHEN ENERGIZED!

FORMAL HARDWARE RAINING F ROM

SPELLMAN HIGH VOLTAGE ELECTRONICS.

IS HIGHLY RECOMMENDED.

Copyright 2000, Spellman High Voltage Electronics Corporation. All Rights Reserved.

This information contained in this publication is derived in part from proprietary and patent data. This information has

been prepared for the express purpose of assisting operating and maintenance personnel in the efficient use of the

model described herein, and publication of this information does not convey any right to reproduce it or to use it for

any purpose other than in connection with installation, operation, and maintenance of the equipment described.

118176-001 REV. A

Page 3

COPYRIGHT NOTICE

Spellman Valhalla 1 Commerce Park Valhalla, NY 10595

Phone: +1 914 686-3600 Fax: +1 914 686-5424

www.spellmanhv.com

This document is copyrighted by LORAD.

No part of this document may be reproduced, transmitted,

or copied without the express written permission of:

LPX-200

Industrial Imaging System

LPX-200 Industrial Imaging System

Copyright© 2002 by LORAD All rights reserved.

Operator’s Manual

Part Number 9-500-0200, Revision 2

Table of Contents

Copyright Notice

i

Page 4

LPX-200

Industrial Imaging System

This Page Is Intentionally Blank

ii

Table of Contents

Page 5

Chapter

1

LPX-200

Industrial Imaging System

Contents

INTRODUCTION & GENERAL INFORMATION

INTRODUCTION ..................................................................1-1

Intended Use......................................................................... 1-1

SYSTEM OVERVIEW ..........................................................1-1

The Control Unit................................................................... 1-2

The Tubehead ....................................................................... 1-2

The Cooling Unit

(liquid-cooled units only) ..................................................... 1-2

Legend - LPX-200 X-ray System ..........................................1-3

MANUAL OUTLINE.............................................................1-4

Chapter 1:

Introduction & General Information....................................1-4

Chapter 2:

Preparation For Use and Shipment ......................................1-4

Chapter 3:

Installing the LPX-200 ......................................................... 1-4

Chapter 4:

LPX-200 X-ray Controls & Indicators .................................1-4

Chapter 5:

LPX-200 X-ray System Operation........................................1-4

Section 6:

Routine Upkeep and Care .................................................... 1-4

SAFETY SUMMARY ............................................................1-5

Radiation Hazard .................................................................1-6

Lethal Voltages ..................................................................... 1-6

Badges .................................................................................. 1-6

Radiation Protection ............................................................ 1-6

Radiation Monitoring...........................................................1-6

Warm-Up Procedures ...........................................................1-6

Operation ............................................................................. 1-6

Cooling Unit Operation ....................................................... 1-6

Care in Handling.................................................................. 1-6

Table of Contents

iii

Page 6

LPX-200

Industrial Imaging System

PREPARATION FOR USE & SHIPMENT

UNP ACKING INSTRUCTIONS...........................................2-1

Reshipment Guidelines .........................................................2-1

Transporting the Unit ........................................................... 2-2

EQUIPMENT CHECKLISTS...............................................2-3

Checklist - Tubehead ............................................................ 2-3

Checklist - Standard Equipment........................................... 2-3

Checklist - Optional Equipment ........................................... 2-3

WARNINGS LABELS &

CONTROL NUMBERS .........................................................2-4

SPECIFICATIONS.................................................................2-5

Specifications - General System ...........................................2-5

Specifications - General Tubehead.......................................2-6

Specifications - Optional Tubehead .....................................2-6

Specifications - Control Unit................................................ 2-7

Specifications - Cooling Unit ............................................... 2-7

INSTALLING THE LPX-200 X-RAY SYSTEM

Chapter

2

Chapter

PRE-OPERATIONAL

CHECKS & INSPECTION ...................................................3-1

Check - Tubehead Gas Pressure........................................... 3-1

Check - Cooling Unit............................................................ 3-1

Check - Control Unit ............................................................3-1

SYSTEM SET UP PROCEDURES.......................................3-2

System Interconnections - Liquid Cooled.............................3-2

System Interconnections - Air Cooled ..................................3-3

Connecting to Power ............................................................ 3-4

EXTERNAL

INTERLOCK CONNECTIONS ...........................................3-4

iv

Table of Contents

3

Page 7

LPX-200

Industrial Imaging System

Chapter

4

LPX-200 X-RAY CONTROLS & INDICATORS

INTRODUCTION ..................................................................4-1

Overview - Control Unit.......................................................4-1

Legend - LPX-200 Control Unit ...........................................4-1

THE LIQUID

CRYSTAL DISPLA Y SCREENS ..........................................4-2

The Message / Mode LCD Display Screen........................... 4-3

FRONT PANEL

CONTROLS AND INDICAT ORS ........................................4-4

The MAINS Switch................................................................4-4

The MAINS ON Indicator.....................................................4-4

The SAFETY Switch..............................................................4-4

The kV SET Controls ............................................................ 4-4

The mA SET Controls ...........................................................4-4

The EXPOSURE SET Controls ............................................4-5

The UNITS Control...............................................................4-5

The TIME Control ................................................................4-5

The RESET Control ..............................................................4-5

The SCROLL Contr ol ........................................................... 4-6

The X-RAY ON Control ........................................................4-6

The X-RAY Indicator ............................................................ 4-6

The X-RAY OFF Control ...................................................... 4-6

Chapter

5

LPX-200 SYSTEM OPERATION

INTRODUCTION ..................................................................5-1

Pre-Operational Safety Precautions ....................................5-1

X-RA Y TUBE WARM UP ......................................................5-2

Autowarm Sequence : > 30 Days.........................................5-2

Autowarm Sequence : 7 - 30 Days ....................................... 5-3

Autowarm Sequence : 16 Hrs. - 7 Days ............................... 5-3

Autowarm Sequence : 8 Hrs. - 16 Hrs..................................5-4

Autowarm Sequence : 4 Hrs. - 8 Hrs....................................5-4

OPERATION -

LPX-200 X-RAY SYSTEM ....................................................5-5

Sequence of Operation ......................................................... 5-5

LPX-200 FAULT MESSAGES...............................................5-7

X-RA Y TUBE SEASONING .................................................5-8

Table of Contents

v

Page 8

LPX-200

Industrial Imaging System

LPX-200 ROUTINE UPKEEP & CARE

INTRODUCTION ..................................................................6-1

INSPECTION CHECKLISTS ..............................................6-1

Tubehead Checklist ..............................................................6-1

Control Unit Chec klist.......................................................... 6-2

Cooling Unit Checklist ......................................................... 6-2

Interconnecting Cables & Hose Checklist ...........................6-2

CLEANING THE

LPX-200 X-RAY UNIT ..........................................................6-3

Required Cleaning Materials ...............................................6-3

Cleaning the X-Ray Unit ...................................................... 6-3

TUBEHEAD MAINTENANCE ............................................6-4

Temperature Compensation.................................................. 6-4

Re-Pressurizing the Tubehead ..............................................6-5

Re-Filling the Tubehead .......................................................6-6

Cleaning - Control Unit Air Filter........................................6-6

COOLING UNIT UPKEEP...................................................6-7

Mixing & Adding Coolant Solution......................................6-7

Cleaning - Cooling Unit Air Filter.......................................6-7

Cleaning - Coolant Filter ..................................................... 6-8

Chapter

6

vi

Table of Contents

Page 9

Chapter 1:

Introduction and General Information

INTRODUCTION

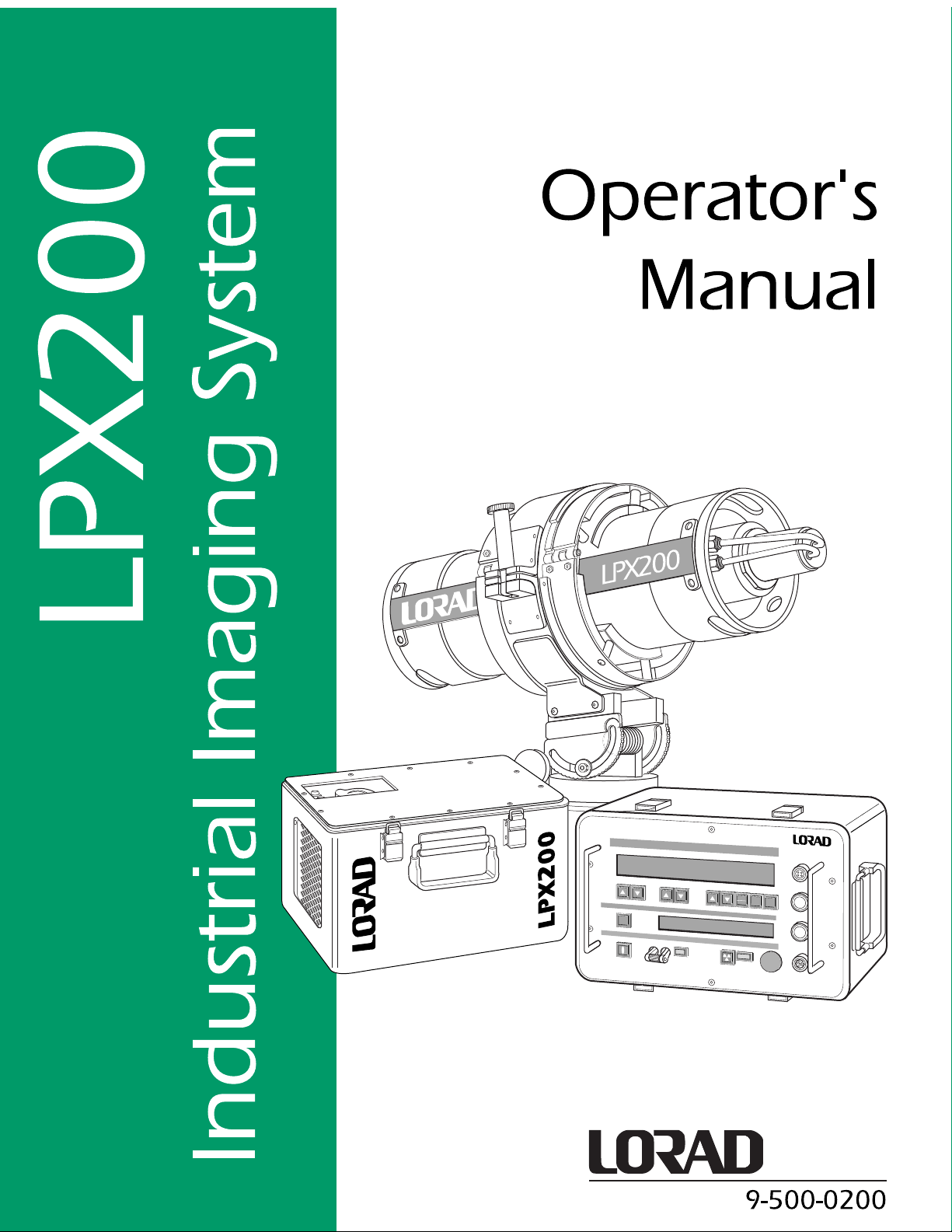

This manual describes the LORAD LPX-200 Portable

Industrial X-ray Unit and explains the procedures to properly

set up, inspect, operate, and maintain this system.

Intended Use

The LPX-200 is designed to meet the needs of the commercial

NDT user. The system is intended for, but not limited to, the

inspection of materials for:

LPX-200

Industrial Imaging System

◆ defects

◆ inclusions

◆ cracks

◆ corrosion

◆ porosity

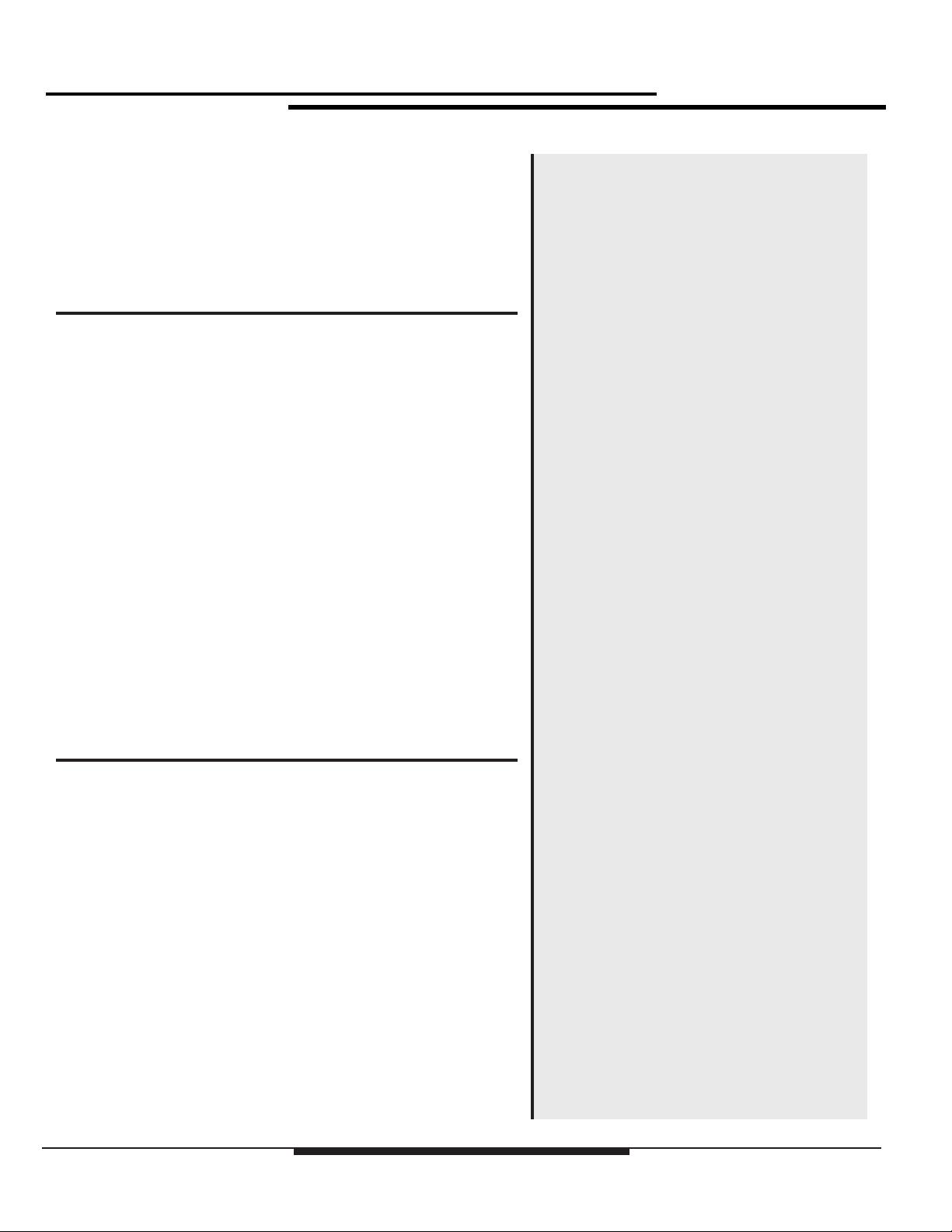

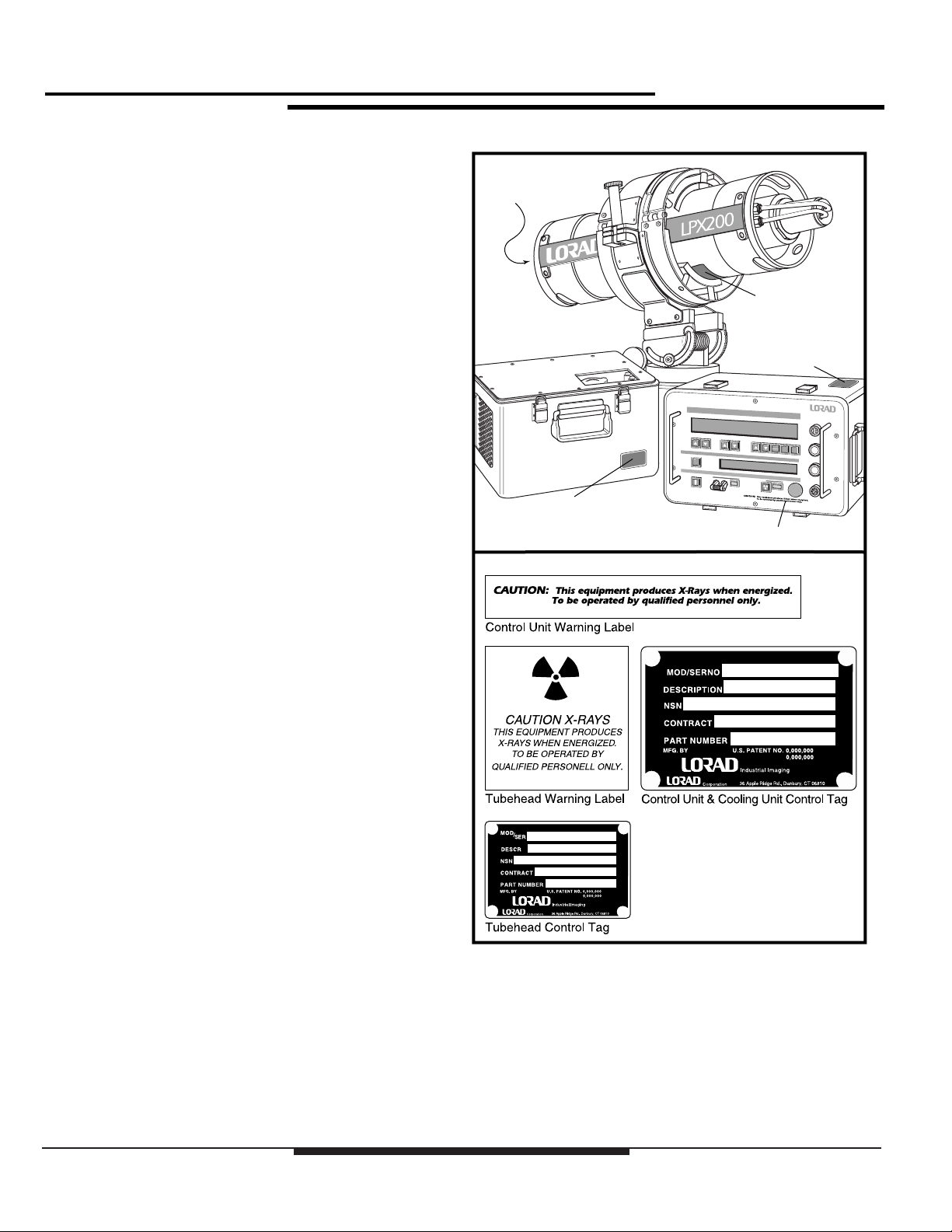

SYSTEM OVERVIEW

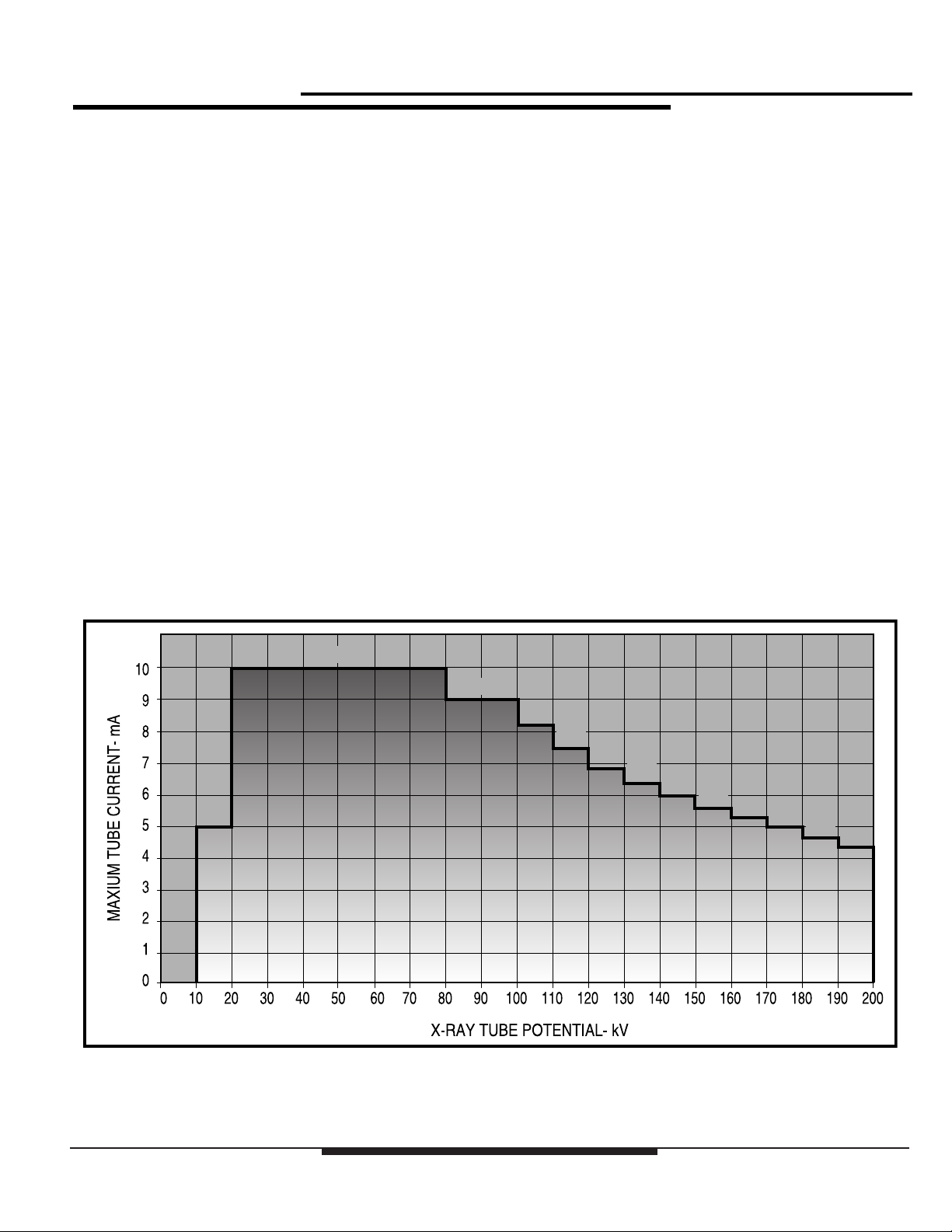

The LPX-200 can generate x-ray potential up to 200 kilovolts

(kV) and tube current up to 10 milliamperes (mA). The

maximum allowable dissipation is 900 watts. Maximum tube

current is limited automatically by the Control Unit to 10mA,

or to a value that does not cause dissipation greater than 900

watts at a set kV level.

The system offers a 100% duty cycle and consists of the

following assemblies:

◆ the Control Unit

◆ the Tube Head

◆ the Cooling Unit, (liquid cooled units only)

◆ the Electric Cooling Fan (air cooled units only)

Figure 1-1:

The LPX-200 X-ray System

These assemblies are described in detail next.

Chapter 1: Introduction & General Inf ormation

1-1

Page 10

LPX-200

Industrial Imaging System

The Control Unit

The radiographer uses the Control Unit to set the radiographic

exposure parameters, and to activate/deactivate x-ray

emissions from the Tubehead. One hundred feet of cable is

supplied with the system, which enables the Control Unit an

operator to maintain a safe distance from the x-ray Tubehead

during use.

The digital-based, microprocessor-regulated Control Unit

houses all the system pushbutton operating controls, an

exposure factor LCD Screen (for display of exposure factors),

a Message LCD Screen (for display of operating mode and

system messages), and the circuitry required to provide power

to the Tubehead and Cooling Unit.

The Control Unit is enclosed in a metal container with a

removable cover. A collapsible handle is attached to the cover

to provide a means of transporting the Control Unit.

The T ubehead

The Tubehead is a cylindrical aluminum shell assembly

housing the x-ray tube, the high voltage power supply, and the

filament supply. It is insulated with sulfur hexafluoride gas,

pressurized to 50 psi @70°F. Power to operate the x-ray tube

is supplied through a shielded cable that connects the

Tubehead to the Control Unit. The x-ray tube is end

grounded, with an exposed anode which contains a beryllium

window approximately 2 inches from the anode end. Built in

carrying handles are at each end of the Tubehead.

The Cooling Unit

(liquid-cooled units only)

The Cooling Unit dissipates heat generated at the anode of the

x-ray tube. Liquid coolant from a self-contained reservoir is

pumped through one side of a twin hose assembly, into the

Tubehead. In the Tubehead, coolant flows through a cooling

manifold, into the anode, and then back to the Cooling Unit

through the second half of the twin hose assembly.

Once in the Cooling Unit, coolant passes through a flow

switch that is electrically interlocked with the Control Unit,

and then through a filter to screen out contaminants. From the

filter, coolant flows through a forced air radiator, where

conducted heat is dissipated, and then back into the reservoir.

An electric motor-driven fan and pump assembly circulates

coolant and creates airflow through the radiator. Power is

supplied via an interconnecting cable from the Control Unit.

When properly connected to the system, the Cooling Unit is

automatically activated by a switching circuit within the

Control Unit.

There are two Tubehead models available:

◆ Liquid-cooled

◆ Air-cooled

The liquid-cooled Tubehead uses a separate Cooling Unit to

dissipate anode heat. These models have a length of twin hose

attaching the Tubehead to the Cooling Unit. Air-cooled

models have an electric cooling fan mounted at the anode end

of the Tubehead. The fan is powered by an interconnecting

cable from the Control Unit.

1-2

Chapter 1: Introduction & General Inf ormation

Page 11

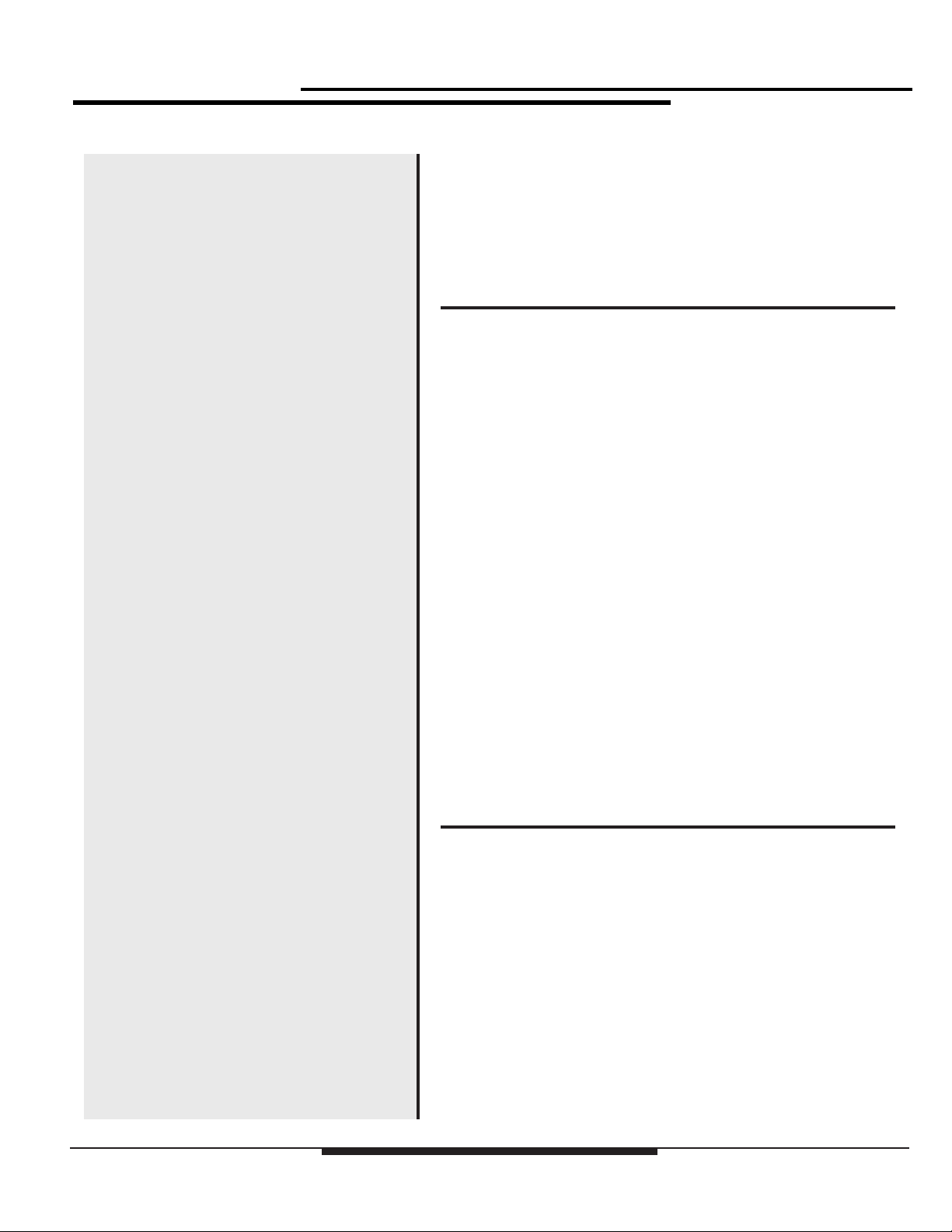

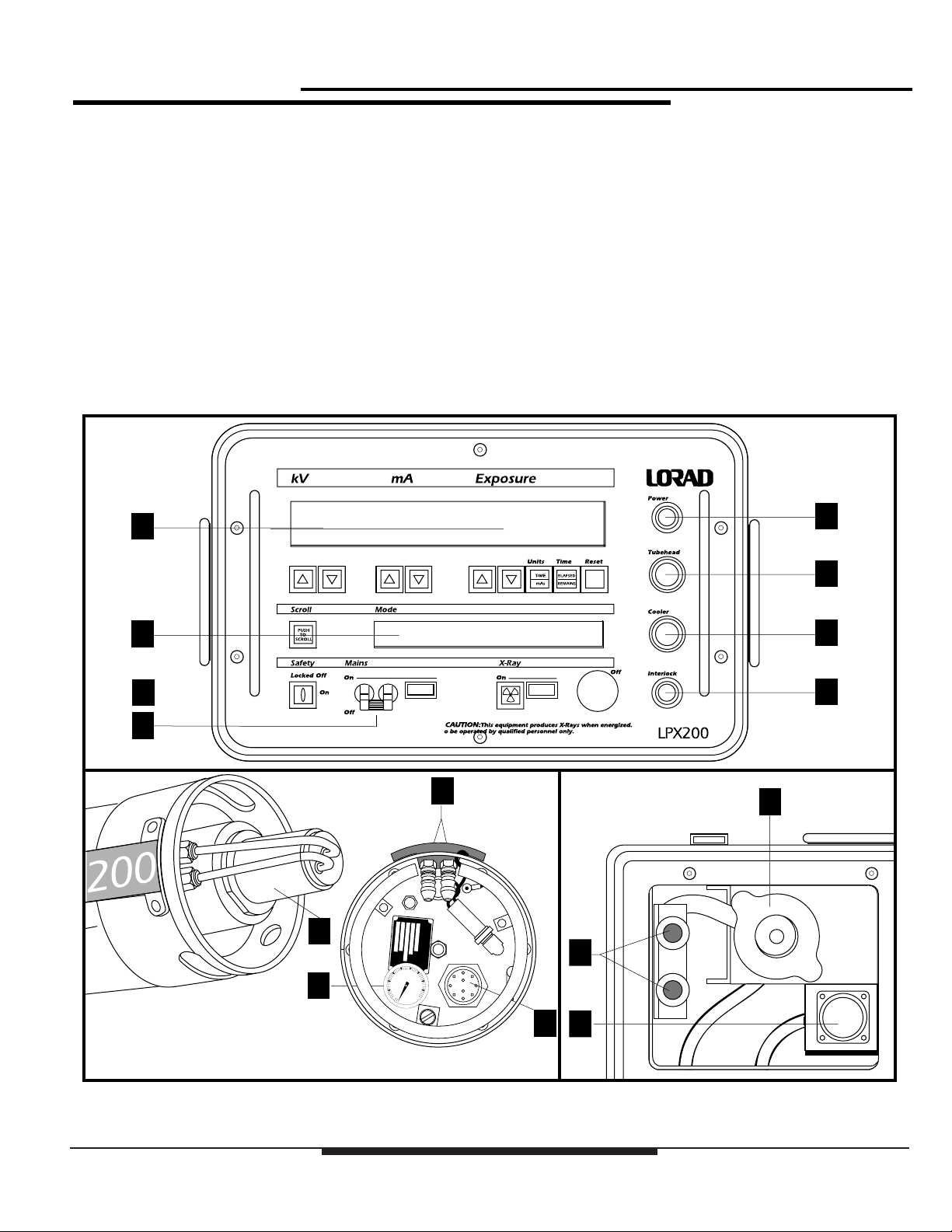

Legend - LPX-200 X-ray System

Use the following legend as a reference for parts

idnetification.

LPX-200

Industrial Imaging System

1. Exposure Technique LCD Display

2. Message LCD Display

3. Power Connector

4. Tubehead Connector

5. Cooler Connector

6. Interlock Connector

7. Mains On/Off Switch

CONTROL

UNIT

1

2

8

8. Lockout Keyswitch

9. Tubehead Anode

10. Tubehead Coolant Hose Fittings

11. Tubehead Gas Pressure Gauge

12. Tubehead Cable Connector

13. Cooling Unit Reservoir Cap

14. Cooling Unit Coolant Hose Fittings

15. Cooling Unit Cable Connector

3

4

5

6

7

TUBEHEAD

ASSEMBLY

10

9

11

Chapter 1: Introduction & General Inf ormation

COOLING

14

12

15

UNIT

13

Figure 1-2:

Legend - LPX-200

1-3

Page 12

LPX-200

Industrial Imaging System

MANUAL OUTLINE

This manual provides qualified radiographers and technicians

with a means to logically inspect, operate, and maintain the

LORAD LPX-200 Portable X-ray Unit. The following

paragraphs describe the arrangement of this manual and the

information contained in each section.

Chapter 1:

Introduction & General Information

This section provides general information about the LPX-200.

Included in this section is a safety summary.

Chapter 2:

Preparation For Use and Shipment

In this chapter, the user is provided instructions for unpacking

and reshipment, along with equipment checklists, and the

basic specifications of for assembly. Also included in

Chapter 2 are the locations of warning labels and I.D. tags.

Chapter 4:

LPX-200 X-ray Controls & Indicators

Chapter 4 details the controls and indicators on the LPX-200

Control Unit. Refer to this chapter during use for operational

details.

Chapter 5:

LPX-200 X-ray System Operation

The warm up and operating instructions for the LPX-200

X-ray Unit are detailed in Chapter 5. Included are

descriptions of error messages.

Section 6:

Routine Upkeep and Care

This chapter covers preventive maintenance and care

schedules for each assembly of the system. Included are

procedures for pressurizing and refilling the Tubehead,

cleaning the apparatus, and various general care practices.

Chapter 3:

Installing the LPX-200

This chapter provides instructions on making the

interconnections for both liquid cooled and air cooled units.

Also includes is a description of possible external interlock

connections.

1-4

Chapter 1: Introduction & General Inf ormation

Page 13

LPX-200

Industrial Imaging System

SAFETY SUMMARY

When properly installed, maintained, and operated, X-ray

equipment can be used effectively and safely. If any

component of this unit is incorrectly installed, and/or operated

by unqualified personnel, or if the maintenance schedule is

neglected, it is a potentially dangerous apparatus.

Before operating or performing any maintenance on the

LPX-200, the user MUST have a thorough understanding of

x-ray machinery, x-ray generation, x-ray potential, and x-ray

control. The user MUST understand all hazards associated

with x-ray generation.

Read this “Safety Summary” completely, and thoroughly

understand its contents. Read all of the safety warnings,

cautions, and notes throughout this manual prior to

commencing any operating or maintenance procedures.

All operators and technicians MUST adhere to the following

safety practices:

◆ Read and understand the x-ray protection warning

published at the front of this manual.

Use the following summary as a checklist to assure

comprehension of the safety indicators.

NOTE:

An essential operating procedure, condition, or

statement, which must be observed to ensure proper

understanding and operation of the system.

! CAUTION !

An operating or maintenance procedure,

practice, condition, or statement, which, if

not strictly observed, could result in

damage to, or destruction of equipment.

! WARNING !

An operating or maintenance

procedure, practice, condition, or

statement, which, if not strictly

observed, could result in injury to or

death of personnel.

◆ Read this manual in its entirety.

◆ Understand and all procedures completely before

operating the unit.

◆ Read thoroughly and understand completely all

NOTE, CAUTION, and WARNING statements

before beginning operation or maintenance

procedures.

Chapter 1: Introduction & General Inf ormation

1-5

Page 14

LPX-200

Industrial Imaging System

Radiation Hazard

This equipment generates X-radiation at levels that can be

lethal. This unit must only be operated by personnel that are

certified and experienced in industrial x-ray generation. All

operators must also understand the characteristics of radiation

and the associated dangers of exposure to primary, secondary,

and residual sources of radiation.

Lethal V oltages

High power radiation sources depend upon the generation of

extremely high, yet well-protected voltages. Under no

circumstances should the operator access the interior of the

Tubehead. Also, under no circumstances should the operator

access the interior of the Control Unit or the Cooling Unit

except for the procedures outlined in Section 5 of this manual.

Badges

All personnel who work around X-ray equipment must wear a

functional exposure dosage indicator.

Operation

Equipment must be operated at correct source voltage and

frequency, and must never be left running unattended. The

gas pressure in the Tubehead must be checked to ensure it is

within allowable limits before operating the unit. Never

operate this apparatus if output voltage/current is unstable.

Cooling Unit Operation

Regularly check the coolant solution in the Cooling Unit to

ensure:

◆ the coolant level is within specification

◆ the pump circulates the coolant properly

◆ the fittings, hoses, and coolant reservoir does not leak

Always allow the Cooling Unit, or the fan on air-cooled units,

to run approximately 5 minutes after completion of x-ray

generation.

Radiation Protection

X-ray equipment must be operated within properly designated

protective barriers. Otherwise, personnel must not approach

closer than 100 feet from the Tubehead, and in no cases cross

the direct path of the primary beam.

Radiation Monitoring

After installation, re-installation, transporting, performing

maintenance, and during all radiographic operations not

within a radiation enclosure, a radiation survey should be

performed.

Warm-Up Procedures

Explicit procedures are outlined for “running-up” high voltage

with new equipment, equipment with a new tube, equipment

that has been inactive for a period of time, and for daily use.

These procedures must be strictly followed at all times.

Care in Handling

Extreme care must be taken when handling this x-ray

apparatus. Exercise caution when packing, unpacking,

shipping, and while performing maintenance. Remember, the

X-ray tube is durable but breakable: be sure to store and ship

it in the upright position.

1-6

Chapter 1: Introduction & General Inf ormation

Page 15

Chapter 2:

Preparation for Use and Shipment

LPX-200

Industrial Imaging System

UNPACKING INSTRUCTIONS

The LPX-200 X-ray Unit is shipped in a single wooden

container. To gain access to the unit, perform the following:

◆ Remove the top cover from the crate.

◆ Carefully lift each component from the container.

◆ Perform a thorough visual inspection on each

component.

If damage to any component has occurred, immediately

contact the carrier. Keep all damaged containers until the

carrier completes an inspection by the carrier. If it is

necessary to re-package and ship the unit, follow the

instructions outlined under “Reshipment Guidelines”.

Reshipment Guidelines

In the event that the LPX-200 X-ray Unit must be transported

or shipped, use the original wooden container and packaging

material whenever possible. If the original shipping material

is not available, comply with the following re-packing

guidelines.

4. Pack the Control Unit in a container rated for 60 lbs.

Surround the Control Unit with a MINIMUM of 2"

of shock absorbent packing material (sheet or loose

type), including the top and bottom.

5. Pack the Cooling Unit in the same manner as the

Control Unit.

! WARNING !

The coolant solution is a flammable

substance and must be drained from

the Cooling Unit’s reservoir before it

can be shipped.

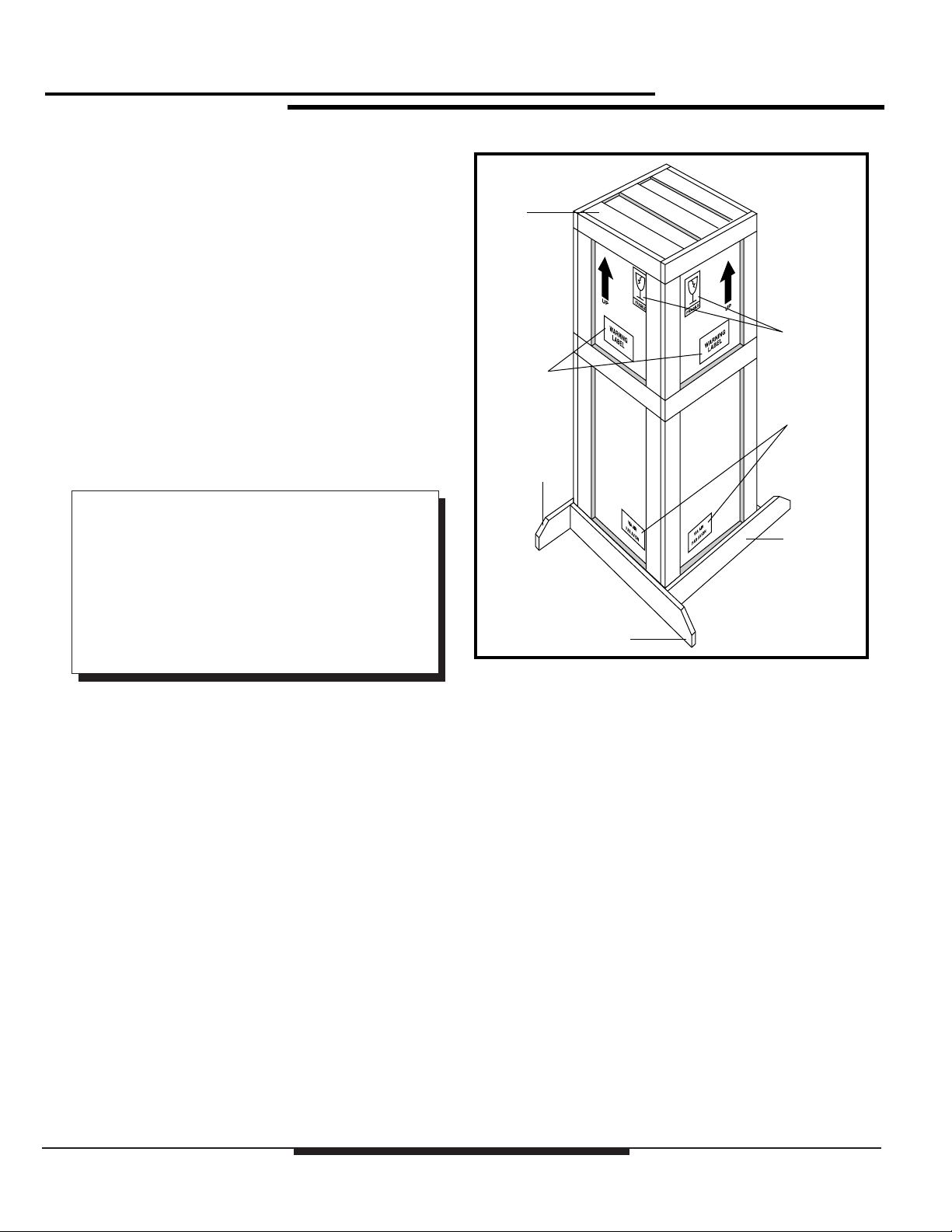

1. Construct a wooden shipping carton for the

Tubehead Assembly similar to the one in Figure 2-1.

Build the carton so that the top can be completely

removed to facilitate packing and unpacking.

2. Cushion the Tubehead with 3" of shock absorbent,

foam type, packing material (MINIMUM). This

material MUST surround the assembly on all sides,

including above and below the Tubehead.

3. Affix supporting legs to the bottom of the carton.

Make sure the legs extend between 7 and 10 inches

from the edges as shown in Figure 2-1.

Chapter 2: Preparation for Use and Shipment

2-1

Page 16

LPX-200

Industrial Imaging System

Transporting the Unit

When transporting by commercial carrier (i.e., truck, rail,

etc.), select the shipping method and carrier on the basis of

safe shipment, especially when shipping the fragile Tubehead

Assembly. Distinctly mark the Tubehead carton on all sides

with labeling which provides the carrier the following

information:

◆ Contents contains fragile glass instrumentation

◆ Container is to be shipped in the upright position

only

Customarily, the Tubehead is shipped via air, generally

avoiding ground transportation if possible. When shipping via

air, affix an additional label to the carton stating the following:

“Sulfur hexafluoride, non-flammable gas is

present in limited quantities in one or more

packages of this shipment. This is to certify that

the above mentioned materials are properly

classified, described, packaged, marked, and

labeled, and are in proper condition for

transportation according to the applicable

regulations of the U.S. Department of

Transportation.”

Removeable

Top

Fragile

Instrument

Label

Warning

Label

SF6 Label

Support

Leg

Support

Leg

Support

Leg

Figure 2-1:

T ubehead Shipping Container

2-2

Chapter 2: Preparation for Use and Shipment

Page 17

LPX-200

Industrial Imaging System

EQUIPMENT CHECKLISTS

The following checklists outline the standard and optional

equipment of the LPX-200 X-ray Unit. After unpacking the

unit, and completing a thorough visual inspection, compare

each item with this list to assure completeness.

Note that several Tubehead models are available. Verify that

the Tubehead shipped with your unit matches the model that

was originally ordered.

Checklist - Tubehead

❏ Assembly, Tubehead* ______ 3-000-3071

Air Cooled Unit; 40° x 60° cone

1.5mm Focal Spot

1mm Beryllium Window

❏ Assembly, Tubehead _______ 3-000-3072

Liquid Cooled; 40° x 60° cone

1.5mm Focal Spot

1mm Beryllium Window

❏ Assembly, Tubehead _______ 3-000-3073

Liquid Cooled; 360° Panoramic

0.4mm x 4.0mm Focal Spot

0.4 Fe/Ni/Co Window Tube

* All Air Cooled Units are equipped with Fan Power

Cable (p/n: 1-040A-0355). The liquid Cooling Unit

is not equipped with this cable.

Checklist - Standard Equipment

❏ Control Unit, Digital (1) ____ 3-000-3074

❏ Cooling Unit Assembly (1) __ 3-000A-0737

(Liquid Cooled Units Only)

❏ Power Cable Assembly (1) __ 1-040A-0825

(3 Pin Connector, 25ft.)

❏ Power Cable Assembly (1) __ 1-040A-0831

(3 Pin Connector, 100ft)

❏ Control Cable Assembly (1) _ 1-040A-0824

(14 Pin Connector, 100ft.)

❏ Cooler Power Cable (1)_____ 1-040A-0823

(Liquid Cooled Units Only, 8 Pin

Connector, 50ft.)

❏ Power Cable, Fan (1)_______ 1-040A-0355

(Air Cooled Units Only, 100ft.)

❏ Interlock Jumper (1) _______ 3-000-3075

(Jumper)

❏ Safety Switch Key (2) ______ 2-230-6201

❏ Interlock Connector (1) _____ 1-600-3218

(Mating Connector)

Checklist - Optional Equipment

❏ X-Ray Tubehead Stand _____ 3-000A-0754

❏ Kit, Tubehead Re-charge____ 9-200A-0102

❏ Laser Pointer _____________ 3-000-0792

❏ Laser Pointer Adapter ______ 3-100-0175

Chapter 2: Preparation for Use and Shipment

2-3

Page 18

LPX-200

eeeeeeeeeeeeeeeeee

eeeeeeeeeeeeeeeeee

eeeeeeeeeeeeeeeeee

eeeeeeeeeeeeeeeeee

eeeeeeeeeeeeeeeeee

eeeeeeeeeeeeeeeeee

eeeeeeeeeeeeeeeeee

eeeeeeeeeeeeeeeeee

eeeeeeeeeeeee

eeeeeeeeeeeee

eeeeeeeeeeeee

eeeeeeeeeeeee

eeeeeeeeeeeee

eeeeeeeeeeeee

eeeeeeeeeeeee

eeeeeeeeeeeee

eeeeeeeeeeeee

eeeeeeeeeeeee

Industrial Imaging System

WARNINGS LABELS &

CONTROL NUMBERS

Each assembly of the LPX-200 X-ray System is equipped

with an I.D. tag (Control Tag) providing the serial number,

description, and part number. This data is used for

identification, if warranty or service information is needed,

and will be requested when contacting LORAD regarding the

apparatus.

Control Tag

Warning Label

Attached to the Control Unit and Tubehead are warning labels.

Figure 2-2 illustrates the location of the I.D. tags and warning

labels for each assembly of the LPX-200.

Control Tag

Control Tag

Warning Label

2-4

Figure 2-2:

Location of Warning Labels and Control Tags

Chapter 2: Preparation for Use and Shipment

Page 19

SPECIFICATIONS

The following tables illustrate the physical, operational, and

environmental specifications for each component of the

LPX-200 System. Conformance with these specifications

ensures maximum system performance, and reduces the

chances of mechanical breakdown and personnel hazard.

Specifications - General System

LPX-200

Industrial Imaging System

The following outlines the general operating and

environmental limits of the LPX-200 System.

❏ Line Voltage * ____________ 100 to 130 VAC - 50/60 Hz, 20

amps (maximum); or 200 to 250

VAC - 50/60 Hz, 10 amps

(maximum)

❏ Operating Potential ________ 10kV to 200kV @ 0.1 to 10.0

mA, 900 Watts maximum

❏ Duty Cycle ______________ 100%

10.0

5.0

❏ Operating Temperature Range -30°F to 120°F (Ambient)

-34°C to 49°C (Ambient)

❏ Humidity ________________ 0 to 100% relative humidity

❏ Stabilization______________ kV and mA remain within 1% of

set levels. Line voltage varied

from 100-130/200-250 VAC.

❏ Storage Temperature Range _ -65°F to 160°F (-54°C to 71°C)

* Line voltage selection is automatic. The system is

operable from either line voltage range without any

switch or jumper configuration.

9.0

8.2

7.5

6.9

6.4

6.0

5.6

5.3

5.0

4.7

4.5

Chapter 2: Preparation for Use and Shipment

Figure 2-3:

LPX-200 Maximum T ube Current

2-5

Page 20

LPX-200

Industrial Imaging System

Specifications - General Tubehead

The following outlines the general operating specifications of

the Tubehead Assembly.

❏ Physical Specifications _____ Water Cooled: 8.5" dia. x 26.5"

length - 32lbs (approx); Air

Cooled: 8.5" dia. x 29" length 36 lbs (approx)

❏ Anode Cooling System _____ Recirculating Liquid Cooling unit

or Fan Forced Air

❏ Radiation Output __________ 20R/minute @200kV, 4.5mA @

50cm through 0.5 in. of

Aluminum

❏ Leakage Radiation_________ 0.8 R / hr

❏ Tube Pressure Sense _______ Monitors pressure of the SF6 gas

within the Tubehead. Shuts unit

down if pressure falls below 25

psi.

❏ Anode Thermal Sense ______ Monitors temperature of the X-ray

Tube Anode. Shuts down unit if

Anode temperature rises above

220°F.

DIRECTIONAL TUBE HEADDIRECTIONAL TUBE HEAD

60˚

40˚

PANORAMIC (360˚)TUBE HEAD

❏ Pressure Relief Valve_______ Automatically releases SF6 gas

from Tubehead if pressure rises

between 75 - 80 psi.

❏ Pressure Gauge ___________ Displays SF6 gas pressure within

Tubehead. Used in conjunction

with Temperature Compensation

chart to visually inspect Tubehead

pressure.

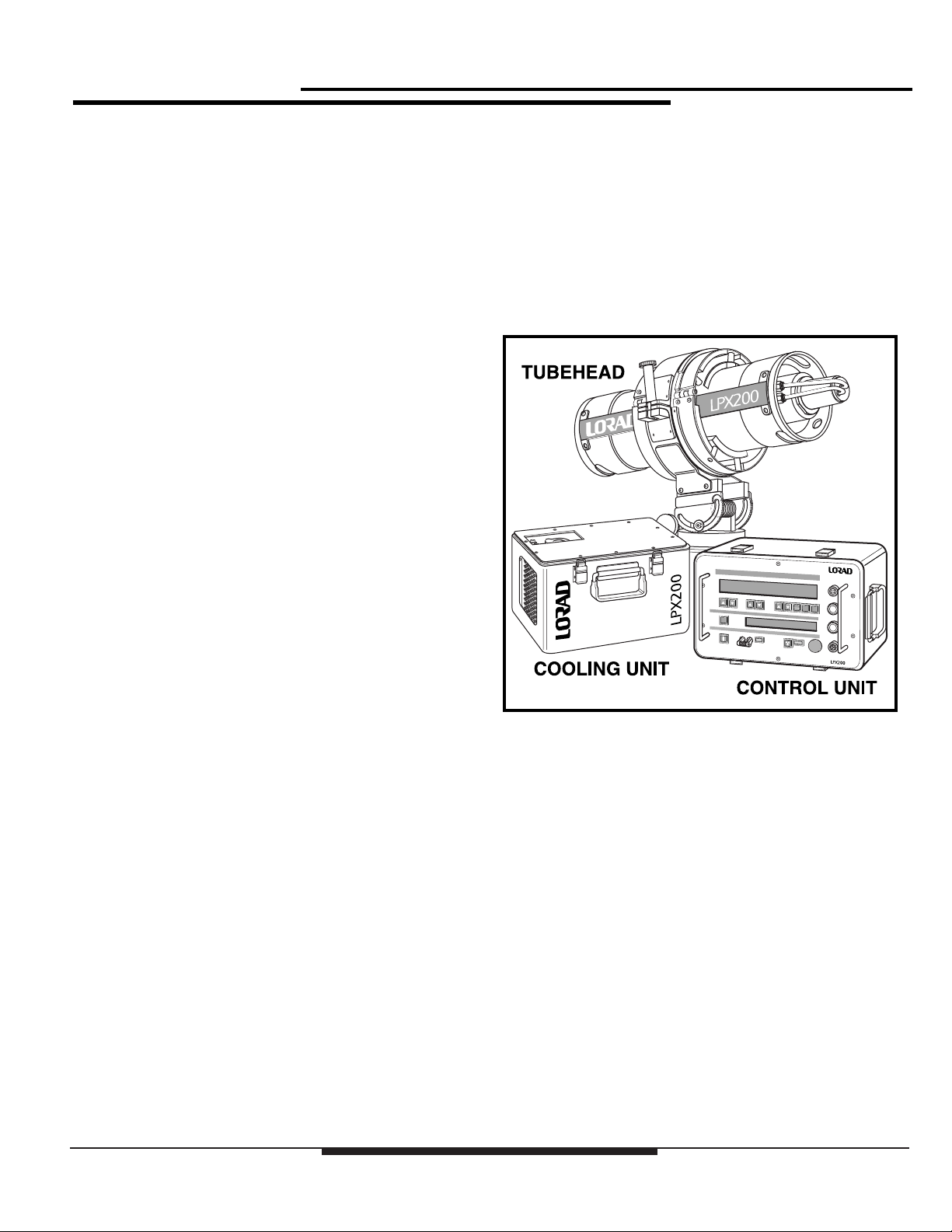

Specifications - Optional Tubehead

The information that follows furnishes the specifications for

several available Tubehead assemblies. Figure 2-4 illustrates

the direction of the X-ray beam for both the 40° x 60° cone

and the 360° panoramic models.

❏ Tubehead 40° x 60° Cone ___ Air or liquid cooled models;

1.5mm Focal spots; 1mm

beryllium window

❏ Tubehead 360° Panoramic __ Liquid cooled, 0.4mm x 4.0mm

focal spot, 0.4 Fe/Ni/Co window

only

44˚

Figure 2-4:

X-ray Beam Path

2-6

Chapter 2: Preparation for Use and Shipment

Page 21

LPX-200

Industrial Imaging System

Specifications - Control Unit

Below are the physical and operating specifications of the

Control Unit. Included are the physical dimensions, and the

operating indicators and controls. The controls are explained

in detail in Section 4 of this manual.

❏ kV Control_______________ Pushbutton switches set kV level

between 0kV to 200kV in 1kV

increments

❏ kV Indicator _____________ LCD Readout on upper display

❏ mA Control ______________ Pushbutton switches set mA level

between 0 and maximum 10.0 mA

in 0.1 mA increments (Control

Unit automatically limits the mA

so that 900 watt maximum is not

exceeded)

❏ mA Indicator _____________ LCD Readout on upper display

❏ X-Ray ON Switch _________ Pushbutton switch with radiation

symbol. Activates x-ray

generation

❏ X-Ray OFF Switch ________ Red mushroom type switch

terminates x-ray generation. May

be depressed anytime while x-rays

are being generated.

Specifications - Cooling Unit

Below are the operating and physical specifications of the

Cooling Unit.

❏ Dimensions ______________ 12" H x 15" W x 14" L

❏ Weight __________________ 55 lbs (approximate)

❏ Coolant Solution __________ 14 parts methyl alcohol, 7 parts

distilled water, 1 part soluble oil

(TEXACO Soluble “D” or

MOBIL S-122 Soluble)

❏ Coolant Flow_____________ 0.5 gallons per minute @ 50 foot

head.

❏ Cooling Unit Connections___ Self sealing quick disconnects.

❏ Key Lock Safety Switch ____ LOCKED OFF position prevents

x-ray generation; ON position

enables X-RAY ON switch

❏ Exposure Timer___________ LCD readout on upper display

❏ Weight __________________ 35 lbs. (approximate)

Dimensions _________________ 12" W x 18" L x 12" H

❏ Power ON Indicator _______ Green LED array on front panel

❏ X-Ray ON Indicator _______ Red LED array on front panel

❏ Interlock Connector________ Pins A and B used for enclosure

door switches which must be

closed to enable the X-RAY ON

switch. Pins C and D used for

external warning devices, pins E

and F used with optional prewarn/

warning systems.

Chapter 2: Preparation for Use and Shipment

2-7

Page 22

LPX-200

Industrial Imaging System

THIS PAGE IS INTENTIONALLY BLANK

2-8

Chapter 2: Preparation for Use and Shipment

Page 23

Chapter 3:

Installing the LPX-200 X-ray System

PRE-OPERATIONAL

CHECKS & INSPECTION

The following paragraphs outline the steps to properly check

and inspect the LPX-200 X-ray unit. Perform these

procedures before setting up the system to ensure integrity.

Check - Tubehead Gas Pressure

LPX-200

Industrial Imaging System

Check - Cooling Unit

This check verifies the integrity of the Cooling Unit (liquid

cooled tubeheads only).

1. Inspect the twin hose assembly and hose connections

for damage. The connector couplings must be firmly

attached to the hose, and the hose must be free of

punctures, frays, or dry rot.

This check verifies that the gas pressure inside the Tubehead

assembly is within limits. Note that Tubehead gas pressure

normally varies 1 psi for every 7°F increase or decrease in

ambient air temperature.

! CAUTION !

DO NOT operate this unit if Tubehead

Pressure is below 50 psi at 70°F or damage

to the Tubehead may occur.

1. Check the Tubehead gas pressure gauge and verify

that the gas pressure is within acceptable limits for

the ambient temperature (see Figure 6-2).

2. If the gauge indicates Tubehead gas pressure below

the acceptable limit, but greater than 5 psi, perform

the procedures for “Pressurizing the Tubehead” (refer

to Section 5).

3. If Tubehead gas pressure is below 5 psi at 70°F,

purge the Tubehead of all remaining gas, then

perform the procedures for “Refilling the Tubehead”

(see Section 5).

2. Remove the Radiator cap on the Cooling Unit and

check that the coolant level is within 1/2" from the

top of the reservoir. Add coolant solution at this time

if necessary (refer to Section Five).

Check - Control Unit

This check verifies the intergrity of the Control Unit.

1. Remove the top cover from the Control Unit and

perform a thorough visual inspection for damage.

2. Check the four connectors along the right side of the

front panel for foreign material and signs of

corrosion.

3. Inspect the front panel controls for missing or

broken switches and displays.

Chapter 3: Installing the LPX-200 X-ray System

3-1

Page 24

LPX-200

Industrial Imaging System

SYSTEM SET UP PROCEDURES

The procedures below describe the set up procedures for both

LPX-200 configurations; liquid-cooled units, and air-cooled

units. Use Figure 3-1 (liquid-cooled), or Figure 3-2 (aircooled) as a reference while making the necessary system

connections.

System Interconnections - Liquid Cooled

The following details the connections for setting up a liquid

cooled LPX-200 X-ray System.

! WARNING !

All cables MUST be connected to their

appropriate connectors on the

Control Unit, Cooling Unit, and

Tubehead before applying power to

the system.

1. Connect the twin hose assembly between the

Tubehead and the Cooling Unit:

◆ Attach the two angled couplings to the fittings on the

back of the Tubehead.

◆ Attached the couplings on the opposite end to the

female fittings on the Cooling Unit.

5. Make the External Interlock connection:

◆ If available, connect the Interlock cable to the

connector labeled “Interlock” on the Control Unit

(see External Interlock instructions later in this

section).

◆ Connect the “jumper” (supplied) to the connector

labeled “Interlock” on the Control Unit for units that

do not employ an external interlock system.

COOLER

Cable

8 pin connector

UNIT

Twin Hose

NOTE:

There is no designated left or right side to the twin

hose assembly. If each coupling is properly seated,

coolant flow through the Tubehead will be achieved.

2. Install the Cooling Unit power cable:

◆ Connect the male end of the power cable to the

connector labeled “Cooler” on the Control Unit.

◆ Connect the female end of the power cable to the

connector on the Cooling Unit.

3. Install the Tubehead Control cable:

◆ Connect the male end of the Control cable to the

connector labeled “Tubehead” on the Control Unit.

◆ Connect the female end of the Control cable to the

connector on the Tubehead base plate.

4. Install the line power cable:

◆ Connect the female end of the line power cable to the

connector labeled “Power” on the Control Unit.

◆ Connect the “plug” end of the line power cable to the

AC voltage source (see Connecting to Power

instructions later in this section).

TUBEHEAD

Line Power Cable

to AC Source

CONTROL

UNIT

LPX-200 Set Up (Liquid Cooled)

Cable

10 pin connector

Interlock Connection

or Jumper

Figure 3-1:

3-2

Chapter 3: Installing the LPX-200 X-ray System

Page 25

System Interconnections - Air Cooled

The following details the connections for setting up a liquid

cooled LPX-200 X-ray System.

! WARNING !

All cables MUST be connected to their

appropriate connectors on the

Control Unit, Cooling Unit, and

Tubehead before applying power to

the system.

1. Install the Cooling Fan power cable:

◆ Connect the male end of the power cable to the

connector labeled “Cooler” on the Control Unit.

◆ Connect the female end of the power cable to the

connector on the Tubehead base plate.

2. Install the Tubehead Control cable:

◆ Connect the male end of the Control cable to the

connector labeled “Tubehead” on the Control Unit.

◆ Connect the female end of the Control cable to the

connector on the Tubehead base plate.

3. Install the line power cable:

◆ Connect the female end of the line power cable to the

connector labeled “Power” on the Control Unit.

◆ Connect the “plug” end of the line power cable to the

AC voltage source (see Connecting to Power

instructions later in this section).

Line Power Cable

to AC Source

CONTROL

UNIT

TUBEHEAD

LPX-200

Industrial Imaging System

Cable

8 pin connector

Cable

10 pin connector

Figure 3-2:

LPX-200 Set Up (Air Cooled)

4. Make the External Interlock connection:

◆ If available, connect the Interlock cable to the

connector labeled “Interlock” on the Control Unit

(see External Interlock instructions later in this

section).

◆ Connect the “jumper” (supplied) to the connector

labeled “Interlock” on the Control Unit for units that

do not employ an external interlock system.

Chapter 3: Installing the LPX-200 X-ray System

3-3

Page 26

LPX-200

Industrial Imaging System

Connecting to Po wer

Note that the AC voltage source MUST be rated as either:

◆ 120 VAC, 20 amps, 50/60 Hz

◆ 230 VAC, 10 amps, 50/60Hz

Line voltage selection is automatic. For 220V input

application, remove the male plug on the supplied power cord

and replace it with one that fits the local AC receptacle, or an

adapter cable can be locally manufactured. See Figure 3-3 for

the correct plug termination.

EXTERNAL

INTERLOCK CONNECTIONS

The INTERLOCK connector on the front panel of the Control

Unit enables interconnection of x-ray enclosure doors and/or

external warning devices with the internal safety interlock

circuitry of the system. Figure 3-4 illustrates the two circuits

provided for this purpose.

Pins “A” and “B” are used to connect enclosure door switches.

When pins A and B are properly connected, x-ray generation

is possible only when the enclosure doors housing the

Tubehead are shut. Note that pins “A” and “B” of the

INTERLOCK connector must form a closed circuit to operate

the X-ray unit. If no external switch interlocks are

incorporated, a jumper (provided) must be installed across

pins “A” and “B” to form this closed circuit.

Pins “C” and “D” provide a switch closure to operate warning

devices such as lights, sirens, or other types of external

warning signals. These signals warn all personnel that x-rays

are being generated.

(Earth Ground)

GREEN

A

B

C

INTERLOCKINTERLOCKINTERLOCK

D

A

B

C

D

External Relay

BLACK

WHITE

Figure 3-3:

220 V olt Plug Termination

F

E

F

E

External Interlocks

Indicator Lamps

30VDC

120/240VAC

3 AMPS (max)

Indicator Lamps

Pins E and F are for use with optional LORAD pre-warning/

warning devices.

! WARNING !

Voltage is present at pins “A” and “B”

of the INTERLOCK when the unit is

powered up. Ensure power is OFF

before making any external

connections or while installing the

jumper.

3-4

Chapter 3: Installing the LPX-200 X-ray System

A

B

C

A

B

C

INTERLOCK

D

F

E

D

F

E

30VDC

120/240VAC

3 AMPS (max)

Jumper

Figure 3-4:

External Interlock Connections

Page 27

Chapter 4:

LPX-200 X-ray Controls and Indicators

LPX-200

Industrial Imaging System

INTRODUCTION

The following paragraphs describe the controls and switches

on the control panel of the LPX-200 Control Unit. The

functions and use of these controls must be thoroughly

understood before operating the x-ray unit.

Overview - Control Unit

The Control Unit’s control panel is comprised of:

◆ 2 liquid crystal display (LCD) screens

◆ exposure parameter pushbutton control switches

◆ a Mains power circuit breaker

◆ LED indicators

Military type connectors, along the right side of the panel, are

used to connect the input power cord and the system’s

interconnecting control cables and hoses.

Legend - LPX-200 Control Unit

Use the following legend as a reference for parts

identification.

1. Exposure Technique LCD Display Screen

2. Message / Mode LCD Display Screen

3. Mains ON/OFF Circuit Breaker

4. Mains LED Indicator

5. Safety Key Lockout Switch

6. kV UP/DOWN Pushbuttons

7. mA UP/DOWN Pushbuttons

8. EXPOSURE (Time/mAs) UP/DO WN Pushb uttons

9. UNITS Select (Time/mAs) Pushb utton

10. TIME Counter Select Pushbutton

11. RESET Pushbutton

12. SCROLL Control

13. X-RAY ON Pushbutton

14. X-RAY OFF Pushbutton

7891011

1

6

12

354 14132

Chapter 4: LPX-200 X-ra y Controls & Indicators

Figure 4-1:

Legend - LPX-200 Control Panel

4-1

Page 28

LPX-200

Industrial Imaging System

THE LIQUID

CRYSTAL DISPLAY SCREENS

The LPX-200 Control Unit incorporates two LCD Display

screens:

◆ The Exposure Technique LCD

◆ The Message / Mode LCD

The following paragraphs describe both LCD screens, and the

information they provide the user.

The Exposure Technique LCD Display Screen

The Exposure Technique LCD (large top screen) displays two

rows of exposure parameters:

◆ the set techniques (top row)

◆ the operating levels (bottom row)

The top row shows the set exposure kV (left side), the mA

(center), and the exposure duration (right side). The exposure

duration displays in minutes and seconds or in mAs,

depending on the selected TIME mode.

The bottom row shows the actual operating levels of the

system during x-ray emission. The operating kV level

displays directly below the set kV level, the actual tube current

(mA) displays directly below the set mA, and the actual time

(or mAs) remaining/elapsed displays directly below the set

exposure duration.

Figure 4-2:

Samples: Exposure Te chnique LCD Display

4-2

Chapter 4: LPX-200 X-ra y Controls & Indicators

Page 29

The Message / Mode LCD Display Screen

The Message / Mode LCD (small bottom screen) displays:

◆ operating mode

◆ user prompts

◆ error messages

The upper left side of the screen indicates the system

operational mode (OPERATE or AUTOWARM), and the

lower left side show the either the type of automatic warm-up

has been selected (i.e., > 30 DAYS), or if an error condition

has been encountered (FAULT).

The right hand side of the screen indicates the following:

◆ the current operating status

◆ the description of the detected fault

Figure 4-3 shows several examples of the information

provided on the Message / Mode screen.

LPX-200

Industrial Imaging System

Samples: Message / Mode LCD Display Screen

Chapter 4: LPX-200 X-ra y Controls & Indicators

Figure 4-3:

4-3

Page 30

LPX-200

Industrial Imaging System

FRONT PANEL

CONTROLS AND INDICATORS

The paragraphs that follow describe each of the controls and

indicators on the front panel of the Control Unit. Refer to

Figure 4-1 for the location of each control and indicator.

The MAINS Switch

The MAINS switch is a two position circuit

breaker that applies power to the Control Unit.

Switching the MAINS breaker ON applies line

power to the Control Unit after a 2 second delay

(approximate). During this delay, the input power detection

circuitry determines the line voltage (100VAC or 200VAC),

and selects the proper line circuitry.

Switching the MAINS breaker OFF immediately disconnects

the system from line power. The MAINS breaker will trip

automatically during over-current conditions, thus protecting

the internal electronics from damage.

The MAINS ON Indicator

The MAINS ON indicator is a light emitting diode

(LED) array located next to the MAINS Switch.

This LED glows green when line power is applied to

the system.

The kV SET Controls

Two pushbuttons, below the kV readout,

comprise the kV SET Controls. Use these

buttons to increment or decrement the kV level

for the exposure. Pressing the kV UP button, identified by the

“up arrow” label, increments the set kV in 1kV steps (up to

200kV maximum). Pressing the kV DOWN button, identified

by the “down arrow” label, decrements the set kV in 1kV

steps (to 0kV minimum).

For rapid change, press and hold the kV UP or DOWN button;

for slow change, press and release the buttons. These switches

are active:

◆ upon initial system power up

◆ during an exposure (OPERATE)

◆ prior to an exposure (provided the Exposure Counter

has been reset)

The mA SET Controls

Two pushbuttons, below the mA readout,

comprise the mA SET Controls. Use these

buttons to increment or decrement the mA

level for the exposure. Pressing the mA UP button, identified

by the “up arrow” label, increments the set mA in 0.1mA steps

(up to 10mA maximum). Pressing the mA DOWN button,

identified by the “down arrow” label, decrements the set mA

in 0.1mA steps (to 0.0mA minimum).

The SAFETY Switch

The 2-position SAFETY switch prevents

unauthorized use of the X-ray Unit. Before the

system can generate x-rays, the operator MUST

insert the key into the SAFETY switch, then rotate

it to the ON position. The SAFETY switch does not activate

x-ray generation; it only permits use of the x-ray apparatus.

Never approach the Tubehead when power is ON without first

placing the SAFETY switch to LOCKED OFF, then removing

the key. NEVER leave the key in the SAFETY switch unattended.

4-4

Chapter 4: LPX-200 X-ra y Controls & Indicators

For rapid change, press and hold the kV UP or DOWN button;

for slow change, press and release the buttons. These switches

are active upon:

◆ upon initial system power up

◆ during an exposure (OPERATE)

◆ prior to an exposure (provided the Exposure Counter

has been reset)

NOTE:

The microcomputer limits the maximum mA to

values which, at the set kV level, provide a

maximum of 900 watts to the tube.

Page 31

LPX-200

Industrial Imaging System

The EXPOSURE SET Controls

Two pushbuttons, below the Exposure readout,

comprise the EXPOSURE SET Controls. Use

these buttons to increment or decrement the

exposure time (Time Mode) or mAs (mAs Mode). Pressing

the EXPOSURE UP button, identified by the “up arrow” label,

increments the set exposure time (up to 99:59 maximum), or

the set mAs (up to 29995 maximum). Pressing the

EXPOSURE DOWN button, identified by the “down arrow”

label, decrements the set exposure time (to 00:00 minimum),

or the set mAs (to 00000mAs minimum).

For rapid change, press and hold the UP or DOWN button;

for slow change, press and release the buttons. These switches

are active:

◆ upon initial system power up

◆ in the OPERATE mode

◆ prior to an exposure (provided the Exposure Counter

has been reset)

The UNITS Control

The UNITS Control is a single pushbutton, next to

the EXPOSURE SET Controls, that changes the

mode that the system uses to determine the exposure

duration. Pressing the UNITS button will toggle the system

exposure determination mode between TIME and mAs.

Selecting TIME causes the x-ray system to terminate the

exposure after a pre-determined “time” has elapsed, regardless

of the set exposure factors (kV and mA). Selecting mAs

causes the x-ray system to terminate the exposure after a

achieving a set tube current / time product (mAs), and does

not require an operator time calculation.

The TIME Control

The TIME Control is a single pushbutton, next to the

UNITS Control, that switches the exposure clock

between ELAPSED mode (count up), and REMAINS

mode (count down). This control is active at all times when

power is ON.

ELAPSED mode sets the time or mAs in the lower Exposure

readout to zero, then increments during the exposure. When

the “elapsed” time or mAs matches the set time or mAs (upper

Exposure readout), the system terminates the exposure.

REMAINS mode sets the time or mAs in the lower Exposure

readout to the set time or mAs (upper Exposure readout), then

decrements during the exposure. When the “remains” time or

mAs reaches zero, the system automatically terminates the

exposure.

The RESET Control

The RESET control is a single pushbutton, next to the TIME

Control, that resets the exposure timer. Pressing the RESET

control causes the exposure duration (lower readout) to do one

of the following:

◆ Return to the set time or mAs (REMAINS mode)

◆ Return to zero (ELAPSED mode)

The RESET pushbutton is active only when:

◆ the system terminates the exposure upon reaching the

set duration

◆ the system terminates the exposure due to a fault

condition

◆ the user interrupts the exposure by pressing STOP

When the x-ray system is in the TIME mode, TIME SET will

appear next to the set exposure time (top row) in the Exposure

Factor LCD. When the x-ray system is in the mAs mode, mAs

will appear next to the set mAs (top row) in the Exposure

Factor LCD.

This switch is active upon:

◆ upon initial system power up

◆ upon system exposure termination

◆ upon exposure interuption

◆ after resetting the Exposure Counter

Chapter 4: LPX-200 X-ra y Controls & Indicators

4-5

Page 32

LPX-200

Industrial Imaging System

The SCROLL Control

The SCROLL Control is a single pushbutton, to the

left of the Message / Mode LCD, that switches the

system status between the available modes. Pressing

the SCROLL button switches the display in the Message /

Mode LCD between:

◆ OPERATE

◆ AUTOWARM > 30 DAYS

◆ AUTOWARM 7 - 30 DAYS

◆ AUTOWARM 16 HRS - 7 DAYS

◆ AUTOWARM 8 HRS - 16 HRS

◆ AUT OWARM 4 HRS - 8 HRS

Select the OPERATE mode to make radiographs after

completing the appropriate warm-up sequence (if required).

Select the appropriate AUTOWARM mode to “run up” to the

required kV level at a fixed rate when the equipment has not

been used for a period of time (see “Warm Up Sequence” in

Chapter 5).

The X-RAY ON Control

The X-RAY ON Control, identified by the radiation

symbol, starts x-ray generation, and turns on the X-

RAY INDICATOR. The X-RAY ON Control is

active only when all of the following conditions are

met:

The X-RAY OFF Control

The X-RAY OFF control is the red, mushroomtype pushbutton switch, near the bottom of the

control panel. Pressing this switch anytime during

an exposure causes:

◆ termination od x-ray production

◆ the exposure counter to stop

◆ the x-ray on LED to extinguish

The timer will continue to display the exposure time or mAs

(elapsed or remaining). To continue with the exposure, repress the X-RAY ON button. The exposure will continue from

the point that the OFF control was originally pressed. To start

a new exposure, press the RESET button, set new exposure

factors, then re-press the X-RAY ON button.

◆ power is applied to the system

◆ The keyswitch is turned ON

◆ all error / fault conditions have been corrected

The X-RAY Indicator

The X-RAY indicator, next to the X-RAY ON

control, is a light emitting diode (LED) that glows

red when x-rays are being generated.

4-6

Chapter 4: LPX-200 X-ra y Controls & Indicators

Page 33

Chapter 5:

LPX-200 X-ray System Operation

LPX-200

Industrial Imaging System

INTRODUCTION

This section provides, as an example, the sequence of

operation required for using the LPX-200 X-ray System for

making x-ray film exposures. ALWAYS keep in mind the

dangers inherent with generating x-radiation, and observe

ALL the relevant precautions and procedures regarding safe

operation, personnel exposure prevention, and exposure dose

monitoring.

Pre-Operational Safety Precautions

Before the x-ray tube is energized for either the warm-up

sequence, or for the exposure, the operator MUST understand

and observe the safety precautions detailed below.

The interconnects supplied with the system help protect the

user, and others in the immediate vicinity, from exposure by

providing a safe distance between the Tubehead and the

Control Unit. Refer to NCRP (National Council on Radiation

Protection) recommended practices for minimum distance

requirements.

! WARNING !

ALWAYS use the cables and hoses

provided with the unit to avoid

radiation hazards in un-shielded,

outdoor operating conditions.

The operator of this apparatus MUST ensure that all personnel

are clear of the hazardous X-ray area before generating

X-rays. Utilize flashing beacons and/or audible alarms during

exposures, which warn personnel of the radiation hazards.

! WARNING !

All personnel in the immediate

vicinity MUST wear personal

radiation monitoring devices. Post

radiation warning signs where

necessary.

The operator of this X-ray unit, or any person in the

immediate vicinity, may be subject to receiving some

exposure to X-radiation during the time that the X-ray unit is

generating X-rays. Since X-rays can cause harmful

effects to the human body, avoid unnecessary exposure.

! WARNING !

Keep all necessary exposure to an

absolute minimum and compatible

with practical requirements and

current safety regulations. An X-ray

survey meter, placed in the vicinity of

the Control Unit and operator, is

recommended.

! WARNING !

Connect all cables to their

appropriate connectors on the

Control Unit, Cooling Unit, and

Tubehead BEFORE applying power to

the system.

Chapter 5: LPX-200 X-r a y System Operation

5-1

Page 34

LPX-200

Industrial Imaging System

X-RA Y TUBE W ARM UP

The X-ray tube provided with the LPX-200 has been pre-aged

by the original manufacturer, and further tested and aged by

LORAD. It is necessary, however, to run the voltage up to the

required kV level at a fixed rate when the equipment has not

been used for a period of time.

The LPX-200 incorporates an AUTOWARM feature, which

permits the user to select and initiate one of five automatic

warm-up sequences. An AUTOWARM sequence is required

whenever the x-ray system:

◆ is to be operated above 100kV

◆ has not been operated at the required kV level for the

next exposure for 4 hours

◆ has a new tube with less than ten hours of operation

The AUTOWARM modes automatically set the run-up level to

200kV. However, it is only necessary to run the x-ray tube to

the kV level required for the next exposure. Run the

appropriate AUTOWARM sequence until the kV advances to

the next level higher than required for the exposure, then

terminate the sequence. Tubes having been previously

operated, but not run over 100kV for 30 days or longer, must

be treated as new tubes.

Note that for ALL AUTOWARM modes, detected tube

instability (as might occur with a new tube) causes the system

to automatically terminate x-ray generation. The Message /

Mode LCD will display an error (FAULT ARC RESTART),

which will require the user to re-activate x-ray generation.

The kV will then rise to a level 20kV below where the fault

occurred and operate for two minutes. After two minutes, the

kV advances to the next highest incremental kV level on the

selected warm-up schedule, and the AUTOWARM sequence

continues normally from that point.

The five AUTOWARM sequences are detailed next.

Autowarm Sequence : > 30 Days

The following procedure outlines the steps to “run-up” the kV

to the level required for the next exposure in cases where the

unit has not been operated for 30 days or more.

1. Prepare the x-ray system for the warm-up sequence:

❏ Turn the anode shield to completely block x-ray port.

❏ Close all interlock connections, or install the jumper

on the INTERLOCK connector.

❏ Place the MAINS circuit breaker ON.

! WARNING !

Although the window is blocked, do

not approach the Tubehead during

the warm up process. Observe all

applicable safety precautions and

survey the area to assure adequate

radiation limits.

2. Begin the AUTOWARM sequence:

❏ Select AUTOWARM : > 30 DAYS by pressing the

SCROLL button.

❏ Clear all unauthorized personnel from the area, and

activate all warning devices.

❏ Press the X-RAY ON button to begin the

AUTOWARM sequence.

! WARNING !

The system will now generate x-rays.

Observe ALL safety precautions.

Upon activation, the kV level rises to 100kV and the mA rises

to 5.0mA. After 2 minutes at this level, the kV automatically

increments 5kV. This slow “ramp up” sequence continues

automatically until 200kV is reached (or until terminated by

the operator or by a fault), then automatically terminates x-ray

generation.

The LPX-200 is ready for use, as indicated by the prompt on

the Message / Mode LCD: OPERATE: X-RAY READY.

5-2

Chapter 5: LPX-200 X-ray System Operation

Page 35

LPX-200

Industrial Imaging System

Autowarm Sequence : 7 - 30 Days

The following procedure outlines the steps to “run-up” the kV

to the level required for the next exposure in cases where the

unit has not been operated in the last 7 days, but within the last

30 days.

1. Prepare the x-ray system for the warm-up sequence:

❏ Turn the anode shield to completely block x-ray port.

❏ Close all interlock connections, or install the jumper

on the INTERLOCK connector.

❏ Place the MAINS circuit breaker ON.

! WARNING !

Although the window is blocked, do

not approach the Tubehead during

the warm up process. Observe all

applicable safety precautions and

survey the area to assure adequate

radiation limits.

2. Begin the AUTOWARM sequence:

❏ Select AUTOWARM : 7 - 30 DAYS by pressing the

SCROLL button.

❏ Clear all unauthorized personnel from the area, and

activate all warning devices.

❏ Press the X-RAY ON button to begin the

AUTOWARM sequence.

Autowarm Sequence : 16 Hrs. - 7 Days

The following procedure outlines the steps to “run-up” the kV

to the level required for the next exposure in cases where the

unit has not been operated in the last 16 hours, but within the

last 7 days.

1. Prepare the x-ray system for the warm-up sequence:

❏ Turn the anode shield to completely block x-ray port.

❏ Close all interlock connections, or install the jumper

on the INTERLOCK connector.

❏ Place the MAINS circuit breaker ON.

! WARNING !

Although the window is blocked, do

not approach the Tubehead during

the warm up process. Observe all

applicable safety precautions and

survey the area to assure adequate

radiation limits.

2. Begin the AUTOWARM sequence:

❏ Select AUTOWARM : 16HRS - 7 DAYS by pressing

the SCROLL button.

❏ Clear all unauthorized personnel from the area, and

activate all warning devices.

❏ Press the X-RAY ON button to begin the

AUTOWARM sequence.

! WARNING !

The system will now generate x-rays.

Observe ALL safety precautions.

Upon activation, the kV level rises to 100kV and mA rises to

5.0mA. After 1 minute at this level, the kV automatically

increments 5kV. This slow “ramp up” sequence continues

automatically until 200kV is reached (or until terminated by

the operator or by a fault), then automatically terminates x-ray

generation.

The LPX-200 is ready for use, as indicated by the prompt on

the Message / Mode LCD: OPERATE: X-RAY READY.

! WARNING !

The system will now generate x-rays.

Observe ALL safety precautions.

Upon activation, the kV level rises to 100kV and mA rises to

5.0mA. After 1 minute at this level, the kV automatically

increments 10kV. This slow “ramp up” sequence continues

automatically until 200kV is reached (or until terminated by

the operator or by a fault), then automatically terminates x-ray

generation.

The LPX-200 is ready for use, as indicated by the prompt on

the Message / Mode LCD: OPERATE: X-RAY READY.

Chapter 5: LPX-200 X-r a y System Operation

5-3

Page 36

LPX-200

Industrial Imaging System

Autowarm Sequence : 8 Hrs. - 16 Hrs.

The following procedure outlines the steps to “run-up” the kV

to the level required for the next exposure in cases where the

unit has not been operated in the last 8 hours, but within the

last 16 hours.

1. Prepare the x-ray system for the warm-up sequence:

❏ Turn the anode shield to completely block x-ray port.

❏ Close all interlock connections, or install the jumper

on the INTERLOCK connector.

❏ Place the MAINS circuit breaker ON.

! WARNING !

Although the window is blocked, do

not approach the Tubehead during

the warm up process. Observe all

applicable safety precautions and

survey the area to assure adequate

radiation limits.

2. Begin the AUTOWARM sequence:

❏ Select AUTOWARM : 8HRS - 16 HRS by pressing

the SCROLL button.

❏ Clear all unauthorized personnel from the area, and

activate all warning devices.

❏ Press the X-RAY ON button to begin the

AUTOWARM sequence.

Autowarm Sequence : 4 Hrs. - 8 Hrs.

The following procedure outlines the steps to “run-up” the kV

to the level required for the next exposure in cases where the

unit has not been operated in the last 4 hours, but within the

last 8 hours.

1. Prepare the x-ray system for the warm-up sequence:

❏ Turn the anode shield to completely block x-ray port.

❏ Close all interlock connections, or install the jumper

on the INTERLOCK connector.

❏ Place the MAINS circuit breaker ON.

! WARNING !

Although the window is blocked, do

not approach the Tubehead during

the warm up process. Observe all

applicable safety precautions and

survey the area to assure adequate

radiation limits.

2. Begin the AUTOWARM sequence:

❏ Select AUTOWARM : 4HRS - 8 HRS by pressing the

SCROLL button.

❏ Clear all unauthorized personnel from the area, and

activate all warning devices.

❏ Press the X-RAY ON button to begin the

AUTOWARM sequence.

! WARNING !

The system will now generate x-rays.

Observe ALL safety precautions.

Upon activation, the kV level rises to 100kV and mA rises to

5.0mA. After 1 minute at this level, the kV automatically

increments 20kV. This slow “ramp up” sequence continues

automatically every 1 minute until 200kV is reached (or until

terminated by the operator or by a fault), then automatically

terminates x-ray generation.

The LPX-200 is ready for use, as indicated by the prompt on

the Message / Mode LCD: OPERATE: X-RAY READY.

! WARNING !

The system will now generate x-rays.

Observe ALL safety precautions.

Upon activation, the kV level rises to 100kV and mA rises to

5.0mA. After 1 minute at this level, the kV automatically

increments 25kV. This slow “ramp up” sequence continues

automatically every 1 minute until 200kV is reached (or until

terminated by the operator or by a fault), then automatically

terminates x-ray generation.

The LPX-200 is ready for use, as indicated by the prompt on

the Message / Mode LCD: OPERATE: X-RAY READY.

5-4

Chapter 5: LPX-200 X-ray System Operation

Page 37

LPX-200

Industrial Imaging System

OPERATION LPX-200 X-RAY SYSTEM

When the x-ray system is properly assembled, all safety

precautions/practices taken, and the appropriate AUTOWARM

sequence complete, the user may make exposures by

performing the sequence of operation that follows.

Strictly observe all NOTES, CAUTIONS, and WARNINGS in

this section to avoid damaging the equipment, or injuring

personnel. Read the “SAFETY SUMMARY” in Section 1,

and the WARNINGS outlined under “Pre-Operational Safety

Precautions” in this section before proceeding.

Sequence of Operation

The following provides, as an example, the sequence required

to make x-ray exposures using the LPX-200 Industrial X-ray

System.

1. Prepare the LPX-200 for use:

❏ Make all the cable and hose interconnections (see

Chapter 2).

❏ Perform all the pre-operational checks and

inspections to confirm system intergrity.

❏ Make the appropriate interlock connections, or install

the interlock jumper.

❏ Place the key in the keylock and turn it to LOCKED

OFF.

❏ Apply power to the system by switching the Power

Circuit Breaker ON.

3. Set the appropriate techniques for the exposure:

❏ Press SCROLL until the Message / Mode LCD reads:

OPERATE : X-RA Y READY.

❏ Use the kV Controls to set the exposure kV level.

❏ Use the mA Controls to set the exposure mA level.

❏ Press the UNITS button to select the exposure timing

method (time or mAs).

❏ Use the Exposure Controls to set the exposure time

or mAs.

❏ Press the TIME button to set the counter for either

count up (elapsed) or count down (remains).

4. Begin the exposure:

❏ Remove the key from the Keyswitch.

❏ Position the film holder and Tubehead for the ensuing

exposure.

❏ Turn the lead shield to completely uncover the anode

port.

❏ Clear all unnecessary personnel from the vicinity.

❏ Check that all external warning devices are working

properly.

❏ Insert the key into the Keyswitch and turn it ON.

❏ Press the X-RAY ON button to begin the exposure.

! WARNING !

NEVER allow the x-ray unit to run

unattended, and NEVER approach the

Tubehead with power applied and

the key in Keyswitch.

After approximately 2 seconds, the green MAINS LED

indicator will illuminate, the Cooling Unit or fan (on

air-cooled units) will start, the Control Unit’s cooling fan will

start, and information will appear in the Exposure Technique

LCD.

2. Perform the appropriate AUTOWARM Sequence:

❏ Determine the amount of time the system has been

idle.

❏ Press SCROLL until the Message / Mode LCD

displays the appropriate AUTOWARM mode.

❏ Cover the anode port with the lead shield.

❏ Turn the Keyswitch to ON.

❏ Press and hold the X-RAY ON button for

approximately 3 seconds to initiate x-ray generation.

❏ Press the OFF button after the x-ray tube ramps up to

the level of the ensuing exposure.

❏ Turn the Keyswitch to LOCKED OFF.

Chapter 5: LPX-200 X-r a y System Operation

5-5

Page 38

LPX-200

Industrial Imaging System

5. Ending the exposure:

❏ X-ray generation ends automatically after the set

time/mAs duration.

❏ Press the OFF button to immediately terminate the

exposure before the set duration.

❏ Place the Keyswitch to LOCKED OFF and remove

the key.

❏ Press the X-RAY ON button to restart an exposure

that was manually terminated.

6. Starting a new exposure:

❏ Remove the key from the Keyswitch.

❏ Reposition the Tubehead as necessary.

❏ Replace the film or film holder as required.

❏ Press the RESET button to reset the exposure time

duration.

❏ Check and adjust the exposure factors as required.

❏ Clear the area of unnecessary personnel.

❏ Close all interlocks and start all warning signals.

❏ Insert the key into the Keylock and place it to ON.

❏ Press the X-RAY ON button to begin x-ray

generation.

Note that if the kV level required for the next exposure is

higher than the kV level for the previous exposure, the x-ray

tube must be “ramped up” to that kV level by performing the

appropriate AUT OWARM cycle.

7. Unit shut down after exposure termination:

❏ Turn the Key lock to LOCKED OFF.

❏ Wait five minutes for the cooling unit or fan to cool

the x-ray tube anode.

❏ Place the MAINS circuit breaker OFF.

❏ Remove the power cord from its source.

❏ Disconnect all cables and hoses, and replace all

covers.

❏ Secure the key in a safe, controlled area to prevent

unauthorized use.

❏ Store the x-ray unit in a cool, dry location that

provides secure storage.

5-6

Chapter 5: LPX-200 X-ray System Operation

Page 39

LPX-200

Industrial Imaging System

LPX-200 FAULT MESSAGES

During operation, if a fault condition occurs, x-ray generation

automatically terminates and F AUL T messages

appear in the Message / Mode LCD. The following is a list of

the fault messages that may appear and instructions on

correcting the fault.

INTERLOCK:

The connection between pins “A” and “B” of the

INTERLOCK connector has been interrupted. Check that the

interlocked enclosure door switches are operable and closed,

or check the jumper for proper installation.

FLOW:

Coolant flow from the Cooling Unit to the Tubehad has been

interrupted. Check that the Cooling Unit is

running, or check the twin coolant hose for proper attachment.

TEMPERATURE/PRESSURE:

EXCESS kV :

This condition occurs if the drive voltage to the high voltage

invertor (in the Control Unit) exceeds a factory set

level. If the Excess kV fault occurs repeatedly after restart,

service is necessary.

X-RA Y SW. ERROR:

Upon power up the computer checks the X-RAY ON button

for a short circuit and displays this message if a short is

detected. X-ray generation cannot be initiated in this

condition, and service is necessary.

The Tubehad has overheated or the gas pressure has dropped

below 25 psi. Make sure the Cooling Unit (liquid-cooled

units) or the cooling fan (air-cooled units) is working properly.

Check the gas pressure within the

Tubehead. If the pressure is below 25 psi @ 70°F, perform the

Re-pressurization or Re-Filling procedure (whichever is

appropriate) in Section 6 of this manual.

ARC DETECTED:

This fault condition is usually due to instability from a new

tube or from an inadequate warm up sequence. Restart the

system and perform another AUTOWARM sequence. If the

ARC DETECTED fault occurs repeatedly on restart, refer to

the X-RAY TUBE SEASONING (later in this section).