Speidel Braumeister 200 L, Braumeister 500 L, Braumeister 1000 L Operating Manual

Translation from the German Original

Operating manual/brewing instructions

Speidels Braumeister

Item No.: 45200, 46500, 4100

Issue October 2018

1 GENERAL INFORMATION ............................................................................... 3

2 SAFETY INSTRUCTIONS ................................................................................. 3

2.1 General safety notes ................................................................................................................................ 3

2.2 Safety instructions .................................................................................................................................. 4

3 COMPONENTS AND SCOPE OF DELIVERY .................................................. 5

4 TECHNICAL SPECIFICATIONS FOR BRAUMEISTER .................................... 6

5 SETTING UP THE BRAUMEISTER .................................................................. 7

6 CLEANING THE BRAUMEISTER ..................................................................... 7

7 STORING THE BRAUMEISTER ....................................................................... 7

8 PRIOR TO FIRST USE ...................................................................................... 7

9 MAINTENANCE AND SERVICES ..................................................................... 8

10 DISPOSAL ......................................................................................................... 8

11 WORKING WITH THE BRAUMEISTER ............................................................ 9

11.1 Language selection/time ......................................................................................................................... 9

11.2 Brewing control information ................................................................................................................. 9

11.3 Circulation pump information............................................................................................................. 10

11.4 Notes on the container lid ..................................................................................................................... 10

11.5 Information pertaining to the piping layout and the position of the valves ..................................... 10

11.6 Lifting equipment information ............................................................................................................ 10

11.7 Notes on hygiene ................................................................................................................................... 11

11.8 Information about the cooling jacket and water quality ................................................................... 11

12 BREWING WITH THE BRAUMEISTER .......................................................... 12

12.1 Introduction .......................................................................................................................................... 12

12.2 Preparations .......................................................................................................................................... 12

12.3 Programming/ starting automatic brewing ........................................................................................ 13

12.4 Mashing ................................................................................................................................................. 13

12.5 Purification ............................................................................................................................................ 16

12.6 Hops boiling process ............................................................................................................................. 17

12.7 Cooling ................................................................................................................................................... 19

12.8 Main fermentation ................................................................................................................................ 20

12.9 Maturation ............................................................................................................................................ 21

13 BREWING EXAMPLE/ BRIEF INSTRUCTIONS ............................................. 22

14 BREWING FAULTS/TROUBLESHOOTING ................................................... 26

15 LEGAL ASPECT OF HOME BREWING (VALID IN GERMANY): .................. 27

16 BREWING RECORD ....................................................................................... 28

17 CLEANING INSTRUCTIONS........................................................................... 29

18 GUARANTEE CONDITIONS, HANDLING A GUARANTEE ........................... 31

Speidels Braumeister

Page 3 of 32

1 General information

Dear customer,

You have purchased a new device from our company. Thank you for your trust in our

product. Quality and functionality of our products rate high on our list of priorities.

Please read the user guide before the first use completely and make this any user of the

master brewer accessible.

Use according to intended purpose:

The Braumeister is designed and produced to brew beer in quantities of approx. 200 L or

500 L or 1000 L. Prior to each brewing procedure, a safety inspection must be performed

for your safety and proper functionality of the Braumeister.

Operating instructions:

These operating and brewing instructions have been compiled to ensure reliable and safe

commissioning and operation of the Braumeister right from the start. Please read the

instructions carefully and in full before brewing your first beer. Compliance with these

notes and instructions will ensure that your Braumeister operates to your utmost

satisfaction, and has a long lifespan.

Conformity declaration:

SPEIDEL Tank- und Behälterbau GmbH hereby declares that the “Braumeister” product

mentioned in these instructions, and to which this declaration applies, complies with the

requirements of the European guidelines.

Manufacturer

Speidel Tank- und Behälterbau GmbH

Krummenstraße 2

72131 Ofterdingen

Germany

www.speidels-braumeister.de

www.speidel-behaelter.de

2 Safety instructions

2.1 General safety notes

The Braumeister consists nearly completely of stainless steel (electrically conductive).

The equipment is categorised as protection class 1 (protective earthing). In operation

the connection of a protective conductor is imperative.

The device and mains cable must be inspected regularly for any signs of damage. In

the event of signs of damage, do not use the device!

Always disconnect the plug from the socket (pull the plug, not the cable) if you no

longer wish to use the device, for cleaning or in the event of a fault. Only properly a

trained electrician shall be permitted to perform maintenance and repair work. The

terminals may still be live after the equipment has been shut down. Wait at least 3

minutes. Risk of electric shock!

Speidels Braumeister

Page 4 of 32

Ensure that you lay the mains cable such that it does not come into contact with sharp

objects. The cable must be fully unwound.

The Braumeister must only be used as intended. It must only be operated in a safe,

fault-free condition. Ensure to check the proper condition prior to each use.

Children, pets and frail persons:

For the safety of your children, keep packaging parts (cartons, polystyrene etc.) out of

children’s reach. Keep foils out of children’s reach. Asphyxiation risk!

This device is not meant to be handled by persons (including children) with limited

physical, sensory or mental capabilities, or lack of experience and/or know-how,

unless they are being supervised by a person responsible for their safety or the person

has received instructions on how to use the device safely.

Children and pets must be supervised to ensure that they are kept away from the

device and do not play with the device.

2.2 Safety instructions

The temperature of the container, lid, and add-on parts can become extremely high.

Towards the end of the brewing process, the boiler contains boiling beer wort.

Observe the installation instructions. Never attempt to move the Braumeister while it

is hot. Always use pot holders or gloves when working on and with the Braumeister.

Risk of burning!

When lifting the lid, ensure that the condensation on the underside of the lid flows

back into the container. For this, hold the lid over the container at an angle. Scalding

risk!

The Braumeister always operate via a residual current circuit breaker with a

tripping current of max. 100 mA type B (AC-DC sensitive). A technical defect

carries the inherent risk of electrical shock!

When performing cleaning activities on the Braumeister always ensure that the plug is

disconnected (disconnection from mains). . The terminals may still be live after the

equipment has been shut down. Wait at least 3 minutes. Do not spray the device down

or allow spray to come into contact with electric components. Danger of electric

shock!

Important: It is imperative that you lock the plug connections at the rear of the device

(pump and heater) during the operation of the device. Operating the device without

securing plug and socket devices can lead to overheating. Fire hazard!

Please use the thermal sleeve available as an accessory for insulation. When using

your own insulation ensure that the electronics and the lower part of the Braumeister

are sufficiently ventilated, as a heat build-up and damage to the control may otherwise

occur.

The pump must be vented prior to each use to prevent dry running. Venting takes

place routinely in automatic operation. In the manual operation, the pump must be

switched on and off several times until no more air bubbles escape.

In order to prevent any danger that may be caused by outdated components,

compliance with the maintenance and inspection instructions is mandatory.

Speidels Braumeister

Page 5 of 32

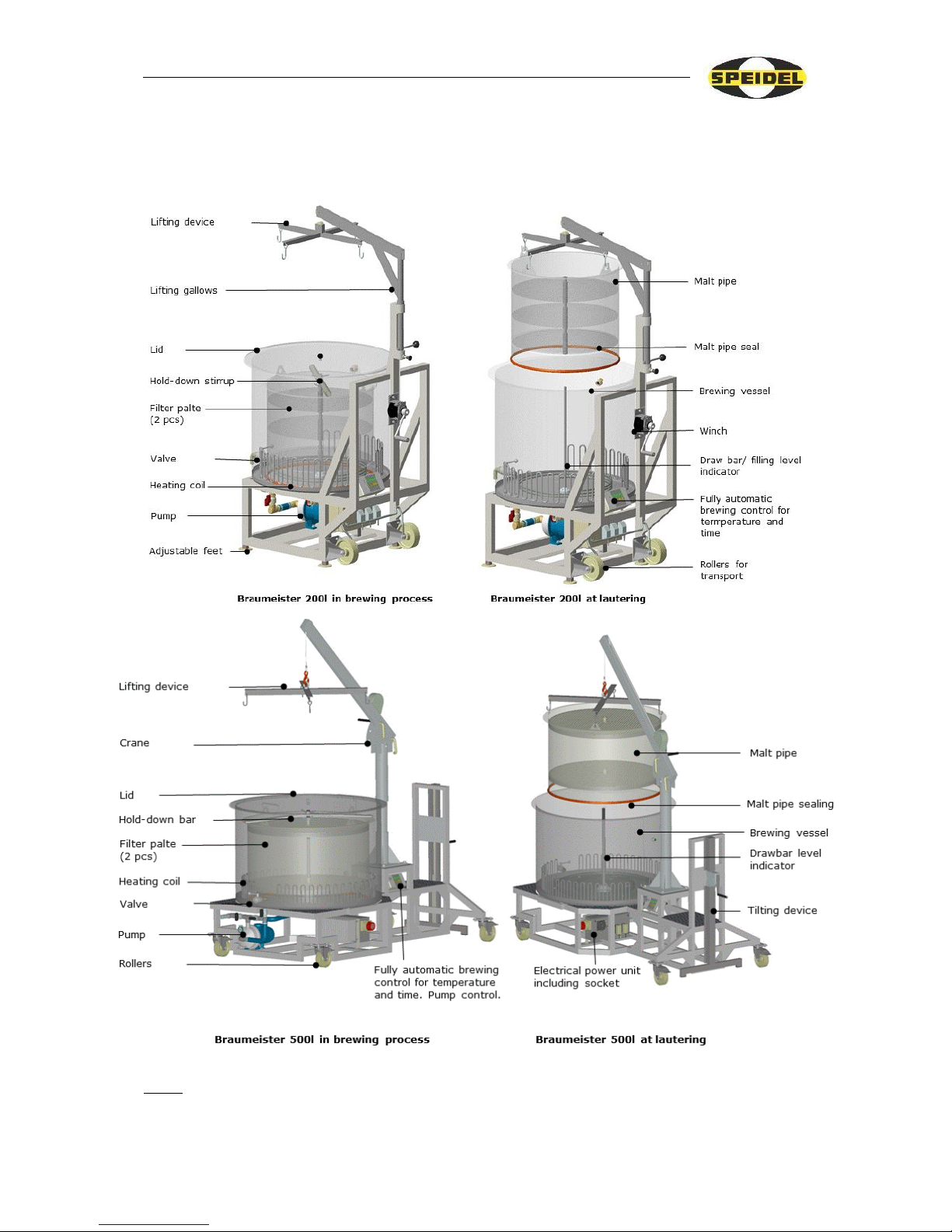

3 Components and scope of delivery

Please refer to the following illustration for components and scope of delivery:

Note: The following illustrations refer to Braumeister 200 L; however, the instruction

for the Braumeister 500 L or 1000 L are similar or identical.

Speidels Braumeister

Page 6 of 32

4 Technical specifications for Braumeister

Braumeister 200 L

Weight 150 kg including internal fittings and lifting equipment

Dimensions: L 136 cm x W 90 cm x H 208 cm

Heating coil: Heating capacity 3 x 3000 Watt

Pump: 1 x 370 Watt – with speed control

Power connection: 400V ~

Min. fuse protection: 16 Amp

Total connection: 9.4 kW

Cooling system: Double-walled shell area 1.2m²

Contents Brewing quantity approx. 200 L ready-to-drink beer (regular

beer) = approx. 210 L beer wort

amount of malt: max. amount of malt 42 kg

max. fill level: upper marking on tie rod = 230 L

min. fill level: lower marking on tie rod = 170 L

Braumeister 500 L

Weight 380 kg including internal fittings and lifting equipment

Dimensions: L 253 cm x W 130 cm x H 277 cm

Heating coil: Heating capacity 6 x 3000 Watt

Pump: 1 x 370 Watt – with speed control

Power connection: 400V ~

Min. fuse protection: 32 Amp

Total connection: 18.4 kW

Cooling system: Double-walled shell area 1.8m² plus cooling spiral (included in

delivery)

Contents Brewing quantity approx. 500 L ready-to-drink beer (regular

beer) = approx. 550 L beer wort

amount of malt: max. amount of malt 120 kg

max. fill level: Upper marking on tie rod = 575 L

min. fill level: lower marking on tie rod = 425 L

Braumeister 1000 L

Weight 850 kg including internal fittings and lifting equipment

Dimensions: L 305 cm x W 180 cm x H 345 cm

Heating coil: Heating capacity 4 x 3000 Watt + 8 x 2725 Watt

Pump: 1 x 370 Watt – with speed control

Power connection: 400V ~

Min. fuse protection: 63 Amp in Star, minimum 125 Amp. In Delta

Total connection: 34.2 kW

Cooling system: Double-walled shell area 2.56m²

Contents Brewing quantity approx. 1000 L ready-to-drink beer (regular

beer) = approx. 1200 L beer wort

amount of malt: max. amount of malt 225 kg

max. fill level: Upper marking on tie rod = 1300 L

min. fill level: lower marking on tie rod = 850 L

Speidels Braumeister

Page 7 of 32

5 Setting up the Braumeister

The Braumeister must be positioned on a stable, secure and horizontal support

structure prior to use. Caution! The Braumeister can weigh up to 420 kg or 1000 kg or

2200 kg while full and that it contains boiling hot beer wort. Horizontal positioning is

a prerequisite for transfer pumping during the brewing process. Avoid placing the

equipment on shaky and uneven ground. The Braumeister may not be moved during

the brewing process. It is imperative to keep children and frail persons away from the

device while it is in operation. Danger of burning! Furthermore, exposure to direct

sunlight (the lifting rope on 200 L equipment may become brittle) and extreme high

temperatures must be avoided

6 Cleaning the Braumeister

The Braumeister must be cleaned immediately after the brewing process. Avoid

surface drying of wort and malt remnants, as this will significantly impair the cleaning

process. All stainless steel components can be cleaned using a conventional detergent.

Abrasive agents and sponges/brushes that cause scratching are not suitable. Ideally,

use washing-up brush to clean the heating coil. The pump, its piping, including all

valves must be thoroughly flushed. During the tank-to-tank pumping, the valves must

be opened and closed during the cleaning process. Once in a while, hoses/pipes must

be removed and cleaned, using a separate brush. When cleaning the brewing vessel,

ensure water spray or moisture does not comes in contact with the electrical

components. The current supply must be disconnected for performing cleaning

activities on the Braumeister. Before starting the brewing process, remove all dust and

dirt from the Braumeister and all internal fittings by means of warm water. Also rinse

the pump and lines by means of transfer pumping. Caution: Ensure that you include

the malt pipe seal and drainage tap as well. Make sure that no detergent remnants

whatsoever remain in the Braumeister, as these could have a negative impact on the

foam stability of the beer. In order to ensure the valves are dry and discharged

completely, they must remain open. Please refer to the detailed cleaning instructions

on page 29 (cleaning set available as an accessory).

7 Storing the Braumeister

The Braumeister must be stored in a dry location. Avoid contact with ferrous or rusty

objects.

8 Prior to first use

Clean the Braumeister thoroughly using lukewarm water prior to initial use (see

Chapter 6). Refer to the safe installation of the Braumeister. See description in Chapter

5. Ensure that the Braumeister is in a flawless condition. Refer to the safety

instructions in Chapter 2. The Braumeister is designed for immediate use. Take care

that the pump is running prior the direction of the arrow. A wrong direction can be

caused by a wrong wiring of the electrical source.

Speidels Braumeister

Page 8 of 32

9 Maintenance and services

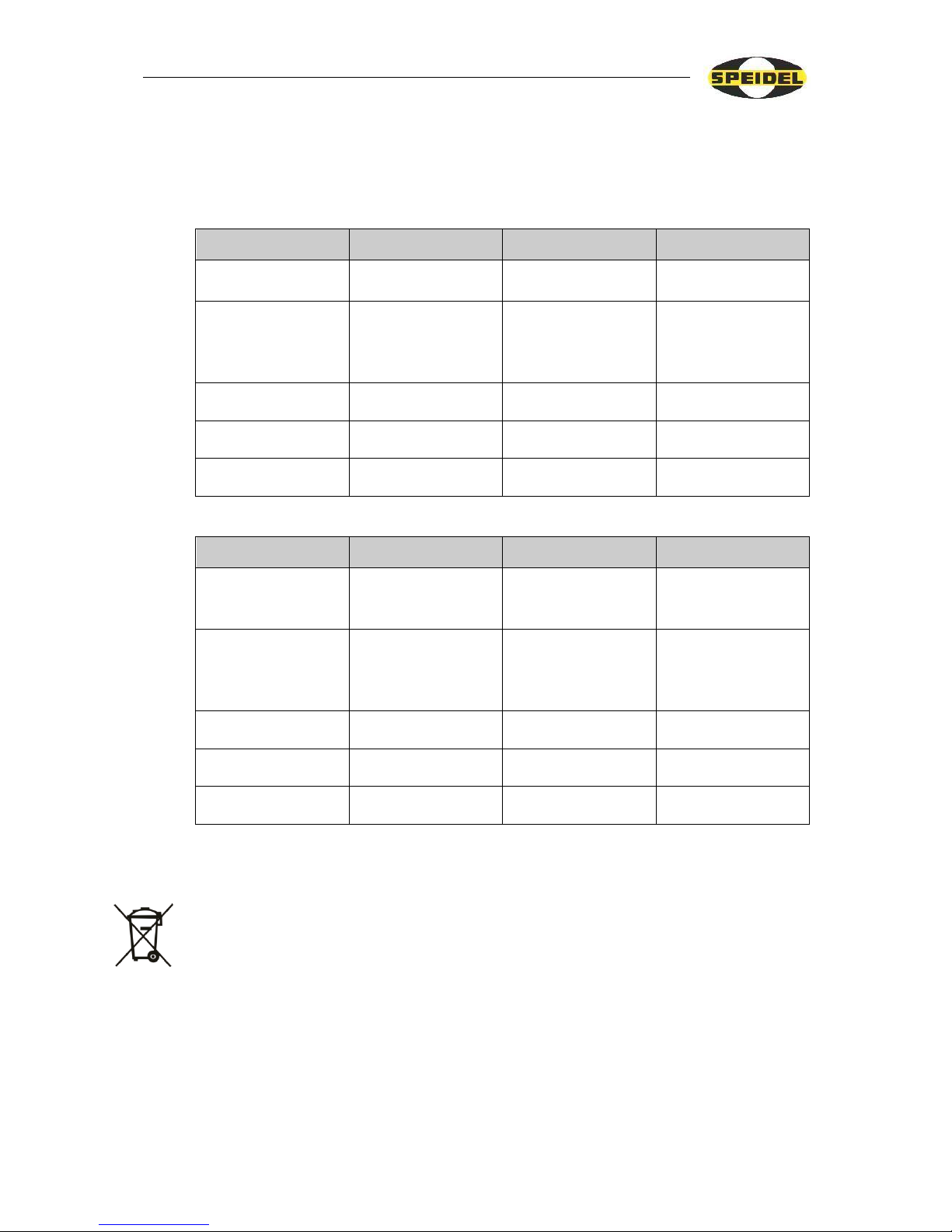

Compliance with the following maintenance and service information as well as the

intervals is highly recommended.

Braumeister 200 L

Component

Prior to any brewing

process

every 12 months or after

20 brewing processes

every 24 months or after

40 brewing processes

Lifting rope

(Item No.: 63212)

Visual inspection

for damage

Replacement

Cable winch

(Item No.: 64272)

Lubrication

according to

separate

instructions

Hoses

(Item No.: 77337)

Replacement

Malt pipe seal (Item

No.: 77362)

Replacement

Filter cloth

(Item No.: 77350)

Replacement

Braumeister 500 L/ 1000 L

Component

Prior to any brewing

process

every 12 months or after

20 brewing processes

every 24 months or after

40 brewing processes

Hoisting

equipment

Visual inspection

for damage

According to

hoisting equipment

instructions

Geared winch for

tilted position

(Item No.: 78030)

Lubrication

according to

separate

instructions

Hoses

(Item No.: 77337)

Replacement

Malt pipe seal (Item

No.: 77381)

Replacement

Filter cloth

(Item No.: 77350)

Replacement

10 Disposal

Meaning of the “refuse bin” symbol on the Braumeister: Protect our environment;

electrical devices should not be disposed of as household refuse. Make use of

collection points for disposal of electrical devices and hand in all electrical devices

that you no longer wish to use at these points. In this manner, you can avoid a

potential impact on the environment and human health caused by incorrect disposal.

This is your contribution to recycling and other forms of use of waste electrical and

electronic equipment. You can find information on where to dispose of the devices

from your district or municipal administration.

Speidels Braumeister

Page 9 of 32

11 Working with the Braumeister

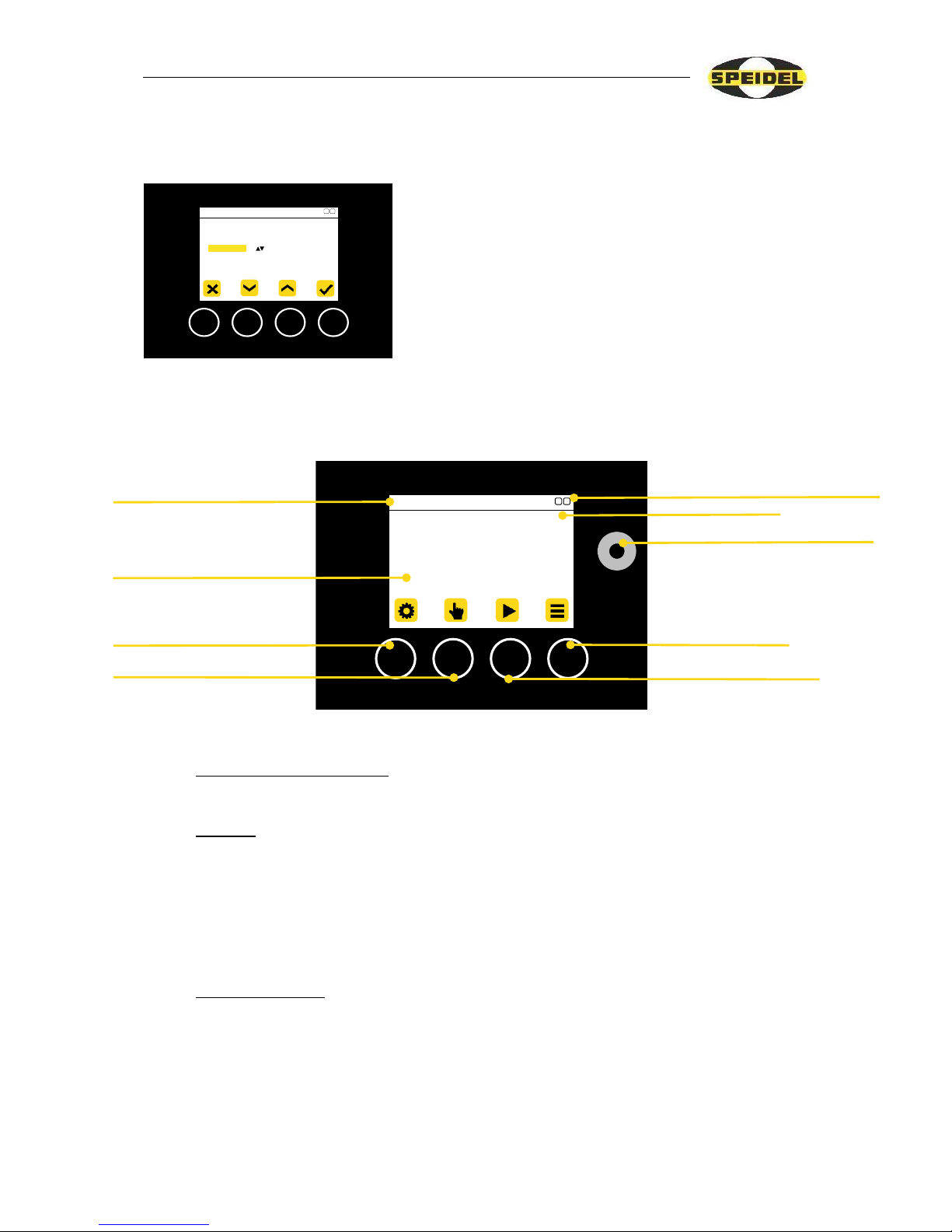

11.1 Language selection/time

When pressing the Settings button in the ‘Start’ menu,

the language, illumination, and time screen opens. The

arrow keys allow you to make a selection, and choosing

the Select function takes you to the various options.

These, in turn, can also be selected by activating the

arrow keys. Acknowledge your selection by pressing the

Select button. Press the Abort button to return to the

Start menu.

11.2 Brewing control information

Automatic operating mode: Press Brewstart, select a recipe and press Select to start.

Follow the instructions. A detailed description can be found in the

chapter below “Brewing with the Braumeister”.

Recipes: Up to 10 recipes can be stored when selecting the Recipe

function. When you receive the equipment, 2 recipes are included.

Use the arrow keys to select a recipe first, create a new one or

delete a recipe. Pressing the Select function to change an existing

recipe. The arrow keys allow you to modify any entries. Use the

Select key to move to the next recipe item until you have reached

the end. Once all items of the recipe have been acknowledged by

pressing the Select key, the recipe is applied and stored.

Manual operation: During the manual operating mode, the pump and the heater can

be switched on and off. The symbols on the upper right-hand

corner indicate whether the pump is on or off. If the symbol is

highlighted in yellow colour, the pump is on A light yellow

colour of the symbol indicates that the pump is activated,

however, it is not started. This indicates that the liquid is still too

hot or the heater is activated but the actual value is higher than the

setpoint. Use the Temperature button on the right-hand side to set

Settings

Abort

Down

Up

Select

11:45

HP

Language

Lightning

Set Time

Temp 15 C

Speidels Braumeister

Main menu 11:45

Settings

Manual Brewstart R ecipe

HP

Menu display/status display

Settings

Time, Diode (P)ump/(H)eater

Display of time, temperature,

recipe, instructions

Progress bar

To manual operating

Starting a brew recipe

Processing a recipe

Potentiometer for controlling

the pump flow

Speidels Braumeister

Page 10 of 32

the target temperature; then, activate the arrow keys and the Select

button.

Cancel: When pressing the Abort button, you are taken back the Start

menu; regardless of the operating mode you are currently in

(Automatic/Brew start/Recipes, and Manual mode). While in

Automatic mode, the red-coloured light elements are lit. A

prompt will be displayed asking whether the procedure shall be

finally aborted or whether this process shall continue.

11.3 Circulation pump information

While in the manual mode, the circulation

pump can be switched on and off. It is

important to vent the pump while in manual

operating mode after filling it with liquid, so

as to ensure that it does not run dry and

possible incur damage. This can be achieved

by filling the pump with water and switching

it on and off several times (until no more air

bubbles escape). The automatic mode occurs

automatically. During the brewing process

and while in manual mode, the pump

switches off automatically as soon as the temperature exceeds 88°C. This protects the

system. If the temperature drops to 84°C the operation continues. The speed and the

flow of the pump can be regulated by using the rotary knob on the control panel.

When using the 200l or 500 L/ 1000 L BM, the recirculation pressure is optimised at

approx. 0.2 bar or 0.15 bar (displayed on the pump’s pressure gauge during the mash

process). In order to prevent excessive pressure in the malt pipe, a pressure of 0.2 bar

or 0.15 bar must not be exceeded. The pump output is limited to approx. 0.25 bar for

the 200 L equipment and 0.2 bar for the 500 L/ 1000 L Braumeister.

11.4 Notes on the container lid

The lid assists in reaching the temperatures more quickly in the heating up phase.

Higher water temperatures cause condensation to occur on the underside of the lid.

When lifting the lid, ensure that you hold the lid rim over the vessel opening (at an

angle) so that the condensation can run back into the vessel.

11.5 Information pertaining to the piping layout and the position of the valves

By default, the Braumeister uses 3 feed-through and drain valves on the bottom as

well as one valve on the vessel itself. Valves at the bottom must be positioned

differently depending on the application and the section of the brewing process. The

valve on top of the vessel is used to remove the wort; at the same time it serves as inlet

for the whirlpool application. The following description of the brewing process

describes the relevant valve positions again and in more detail.

11.6 Lifting equipment information

The entire equipment comprises the lifting device, the cable winch, the cable, and

cross bar incl. hooks. Prior to each brewing process, these components must be

visually inspected for damage and their flawless condition must be insured. Additional

information and safety instructions can be found in the attached winch instructions. If

Loading...

Loading...