Speed Queen SLW330RAW, PSLW330RAW Technical Information

Speed Queen R Domestic WasherTechnical Information

!

!

120 V, 60 Hz Models

SLW330RAW PSLW330RAW

• Due to possibility of personal injury or property damage, always contact an authorized technician for servicing or

repair of this unit.

• Refer to Service Manual RS3100007 for detailed installation, operating, testing, troubleshooting, and disassembly

instructions.

• Refer to Parts Manual RP3100017 for part number information.

CAUTION

All safety information must be followed as provided in this Technical Sheet and in Service Manual RS3100007.

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to unit and discharge capacitor

before servicing, unless testing requires it.

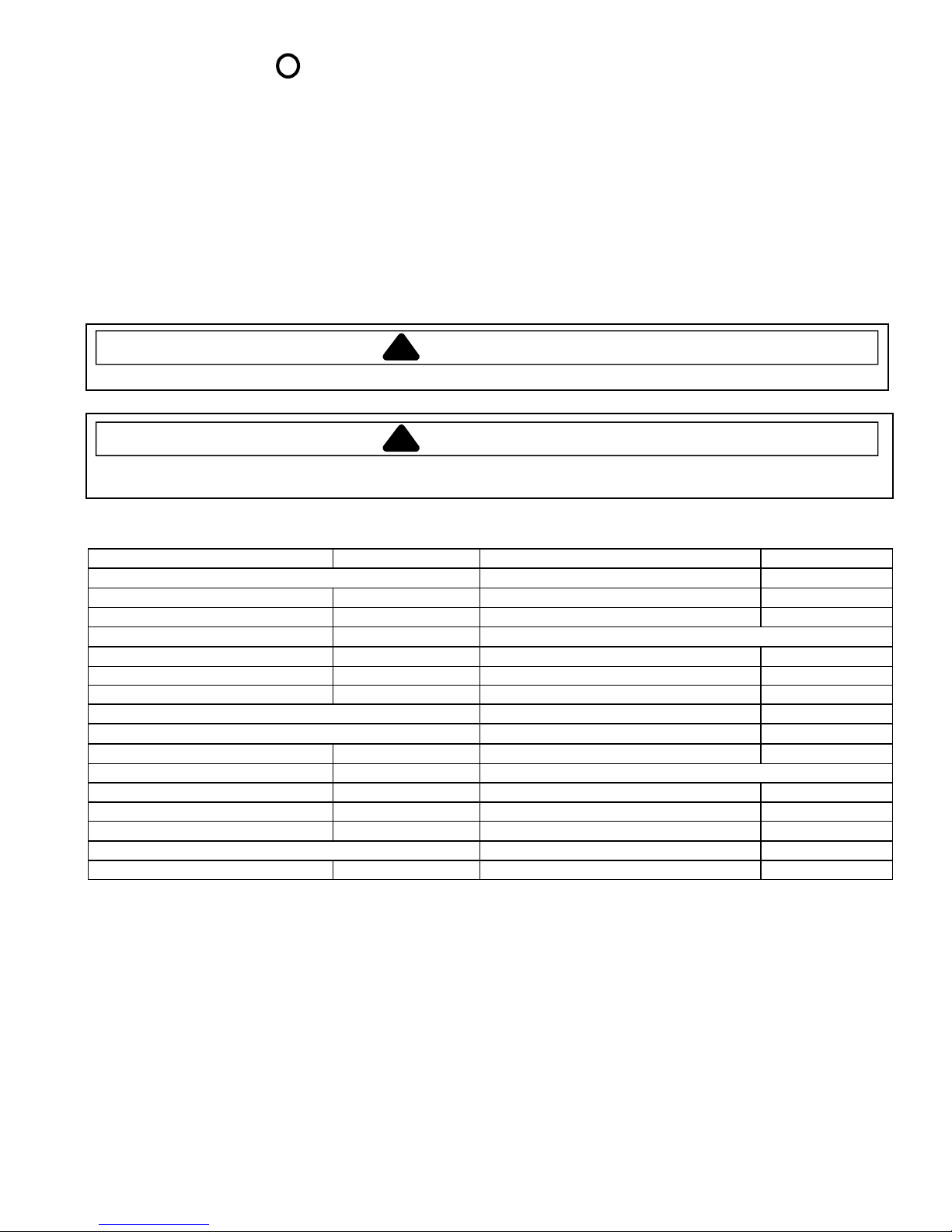

Models SLW330RAW Models SLW330RAW

Power Source Wash cyles

Voltage AC 120 VAC

Amperage (Single Unit) 10 A

Frequency 60 Hz

Motor horsepower 1/2

Receptacle 6-20R Self-cleaning lint filter X

Plug 6-20P Self-adjusting rear leveling legs X

Dimensions

Cabinet

Height−overall

Height of cabinet 36”

Width 27”

Depth 28” Spin speed (revolutions per minute) 640 / 427 rpm

Clearance−washer lid

Weight

Crated 193 lbs. Medium 46 spm

43” Fabric softener dispenser X

17 1/2”

Water temperatures

Water level

Features

Steady Spin Balance Sy stem

210 Agitation stroke X

Tri−Action wash system

Motor speed

Agitation speed

High 69 spm

(strokes per minute)

Variable

2 speed

7

3

X

X

August 2000 RT3100014 Rev. 01

Component Testing Information

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing, unless

testing requires it.

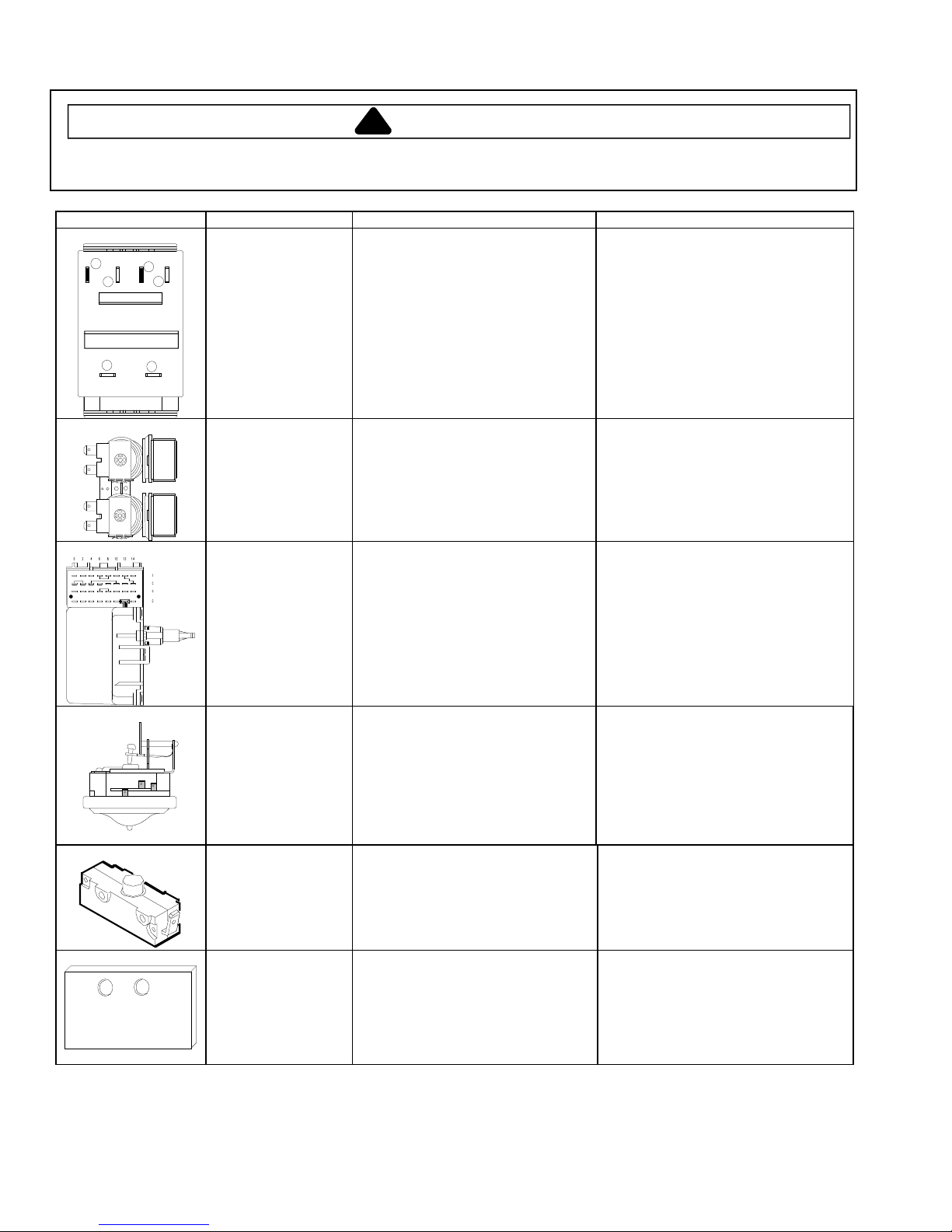

Illustration Component Test Procedure Results

40077101

1

2

3

A

L1

4

L2

Temperature switc h

3

4

B

L1 = A

L2 = B

3 = 1, 2

4 = 3, 4

Disconnect wires from component to

properly measure the resistance of t he

component.

Place switch in the following positions

and measure across the terminals

below:

Hot / Cold L1-4

Warm / Cold L1-3, L1-4, 3-4 Cold / Cold L1-3

>1

>1

>1

Ω

Ω

Ω

40097701 Mixing valve Measure resistance of terminals on

40058801 Timer Verify input and out put voltage is

40077201

40035001

2

1

3

Pressure swi tch Do not disconnect the pressure hose

Lid switch−SPST

each valve.

Resistance across each valve.

present.

Verify wiring is correctly connec ted to

the timer.

from pressure switch to perform

measurements.

Measure resistance across t he

following termi nals on the pressure

switch:

Terminal 1 to 2

Terminal 1 to 3

Disconnect wire terminals from s witch.

Test terminals with switch closed.

Test terminals with switch open.

Approximately 1000 Ω ± 10%

See timing sequence chart for functi onal

description of the component.

Refer to wiring diagram/schematic for

correct contacts.

Air pressure that actuates swit ch is

determined by the water level of the

tub.

Continuity (no pres sure)

Continuity (pres sure)

Continuity >1

Infinite 1 M

Ω

Ω

R0000014 Brake pad kit If washtub does not stop spinning

RT3100014 Rev. 0 August 20002

within seven seconds after opening

loading door.

If brake pads make noises.

Replace all three br ake pads.

Apply a thin layer of silicone (26594P)

on pads, see Service Bulletin

“ASQ−213−B”

Component Testing Information

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing, unless

testing requires it.

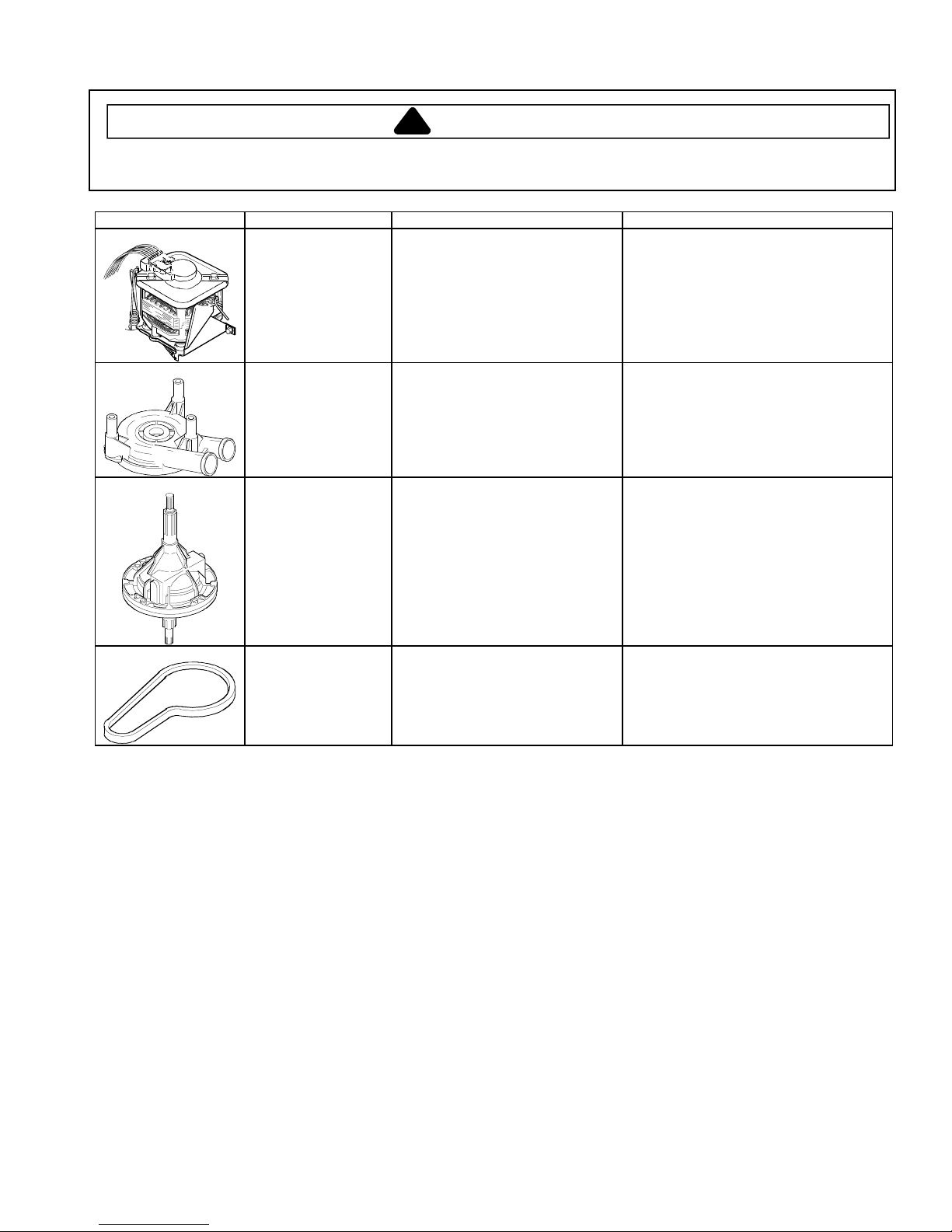

Illustration Component Test Procedure Results

40095001 Motor Type of motor:

Two speed

See following section “Internal Motor

Diagram and Schematic” for correct

wiring contacts.

40040301 Drain pump Veri fy drain pump is not clogged or

40065301 Transmission

assembly

40053602 Drive belt Type of drive belt:

damaged.

Type of transmiss ion:

640 rpm

640 rpm

Refer to “Parts Manual” for proper

pulley size.

Remove clog and verify proper operation.

Replace drain pump if damaged.

Externally identical, must be identified by

part number.

If transmission locks-up, replace.

Refer to “Parts Manual”, to verify whic h

drive belt and pulley size is required.

August 2000 3 RT3100014 Rev. 0

Loading...

Loading...