Page 1

Industry’s Largest Door

Opening 2.06 sq. ft. (1914 cm²)

MULTI-HOUSING

Quiet, Efficient Blower System

End-of-Cycle Signal

Control Options Enable User

Cycles to Fit Needs

Stack Dryer

Front Control

Durable

Galvanized Steel

Cylinder

Prep for Card

(“Y”)

Prep for Coin

(“X”)

Coin

(“C”)

RELIABLE COMMERCIAL PRODUCTS

Upfront Lint Filter

Easy to Clean and

Secured

High Efficiency Exhaust Blower

With Superior Airflow of 220 cfm

(105 liters/sec)

100% Serviceable From the Front

Space-Saving Narrow Cabinet

26-7/8" (683 mm)

Secured Automated Audits

Page 2

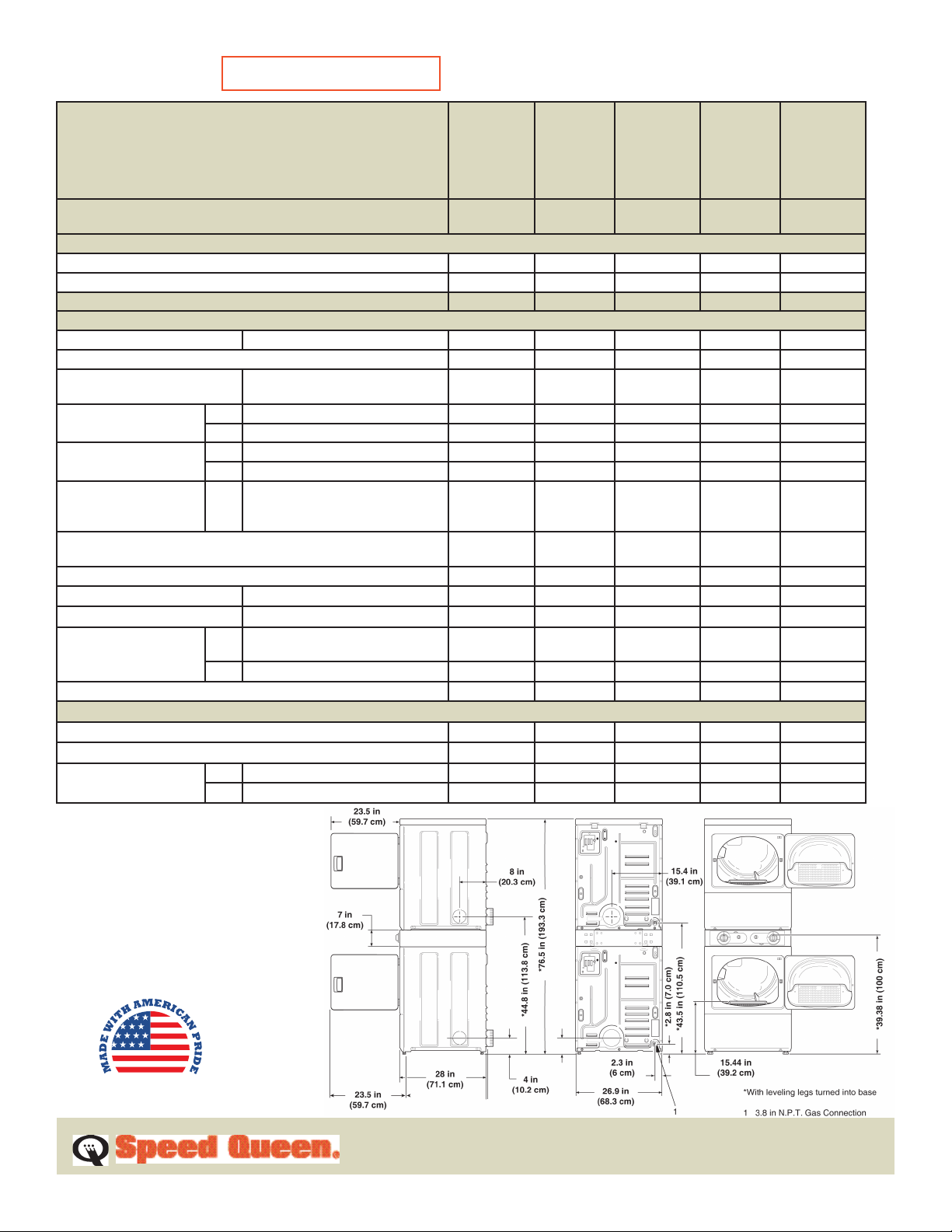

QUANTUM STACK DRYER SPECIFICATIONS

Elec “E”

Gas “G”

Activation

SSELYFGS

171TW01

SSGLYFGS

111TW01

Prep Card

“Y”

SSELYFGW

171TW01

SSGLYFGW

111TW01

Prep Coin

“X”

SSELXFGW

171TW01

SSGLXFGW

111TW01

Prep Coin

“X”

SSELCFGS

151TW01

SSELCFGS

171TW01

SSGLCFGS

111TW01

Coin

“C”

SSELCFGW

151TW01

SSELCFGW

171TW01

SSGLCFGW

111TW01

Coin

“C”

Appearance

Color - White √ √ √ √ √

Door - Window (W), Solid (S) Solid Window Window Solid Window

Control Panel Selection Front Front Front Front Front

Technical Info

Cylinder Volume - cu. ft. (liters) 7.0 (198) Galvanized Galvanized Galvanized Galvanized Galvanized

Cycle Temp - High 160º, Med 155º, Low 145º, Delicate 115º √ √ √ √ √

Motor (Capacitor Start and

Thermal Protected)

Weight - lb (kg)

Shipping Weight - lb (kg)

Electrical Requirements

Overall Dimensions WxDxH: mm (in)

26 7/8” (683) x 28” (711) x 76 5/8” (1946)

1/3 HP √ √ √ √ √

Elec 265 (120 √ √ √ √ √

Gas 275 (125) √ √ √ √ √

Elec 280 (127) √ √ √ √ √

Gas 290 (132) √ √ √ √ √

120/208/60/1-30 amp

Elec

120/240/60/1-30 amp *

Gas

120/60/1-15 amp

√

√

√

√

√

√

√

√

√

√ √ √ √ √

√

√

√

Type of Gas (Gas Models Only) Factory-Equipped Natural/Mixed Gas** √ √ √ √ √

Air Outlet Diameter - in (mm)

4” (102) √ √ √ √ √

Exhaust Airflow - cfm (liters/sec) 220 (105) √ √ √ √ √

Heating Element

Elec

4750W, 208V

5350W, 240V

√

√

√

√

√

√

√

Gas 25,000 Btu √ √ √ √ √

ADA Compliant (bottom dryer only) √ √ √ √ √

Performance/Features

Cycle Status Indicators √ √ √ √ √

Touch Pad Control with Sound Annunciator √ √ √ √ √

Agency Approval

* Electric dryers come equipped for 120/240/60/1

operation. They can be field converted to operate on

120/208/60/1 with optional 61928 conversion kit.

** Gas dryers can be field converted for operation

on LP gas with optional 458P3 conversion kit.

For the most accurate information, the installation

guide should be used for all design and construction

purposes. Due to continuous product improvements,

design and specifications subject to change without

notice. The quality management system of Alliance

Laundry Systems’ Ripon facility has been registered

to ISO9001:2008.

Elec cULus

CSA

Gas c

us

√ √ √ √ √

√ √ √ √ √

Manufactured in Ripon, WI

since 1908

© 2011 Alliance Laundry Systems LLC AM11-0745

Speed Queen | 800-345-3649 | www.speedqueen.com/route

Loading...

Loading...