Page 1

Installation and Maintenance

Instructions for Drying

Tumblers

30 Pound (13 Kg) Capacity

JCB30CE, JCB30CG, JCB30CSH, JCB30CSL, JCB30WE, JCB30XG,

SCB30CE, SCB30CG, SCB30CSH, SCB30CSL, SCB30WE and SCB30XG

50 Pound (22 Kg) Capacity

JC50CE, JC50CG, JC50CSH, JC50EG, JCB50CE, JCB50CG, JCB50CSH,

JCB50EG, SC50CE, SC50CG, SC50CSH, SC50EG, SCB50CE, SCB50CG,

SCB50CSH and SCB50EG

75 Pound (34 Kg) Capacity

JC75CE, JC75CG, JC75CSH, JCB75CE, JCB75CG, JCB75CSH, SC75CE,

SC75CG, SC75CSH, SCB75CE, SCB75CG and SCB75CSH

ATTENTION: Please read the enclosed instructions before using the machine.

KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE.

(If this tumbler changes ownership, be sure this manual

accompanies the tumbler).

A copy of the operating instruction must remain with the tumbler after

installation.

To locate the servicer nearest you, call (414) 748-3121.

Manufactured By:

Speed Queen Company

P.O. Box 990

Ripon, WI 54971-0990

U.S.A.

Part No. M412616

1/95

Distributed By:

Page 2

Page 3

WARNINGS AND LABELS

aWARNING

FAILURE TO INSTALL, MAINTAIN, AND/OR OPERATE THIS MACHINE ACCORDING TO

MANUFACTURER’S INSTRUCTIONS MAY RESULT IN CONDITIONS WHICH CAN

PRODUCE SERIOUS INJURY, DEATH AND/OR PROPERTY DAMAGE.

NOTE: The WARNING and IMPORTANT instructions appearing in this manual are not meant to cover all

possible conditions and situations that may occur. It must be understood that common sense, caution

and carefulness are factors which CANNOT be built into this tumbler. These factors MUST BE supplied

by the person(s) installing, maintaining or operating the tumbler.

Always contact your dealer, distributor, service agent or the manufacturer on any problems or conditions you do

not understand.

aWARNING

To reduce the risk of fire, electrical shock, serious injury or death to persons do not

operate the tumbler if it does not perform according to these instructions. Immediately

disconnect electrical service, shut off gas supply and contact an authorized service

representative. Service and repairs are to be performed by authorized service

representatives only.

aWARNING

To reduce the risk of fire, electrical shock, serious injury or death to persons when

using the tumbler unit, follow these basic precautions:

· Read all instructions before using tumbler.

· DO NOT tamper with controls.

· DO NOT bypass any safety devices.

· Always follow the fabric care instructions supplied by the garment manufacturer.

· Remove laundry immediately after the tumbler stops.

· DO NOT reach into tumbler if cylinder is revolving.

aWARNING

To avoid creating any flammable vapors which may explode, ignite or cause corrosive

damage, DO NOT dry the following materials:

· Articles that have been cleaned in, soaked in, washed in or spotted with gasoline,

dry cleaning solvents or other flammable/explosive substances.

· Plastics or articles containing foam rubber or similarly textured rubberlike

materials.

· Articles that have traces of flammable substances like cooking oil, machine, oil,

flammable chemicals or thinner.

· Articles containing wax or cleaning chemicals.

· Fiberglass curtains or draperies (unless the label says it can be done).

aWARNING

To reduce the risk of serious injury, install lockable door(s) to prevent public access to

rear of tumblers.

© Copyright 1994. All Rights Reserved.

M412616

1

Page 4

WARNING

維

To reduce the risk of fire, electric shock, serious injury or death to persons when using

your dryer, follow these basic precautions:

1. Do not allow children to play on or in the tumbler. Close supervision of children is necessary when the tumbler

is used near children. This is a safety rule for all appliances.

2. Before the tumbler is removed from service or discarded, remove the door to the drying compartment.

3. Do not install or store the tumbler where it will be exposed to water and/or weather.

4. Failure to install, maintain, and/or operate this machine according to the manufacturer’s instructions may

result in conditions which can produce serious injury, death and/or property damage.

5. Run tumbler with a load before putting tumbler into service.

6. Always disconnect the electrical power to the tumbler before servicing. Disconnect power by shutting off

appropriate circuit breaker or fuse and by turning off the disconnect switch located on the rear of te tumbler.

7. All manually operated models are factory-equipped with an emergency stop button located on the front panel.

If the emergency stop function is desired on coin-operated models, an external emergency stop switch may

be installed as specified on the machine wiring diagram.

NOTE: Activation of the emergency stop switch stops all machine control circuit functions, but does not

remove all electrical power from machine.

NOTE: This drying tumbler produces sound rated at 65 dbA.

The following warning labels will be found on the drying tumbler:

A clothes dryer produces combustible

lint. TUMBLER MUST BE

EXHAUSTED OUTDOORS.

Do not touch surface until it has

cooled.

Do not operate without guards in

place.

Disconnect electrical power before

servicing.

Do not touch rotating parts.

WARNING!

To reduce risk of accumulating

unsafe concentrations of combustion

gases, tumbler MUST BE

EXHAUSTED OUTDOORS.

2

M412616

Page 5

TABLE OF CONTENTS

NAMEPLATE LOCATION ........................................4

REPLACEMENT PARTS INFORMATION ................4

SECTION I

ROUGHING-IN DIMENSIONS AND

SPECIFICATIONS

30 pound (13 kg) Narrow Cabinet:

Gas Tumblers ........................................................5

Electric Tumblers ...................................................7

30 Pound (13 kg):

Gas Tumblers ........................................................9

Electric Tumblers .................................................11

Steam Tumblers ..................................................13

50 Pound (22 kg):

Gas Non-reversing Tumblers ..............................15

Gas and Steam Reversing Tumblers...................17

Electric Non-reversing Tumblers .........................18

Electric Reversing Tumblers................................20

Steam Non-reversing Tumblers ........................... 21

Electrical Requirements:

30 Pound (13 kg) Narrow Cabinet Tumblers ...... 35

30 Pound (13 kg) Tumblers ................................ 36

50 Pound (22 kg) Tumblers ................................ 38

75 Pound (34 kg) Tumblers ................................ 40

Electrical Connections............................................ 41

Positioning the Drying Tumbler .............................. 42

Leveling the Drying Tumbler .................................. 42

Gas Requirements (Gas Drying Tumblers) ............ 42

Example of Gas Loop Piping .............................. 43

Example of Gas Supply Piping ........................... 43

Gas Connections (Gas Drying Tumblers) .............. 45

Drying Tumbler Enclosure Construction ................ 46

Steam Requirements (Steam Drying Tumblers) .... 47

Steam Connections (Steam Drying Tumblers) ....... 47

Lighting and Shutting Down Gas Ignition System .. 49

Accessory Timing Cam Installation ........................ 50

Preliminary Operating Checks ............................... 51

Final Operating Checks.......................................... 51

SECTION III

ADJUSTMENTS

75 Pound (34 kg):

Gas Non-reversing Tumblers ..............................23

Gas and Steam Reversing Tumblers...................24

Electric Non-reversing Tumblers .........................26

Electric Reversing Tumblers................................27

Steam Non-reversing Tumblers ........................... 29

SECTION II

INSTALLATION INSTRUCTIONS

Receiving Inspection ...............................................31

Materials Required (Obtain Locally) ........................31

Facilities Required:

Floor .................................................................... 31

Layout ..................................................................31

Venting ................................................................31

Make-Up Air.........................................................32

Main Gas Burner Air Shutter (All Gas Models)....... 53

Air Flow Switch (Gas and Electric Models) ............ 53

Loading Door Switch .............................................. 55

Cylinder Door Strike ............................................... 55

Drive V-Belt ............................................................ 56

SECTION IV

PREVENTIVE MAINTENANCE INSTRUCTIONS

Daily ....................................................................... 57

Monthly................................................................... 57

Quarterly ................................................................ 58

Biannually............................................................... 58

Maintenance Check Chart...................................... 59

SECTION V

DECOMMISSIONING INSTRUCTIONS

Decommissioning Instructions .............................. 61

M412616

3

Page 6

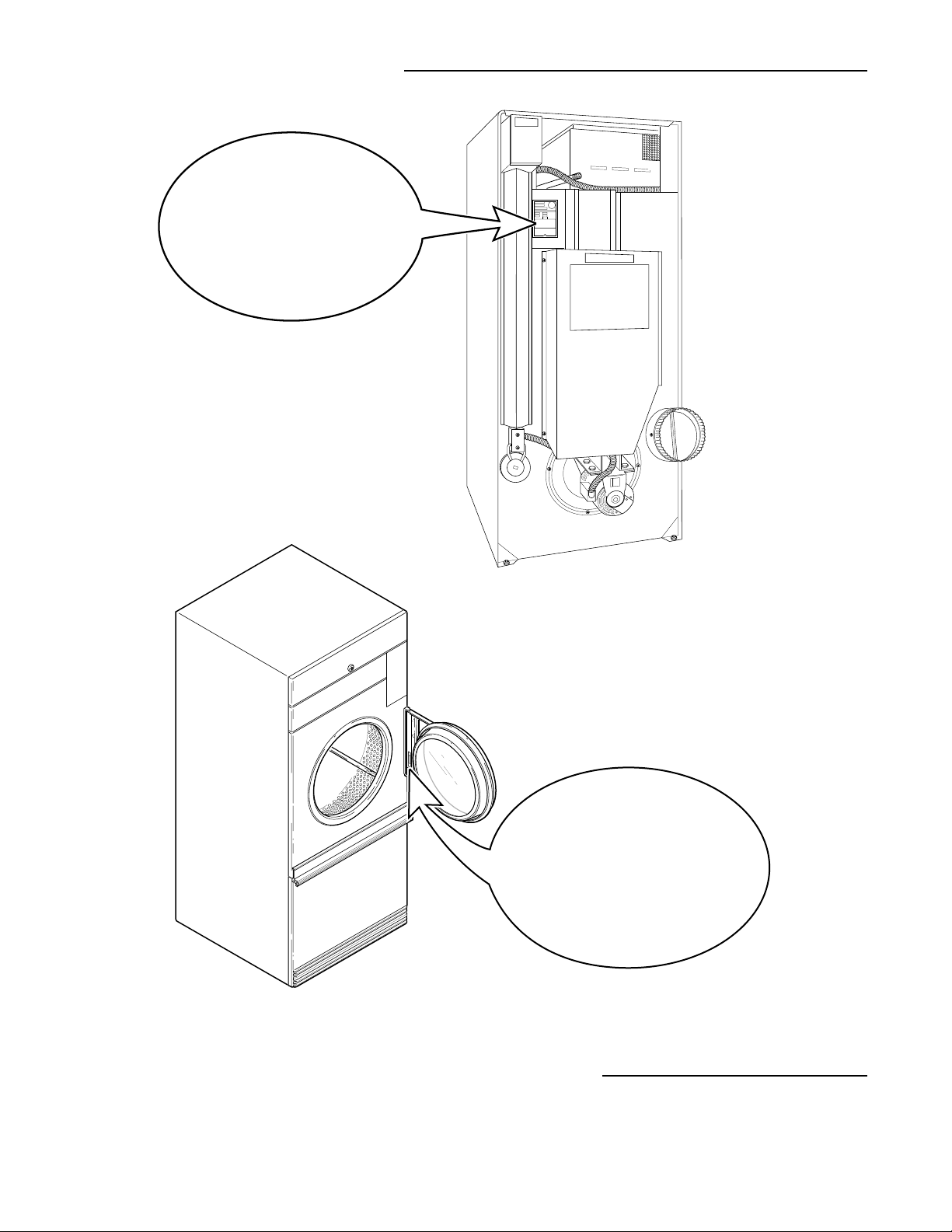

NAMEPLATE LOCATION

IMPORTANT

When writing for information on

any tumbler, be sure to mention

model and serial numbers. The

model and serial numbers will

be found on the nameplate as

shown on rear of tumbler or

underneath the door hinge.

T238IE3A

IMPORTANT

When writing for information on any

tumbler, be sure to mention model and

serial numbers. The model and serial

numbers will be found on the nameplate

as shown on the rear of tumbler or

underneath the door hinge.

T276IE3A

REPLACEMENT PARTS INFORMATION

If replacement parts are required, contact the source from whom you purchased your tumbler or, contact the

Ripon Service Parts Center, P.O. Box 990, Ripon, Wisconsin 54971-0990, for the name and address of the

nearest authorized parts distributor.

4

M412616

Page 7

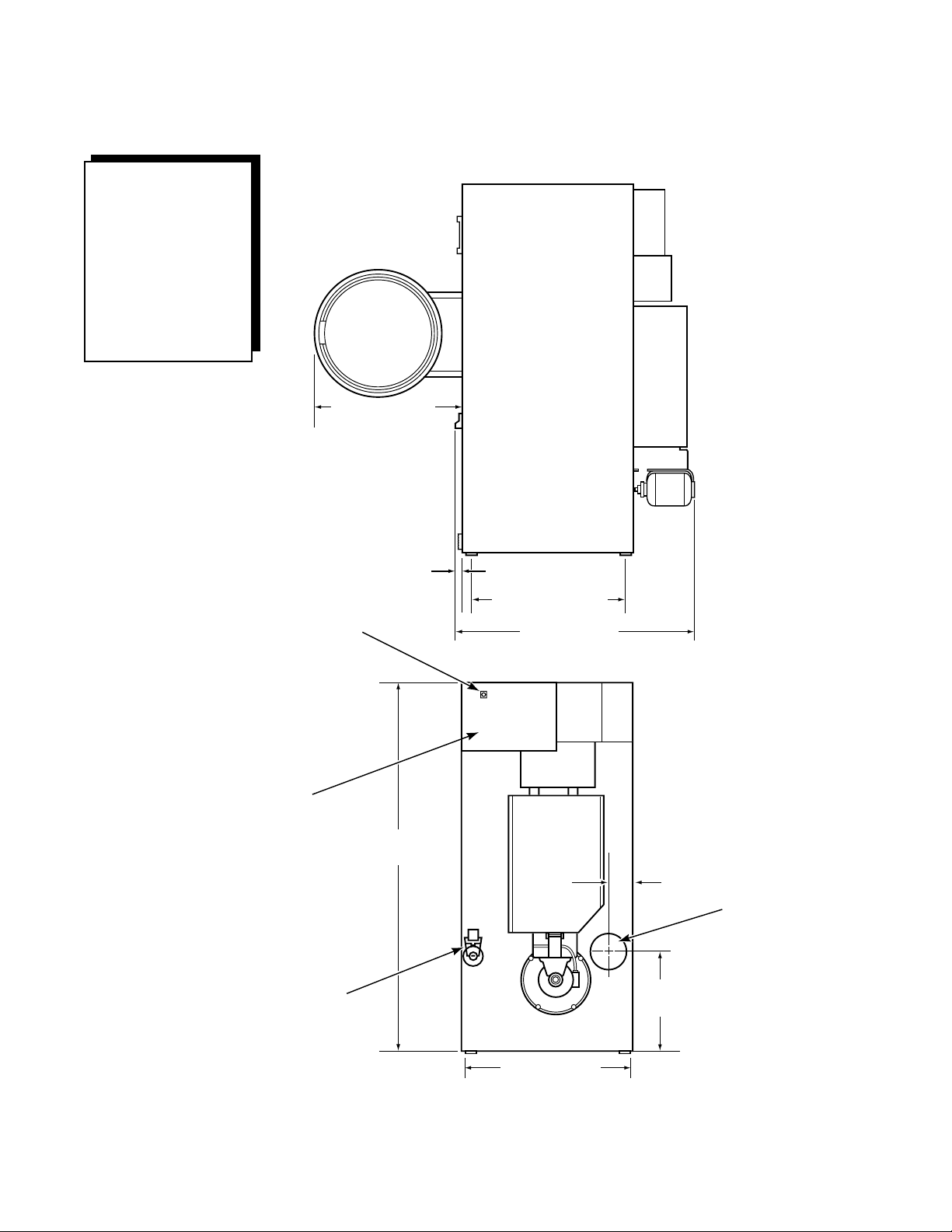

SECTION I

Roughing-In Dimensions and Specifications

30 Pound (13 kg) Narrow Cabinet Gas Tumbler

SIDE

PANEL

8.59 cm

(3-3/8")

67.95 cm

(26-3/4")

3.81 cm

(1-1/2")

DISCONNECT

SWITCH

183.52 cm (72-1/4")

81.76 cm (32-3/16")

113.98 cm (44-7/8")

T258IE3A

15.24 cm (6")

DIAMETER

EXHAUST

AIR FLOW

SWITCH

CONNECTION

AND SHUT OFF

ELECTRICAL

JUNCTION BOX

8.59 cm

(3-3/8")

T024IE3B

TOP VIEW

OF EXHAUST

GAS

VALVE

CLEARANCES: Minimum

to nearest Combustible

Material

Top —

12" (30.5 cm) Minimum.

0" permitted for first 4"

(10.2 cm) along front of

machine.

Back — 0" - 24" (61 cm)

Minimum recommended

for service access.

Sides — 0" Permitted.

M412616

71.12 cm (28")

T257IE3B

5

Page 8

30 Pound (13 kg) Narrow Cabinet Gas Tumbler

Cabinet Finish: Electrostatically applied thermosetting polyester.

Cylinder: 26.5" x 30" (67.3 cm x 76.2 cm)

perforated galvanized steel with three baffles

Motor: ¹⁄₃ H.P., lifetime lubricated, internal overload protected

Electrical Requirements: 230 Volt, 50 Hertz, 1 Phase; 5.5 Amps

Gas Consumption: 75,000 BTU per hour (79.1 MJ/hr.)

Gas Connection: 1/2" (12.7 mm) N.P.T.

Types of Gas: Factory equipped with Natural/Mixed Gas

(6¹⁄₂ ± 1¹⁄₂ inch water column line pressure)

(1.62 ± .37 kPa); or Liquefied Petroleum gas

(11 ± .3" water column line pressure) (2.74 ± .07 kPa)

Air Flow: 370 C.F.M. at 0.5" W.C. (175 liters/sec. at 1.25 mBar)

Net Weight: 350 Pounds (159 kg) (approximate)

6

M412616

Page 9

30 Pound (13 kg) Narrow Cabinet Electric Tumbler

SIDE

PANEL

8.59 cm

(3-3/8")

67.95 cm

(26-3/4")

3.81 cm

(1-1/2")

ELECTRICAL

JUNCTION BOX

81.76 cm (32-3/16")

113.98 cm (44-7/8")

DISCONNECT

SWITCH

8.59 cm

(3-3/8")

T024IE3B

TOP VIEW

OF EXHAUST

T258IE3A

15.24 cm (6")

DIAMETER

EXHAUST

M412616

AIR FLOW

SWITCH

183.52 cm (72-1/4")

71.12 cm (28")

CLEARANCES: Minimum

to nearest Combustible

Material

Top —

12" (30.5 cm) Minimum.

0" permitted for first 4"

(10.2 cm) along front of

machine.

Back — 0" - 24" (61 cm)

Minimum recommended

for service access.

Sides — 0" Permitted.

T259IE3B

7

Page 10

30 Pound (13 kg) Narrow Cabinet Electric Tumbler

Cabinet Finish: Electrostatically applied thermosetting polyester.

Cylinder: 26.5" x 30" (67.3 cm x 76.2 cm)

perforated galvanized steel with three baffles

Motor: ¹⁄₃ H.P., lifetime lubricated, internal overload protected

Electrical Requirements: 230 Volt, 50 Hertz, 1 Phase; 90 Amps

(See nameplate for 230 Volt, 50 Hertz, 3 Phase; 53 Amps

voltage of your tumbler) 380 Volt, 50 Hertz, 3 Phase; 33 Amps

415 Volt, 50 Hertz, 3 Phase; 30 Amps

Element: 18,000 Watts

Air Flow : 625 C.F.M. at 0.5" W.C. (294 liters/sec. at 1.25 mBar)

Net Weight: 410 Pounds (184.5 kg) (approximate)

8

M412616

Page 11

CLEARANCES: Minimum

to nearest Combustible

Material

Top — 12" (30.5 cm)

Minimum.

0" permitted for first 4"

(10.2 cm) along front of

machine.

Back — 0" - 24" (61 cm)

Minimum recommended

for service access.

Sides — 0" Permitted.

30 Pound (13 kg) Gas Tumbler

71.5 cm (28-1/4")

DISCONNECT

GAS CONNECTION

AND

SHUT OFF VALVE

ELECTRICAL

JUNCTION BOX

AIR FLOW SWITCH

(Energy Saver Models)

SWITCH

3.81 cm

(1-1/2")

183.5 cm (72-1/4")

157.8 cm (62-1/8")

81.75 cm (32-3/16")

114 cm (44-7/8")

118.6 cm (46-11/16")

11.3 cm

(4-7/16")

AIR FLOW SWITCH

(Standard Models)

140.7 cm

(55-3/8")

55.6 cm

(21-7/8")

20.3 cm (8")

DIAMETER

EXHAUST DUCT

THIMBLE

CONNECTION

(Energy Saver

Models)

20.3 cm (8")

DIAMETER

EXHAUST DUCT

THIMBLE

CONNECTION

(Standard

Models)

M412616

80 cm (31-1/2")

9

T266IE3B

Page 12

30 Pound (13 kg) Gas Tumbler

Cabinet Finish: Electrostatically applied thermosetting polyester

Cylinder: 30" x 30" (76.2 x 76.2 cm) perforated galvanized steel with three baffles;

30 pounds (13.6 kg) dry weight (cotton load)

Motor: ¹⁄₃ H.P., lifetime lubricated, internal overload protected

Electrical Requirements: 230 Volt, 50 Hertz, 1 Phase, 5.5 Amp

Gas Consumption: Energy Saver Models — 80,000 BTU per hour (84.4 MJ/hr.)

Standard Models — 105,000 BTU per hour (110.8 MJ/hr.)

Types of Gas: Factory equipped with Natural/Mixed Gas

(6¹⁄₂ ± 1¹⁄₂ inch water column line pressure) (1.62 ± .37 kPa); or

Liquefied Petroleum gas (11 ± .3" water column line pressure)

(2.74 ± .07 kPa)

Gas Connection: ¹⁄₂ inch (12.7 mm) N.P.T.

Air Flow: 600 C.F.M. at 0.5 " W.C. (283 liters/sec. at 1.25 mBar)

Net Weight: 450 Pounds (204 kg.) (approximate)

Calorific Value: Natural Gas — 8900 kCal/m3 (37.2 MJ/m3)

L.P. Gas — 22,250 kCal/m3 (93.1 MJ/m3)

10

M412616

Page 13

30 Pound (13 kg) Electric Tumbler

CLEARANCES: Minimum

to nearest Combustible

Material

Top — 12" (30.5 cm)

Minimum.

0" permitted for first 4"

(10.2 cm) along front of

machine.

Back — 0" - 24" (61 cm)

Minimum recommended

for service access.

Sides — 0" Permitted.

71.7 cm (28-1/4")

DISCONNECT

ELECTRICAL

JUNCTION BOX

SWITCH

AIR FLOW

SWITCH

3.81 cm

(1-1/2")

81.75 cm (32-3/16")

114 cm (44-7/8")

183.5 cm

(72-1/2")

11.3 cm

(4-7/16")

20.3 cm (8")

DIAMETER

EXHAUST DUCT

THIMBLE

CONNECTION

55.6 cm

(21-7/8")

M412616

11

80 cm (31-1/2")

T267IE3B

Page 14

30 Pound (13 kg) Electric Tumbler

Cabinet Finish: Electrostatically applied thermosetting polyester

Cylinder: 30" x 30" (76.2 x 76.2 cm) perforated galvanized steel with three baffles;

30 pounds (13.6 kg) dry weight (cotton load)

Motor: ¹⁄₃ H.P., lifetime lubricated, internal overload protected

Electrical Requirements: 230 Volt, 50 Hertz, 1 Phase, 90 Amp

(see nameplate for voltage 230 Volt, 50 Hertz, 3 Phase, 54 Amp

of your tumbler) 380 Volt, 50 Hertz, 3 Phase, 33 Amp

415 Volt, 50 Hertz, 3 Phase, 30 Amp

Element: 21,000 Watts (all voltages)

Air Flow: 600 C.F.M. at 0.5" W.C. (283 liters/sec. at 1.25 mBar)

Net Weight: 450 pounds (204 kg) (approximate)

12

M412616

Page 15

30 Pound (13 kg) Steam Tumbler

CLEARANCES: Minimum

to nearest Combustible

Material

Top — 12" (30.5 cm)

Minimum.

0" permitted for first 4"

(10.2 cm) along front of

machine.

Back — 0" - 24" (61 cm)

Minimum recommended

for service access.

Sides — 0" Permitted.

71.75 cm (28-1/4")

DISCONNECT

SWITCH

ELECTRICAL

JUNCTION BOX

3.81 cm

(1-1/2")

183.5 cm (72-1/4")

174.6 cm (68-3/4")

155.6 cm (61-1/4")

81.75 cm (32-3/16")

114 cm (44-7/8")

(High Pressure Models)

114.4 cm (45-1/32")

(Low Pressure Models)

35.6 cm

(14")

11.27 cm

(4-7/16")

19.05 cm (7-1/2")

1.9 cm (3/4")

I.D. STEAM

OUTLET

1.9 cm (3/4") I.D.

STEAM OUTLET

20.3 cm (8")

DIAMETER

EXHAUST DUCT

THIMBLE

CONNECTION

M412616

80 cm (31-1/2")

13

(21-7/8")

55.56 cm

T268IE3B

Page 16

30 Pound (13 kg) Steam Tumbler

Cabinet Finish: Electrostatically applied thermosetting polyester

Cylinder: 30" x 30" (76.2 x 76.2 cm) perforated galvanized steel with three baffles;

30 pounds dry weight (13.6 kg) (cotton load)

Motor: High Pressure (4 coils) ¹⁄₂ H.P.

Low Pressure (4 coils) ³⁄₄ H.P.

Boiler Horsepower: 4 coil High Pressure – 3.7 Bhp (123,950 BTU/hr., 58 kg/hr, 31,235 kCal/hr.)

4 coil Low Pressure – 2.6 Bhp (87,100 BTU/hr., 40 kg/hr, 21,949 kCal/hr.)

Electrical Requirements: Low Pressure:

(see nameplate for 230 Volt, 50 Hertz, 1 Phase, 8 Amp

voltage of tumbler) 380 Volt, 50 Hertz, 3 Phase, 3 Amp

415 Volt, 50 Hertz, 3 Phase, 3 Amp

High Pressure:

230 Volt, 50 Hertz, 1 Phase, 4 Amp

380-415 Volt, 50 Hertz, 3 Phase, 2 Amp

Air Flow: Low Pressure — 600 C.F.M. at 0.5 W.C. (283 liters/sec. at 1.25 mBar)

High Pressure — 600 C.F.M. at 0.5 W.C. (283 liters/sec. at 1.25 mBar)

Net Weight: 470 pounds (214 kg) (approximate)

14

M412616

Page 17

50 Pound (22 kg) Gas Non-reversing Tumblers

CLEARANCES: Minimum

to nearest Combustible

Material

Top — 12" (30.5 cm)

Back — 0" - 24" (61 cm)

Sides — 0" Permitted.

Minimum.

0" permitted for first 4"

(10.2 cm) along front of

machine.

Minimum recommended

for service access.

71.75 cm (28-1/4")

DISCONNECT

ELECTRICAL

JUNCTION BOX

AIR FLOW

SWITCH

(Energy Saver

Models)

SWITCH

3.81 cm

(1-1/2")

GAS CONNECTION

194.6 cm (76-5/8")

167 cm (65-3/4")

81.75 cm (32-3/16")

119.4 cm (47")

AND SHUT OFF

VALVE

13.65 cm

(5-3/8")

AIR FLOW SWITCH

(Standard Models)

146.37 cm (57-5/8")

34 cm

(13-3/8")

20.3 cm (8")

DIAMETER

EXHAUST DUCT

THIMBLE

CONNECTION

(Energy Saver

Models)

20.3 cm (8")

DIAMETER

EXHAUST DUCT

THIMBLE

CONNECTION

(Standard

Models)

M412616

98.1 cm (38-5/8")

15

T269IE3B

Page 18

50 Pound (22 kg) Gas Tumblers

Cabinet Finish: Electrostatically applied thermosetting polyester

Cylinder: 37" x 30" (94 cm x 76.2 cm) perforated galvanized steel with four baffles;

50 pounds (22.7 kg) dry weight (cotton load)

Motor: 1/2 H.P., lifetime lubricated, internal overload protected

(Nonreversing Models) (See below for reversing models.)

Electrical Requirements: 230 Volt, 50 Hertz, 1 Phase, 6.0 Amp

Non-Reversing Models

Electrical Requirements: 230 Volt, 50 Hertz, 1 Phase, 8.0 Amp

Reversing Models

Gas Consumption: Energy Saver Models — 95,000 BTU per hour (100.2 MJ/hr.)

Standard Models — 120,000 BTU per hour (126.6 MJ/hr.)

Types of Gas: Factory equipped with Natural/Mixed Gas

(6-1/2 ± 1-1/2 inch water column line pressure) (1.62 ± .37 kPa); or

Liquefied Petroleum gas (11 ± .3" water column line pressure)

(2.74 ± .07 kPa)

Gas Connection: 1/2 inch (12.7 mm) N.P.T.

Air Flow: Energy Saver Models — 390 C.F.M. at 0.5" W.C. (185 liters/sec. at 1.25 mBar)

Standard Models — 600 C.F.M. at 0.5" W.C. (284 liters/sec. at 1.25 mBar)

Net Weight: 545 Pounds (247 kg) (approximate)

Calorific Value: Natural Gas — 8900 kCal/m3 (37.2 MJ/m3)

L.P. Gas — 22,250 kCal/m3 (93.1 MJ/m3)

REVERSING MOTOR SIZES

STEAM

GAS ELECTRIC

HIGH PRESSURE LOW PRESSURE

FAN

50 LB.

CYLINDER

1/3 H.P. 1/3 H.P. 1/3 H.P. 1/2 H.P.

1/3 H.P. 1/3 H.P. 1/3 H.P. 1/3 H.P.

16

M412616

Page 19

50 Pound (22 kg) Gas and Steam Reversing

Tumblers

ELECTRICAL

DISCONNECT

SWITCH

JUNCTION BOX

CYLINDER

MOTOR

20.3 cm (8")

DIAMETER

EXHAUST THIMBLE

CONNECTOR

(Energy Saver

Gas Models)

AIRFLOW

SWITCH

194.6 cm

(76-5/8")

146.4 cm

(57-5/8")

20.3 cm (8")

DIAMETER

EXHAUST

THIMBLE

CONNECTION

34 cm

(13-3/8")

M412616

FAN

MOTOR

13.65 cm

(5-3/8")

98.1 cm

(38-5/8")

T264IE3B

17

Page 20

50 Pound (22 kg) Electric Non-reversing Tumblers

CLEARANCES: Minimum

to nearest Combustible

Material

Top — 12" (30.5 cm)

Back — 0" - 24" (61 cm)

Sides — 0" Permitted.

Minimum.

0" permitted for first 4"

(10.2 cm) along front of

machine.

Minimum recommended

for service access.

71.75 cm (28-1/4")

DISCONNECT

SWITCH

ELECTRICAL

JUNCTION BOX

AIR FLOW

SWITCH

3.81 cm

(1-1/2")

81.75 cm (32-3/16")

13.65 cm

194.6 cm (76-5/8")

119.4 cm (47")

(5-3/8")

20.3 cm (8")

DIAMETER

EXHAUST DUCT

THIMBLE

CONNECTION

34 cm

(13-3/8")

98.1 cm (38-5/8")

18

T270IE3B

M412616

Page 21

50 Pound (22 kg) Electric Tumblers

Cabinet Finish: Electrostatically applied thermosetting polyester

Cylinder: 37" x 30" (94 x 76.2 cm) perforated galvanized steel with four baffles;

50 pounds (22.7 kg) dry weight (cotton load)

Motor: 1/2 H.P., lifetime lubricated, internal overload protected

(Nonreversing models) (See below for reversing models.)

Electrical Requirements: 230 Volt, 50 Hertz, 1 Phase, 90 Amp

(see nameplate for voltage 230 Volt, 50 Hertz, 3 Phase, 78 Amp

of your tumbler) 380 Volt, 50 Hertz, 3 Phase, 48 Amp

415 Volt, 50 Hertz, 3 Phase, 45 Amp

Element: 30,000 watts (all voltages) Long life nichrome wire

Air Flow: 900 C.F.M. maximum at .5" W.C.

(425 liters/sec at 1.25 mBar)

Net Weight: 550 pounds (250 kg) (approximate)

REVERSING MOTOR SIZES

GAS ELECTRIC

FAN

50 LB.

CYLINDER

1/3 H.P. 1/3 H.P. 1/3 H.P. 1/2 H.P.

1/3 H.P. 1/3 H.P. 1/3 H.P. 1/3 H.P.

STEAM

HIGH PRESSURE LOW PRESSURE

M412616

19

Page 22

50 Pound (22 kg) Electric Reversing Tumblers

CYLINDER

MOTOR

DISCONNECT

194.6 cm

(76-5/8")

SWITCH

ELECTRICAL

JUNCTION BOX

AIRFLOW

SWITCH

MOTOR

FAN

20.3 cm (8")

DIAMETER

EXHAUST

THIMBLE

CONNECTION

34 cm

(13-3/8")

13.65 cm

(5-3/8")

98.1 cm

(38-5/8")

T263IE3B

20

M412616

Page 23

50 Pound (22 kg) Steam Non-reversing Tumblers

71.75 cm (28-1/4")

203.2 cm (80") (6 Coil)

194. 6 cm (76-5/8") (4 Coil)

ELECTRICAL

JUNCTION BOX

3.81 cm

(1-1/2")

81.75 cm (32-3/16")

119.4 cm (47")

38.7 cm (15-1/4") 19.05 cm (7-1/2")

1.9 cm (3/4") I.D.

STEAM OUTLET

13.65 cm

(5-3/8")

200 cm (78-3/4") (6 Coil)

164.5 cm (64-3/4")

184.8 cm (72-3/4") (4 Coil)

1.9 cm (3/4") I.D.

STEAM INLET

20.3 cm (8")

DIAMETER

EXHAUST DUCT

THIMBLE

CONNECTION

M412616

98.1 cm (38-5/8")

21

34 cm (13-3/8")

T271IE3A

Page 24

50 Pound (22 kg) Steam Tumblers

Cabinet Finish: Electrostatically applied thermosetting polyester

Cylinder: 37" x 30" (94 x 76.2 cm) perforated galvanized steel with four baffles;

50 pounds (22.7 kg) dry weight (cotton load)

Motor: High Pressure Steam — 1/2 H.P.

(Nonreversing Models) Low Pressure Steam — 3/4 H.P.

Both motors are lifetime lubricated, internal

overload protected

(See below for reversing models.)

Boiler Horsepower: High Pressure Steam (6 Coil) — 4.60 BHP

(154,100 BTU/hr, 72.1 kg/hr, 38,833 kCal/nr.)

Low Pressure Steam (4 Coil) — 3.00 BHP

(134,000 BTU/hr, 62.7 kg/hr, 33,768 kCal/hr.)

Electrical Requirements: Low Pressure

(see nameplate for voltage 230 Volt, 50 Hertz, 1 Phase, 7.0 Amp

of your tumbler)

High Pressure

230 Volt, 50 Hertz, 1 Phase, 7.0 Amp

380 Volt, 50 Hertz, 3 Phase, 3.0 Amp

415 Volt, 50 Hertz, 3 Phase, 2.5 Amp

Air Flow: Low Pressure — 950 C.F.M. at 0.5" W.C. (449 liters/sec. at 1.25 mBar)

High Pressure — 900 C.F.M. at 0.5" W.C. (426 liters/sec. at 1.25 mBar)

Net Weight: 4 Coil Tumbler — 565 pounds (257 kg) (approximate)

6 Coil Tumbler — 580 pounds (263 kg) (approximate)

REVERSING MOTOR SIZES

STEAM

GAS ELECTRIC

HIGH PRESSURE LOW PRESSURE

FAN

50 LB.

CYLINDER

1/3 H.P. 1/3 H.P. 1/3 H.P. 1/2 H.P.

1/3 H.P. 1/3 H.P. 1/3 H.P. 1/3 H.P.

22

M412616

Page 25

75 Pound (34 kg) Gas Non-reversing Tumblers

71.75 cm (28-1/4")

CLEARANCES: Minimum

to nearest Combustible

Material

Top — 12" (30.5 cm)

Minimum.

0" permitted for first 4"

(10.2 cm) along front of

machine.

Back — 0" - 24" (61 cm)

Minimum recommended

for service access.

Sides — 0" Permitted.

DISCONNECT

SWITCH

ELECTRICAL

JUNCTION BOX

AIR FLOW

SWITCH

3.81 cm

(1-1/2")

194.6 cm (76-5/8")

167 cm (65-3/4")

97 cm (38-3/16")

134.6 cm (53")

13.65 cm

(5-3/8")

GAS CONNECTION

AND

SHUT OFF VALVE

20.3 cm (8")

DIAMETER

EXHAUST DUCT

THIMBLE

CONNECTION

(Standard Models)

34 cm

(13-3/8")

M412616

23

98.1 cm (38-5/8")

T272IE3B

Page 26

75 Pound (34 kg) Gas and Steam Reversing

Tumblers

DISCONNECT

SWITCH

194.6 cm

(76-5/8")

ELECTRICAL

JUNCTION BOX

CYLINDER

MOTOR

AIRFLOW

SWITCH

FAN

MOTOR

20.3 cm (8")

DIAMETER

EXHAUST

THIMBLE

CONNECTION

34 cm

(13-3/8")

13.65 cm

(5-3/8")

98.1 cm

(38-5/8")

T265IE3B

24

M412616

Page 27

75 Pound (34 kg) Gas Tumblers

Cabinet Finish: Electrostatically applied thermosetting polyester

Cylinder: 37" x 36" (94 x 91.4 cm) perforated galvanized steel cylinder with four baffles;

75 pounds (34.1 kg) dry weight (cotton load)

Motor: 3/4 H.P., lifetime lubricated, internal overload protected.

(Non-reversing models) (See below for reversing models.)

Electrical Requirements

Nonreversing Models: 230 Volt, 50 Hertz, 1 Phase, 9.0 Amp

Electrical Requirements

Reversing Models: 230 Volt, 50 Hertz, 1 Phase, 9.0 Amp

Gas Consumption: 165,000 B.T.U. per hour (174.1 MJ/hr.)

Types of Gas: Factory equipped with Natural/Mixed gas (6-1/2 A 1-1/2 inch

water column line pressure) (1.62 A .37 kPa); or Liquefied Petroleum gas

(11.0 A .3 inch water column line pressure) (2.74 A .07 kPa)

Gas Connection: 1/2 inch (12.7 mm) N.P.T.

Air Flow: 1000 C.F.M. at 0.5" W.C.

(472 liters/sec. at 1.25 mBar)

Net Weight: 550 Pounds (250 kg) (approximate)

Calorific Value: Natural Gas — 8900 kCal/m

3

(37.2 MJ/m3)

L.P. Gas — 22250 kCal/m3 (93.1 MJ/m3)

REVERSING MOTOR SIZES

GAS ELECTRIC

HIGH PRESSURE LOW PRESSURE

FAN

75 LB.

CYLINDER

1/3 H.P. 1/3 H.P. 1/3 H.P. 1/2 H.P.

1/3 H.P. 1/3 H.P. 1/3 H.P. 1/3 H.P.

STEAM

M412616

25

Page 28

75 Pound (34 kg) Electric Non-reversing Tumblers

CLEARANCES: Minimum

to nearest Combustible

Material

Top — 12" (30.5 cm)

Back — 0" - 24" (61 cm)

Sides — 0" Permitted.

Minimum.

0" permitted for first 4"

(10.2 cm) along front of

machine.

Minimum recommended

for service access.

71.75 cm (28-1/4")

DISCONNECT

SWITCH

ELECTRICAL

JUNCTION BOX

AIR FLOW

SWITCH

3.81 cm

(1-1/2")

97 cm (38-3/16")

194.6 cm (76-5/8")

134.6 cm (53")

13.65 cm

(5-3/8")

20.3 cm (8")

DIAMETER

EXHAUST DUCT

THIMBLE

CONNECTION

26

98.1 cm (38-5/8")

34 cm

(13-3/8")

T273IE3B

M412616

Page 29

75 Pound (34 kg) Electric Reversing Tumblers

CYLINDER

MOTOR

DISCONNECT

194.6 cm

(76-5/8")

SWITCH

ELECTRICAL

JUNCTION BOX

AIRFLOW

SWITCH

MOTOR

FAN

20.3 cm (8")

DIAMETER

EXHAUST

THIMBLE

CONNECTION

34 cm

(13-3/8")

13.65 cm

(5-3/8")

98.1 cm

(38-5/8")

T263IE3B

M412616

27

Page 30

75 Pound (34 kg) Electric Tumblers

Cabinet

Finish: Electrostatically applied thermosetting polyester

Cylinder: 3 7" x 36" (94 x 91.4 cm) perforated galvanized steel with four baffles;

75 pounds (34.1 kg) dry weight (cotton load)

Motor: 3/4 H.P., lifetime lubricated internal overload protected.

(Non-reversing models) (See below for reversing models.)

Electrical

Requirements: 230 Volt, 50 Hertz, 3 Phase, 77 Amps

(See nameplate 380 Volt, 50 Hertz, 3 Phase, 50 Amps

for voltage of 415 Volt, 50 Hertz, 3 Phase, 45 Amps

your tumbler)

Element: 30,000 Watts (all models)

Air Flow: 850 C.F.M. at 0.5" W.C. (401 liters/sec at 1.25 mBar)

Net Weight: 555 Pounds (252 kg) (approximate)

75 LB.

FAN

CYLINDER

REVERSING MOTOR SIZES

STEAM

GAS ELECTRIC

HIGH PRESSURE LOW PRESSURE

1/3 H.P. 1/3 H.P. 1/3 H.P. 1/2 H.P.

1/3 H.P. 1/3 H.P. 1/3 H.P. 1/3 H.P.

28

M412616

Page 31

75 Pound (34 kg) Steam Non-reversing Tumblers

CLEARANCES: Minimum

to nearest Combustible

Material

Top — 12" (30.5 cm)

Back — 0" - 24" (61 cm)

Sides — 0" Permitted.

Minimum.

0" permitted for first 4"

(10.2 cm) along front of

machine.

Minimum recommended

for service access.

DISCONNECT

ELECTRICAL

JUNCTION BOX

71.75 cm (28-1/4")

SWITCH

3.81 cm

(1-1/2")

97 cm (38-3/16")

39.1 cm

(15-1/4")

203 cm (80") (6 Coil)

194.6 cm (76-5/8") (4 Coil)

134.6 cm (53")

19 cm (7-1/2")

1.9 cm (3/4")

I.D. STEAM INLET

1.9 cm (3/4")

I.D. STEAM OUTLET

M412616

200 cm (78-3/4") (6 Coil)

164.5 cm (64-3/4")

184.8 cm (72-3/4") (4 Coil)

98.1 cm (38-5/8")

29

13.65 cm

(5-3/8")

20.3 cm (8")

DIAMETER

EXHAUST DUCT

THIMBLE

CONNECTION

34 cm

(13-3/8")

T274IE3B

Page 32

75 (34 kg) Pound Steam Tumblers

Cabinet Finish: Electrostatically applied thermosetting polyester

Cylinder: 37" x 36" (94 x 91.4 cm) perforated galvanized steel with four baffles;

75 pounds (34.1 kg) dry weight (cotton load)

Motor: High Pressure Steam — 3/4 H.P.

(Non-reversing models) Low Pressure Steam — 3/4 H.P.

Both motors are lifetime lubricated, internal overload protected.

(See below for reversing models.)

Boiler High Pressure Steam (6 Coil) — 4.60 BPH

Horsepower: (154,100 BTU/hr., 72.1 kg/hr., 38,833 kCal/hr.)

Low Pressure Steam (4 Coil) — 4.00 BHP

(134,000 BTU/hr., 62.7 kg/hr., 33,768 kCal/hr.)

Electrical Requirements: Low Pressure — 230 Volt, 50 Hertz, 1 Phase, 8.5 Amp

(See nameplate for voltage

of your tumbler) High Pressure — 230 Volt, 50 Hertz, 1 Phase, 9.0 Amp

Air Flow: Low Pressure — 950 C.F.M. at 0.5" W.C. (449 liters/sec at 1.25 mBar)

High Pressure — 900 C.F.M. at 0.5" W.C. (425 liters/sec at 1.25 mBar)

Net Weight: 615 Pounds (280 kg) (approx.)

REVERSING MOTOR SIZES

GAS ELECTRIC

FAN

75 LB.

CYLINDER

1/3 H.P. 1/3 H.P. 1/3 H.P. 1/2 H.P.

1/3 H.P. 1/3 H.P. 1/3 H.P. 1/3 H.P.

STEAM

HIGH PRESSURE LOW PRESSURE

30

M412616

Page 33

SECTION II

Installation Instructions

RECEIVING INSPECTION

Upon delivery, visually inspect crate carton and parts

for any visible shipping damage. If crate, carton

or cover are damaged or signs of possible damage

are evident, have carrier note condition on shipping

papers before shipping receipt is signed, or advise

carrier of condition as soon as it is discovered.

Remove crate and protective cover as soon as

possible and check items listed on packing list.

Advise carrier of any damaged or missing articles as

soon as possible. A written claim should be filed with

carrier immediately if articles are damaged or

missing.

IMPORTANT: Remove shipping tape from two

back draft dampers located in exhaust thimble

MATERIALS REQUIRED (Obtain Locally)

GAS, ELECTRIC OR STEAM DRYING

TUMBLERS

••

• One circuit breaker.

••

GAS DRYING TUMBLERS ONLY

••

• One gas shut-off valve for gas service line to each

••

tumbler.

STEAM DRYING TUMBLERS ONLY

••

• One steam shut-off gate valve for steam service

••

line to be connected upstream of solenoid steam

valve.

••

• Two steam shut-off gate valves for each

••

condensate return line.

••

• Flexible steam hoses with a 125 psig (pounds per

••

square inch gauge) (8.79 kg/sq. cm) working

pressure for connecting steam coils,

and 25.

••

• Two steam traps for steam coil outlet to

••

condensate return line.

••

• One steam pressure relief valve rated at 125 psig.

••

(8.79 kg/cm2).

.

Figures 24

FACILITIES REQUIRED

FLOOR

Drying tumbler may be installed on any level floor

capable of supporting 100 pounds per square foot

(488 kg/m2). Floor covering materials such as

carpeting or tile should be removed.

LAYOUT

Whenever possible, tumbler should be installed along

an outside wall where duct length can be kept to a

minimum, and make-up air can be easily accessed.

M412616

Construction must not block airflow at top rear of

tumbler. Doing so would prevent adequate air supply

to tumbler’s combustion chamber.

VENTING

For maximum efficiency and minimum lint

accumulation, tumbler air must be exhausted to

outdoors by shortest possible route.

31

Page 34

Proper sized exhaust ducts are essential for proper

operation. All elbows should be sweep type. Do not

install elbows with a radius less than shown in table

below. Exhaust ducts must be assembled so interior

surfaces are smooth to reduce accumulation of lint.

Do not use sheet metal screws to join vent sections.

Improperly sized or assembled ductwork causes

excess back pressure which results in slow drying,

lint collecting in duct, lint blowing back into room, and

increased fire hazard.

Exhaust ducts shall be constructed of sheet metal

or other noncombustible material. Such ducts

must be equivalent in strength and corrosion

resistance to ducts made of galvanized sheet

steel not less than 0.0195 inches (0.495 mm)

thick.

Where exhaust duct pierces a combustible wall or

ceiling, an opening having a diameter of 4 inches

(10.2 cm) larger than diameter of exhaust duct shall

be provided, with duct centered in opening. When

ducts pass through walls, ceilings, floors or partitions,

space around the duct shall be sealed with noncombustible material. See

••

• Individual Venting

••

Figures 1, 2

and

3.

For maximum efficiency and performance, it is

preferred to exhaust tumbler(s) individually to

outdoors. At no point may cross area of

installed venting be less than cross area of

exhaust thimble of tumbler.

Maximum allowable length of venting is 14 feet

(4.3 m) and two 90° elbows or equivalent. If

equivalent length of a duct required for an

installation exceeds maximum allowable

equivalent length, diameter of a round duct must

be increased by 10% for each additional 20 feet

(6.1 m). Cross section area of a rectangular duct

must be increased by 20% for each additional 20

feet (6.1 m). Table below shows how to determine

equivalent venting:

DUCT

DIAMETER

6" (15.2 cm)

8" (20.3 cm)

10" (25.4 cm)

12" (30.5 cm)

EQUIVALENT LENGTH OF

STRAIGHT DUCT

One 90° elbow = 7' (2.1 m)

One 90° elbow = 9.3' (2.83 m)

One 90° elbow = 11.6' (3.5 m)

One 90° elbow = 14' (4.3 m)

With tumbler in operation, airflow at any point in

duct must be at least 1200 feet (366 m) per

minute to insure that lint remains airborne.

••

• Collector Venting

••

While it is preferable to exhaust tumblers

individually to outdoors, a main collector duct may

be used if it is sized according to

Figure 3.

NOTE: This illustration indicates minimum

diameters, and should be increased if collector

length exceeds 20 feet (6.1 m).

Collector duct may be rectangular in cross

section, as long as area is not reduced. Provisions

should be made for lint removal and cleaning of

collector duct.

Collector duct must be tapered, as shown in

Figure 3.

Individual tumbler ducts must enter the

collector duct at a 45° angle in direction of air flow.

Never connect a tumbler duct at a 90° angle to

collector duct. Doing so will cause excessive

back pressure, resulting in poor performance.

Never connect two tumbler exhaust ducts

directly across from each other at point of

entry to collector duct.

Collector system must be designed so static back

pressure measured 12 inches (30.5 cm) from

exhaust thimble does not exceed maximum

allowable pressure specified on installation sticker

on rear of tumbler. Measured with all tumblers

running that are vented into collector.

MAKE-UP AIR

A tumbler is forced air exhausted and requires

provisions for make-up air to replace the air

exhausted by tumbler.

Manufacturer’s recommended make-up air opening

for each tumbler is 144 square inches (928 sq. cm)

for 30 and 50 pound tumblers and 195 square inches

(1258 sq. cm) for 75 pound tumblers. At a minimum,

tumblers must have at least 1 in2 (2.54 cm2) of

opening for every 1000 BTU/hr (252 Kcal/hr) of

input rating for proper combustion.

Example: A tumbler with a rated input of 120,000

BTU/hr (30,240 Kcal) requires 120 in

(774 cm2) of free opening.

2

Equivalent Length (feet) (m) =

1.17 x Duct Diameter (inches) (cm)

Example: A 6-inch (15.2 cm) diameter duct’s

equivalent length of 14 feet (4.3 m) of duct

and two 90° elbows is:

Equivalent length

= 14 feet (4.3 m) + (2) 90° elbows

= 14 feet (4.3 m) + 7 feet (2.1 m) + 7 feet (2.1 m)

= 28 feet (8.5 m)

Protective louvers in opening to outdoors can reduce

air movement by approximately 40%. Opening must

compensate for area taken up by louvers.

Make-up air openings for a room containing

tumbler(s) and/or gas fired hot water heater or other

gravity vented appliances must be increased

sufficiently to prevent downdrafts in any vents when

all tumblers are in operation. Do not locate gravity

vented appliances between tumbler(s) and make-up

air openings. If it is necessary to duct make-up air to

tumbler(s), increase area of work by 25% to

compensate for any restriction in air movement.

32

M412616

Page 35

WARNINGWARNING

WARNING

WARNINGWARNING

維

Solvent gases and vapors from dry

cleaning machines create acids when

drawn through the heater of a drying

tumbler. These acids are corrosive to

the drying tumbler as well as to the

laundry load being dried. Be sure

make-up air is free of solvent gases

and vapors.

If the dry cleaning machines are in the

same area as the tumbler, then the

tumbler make-up air must come from

a source free of solvent gases and

vapors.

FOR BEST PERFORMANCE

Provide an individual exhaust

duct for each tumbler. Do not

install a hot water heater in

room containing tumblers. It is

better to have the water heater

in a separate room with a

separate air inlet.

WARNINGWARNING

WARNING

WARNINGWARNING

維

To reduce the risk of fire and

accumulation of combustible gases,

DO NOT exhaust tumbler air into a

window well, gas vent, chimney or

enclosed, unventilated area such as an

attic wall, ceiling, crawl space under a

building, or concealed space of a

building.

NOTE: Do not install wire

mesh or screen in this

opening as lint will build up

and prevent proper discharge

of air from tumblers.

ROOF 30" (76.2 CM)

T075IE3A

REMOVABLE STRIP OF PANEL IN FRAMING WALL TO

PERMIT REMOVAL OF TUMBLER FROM FRAMING WALL

ONE

TUMBLER

T108IE3A

TWO

TUMBLERS

THREE

TUMBLERS

ROOF 30" (76.2 cm)

PARTITION OR

BULKHEAD

CONSULT YOUR LOCAL BUILDING

CODE FOR REGULATIONS WHICH

MAY ALSO APPLY

NOTE: Inside of duct shall be

smooth. Do not use sheet

metal screws to join sections.

CEILING

WALL

36 INCHES

(91.4 cm)

RECOMMENDED

SERVICE AREA

24 INCHES

(61.0 cm)

MINIMUM

T108IE3B

M412616

Figure 1

33

Page 36

VERTICAL EXHAUST INSTALLATION

HORIZONTAL EXHAUST INSTALLATION

WALL

CONNECT TO

TUMBLER

2" (5.1 cm)

MINIMUM

WALL

2" (5.1 cm)

MINIMUM

WALL

CONNECT TO

TUMBLER

EXHAUST AIR FLOW

MAXIMUM LENGTH OF

DUCT 14 FEET

(4.3 m)

NOTE: WHERE THE EXHAUST DUCT PIERCES A COMBUSTIBLE WALL

OR CEILING, AN OPENING HAVING A DIAMETER FOUR INCHES (10.2 cm)

LARGER THAN THE DIAMETER OF THE EXHAUST DUCT SHALL BE

PROVIDED, AND THE EXHAUST DUCT CENTERED WITHIN THE OPENING.

Figure 2

NOTE: WHERE THE EXHAUST DUCT PIERCES A COMBUSTIBLE WALL

OR CEILING, AN OPENING HAVING A DIAMETER FOUR INCHES (10.2 cm)

LARGER THAN THE DIAMETER OF THE EXHAUST DUCT SHALL BE

PROVIDED, AND THE EXHAUST DUCT CENTERED WITHIN THE OPENING.

T030IE3B

2" (5.1 cm)

MINIMUM

EXHAUST

OUTLET

NO SCREEN

OR CAP

INSPECTION OR

CLEANOUT COVER

ALKJ I HGF EDCB

NO SCREEN

OR CAP

AIR OUT

DUCT

STATION

MINIMUM DIAMETER

*GAS

ELECTRIC

STEAM

DUCT

STATION

MINIMUM DIAMETER

*GAS

ELECTRIC

STEAM

A 9" (22.9 cm) 10" (25.4 cm) G 23" (58.4 cm) 26" (66 cm)

B 12" (30.5 cm) 14" (35.6 cm) H 25" (63.5 cm) 28" (71.1 cm)

C 15" (38.1 cm) 17" (43.2 cm) I 26" (66 cm) 30" (76.2 cm)

D 17" (43.2 cm) 20" (50.8 cm) J 27" (68.6 cm) 31" (78 cm)

E 19" (48.3 cm) 22" (55.9 cm) K 29" (73.9 cm) 33" (83.8 cm)

F 21" (53.3 cm) 24" (61 cm) L 30" (76.2 cm) 34" (86.4 cm)

Figure 3

34

45˚

T056IE3B

M412616

Page 37

ELECTRICAL REQUIREMENTS

For 30 Pound (13 kg) Narrow Cabinet Tumblers

REQUIREMENTS

Heat Source Electrical Specs Wires Required and Terminal Block Connection

Gas 230-50-1 L1 L2 Ground to PE Busbar

Electric 230-50-1 L1 L2 Ground to PE Busbar

Electric 230-50-3 L1 L2 L3 Ground to PE Busbar

Electric 380-50-3 L1 L2 L3 Ground to PE Busbar

Electric 415-50-3 L1 L2 L3 Ground to PE Busbar

Figure 4

GAS DRYING TUMBLERS

GAS DRYING TUMBLERS

240V, 1 Phase, 50 Hz. 120V, 1 Phase, 30 Hz.

Minimum Wire Size 14 AWG (2.081 mm²) 14 AWG (2.081 mm²)

Circuit Breaker 15 AMP 15 AMP

No. of Poles 2 2

Figure 5

ELECTRIC DRYING TUMBLERS

ELECTRIC DRYING TUMBLERS

240V 50 Hz. 1 Ph 240V 50 Hz. 3 Ph 380V 50 Hz. 3 Ph 415V 50 Hz. 3 Ph

Amp Rating 91 Amp 55 Amp 34 Amp 31 Amp

Circuit Breaker 100 Amp 60 Amp 40 Amp 35 Amp

Poles 2 3 3 3

Minimum Wire Size 2 AWG (33.63 mm²) 6 AWG (13.32 mm²) 8 AWG (8.366 mm²) 8 AWG (8.366 mm²)

Figure 6

GROUNDING INSTRUCTIONS

Drying tumbler must be grounded. In event of malfunction or breakdown, grounding will reduce risk of electric

shock by providing a path of least resistance for electric current. Drying tumbler must be connected to a

grounded metal, permanent wiring system; or an equipment grounding conductor must be run with circuit

conductors and connected to PE Busbar.

維

WARNING

To reduce the risk of fire and electric shock, check with a qualified serviceman for

proper grounding procedures. Improper connection of the equipment grounding

conductor can result in a risk of electric shock.

WARNING

維

To reduce the risk of fire and electric shock, if electrical supply is coming from a

three phase service, DO NOT connect a “Stinger Leg” to a single phase machine.

M412616

35

Page 38

ELECTRICAL REQUIREMENTS

For 30 Pound (13 kg) Tumblers

REQUIREMENTS

Heat Source Electrical Specs Wires Required and Terminal Block Connection

Gas & Steam 230/50/1 L1 L2 Ground to PE Busbar

Electric 230/50/1 L1 L2 Ground to PE Busbar

Electric 380/50/3 L1 L2 L3 Ground to PE Busbar

Electric 415/50/3 L1 L2 L3 Ground to PE Busbar

Steam 380/50/3 L1 L2 L3 Ground to PE Busbar

Figure 7

GAS AND HIGH PRESSURE STEAM DRYING TUMBLERS

GAS AND HIGH PRESSURE STEAM DRYING TUMBLERS

240 V, 1 Phase, 50 Hz. 380 V, 3 Phase, 50 Hz.

Minimum Wire Size 14 AWG (2.081 mm²) 14 AWG (2.081 mm²)

Circuit Breaker 15 AMP 15 AMP

Poles 2 2

Figure 8

ELECTRIC DRYING TUMBLERS

NOTE: DO NOT use aluminum wire.

ELECTRIC DRYING TUMBLERS

240 V, 1 Ph, 50 Hz. 240 V, 3 Ph, 50 Hz. 380 V, 3 Ph, 50 Hz. 415 V, 3 Ph, 50 Hz.

Minimum Wire Size 2 AWG (33.63 mm²) 6 AWG (13.32 mm²) 8 AWG (8.366 mm²) 8 AWG (8.366 mm²)

AMP Rating 90 Amp 54 Amp 33 Amp 30 Amp

Circuit Breaker 100 Amp 60 Amp 40 Amp 35 Amp

Poles 2 3 3 3

Figure 9

36

M412616

Page 39

30 Pound (13 kg) Tumblers

LOW STEAM DRYING TUMBLERS

LOW PRESSURE STEAM DRYING TUMBLERS

240 V, 1 Phase 50 Hz.

Minimum Wire Size 16 AWG (1.309 mm²)

Circuit Breaker 20 AMP

Poles 2

Figure 10

GROUNDING INSTRUCTIONS

Drying tumbler must be grounded. In event of malfunction or breakdown, grounding will reduce risk of electric

shock by providing a path of least resistance for electric current. Drying tumbler must be connected to a

grounded metal, permanent wiring system; or an equipment grounding conductor must be run with circuit

conductors and connected to PE Busbar.

維

WARNING

To reduce the risk of fire and electric shock, check with a qualified serviceman for

proper grounding procedures. Improper connection of the equipment grounding

conductor may result in a risk of electric shock.

WARNING

維

To reduce the risk of fire and electric shock, if electrical supply is coming from a three

phase service, DO NOT connect a “Stinger Leg” to a single phase machine.

M412616

37

Page 40

ELECTRICAL REQUIREMENTS

For 50 Pound (22 kg) Tumblers

REQUIREMENTS

Heat Source Electrical Specs Wires Required and Terminal Block Connection

Non-Reversing Models

Gas & Steam 230/50/1 L1 L2 Ground to PE Busbar

Steam 380-415/50/3 L1 L2 L3 Ground to PE Busbar

Electric 230/50/1 L1 L2 Ground to PE Busbar

Electric 380-415/50/3 L1 L2 L3 Ground to PE Busbar

Reversing Models

Gas & Steam 230/50/1 L1 L2 Ground to PE Busbar

Gas & Steam 380-415/50/3 L1 L2 L3 Ground to PE Busbar

Electric 230/50/3 L1 L2 L3 Ground to PE Busbar

Electric 380-415/50/3 L1 L2 L3 Ground to PE Busbar

Figure 11

GAS AND HIGH PRESSURE STEAM DRYING TUMBLER

GAS AND HIGH PRESSURE STEAM DRYING TUMBLERS

208V / 240 V

1 Phase, 50 Hz.

Minimum Wire Size 14 AWG (2.081 mm²) 14 AWG (2.081 mm²) 14 AWG (2.081 mm²)

Circuit Breaker 15 AMP 15 AMP 15 AMP

Poles 2 3 3

Figure 12

208 / 240 V

3 Phase, 50 Hz.

380 / 415 V

3 Phase, 50 Hz.

ELECTRIC DRYING TUMBLERS

NOTE: DO NOT use aluminum wire.

ELECTRIC DRYING TUMBLERS

240 V, 3 Phase

50 Hz.

Minimum Wire Size 3 AWG (26.67 mm²) 6 AWG (13.32 mm²) 6 AWG (13.32 mm²)

AMP Rating 78 AMP 48 AMP 45 AMP

380 V, 3 Phase

50 Hz.

415 V, 3 Phase

50 Hz.

Circuit Breaker 80 AMP 50 AMP 50 AMP

Poles 3 3 3

Figure 13

38

M412616

Page 41

50 Pound (22 kg) Tumblers

LOW PRESSURE STEAM DRYING TUMBLERS

LOW PRESSURE STEAM DRYING TUMBLERS

240 V

1 Phase, 50 Hz.

Minimum Wire Size 14 AWG (2.081 mm²)

Circuit Breaker 15 AMP

Poles 2

Figure 14

GROUNDING INSTRUCTIONS

Drying tumbler must be grounded. In event of malfunction or breakdown, grounding will reduce risk of electric

shock by providing a path of least resistance for electric current. Drying tumbler must be connected to a

grounded metal, permanent wiring system; or an equipment grounding conductor must be run with circuit

conductors and connected to the PE Busbar.

維

WARNING

To reduce the risk of fire and electric shock, check with a qualified service technician

for proper grounding procedures. Improper connection of the equipment grounding

conductor can result in a risk of electric shock.

WARNING

維

To reduce the risk of fire and electric shock, if electrical supply is coming from a three

phase service, DO NOT connect a “Stinger Leg” to a single phase machine.

M412616

39

Page 42

ELECTRICAL REQUIREMENTS

For 75 Pound (34 kg) Tumblers

REQUIREMENTS

Heat Source Electrical Specs Wires Required and Terminal Block Connection

Gas & Steam 230/50/1 L1 L2 Ground to PE Busbar

Electric 208-230/50-60/3 L1 L2 L3 Ground to PE Busbar

Electric 380/50/3 L1 L2 L3 Ground to PE Busbar

Electric 415/50/3 L1 L2 L3 Ground to PE Busbar

Steam 380/50/3 L1 L2 L3 Ground to PE Busbar

Figure 15

GAS AND HIGH PRESSURE STEAM DRYING TUMBLERS

GAS AND HIGH PRESSURE STEAM DRYING TUMBLERS

208V / 240 V

1 Phase, 50 Hz.

Minimum Wire Size 14 AWG (2.081 mm²) 14 AWG (2.081 mm²) 14 AWG (2.081 mm²)

Circuit Breaker 15 AMP 15 AMP 15 AMP

Poles 2 3 3

Figure 16

208 / 240 V

3 Phase, 50 Hz.

380 / 415 V

3 Phase, 50 Hz.

ELECTRIC DRYING TUMBLERS

NOTE: DO NOT use aluminum wire.

ELECTRIC DRYING TUMBLERS

380 V, 3 Ph, 50 Hz. 415 V, 3 Ph, 50 Hz.

Minimum Wire Size 6 AWG (13.32 mm²) 6 AWG (13.32 mm²)

AMP Rating 48 Amp 45 Amp

Circuit Breaker 50 Amp 50 Amp

Poles 3 3

Figure 17

GROUNDING INSTRUCTIONS

Drying tumbler must be grounded. In event of malfunction or breakdown. Grounding will reduce risk of electric

shock by providing a path of least resistance for electric current. Drying tumbler must be connected to a

grounded metal, permanent wiring system; or an equipment grounding conductor must be run with circuit

conductors and connected to PE Busbar.

aWARNING

To reduce the risk of fire and electric shock, check with a qualified service technician

for proper ground procedures. Improper connection of the equipment grounding

conductor may result in risk of electric shock.

WARNING

維

To reduce the risk of fire and electric shock, if electrical supply is coming from a

three phase service, DO NOT connect a “Stinger Leg” to a single phase machine.

40

M412616

Page 43

ELECTRICAL CONNECTIONS

T260IE1A

NAMEPLATE

GUARD

JUNCTION

BOX

COVER

DISCONNECT

SWITCH

維

WARNING

All electrical connections should be

made by a qualified electrician.

To reduce the risk of electrical shock,

de-energize the electrical circuit being

connected to the tumbler before making any electrical connections. Never

attempt to connect a live circuit.

Use the following steps to connect electrical service

to the tumbler:

1. Install a circuit breaker, as close to tumbler as

possible. If more than one tumbler is being

installed, a circuit breaker should be provided

for each tumbler. This will make it possible to

disconnect each tumbler for maintenance

purposes.

2. a. Connect conduit-encased leads to circuit

breaker.

b. Turn “off” disconnect switch on tumbler and

open junction box.

c. Insert conduit-encased leads through

one of the knockout holes in junction box.

d. Connect wire leads to disconnect switch.

Figure 18

ELECTRICAL CONNECTIONS

1 Phase Units: Connect one lead to top left

connection point. Connect other lead to top

right connection point.

3 Phase Units: Connect one lead to each

connection point.

e. Connect a ground wire to PE Busbar,

Figure 19,

in junction box.

3. Check electrical service phase sequence

(three phase only) as follows:

a. Energize electrical service and momentarily

start tumbler. Check direction of the cylinder

rotation. If cylinder rotates clockwise (viewed

from front), phase sequence is correct. If

cylinder rotates counterclockwise, proceed

with step “b”.

b. Disconnect and reverse any two leads at

connections.

4. Close junction box cover and turn “on”

disconnect

switch.

ELECTRICAL

DISCONNECT

GAS AND STEAM

BUSBAR

MODELS

PE

ELECTRICAL

DISCONNECT

Figure 19

PE

BUSBAR

ELECTRIC

MODELS

T277IE1A

M412616

41

Page 44

POSITIONING DRYING TUMBLER

Tumbler may be removed from skid before moving to

installation location or moved while still attached to

skid. Remove tumbler from skid by unscrewing four

shipping capscrews (one at each corner) and remove

tumbler from skid. Lint panel door will have to be

removed in order to remove two front capscrews.

NOTE: Do not throw these four capscrews away

— they are the leveling legs.

LEVELING DRYING TUMBLER

Each tumbler should be leveled within ¹⁄₈ inch

(3.2 mm) from front to rear, and ¹⁄₈ inch (3.2 mm) from

side to side. Check front to rear level by rotating

clothes cylinder until one rib is at bottom, then place a

Screw four leveling legs back into level adjusting

fittings from top. Slide tumbler to its permanent

location and level. Keep tumbler as close to floor as

possible. All four legs must rest firmly on floor so

weight of tumbler is evenly distributed. Tumbler must

not rock.

level on bottom rib. Side to side level should be

checked by placing a level on front and rear of top

panel.

GAS REQUIREMENTS (Gas Drying Tumblers)

WARNING

Size of gas service pipe is dependent upon many

variables (lengths, tees, etc.). Specific pipe size

information should be obtained from gas supplier.

Refer to table in

It is important that equal gas pressure be maintained

at all tumbler gas connections. This can best be done

by installing a one inch pipe gas loop as shown in

Figures 20 and 21.

Figure 22

for general pipe size data.

維

To reduce the risk of fire or explosion,

if the tumbler is to be connected to

Liquefied Petroleum (L.P.) gas, a vent

to the outdoors must be provided in

the room where the tumbler is

installed.

42

M412616

Page 45

Example of Gas Loop Piping

IMPORTANT: Gas loop piping must be installed

as illustrated to equalize gas pressure for all

tumblers connected to single gas service.

Other gas using appliances should be

connected upstream from loop.

MAIN

REGULATOR

GAS SPACE HEATER

TUMBLERS

GAS

SHUT-OFF

VALVES

GAS LINE

PRESSURE TAP

GAS

METER

IMPORTANT: Line pressure must be maintained at 6-1/2" ± 1-1/2" water column inches (1.62 ± .37 kPa) for Natural Gas

(11 ± .3 water column inches for L.P. Gas) (2.74 ± .07 kPa) with all gas appliances running (tumblers, water heaters, space

heaters, furnace, etc.).

An in-line pressure regulator may be required on Natural Gas models if the line pressure exceeds eight water column inches

(2.00 kPa) pressure with all gas appliances firing.

GAS WATER

HEATERS

PRESSURE

REGULATOR

(If required)

NOTE: Minimum pipe size to

tumbler is 1/2" (1.27 cm)

T034IE3D

ONE INCH

(2.54 cm)

GAS LOOP

Figure 20

Example of Gas Supply Piping

NOTE: See BTU/HR. rating

on dryer nameplate.

GAS SPACE

HEATERS

(70,000 BTU/HR. each)

GAS TUMBLER DRYERS

(75,000 BTU/HR. each)

123456789

FURNACE

(120,000 BTU/HR.)

MAIN

REGULATOR

GAS

GAS WATER

HEATERS

(400,000 BTU/HR. each)

GAS

METER

PIPE

PRESSURE

25' (7.6 m)

SAMPLE CALCULATIONS:

Equivalent Length = Total length of main gas supply pipe from

the gas meter to the far end of the tumbler dryers.

= 25' + 19' (7.6 m + 5.8 m) gas supply pipe.

= 44' (13.4 m) Total Gas Liner

Using the table in Figure 22, the main supply pipe diameter should be 2" (5.08 cm).

REGULATOR

Total BTU/HR = The sum of the BTU/HR. of all

tumblers being fed by the main

gas supply pipe.

= 9 x 75,000

= 675,000 BTU/HR.

Figure 21

M412616

43

19' (5.8 m)

19' (5.8 m)

T035IE3E

Page 46

GAS PIPE SIZE REQUIRED FOR 1,000 BTU NATURAL GAS — .64 SPECIFIC GRAVITY

AT 6½

±±

± 1½ INCH WATER COLUMN PRESSURE (1.62 ± .37 kPa)

±±

EQUIVALENT LENGTH

GAS

APPLIANCES

TOTAL

BTU/HR. (Kcal/hr)

100,000 (25,200)

120,000 (30,240)

140,000 (35,280)

160,000 (40,320)

180,000 (45,360)

200,000 (50,400)

300,000 (75,600)

400,000 (100,800)

500,000 (126,000)

600,000 (151,200)

700,000 (176,400)

800,000 (201,600)

900,000 (226,800)

25 FT.

(7.63 m)

50 FT.

(15.25 m)

75 FT.

(22.88 m)

100 FT.

(30.50 m)

125 FT.

(38.13 m)

150 FT.

(45.75 m)

BASED ON 0.3" WATER COLUMN (0.75 mBar) PRESSURE DROP FOR LENGTH GIVEN

³⁄₄" (1.905cm)

³⁄₄" (1.905cm)

³⁄₄" (1.905cm)

³⁄₄" (1.905cm)

1" (2.54cm)

1" (2.54cm)

1" (2.54cm)

1¹⁄₄" (3.18cm)

1¹⁄₄" (3.18cm)

1¹⁄₂" (3.81cm)

1¹⁄₂" (3.81cm)

1¹⁄₂" (3.81cm)

2" (5.08cm)

³⁄₄" (1.905cm)

1" (2.54cm)

1" (2.54cm)

1" (2.54cm)

1" (2.54cm)

1" (2.54cm)

1¹⁄₄" (3.18cm)

1¹⁄₄" (3.18cm)

1¹⁄₂" (3.81cm)

1¹⁄₂" (3.81cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

1" (2.54cm)

1" (2.54cm)

1" (2.54cm)

1" (2.54cm)

1" (2.54cm)

1¹⁄₄" (3.18cm)

1¹⁄₄" (3.18cm)

1¹⁄₂" (3.81cm)

1¹⁄₂" (3.81cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

1" (2.54cm)

1" (2.54cm)

1" (2.54cm)

1¹⁄₄" (3.18cm)

1¹⁄₄" (3.18cm)

1¹⁄₄" (3.18cm)

1¹⁄₂" (3.81cm)

1¹⁄₂" (3.81cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2¹⁄₂" (6.35cm)

1" (2.54cm)

1" (2.54cm)

1" (2.54cm)

1¹⁄₄" (3.18cm)

1¹⁄₄" (3.18cm)

1¹⁄₄" (3.18cm)

1¹⁄₂" (3.81cm)

1¹⁄₂" (3.81cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

1" (2.54cm)

1" (2.54cm)

1¹⁄₄" (3.18cm)

1¹⁄₄" (3.18cm)

1¹⁄₄" (3.18cm)

1¹⁄₂" (3.81cm)

1¹⁄₂" (3.81cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

1,000,000 (252,000)

1,100,000 (277,200)

1,200,000 (302,400)

1,300,000 (327,600)

1,400,000 (352,800)

1,500,000 (378,600)

1,600,000 (403,200)

1,700,000 (428,400)

1,800,000 (453,600)

1,900,000 (478,800)

2,000,000 (504,000)

2,200,000 (554,400)

2,400,000 (604,800)

2,600,000 (655,200)

2,800,000 (705,600)

3,000,000 (756,000)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2¹⁄₂” (6.35cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

2" (5.08cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3¹⁄₂" (8.89cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3¹⁄₂" (8.89cm)

3¹⁄₂" (8.89cm)

3¹⁄₂" (8.89cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3¹⁄₂" (8.89cm)

3¹⁄₂" (8.89cm)

3¹⁄₂" (8.89cm)

3¹⁄₂" (8.89cm)

3¹⁄₂" (8.89cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

2¹⁄₂" (6.35cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3¹⁄₂" (8.89cm)

3¹⁄₂" (8.89cm)

3¹⁄₂" (8.89cm)

3¹⁄₂" (8.89cm)

3¹⁄₂" (8.89cm)

4" (10.16cm)

Figure 22

44

M412616

Page 47

GAS CONNECTIONS (Gas Drying Tumblers)

Before connecting gas piping to tumbler, make

certain gas service is same as that specified on

nameplate (near gas connection), Page 5.

NATURAL GAS service must be supplied at 6¹⁄₂ ± 1¹⁄₂

inch water column pressure (1.62 ± .37 kPa).

L.P. GAS service must be supplied at 11 ± .3 inch

water column pressure (2.74 ± .07 kPa).

If gas service is not same as that specified, DO NOT

CONNECT THE GAS LINE TO TUMBLER! It will first

be necessary to convert gas burner orifice and gas

valve.

IMPORTANT: Any product revisions or

conversions must be made by the Manufacturer’s

Authorized Dealers, Distributors or local service

personnel.

維

WARNING

The tumbler and its individual shut-off

valve must be disconnected from the

gas supply piping system during any

pressure testing of that system at test

pressures in excess of 1/2 psig (3.45

kPa).

Purge air and sediment from gas service line before

connecting it loosely to tumbler. Purge remaining air

until odor of gas is detected, then tighten connection.

Use pipe compound, resistant to actions of L.P.

gas, on all pipe threads.

WARNING

維

Check all pipe connections, internal

and external, for gas leaks using a

soapy solution. To reduce the risk of

explosion or fire, DO NOT USE AN

OPEN FLAME TO CHECK FOR GAS

LEAKS! Gas connections should be

checked annually for leakage.

The tumbler must be isolated from the

gas supply piping system by closing its

individual manual shut-off valve during

any pressure testing of the gas supply

piping system at test pressure equal to

or less than 1/2 psig (3.45 kPa).

M412616

45

Page 48

DRYING TUMBLER ENCLOSURE CONSTRUCTION

維

IMPORTANT: DO NOT block airflow at top rear of

tumbler with laundry, etc. Doing so would prevent

adequate air supply to tumbler’s heat chamber.

A typical tumbler enclosure is shown in

Figure 23.

Note that enclosure does touch tumbler top and side

panels. Note, too, minimum and maximum

dimensions. Be aware that there may be local codes

and ordinances which must be complied with.

NOTICE: CLEARANCE OF TUMBLER CABINET FROM COMBUSTIBLE

CONSTRUCTION MUST BE A MINIMUM OF 12 INCHES (30.5 cm) AT TOP.

WARNING

To reduce the risk of serious injury,

install lockable doors to prevent public

access to rear of tumblers.

IMPORTANT: Install tumblers with sufficient

clearance for servicing and operating, see

Figure 23.

NOTE: Shaded areas

indicate adjacent structure.

0" CLEARANCE

PERMITTED FOR

FIRST 4" (10.16 cm)

4" (10.16 cm)

MAXIMUM

12" (30.5 cm)

MINIMUM

CLEARANCE

GUARD

PROVISION

FOR

MAKE-UP

AIR

T038IE3B

0" CLEARANCE

Figure 23

46

24" (61 cm)

MINIMUM

36" (91.4 cm)

RECOMMENDED

FOR

MAINTENANCE

PURPOSES

M412616

Page 49

STEAM REQUIREMENTS (Steam Drying Tumblers)

Size of steam service pipe is dependent upon many

variables (length, tees, high pressure system, low

pressure system, etc.) Specific pipe size

information should be obtained from the steam

system supplier or a qualified steam fitter.

STEAM CONNECTIONS (Steam Drying Tumblers)

INSTALLING STEAM SOLENOID VALVE

AND MAKING STEAM INLET

CONNECTIONS

High pressure machines require a (constant) 80 to

100 psig (5.62 to 7.03 kg/sq. cm) steam service for

optimum operation. Low pressure machines require a

(constant) 10 to 15 psig (.70 to 1.05 kg/sq. cm) steam

service for optimum operation. The following steps

outline procedure for installing steam solenoid valve

and connecting steam service.

a. Install a manual shut-off gate valve in condensate

return line after steam trap for each coil.

b. Connect steam solenoid valve to related steam

coil inlet connection with nipples, flex hoses,

unions, tee and pressure relief valve. See

24

for a typical installation.

c. Install a gate shut-off valve in steam supply

line,

Figure 24.

outlet to solenoid steam valve inlet connection.

aWARNING

The flexible steam hoses connecting

the solenoid steam valve to the coil

inlets must have a 125 psig (pounds

per square inch gauge) (8.79 kg/sq.

cm) working pressure. A shut-off gate

valve must be installed upstream from

the solenoid steam valve. This way,

steam can be shut off for maintenance

purposes, or in the event the hose

ruptures.

The steam solenoid valve must be

supported so minimum load is exerted

on the steam coil inlet connections.

Connect shut-off gate valve

Figure

INSTALLING STEAM TRAP AND MAKING

CONDENSATE RETURN CONNECTIONS

Steam trap must be installed and coil outlet

connections must be connected to condensate return

lines. The following steps outline the procedure for

installing steam trap and connecting condensate

return lines. See

a. Connect a flexible hose to each steam coil outlet,

Figure 24.

b. Install a strainer to the ends of each flexible hose.

c. Install a steam trap to each strainer.

IMPORTANT: Steam trap must be installed a

minimum of 10 inches (25.4 cm) below steam coil

outlet connections, see

d. Install a gate shut-off valve to each steam trap.

e. Connect to condensate return lines.

aWARNING

The flexible steam hoses connecting

the coil outlet connections and steam

traps must have a minimum of 125

psig (pounds per square inch gauge)

(8.79 kg/sq. cm.) working pressure. A

shutoff gate valve must be installed

downstream from each steam trap so

the condensate return line can be

isolated in event a steam trap requires

maintenance.

Each steam trap must be supported so

minimum load is exerted on the coil

outlet connection.

Figure 24

for a typical installation.

Figure 24.

M412616

47

Page 50

STEAM CONNECTIONS (Steam Drying Tumblers)

NOTE: See Figure 25 for sizing

of steam lines. Piping must

also be sized accordingly for

length of runs, and number

of elbows.

SUPPLY

RETURN

UNION

30.5 cm (12")

RISERS

CHECK

VALVE

TRAP WITH

BUILT-IN

STRAINER

STEAM

BONNET

RELIEF

VALVE

SOLENOID

VALVE

(Supplied with

machine)

OPTIONAL

VACUUM

BREAKER

CONDENSATE

RETURN LINE

FROM

SUPPLY LINE

CHECK

VALVE

Figure 24

TUMBLER

MODEL

STEAM PRESSURE

(PSI)

MINIMUM

PIPE DIAMETER

STEAM TRAP SIZE

(Pounds Condensate/Hour)

30CSL 7-15 3/4" (1.9 cm) 140

GATE

VALVE

T262IE3A

30 CSH 80-100 3/4" (1.9 cm) 140

50 CSL 7-15 3/4" (1.9 cm) 140

50 CSH 80-100 3/4" (1.9 cm) 160

75 CSL 7-15 3/4" (1.9 cm) 140

75 CSH 80-100 3/4" (1.9 cm) 160

Figure 25

48

M412616

Page 51

LIGHTING AND SHUTTING DOWN

GAS IGNITION SYSTEM

1. Turn machine disconnect switch, located on rear

of tumbler, to the “on” position.

2. Turn gas shut-off valve, located on rear of

tumbler, to the “on” position (gas valve handle

should be parallel with gas line).

3. Start tumbler, following operating instructions

which accompanied it.

NOTE: Ignition control circuitry will verify airflow

switch, located on rear of tumbler, is open before

starting cylinder motor. Once cylinder motor is

started, air flowing through tumbler will cause

airflow switch to close. Tumbler will purge air

from tumbler for 18 seconds. Ignition will start by

a three second release of gas from gas valve and

sparking of ignitor. If ignition does not occur

during first three seconds ignition control will

“lockout” causing gas valve to close and a red

button on ignition control to illuminate.

To reset ignition system , open access door and

press red button on ignition control. Close and

lock access door, verify that gas shut-off valve is

in the “on” position and return to step three.

4. If tumbler will not start, remove it from service by

turning machine disconnect switch, located on

rear of tumbler, to the “off” position and turn the

gas shut-off valve, located on rear of tumbler, to

the “off” position (gas valve handle should be at a

right angle to gas line).

SPARK

IGNITER

TO GAS VALVE

GAS

VALVE

ELECTRONIC

IGNITION

POWER TO

IGNITION SYSTEM

T261IE3B

M412616

Figure 26

49

Page 52

ACCESSORY TIMING CAM INSTALLATION

T039IE1A

LINE UP NOTCH

TO CLEAR RATCHET

TOOTH

LIFT GENTLY

WITH NARROW

BLADE

(Coin Meter Models)

REMOVAL OF EXISTING TIMING CAM

No. of Pins in Cam

6

5

4

Cycle Length (Minutes)

10

12

15

Figure 27

1. Rotate cam by hand until "V" notch lines up

beneath the ratchet tooth see

2. Insert narrow screwdriver under nylon cam, close

to the clock shaft. Lift gently off shaft. Make sure

that pressure is directed upward and that the "V"

notch clears the ratchet tooth.

Figure 28.

Cams that allow other timer increments are available

through your distributor.

To figure time increments, use this formula: Timer

Motor Speed (60) divided by number of pins on

cam = Cycle Length (minutes). Cams are available

with 1 to 12 pins.

Example: 60 ÷ 5 (Pin cam) = 12 minute cycle.

INSTALLATION OF NEW TIMING CAM

1. Insert drive into timing cam with wide prong in

wide hole of cam.

2. Position timing cam and drive fork over the timer

shaft, aligning the timer flat with the drive fork and

the "V" notch with one of the ratchet teeth.

3. Press timing cam down firmly to seat timing cam

onto the motor shaft.

Figure 28

4. Remove all accumulated time by turning cam

counterclockwise until switch shuts off. Apply

moderate clockwise pressure to fully seated

timing cam and drive against the timing motor

shaft. Meter must be advanced electrically for one

cycle before an accurate measure of time can be

made.

50

M412616

Page 53

PRELIMINARY OPERATING CHECKS

1. Remove or open all panels and inspect accessible

bolts, nuts, screws, terminals and fittings for

security.

2. Check belt tension, adjust if necessary (refer to

Adjustment Section).

3. Energize electrical circuit to tumbler circuit

breaker and turn on tumbler disconnect switch.

4. Turn on gas supply at manual gas shut off valve in

gas supply line (gas models only). Handle of gas

shut off valve should be parallel with gas supply

line when in “ON” position.

5. Press and hold in Push-to-Start Button for

approximately three (3) seconds. Release button

and open cylinder door. Cylinder should stop