Page 1

Instruction Manual

MODEL :

SERIAL# :

DATE :

SPELLMAN

HIGH VOLTAGE ELECTRONICS

CORPORATION

475 Wireless Blvd.

Hauppauge, New York, 11788

+1(631) 630-3000*FAX: +1(631) 435-1620*

E-mail: sales@spellmanhv.com

Website: www.spellmanhv.com

DXM100 SERIES

High Voltage Power Supply

R

DXM100 SERIES MANUAL 118146-001 Rev A

Page 2

IMPORTANT SAFETY PRECAUTIONS

SAFETY

THIS POWER SUPPLY GENERATES VOLTAGES THAT ARE DANGEROUS AND MAY BE FATAL.

OBSERVE EXTREME CAUTION WHEN WORKING WITH THIS EQUIPMENT.

High voltage power supplies must always be grounded.

Do not touch connections unless the equipment is off and the

Capacitance of both the load and power supply is discharged.

Allow five minutes for discharge of internal capacitance of the power supply.

Do not ground yourself or work under wet or damp conditions.

SERVICING SAFETY

.

Maintenance may require removing the instrument cover with the power on.

Servicing should be done by qualified personnel aware of the electrical hazards.

WARNING note in the text call attention to hazards in operation of these units

that could lead to possible injury or death.

CAUTION notes in the text indicate procedures to be followed to avoid possible

damage to equipment.

Copyright © 2000, Spellman High Voltage Electronics Corporation. All Rights Reserved.

This information contained in this publication is derived in part from proprietary and patent data. This information has

been prepared for the express purpose of assisting operating and maintenance personnel in the efficient use of the

model described herein, and publication of this information does not convey any right to reproduce it or to use it for

any purpose other than in connection with installation, operation, and maintenance of the equipment described.

118004-001 REV. B

Page 3

WICHTIGE SICHERHEITSHINWEISE

SICHERHEIT

DIESES HOCHSPANNUNGSNETZTEIL ERZEUGT LEBENSGEFÄHRLICHE HOCHSPANNUNG.

SEIN SIE SEHR VORSICHTIG BEI DER ARBEIT MIT DIESEM GERÄT.

Das Hochspannungsnetzteil muß immer geerdet sein.

Berühren Sie die Stecker des Netzteiles nur, wenn das Gerät ausgeschaltet ist und die elektrischen

Kapazitäten des Netzteiles und der angeschlossenen Last entladen sind.

Die internen Kapazitäten des Hochspannungsnetzteiles benötigen ca. 5 Minuten, um sich zu entladen.

Erden Sie sich nicht, und arbeiten Sie nicht in feuchter oder nasser Umgebung.

SERVICESICHERHEIT

Notwendige Reparaturen können es erforderlich machen, den Gehäusedeckel während des Betriebes zu

entfernen.

Reparaturen dürfen nur von qualifiziertem, eingewiesenem Personal ausgeführt werden.

“WARNING” im folgenden Text weist auf gefährliche Operationen hin, die zu Verletzungen oder zum Tod

führen können.

“CAUTION” im folgenden Text weist auf Prozeduren hin, die genauestens befolgt werden müssen, um

eventuelle Beschädigungen des Gerätes zu vermeiden.

118004-001 REV. B

Page 4

PRECAUTIONS IMPORTANTES POUR VOTRE SECURITE

CONSIGNES DE SÉCURITÉ

CETTE ALIMENTATION GÉNÈRE DES TENSIONS QUI SONT DANGEUREUSES ET PEUVENT ÊTRE FATALES.

OYEZ EXTRÊMENT VIGILANTS LORSQUE VOUS UTILISEZ CET ÉQUIPEMENT.

S

Les alimentations haute tension doivent toujours être mises à la masse.

Ne touchez pas les connectiques sans que l’équipement soit éteint et que la capacité à la fois de la charge et de

l’alimentation soient déchargées.

Prévoyez 5 minutes pour la décharge de la capacité interne de l’alimentation.

Ne vous mettez pas à la masse, ou ne travaillez pas sous conditions mouillées ou humides.

CONSIGNES DE SÉCURITÉ EN CAS DE REPARATION

La maintenance peut nécessiter l’enlèvement du couvercle lorsque l’alimentation est encore allumée.

Les réparations doivent être effectuées par une personne qualifiée et connaissant les risques électriques.

Dans le manuel, les notes marquées « WARNING » attire l’attention sur les risques lors de la manipulation de ces

équipements, qui peuvent entrainer de possibles blessures voire la mort.

Dans le manuel, les notes marquées « CAUTION » indiquent les procédures qui doivent être suivies afin d’éviter

d’éventuels dommages sur l’équipement.

118004-001 REV. B

Page 5

IMPORTANTI PRECAUZIONI DI SICUREZZA

SICUREZZA

QUESTO ALIMENTATORE GENERA TENSIONI CHE SONO PERICOLOSE E

POTREBBERO ESSERE MORTALI.

PONI ESTREMA CAUTELA QUANDO OPERI CON QUESO APPARECCHIO.

Gli alimentatori ad alta tensione devono sempre essere collegati ad un impianto di terra.

Non toccare le connessioni a meno che l’apparecchio sia stato spento e la capacità interna

del carico e dell’alimentatore stesso siano scariche.

Attendere cinque minuti per permettere la scarica della capacità interna dell’alimentatore

ad alta tensione.

Non mettere a terra il proprio corpo oppure operare in ambienti bagnati o saturi d’umidità.

SICUREZZA NELLA MANUTENZIONE.

Manutenzione potrebbe essere richiesta, rimuovendo la copertura con apparecchio

acceso.

La manutenzione deve essere svolta da personale qualificato, coscio dei rischi elettrici.

Attenzione alle AVVERTENZE contenute nel manuale, che richiamano all’attenzione ai

rischi quando si opera con tali unità e che potrebbero causare possibili ferite o morte.

Le note di CAUTELA contenute nel manuale, indicano le procedure da seguire per evitare

possibili danni all’apparecchio.

118004-001 REV. B

Page 6

Table of Contents

1. INTRODUCTION

1.1 Description of the DXM100 Series ......................................................................1

1.2 Standard Features .................................................................................................1

1.3 System Status and Fault Diagnostic Display .......................................................2

1.4 Interpreting the Model Number ...........................................................................2

1.5 High Voltage Connector Pin out Diagram ...........................................................3

2. INSPECTION & INSTALLATION

2.1 Initial Inspection ..................................................................................................4

2.2 Mechanical Installation ........................................................................................4

3. OPERATING INSTRUCTIONS

3.1 Operation ..............................................................................................................6

3.2 Standard Features .................................................................................................7

4. PRINCIPLES OF OPERATION

4.1 AC to DC Rectifier and Associated Circuits .......................................................13

4.2 High Frequency Inverter ......................................................................................13

PAGE

4.3 High Voltage Circuits ..........................................................................................13

4.4 Control Circuits ....................................................................................................14

4.5 Options .................................................................................................................14

5. OPTIONS

5.7 Custom Designed Models ....................................................................................15

5.8 Filament ..............................................................................................................15

6. MAINTENANCE

6.1 Periodic Servicing ................................................................................................16

6.2 Performance Test .................................................................................................16

6.3 High Voltage Dividers .........................................................................................16

7. FACTORY SERVICE

7.1 Warranty Repairs .................................................................................................17

7.2 Factory Service Procedures ..................................................................................17

7.3 Ordering Options and Modifications ...................................................................17

7.4 Shipping Instructions ...........................................................................................17

APPENDIX

A. Specification Controls (Custom Models Only)

DXM100 MANUAL i 118147-001 Rev. D

Page 7

LOCAL Operating Features

T

Chapter 1

INTRODUCTION

1.1 Description of the DXM100

Series

he DXM100 Series of X-ray generator module is

designed for OEM applications up to 100kV and

1200 watts. Its universal input, small package size

and choice of three standard digital interfaces simplifies

integrating the DX M100 into your X-ray analysis system.

Models have a floating filament (negative HV polarity)

based X-ray tube designs. DSP based emission control

circuitry provides excellent regulation of emission current,

along with outstanding stability performance.

The dramatically reduced size of the DXM100 Module,

compared to traditional high voltage modules, is obtained

by a state of the art off-line resonant converter. The

resonant converter utilizes a unique control scheme, which

allows constant frequency operation while maintaining

high efficiency. T he high efficiency is obtained by zero

current switching (ZCS) resonant control . High operating

frequency, typically 50kHz, allows for low ripple and

excellent dynamic response capabilities.

The DC output voltage and current are controllable over

the full range of operation. Monitoring and control

signals are provided for simple, yet flexible control of the

power supply. The DXM100 series operates 180 –

264vac, at 50/60 Hz single phase. The input power factor

corrected. The DXM100 series operates at full power

continuous. The ambient temperature must be kept below

the maximum rating as specified in 1.2. The standard

warranty applies to the modules. Consult factory about

the warranty for custom DXM100 modules.

IMPORTANT

This control signal in not a safety

interlock and should not be used for

protection from high voltage generation

for safety purposes.

(1) Output Control: Voltage, current filament limit

and preheat level are externally programmable over

the entire range from zero to maximum rating via 010VDC input.

(2) +10VDC Reference: A +10VDC reference is

provided for local programming via two

potentiometers to be used to adjust filament limit and

preheat level.

(3) High Voltage Enable: A hardware based, dry

contact closure will enable the power supply into the

high voltage on mode. .

1.2 Standard Features

The DXM100 series incorporates several standard

features designed to optimize user operation.

Slow Start: Provides a gr adual increa s e in high voltage

output until the maximum set point is reached. The

standard ramp time is 5 seconds. Various slow start times

can be accommodated. Consult Spellman’s Sales

Department for information on slow start options.

If a fault occurs, the power supply will revert to the

Shutdown mode indica ted by extinguishing of X-ray ON

LED and the via RS-232 as HV OFF. To reset a fault, a

clear command followed by HV ON command must be

sent via RS-232.

Power Facto r and Universal Input: The input voltage

of the DXM100 can operate within the range from 180 –

264vac. The power factor is actively corrected across this

entire range and is better than 0.99 at full load.

Internal EMI Filter and Fuse Protection: An internal

EMI filter and fuse provide protection against line voltage

surges and po wer s upply faults.

Remote Operating Features

Remote Control: USB, Ethernet and RS232 are standard.

A provided G.U.I allow user to control the unit via RS232

and USB interfaces. An imbedded Applet web Brower allow

user to control the unit via Ethernet. Refer to DXM100

Digital Protocol spec for Details.

Remote Monitor: Allows remote monitoring of the

Output voltage, current, filament limit, preheat level and

total HV On clock counter via the USB, Ethernet or RS232.

DXM100 MANUAL 1 118147-001 Rev. D

Page 8

Remote Programming: Allows remote programming of

the Output vol tage, current, filament limit and preheat level

via the USB, Ethernet or R S232.

X-ray Enable/Interlock: In local mode, allows remote

ON/OFF contr ol of the high vol tage. In remot e mode, the

hardware based dry contact closure must be closed in

order to enable the high voltage via the USB, Ether net or

RS232.

1.3 System Status and Fault

Diagnostic Displ a y

If a fault occurs, the power supply will revert to the

Shutdown mode indica ted by extinguishing of X-ray ON

led and via RS-232 as HV OFF. T o reset a fault in local

mode the enable must be reset. To reset a fault in remote

mode a HV ON command must be sent via the RS-232,

USB or Ethernet.

• OVER CURRENT FAULT: Indicates the over

current protection circuitry has caused the high

voltage to turn off. This fault will occur if the output

current exceeds 110% of full scale or 110% of current

program value. This fault is indicated by illumination

of over curr ent led status on the front cove r and via

RS-232, USB or Ethernet as Over Current.

• OVERVOLTAGE: Indicates the over voltage

protection circuitry has caused the high voltage to

turn off. This fault will occur if the output voltage

exceeds 110% of full scale or 110% of program

value. This fault is indicated by over voltage led

status on the front c over and vi a the RS-232, USB or

Ethernet as Over voltage.

• ARC FAULT: Indicates that an arc has occurred.

When a single arc occurs, the high voltage will be

quenched for 150ms and the Arc Fault led will

illuminate for 1 second and be r epo rted via the digital

interface for 1 second as arc fault. If 4 arcs occur

within 10 seconds a HVPS fault will occur and the

HVPS will be shutdown. This fault is indicated by

illumination of Arc Fault led status on front cover and

via RS-232, USB or Ethernet as arc fault.

• UNDER VOLTAGE: Indicates a failure in the

voltage regulation circuitry. This fault occurs when

there is a lack of output power to maintain regulation

and will result in shutdown of the HV. This fault will

occur if the output voltage less than 10% below the

program value. This fault is indica ted by illumination

of under volta ge led status o n the front cover and via

RS-232, USB or Ethernet a s under voltage.

• UNDER CURENT: Indicates failure in the current

regulation circuitry. This fault occurs when the

allowable percentage of error between actual and

programmed emission current is exceeded. This fault

will not cause a shutdown of the HV. This fault will

occur if the output current less than 10% below the

program value. This fault is indicated by illumination

of under curr ent led status on fr ont co ver and via RS232, USB or Ethernet as under current.

• OVER TEMPERATUR E: Indicates either a failure

in the cooling system that would cause the internal

heat sink temperature to exceed it’s operating range

or the ambient temperature to exceed 40degC,

resulting in shutdown of HV. This fault is indicated

by over temperature led status on the front cover and

via RS-232, USB or Ethernet as over temperature.

• Filament Protection: If the output voltage goes

below 30% of full rating the filament power will be

disable to protect the filament in the users X-ray tube,

but the filament preheat will still be active. This will

cause an undercurrent fault.

• PS Fault Indication: PS Faults an open collector

output with a 1k ohm series impedance on J2-1,

indicates that a fault has occurred. High = no faults

• X-ray On Indication: X-ray On Signal is an open

collector output a 1k ohm series impedance on J2-14,

indicates X-ray status. High = X-ray Off, Low =X ray On

• X-ray On LED: when the high voltage status is

“On” state it is indicate d by X-RAY ON led status on

the front cover

• Power On LED: when the input power is applied to

the unit it is indicated by PWR ON led status on the

front cover

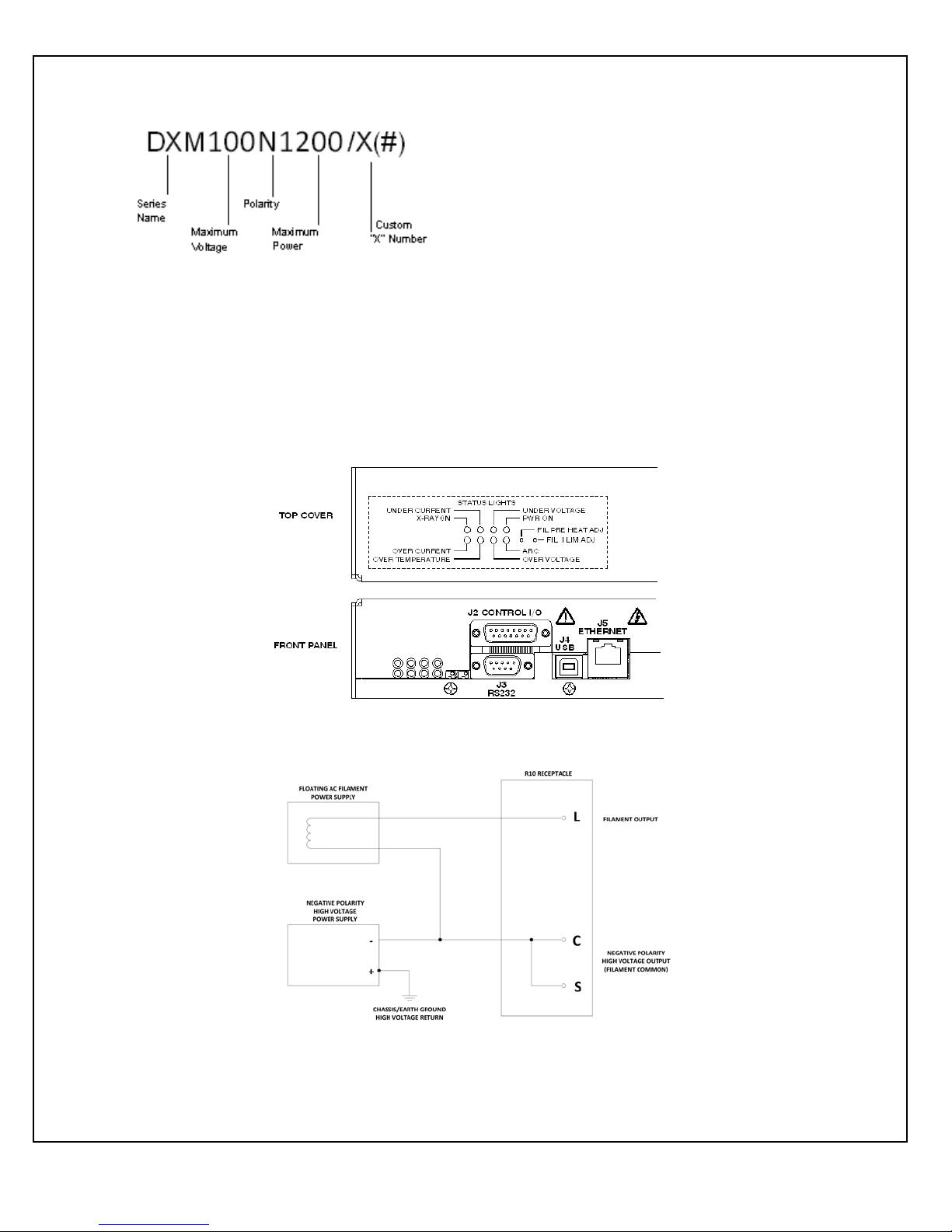

1.4 Interpreting the Model Number:

The model number of the power supply describes its

capabilities. After the series name is:

(1) The maximum voltage in kilo volts.

(2) The polarity of the output – positive (P), or

negative (N).

(3) The maximum output in watts.

(4) Custom “X” number representing details listed in

a separate specification control drawing.

DXM100 MANUAL 2 118147-001 Rev. D

Page 9

• POWER LIMIT FAULT: Indicates the po wer limit

protection circuitry has caused the high voltage to

turn off. This fault will occur if the output power

exceeds 105% of programmed value. This fault is

indicated by illumination of both the over voltage and

under voltage led status on the front cover and via

RS-232, USB or Ethernet as Power limit. This is

maximum power limit that can be set 0-1200 watts

via the digital interface. This value is stored in HVPS

memory.

Figure 1.1 LED Legend

DXM100 – NEGATIVE POLARITY

DXM100 MANUAL 3 118147-001 Rev. D

Page 10

Chapter 2

I

INSPECTION AND

INSTALLATION

nitial inspection and preliminary checkout procedures

are recommended. For safe operation, please follow

the step-by-step procedures described in Chapter 3,

Operating Ins t ructions.

2.1 Initial Inspection

Inspect the package exterior for evidence of damage due

to handling in transit. Notify the carrier and Spellman

immediately if damage is evident. Do not destroy or

remove any of the packing material used in a damaged

shipment. After unpacki ng, inspect the pa nel and chassis

for visible damage.

Fill out and mail the Warranty Registration card

accompanying the unit. Standard DXM100 high voltage

power supplies and components are covered by warranty.

Custom and special order models (with an X suffix in the

model number) are also covered by warranty.

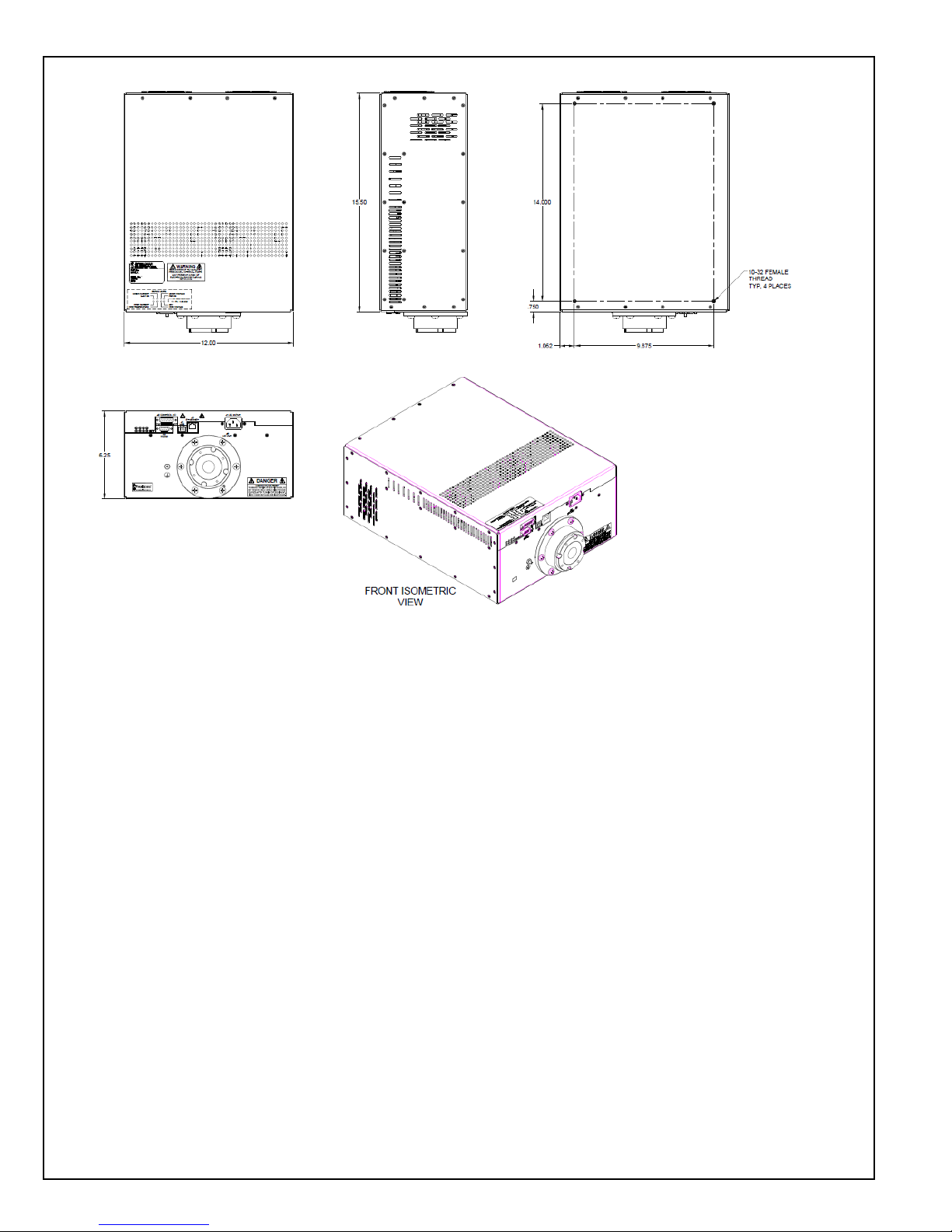

2.2 Mechanical Installation

The DXM100 series module power supplies are

designed for installation into existing or newly

developed OEM equipment. The power supply

can also easily fit into bench top applications or

test set requirements. Standard unit dimensions

are shown in Figure 2 .1

For custom mounting requirements or specific

package size requirements consult Spellman’s

Sales Department. Spellman has many package

designs available, or can design a specific

enclosure for your requirements.

The DXM100 serie s utilizes solid encapsulations

for corona free operation. No periodic

maintenance is required.

DXM100 MANUAL 4 118147-001 Rev. D

Page 11

Figure 2.1 Unit Dimensions

DXM100 MANUAL 5 118147-001 Rev. D

Page 12

Chapter 3

OPERATING INSTRUCTIONS

3.1 Operation

WARNING

THIS EQUIPMENT GENERATES

DANGEROUS VOLTAGES THAT MAY BE

FATAL. PROPER GROUNDING OF ALL HIGH

VOLTAGE EQUIPMENT IS ESSENTIAL.

IMPORTANT:

Before connecting the power supply to the

AC line, follow this step-by-step procedure.

Do not connect the power supply to the AC

line until Step F is reached.

Failure to follow these procedures may void

the warranty.

A) Insure that the high voltage cable is properly

greased and installed in accordance to the High

voltage cable manufacturer instructions and terminated

to the load. Insure that all circuits connected to the high

voltage output are safely interlocked against accidental

contact. Insure external load is discharged.

B) Check the input voltage rating on the serial

nameplate of the supply and make certain that this is the

rating of the available power source

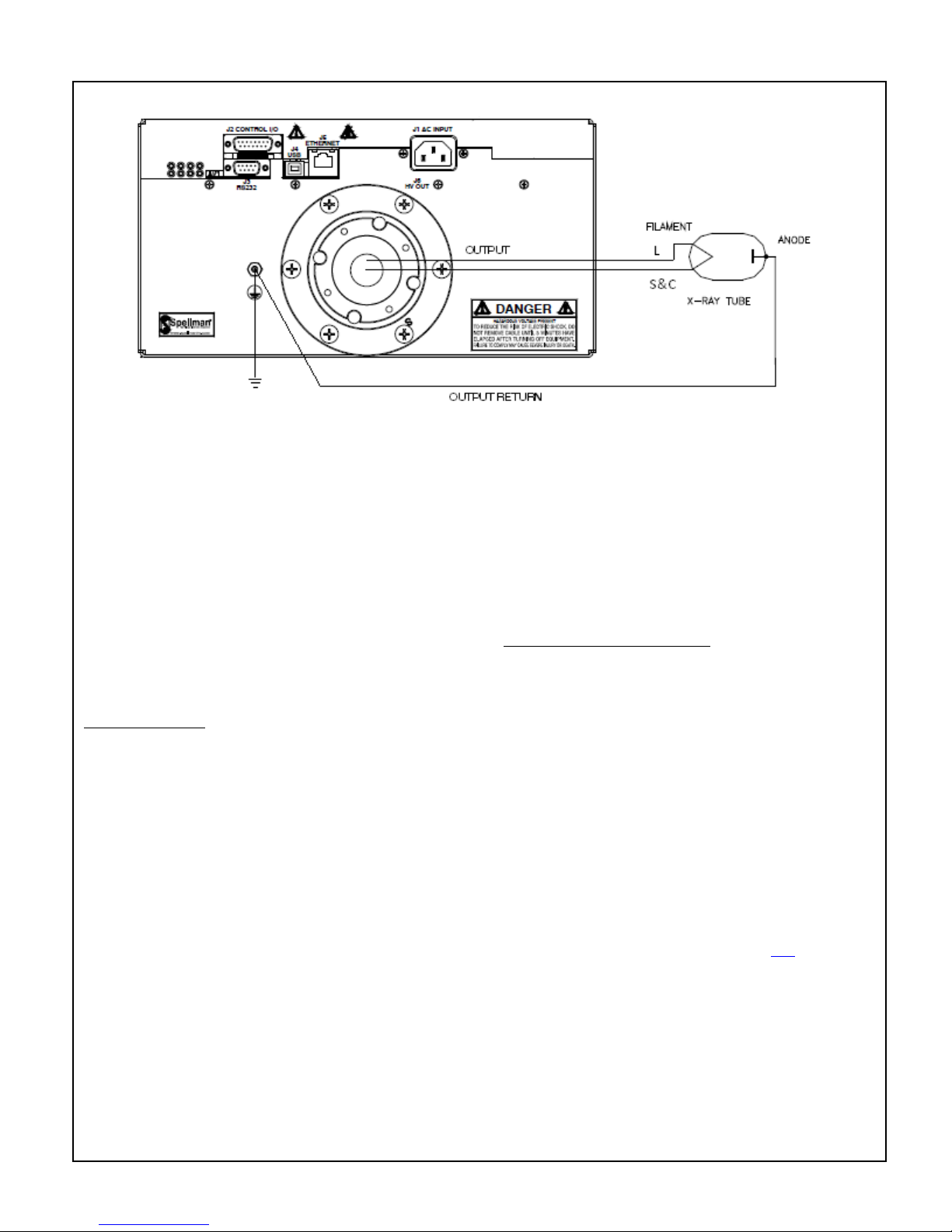

C) PROPER GROUNDING TECHNIQUE: The

chassis of high volta ge power supp lies must be grounded,

preferably to a water system ground using copper pipe or

other earth gr ound . A gro und stud is p rovi ded on the front

panel .See Figure 3.1 for a typical operating setup. The

return line from the load should be connected to the power

supply chassis. Using a separate external ground at the

load is not recommended. An IEC 320 connector is

provided for connection to the line voltage source. A

standard line cord is also provided.

D) Hook-up: Connect control and monitoring

connections as described in this manual.

E) For initial turn-on, program the voltage and

current for zero output. Connect the enable/disable signal

to disable.

F) The input power cable may now be connected to

the AC power line.

G) Enable the power supply via the enable/disable

hardware based, dry contact closure.

H) Slo wly progra m the outp ut vol tage a nd cur rent to

desired level. Monitor the output voltage and curr ent via

the monitoring test points. Note equipment operation is

normal, i.e. Load is behaving as predicted.

I) To turn high voltage off, use the enable/disable

signal. If equipment is to be kept off for extended

periods, disconnect power supply from line voltage

source.

WARNING

AFTER TURNOFF, DO NOT HANDLE THE LOAD

UNTIL THE CAPACITANCE HAS BEEN

DISCHARGED!

LOAD CAPACITANCE MAY BE DISCHARGED BY

SHORTING TO GROUND.

WARNING

THE VOLTAGE MONITOR ON THE POWER

SUPPLY FRONT PANEL DOES NOT READ THE

OUTPUT VOLTAGE WHEN THE POWER IS

TURNED OFF, EVEN IF A CHARGE STILL EXISTS

ON THE LOAD.

CAUTION

ALWAYS OPERATE THE UNIT WITH THE COVER

ON. DO NOT ATTEMPT TO ACCESS OR REPAIR

ANY INTERNAL CIRCUITS. DANGEROUS AND

LETHAL VOLTAGES ARE GENERATED INSIDE

THE MODULE.

DXM100 MANUAL 6 118147-001 Rev. D

Page 13

Figure 3.1 Proper Grounding Technique

3.1.1 X-ray Tube Operation

The X-ray tube should be operated according to the X-ray

manufacturers specifications. Filament Limit program

and Filament Preheat program shall be set so not to

exceed maximum filament current as per the X-ray tube

manufacturers specifications. X-ray tube seasoning

schedules and kV ramp profiles should also be per the Xray tube manufacturers specification.

Set Filament Limit: One of the most critical settings is the

Filament Limit adjustment. The Filament Limit set point

limits that maximum output current of the filament power

supply to protect the filament of the X-Ray tube. This

setting will make it impossible for the X-Ray generator to

exceed this value under any circumstance. It should be set

at or below the X-Ray tube manufacturer’s specification.

Filament Limit program scaling is 0 to 10Vdc = 0 to 5

amps.

When setting the Filament Limit below the maximum XRay tube specification, the Filament Limit should be 1015% higher than the filament current required to achieve

the maximum programmed emission current (mA) at the

lowest kV setting to be used. Remember, filament

maximum values are different than the REQUIRED values

for emission. Setting 10-15% over the needed emission

current values provides headroom as well as better trainset

response characteristics.

Always keep the Filament Limit level at or below the

manufacturers recommended maximum filament

current specification.

Set Filament Standby (Preheat): The Filament Standby

current (referred to as Filament Preheat on some product

lines) is the idle current supplied to the X-Ray tube

filament during X-Ray Standby (HV OFF/X-Ray

disabled) conditions.

Filament Standby programing scaling is 0 to 10Vdc = 0 to

2.5 amps.

The Filament Preheat set point is typically around 1 amp

to 2 amps, but the X-Ray tube manufacturer should be

consulted. A good guideline to consider is the maximum

Filament Preheat level should be limited to 50% of the

Filament Limit specification. It is perfectly fine to set

standby current to zero if fast emission current ramping is

not required.

For additional information please visit this link

.

3.2 Standard Features

A note on remote interface circuitry and remote signal

grounding: whenever possible, electrical isolation should

be provi d ed when int er fac ing with any high vol ta ge p o wer

DXM100 MANUAL 7 118147-001 Rev. D

Page 14

supply. For enable/disable signal connections, an isolated

relay or optocoupler should be used. For PS Fault

indication an optocoupler should be used. If possible,

analog programming and monitoring signals should be

isolated via analog isolation amplifiers. Spellman

application engineers are available to assist in interface

circuitry design. All interface cables should be properly

shielded. All power supply signals should be referenced

to the power supplies signal ground or power supply

chassis ground

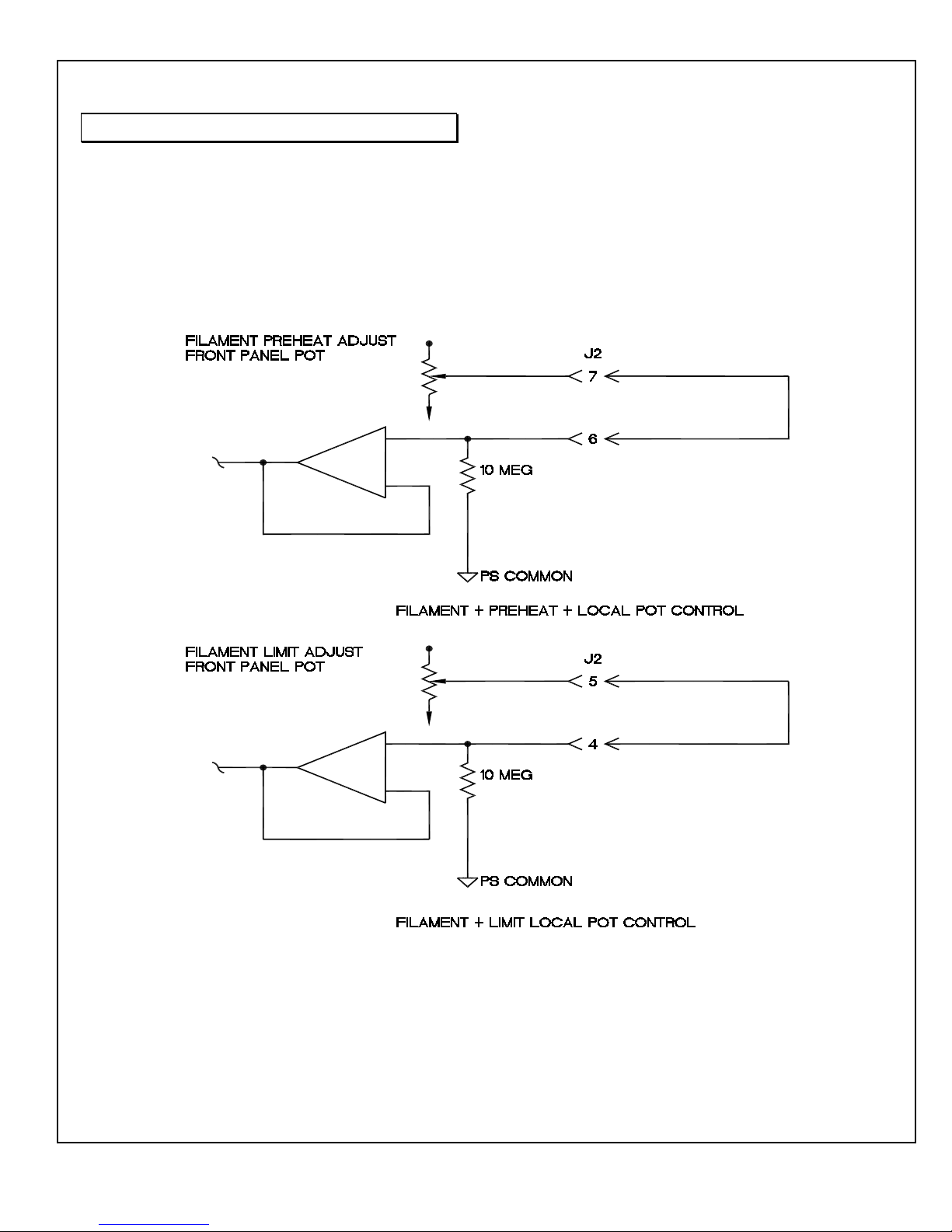

Local Programming potentiometers: The filament limit

and preheat level controls on the front panel can be used

as follows: For local filament limit control, jump J2-4 to

J2-5. For local preheat control, jump J2-6 to J2-7. See

Figure 3.2.

REMOTE PROGRAMMING:

After establishing co mmunication with the UUT as pe r

the DXM100 Digital Protocol spec. Switch the UUT to

Remote Mode by sending a Program Local/Remote Mode

command. If the unit is in Local Mode and enabled prior

to switching it to Remote Mode, the UUT will shutdown

and a P.S Fault indictor will occur when it is switch to

Remote Mode. A clear command can be sent to clear this

fault.

Remote Control: USB, Ethernet and RS232 are standard

Refer to DXM100 Digital Protocol spec for Details.

Remote Monitor: Allows remote monitoring of the

Output volta ge, current, filament limit and preheat level via

the USB, Ethernet or RS 232.

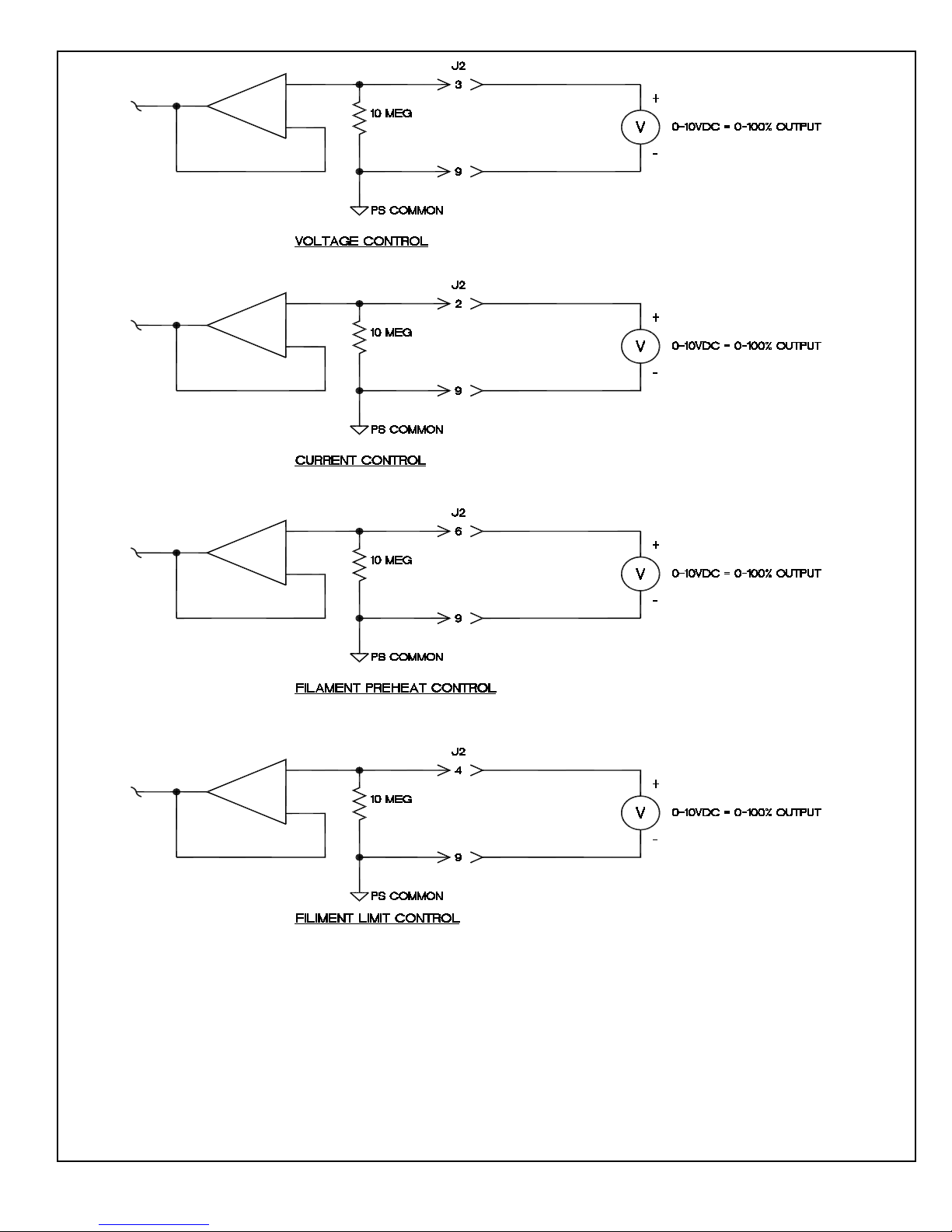

LOCAL PROGRAMMING: Allows local adjustment

of the output voltage, current filament limit and preheat

level via an external voltage source. 0-10VDC signal is

supplied to pin 3 of the J2 for voltage programming and 010 VDC signal is supplied to Pin 2 J2 for current

programming. 0-10VDC signal is supplied to pin 4 of the

J2 for filament limit programming. 0-10VDC signal is

supplied to pin 6 of the J2 for filament preheat

programming (2.5 a max). Pr ogra mming signals should be

referenced to Pi n 9 of J 2, signal ground. By adjust ing the

voltage source from 0 volts (zero output) to 10 volts (full

rated output) the desired output can be selected. See

Figure 3.3 for wiring diagram and specifications.

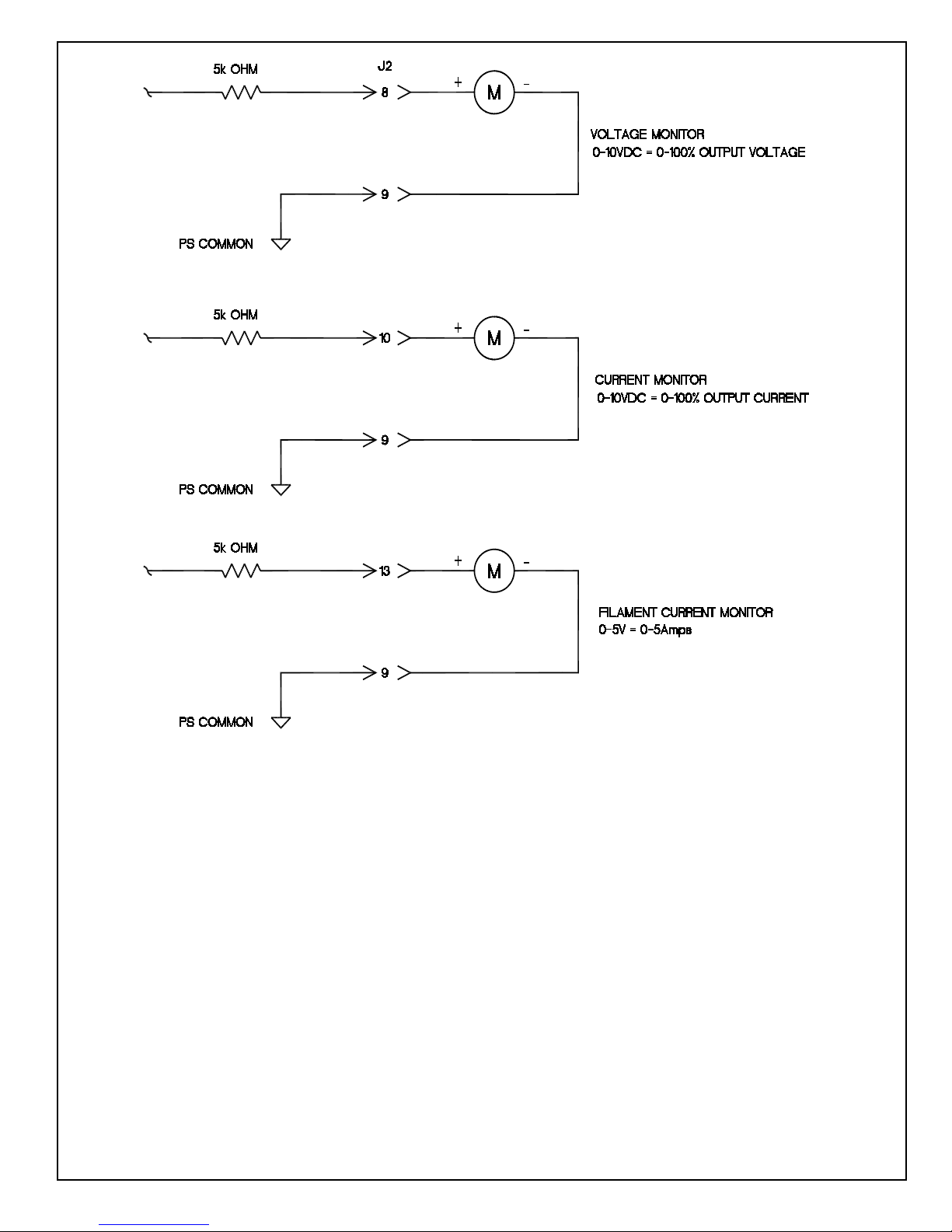

Local Monitoring: Monitor outputs are made available

for monitoring the voltage, current output and filament

preheat level. The Monitor outputs are always positive

regardless of the output polarity, where zero (0) to 10 (10)

volts equals 0-100% of output. See Figure 3.4 for

monitoring wiring and see data sheet for pin outs.

X-RAY Enable/Interlock: In Local Mode allows

ON/OFF cont rol of the high voltage. The hardware based

dry contact closure must be closed in to enable the high

voltage. In Remote Mode this I/O acts as an Interlock.

The hardware based dry contact closure must be closed in

order t o enable the high vol tage via the USB , Ethernet or

RS232. This can be done by connecting pins 11 and 12

on J2. See Figure 3.5.

Remote Programming: Allows remote programming o f

the Output vol tage, curre nt, filament limit and preheat level

via the USB, Ethernet or R S232.

DXM100 MANUAL 8 118147-001 Rev. D

Page 15

WARNING

It is extremely dangerous to use this

circuit to inhibit high voltage generation

for the purpose of servicing or

approaching any area of load

considered unsafe during normal use.

Figure 3.2 Local Programming Via Internal Front Panel Pot Voltage Source.

DXM100 MANUAL 9 118147-001 Rev. D

Page 16

Figure 3.3 Local Programming Via External Voltage Source

DXM100 MANUAL 10 118147-001 Rev. D

Page 17

Figure 3.4 Remote Monitoring

DXM100 MANUAL 11 118147-001 Rev. D

Page 18

RELAY

Figure 3.5 Enable/Interlock Logic Control

DXM100 MANUAL 12 118147-001 Rev. D

Page 19

Chapter 4

T

PRINCIPLES OF OPERATION

he DXM100 Series of high voltage power supplies

utilizes sophisticated power conversion technology.

Advanced analog and power conversion techniques

are used in the DXM100 series. The intention of the

Principles o f Operation is to introduce the basic function

blocks that comprise the DXM100 power supply. For

details on a specific circuit, consult Spellman’s

Engineering Department.

The DXM100 power supply is basically an AC to DC

power converter. Within the power supply, conversions

of AC to DC then to high frequency AC, then to high

voltage DC take place.

Typical DXM100 power supplies comprise a few basic

building blocks. These are: 1) AC to DC rectifier, 2)

Power Factor correction boo st circuitry 3) High frequency

quasi-resonant inverter, 4) High voltage transformer and

rectifier circuits, and 5) Contro l and monitoring circuits.

The following is a brief description of each building

block.

4.1 Power Factor and Associated

Circuits

The DXM100 series can operate from 180 - 265VAC.

The input voltage is connected via a typical IEC 320 type

input connec tor. An inte rnal EMI filter and fuse housing

is an integral part of the DXM100 module. The input

circuits actively correct the power factor.

The input line voltage is applied to a current limit device

to reduce the initial inrush current. The input line voltage

is converted to a 400VDC voltage via an active PFC

Converter.

WARNING

The energy levels used and generated by the

power supply can be lethal! Do not attempt to

operate the power supply unless the user has a

sufficient knowledge of the danger s and hazards

of working with high voltage. Do not attempt to

approach or touch any internal or external

circuits or components that are connected or

have been connected to the power supply. Be

certain to discharge any stored energy that may

be present before and after the power supply is

used. Consult IEEE recommended practices for

safety in high voltage testing #510-1983.

4.2 High Frequency Inverter

The DXM100 is a resonant converter operating in a zero

current switching, series resonant, parallel loaded

topology. MOSFET transistors switch the 400 VDC

voltage to the resonant tank circuit. Typical operating

frequency is in the range of 35-65kHz depending on

model. Control of the resonant circuit output is done by

the low voltage control circuits, and are isolated by an

isolated pulse transformer. The output of the resonant

circuit is applied to the primary of the high voltage

transformer.

4.3 High Voltage Circuits

The high voltage transformer is a step-up type. The

secondary of the high voltage transformer is connected to

the high voltage rectifier circuit. The rectifier circuit will

vary depending up on the rated output voltage. For lower

power a half wave Cockroft-Walton multiplier is used, for

higher power a full wave Cockroft-Walton multiplier is

used. A feedback signal is generated by the high voltage

resistor divider. This feedback signal is sent to control

circuits to provide voltage regulation and monitoring. A

current sense resistor is connected at the low voltage end

of the rectifier circuit. The circuit sense signal is sent to

the control circuits to provide current regulation and

monitoring.

The high voltage rectifier output is connected to the

output limiting resistors. These resistors limit the peak

surge current in the event an arc or discharge occurs. The

limiting resistor output is connected to the output

connector provided.

DXM100 MANUAL 13 118147-001 Rev. D

Page 20

4.4 Cont rol Circuits

Control circuits are used for regulation, monitoring, pul sewidth, control, slow-start and inhibit control. Feedback

signals are calibrated and buffered via general purpose

OP-AMPS. Pulse width control is accomplished by a

typical PWM type control I.C. Logic enable/disable is

provided by a logic gate I.C. Regulators generate +/- 15V

and 10VDC. DSP based control circuitry provides

excellent regulation, along with outstanding stability

performance

WARNING

LINE VOLTAGE IS PRESENT

WHENEVER THE POWER SUPPLY IS

CONNECTED TO EXTERNAL LINE

VOLTAGES. BE SURE TO DISCONNECT

THE LINE CORD BEFORE OPENING T HE

UNIT. ALLOW 5 MINUTES FOR

INTERNAL CAPACITANCE TO

DISCHARGE BEFORE REMOVING ANY

COVER.

4.5 Options

Due to the variations of models and options provided in

the DXM100 series, details of actual circuits used may

differ slightly from above descriptions. Consult

Spellman’s Engineering Department for questions

regarding the principles of operations for the DXM100

series.

DXM100 MANUAL 14 118147-001 Rev. D

Page 21

T

Chapter 5

OPTIONS

He options available for this power supply are

described in this section. Interface diagrams are

shown where required. Options are specified by

including the option code in the model number as

described in Section 1.4.

5.1 Custom Designed Models X (#)

Units built to customer specifications are assigned an X

number be the factory. If this unit is an X model,

specification control sheet is added at the end of this

instruction manual.

5.2 Filament

Filament outputs with an emission control loop are

available for use with X-ray tubes. Generally, filament

outputs are in the range of 3V – 10V, at currents up to 5A.

A floating AC filament is provided. The filament on a

standard DXM100 Module is calibrated to 5a@10V using

either a 10ft High Voltage .

Spellman welcomes the opportunity to tailor units to fit

your requirements or to develop new products for your

applications. Contact Spellman Sales Department.

Note: Before operating this system, refer to operating

instructions in Chapter 3.

DXM100 MANUAL 15 118147-001 Rev. D

Page 22

Chapter 6

T

WARNING

WARNING

MAINTENANCE

his section describes periodic servicing and

performance testing procedures.

THIS POWER SUPPLY GENERATES VOLTAGES

THAT ARE DANGEROUS AND MAY BE FATAL.

OBSERVE EXTREME CAUTION WHEN WORKING

WITH HIGH VOLTAGE.

6.1 Periodic Servicing

Approximately once a year (more often in high dust

environments), disconnect the power to the unit. Use

compressed air to blow dust out of the inside of the unit.

Avoid touching or handling the high voltage assembly.

High Voltage Cable Plug/Receptacle should be greased

and maintained in accordance to the High voltage

cable manufacturer instructions.

6.2 Performance Test

High voltage test procedures are described in Bulletin

STP-783, Standard Test Procedures for High Voltage

Power Supplies. Copies can be obtained from the

Spellman Customer Service Department. Test equipment,

including an oscilloscope, a high impedance voltmeter,

and a high vol ta ge d ivi de r such a s the Sp el lman HV D-100

or HVD-200, is needed for performance tests. All test

components must be rated for operating voltage.

6.3 High Voltage Dividers

High voltage dividers for precise measurements of output

voltage with an accuracy up to 0.1% are available from

Spellman. The HVD-100 is used for voltages up to

100KV. The HVD-200 measures up to 200KV. The

Spellman divider is designed for use with differential

voltmeters or high impedance digital voltmeters. The high

input impedanc e is ideal for measuring hi gh voltage low

current sources, which would be overloaded by traditional

lower impedance dividers.

HIGH VOLTAGE IS DANGEROUS.

ONLY QUALIFIED PERSONNEL SHOULD

PERFORM THESE TESTS.

DXM100 MANUAL 16 118147-001 Rev. D

Page 23

Chapter 7

FACTORY SERVICE

7.1 Warranty Repairs

During the Warranty period, Spellman will repair all units

free of charge. The Warranty is void if the unit is worked

on by other than Spellman personnel. See the Warranty in

the rear of this manual for more information. Follow the

return procedures described in Section 7.2. The customer

shall pay for shipping to and from Spellman.

7.2 Factory Service Procedures

Spellman has a well-equipped factory repair department.

If a unit is returned to the facto ry for calibration o r repair ,

a detailed description of the specific problem should be

attached.

For all units returned for repair, please obtain an

authorization to ship from the Customer Service

Department, either by phone or mail prior to shipping.

When you call, please state the model and serial numbers,

which are on the plate on the rear of the power supply,

and the purchase order number for the repair. A Return

Material Authorization Code Number (RMA Number) is

needed for all returns. This RMA Number should be

marked clearly on the outside of the shipping container.

Packages received without an RMA Number will be

returned to the customer. The Customer shall pay for

shipping to and from Spellman.

A preliminary estimate for repairs will be given by phone

by Customer Service. A purchase order for this amount is

requested upon issuance of the RMA Number. A more

detailed estimate will be made when the power supply is

received at the Spellman Repair Center. In the event that

repair work is extensive, Spellman will call to seek

additional authorization from your company before

completing the repairs.

7.3 Ordering O pt ions and

Modifications

Many of the options listed in Chapter 5 can be retrofitted

into Spellman power supplies by our factory. For prices

and arrangements, contact our Sales Department.

7.4 Shipping Inst ructions

All power supplies returned to Spellman must be sent

shipping prepaid. Pack the units carefully and securely in

a suitable container, preferably in the original container, if

available. The power supply should be surrounded by at

least four inches of shock absorbing material. Please

return all associated materials, i.e. high voltage output

cables, interconnection cables, etc., so that we can

examine and test the entire system.

All correspondence and phone calls should be directed to:

Spellman High Voltage Electronics Corp.

475 Wireless Boulevard

Hauppauge, New York 11788

TEL: (631) 630-3000 FAX: (631) 435-1620

E-Mail: sales@Spellmanhv.com

http://www.spellmanhv.com

DXM100 MANUAL 17 118147-001 REV. D

Page 24

To obtain information on Spellman’s product warranty please visit our website at:

http://www.spellmanhv.com/en/About/Warranty.aspx

Page 25

DXM100 Digital Interface

Manual

Ethernet

Serial – RS-232

Universal Serial Bus - USB

Copyright 2013, Spellman High Voltage Electronics Corporation. All Rights Reserved.

This information contained in this publication is derived in part from proprietary and patent data. This information has

been prepared for the express purpose of assisting operating and maintenance personnel in the efficient use of the

model described herein, and publication of this information does not convey any right to reproduce it or to use it for

any purpose other than in connection with installation, operation, and maintenance of the equipment described.

118142-001 Rev B

475 Wireless Boulevard • Hauppauge, New York 11788, USA • www.spellmanhv.com • T:+1 631.630.3000 • F:+1 631.435.1620

Page 26

Table Of Contents

1.0 Scope ....................................................................................................................... 3

2.0 Functional Description ........................................................................................... 3

3.0 Getting Started - Interface Wiring and Pin-outs ................................................... 3

3.1 RS232 Interface .................................................................................................................... 3

3.2 Ethernet Interface .................................................................................................................. 5

3.3 Universal Serial Bus Interface .............................................................................................. 6

3.4 RS-232 Cabling ..................................................................................................................... 6

3.5 Ethernet Cabling ................................................................................................................... 6

3.6 USB Cabling ......................................................................................................................... 8

4.0 Getting Started - Software .................................................................................... 10

4.1 RS-232 ................................................................................................................................ 10

4.2 Ethernet ............................................................................................................................... 12

4.3 USB ..................................................................................................................................... 31

5.0 Ethernet Commands ............................................................................................. 39

5.1 TCP/IP Format .................................................................................................................... 39

5.2 Command Arguments ......................................................................................................... 40

5.3 Command Overview ........................................................................................................... 40

5.4 Response Overview ............................................................................................................ 41

5.5 Command Structure ............................................................................................................ 43

6.0 Serial Commands – RS-232 / USB ....................................................................... 73

6.1 Serial Interface Protocol ..................................................................................................... 73

6.2 Command Arguments ......................................................................................................... 73

6.3 Checksums .......................................................................................................................... 73

6.4 Command Overview ........................................................................................................... 75

6.5 Response Overview ............................................................................................................ 76

6.6 Command Structure ............................................................................................................ 78

6.7 Spellman Test Commands ................................................................................................ 103

6.8 Serial Command Handling ................................................................................................ 104

118142-001 Rev B Page 2 of 104

Page 27

WARNING

THIS EQUIPMENT GENERATES DANGEROUS VOLTAGES THAT MAY BE FATAL.

PROPER GROUNDING OF ALL HIGH VOLTAGE EQUIPMENT IS ESSENTIAL.SEE DXM100

OWNERS MANUAL FOR PROPER GROUNDING TECHNIQUE AND SAFETY

PRECAUTIONS BEFORE APPLING AC INPUT POWER TO THE DXM100 UNIT.

TO PREVENT DAMAGE TO THE HOST COMPUTER THE COMPUTER SHOULD BE

GROUNDED TO THE SAME GROUND AS THE UUT.

1.0 SCOPE

This document applies to the communications interfaces on the DXM100 ,

assembly 460188.

2.0 FUNCTIONAL DESCRIPTION

The DXM100 provides 3 different types of digital communications interfaces:

RS-232 on J3

Ethernet (10/100-Base-T) on J5

Universal Serial Bus on J4.

3.0 GETTING STARTED - INTERFACE WIRING AND PIN-OUTS

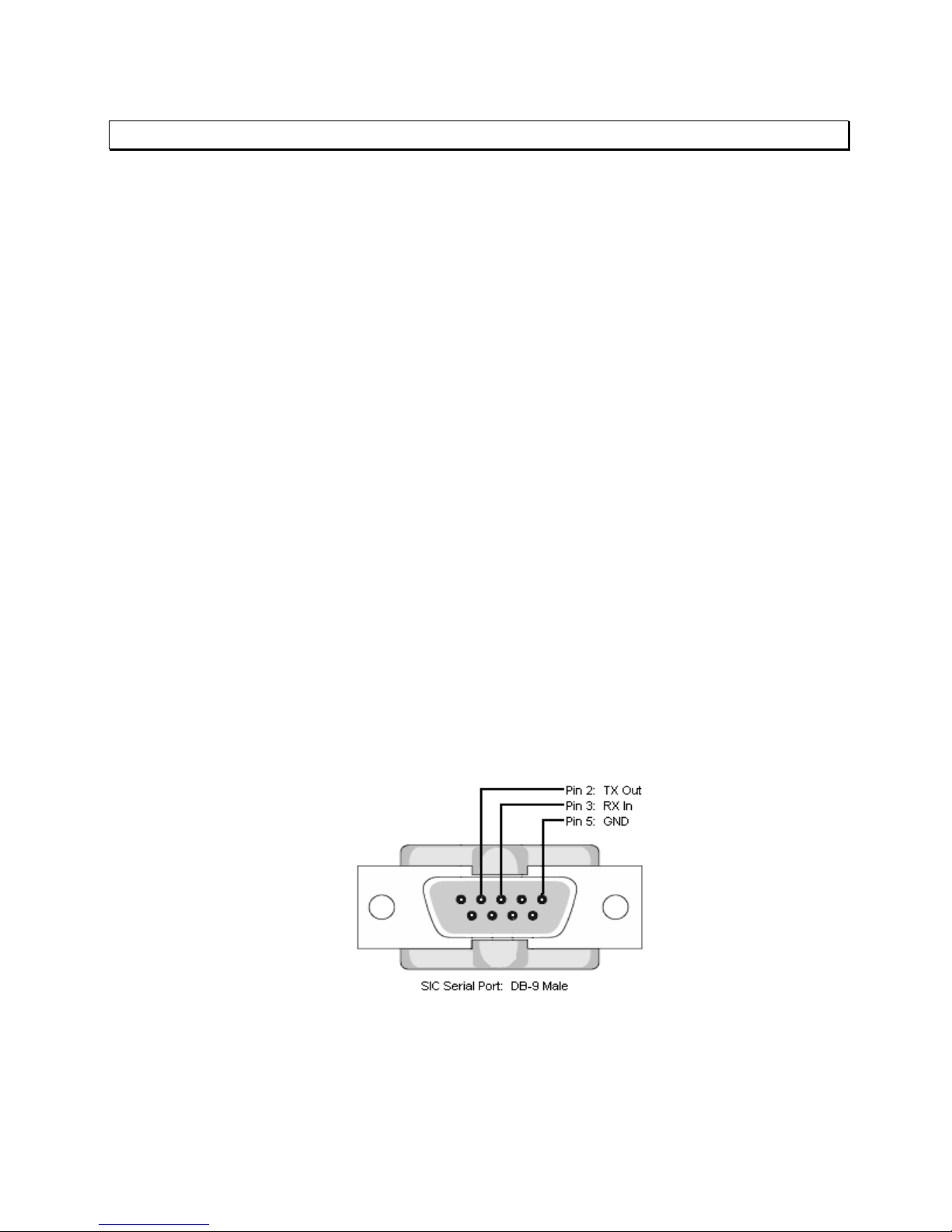

3.1 RS232 INTERFACE

The RS232C interface has the following attributes:

115K bits per second

No Parity

8 Data Bits

1 Stop Bit

No handshaking

DB-9 connector as shown

118142-001 Rev B Page 3 of 104

Page 28

Figure 1 – J3, RS-232 DB-9M pinout (front view)

PIN DESCRIPTION

1 2 Tx Out

3 Rx In

4 5 Ground

6 7 8 9 -

118142-001 Rev B Page 4 of 104

Page 29

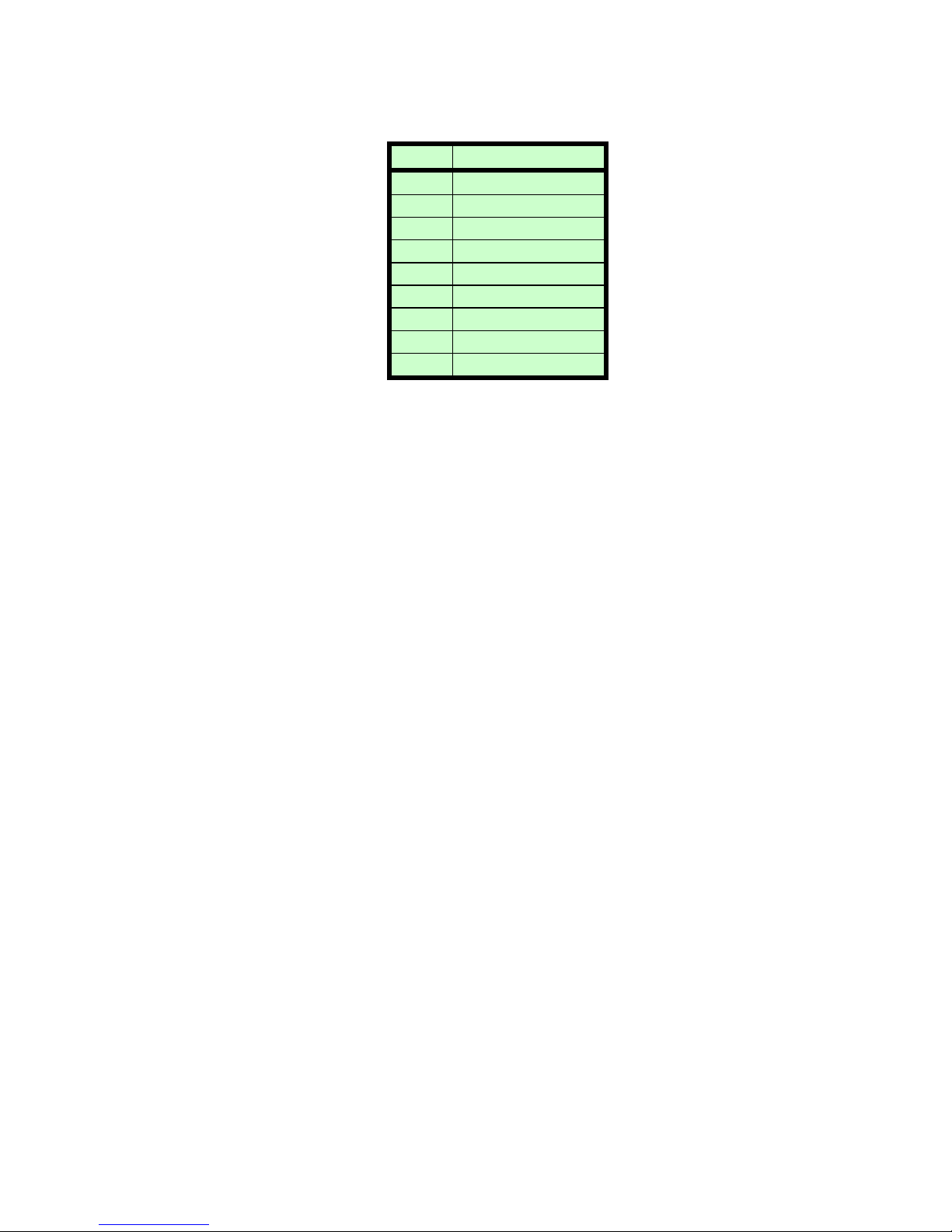

3.2 ETHERNET INTERFACE

The Ethernet interface has the following attributes:

10/100-Base-T

IP address can be set by the system integrator

Network Mask can be set by the system integrator

TCP Port Number can be set by the system integrator

RJ-45 connector

Network attachment via Crossover and Standard Ethernet cables.

Supported Operating Systems: Windows 98 2ED, Windows 2000

(SP2), Windows NT (SP6), Windows XP Professional

LED 1 LED 2

Figure 2 – J5, Ethernet RJ45 Jack (front view)

PIN DESCRIPTION

1 TX+

2 TX3 RX+

4 5 6 RX7 8 -

The Ethernet RJ-45 has two LED indicators, as shown in Figure 2. The left

LED, LED1 indicates that the network processor has a valid network link.

The right LED, LED2 indicates network activity.

8 7 6 5 4 3 2 1

118142-001 Rev B Page 5 of 104

Page 30

3.3 USB – UNIVERSAL SERIAL BUS INTERFACE

The USB interface has the following attributes:

Compliant with USB 1.1 and USB 2.0 specifications

Type B male connector

Included driver can be communicated with via standard Windows

serial communications methods

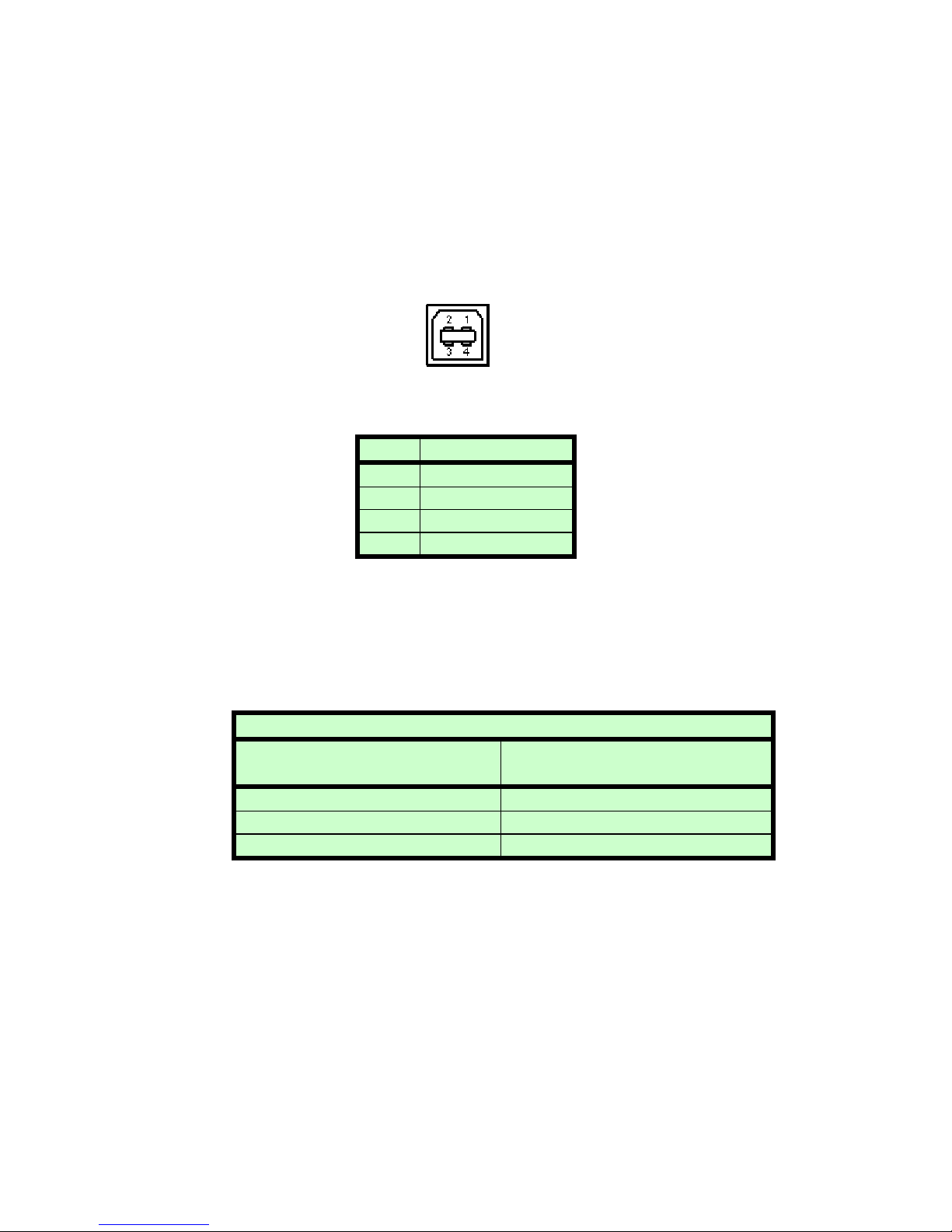

Figure 3 – J4, USB Type B (front view)

PIN DESCRIPTION

1 Vbus +5V

2 D3 D+

4 Ground

3.4 RS-232 CABLING

A standard shielded RS-232 cable is used to connect the DXM100 serial

port to the serial port on a standard personal computer. Please refer to the

following chart.

PC Connector (DB-9 Female)

Pin 2: RX In Pin 2: TX Out

Pin 3: TX Out Pin 3: RX In

Pin 5: Ground Pin 5: Ground

PC to DXM100 Board Cable Details

3.5 ETHERNET CABLING

Shielded Category 5 (CAT5) Ethernet patch cables are used to connect

the DXM100 to the host computer. There are two ways to connect to the

DXM100 board via Ethernet: the first is to directly cable between the host

and the DXM100 board, and the second is through the use of a switch,

hub, or network.

DXM100 Connector (DB-9

Male)

118142-001 Rev B Page 6 of 104

Page 31

A direct connection requires a non-standard cable where the wires are not

run straight through. Please refer to the two cable ends shown below in

figure 4.

Figure 4 – Crossover Cable for Direct Connection

A standard connection through a hub, switch, or network uses a standard

CAT5 patch cable. Please refer to the two cable ends shown below in

figure 5.

Figure 5 – Standard Straight Through Cable – Standard CAT5 Patch

118142-001 Rev B Page 7 of 104

Page 32

3.6 USB CABLING

A high-quality double shielded USB 2.0 Type A to B (host to slave) cable

should be used in all applications. This type of cable is a standard PC to

peripheral cable that utilizes full-size connectors.

Figure 6 – USB A-to-B cable

3.6.1 HIGH EMI ENVIRONMENTS

If the DXM100 USB interface is being used in a high-EMI environment,

ferrites should be added to the USB cable. Figure 7 illustrates the possible

combinations of ferrites that can be used to achieve acceptable operation

under these conditions.

POW ER SUPPLY

WITH

USB

FERRITE

CORE

(cable)

24 V DC

FERRITE

BEAD

(cable)

FERRITE

CORE

(cable)

FERRITE

CORE

(cable)

USB CABLE

FERRITE

BEAD

(cable)

PC

WITH

USB

118142-001 Rev B Page 8 of 104

Page 33

Figure 7 – Block Diagram of USB Cable Utilizing Ferrites

Ferrite beads should be attached to the USB cable next to the connectors

– both sides should be installed. In extreme cases ferrite cores may be

added where the cable is looped 3 or 4 times around the core as shown in

figure 8. Cores of 1.5 to 2 inches should be used at both ends of the

cable.

Figure 8 - Example of a USB Cable Using Ferrites

Please refer to the USB Interface Setup section, for an explanation of how

USB works and why EMI may present a problem for this communications

interface.

118142-001 Rev B Page 9 of 104

Page 34

4.0 GETTING STARTED – SOFTWARE

The following sections detail how to create software to interface to the DXM100

communications interfaces.

4.1 RS-232

The RS-232 interface makes use of a standard ‘command/response’

communications protocol. See section 6.0 for the syntax of the serial

interface protocol. The programmer should also review section 4.3 for

programming considerations for the USB interface as the code is nearly

identical for the RS-232 interface.

All software that addresses the RS-232 interface must adhere to the

following parameters:

A default Baud rate of 115.2K bps

No Parity

8 Data Bits

1 Stop Bit

No handshaking

The Baud rate can be changed to 115.2K ,57.6k,38.4k,19.2k or 9600 bps

and stored in the unit.

4.1.1 Enabling Communications Objects in Visual Basic for RS-232

Communications in Microsoft Visual Basic 6.0 are directed to a control

that abstracts the port. In the case of serial and USB we need

Microsoft Comm Control 6.0. To enable this in your VB 6 project, go to:

Project -> Components

Then in the list make sure that Microsoft Comm Control 6.0 has a

check next to it. The Comm Control Object should then appear in your

toolbox. It will have an icon of a telephone and will be named:

MSComm. This can be dragged and dropped into your application.

You will then need to set the object’s properties.

4.1.2 Configuring Communications in Visual Basic for RS-232

In order to configure the MSComm Object, first you must initialize it

in the Object properties:

Settings 115200,n,8,1

Handshaking 0 – comNone

The application can be set to either default to a specific COM Port

or the End User can be allowed to choose one for the particular PC.

118142-001 Rev B Page 10 of 104

Page 35

For the “Default” scenario, include the following commands in the

Form_Load() routine:

MSComm1.CommPort = portNumber

MSComm1.PortOpen = True

For the “Choice” scenario, place the above two commands in a

selectable menu item.

118142-001 Rev B Page 11 of 104

Page 36

4.2 ETHERNET

The DXM100 contains an embedded diagnostic web server that can be

accessed through any standard web browser by browsing to the

DXM100’s IP address. For example:

http://192.168.1.4

The Ethernet interface communicates using the following protocols:

TCP/IP

HTTP

TFTP

FTP

4.2.1 Diagnostic Web Server

The diagnostic web server can control and monitor a DXM100 equiped

power supply from a web browser. It displays operating status of the

Power Supply and allows the unit to be configured in real time. The

application consists of three web pages; a page displaying contact

information, a license agreement, and a monitoring and control applet that

is at the heart of this application. The Web Server application for the

DXM100 is presented as an example in the following pages.

4.2.2 Web Pages

4.2.2.1 Web Page 1: Contact Information Page

Figure 9 displays a picture of the DXM100N1200 and information

on how to contact Spellman High Voltage Electronics Corporation.

By clicking on the picture of the DXM100N1200 or on the button

labeled “Click Here to Monitor and Control” one can move on to the

next screen, the license agreement.

118142-001 Rev B Page 12 of 104

Page 37

Figure 9 - Web Page 1- Contact Information

118142-001 Rev B Page 13 of 104

Page 38

4.2.2.2 Web Page 2: License Agreement Page

Figure 10 displays the license agreement. Here the user can either

agree or disagree with the Spellman license agreement. Click on “I

Accept” to continue on to the applet.

Figure 10 - Web Page 2 – License Agreement

118142-001 Rev B Page 14 of 104

Page 39

4.2.2.3 Web Page 3 - Monitor and Control Applet

4.2.2.3.1 Requirements

The Monitor and Control Applet is a java “applet” (“small java

application” specifically written to be embedded in a web page and

invoked from a browser) that requires an Internet browser with an

installed JVM (Java Virtual Machine). The Default username and

password for the applet is: Username: admin, Password:

SHV_Applet. We have tested under Internet Explorer 5 and 6,

Microsoft JVM 5 and Sun JVM versions 1.4.1 and 1.4.2.

4.2.2.3.2 Description of Monitor and Control Applet

Figure 11 displays an example of an embedded monitor and

control application.

118142-001 Rev B Page 15 of 104

Figure 11 - Control and Monitor Applet

Page 40

Broadly one can view the screen as a “left” and a “right” with

the left half containing status values (read backs) read from

the DXM100 and the right half containing the values that are

configurable by the user. Notice that the top of the right half

contains the label “Click to Set”. For any configurable setting

you click on the button to the left of the setting, which brings

up the program set point screen. For example, click on the

button labeled, ‘V’ to set the output voltage set point. Refer

to figure 12.

4.2.2.4 Program Set Point Screen

On the program set point screen (Reference figure 12 there are two

fields: a top field labeld ‘V’ and a bottom field labeled ‘DAC’.

Figure 12 - Program Configurable Values Screen

The top field is the scaled value or real world value, which is the

field the user is going to use most of the time. The bottom field is

the raw digital-to-analog converter (DAC) value that is actually sent

to the DXM100. Enter either the desired set point level in the top

field or the DAC value between 0 and 4095 in the bottom field.

The user can then click Apply to send the set point to the DXM100

and remain in the set point screen, or click OK to send the set point

and close the set point entry window. The Maximum and Zero

buttons will set both fields to the indicated end point value. The

user may also click on Cancel to close the window without sending

any changes.

To reset the Total hour On meter to zero via the Applet a password

is required.The password is “SHV_Reset”

4.2.2.5 Java Warning Messages

You may notice a message at the bottom of all dialog windows that

are displayed from the DXM100 Control and Monitor Applet. The

wording may vary slightly depending on the JVM version but on

118142-001 Rev B Page 16 of 104

Page 41

some the message is “Warning: Applet Window”. This message is

letting you know that the dialog window was generated by an

applet. The design philosophy for the JVM was for secure

computing so the origins of new windows are supposed to be as

obvious as possible.

4.2.2.6 Menu Item “Settings” on Applet

The user can view and set operating parameters of the applet or

network configurations of the DXM100 or view firmware version

information for both through the settings menu. Click on the button

at the top of the Monitor and Control Applet that has the label

“Settings”. This displays the settings popup menu as shown in

figure 13.

Figure 13 – Settings Pop up Menus

Notice that there are three choices. The first, “Network Settings”

refers to the network settings for the network component of the

DXM100 and not the Monitor and Control applet. The second

option, “Poll Rate” affects refresh rate of the Monitor and Control

Applet and will be discussed in the next section. In the “about”

choice firmware version information is displayed, both for the

Monitor and Control Applet and for the DXM100 hardware.

4.2.2.7 Refresh rate for monitored values

The refresh rate for the applet display of the DXM100 is dependent

upon the rate of placement of status requests in the internal send

queue and how fast responses are sent back from the DXM100 in

response to the requests. The default value for queuing responses

is every 600ms and this is a configurable value in the

Settings->Poll rate screen. Please refer to figure 14.

118142-001 Rev B Page 17 of 104

Page 42

Figure 14 - Configure Polling Rate Screen

Setting this value lower may make the screen refresh quicker.

However, setting it too low may cause requests to queue up in the

send queue. This may make controlling the DXM100 very slow, as

control requests now must wait behind queued status requests. We

recommend leaving the delay set at the default value.

4.2.2.8 Version Information

118142-001 Rev B Page 18 of 104

Figure 15 – Version Information

Page 43

4.2.2.9 Turning the DXM100 HVOn/Off and Connection

Status

Please refer to Figure 11, the Monitor and Control Applet.

Setting Name Range Values

Local/Remote Local mode/Remote mode

HV On/Off

Interlock Open/Closed

Fault Status OK/Fault

Connection Status Connected/No Data Received/Disconnected

Unlike the controls we previously discussed at the top of the screen

which required a separate dialog screen to enter values, these are

controlled by a button. For example, an On/Off button controls the

HV. When HV is on, the Control is labeled “Click to Turn HV Off”.

When HV is off, the control is labeled “Click to Turn HV On”.

Thereby handling the two distinct states.

Notice that at the very bottom of the screen is a text field that

displays the current connection status, which as mentioned above

is one of three values. “Connected” is displayed when there exists a

valid TCP/IP session connecting the DXM100 and the Applet and

data is being received by the applet from the DXM100. The next

state is “No Data Received” which is when there is still a valid

connection but no responses have been received from the DXM100

for 2 seconds. Lastly, the text field displays “Disconnected” when

the TCP/IP session has been disconnected.To operate the UUT

using the Computer interface the UUT must be set to Remote Mode

by Clicking “Click to Set Remote.

When the Applet is first started and anytime the “Click To Connect”

button is clicked there is a 5 second delay as the Applet starts up

the threads necessary for communication between it and the

DXM100.

4.2.2 Direct Connection between the DXM100 and a Computer

A direct Ethernet connection between the DXM100 and the

computer requires an RJ45 crossover cable. The end connectors

will look identical to a “normal” RJ45 connector but the colors of

some of the wires in the connectors will be “reversed”. Hold up the

two ends of the RJ45 cable and look at the color of the wires from

left to right. They should differ on the two connectors.

When direct connecting the DXM100 to a computer using a

crossover cable over Ethernet they are essentially participating in a

118142-001 Rev B Page 19 of 104

Page 44

private network. As such you need to pick two valid IP addresses,

one for each device.

The table below illustrates that not all IP addresses are actually

valid IP addresses. For example, IP addresses beginning with 127

are not valid.

Class Address Range

A 1.0.0.0-126.255.255.255

B 128.0.0.0-191.255.255.255

C 192.0.0.0-223.255.255.255

4.2.2.1 Configuring the Computer for Direct Ethernet

Connection

As mentioned above both the IP Address and Subnet Mask need to

be configured. In our environment computers normally are assigned

IP addresses dynamically, using DHCP. We need to change this

and assign the IP Address statically to the one we have selected.

Here are the steps on Windows XP. On the desktop right click on

“My Network Places” and select properties at the bottom of the

menu.

Figure 16 – Right Click on Desktop

118142-001 Rev B Page 20 of 104

Page 45

Figure 17 – Select Properties

After selecting properties you are brought up to the screen below

(Figure 18). You must RIGHT CLICK and select Properties on

Local Area Connection, and not double click which will display a

window similar to figure 19.

Figure 18 – Here you must Right Click and Select Properties

118142-001 Rev B Page 21 of 104

Page 46

Figure 19 – Local Area Connection Properties

Now you must select “Internet Protocol (TCP/IP)” and click on the

Properties button to be brought to figure 20. Lastly you must

disable any firewall software you have running. If you are running a

proxy server for Internet access, you must also disable the proxy

client. Disabling this also requires a reboot.

118142-001 Rev B Page 22 of 104

Page 47

Figure 20 – TCP/IP Properties

4.2.2.2 Testing a Direct Connection

You can use the program “Ping” to test a network connection

between the computer and the DXM100. “Ping” is a command line

tool so we will need to bring up a command prompt. Under

Windows NT, 2000 and XP the name of this command is “CMD”.

Under Windows 98 the name of this command is “Command”.

To do this, click on Start->Run->Cmd

Then on the command line type

Ping <IP Address>

For example

Ping 192.168.1.4

If the DXM100 is found at the specified IP address, the Ping

command will respond with a report that is similar to:

118142-001 Rev B Page 23 of 104

Page 48

Pinging 192.168.1.4 with 32 bytes of data:

Reply from 192.168.1.4: bytes=32 time<1ms TTL=64

Reply from 192.168.1.4: bytes=32 time<1ms TTL=64

Reply from 192.168.1.4: bytes=32 time<1ms TTL=64

Reply from 192.168.1.4: bytes=32 time<1ms TTL=64

Ping statistics for 192.168.1.4:

Packets: Sent = 4, Received = 4, Lost = 0 (0% loss),

Approximate round trip times in milli-seconds:

Minimum = 0ms, Maximum = 0ms, Average = 0ms

4.2.3 Configuring the DXM100 For a Local Area Network (LAN)

If you have chosen to place the DXM100 onto your local area

network you will need:

A CAT5 network patch cable to physically connect the

DXM100 to the LAN

A static IP address to assign to the DXM100.

Remember that even if the IP address you have selected is in

general a valid IP address it needs to be valid for your LAN (local

area network). Otherwise the device will not be accessible from an

Internet browser or Ping.

4.2.3.1 Configuring the Network Settings from the

Monitor and Configure Applet

The network settings are configurable from the Settings->Network

Settings screen, refer to figure 21.

118142-001 Rev B Page 24 of 104

Page 49

Figure 21 - Configure Network Settings

The settings that can be changed are the:

Device Name

IP Address

TCP Port

Subnet Mask

Default Gateway

Once the Apply button is clicked on the network settings screen the

network component of the DXM100 is configured, rebooted and the

applet is disconnected from the DXM100. You must type the NEW

IP address into a web browser to bring up a new instance of the

applet to monitor and control the DXM100 after reconfiguring it.

This may also require reconfiguring the host computer with the

correct host IP address, subnet mask, and TCP port.

The device name does not affect the operation of the DXM100; it is

simply a way for the user to differentiate multiple units on the same

network.

Depending on the type of network you are attaching the DXM100

to, you may need to configure the host PC’s IP address and subnet

mask as shown in section 4.2.2.1. You can also test a network

connection to the DXM100 by following the instructions listed in

section 4.2.2.2.

118142-001 Rev B Page 25 of 104

Page 50

After the changes are completed. The Apply button is clicked and

the window of Figure 21.1 will pop up. Click OK to start the change

process.

WARNING !

After the OK button is clicked , a confirmation warning window in

Figure 21.2 is shown. Check and record the data in the User

Record Table below. If the desired change is correct click on the

Yes button. Clicking on Cancel will cancel any changes made.

Figure 21.1 – Prompt To Execute Change

Figure 21.2 – Warning Review Screen

User Record Table:

IP Address: _______________________________________

Port Address: _____________________________________

Subnet Mask: _____________________________________

WARNING !

Port address 50000 is reserved for Spellman, attempting to use this

port address will result in the message window Figure 21.3..

118142-001 Rev B Page 26 of 104

Page 51

Figure 21.3 – Port Error Selection Screen

The TCP/IP Status field in the applet window will show

“Connected – No Data Received as shown in Figure 21.4

Figure 21.4 – TCP/IP Status Field (No Data Received)

118142-001 Rev B Page 27 of 104

Page 52

Then wait for about a minute for the The TCP/IP Status field in the

applet window to show “Disconnected”as shown in Figure 21.5

Figure 21.5 – TCP/IP Status Field (Disconnected)

At this point recycle the power to the DXM100, and close out all

browser windows on the PC. Then open up a browser again and relog in to the changed IP address.

Note: Again please remember the changed parameters, as there is

no procedure at this time to recover the default parameters.

4.2.4 Enabling Communications Objects in Visual Basic for Ethernet

Communications

For Ethernet communications, we need Microsoft Winsock Control 6.0 and

SP5. To enable this in your VB 6 project, go to:

Project -> Components

118142-001 Rev B Page 28 of 104

Page 53

Once selected in your toolbox you will have an icon of two computers

linked together and it will be named: Winsock.This can be dragged and

dropped into your application. Then set the object’s properties.

4.2.5 Configuring Communications in Visual Basic for Ethernet

In order to configure the Winsock Object, you must make the following

initialization in the object’s properties:

Protocol 0 – sckTCPProtocol

Then, in the application code, include the following commands:

tcpClient.RemoteHost = host

tcpClient.RemotePort = portNumber

tcpClient.Connect

For further information regarding the use of the above commands, please

refer to your Visual Studio Help File.

4.2.5.1 Data Output Example

MSComm1 is both the serial and USB port. TcpClient is the

Ethernet port.

If (portType = "ethernet") Then

tcpClient.SendData (str)

Else

MSComm1.InBufferCount = 0

On Error GoTo done

MSComm1.Output = str

done:

tmrOpenClose.Enabled = True

End If

4.2.5.2 Data Input Example

If (portType = "ethernet") Then

Do

DoEvents

tcpClient.GetData temp$

str = str + temp$

Loop Until InStr(str, Chr(3)) Or Timer - t1 > 1

On Error Resume Next

Else

Do

DoEvents

If MSComm1.InBufferCount > 0 Then

118142-001 Rev B Page 29 of 104

Page 54

str = str & MSComm1.Input

End If

Loop Until InStr(str, Chr(3)) Or Timer - t1 > 1

If InStr(str, Chr(3)) > 0 Then

tmrOpenClose.Enabled = False

End If

End If

118142-001 Rev B Page 30 of 104

Page 55

4.3 USB

The USB interface makes use of a standard ‘command/response’

communications protocol. See section 6.0 for the syntax of the serial

interface protocol.

The USB interface is accessed through a Windows USB Human Interface

driver (HID).

4.3.1 USB Driver Installation

The HID driver is a Windows driver installed with the operating system. To

determine if the driver had been acquired open the System properties

window selecting the Control Panel System Properties.

Then select Device Manager and expand the Human Interface Devices.

View the properties of the USB Human Interface Device icon and verify

that Spellman USB HID appears in the Location section.

118142-001 Rev B Page 31 of 104

Figure 22 – System Properties

Page 56

Figure 23 – Device Manager showing USB HID

4.3.2 USB and EMI

The USB protocol utilizes a heartbeat signal from each client device back

to the host (PC). If the heartbeat is interrupted due to radiated or

conducted transient noise, it is possible that the host may lose connection

with the client. This can cause problems with data transfers over the USB

cable.

The DXM100 when used in combination with the HID Windows driver

makes it possible for the host to renumerate the client connection and

reestablish communications. This is providing the control application

implements a method of timeout and retry.

NOTE: If an EMI disruption occurrs the DXM100 will continue to

renumerate until a connection with the GUI is re-established.

118142-001 Rev B Page 32 of 104

Page 57

4.3.3 Enabling Communications Objects in Visual Basic for USB

The dynamic link library USB_dll.dll will be provided which needs to be

added to the project. The library has three functions that can be called

from the VB code.

The three functions are:

FindTheHid – finds the connection with the correct VID, PID and Serial

Number

WriteReport(str) – Writes a string to the connected HID interface

ReadReport() – Returns a string from the connected HID interface

4.3.4 Configuring Communications in Visual Basic for USB

To use the USB_dll.dll in VB the following statements are needed.

Dim usb As usbDll

Dim MyDeviceDetected As Boolean

Set usb = New usbDll

Using this statement determines whether a connection is present.

MyDeviceDetected = usb.FindTheHid

If MyDeviceDetected is true then the connection is present.

4.3.5 Software Considerations for USB Reconnection

The following Visual Basic code snippets are presented as a guideline for

implementation with revision C and higher assemblies.

4.3.5.1 Recognize partial, corrupt, or absent data

1: temp2$ = inputInputString

2: If temp2$ <> "" Then

3: btn_UPDATEDATA.Value = False

4: CommStatusFlag = True

5: CommaPos = InStr(Start, temp2$, Comma, vbTextCompare)

6: ' Channel 0

7: On Error GoTo endhere

8: AmbTemp = Mid(temp2$, Start, (CommaPos - Start))

Please note that even though we have guarded against no data, in

line 2, we still need to guard against bad data, in this case no

comma, on line 8. If there is no comma, we wind up passing a

negative value to Mid, which is an error, that we should trap for.

118142-001 Rev B Page 33 of 104

Page 58

4.3.5.2 Retrieve data only if it exists

1: Do

2: DoEvents

3: If MSComm1.InBufferCount > 0 Then

4: str = str & MSComm1.Input

5: End If

6: Loop Until InStr(str, Chr(3)) Or Timer - t1 > 1

7: 'str = str & MSComm1.Input

8: If InStr(str, Chr(3)) > 0 Then

9: tmrOpenClose.Enabled = False

10: End If

Notice that in line 3 we check for the existence of data before we

extract data from the USB port. Normally, if there is no data, line 4

would append an empty string. However, during a noise event,

retrieving data without first checking the existence of data could

hang.

4.3.5.3 Example Output Routine

Notice that on line 13 we register an error handler in case the port

is invalid because we have closed it in another routine. Notice that

on line 16 we start a timer. When we output data on the port we

start a timer to keep track of incoming data. If we get no incoming

data it means that communications have been interrupted.

1: Private Sub outputOutputString(outputString As String)

2: Dim str As String

3: str = ProcessOutputString(outputString)

4: StatusBar1.Panels(4).Text = "TX: " & str

5: 'StatusBar1.Panels(3).Text = "RX: Waiting"

6: If (portType = "ethernet") Then

7: tcpClient.SendData (str)

8: ElseIf (portType = "USB") Then

9: usb.WriteReport (str)

10: Else

11: MSComm1.InBufferCount = 0

12:

13: On Error GoTo done

14: MSComm1.Output = str

15: done:

16: tmrOpenClose.Enabled = True

17: End If

18: End Sub

118142-001 Rev B Page 34 of 104

Page 59

4.3.5.4 Example Input Routine

Notice on line 26 we check for data first before extracting data from

the input. Then if we have actual data we turn off the timer.

Otherwise the timer routine toggles the port open/close.

1: Private Function inputInputString() As String

2: Dim str As String

3: Dim t1 As Single

4: Dim temp$

5: Dim stra As String

6: Dim stri(300) As String

7: t1 = Timer

8:

9: If (portType = "ethernet") Then

10: Do

11: DoEvents

12: tcpClient.GetData temp$

13: str = str + temp$

14: Loop Until InStr(str, Chr(3)) Or Timer - t1 > 1

15: On Error Resume Next

16: ElseIf (portType = "USB") Then

17: Do

18: DoEvents

19: stra = usb.ReadReport

20: str = str & stra

21: 'str = str & ReadReport

22: Loop Until InStr(str, Asc(3)) Or Timer - t1 > 0.09

23: Else

24: Do

25: DoEvents

26: If MSComm1.InBufferCount > 0 Then

27: str = str & MSComm1.Input

28: End If

29: Loop Until InStr(str, Chr(3)) Or Timer - t1 > 1

30:

31: If InStr(str, Chr(3)) > 0 Then

32: tmrOpenClose.Enabled = False

33: End If

34:

35: frm_EXTRAS.txt_MSCOMMBUFF.Text = str

36: tmr_COMMWDT.Enabled = True

37: On Error Resume Next

118142-001 Rev B Page 35 of 104

Page 60

38: End If

39: StatusBar1.Panels(3).Text = "RX: " & str

40: inputInputString = str

41: tmr_RCVTIMER.Enabled = True

42: End Function

4.3.5.5 Example Timer Routine: Toggle Port State

This is the timer routine in which the open/closed state of the port is

toggled. If communications are interrupted, the USB device will re-

register itself with the OS (vendor term: renumeration). Once this

happens, re-opening the port will enable communications. Until the

re-registration happens, open operations will fail. Notice line 5

where we register an error handler.

1:Private Sub tmrOpenClose_Timer()

2: If MSComm1.PortOpen = True Then

3:

4: MSComm1.PortOpen = False

5: On Error GoTo done

6: MSComm1.PortOpen = True

7: done:

8: tmrOpenClose.Enabled = False

9: End If

10:

11: End Sub