Speidel 47070 Operating And Brewing Instructions

Operating and brewing instructions

for

Speidel´s Master Brewer

Updated July 2008

1 GENERAL........................................................................................................... 1

2 PRESENTATION OF THE MASTER BREWER ................................................. 2

2.1

Components and extent of supply ......................................................................................................... 2

2.2

Installation of the Master Brewer ......................................................................................................... 2

2.3

Cleaning the Master Brewer .................................................................................................................. 2

2.4

Storage of the Master Brewer ................................................................................................................ 3

2.5

Technical data about the Master Brewer ............................................................................................. 3

2.6

Language selection.................................................................................................................................. 3

3 WORKING WITH THE MASTER BREWER ....................................................... 4

3.1

Advice about safety................................................................................................................................. 4

3.2

Advice about the temperature control unit .......................................................................................... 4

3.3

Advice about the recirculating pump.................................................................................................... 5

3.4

Advice about the container’s lid ............................................................................................................ 5

3.5

Advice about hygiene.............................................................................................................................. 5

4 BREWING WITH THE MASTER BREWER........................................................ 6

4.1

Introduction ............................................................................................................................................ 6

4.2

Preparations ............................................................................................................................................ 6

4.3

Programming / starting the Master Brewer ......................................................................................... 7

4.4

Mashing (brewing).................................................................................................................................. 7

4.5

Running off.............................................................................................................................................. 9

4.6

Boiling the hops..................................................................................................................................... 10

4.7

Cooling................................................................................................................................................... 12

4.8

Main fermentation ................................................................................................................................ 12

4.9

Maturation (ripening)........................................................................................................................... 13

5 A BREWING EXAMPLE AND BRIEF INSTRUCTIONS ................................... 15

6 BREWING DEFECTS AND ELIMINATING PROBLEMS ................................. 18

7 LEGAL ASPECTS OF DOMESTIC BREWING

(VALID JUST FOR GERMANY)

..... 20

8 ADVICE ABOUT LITERATURE AND PURCHASING SOURCES ................... 21

9 BREWING RECORD......................................................................................... 22

10 PUMP CLEANING......................................................................................... 23

11 WARNINGS................................................................................................... 26

Speidel’s Master Brewer

Page 1 of 26

1 General

Dear Customer,

You have acquired a new device from our company. We thank you for choosing it.

We give priority to the quality and functionality of our products.

Use:

The Master Brewer is designed and produced to brew small quantities of beer (approx.

20 litres).

Operating instructions:

We have written these operating and brewing instructions in order to ensure that the

Master Brewer is commissioned and operated reliably and safely from the start. Please

read them through carefully and completely, before you start to brew for the first time.

Your Master Brewer will work to your full satisfaction and have a long service life, if you

have followed this advice and instructions precisely.

Advice about safety:

Please follow the advice about safety.

Declaration of conformity:

We, SPEIDEL Tank- und Behälterbau GmbH, of Krummenstrasse 2, D-72131

Ofterdingen, declare ourselves to be solely responsible for the product - which is named

in these instructions as ‘Speidel’s Master Brewer’ and to which this declaration refers complying with the regulations of the following European Guidelines: 89/336/EWG and

72/73/EWG.

Legally binding signature: Ofterdingen, November 2006.

Stefan Speidel

Speidel Tank- und Behälterbau GmbH

Krummenstrasse 2, D-72131 Ofterdingen.

Speidel’s Master Brewer

Page 2 of 26

2 Presentation of the Master Brewer

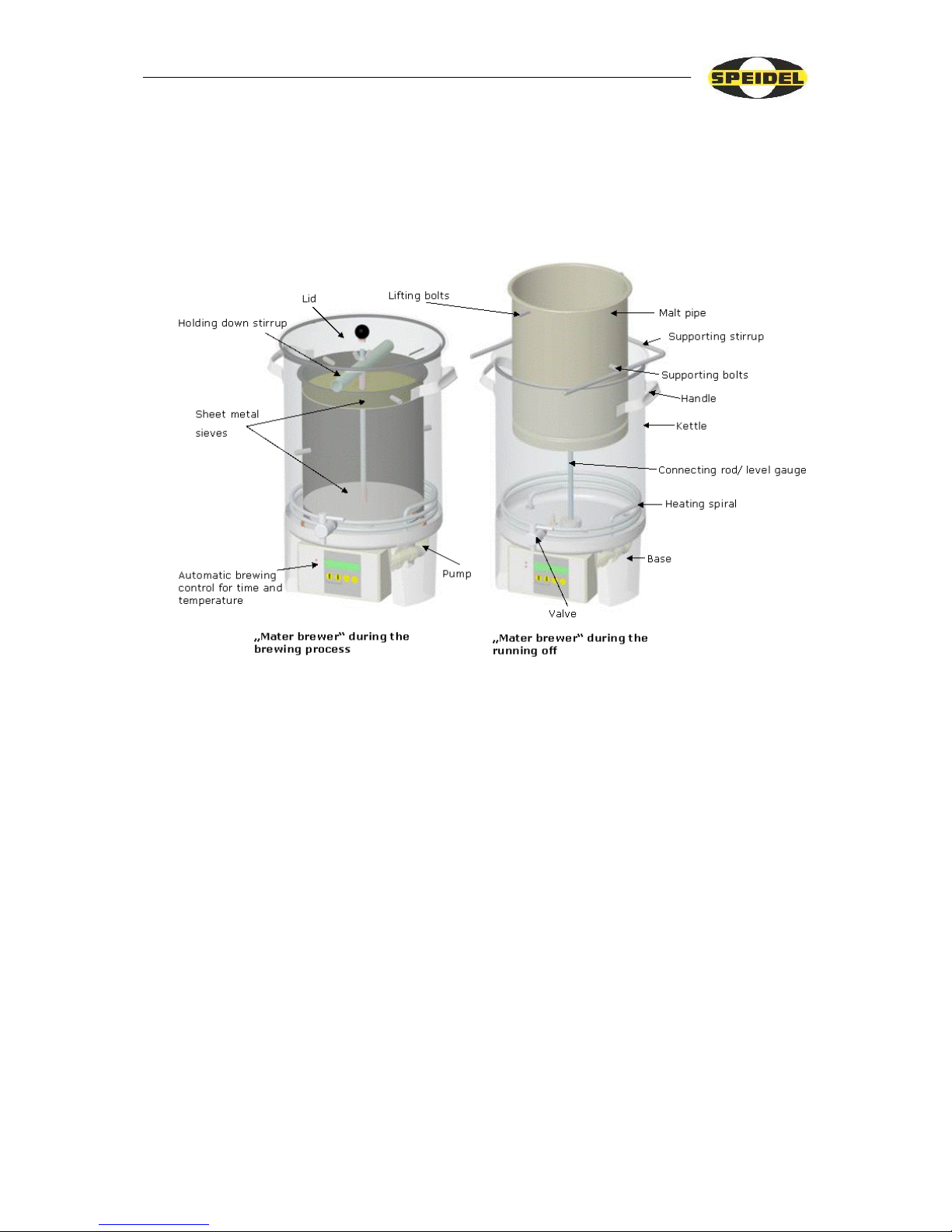

2.1 Components and extent of supply

Please find out about the components and the extent of supply from the

following illustration (the cooling spiral and fermenting cask are not included).

2.2 Installation of the Master Brewer

The Master Brewer must be placed on a sturdy, stable and horizontal base before use

or before the brewing process. Note that the Master Brewer can weigh up to 50 kg

when it is in a filled condition and full up with boiling hot wort. Horizontal installation

is a prerequisite for the pumped recirculation during the brewing process. Avoid a

wobbly base. A sturdy wooden box or a table that is not too high is ideally suitable.

The Master Brewer is not allowed to be moved during the brewing process.

The handles are only intended for transporting and handling it in an empty condition.

It is imperative to keep children away from the device when it is in use.

2.3 Cleaning the Master Brewer

The Master Brewer must be cleaned immediately after the brewing process.

The cleaning is considerably eased by preventing the residual wort and malt from

drying out. All stainless steel parts can be cleaned with a conventional, domestic

washing-up liquid [mixed with water]. Scouring agents and sponges or brushes that

cause scratches are unsuitable. The heating spiral can best be cleaned with a pipecleaning thread. The pump and the drive ball located inside it should also be flushed

out regularly. Fresh water is pumped through the pump several times beforehand. Just

invert the Master Brewer and loosed the screwed connection – which should only be

tightened manually – in order to open the pump. The pump can be easily removed by

completely detaching the plug’s screwed connection from the Master Brewer.

Speidel’s Master Brewer

Page 3 of 26

Speidels Braumeister

Ist Temp T=015°C

Care must be taken when cleaning the brewing boiler, that no sprayed water or

moisture comes into contact with the electrical components. The power supply must

be disconnected in order to clean the Master Brewer. The Master Brewer and the

associated internal fitments only have to be freed of dust and dirt with warm water

before the brewing begins. The pump and conduits also have to be rinsed out by means

of pumped recirculation. Take care that you also include the malt pipe’s seal and the

stop cock. Ensure that no residue at all from the flushing agent remains in the Master

Brewer any longer, which could have a negative effect on the beer’s content of foam.

2.4 Storage of the Master Brewer

The Master Brewer must be stored in dry conditions. Avoid contact with ferrous or

rusty objects.

2.5 Technical data about the Master Brewer

Weight: 15 kg with fittings and the lifting stirrup.

Heating spiral: 2,000 watts of heat output.

Pump: 23 watts.

Mains power supply: 230 V.

Capacity: a brewing quantity of approx. 20 litres of manufactured beer

(normal beer) = approx. 23 litres of wort.

2.6 Language selection

The language selection menu is accessed from the basic

display by pressing and holding the UP ARROW (LNG)

for 3 seconds. The language can then be set using the arrow

buttons to GERMAN, ENGLISH, FRENCH or SPANISH.

The selected language is accepted by pressing the ENTER

button.

Speidel’s Master Brewer

Page 4 of 26

3 Working with the Master Brewer

3.1 Advice about safety

Caution: danger of burning! The container, lid and fittings become very hot.

The boiler contains boiling wort at the end of the brewing process. Follow the advice

about installation. Never move the Master Brewer when it is in a hot condition.

Keep children away. You should always use oven cloths or gloves when working on

and with the Master Brewer.

Caution: danger of condensation! Take care when lifting the lid that the condensed

water on its underside runs back into the container. Hold the lid obliquely over the

container accordingly.

Caution: electricity! Only carry out cleaning work on the Master Brewer when the

plug has been pulled out of the mains socket outlet (separated from the mains power

supply). Avoid overloading the electrical fuse. Do not connect any other appliance

with a high electrical rating to the same fuse because the Master Brewer has a high

consumption of electricity. Important: for operation of the control unit, the plug

connections on the rear side (pump and heating) of the unit must be locked at all times.

Operating the unit without the plug connections locked will create the danger of

overheating, damage to the Master Brewer and danger to the user.

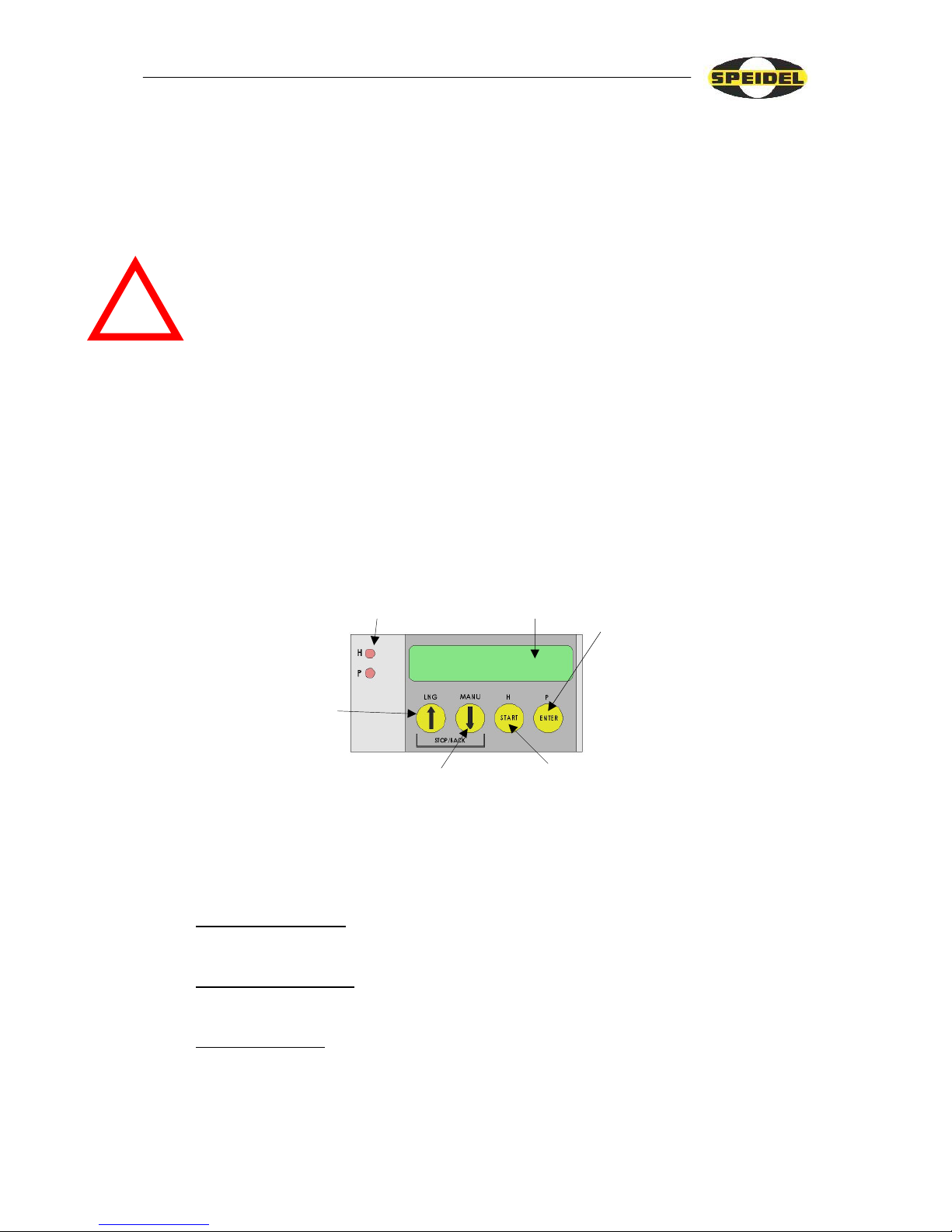

3.2 Advice about the temperature control unit

Automatic operation: Start by pressing START (1 sec). A comprehensive description

is given in the following chapter “Brewing with the Master

Brewer”.

Programming module: The programming module is accessed by pressing the ENTER

button (1 sec). A comprehensive description is also given in

the following chapter “Brewing with the Master Brewer”.

Manual operation: Press ↓ (1sec) to switch to manual operation of the Master

Brewer. The heating (H) is switched on/off by pressing

START. Pressing ENTER also activates the pump (P). The

temperature can be set by means of the arrow buttons.

Display

ENTER

• Switch to programming mode (1 sec)

• Confirmation of values in programming

mode

• Technology of requests in automatic

operation

• Pump On/Off in manual operation

LED heating

LED pump

START

• Start automatic brewing (1 sec)

• Confirmation but within the brewing process

• Heating On/Off in manual operation

UP ARROW

• Increase time / temperature in

programming mode and in

manual operation

• Language settings (3 sec)

• Up + down arrows = Stop

automatic or return from manual

operation

DOWN ARROW

• Reduce time / temperature in programming mode and in

manual operation

• Switch to manual operation (1sec)

• Up + down arrows = Stop automatic or return from

manual operation

!

Speidel’s Master Brewer

Page 5 of 26

Pressing ↓+↑ simultaneously returns to the initial display of the

Master Brewer.

Cancel / back: In all operating modes (automatic, programming mode and

manual operation), pressing the buttons ↓+↑ returns the user to

the initial position.

3.3 Advice about the recirculating pump

The recirculating pump can be switched on and off via the switch that is located on the

electrical box. It is important that the pump is ventilated after filling up with brewing

water, so that it has the full output. This is done by switching the pump on and off

several times when filled up with water and a mounting position of the pump of 45°

(until no bubbles of air escape any longer and hardly any noise can be heard from the

pump).

3.4 Advice about the container’s lid

The lid assists the temperature being reached more quickly during heating. The

ventilating slots avoid pressure building up in the boiler and they allow the air to

circulate slightly. Water condenses on the lid’s underside at higher temperatures. Care

must be taken when lifting the lid, that the lid’s rim is held over the boiler’s opening,

so that the condensation which runs off (when holding the lid obliquely), runs back

into the boiler and does not run down outside it.

3.5 Advice about hygiene

Hygiene is of paramount importance when brewing beer. The beer or the wort is

exposed to the danger of infection in the cold area especially (when cooling, bottling

[decanting] and fermenting), which can spoil the beer and ruin the whole work.

Therefore pay special attention to absolutely clean containers, (fermenting cask and

bottles) and working materials (spoons, stop cocks and seals). Sulphurous acid is

particularly suitable for disinfecting these containers and objects: it is obtainable from

specialized vintners and hobby-brewing shops. This powder is mixed with water and

thinned: it is suitable for pouring into the fermenting bung, for disinfecting the

fermenting container, other utensils and even the hands. It is typically recommended to

use a bucket of sulphurous acid, in which the hands and utensils are disinfected during

the brewing and before the bottling. The fermenting cask containing 3 to 5 litres of

sulphurous acid is sealed and allowed to stand for several hours. Shake the cask

several times in the meantime, then empty it and allow droplets to drain out before

use. It is unnecessary to rinse it out with water. A few droplets or residue from the

sulphurous acid in the beer are not a cause for concern as a result. Storage casks and

maturing casks are disinfected just like the fermenting containers. The bottles are

disinfected by heating them up in an oven, if the beer is decanted into bottles with

stirrup stoppers for maturation and storage after the fermentation. The rubber seals are

removed from the stirrup stoppers and then boiled in hot water or immersed in

sulphurous acid. The bottles are heated up in the oven to a temperature of approx.

130°C. The bottles are allowed to cool down to room temperature after that by means

of switching off the oven and they are then sealed with the disinfected seals. It is thus

guaranteed that the fermented beer will be decanted into absolutely sterile containers.

This work should be done several days before the fermenting, so that the decanting

process can take place quickly and not at a frantic pace.

Speidel’s Master Brewer

Page 6 of 26

4 Brewing with the Master Brewer

4.1 Introduction

Manufacturing beer with the Master Brewer can be split up into different phases: each

of which is described in detail below. These phases are described generally first of all,

in order to cover the brewing process and all sorts of beer and recipes for them. The

following section gives a definitive example of brewing for the novice brewer, as well

as a special recipe with exact information about quantities, brewing times and

temperature levels. It would be ideal if you could review the individual steps that lead

to the manufactured beverage first of all, before you begin with brewing the beer. It is

recommended to keep a record [e.g., a logbook] of brewing (refer to the record in the

appendix or at www.speidel-behaelter.de), so as to ensure that you do not omit any

steps: it will give you a review of your brewing processes retrospectively too. Some

more advice: you should allow a whole day for your first brewing attempt and do the

brewing with another person because that is more enjoyable and one can make good

use of the extra help. You should also bear in mind that brewing beer requires some

experience and one becomes more proficient when progressing from one brewing

process to the other. Do not be disappointed therefore, if the first beer does not meet

your expectations completely. A poem expresses this idea best of all.

“The first beer tastes so awful

that the farmer wets his trousers:

as an example for the others.

The second beer is a mediocre score,

you drink three measures and then pee four.

The third beer is from the core,

men and women drink it gladly for ever more.”

4.2 Preparations

Obtaining the ingredients

Obtain the requisite brewing ingredients in good time (hops, malt and yeast). It is

important that the malt is fresh while doing so. The malt should be used as quickly as

possible after the milling (grinding or crushing of the grains – not too finely). The

quantitative information varies somewhat according to the recipe: whereby the amount

of malt should be about 4-5 kg, whereas the amount of hops should be between 30 g

and 50 g. The hops are usually offered in pressed form as pellets. Dry yeast is

recommended for the fermentation because it is easier to store and it has a longer shelf

life. These ingredients have to be bought in a hobby-brewing shop or via the internet.

A third possibility of procuring the ingredients is from a brewery in your vicinity. Just

have a go at making enquiries!

Cleaning the equipment

The Master Brewer is rinsed out with warm water and the pump is rinsed through by

means of switching it on, before the brewing. The other utensils like beer spindles, a

wooden spoon and fermenting container should be ready for use and they must have

been cleaned too. Refer to the advice in the sections entitled “Advice about hygiene”

and “Cleaning the Master Brewer” for this purpose.

Speidel’s Master Brewer

Page 7 of 26

Speidels Braumeister

act temp T=015°C

prog 1. phase

set time t=005min

Water filled in ?

start

Softening the brewing water

The brewing water can be softened if necessary. The water (cold tap water) is boiled

for 30 minutes in the Master Brewer for this purpose, then it is cooled and stored

temporarily – e.g., in the fermenting container – until the brewing. The separated lime

has been deposited on the bottom of the container and it will be disposed of. The

Master Brewer is designed to brew approximately 20 litres of manufactured beer

(normal beer). Between 25 and 30 litres of brewing water will be required for this

purpose in that case. However, normal (hygienically faultless, colourless and

odourless) cold tap water is also usable for the novice or for the first brewing attempts,

in order to keep the expense and effort somewhat limited at the beginning. The

brewing water should have a hardness of less than 10° dH on principle. The softer the

water, the more suitable it is for brewing.

4.3 Programming / starting the Master Brewer

Connect the Master Brewer. The controls are then in the basic

condition. To programme a recipe and its time and temperature

values, press the ENTER button for 1 sec.

Select the time and temperature with the aid of the ARROW

BUTTONS, confirming each value by pressing the ENTER

button. Programme the mashing, phases 1-5 and the boiling of

the hops. The mode 5 is set to 0 and is only used for special

recipes.

After confirming all programme stages with ENTER, the

display returns to the basic condition. From here, you can now

start the automatic brewing by pressing the START button (1

sec). Now follow the instructions of the programme!

4.4 Mashing (brewing)

The mixing of crushed malt [i.e. grist] and water is described as mashing. The

objective of the entire mashing process is to dissolve the malt starch that is stored in

the malt and to convert it into sugar with the aid of enzymes that are present in the

malt. The various enzymes are effective at different temperatures, which is why the

various temperature stages are then passed through as well.

Mashing

About 23 litres of brewing water is poured into the boiler (up to approx. 2 cm below

the upper marker) first of all. The malt pipe is not installed yet while doing so. The

markers that are fitted on the connecting rod indicate the level of 15 litres, 20 litres

and 25 litres. Confirm that you have added the water by pressing START. This

switches the pump and heating on. The pump switches on and off several times in

order to ventilate it.

Loading...

Loading...