Speidel Braumeister 47070, Braumeister 45050 Operating Instructions Manual

Translated from Original

Operating/ Brewing Instructions

for

Speidels Braumeister

Item no.: 47070, 45050

Version February 2011

1

GENERAL ......................................................................................................... 3

2

SAFETY NOTES: .............................................................................................. 3

2.1 General safety notes .................................................................................................................................... 3

2.2 Special safety notes...................................................................................................................................... 4

3

COMPONENTS AND SCOPE OF DELIVERY .................................................. 5

4

TECHNICAL SPECIFICATIONS FOR BRAUMEISTER.................................... 5

5

SETTING UP THE BRAUMEISTER .................................................................. 6

6

CLEANING THE BRAUMEISTER ..................................................................... 6

7

STORING THE BRAUMEISTER ....................................................................... 6

8

PRIOR TO FIRST USE ...................................................................................... 6

9

DISPOSAL......................................................................................................... 7

10 WORKING WITH THE BRAUMEISTER............................................................ 8

10.1 Language selection.................................................................................................................................. 8

10.2 Notes on temperature control ................................................................................................................ 8

10.3 Notes on the circulating pump............................................................................................................... 8

10.4 Notes on the container lid....................................................................................................................... 9

10.5 Notes on hygiene ..................................................................................................................................... 9

11 BREWING WITH THE BRAUMEISTER .......................................................... 10

11.1 Introduction .......................................................................................................................................... 10

11.2 Preparations .......................................................................................................................................... 10

11.3 Programming/ starting automatic brewing ........................................................................................ 11

11.4 Mashing ................................................................................................................................................. 11

11.5 Purification............................................................................................................................................ 13

11.6 Hops boiling........................................................................................................................................... 14

11.7 Cooling................................................................................................................................................... 15

11.8 Main fermentation ................................................................................................................................ 16

11.9 Maturation ............................................................................................................................................ 17

12 BREWING EXAMPLE/ BRIEF INSTRUCTIONS ............................................. 18

13 BREWING FAULTS/ TROUBLESHOOTING .................................................. 21

14 LEGAL ASPECT OF HOME BREWING ......................................................... 23

15 BREWING RECORD ....................................................................................... 24

16 CLEANING INSTRUCTIONS........................................................................... 25

17 GUARANTEE CONDITIONS, HANDLING A GUARANTEE ........................... 27

Speidel’s Braumeister

Page 3 of 32

1 General

Dear customer

You have purchased a new device from our company. Many thanks for trusting in us.

Quality and functionality of our products rate high on our list of priorities.

Use according to intended purpose:

The Braumeister has been designed and produced for brewing smaller quantities (approx.

20l / 50l) of beer. Prior to each brewing procedure, a safety inspection must be performed

for proper functionality of the Braumeister.

Operating instructions:

These operating and brewing instructions have been compiled to ensure reliable and safe

commissioning and operation of the Braumeister right from the start. Please read the

instructions carefully and in full before brewing your first beer. Compliance with these

notes and instructions will ensure that your Braumeister operates to your utmost

satisfaction, and has a long lifespan. Weight and volume indications are always for 20l/

50l. The first specification applies to the 20l Braumeister and the second to the 50l

Braumeister.

Conformity declaration:

SPEIDEL Tank- und Behälterbau GmbH hereby declares that the “Braumeister” product

mentioned in these instructions and to which this declaration applies complies with the

regulations of the following European guidelines:

EMC 2004/108/EC, Low Voltage 2006/95/EC

Manufacturer:

Speidel Tank- und Behälterbau GmbH

Krummenstrasse 2

72131 Ofterdingen

Germany

www.speidels-braumeister.de

www.speidel-behaelter.de

2 Safety notes:

2.1 General safety notes

• The device and mains cable must be inspected regularly for any signs of damage. In

the event of signs of damage, the device may no longer be used.

• Always disconnect the plug from the socket (pull the plug, not the cable) if you no

longer wish to use the device, for cleaning or in the event of a fault.

• Ensure that you lay the mains cable such that it does not come into contact with sharp

objects. The cable must be fully unwound.

• Where extension cables are used, these must have the same wire gauge and also be

fully unwound. Do not use multi sockets as the output of this device is too high.

Overloading the electric fuse must be avoided. As the Braumeister requires extra

power, do not switch any additional “large consumers” to the same fuse. Fire hazard!

Speidel’s Braumeister

Page 4 of 32

• The Braumeister may only be used as intended and in a safe, fault-free condition.

Ensure that you check the proper condition prior to each use.

Children and frail persons:

• For the safety of your children, do not allow packaging parts (cartons, polystyrene

etc.) to be readily accessible. Do not allow small children to play with foil. A risk of

suffocation exists!

• This device is not meant to be handled by persons (including children) with limited

physical, sensory or mental capabilities, or lack of experience and/or know-how,

unless they are being supervised by a person responsible for their safety or have

received instructions on how to use the device.

• Children should be supervised to ensure that they are kept away from the device and

do not play with the device.

2.2 Special safety notes

• The container, lid and add-on parts reach an extremely high temperature. Towards the

end of the brewing process, the boiler contains boiling beer wort. Pay attention to the

notes on setup. Never move the Braumeister in a hot state. Always use pot holders or

gloves when working on and with the Braumeister. Risk of burning!

• When lifting the lid, ensure that the condensation on the underside of the lid flows

back into the container. For this, hold the lid over the container at an angle. Scalding

risk!

• When performing cleaning activities on the Braumeister always ensure that the plug is

disconnected (disconnection from mains). Do not spray the device down or allow

spray to come into contact with electric components. Risk of electric shock!

• Important: It is imperative that you secure the plug connections at the rear of the

device (pump and heating) during operation of the device. Operating the device

without securing plug and socket devices can lead to overheating. Fire hazard!

• Please use the thermal sleeve available as an accessory for insulation. When using

your own insulation ensure that the electronics and the lower part of the Braumeister

are sufficiently ventilated, as a heat build-up and damage to the control may otherwise

occur.

• The pump must be vented prior to each use to prevent dry running. Venting takes

place routinely in automatic operation. In manual operation, the pump must be

switched on and off several times until no more air bubbles escape.

Speidel’s Braumeister

Page 5 of 32

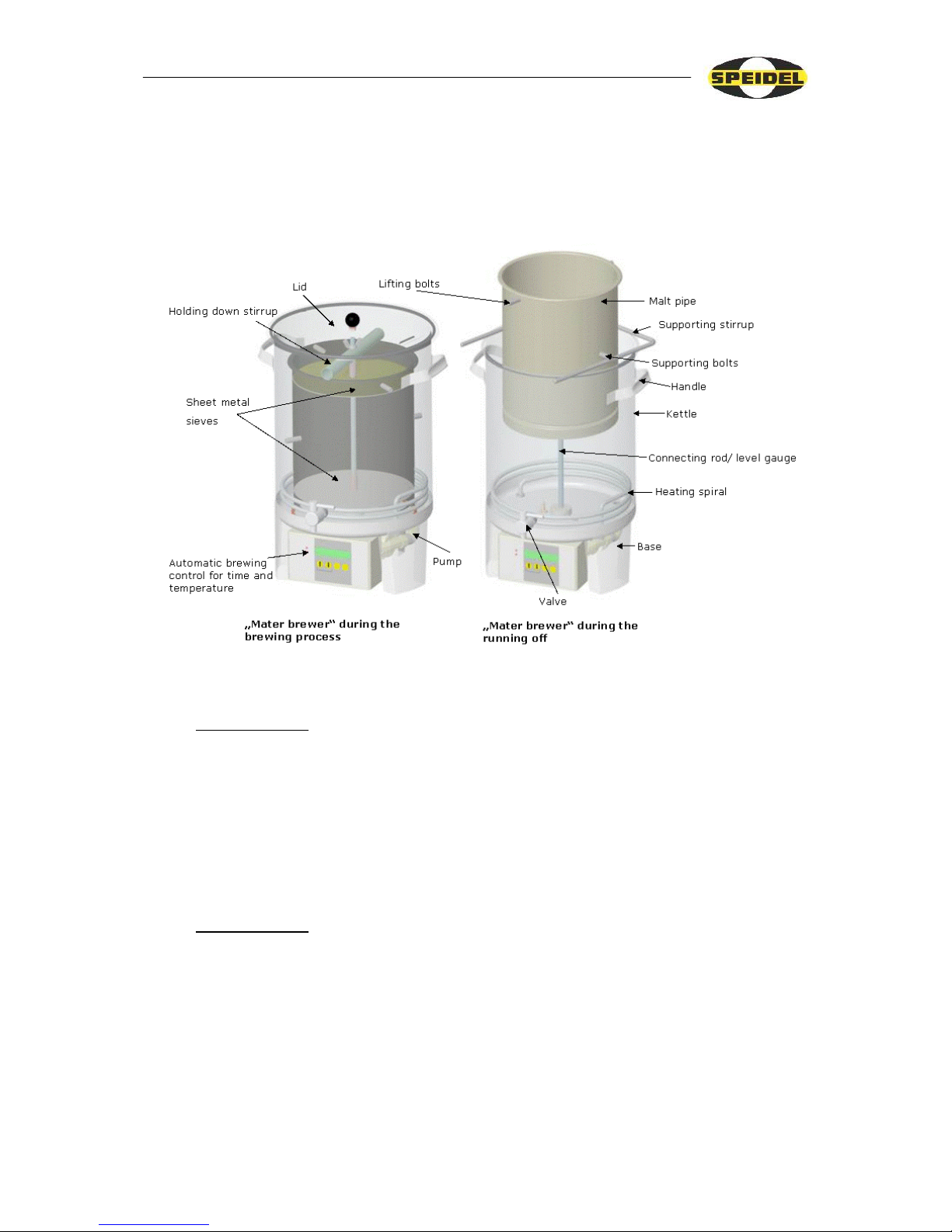

3 Components and scope of delivery

Please refer to the following illustration for components and the scope of delivery

(cooling coil and fermentation vessel not included): The 50l Braumeister is operated

with 2 circulation pumps and 2 heating coils, and has an additional handle on the rear

(not illustrated here).

4 Technical specifications for Braumeister

Braumeister 20l

Weight: 15 kg including internal fittings and lifting bows

Heating coil: 2000 Watt heating capacity

Pump : 1 x 23 Watt

Power connection: 230 V ~

Min. fuse protection: 10 Amp

Contents Brewing quantity approx. 20l ready-to-drink beer (regular beer)

= approx. 23l beer wort

Max. filling level: Upper marking on tie rod = 25l

Braumeister 50l

Weight: 24 kg including internal fittings and lifting bows

Heating coil: 3200 Watt heating capacity

Pump: 2 x 23 Watt

Power connection: 230 V ~

Min. fuse protection: 16 Amp

Contents: Brewing quantity approx. 50l ready-to-drink beer (regular beer)

= approx. 53l beer wort

Max. filling level: Upper marking on tie rod = 55l

Speidel’s Braumeister

Page 6 of 32

5 Setting up the Braumeister

The Braumeister must be positioned on a stable, secure and horizontal support

structure prior to use. Take note that the Braumeister can weigh up to 50kg/ 90kg in a

filled state and that it contains boiling hot beer wort. Horizontal positioning is a

prerequisite for transfer pumping during the brewing process. Avoid an unsteady base.

Most suitable are a stable wooden box or a table that is not too high. The Braumeister

may not be moved during the brewing process. The handles are only meant for

transporting the device in an empty state. It is imperative to keep children and frail

persons away from the device while it is in operation.

6 Cleaning the Braumeister

The Braumeister must be cleaned immediately after the brewing process. Avoid

surface drying of wort and malt remnants, as this will significantly impair the cleaning

process. All stainless steel components can be cleaned using a conventional detergent.

Abrasive agents and sponges/brushes that cause scratching are not suitable. Ideally use

a pipe cleaner thread to clean the heating coil. The pump and its internal drive ball

should also be rinsed regularly. For this, simple turn the Braumeister upside down and

loosen the screws, which should at all times only be hand tightened. The pump can be

removed completely from the Braumeister by simply loosening the plug screws. When

cleaning the brewing vessel ensure that no water spray or moisture comes into contact

with the electrical components. The current supply must be disconnected for

performing cleaning activities on the Braumeister. Before starting the brewing process,

remove all dust and dirt from the Braumeister and all internal fittings by means of

warm water. Also rinse the pump and lines by means of transfer pumping. Caution: If

you allow the pump to run longer than a few seconds for cleaning, ensure that it is

sufficiently vented to avoid dry running (switching the pump on and off several times

provides good venting). Ensure that you include the malt pipe seal and drainage tap as

well. Make sure that no detergent remnants whatsoever remain in the Braumeister, as

these could have a negative impact on the foam stability of the beer. Please refer to the

detailed cleaning instructions on page 26 (cleaning set available as an accessory).

7 Storing the Braumeister

The Braumeister must be stored in a dry location. Avoid contact with ferrous or rusty

objects.

8 Prior to first use

Clean the Braumeister thoroughly using lukewarm water prior to initial use (see

Chapter 6). Also ensure that the Braumeister is securely set up as per Chapter 5.

Confirm that the Braumeister is in proper condition. Also take notice of the safety

notes in Chapter 2. For the rest, the Braumeister has been constructed for immediate

commissioning.

Speidel’s Braumeister

Page 7 of 32

9 Disposal

Meaning of the “refuse bin” symbol on the Braumeister: Protect our environment;

electrical devices should not be disposed of as household refuse. Make use of

collection points for disposal of electrical devices and hand in all electrical devices

that you no longer wish to use at these points. In this manner, you can avoid a

potential impact on the environment and human health caused by incorrect disposal.

This is your contribution to recycling and other forms of use of waste electrical and

electronic equipment. You can find information on where to dispose of the devices

from your district or municipal administration.

Speidel’s Braumeister

Page 8 of 32

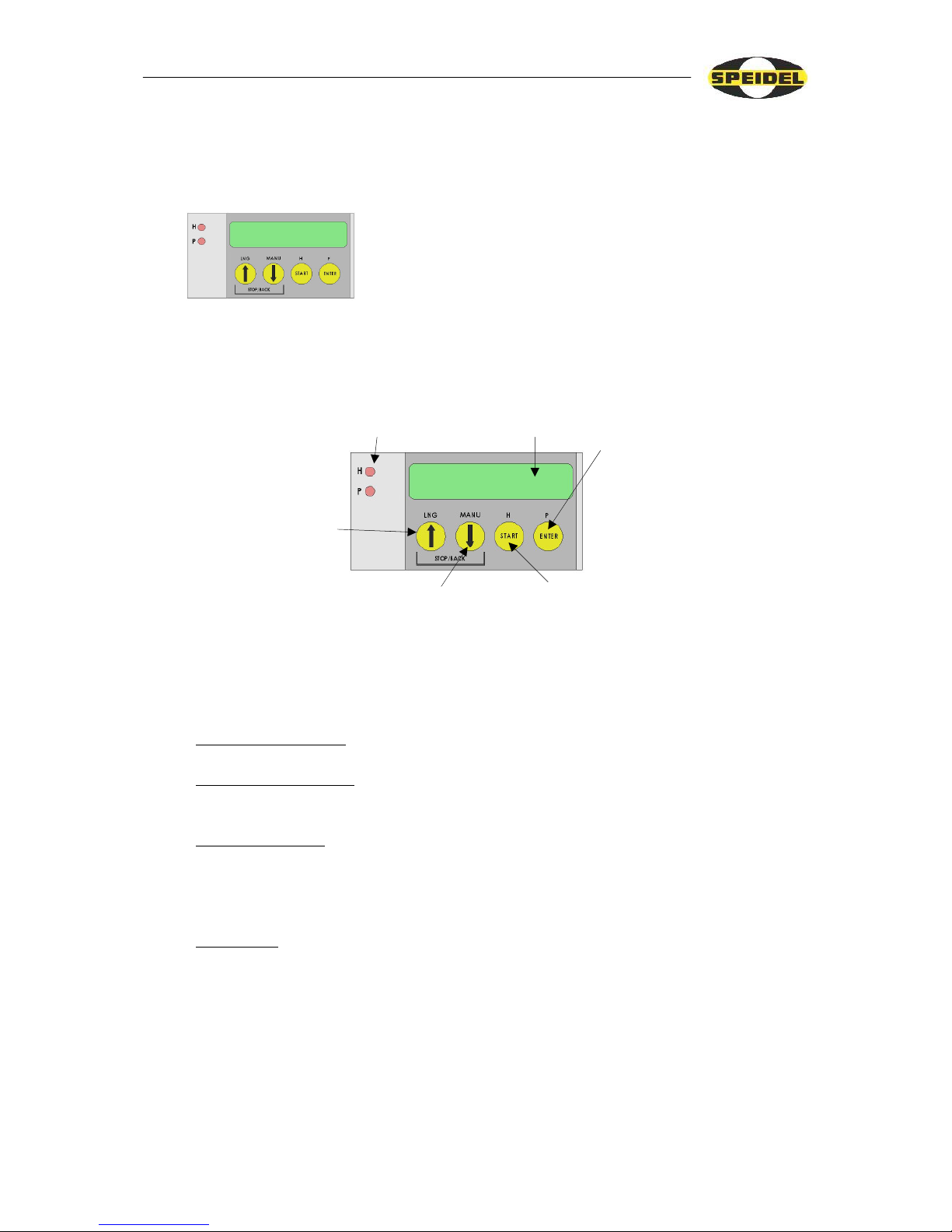

Speidels Braumeister

act temp T=015°C

10 Working with the Braumeister

10.1 Language selection

Press the UP ARROW (LNG) for 3 seconds to move from

the basic setting to the language selection menu. Use the

arrows to select between GERMAN, ENGLISH, FRENCH

and SPANISH. Press enter to set the language selected.

10.2 Notes on temperature control

Automatic operation: Begin with START (1 sec). A detailed description can be

found in the chapter below – “Brewing with the Braumeister”.

Programming module: Use the ENTER button (1 sec) to enter programming mode. A

detailed description can also be found in the chapter below –

“Brewing with the Braumeister”.

Manual operation: Press the ↓ (1 sec) to go to manual operation of the

Braumeister. Press START to switch the heating (H) on/off.

Press ENTER to switch the pump (P). Set the temperature by

means of the arrow keys. Return to the initial display of the

Braumeister by simultaneously pressing ↓+↑.

Stop/ Back: Press the keys ↓+↑ simultaneously to return to the initial

setting from all operation types (automatic, programming

mode and manual operation).

10.3 Notes on the circulating pump

Switch the circulating pump on and off in manual operation using the “Enter” or “P”

key. It is important to vent the pump in manual operation after filling it with liquid, so

as to ensure that it does not run dry and possible incur damage. This can be achieved

by filling the pump with water and switching it on and off several times at an

installation position of approx. 45° (until no more air bubbles escape and the sound of

Display

ENTER

• Change in programming mode (1 sec)

• Confirmation of values in programming

mode

• Acknowledgement of prompts in automatic

operation

• Pump On/Off in manual operation

LED heating

LED pump

START

• Starting automatic brewing (1 sec)

• Confirmation button during brewing process

• Heating On/Off in manual operation

ARROW UP

• Increase time/ temp in

programming mode and in

manual operation

• Language settings (3 sec)

• Arrow up + arrow down = Stop

automatic operation or return

ARROW DOWN

• Decrease time/ temp in programming mode and in

manual operation

• Change in manual operation (1 sec)

• Arrow up + arrow down = Stop automatic operation or

return from manual operation

Speidel’s Braumeister

Page 9 of 32

the pump is almost inaudible). During the brewing process, the pump switches off

automatically in manual operation for purposes of protection as soon as the

temperature exceeds 88°C.

10.4 Notes on the container lid

The lid assists in reaching the temperatures more quickly in the heating up phase. The

ventilation slits avoid pressure forming in the vessel and allow for light air circulation.

Higher water temperatures cause condensation to occur on the underside of the lid.

When lifting the lid, ensure that you hold the lid rim over the vessel opening (at an

angle) so that the condensation can run back into the vessel.

10.5 Notes on hygiene

Hygiene is of top priority when brewing beer. Especially in the cold process area

(while cooling off, when decanting and while fermenting), the beer and the wort are

susceptible to infection, which causes the beer to spoil, meaning that all work could be

in vain. For this reason, take particular care in ensuring that all containers

(fermentation vessel, bottles) and work materials (spoon, taps, seals) are meticulously

clean. Sulphuric acid or a similar substance is particularly suitable for disinfecting

these containers and objects, and can be purchased at specialist winery shops and

commercial outlets that specialise in hobby brewing equipment. Mix and dilute the

powder with water and push this solution into the fermentation lock for disinfection of

the fermentation vessel, all other equipment and even your hands. We recommend

preparing a bucket with sulphuric acid, for example, and using this solution for

disinfecting your hands and all equipment during the brewing process and prior to

decanting. Fill the fermentation vessel with a little sulphuric acid and leave to stand

for a few hours. Shake the vessel several times at intervals. Empty it and allow to dripdry prior to use. Rinsing the vessel with water is not necessary. A few drops or a little

residue of the sulphuric acid in the beer is completely harmless. Storage and

maturation vessels are disinfected in the same way as fermentation vessels. Where the

beer is filled into flip-top bottles for maturation after fermenting, disinfect the bottles

by heating in the oven. Remove rubber seals and disinfect by boiling in hot water or

bathing in sulphuric acid. Heat the bottles in the oven until they reach a temperature of

approx. 130°C. Then switch the oven off and allow the bottles to cool to room

temperature again. Cap using the disinfected seals. In this manner you can ensure that

the fermented beer is filled into meticulously clean bottles. The disinfection process

should be performed a few days before the end of maturation, to ensure that the filling

procedure can take place quickly and without rush.

Speidel’s Braumeister

Page 10 of 32

11 Brewing with the Braumeister

11.1 Introduction

Making beer with the Braumeister can be split into different phases, whereby each

phase is individually described below. To start off, all phases are described in general:

The brewing procedure applies to all beer types and recipes. An actual brewing

example for first-time brewers and a special recipe with precise indications of

quantity, brewing times and temperature levels are provided in the chapters that

follow. Before starting to brew beer, we recommend that you gain an overview of the

individual steps required for preparing a ready-to-drink beverage. To ensure that you

do not leave out any steps and to allow you to gain an overview of your brewing

procedures in retrospect, we recommend keeping a brewing record (see Record in

attachment or at www.speidels-braumeister.de ). Another tip: Allow yourself a day for

your first brewing attempt, and where possible have another person join you, as it is

much more fun together and another set of hands can be very helpful. Note that

brewing beer requires a little experience and that each brewing process is an

improvement on the previous one. So don’t be disappointed if your first beer does not

quite meet your expectations. This is perhaps best illustrated by the words of a witty

German poem that suggests that the beer from the first attempt is neither here nor there

and is bound to cause flatulence, while the second is mediocre, causing you to pass

more liquid than you consumed. The third attempt results in a true beer enjoyed by

men and women alike:

„Das erste Bier ist ein Plempel,

der den Bauern d´Hosen z´sprengt:

Andern zum Exempel.

Das zweite ist ein Mittelbier,

Trinkst drei Maß, so pieselst vier.

Das dritte ist ein Bier vom Kern,

das trinken d`Herrn und d´Frauen gern.“

11.2 Preparations

Procuring the ingredients

Organise the required brewing ingredients (hops, malt and yeast) in good time. Ensure

that the malt is fresh. After crushing the malt (breaking open the corns – not too fine)

use it up as quickly as possible. Quantity indications vary according to recipe,

whereby the malt quantity is between 4-5/ 9-11 kg and the hops quantity between 2050/ 50-100 g. Hops is mostly available in a pressed form, as pellets. We recommend

using dry yeast for fermentation as it can be more easily stored and has a longer shelf

life. These ingredients are available at commercial outlets for hobby brewers and via

the internet. A third option for procuring the ingredients is a brewery in your vicinity.

Why not just ask?

Cleaning the devices

Before starting the brewing process, rinse the Braumeister with warm water and flush

the pump by switching it on. All other equipment such as the beer spindle, wooden

spoon and fermentation vessel should be ready for use and clean. See also the notes in

the chapters “Notes on hygiene” and “Cleaning the Braumeister” in this regard.

Loading...

Loading...