Speed Queen LTZ90A*N1102 Front-Load Parts Diagram

Homestyle

Frontload

Washers

Refer to Page 2 for Model Numbers

Service

www.comlaundry.com

FLW1515C

Part No. 801728R3

May 2007

Table of Contents

Model Identification ................................................2

Section 1 – Safety Information

Locating an Authorized Servicer ............................4

Section 2 – Introduction

Customer Service ....................................................5

Nameplate Location ................................................5

How Your Washer Works .......................................6

Section 3 – Troubleshooting

1. Motor Circuit ....................................................9

2. Troubleshooting Knocking Noise ....................9

3. Error Code Listing .........................................10

4. Washer Will Not Start – No LEDs/Lights lit

(No response to start switch) ..........................12

5. Washer Will Not Start – Door Open Error

(Wash/Rinse LEDs Flashing – Door must be

closed and attempting to lock) .......................14

6. Washer Will Not Start – No Door Lock

(Door LED Flashing) .....................................16

7. Motor Will Not Run

(Door/Final Spin LEDs Flashing) ..................18

8. Washer Will Not Fill – No Communication

Error

(Wash/Door LEDs Flashing) .........................20

9. Washer Overflows ..........................................22

10. Pump Does Not Operate ................................24

11. Serial Communication Error

(Final Spin/Rinse LEDs Flashing) .................26

12. Washer Will Not Heat – Open/Shorted

Temperature Sensor

(Heating LED flashing at end of cycle)

(Models equipped with heater) ......................28

13. Washer Will Not Heat (Models equipped with

heater) .............................................................30

Section 4 – Grounding

14. Wall Receptacle Polarity Check ....................33

15. Machine Ground Connections - Front Control

Washers ..........................................................34

16. Machine Ground Connections - Front Control

Washers with Suffix 3050

in Model Number ...........................................36

17. Machine Ground Connections - Rear Control

Washers ..........................................................38

Section 5 – Service Procedures

18. Control Cabinet (Front Control Washers) ......41

19. Control Hood Assembly (Rear Control

Washers) ........................................................43

20. Cycle Switch ..................................................45

21. Temperature Switch .......................................45

22. Pressure Switch ..............................................46

23. Control ...........................................................46

24. Indicator Lights ..............................................47

25. Push-to-Start/Rocker Switch ..........................47

26. Graphic Panel .................................................48

27. Lower Access Panel .......................................48

28. Cabinet Top Assembly ...................................48

29. Mixing Valve .................................................52

30. Junction Box and Line Filter ..........................54

31. Inverter Control ..............................................55

32. Electric Drain Pump .......................................56

33. Belt .................................................................57

34. Front Panel .....................................................59

35. Loading Door .................................................61

36. Door Seal And Hose Assembly .....................62

37. Door Switch ...................................................63

38. Door Latch Switch .........................................63

39. Motor ..............................................................63

40. Heating Element (Models equipped

with heater) ....................................................66

41. Outer Tub Front Panel ...................................67

42. Inner Basket Pulley ........................................69

43. Inner Basket Assembly ..................................70

44. Bearing Housing ............................................75

Section 6 – Adjustments

45. Cabinet Leveling Legs ...................................79

46. Loading Door .................................................80

47. Door Catch .....................................................81

48. Motor Belt Tension ........................................82

49. Shipping Braces .............................................83

© Copyright 2007, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any means without

the expressed written consent of the publisher.

801728 1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Model Identification

Information in this manual is applicable to these machines:

ATZ90A*N1102

ATZ95A*N1102

FTS90A*N3000

FTS90A*N3050

FTS90A*N3300

FTZ90A*N1102

FTZ91A*N1102

LTK95A*N3050

LTS95A*N3000

LTS95A*N3020

LTZ90A*N1102

* Add Letter To Designate Color. W – White Q – Bisque

2 801728

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 1

Safety Information

Throughout this manual and on machine decals, you will find precautionary statements (“CAUTION,”

“WARNING” and “DANGER”) followed by specific instructions. These precautions are intended for the personal

safety of the operator, user, servicer, and those maintaining the machine.

a DANGER

Danger indicates an imminently hazardous situation that, if not avoided, will cause severe personal injury or death.

a WARNING

Warning indicates a hazardous situation that, if not avoided, could cause severe personal injury or death.

a CAUTION

Caution indicates a hazardous situation that, if not avoided, may cause minor or moderate personal injury or property

damage.

Additional precautionary statements (“IMPORTANT” and “NOTE”) are followed by specific instructions.

IMPORTANT

The word “IMPORTANT” is used to inform the reader of specific procedures where minor machine damage will

occur if the procedure is not followed.

NOTE

The word “NOTE” is used to communicate installation, operation, maintenance or servicing information that is

important but not hazard related.

In the interest of safety, some general precautions relating to the operation of this machine follow.

WARNING

• Failure to install, maintain and/or operate this product according to the manufacturer’s

instructions may result in conditions which can produce serious injury, death and/or property

damage.

• Do not repair or replace any part of the product or attempt any servicing unless specifically

recommended or published in this Service Manual and unless you understand and have the

skills to carry out the servicing.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the product is properly grounded and to reduce the risk of fire,

electric shock, serious injury or death.

W006R2

801728 3

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 1 Safety Information

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

• Motor not grounded! Disconnect electric power before servicing motor.

WARNING

Repairs that are made to your products by unqualified persons can result in hazards due to

improper assembly or adjustments subjecting you or the inexperienced person making such

repairs to the risk of serious injury, electrical shock or death.

WARNING

W485

W007

If you or an unqualified person perform service on your product, you must assume the

responsibility for any personal injury or property damage which may result. The manufacturer

will not be responsible for any injury or property damage arising from improper service and/or

service procedures.

W008

NOTE: The WARNINGS and IMPORTANT INSTRUCTIONS appearing in this manual are not meant to

cover all possible conditions and situations that may occur. Common sense, caution and care must be

exercised when installing, maintaining or operating the washer.

Always contact your dealer, distributor, service agent or the manufacturer about any problems or conditions you do

not understand.

Locating an Authorized Servicer

Alliance Laundry Systems is not responsible for personal injury or property damage resulting from improper

service. Review all service information before beginning repairs.

Warranty service must be performed by an authorized technician, using authorized factory parts. If service is

required after the warranty expires, Alliance Laundry Systems also recommends contacting an authorized

technician and using authorized factory parts.

4 801728

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 2

Introduction

Customer Service

If literature or replacement parts are required, contact

the source from whom the machine was purchased or

contact Alliance Laundry Systems at (920) 748-3950

for the name and address of the nearest authorized

parts distributor.

For technical assistance, call (920) 748-3121.

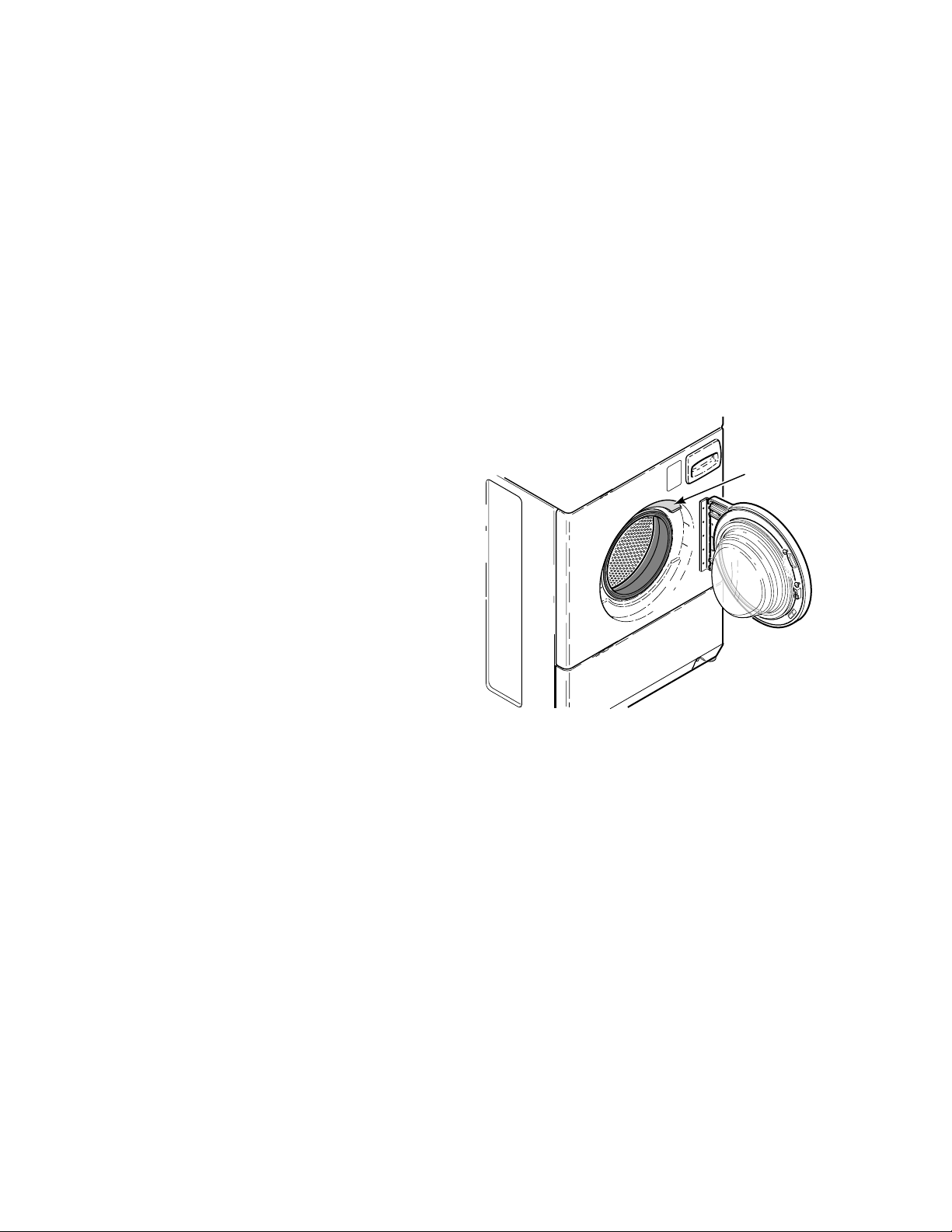

Nameplate Location

When calling or writing about your product, be sure to

mention model and serial numbers. Model and serial

numbers are located on nameplate(s) as shown.

NAMEPLATE

LOCATION

H129PE1A

801728 5

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 2 Introduction

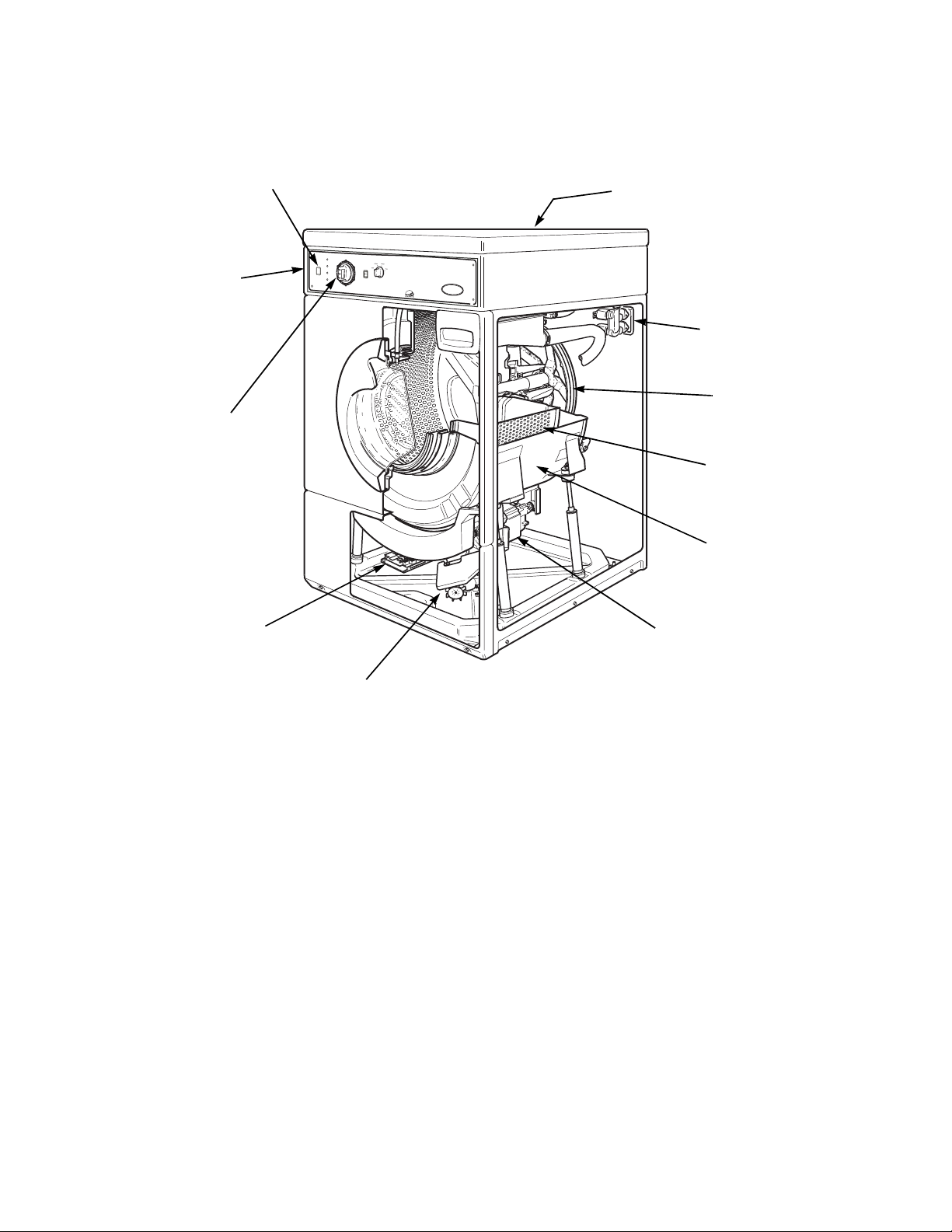

How Your Washer Works

(Front Control Shown)

Start

Switch

Control

(Located in control

cabinet)

Cycle

Selector

Pressure Switch

(Located in control

cabinet)

S

T

A

T

U

S

C

Y

C

L

E

S

E

L

E

C

T

IO

N

E

X

T

R

A

O

T

F

E

F

M

P

E

R

A

T

U

R

E

R

I

N

S

E

D

O

O

R

W

AR

M

W

S

P

I

N

S

T

A

R

O

T

N

L

Y

W

A

S

H

R

I

N

S

E

R

I

N

S

E

&

S

P

I

N

F

IN

A

L

S

P

I

N

ARM

WA

R

M

C

O

LD

R

E

G

U

L

A

R

H

OT

C

O

LD

C

O

LD

O

N

C

O

LD

O

F

F

P

E

R

M

A

N

E

N

T

P

R

E

S

S

D

E

L

I

C

A

T

E

C

o

m

m

e

r

c

i

a

l

H

i

g

h

E

f

f

i

c

i

e

n

c

y

W

a

s

h

e

r

801141

Mixing

Valve

Belt

Inner

Basket

Outer

Tub

Inverter

Control

Electric

Drain

Pump

Motor

FLW1734S

6 801728

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 2 Introduction

General

This frontload washer provides some of the same

principles of operation as the typical topload washers.

It senses water level, it dispenses the desired laundry

detergent, agitates the clothes for good cleaning

action, pumps the water out of the washer and spins

the clothing in preparation for the dryer.

The difference in operation is primarily the rotational

washing agitation created for the horizontal basket and

drum. This agitation tumbles the clothes in a

clockwise, pause, and counter-clockwise direction.

This reversing tumbling action provides an efficient

washing process and requires less water.

The cycle begins by pressing the start button, which

locks the loading door after the vend is satisfied. The

type of cycle and water temperature are determined by

the temperature selector switch and the cycle select

switch.

The inner basket starts agitating during the wash water

fill. A column of air is trapped in a pressure bulb and

hose. The air pressure continues to increase as the

inner basket fills with water until it is great enough to

activate the pressure switch which then causes the

wash fill to stop.

The regular and perm press agitate cycle tumble the

clothing in a clockwise direction for a period of 15

seconds, pauses for nine seconds and then tumbles the

clothing in a counterclockwise direction for 15

seconds. This agitation continues until the wash soak

cycle. The machine stops agitating and turns on the

pump which removes the wash water.

Upon completion of the wash cycle, the machine goes

into two rinse cycles. Fresh cold water is brought into

the inner basket via the mixing valve until the pressure

switch shuts off the water while agitating. The rinse

cycle consists of agitation for a predetermined amount

of time, then a spin mode with the pump running while

the machine goes into a series of 4 short 500 RPM

spins.

NOTE: Washer may not reach 1000 RPM because

of an out-of balance condition. Control may limit

speed to 850, 650 or 500 RPM depending on severity

of out-of-balance condition.

Perm

Press

minutes

minutes

Delicate

4

4

minutes

2

0

minutes

650 RPM

1000

RPM

Regular

3

minutes

3

minutes

Technical

The basic operational system of this washer consists of

the control, temperature switch, inverter control,

pressure switch, water valves, electric pump, A.C.

motor and cycle select switch.

The control performs all timing functions like the

timer in a topload washer.

The inverter control uses a speed sensor on the motor

to measure the drum RPM. Before entering any spin

step, the inverter control measures the RPM of motor

to sense out-of-balance. The inverter control will try to

redistribute the clothes if an out-of-balance condition

exists; the inverter control will limit the spin speed to

several speeds depending on the severity of the out-ofbalance condition. If the out-of-balance condition is

severe enough, the inverter control will limit speed to

90 RPM and will not spin.

NOTE: An additional out-of-balance switch is used

to detect any out-of-balance condition during spins.

If this switch opens during a spin step, the inverter

control immediately stops and then restarts the

spin.

After all the rinse cycles have been completed, the

washer goes into a final high spin cycle to extract as

much water as possible from the clothing to prepare

them for the dryer. The spin speeds and duration of

this final high spin cycle are determined by the type of

wash cycle selected (refer to table).

801728 7

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 2 Introduction

Notes

8 801728

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 3

Troubleshooting

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

• Motor not grounded! Disconnect electric power before servicing motor.

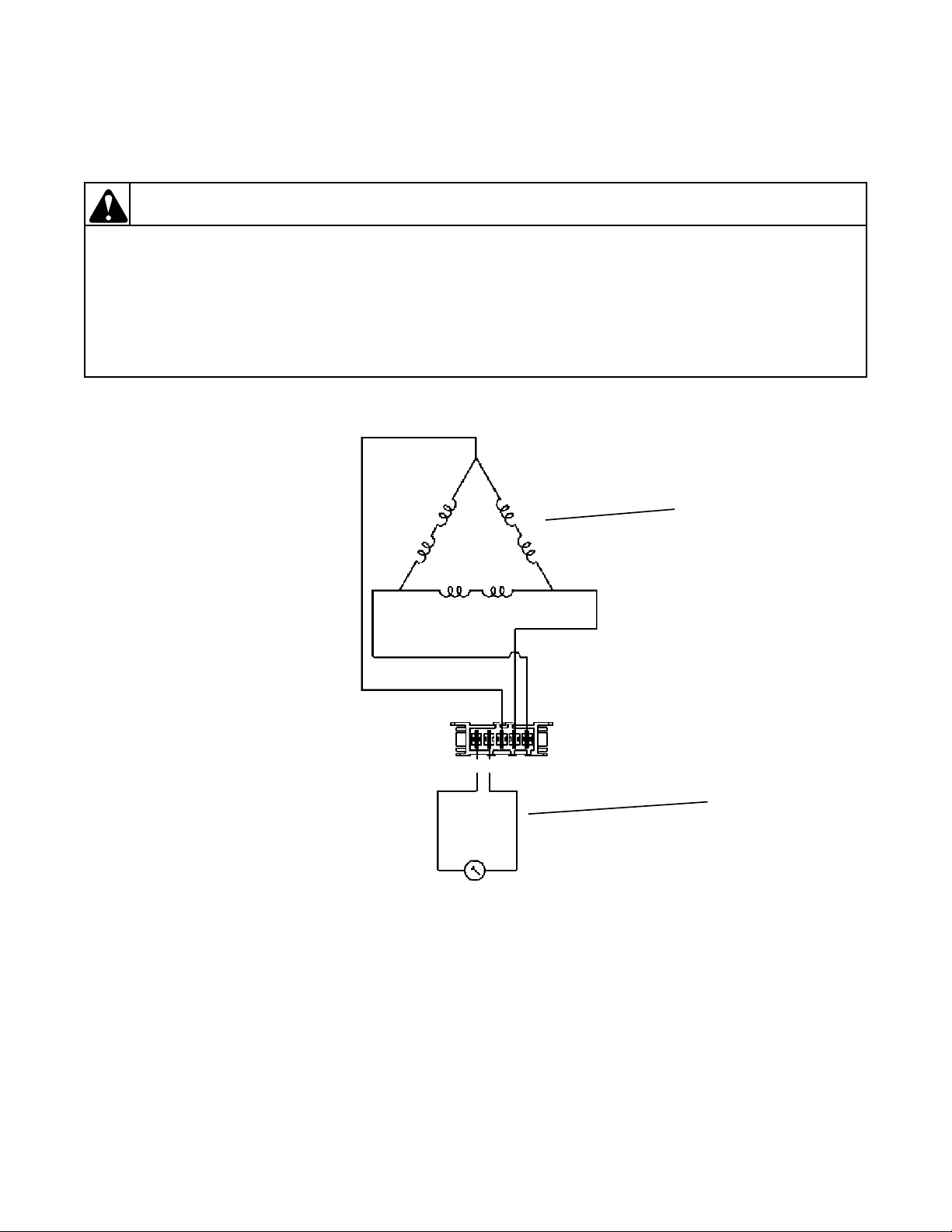

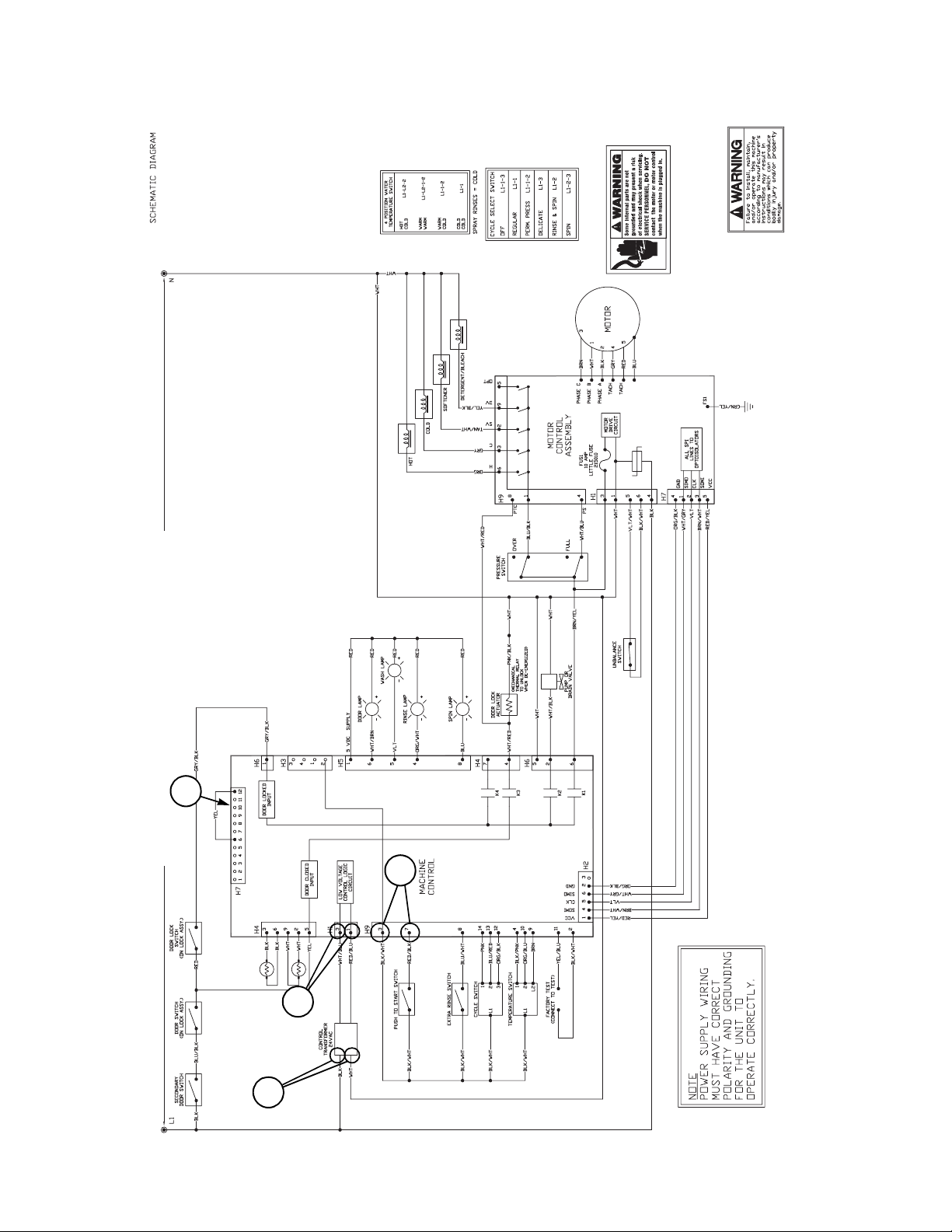

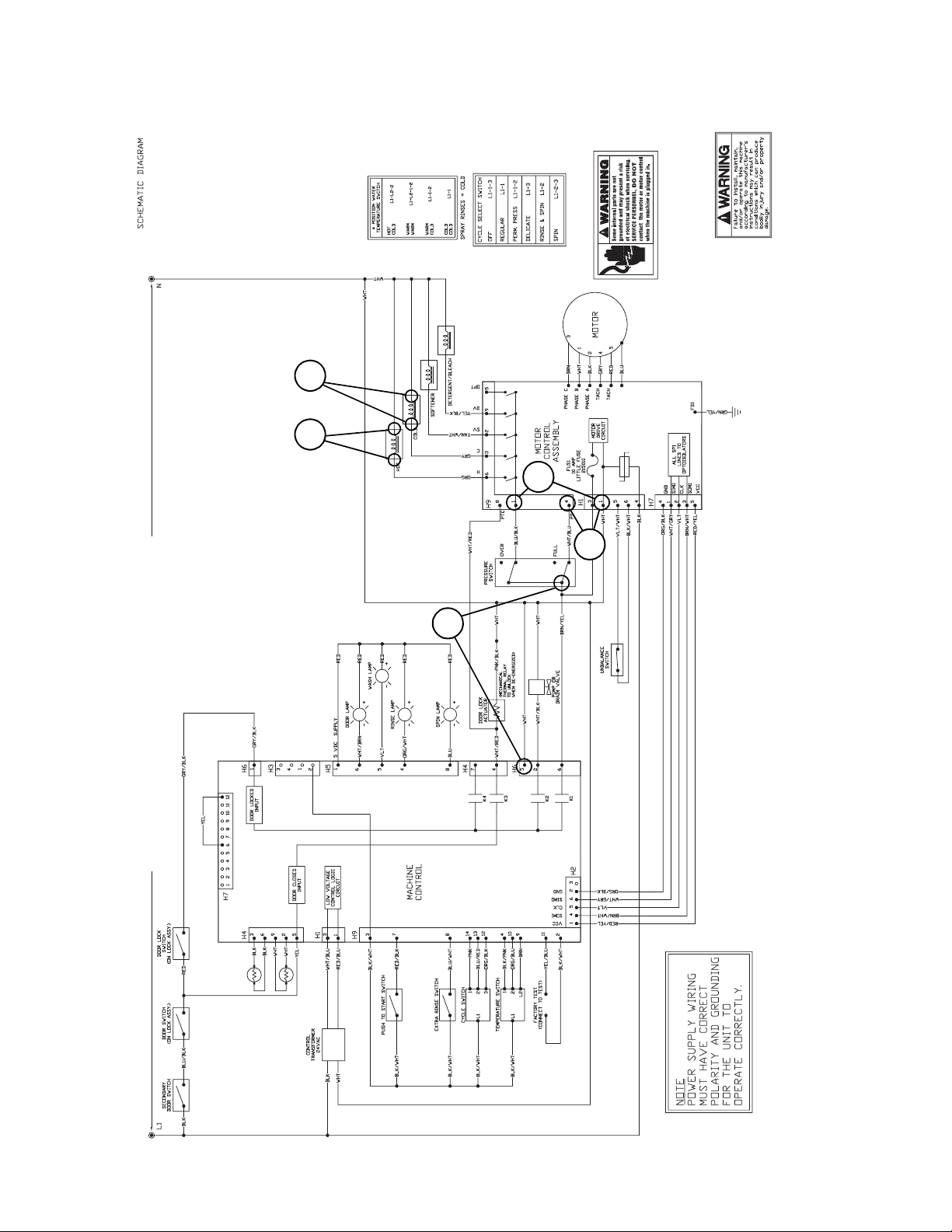

1. MOTOR CIRCUIT

Windings

W485

Gray

Red

Red

Resistance Values:

Tachometer Circuit:

Terminals 4–5

Approx. 115 ohms

2. TROUBLESHOOTING KNOCKING NOISE

If a frontload washer produces a noise similar to a

knock on a door, it might be due to a flat spot on

the belt. The knocking sound is made when the flat

spot hits the pulley. The knocking may occur

during a pulse spin and fade after reaching a

higher RPM.

White

1

4

5

2

3

Red

Windings:

Terminals 1–2, 2–3, 1-3

Approx. 4.5 ohms

To correct this condition, replace the belt. Refer to

Paragraph 33.

Tach. Circ uit

801728 9

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 3 Troubleshooting

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

• Motor not grounded! Disconnect electric power before servicing motor.

3. ERROR CODE LISTING Error Conditions

If any of the following errors occur, the control enters Error Mode. For all fatal errors, the control will terminate

the current cycle, turn off all outputs, and flash two LEDs one second on/one second off to indicate the error.

W485

Motor Failure

Error.

Fill

Error.

Door Open

Error.

Door Lock/Unlock

Error.

If the control receives the motor failure signal from the motor control, the control will

enter Error Mode. The control will turn off all outputs and flash the DOOR and FINAL

SPIN LEDs one second on/one second off to indicate a motor failure error. This is a fatal

error. The machine must be unpowered to clear this error.

If the control receives no full input from the pressure switch indicating the cylinder is full

within 30 minutes of starting the fill, the control will enter Error Mode. The control will

turn off all outputs and flash the WASH and DOOR LEDs one second on/one second off

to indicate a fill error. This is a fatal error. The machine must be unpowered to clear this

error.

If the control senses the door open during Run Mode, the control will enter Error Mode.

The control will turn off all outputs and flash the WASH and RINSE LEDs one second

on/one second off to indicate a door open error. This is a fatal error. The machine must

be unpowered to clear this error.

If the door doesn’t lock in 15 seconds in Door Locking Mode or the door doesn’t unlock

in 3 minutes in Door Unlocking Mode, the control will enter Door Lock Error Mode. The

control will turn off all outputs and flash the DOOR LED one second on/one second off

to indicate a door lock/unlock error.

To clear this error in Door Locked Mode the door must either open or lock. If the door

locks, the cycle will start normally. If the door opens, the control will revert back to Start

Mode.

To clear this error in Door Unlocking Mode the door must unlock or open. If the door

unlocks or opens, the control will enter End of Cycle Mode.

SPI

Communications

Error.

This error occurs when there is a problem with communications between the front-end

control and the motor control. The control will turn off all outputs and flash the FINAL

SPIN and RINSE LEDs one second on/one second off to indicate an SPI

communications error. This is a fatal error. The machine must be powered down at this

point.

Open/Shorted

Temperature

Sensor Error

(Models equipped

with heater)

Any time the control senses a temperature less than 32°F (0°C) or greater than 212°F

(100°C) while heating, the control will turn off the heater output and not attempt to heat.

The control will continue and finish the cycle normally. At the end of the cycle the

control will flash the HEATING LED one-second on/one second off to indicate an open/

shorted temperature sensor error. This error will be cleared when the door is opened at

the end of the cycle.

10 801728

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Notes

Section 3 Troubleshooting

801728 11

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 3 Troubleshooting

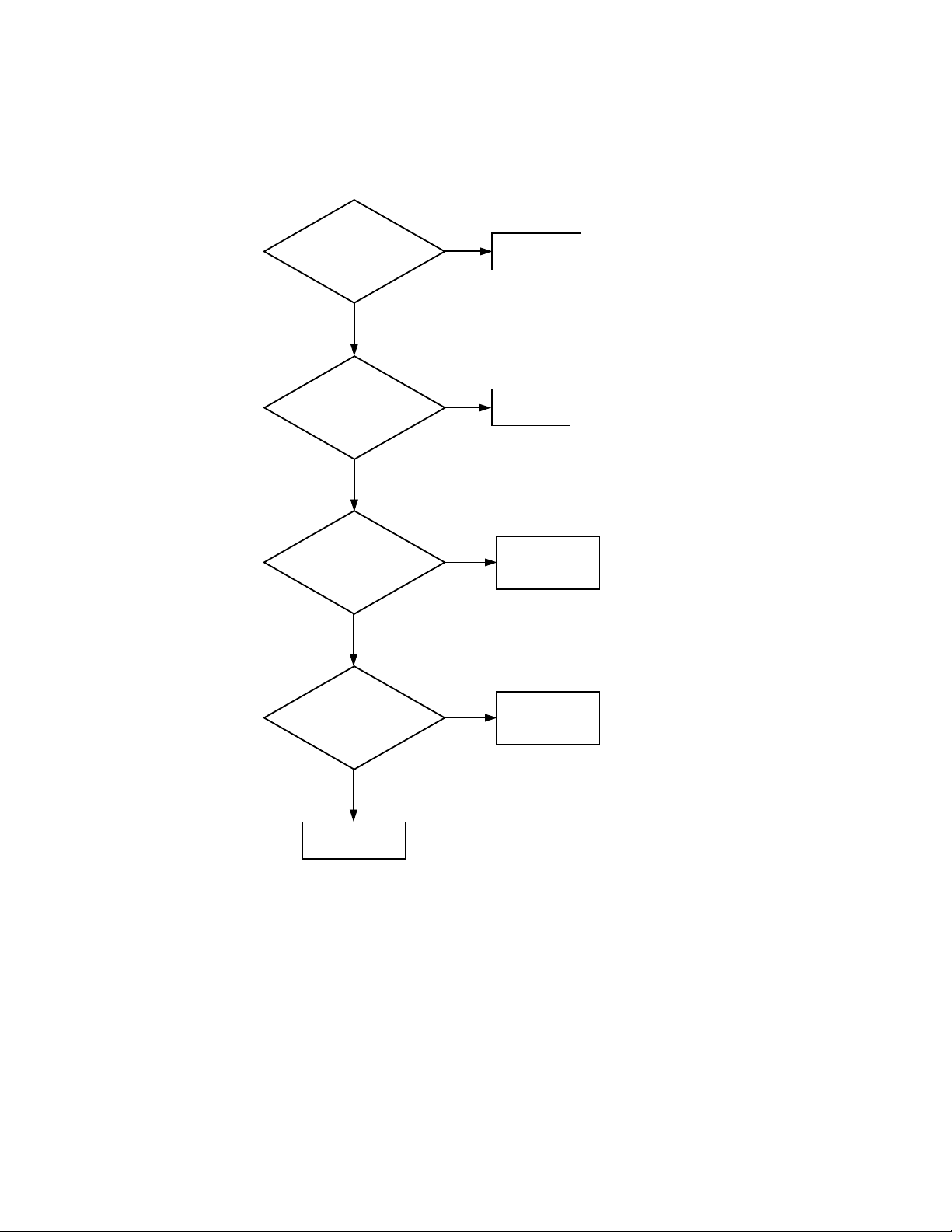

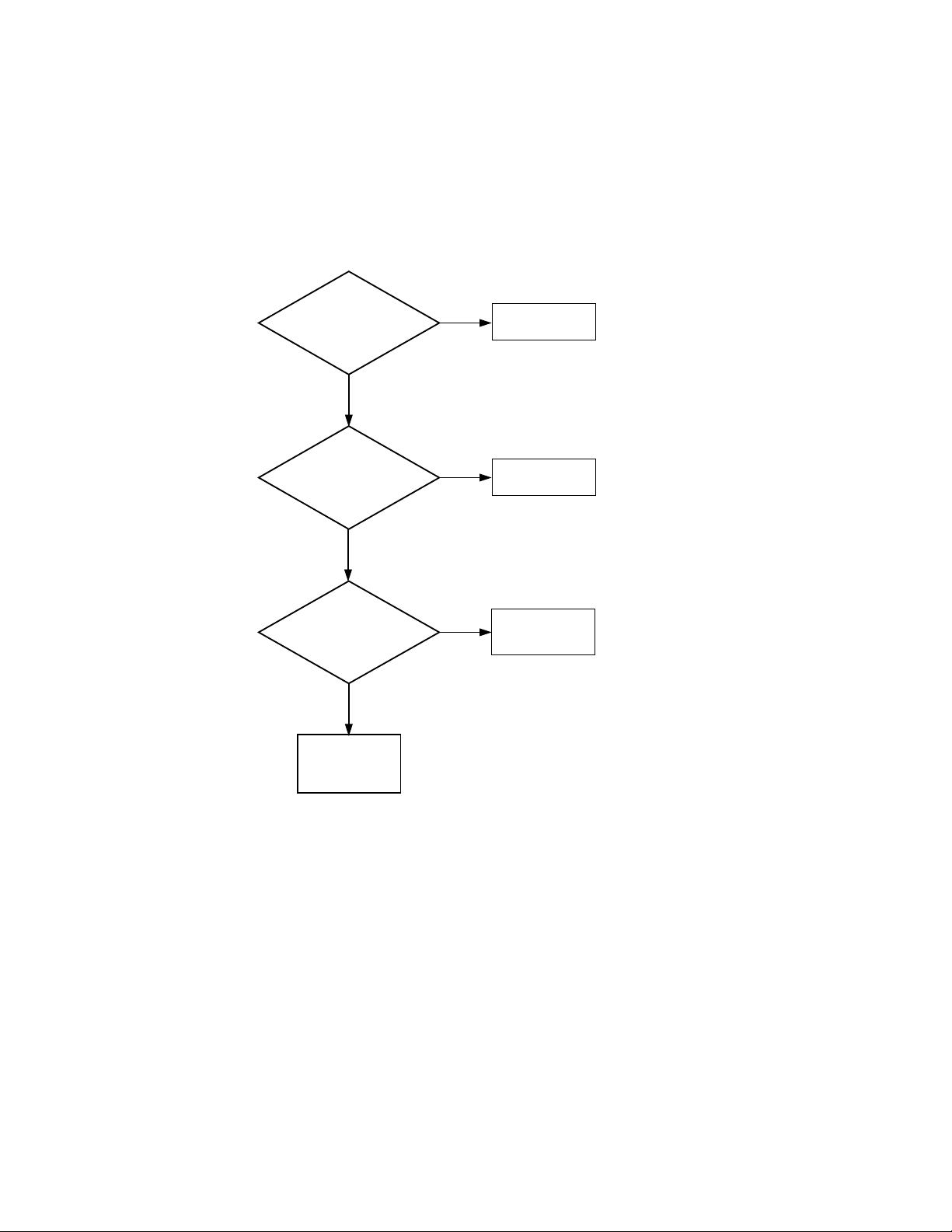

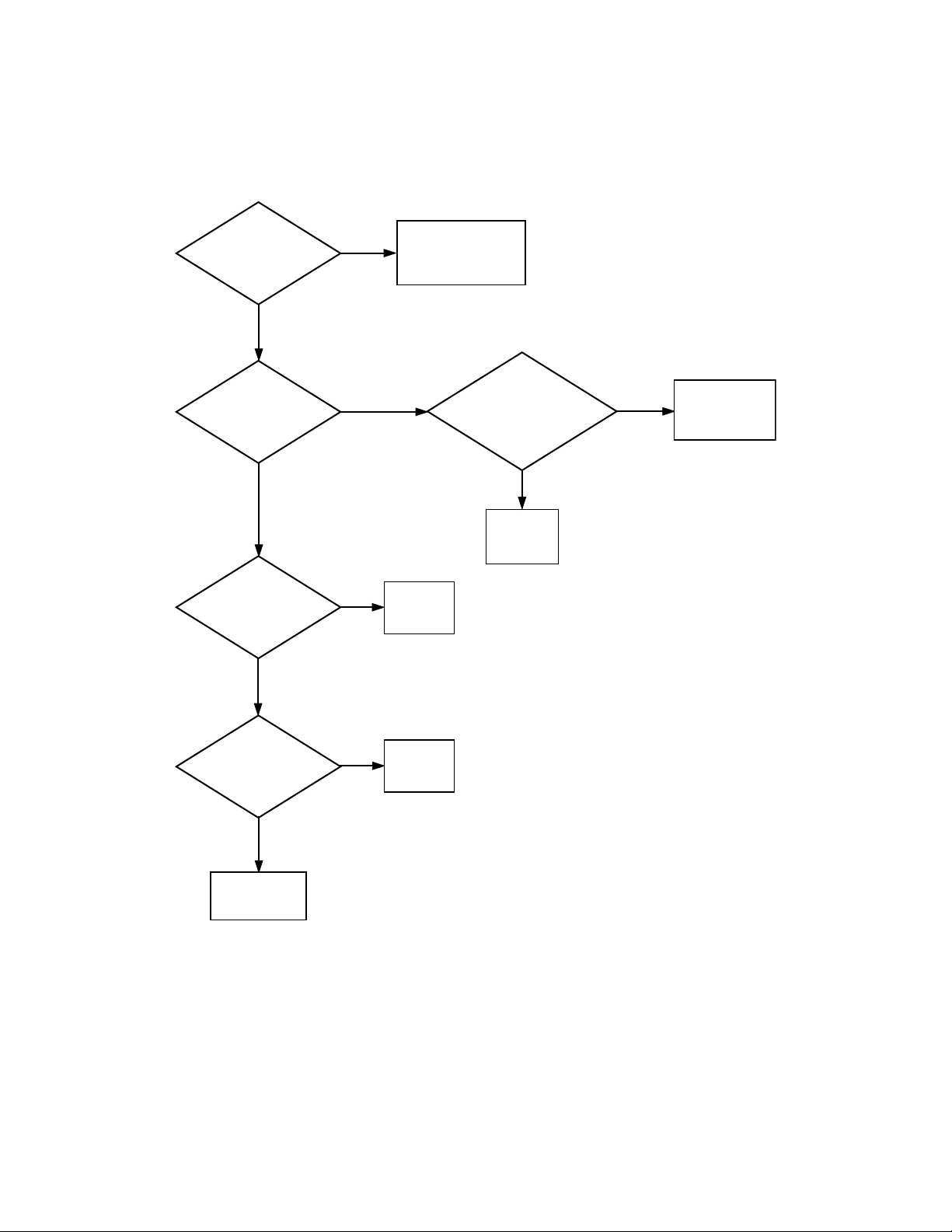

4. WASHER WILL NOT START – NO LEDS/LIGHTS LIT

(NO RESPONSE TO START SWITCH)

(1)

Is there

220-240 VAC

(or 120 Volts)*

to control

transformer?

Yes

(2)

No

Check wiring

to transformer.

Is there 24 VAC

from "H1-1" to "H1-3"

on the machine control ?

Yes

(3)

Is there

continuity across

terminals "H9-3" to "H9-7"

on the machine control when

the start switch is

depressed?

Yes

(4)

Is the

configuration

header plugged

into "H7"?

Yes

Replace machine

control.

No

No

No

Replace

transformer.

Correct wiring

to and/or replace

start switch.

Correct wiring

on "H7"

configuration plug.

*Refer to machine serial plate

for correct voltage.

FLW1727S

12 801728

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

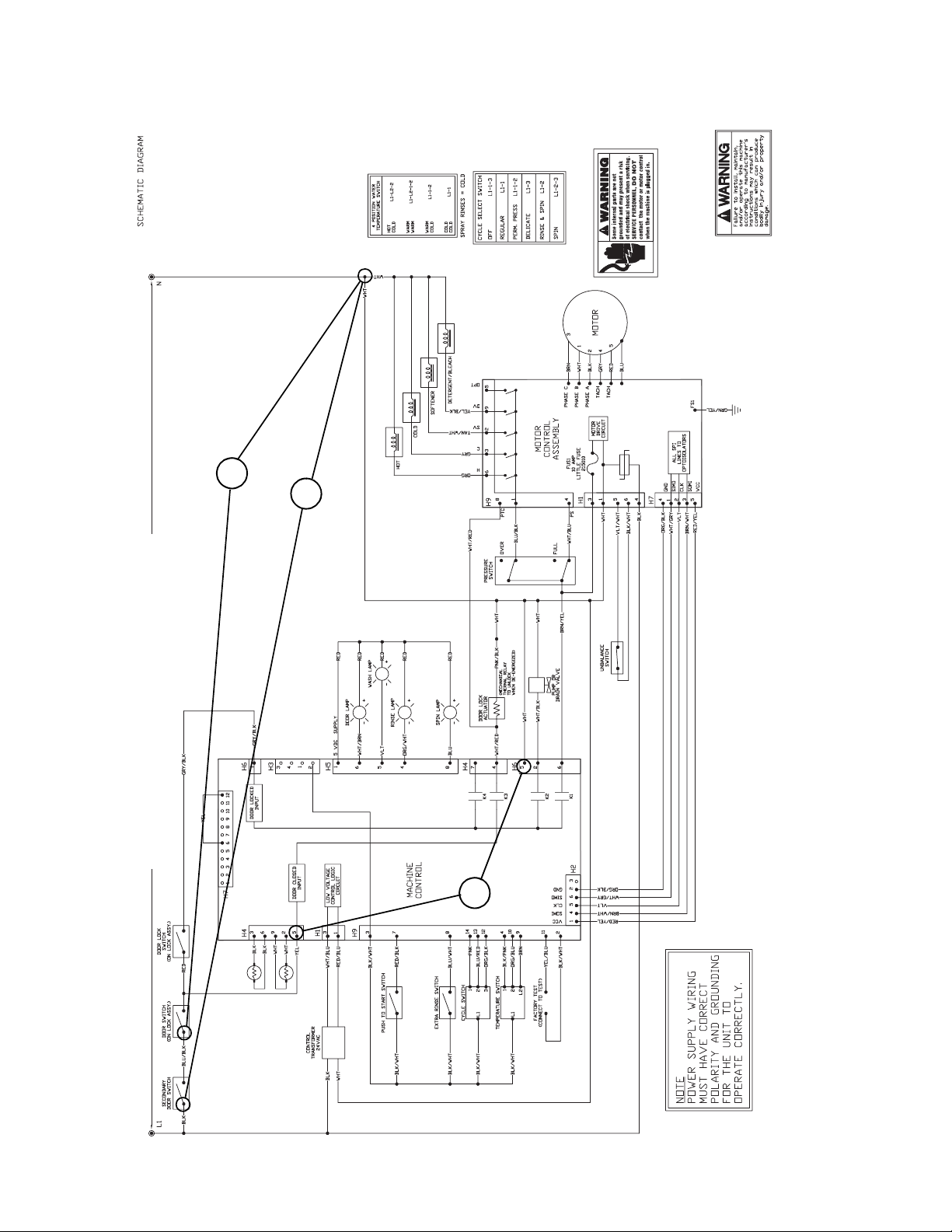

WASHER WILL NOT START – NO LEDS/LIGHTS LIT

(NO RESPONSE TO START SWITCH)

Section 3 Troubleshooting

4

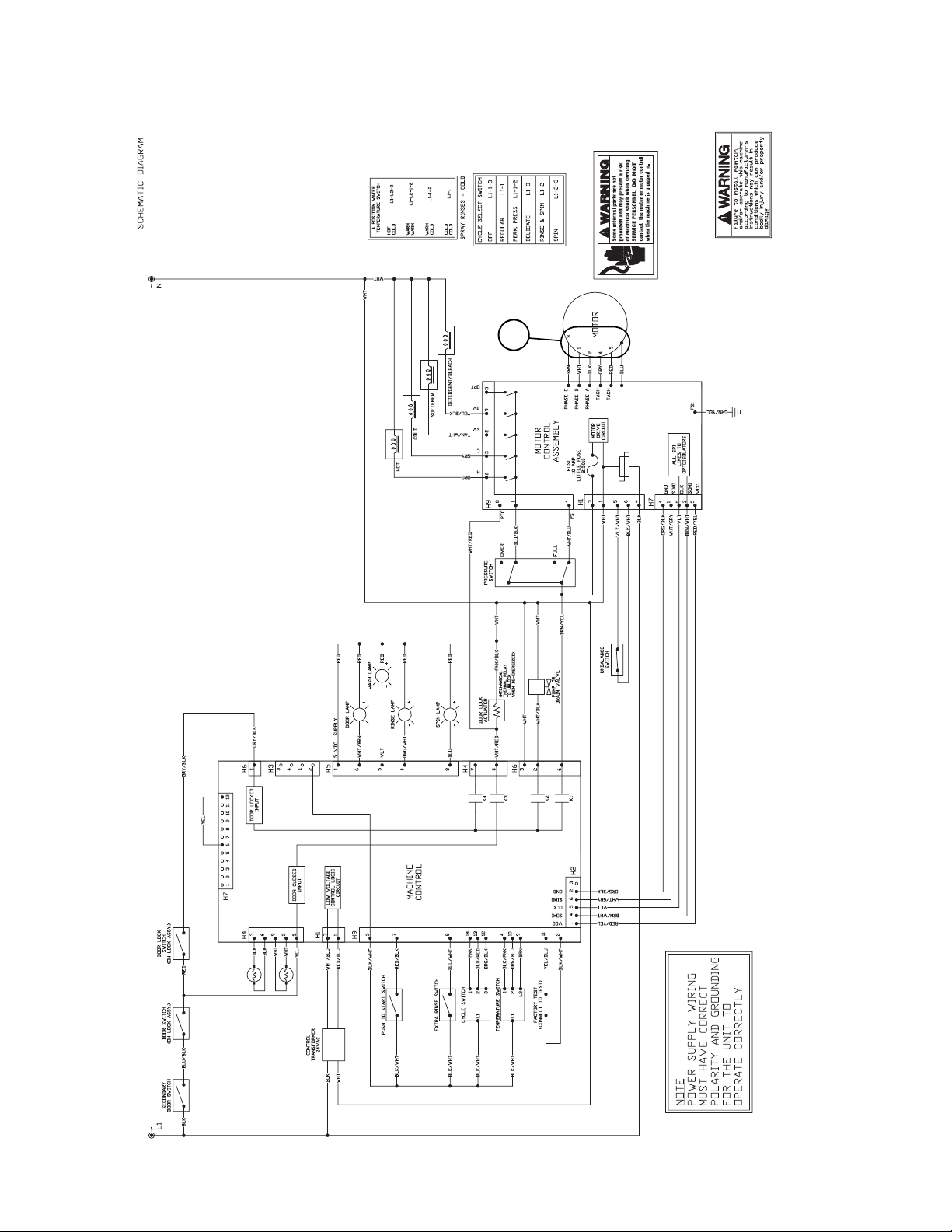

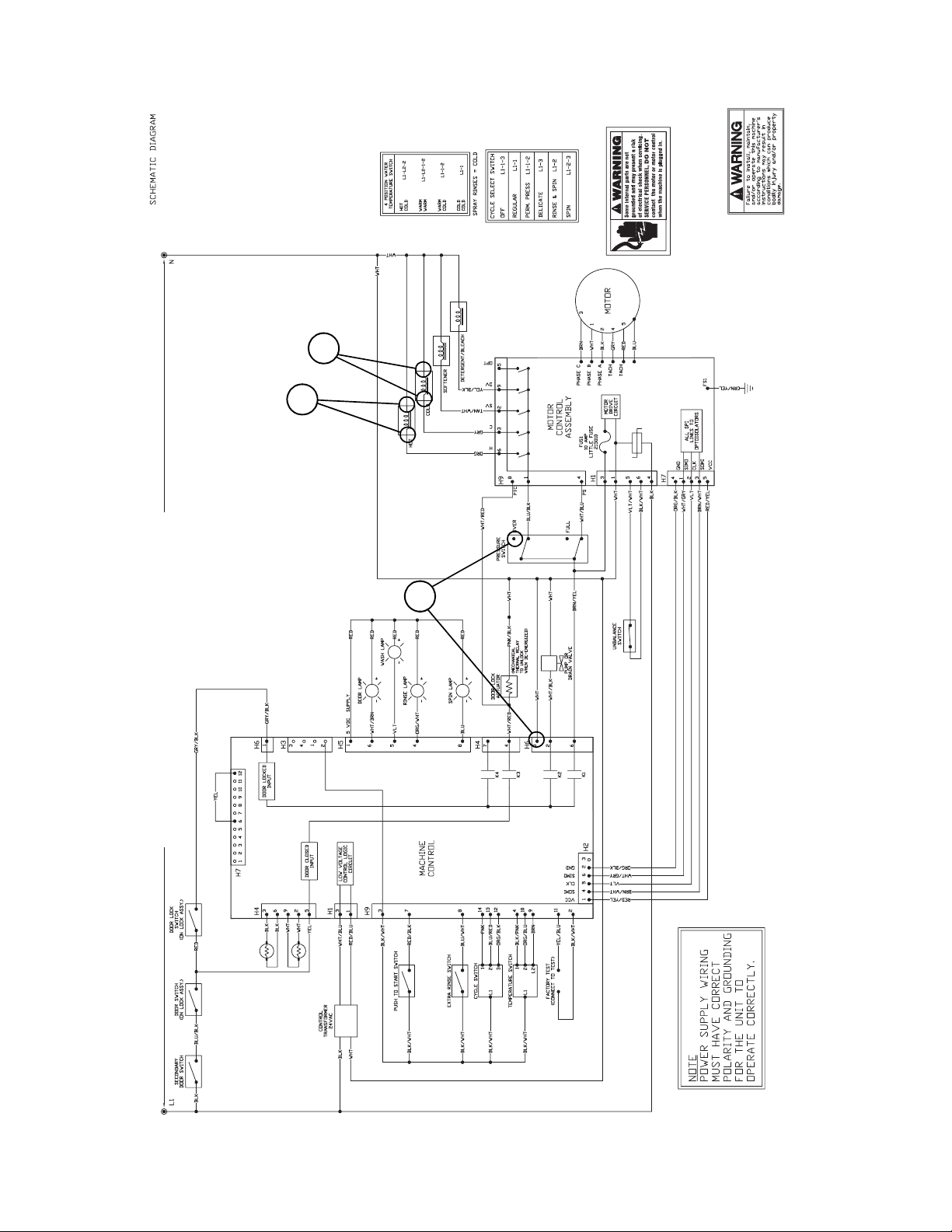

220-240 VAC (or 120 VAC) 50/60Hz (SEE MACHINE SERIAL PLATE)

3

6.8k Ohm

CONFIG. RESISTOR

(Models with 220-240 VAC)

2

1

801728 13

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 3 Troubleshooting

5. WASHER WILL NOT START – DOOR OPEN ERROR

(WASH/RINSE LEDS FLASHING – DOOR MUST BE CLOSED AND ATTEMPTING TO LOCK)

(1)

Is there

220-240 VAC (or

120 Volts)* across

"H4-5" to "H6-5" on

the machine

control?

No

(2)

Is there

220-240 VAC (or

120 Volts)* from the

BLU/BLK wire on door

lock assembly

to neutral?

Yes

Yes

Replace machine

control.

Replace door

lock assembly.

No

(3)

Is there

220-240 VAC (or

120 Volts)* from the

BLK wire on the secondary

door switch to

neutral?

No

Correct wiring

to the secondary

door switch.

*Refer to machine serial plate

for correct voltage.

Yes

Replace the

secondary door

switch.

FLW1728S

14 801728

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 3 Troubleshooting

WASHER WILL NOT START – DOOR OPEN ERROR

(WASH/RINSE LEDS FLASHING – DOOR MUST BE CLOSED AND ATTEMPTING TO LOCK)

2

3

220-240 VAC (or 120 VAC) 50/60Hz (SEE MACHINE SERIAL PLATE)

1

6.8k Ohm

CONFIG. RESISTOR

(Models with 220-240 VAC)

801728 15

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 3 Troubleshooting

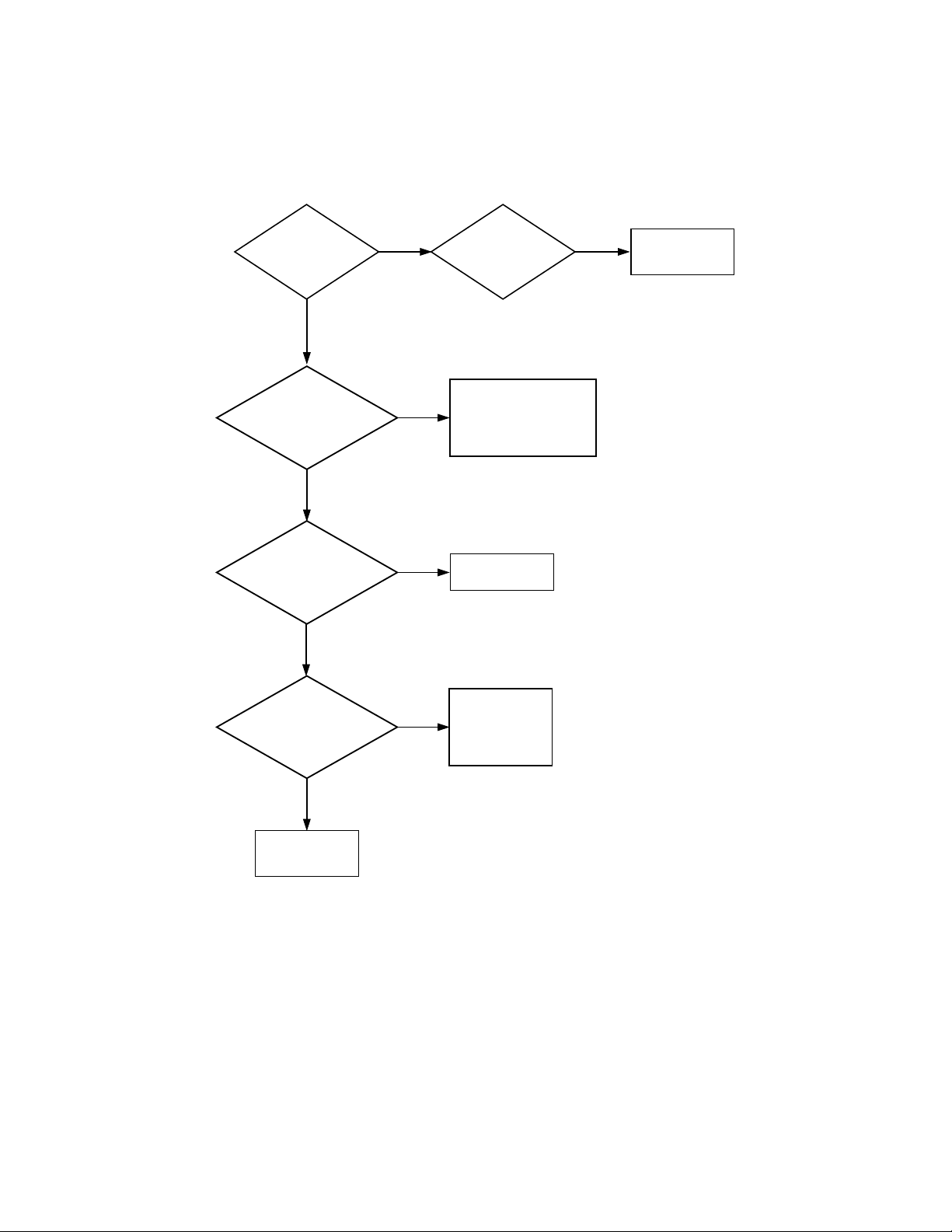

6. WASHER WILL NOT START – NO DOOR LOCK

(DOOR LED FLASHING)

Is the

"Wash" light

lit?

Yes

(2)

Is there

220-240 VAC (or

120 Volts)* at machine

control terminals

"H4-5" to "H6-5"?

Yes

No No

No

(1)

Is there

24 VAC from

"H1-1" to "H1-3"

on the machine

control?

Check secondary door

switch, door strike

adjustment, and/or wiring.

Replace door lock if

necessary.

Replace

transformer.

(3)

Is there

220-240 VAC (or

120 Volts)* at machine

control terminals

"H4-4" to "H6-5"?

Yes

(4)

Is there

220-240 VAC (or

120 Volts)* at the door

lock between the WHT/RED

and the PNK/BLK

wires?

Yes

Replace door

lock assembly.

*Refer to machine serial plate

for correct voltage.

No

No

Replace machine

control.

Correct wiring

between machine

control and door

lock assembly.

FLW1729S

16 801728

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

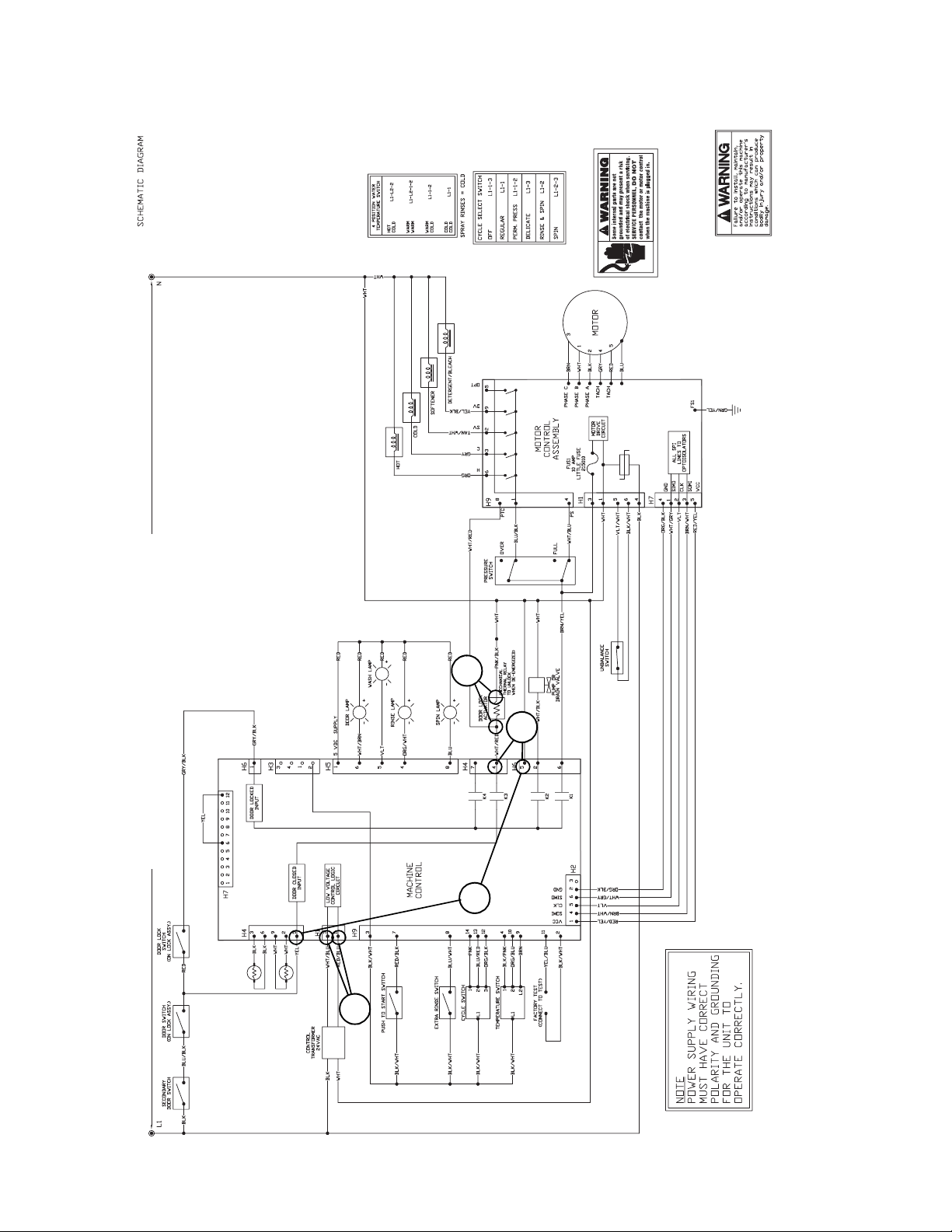

WASHER WILL NOT START – NO DOOR LOCK

(DOOR LED FLASHING)

Section 3 Troubleshooting

220-240 VAC (or 120 VAC) 50/60Hz (SEE MACHINE SERIAL PLATE)

6.8k Ohm

CONFIG. RESISTOR

(Models with 220-240 VAC)

1

4

3

2

801728 17

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 3 Troubleshooting

7. MOTOR WILL NOT RUN (DOOR/FINAL SPIN LEDS FLASHING)

(1)

Is there

continuity between

motor terminals?

Refer to values

at right.

No

Yes

Replace motor

control.

Motor Resistance Values:

Tach. Circuit: Approx. 115 ohms (Terminals 4-5)

Windings: Approx. 4 - 5 ohms (Terminals 1-2, 1-3, 2-3)

Replace motor.

FLW1712S

18 801728

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

MOTOR WILL NOT RUN

(DOOR/FINAL SPIN LEDS FLASHING)

1

Section 3 Troubleshooting

220-240 VAC (or 120 VAC) 50/60Hz (SEE MACHINE SERIAL PLATE)

6.8k Ohm

CONFIG. RESISTOR

(Models with 220-240 VAC)

801728 19

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 3 Troubleshooting

8. WASHER WILL NOT FILL – NO COMMUNICATION ERROR

(WASH/DOOR LEDS FLASHING)

Is the door

locked?

Yes

(1)

Is there

220-240 VAC (or

120 Volts)*

"H9-4" and "H1-1" on the

120 Volts)*

"H9-1" to "H1-1" on the

at terminals

motor control

board?

Yes

(3)

Is there

220-240 VAC (or

at terminals

motor control

board?

Yes

No

No

No

Washer Will Not Start -

Replace

pressure

switch.

Refer to section:

No Door Lock .

220-240 VAC (or

120 Volts)*

the BRN/YEL wire on the

pressure switch and

"H6-5" on machine

Is there

control?

Yes

Replace

pressure

switch.

(2)

between

No

Correct wiring

between machine

control and

pressure switch.

(4)

Is there

220-240 VAC

(or 120 Volts)*

at the

mixing valve?

Yes

Replace mixing

valve.

*Refer to machine serial plate

for correct voltage.

No

Replace

motor

control.

FLW1730S

20 801728

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 3 Troubleshooting

WASHER WILL NOT FILL – NO COMMUNICATION ERROR

(WASH/DOOR LEDS FLASHING)

4 4

3

2

220-240 VAC (or 120 VAC) 50/60Hz (SEE MACHINE SERIAL PLATE)

6.8k Ohm

CONFIG. RESISTOR

(Models with 220-240 VAC)

1

801728 21

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 3 Troubleshooting

9. WASHER OVERFLOWS

Washer Overflows

(1)

Is there

220-240 VAC (or

120 Volts)*

terminal on pressure switch

at the over level

to "H6-5" on machine

control?

Yes

No

Replace

inoperative

pressure switch.

(2)

Is there

220-240 VAC (or

120 Volts)*

*Refer to machine serial plate for correct voltage.

across the coil of

either the hot or cold

water solenoid?

No

Replace

inoperative

mixing valve.

Yes

Check for

improper wiring

and replace

inoperative

pressure switch

if necessary.

FLW1691S

22 801728

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 3 Troubleshooting

WASHER OVERFLOWS

2

2

1

220-240 VAC (or 120 VAC) 50/60Hz (SEE MACHINE SERIAL PLATE)

6.8k Ohm

CONFIG. RESISTOR

(Models with 220-240 VAC)

801728 23

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 3 Troubleshooting

10. PUMP DOES NOT OPERATE

NOTE: Check at beginning of spin/drain portion of cycle.

Pump or Drain Valve Does Not Operate

120 Volts)*

1

(1)

Is there

220-240 VAC (or

across the WHT/BLK

and the WHT wire going

to the pump?

NOTE: Check at

beginning of spin/drain

portion of cycle.

Yes

If the pump

does not operate

check for

obstruction and

replace if necessary.

No

2

(2)

Is there

220-240 VAC (or

120 Volts)*

"H6-2" to "H6-5" on the

machine control?

machine control.

*Refer to machine serial plate for correct voltage.

from

No

Replace

Yes

Correct wiring

between pump

and

machine control.

FLW1692S

24 801728

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Loading...

Loading...