Page 1

Frontload Washers

3

NOTA: El manual en

español aparece después

del manual en inglés.

Installation

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

H370I

H

Part No. 801561R1

May 2004

Page 2

Page 3

Table of

Contents

Replacement Parts.............................................................................. 3

Installation........................................................................................... 5

Dimensions and Specifications............................................................. 5

Before You Start................................................................................... 6

Tools ................................................................................................ 6

Electrical .......................................................................................... 6

Water................................................................................................ 6

Accessories Bag............................................................................... 6

Installing the Washer............................................................................ 7

Step 1: Position Washer Near Installation Area .............................. 7

Step 2: Connect Water Inlet Hoses.................................................. 7

Step 3: Connect Drain Hose to Drain Receptacle............................ 8

Step 4: Position and Level the Washer ............................................ 10

Step 5: Remove the Shock Sleeves and Shipping Brace ................. 11

Step 6: Wipe Out Inside of Washer Drum....................................... 12

Step 7: Connect the Washer to Electrical Power ............................. 12

Step 8: Check Installation................................................................ 13

Moving Unit to a New Location...................................................... 13

Electrical Requirements........................................................................ 13

240 Volt, 50 Hertz............................................................................ 14

120 Volt, 60 Hertz with 3-Prong Grounding Plug........................... 14

Water Supply Requirements................................................................. 15

Water Temperature .......................................................................... 16

Water Pressure ................................................................................. 16

Risers................................................................................................ 16

Information for Handy Reference......................................................... 17

Installer Checklist................................................................ Back Cover

© Copyright 2004, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

801561

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Page 4

Notes

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801561

Page 5

Replacement Parts

If replacement parts are required, contact the source

from which you purchased your washer, or contact:

Alliance Laundry Systems

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

U.S.A.

Phone: (920) 748-3950

for the name and address of the nearest authorized

parts distributor.

801561

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Page 6

Notes

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801561

Page 7

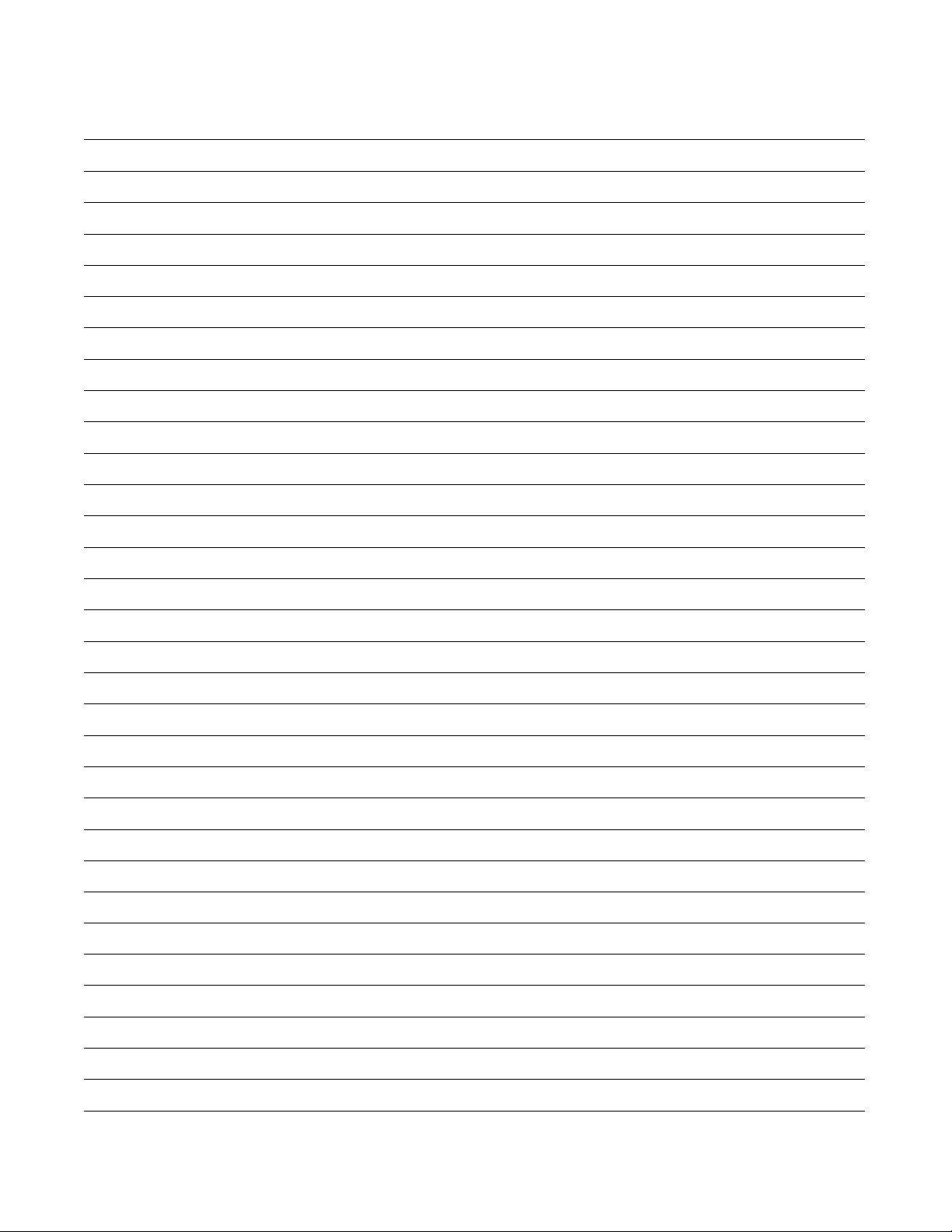

Installation

Dimensions and Specifications

44.8 cm

(17.5 in.)

37.9 cm

(14.9 in.)

109.2 cm (43 in.)

93 cm (36.6 in.)

79 cm (31.1 in.)

75.1 cm (29.6 in.)

71.1 cm

(28 in.)

5.1 cm (2 in.)

68.3 cm

(26.9 in.)

FLW2007N

FLW2007N

801561

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Page 8

Installation

1

2

3

4

5

Before You Start

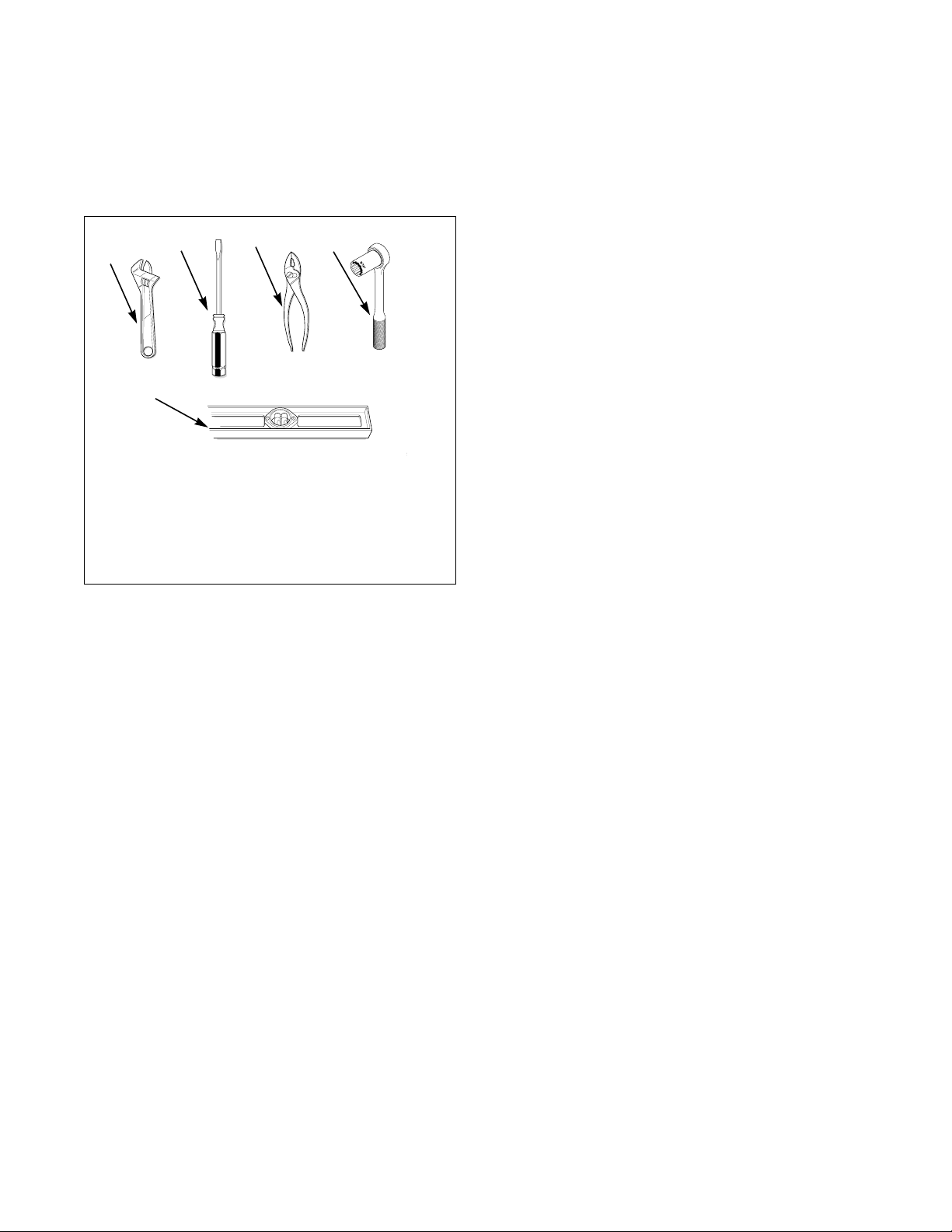

Tools

For most installations, the basic tools you will need

are:

D820I

1 Wrench

2 Screwdriver

3 Pliers

4 Socket Wrench

5 Level

Water

Washer needs two standard 19.1 mm (3/4 in.) water

supply faucets with a pressure between 138 and

827 kPa (20 to 120 pounds per square inch). For more

detailed information refer to section on Water Supply

Requirements.

Accessories Bag

An accessories bag has been shipped inside your

washer. It includes:

● Two inlet hoses with washers. Refer to step 2 of

Installation.

● Four rubber feet. Refer to step 4 of Installation.

● Beaded tie-down strap. Refer to step 3 of

Installation.

● Installation instructions.

● Operating instructions.

● Warranty bond.

● Bag for storing shipping materials.

Figure 1

Electrical

Refer to serial plate for specific electrical

requirements. For more detailed information refer to

section on Electrical Requirements.

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801561

Page 9

Installation

Installing the Washer

NOTE: If the washer is delivered on a cold day

(below freezing), or is stored in an unheated room

or area during the cold months, do not attempt to

operate it until the washer has had a chance to

warm up.

Step 1: Position Washer Near Installation

Area

IMPORTANT: Install dryer before washer. This

allows room for attaching exhaust duct.

Move washer as close to the desired area of

installation as possible.

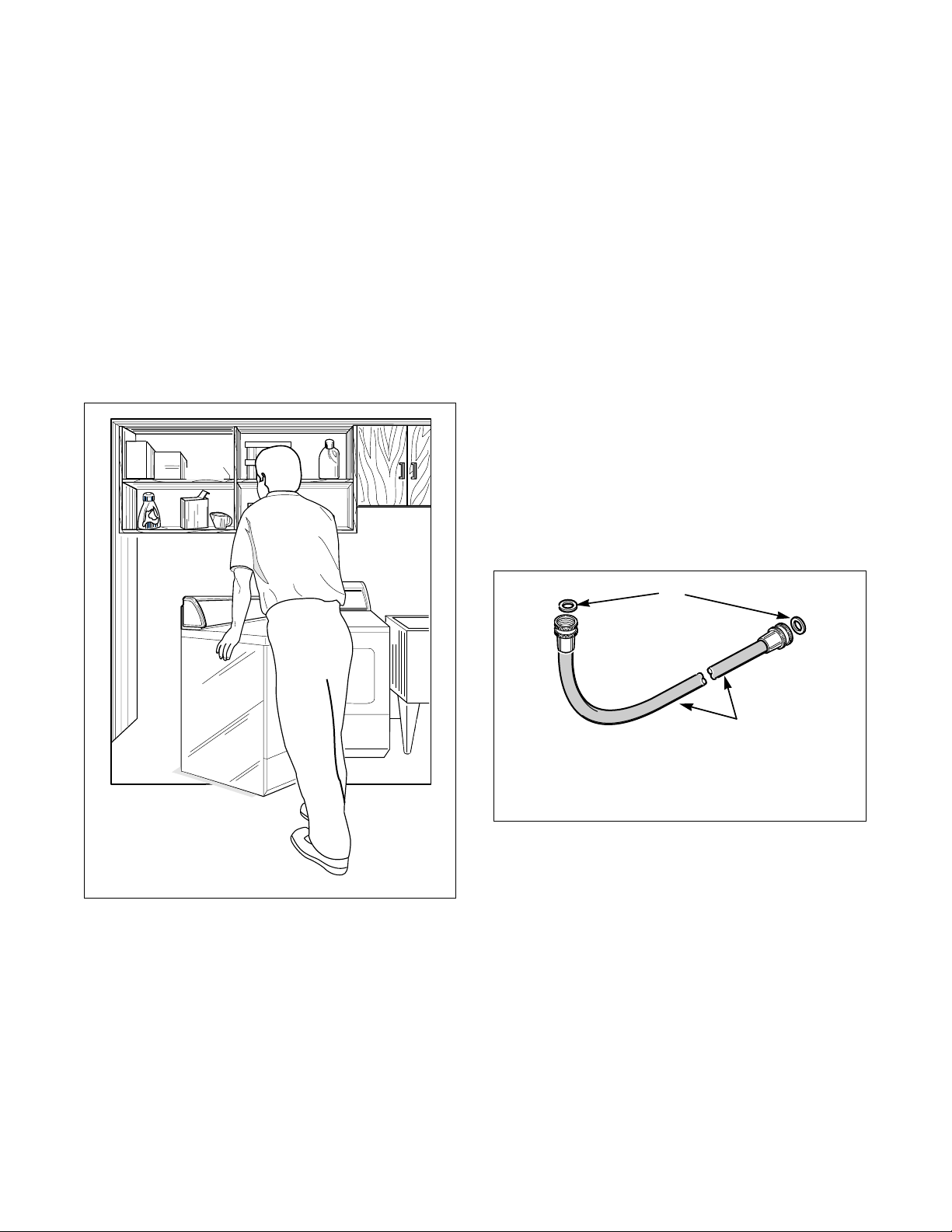

Step 2: Connect Water Inlet Hoses

NOTE: Refer to section on Water Supply

Requirements before connecting water inlet hoses.

Turn on the water supply faucets and flush the lines for

approximately two minutes to remove any foreign

materials that could clog the screens in the water

mixing valve.

NOTE: When installing in newly constructed or

renovated building, it is very important to flush the

lines since build-up may have occurred during

construction.

Remove the four plain rubber washers from accessories

bag, and install them according to Figure 3.

IMPORTANT: Thread hose couplings onto valve

connections finger-tight, then approximately

1/4 turn with pliers. DO NOT cross thread or

overtighten couplings.

Turn water on and check for leaks. If leaks are found,

retighten the hose couplings. Continue tightening and

rechecking until no leaks are found.

Figure 2

D772I

D772I

1

1 Rubber Washer (Plain)

2 Inlet Hose

Figure 3

2

H091I

H091I

801561

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Page 10

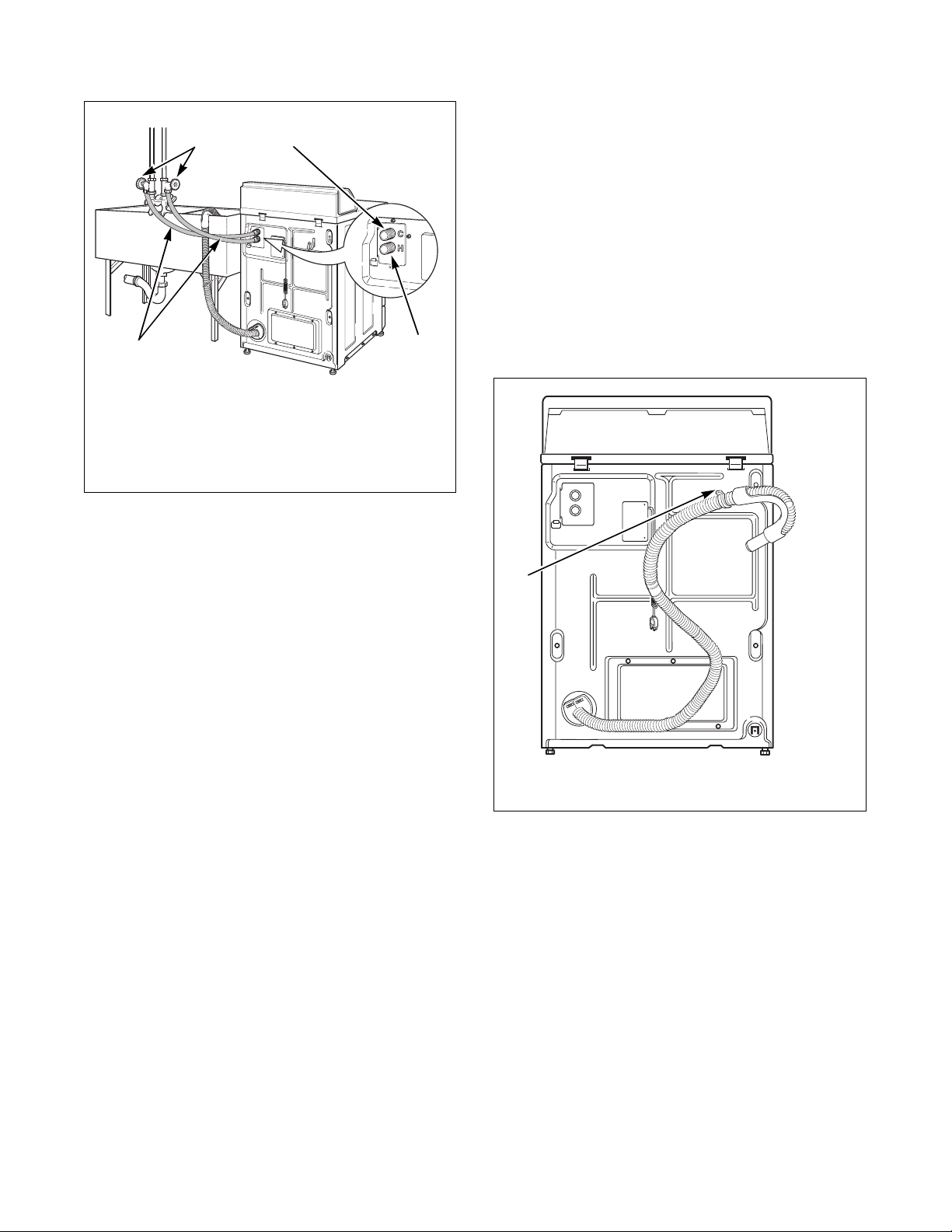

Installation

1

2

3

WATER

MIXING

VALVE

4

1 Water Supply Faucets

2 Cold Water Connection

3 Hot Water Connection

4 Water Inlet Hoses

Step 3: Connect Drain Hose to Drain

Receptacle

Remove the drain hose from its shipping position on

the rear of the washer by unhooking the hose from the

retainer clamp and by removing shipping tape.

Find the instructions, on the following pages, that are

appropriate for your type of drain receptacle

(standpipe, sink, wall, or laundry tub). Follow these

instructions to properly install the drain hose.

IMPORTANT: Drain receptacle must be capable of

handling a minimum of 3.2 cm (1-1/4 inch) outside

diameter drain hose.

FLW2008N

FLW2008N

Figure 4

IMPORTANT: Hoses and other natural rubber

parts deteriorate after extended use. Hoses may

develop cracks, blisters or material wear from the

temperature and constant high pressure they are

subjected to.

All hoses should be checked on a yearly basis for

any visible signs of deterioration. Any hose showing

the signs of deterioration listed above should be

replaced immediately. All hoses should be replaced

every five years.

1

FLW2009N

1 Retainer Clamp

Figure 5

Standpipe Installation

Place the drain hose into the standpipe.

Remove the beaded tie-down strap from accessories

bag and place around standpipe and drain hose and

tighten strap to hold hose to standpipe. This will

prevent the drain hose from dislodging from drain

receptacle during use.

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801561

Page 11

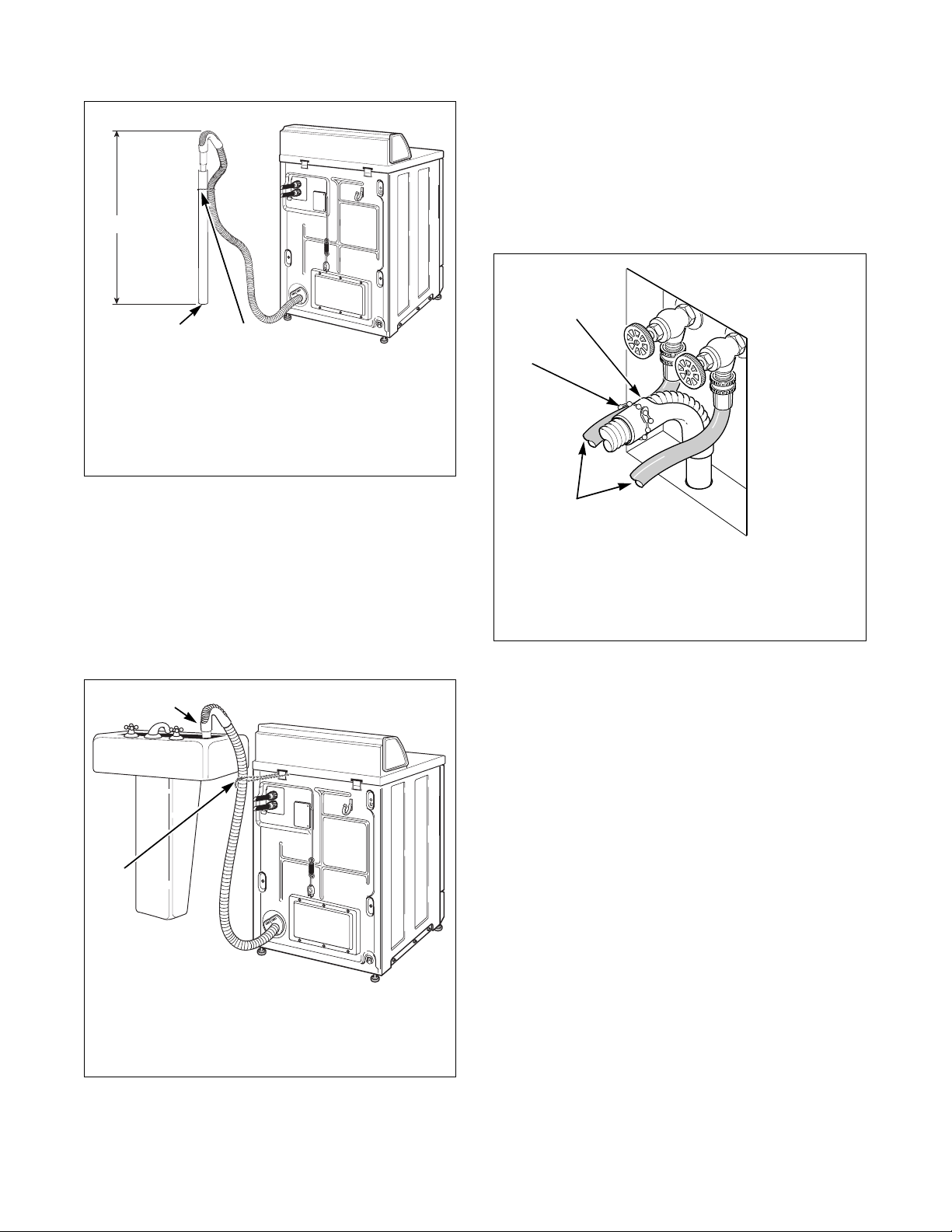

Installation

1

2

3

1

2

In-the-Wall Installation

For installations of this type, the drain hose MUST be

secured to one of the inlet hoses using the beaded tiedown strap from accessories bag.

NOTE: End of drain hose must not be below 61 cm

(24 in.).

1

FLW2010N

1 61 to 91.44 cm (24 to 36 in.) Recommended

Height

2 Standpipe – 5.08 cm (2 in.) or 4 cm

(1-1/2 in.)

3 Beaded Tie-Down Strap

Figure 6

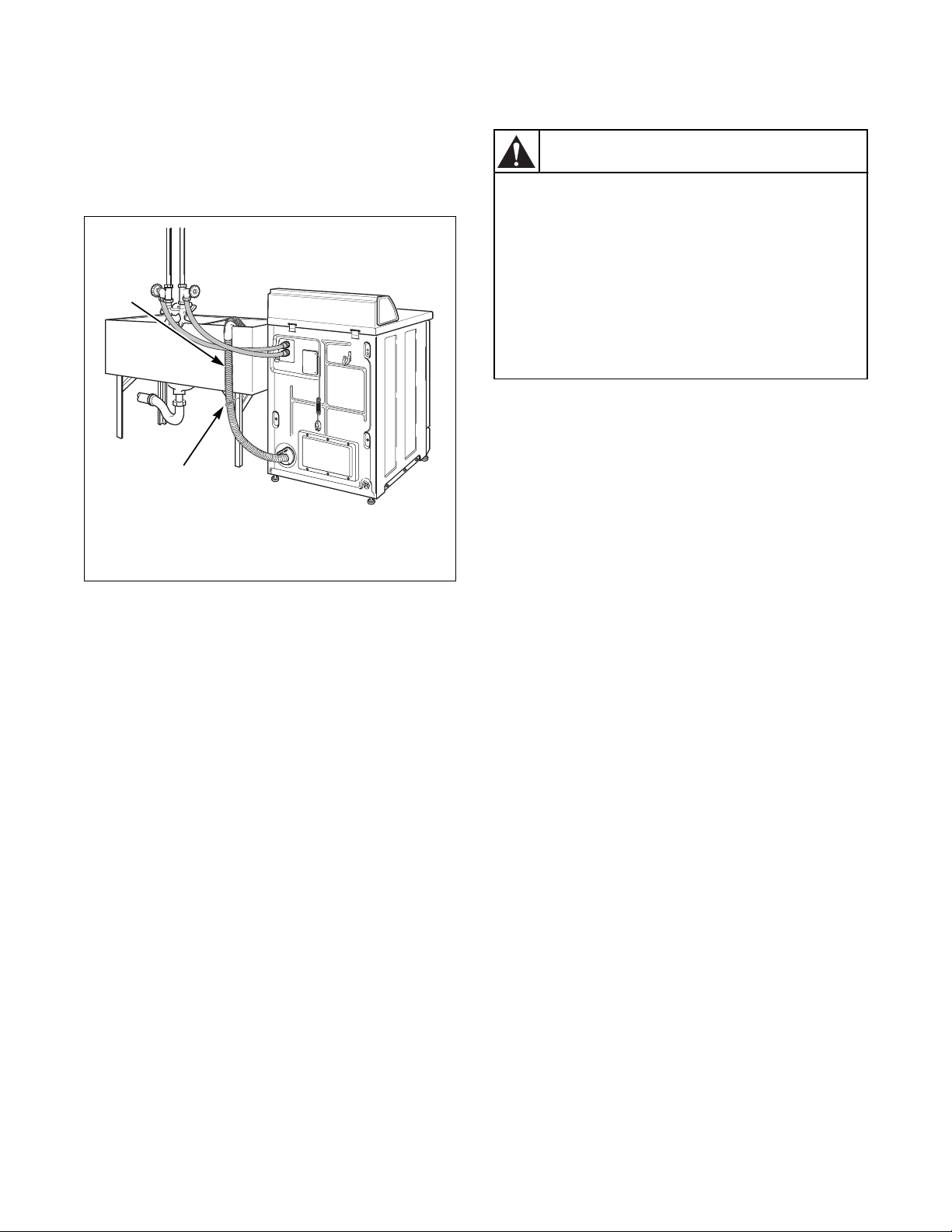

Sink Installation

For this type of installation, use the beaded tie-down

strap (supplied in accessories bag) or use a large wire

tie (available from your local hardware store), and

secure the drain hose to the cabinet top hinge (refer to

Figure 7). This will prevent the drain hose from

dislodging during use.

2

3

H023I

1 Drain Hose

2 Tie-Down Strap (Tape if necessary)

3 Inlet Hoses

Figure 8

FLW2011N

FLW2011N

1 Drain Hose

2 Tie-Down Strap (Wire tie or tape if

necessary)

Figure 7

801561

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Page 12

Installation

1

2

Laundry Tub Installation

For this type of installation, the drain hose MUST be

secured to the stationary tub to prevent hose from

dislodging during use. Use the beaded tie-down strap

(supplied in accessories bag) to secure hose.

FLW2012N

1 Drain Hose

2 Tie-Down Strap (Tape if necessary)

Step 4: Position and Level the Washer

WARNING

Washers elevated above floor level must be

anchored to that elevated surface, base or

platform. The material used to elevate the

washer should also be anchored to the floor

to ensure that the washer will not walk or

that the washer can not be physically

pulled, tipped or slid from its installed

position. Failure to do so may result in

conditions which can produce serious

injury, death and/or property damage.

W306

Place washer in position on a clean, firm and

reasonably level floor. Installing the washer on any

type of carpeting is not recommended.

Loosen 7/8 in. locknut and adjust the front and rear

leveling legs until the washer is level from side to side

and front to back (using a level). Washer should not

rock.

NOTE: Level must rest on raised portion of top

panel. Refer to Figure 10.

Figure 9

Tighten the locknuts securely against the washer

base using the 7/8 in. wrench. If the locknuts are not

tight, washer will move out of position during operation.

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801561

Page 13

Installation

1

4

5

2

3

NOTE: DO NOT slide washer across floor if the

leveling legs have been extended, as legs and base

could become damaged.

NOTE: Use of the dispenser drawer or washer door

as a handle in the transportation of the washer may

cause damage to the dispenser or door.

Remove rubber feet from accessories bag and place on

all four leveling legs.

Verify that unit does not rock.

Step 5: Remove the Shock Sleeves and

Shipping Brace

Remove front access panel by removing the two

screws.

Remove bolts and lockwashers from shipping brace

with 9/16 in. wrench and remove brace. Remove shock

sleeves by pulling on the yellow rope.

Remove label from front side of front access panel and

place on backside of front access panel.

NOTE: The shipping brace, bolts, lockwashers and

shock sleeves should be saved and MUST be

reinstalled whenever the unit is moved more than

four feet. Do not lift or transport unit from front or

without shipping materials installed.

Store the shipping materials in the bag provided in the

accessories bag. Save materials for use whenever the

unit is moved.

NOTE: The shipping materials MUST be reinstalled

whenever the unit is moved. Refer to Moving Unit

to a New Location section for proper instructions on

reinstalling the shipping materials.

Reinstall front access panel.

H381I

1 Leveling Leg

2 Washer Base

3 Level

4 Locknut

5 Rubber Foot

Figure 10

IMPORTANT: DO NOT tip washer more than

152.4 mm (6 inches) in any direction after shipping

brace has been removed. Shock absorbers may

separate and damage machine. For leveling

purposes, the washer may be tilted a maximum of

152.4 mm (6 inches) in any direction.

801561

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Page 14

Installation

4

3

1 Shock Sleeves

2 Motor Mount

3 Bolts and Lockwashers

4 Hooked End of Shipping Brace

Figure 11

1

2

H336I

Before using the washer for the first time, use an allpurpose cleaner, or a detergent and water solution, and

a damp cloth to remove shipping dust from inside the

drum.

H337I

Figure 12

Step 7: Connect the Washer to Electrical

Power

Refer to section on Electrical Requirements and connect

the washer to an electrical power source.

Step 6: Wipe Out Inside of Washer Drum

12

Figure 13

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

W504SE3B

801561

Page 15

Installation

Step 8: Check Installation

Refer to Installer Checklist on the back cover and

make sure that unit is installed correctly.

Moving Unit to a New Location

To prevent damage while moving the unit, the

shipping materials MUST BE reinstalled.

Reinstallation of Shipping Materials

Disconnect washer from electrical supply.

Remove front access panel by removing two screws.

Place the shock sleeves on all four shock absorbers.

Refer to Figure 14.

Insert hooked end of shipping brace into the open slot

of the motor mount. Attach with bolts and lockwashers.

Refer to Figure 14.

Reinstall front access panel.

1

Electrical Requirements

NOTE: The wiring diagram is located behind the

control panel, inside the control hood.

WARNING

To reduce the risk of fire, electric shock,

serious injury or death, all wiring and

earthing MUST abide with local electrical

codes. It is the customer’s responsibility to

have the wiring and fuses checked by a

qualified electrician to make sure the

laundry room has adequate electrical power

to operate the washer.

W246

DO NOT OVERLOAD

CIRCUITS

DO NOT USE AN

ADAPTER

DO NOT USE AN

EXTENSION CORD

2

4

3

1 Shock Sleeves

2 Motor Mount

3 Bolts and Lockwashers

4 Hooked End of Shipping Brace

Figure 14

Refer to step 5 for proper procedures whenever the

unit is moved.

D009I

Figure 15

NOTE: Refer to the washer nameplate for proper

voltage and Hertz the washer is designed to operate

on. Refer to Figure 16.

1

H336I

801561

1 Nameplate

Figure 16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

H129P

13

Page 16

Installation

To reduce the risk of an electric shock or

fire, DO NOT use an extension cord or an

adapter to connect the washer to the

electric power source.

W082

WARNING

WARNING

Improper connection of the equipmentearthing conductor can result in a risk of

electric shock. Check with a qualified

electrician or service person if you are in

doubt as to whether the washer is properly

earthed.

W032

240 Volt, 50 Hertz

The washer is designed to be operated on a separate

branch, polarized, three-wire, effectively earthed,

240 Volt, 50 Hertz, AC (alternating current) circuit

protected by a 10 Ampere fuse, equivalent fusetron or

circuit breaker.

Earthing Instructions

The washer must be earthed. In the event of

malfunction or breakdown, earthing will reduce the

risk of electric shock by providing a path of least

resistance for electric current. The washer is equipped

with a cord having an equipment-earthing conductor.

The washer must be plugged or hardwired into an

appropriate power source that is properly installed and

earthed in accordance with all local codes and

ordinances.

120 Volt, 60 Hertz with 3-Prong Grounding

Plug

The washer is designed to be operated on a separate

branch, polarized, three-wire, effectively earthed, 120

Volt, 60 Hertz, AC (alternating current) circuit

protected by a 15 Ampere fuse, equivalent fusetron or

circuit breaker.

The three-prong earthed plug on the power cord

should be plugged directly into a polarized three-slot

effectively earthed receptacle rated 110/120 Volts AC

(alternating current) 15 Amps. Refer to Figure 17 to

determine correct polarity of the wall receptacle.

Earthing Instructions

The washer must be earthed. In the event of

malfunction or breakdown, earthing will reduce the

risk of electric shock by providing a path of least

resistance for electric current. The washer is equipped

with a cord having an equipment-earthing conductor

and a 3-prong earthing plug. The plug must be plugged

into an appropriate outlet that is properly installed and

earthed in accordance with all local codes and

ordinances.

WARNING

NOTE: Have a qualified electrician check the

polarity of the power source.

DO NOT OPERATE OTHER APPLIANCES ON

THE SAME CIRCUIT. DO NOT OVERLOAD

CIRCUITS!

Do not operate both a washer and gas dryer on the

same circuit. Use separately fused 10 Amp circuits.

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Improper connection of the equipmentearthing conductor can result in a risk of

electric shock. Check with a qualified

electrician or service person if you are in

doubt as to whether the washer is properly

earthed.

W032

DO NOT modify the plug provided with the washer –

if it will not fit the outlet, have a proper outlet installed

by a qualified electrician.

NOTE: Have a qualified electrician check the

polarity of the wall receptacle. If a voltage reading

is measured other than that illustrated, the

qualified electrician should correct the problem.

WARNING

This unit is equipped with a three-prong

(earthing) plug for your protection against

shock hazard and should be plugged

directly into a properly earthed three-prong

receptacle. Do not cut or remove the

earthing prong from this plug.

W477

801561

Page 17

1 L1

1

2

3

4

5

120 ± 12

V.A.C.

120 ± 12

V.A.C.

0

V.A.C.

STANDARD 120 VOLT, 60 HERTZ, 3-WIRE

EFFECTIVELY GROUNDED CIRCUIT

WARNING

To reduce the risk of electric shock or fire,

DO NOT use an extension cord or an

adapter to connect the washer to the

electrical power source.

W031

2 Ground

3 Neutral Side

4 Round Grounding Prong

5 Neutral

Installation

Water Supply Requirements

WARNING

Under certain conditions, hydrogen gas may

be produced in a hot water system that has

not been used for two weeks or more.

HYDROGEN GAS IS EXPLOSIVE. If the hot

water system has not been used for such a

period and before using the washer, turn on

all hot water faucets and let the water flow

from each for several minutes. This will

release any accumulated hydrogen gas. The

gas is flammable. Do not smoke or use an

open flame during this time.

W029

NOTE: Water supply faucets must fit standard

19.1 mm (3/4 in.) female garden hose couplings.

DO NOT USE SLIP-ON OR CLAMP-ON

CONNECTIONS.

NOTE: Water supply faucets should be readily

accessible to permit turning them off when washer

is not being used.

D799I

Figure 17

DO NOT OPERATE OTHER APPLIANCES ON

THE SAME CIRCUIT. DO NOT OVERLOAD

CIRCUITS!

Do not operate both a washer and gas dryer on the

same circuit. Use separately fused 15 Amp circuits.

801561

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

Page 18

Installation

1

2

3

WATER

MIXING

VALVE

4

Water Temperature

Cold:

Recommended cold water temperature is 16° to

27° Celsius (60° to 80° Fahrenheit).

Hot:

Recommended hot water temperature is 49° to

60° Celsius (120° to 140° Fahrenheit).

Warm:

Mixture of hot and cold water (warm water

temperature is dependent upon the water temperature

and the pressure of both the hot and cold water supply

lines).

IMPORTANT: Turn off water supply faucets after

check-out and demonstration. Owner should turn

off water supply whenever there will be an

extended period of non-use.

NOTE: Longer inlet hoses are available (as

optional equipment at extra cost) if the hoses

(supplied with the washer) are not long enough for

the installation. Order hoses as follows:

Water Pressure

Pressure must be a minimum of 138 to a maximum of

827 kPa (20 to 120 pounds per square inch) static

pressure measured at the faucet.

NOTE: Water pressure under 138 kPa (20 pounds

per square inch) will cause an extended fill time in

the washer and may not properly flush out the

detergent dispenser.

Risers

Risers (or air cushions) may have to be installed if the

pipes knock or pound when flow of water stops. The

risers are more efficient when installed as close as

possible to the water supply faucets (refer to Figure 19).

2

1

No. 20617 Inlet Hose (2.44 m) (8 ft.)

No. 20618 Inlet Hose (3.05 m) (10 ft.)

1 Water Supply Faucets

2 Cold Water Connection

3 Hot Water Connection

4 Water Inlet Hoses

Figure 18

W005I

W005I

1 Water Supply Faucets

2 Risers (Air Cushions)

Figure 19

FLW2008N

FLW2008N

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801561

Page 19

Installation

Information for Handy Reference

Alliance Laundry Systems

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

U.S.A.

Date Purchased

Model Number Serial Number

Dealer’s Name

Dealer’s Address Phone Number

Service Agency

Service Agency Address Phone Number

NOTE: Record the above information and keep your sales slip. Model and serial numbers are located on

the nameplate.

801561

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Page 20

Page 21

Lavadoras con

7

carga frontal

Instalación

H370I

H3

Guarde estas instrucciones para referencia en el futuro.

(Si la lavadora cambia de dueño, asegúrese de que vaya acompañada de estas instrucciones).

www.comlaundry.com

Pieza No. 801561R1

Mayo 2004

Page 22

Page 23

Tabla de

contenido

Piezas de repuesto............................................................................... 23

Instalación ........................................................................................... 25

Especificaciones y dimensiones ........................................................... 25

Antes de comenzar................................................................................ 26

Herramientas.................................................................................... 26

Suministro eléctrico ......................................................................... 26

Agua................................................................................................. 26

Bolsa de accesorios.......................................................................... 26

Instalación de la lavadora ..................................................................... 27

Paso 1: Colocación de la lavadora cerca del área de instalación ..... 27

Paso 2: Conexión de las mangueras de suministro de agua............. 27

Paso 3: Conexión de la manguera de desagüe al receptáculo

de desagüe ...................................................................................... 28

Paso 4: Coloque la lavadora en su lugar y nivélela ......................... 30

Paso 5: Saque los manguitos de amortiguador y el

tirante sujetador.............................................................................. 31

Paso 6: Limpie el interior del tambor de la lavadora....................... 32

Paso 7: Conecte la lavadora a la corriente eléctrica......................... 32

Paso 8: Revise la instalación............................................................ 33

Desplazamiento de la unidad a un nuevo sitio................................. 33

Requisitos eléctricos............................................................................. 33

240 voltios, 50 Hertzios................................................................... 35

120 voltios, 60 hertz con enchufe de conexión a tierra de

3 clavijas......................................................................................... 35

Requisitos de suministro de agua ......................................................... 36

Temperatura del agua....................................................................... 37

Presión del agua ............................................................................... 37

Tubos ascendentes ........................................................................... 37

Información de referencia..................................................................... 38

Lista de comprobación del instalador............................. Contraportada

© Copyright 2004, Alliance Laundry Systems LLC

Reservados todos los derechos. Ninguna sección del presente manual puede ser reproducida o transmitida en forma

alguna o a través de ningún medio sin el expreso consentimiento por escrito del editor.

801561 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

21

Page 24

Notas

22

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801561 (SP)

Page 25

Piezas de repuesto

Si se necesitan piezas de repuesto comuníquese con el

vendedor o con:

Alliance Laundry Systems

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

U.S.A.

Tel éfono: (920) 748-3950

para obtener el nombre y la dirección del distribuidor

autorizado de piezas de repuesto más cercano.

801561 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

23

Page 26

Notas

24

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801561 (SP)

Page 27

Instalación

Especificaciones y dimensiones

44,8 cm

(17,5 plg)

93 cm (36,6 plg)

109,2 cm (43 plg)

37,9 cm

(14,9 plg)

71,1 cm

(28 plg)

79 cm (31,1 plg)

5,1 cm (2 plg)

75,1 cm (29,6 plg)

68,3 cm

(26,9 plg)

FLW2007N

FLW2007N

801561 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

25

Page 28

Instalación

1

2

3

4

5

Antes de comenzar

Herramientas

Éstas son las principales herramientas que necesitará

en la mayoría de las instalaciones:

D820I

1 Llave de tuercas

2 Destornilladores

3 Pinzas

4 Llave de cubo

5 Nivel

Agua

La lavadora trabaja con dos grifos estándar de

19,1 mm (3/4 plg) para el suministro de agua con una

presión que oscile entre 138 y 827 kPa (20 a 120 libras

por pulgada cuadrada). Para obtener más detalles,

consulte la sección de Requisitos de suministro de

agua.

Bolsa de accesorios

Se incluye una bolsa de accesorios dentro de la

lavadora que contiene lo siguiente:

● Dos mangueras de suministro con arandelas.

Consulte el paso 2 de la sección Instalación.

● Cuatro patas de goma. Consulte el paso 4 de la

sección Instalación.

● Abrazadera perlada. Consulte el paso 3 de la

sección Instalación.

● Instrucciones de instalación.

● Instrucciones de operación.

● Certificado de garantía.

● Bolsa para guardar los materiales de transporte.

Figura 1

Suministro eléctrico

Consulte la placa de número de serie para determinar

los requisitos eléctricos específicos. Para obtener más

detalles, consulte la sección de Requisitos eléctricos.

26

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801561 (SP)

Page 29

Instalación

Instalación de la lavadora

NOTA: Si la lavadora se entrega en un día

extremadamente frío (temperatura por debajo del

nivel de congelamiento) o se coloca en un área o

salón sin calefacción durante los meses fríos, no

trate de poner a funcionar la lavadora antes de que

se caliente.

Paso 1: Colocación de la lavadora cerca

del área de instalación

IMPORTANTE: Instale la secadora antes de

instalar la lavadora. Así tendrá espacio para

acoplar el ducto de escape.

Coloque la lavadora los más cerca del área de instalación.

Paso 2: Conexión de las mangueras de

suministro de agua

NOTA: Consulte la sección de Requisitos de

suministro de agua antes de conectar las mangueras

de suministro de agua.

Abra los grifos de suministro de agua y limpie las

tuberías dejando que el agua fluya por

aproximadamente dos minutos para eliminar cualquier

material extraño que pueda obstruir las mallas de la

válvula para mezclar el agua.

NOTA: Cuando instale la lavadora en una vivienda

recién construida o remodelada es muy importante

que limpie las tuberías dejando que el agua fluya,

ya que pudo haberse acumulado material en las

mismas durante la construcción.

Saque las cuatro arandelas de goma planas de la bolsa

de accesorios e instálelas como se indica en la Figura 3.

IMPORTANTE: Enrosque a mano las uniones en

las conexiones de válvula y seguidamente gire

aproximadamente un 1/4 de vuelta con la ayuda de

una tenaza. Tenga cuidado de NO apretar

excesivamente las uniones ni pasarlas de rosca.

Abra el grifo de agua y determine si hay fugas. Si

detecta alguna fuga, reajuste las uniones de la manguera.

Siga apretando y revise hasta eliminar las fugas.

Figura 2

D772I

1

2

H091I

1 Arandela de goma (sencilla)

2 Manguera de suministro de agua

D772I

Figura 3

801561 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

27

Page 30

Instalación

1

2

3

4

VÁLVULA

PARA

MEZCLAR

EL AGUA

1 Grifos de suministro de agua

2 Conexión de agua fria

3 Conexión de agua caliente

4 Mangueras de suministro de agua

Figura 4

FLW2008N

FLW2008N

Paso 3: Conexión de la manguera de

desagüe al receptáculo de desagüe

Saque la manguera del lugar de embarque en la parte

trasera de la lavadora, desenganchando la manguera de

la abrazadera de fijación y retirando la cinta de

embarque.

Busque en las páginas siguientes las instrucciones que

se adapten a su tipo de receptáculo de desagüe (tubo

vertical de desagüe, lavamanos, pared o batea). Siga

las instrucciones para una instalación apropiada de la

manguera de desagüe.

IMPORTANTE: El receptáculo de desagüe debe

ser el apropiado para una manguera de desagüe

con un diámetro exterior de 3,2 cm (1-1/4 plg) como

mínimo.

IMPORTANTE: Las mangueras y otras piezas de

goma natural se deterioran después de períodos

prolongados de uso. En las mangueras pueden

producirse grietas, poros o desgaste del material

debido a la temperatura y a la elevada presión

constante a que están sometidas.

Todas las mangueras deben revisarse cada año

para detectar posibles indicios de deterioro.

Cualquier manguera que muestre alguno de los

indicios de deterioro indicados anteriormente

deberá ser reemplazada. Todas las mangueras

deberán reemplazarse cada cinco años.

1

FLW2009N

1 Arbrazadera de fijación

Figura 5

Instalación del tubo vertical de desagüe

Coloque el adaptador dentro del tubo vertical de

desagüe.

Saque la abrazadera perlada de la bolsa de accesorios,

colóquela alrededor del tubo vertical de desagüe y la

manguera de desagüe, y apriete la correa para sujetar

la manguera al tubo vertical de desagüe. Así se evita

que se salga la manguera del receptáculo de desagüe

cuando se esté utilizando.

28

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801561 (SP)

Page 31

Instalación

1

2

3

1

2

Instalación en la pared

En este tipo de instalación, la manguera de desagüe

DEBERÁ asegurarse a una de las mangueras de

suministro de agua utilizando la abrazadera perlada

que viene en la bolsa de accesorios.

NOTA: El extremo de la manguera de desagüe no

debe quedar a una altura meno que 61 cm (24 plg).

FLW2010N

1 61 a 91,44 cm (24 a 36 plg) altura

recomendada

2 Tubo vertical de desagüe – 5,08 cm (2 plg) ó

4 cm (1-1/2 plg)

3 Abrazadera perlada

Figura 6

Instalación a un lavamanos

Para este tipo de instalación utilice la abrazadera

perlada (que viene en la bolsa de accesorios) o una

abrazadera grande para cable (que puede adquirir en

una tienda de herramientas local) y fije la manguera

de desagüe a la bisagra de la parte superior del

gabinete (consulte la Figura 7). Así se evita que la

manguera de desagüe se salga cuando se esté

utilizando.

1

2

3

H023I

1 Manguera de desagüe

2 Abrazadera (utilice cinta aisladora si es

necessario)

3 Mangueras de suministro

Figura 8

FLW2011N

FLW2011N

1 Manguera de desagüe

2 Abrazadera (utilice abrazadera para cable ò

cinta aisladora si es necessario)

801561 (SP)

Figura 7

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

29

Page 32

Instalación

1

2

Instalación a una batea

En este tipo de instalación, la manguera de desagüe

DEBERÁ asegurarse a la batea fija, para evitar que la

manguera se salga cuando se esté utilizando. Use la

abrazadera perlada (que viene en la bolsa de

accesorios) para fijar la manguera.

FLW2012N

1 Manguera de desagüe

2 Abrazadera (use cinta aisladora si es

necesario)

Figura 9

Paso 4: Coloque la lavadora en su lugar y

nivélela

ADVERTENCIA

Las lavadoras elevadas sobre el nivel del

piso deberán fijarse mediante pernos de

anclaje a la superficie elevada, base o

plataforma. El material usado para elevar la

lavadora deberá estar también anclado al

piso para impedir que la lavadora se

desplace de su lugar al funcionar, y para

evitar que pueda ser empujada, inclinada o

deslizada de su posición de instalación. De

no hacerlo, pueden presentarse

condiciones peligrosas que podrian

ocasionar daños a la propiedad o lesiones

graves e incluso fatales.

W306S

Coloque la lavadora en su posición sobre un piso

limpio, firme y suficientemente nivelado. No es

recomendable instalar la lavadora sobre alfombras de

ningún tipo.

Afloje las tuercas de seguridad de 7/8 plg y ajuste las

patas de nivelación frontales y posteriores hasta que la

lavadora quede nivelada, no solo en sentido lateral

sino también de atrás hacia adelante (use un nivel para

este procedimiento). La lavadora no debe cojear.

NOTA: El nivel deberá colocarse sobre la posición

elevada del panel superior. Consulte la Figura 10.

Apriete las tuercas de seguridad firmemente contra

la base de la lavadora con una llave de 7/8 plg. Si las

tuercas de seguridad no se aprietan debidamente, la

lavadora se moverá de su posición al funcionar.

30

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801561 (SP)

Page 33

Instalación

1

4

5

2

3

NOTA: NO deslice la lavadora sobre el piso con las

patas niveladoras extendidas ya que podrían

resultar dañadas.

NOTA: El uso de la gaveta del surtidor o de la

compuerta de la lavadora como agarradera al

transportar la lavadora puede dañar el surtidor o

la compuerta.

Saque las patas de goma que vienen en la bolsa de

accesorios y colóquelas en las patas de nivelación.

Verifique que la unidad no oscile.

Paso 5: Saque los manguitos de

amortiguador y el tirante sujetador

Desmonte el panel de acceso frontal sacando los dos

tornillos.

Saque los pernos y arandelas de seguridad del tirante

sujetador con una llave de tuercas de 9/16 plg y saque

el tirante sujetador. Desmonte los manguitos de

amortiguador tirando de la cuerda amarilla.

Quite la etiqueta de la parte lateral delantera del panel

de acceso frontal y colóquela en la parte posterior de

dicho panel.

NOTA: El tirante sujetador, así como los pernos,

arandelas de seguridad y manguitos de amortiguador

deben conservarse y VOLVER A INSTALARSE si

fuera necesario desplazar la lavadora una distancia

mayor de 1,2 metros (4 pies). No levante o transporte

la lavadora por el frente o sin haber instalado

previamente los materiales de transporte.

Guarde los materiales de transporte en la bolsa

provista dentro de la bolsa de accesorios. Conserve los

materiales para usarlos cuando haya que desplazar la

lavadora.

NOTA: Los materiales de transporte DEBERÁN

reinstalarse al mover la unidad de un lugar a otro.

Las instrucciones para reinstalar estos materiales

H381I

1 Pata de nivelción

2 Base de arandela

3 Nivel

4 Contratuerca

5 Pata de goma

se encuentran en la sección Desplazamiento de la

unidad a un nuevo sitio.

Vuelva a instalar el panel de acceso delantero.

IMPORTANTE: NO incline la lavadora más de

152,4 mm (6 pulgadas) en ninguna dirección una

vez que la abrazadera de envío haya sido retirada.

Figura 10

Los amortiguadores podrían separarse y dañar la

máquina. Para nivelación, la lavadora puede

inclinarse un máximo de 152,4 mm (6 pulgadas) en

cualquier dirección.

801561 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

31

Page 34

Instalación

4

3

1 Manguitos de amortiguador

2 Montaje del motor

3 Pernos y arandelas de seguridad

4 Extremo en forma de gancho

del tirante sujetador

Figura 11

1

Paso 6: Limpie el interior del tambor de la

lavadora

Antes de utilizar la lavadora por primera vez, aplique

un limpiador para todo uso o una solución de agua y

detergente con un paño húmedo a fin de eliminar el

polvo que pueda haber caído en el tambor durante el

transporte.

2

H336I

H337I

Figura 12

Paso 7: Conecte la lavadora a la corriente

eléctrica

Consulte la sección Requisitos eléctricos y conecte la

lavadora a una toma de corriente.

W504SE3B

Figura 13

32

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801561 (SP)

Page 35

Instalación

Paso 8: Revise la instalación

Consulte la Lista de comprobación del instalador que

aparece en la contraportada y asegúrese de que la

unidad esté correctamente instalada.

Desplazamiento de la unidad a un nuevo

sitio

Para prevenir daños durante el desplazamiento de la

unidad, DEBERÁ volver a instalar los materiales de

transporte.

Reinstalación de los materiales de transporte

Desconecte la lavadora de la corriente eléctrica.

Saque el panel de acceso frontal retirando dos

tornillos.

Coloque los manguitos de amortiguador sobre los

cuatro amortiguadores. Consulte la Figura 14.

Inserte el lado en forma de gancho del tirante sujetador

de embarque dentro de la ranura del montaje del

motor. Asegure con pernos y arandelas de seguridad.

Consulte la Figura 14.

Reinstale el panel de acceso frontal.

1

Requisitos eléctricos

NOTA: El diagrama de cableado se encuentra

detrás del panel de control, dentro de la campana

de control.

ADVERTENCIA

Para disminuir el riesgo de incendios,

electrocución, lesiones personales de

gravedad o mortales, todas las conexiones

incluida la puesta a tierra DEBERÁN

atenerse a los códigos eléctricos locales. El

cliente tiene la responsabilidad de que un

electricista cualificado compruebe las

conexiones y fusibles para asegurarse de

que la sala en que se instale la lavadora

disponga de corriente eléctrica adecuada

para el funcionamiento de la misma.

W246S

NO SOBRECARGUE

LOS CIRCUITOS

NO UTILICE

ADAPTADOR

NO UTILICE

CORDÓN DE

EXTENSIÓN

2

4

3

H336I

1 Manguitos de amortiguador

2 Montaje del motor

3 Pernos y arandelas de seguridad

4 Extremo en forma de gancho

del tirante sujetador

Figura 14

Para consultar los procedimientos adecuados al

momento de desplazar la unidad, consulte el paso 5.

D009I

Figura 15

801561 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

33

Page 36

Instalación

NOTE: Consulte la placa de identificación de la

lavadora para comprobar el voltaje y los hertzios

apropiados para los que se haya diseñado el

funcionamiento de la lavadora. Consulte la

Figura 16.

1

1 Placa de identificación

Figura 16

H129P

34

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801561 (SP)

Page 37

Instalación

Para reducir el riesgo de descargas

eléctricas o incendio, NO utilice un

adaptador o cordón de extensión para

conectar la lavadora a la fuente de

suministro de energía eléctrica.

W082SA

ADVERTENCIA

ADVERTENCIA

La conexión indebida del conductor de

tierra del equipo puede representar en un

peligro de descarga eléctrica. Consulte a

un técnico de mantenimiento o electricista

calificado si no está seguro de que su

lavadora está bien conectada a tierra.

W032SA

240 voltios, 50 Hertzios

La lavadora está diseñada para funcionar al ser

conectada en una ramal independiente, polarizada, de

tres conductores, con conexión a tierra, de 240 Voltios,

50 Hertzios, circuito de corriente alterna (CA),

protegido por un fusible de 10 amperios, un fusetrón

(fusible de acción lenta) o un interruptor de circuito.

Instrucciones para la conexión a tierra

La lavadora debe conectarse a tierra. La conexión a

tierra reduce los riesgos de descarga eléctrica en el caso

de mal funcionamiento o averías eléctricas, creando una

ruta de menor resistencia para la corriente eléctrica. La

lavadora tiene un cordón con un conductor de tierra

del equipo. La lavadora deberá conectarse

directamente a un tomacorriente debidamente

instalado y conectado a tierra según los códigos y

ordenanzas locales.

120 voltios, 60 hertz con enchufe de

conexión a tierra de 3 clavijas

La lavadora está diseñada para funcionar al ser

conectada en una ramal independiente, polarizada, de

tres conductores, con conexión a tierra, de 120 Voltios,

60 Hertzios, circuito de corriente alterna (CA),

protegido por un fusible de 15 amperios, un fusetrón

(fusible de acción lenta) o un interruptor de circuito.

La clavija de conexión a tierra de tres patillas en el

cable de corriente debe ser conectada directamente en

un tomacorriente con conexión a tierra de tres ranuras

de 110/120 Voltios de CA (corriente alterna) de

15 amperios. Consulte la Figura 17 para determinar la

polaridad correcta del receptáculos de la pared.

Instrucciones para la conexión a tierra

La lavadora debe conectarse a tierra. La conexión a

tierra reduce los riesgos de descarga eléctrica en el caso

de mal funcionamiento o averías eléctricas, creando una

ruta de menor resistencia para la corriente eléctrica. La

lavadora tiene un cordón con un conductor de tierra

del equipo y un enchufe de tierra de tres terminales.

Dicho enchufe debe conectarse directamente a un

receptáculo apropiado que esté debidamente instalado y

conectado a tierra, de conformidad con las normas y

ordenanzas locales.

NOTA: Llame a un electricista calificado para que

revise la polaridad del tomacorriente.

NO USE OTROS APARATOS ELECTRODOMÉSTICOS EN EL MISMO CIRCUITO.

¡NO SOBRECARGUE LOS CIRCUITOS!

No haga funcionar la lavadora y la secadora

simultáneamente si están conectadas al mismo

circuito. Utilice circuitos separados de 10 amperios

protegidos con fusibles.

801561 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

ADVERTENCIA

La conexión indebida del conductor de

tierra del equipo puede representar en un

peligro de descarga eléctrica. Consulte a

un técnico de mantenimiento o electricista

calificado si no está seguro de que su

lavadora está bien conectada a tierra.

W032SA

NO REALICE modificaciones en el enchufe que trae

la lavadora – Si el mismo no entra en el receptáculo,

contrate los servicios de un electricista calificado para

que le instale el receptáculo de pared apropiado.

NOTA: Llame a un electricista calificado para que

revise la polaridad del receptáculo de pared. Si la

lectura del voltaje difiere de la que aparece en la

ilustración, el electricista debe solucionar el

problema.

35

Page 38

Instalación

Esta unidad está equipada con un enchufe

de tres terminales (con conexión a tierra)

para su protección contra peligros de

descargas eléctricas y deberá estar

enchufada directamente a una toma de

corriente para tres clavijas y con conexión

a tierra. No corte ni elimine la clavija de

conexión a tierra de este enchufe.

W477S

ADVERTENCIA

1

3

4

2

120 ± 12

V.C.A.

0

V.C.A.

120 + 12

V.C.A.

CIRCUITO ESTÁNDAR DE TRES CONDUCTORES

DE 120 VOLTIOS, 60 HERTZIOS DEBIDAMENTE

CONECTADO A TIERRA

5

ADVERTENCIA

Para reducir el riesgo de descargas

eléctricas o incendio, NO utilice un

adaptador o cordón de extensión para

conectar la secadora a la fuente de energía

eléctrica.

W031S

Requisitos de suministro de agua

ADVERTENCIA

En ciertos casos, puede acumularse gas

hidrógeno en el sistema de agua caliente si

el agua no ha sido utilizada durante dos

semanas o más. EL HIDRÓGENO ES UN

GAS EXPLOSIVO. Si no se ha utilizado el

sistema de agua caliente durante este lapso

de tiempo, antes de usar la lavadora abra

los grifos de agua caliente y deje que el

agua fluya durante varios minutos. De esta

manera se liberará el gas hidrógeno

acumulado. Este gas es inflamable. No fume

ni use una llama abierta durante este

procedimiento.

W029SC

1 Ter mi nal “L1”

2 Tierra

3 Terminal neutro

4 Terminal redondo de tierra

5 Lado neutro

NO USE OTROS APARATOS ELECTRO-

Figura 17

DOMÉSTICOS EN EL MISMO CIRCUITO.

¡NO SOBRECARGUE LOS CIRCUITOS!

No haga funcionar la lavadora y la secadora

simultáneamente si están conectadas al mismo

circuito. Utilice circuitos separados de 15 amperios

protegidos con fusibles.

36

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

D799I

NOTA: Los grifos de suministro de agua deben

entrar en uniones hembra estándar de 19,1 mm

(3/4 plg) para mangueras de jardín. NO USE

CONEXIONES DE GANCHO O DE

DESLIZAMIENTO.

NOTA: Debe tenerse un fácil acceso a los grifos de

suministro de agua para poder cerrarlos cuando no

se esté utilizando la lavadora.

801561 (SP)

Page 39

Instalación

1

2

3

4

VÁLVULA

PARA

MEZCLAR

EL AGUA

Temperatura del agua

Fría:

Se recomienda una temperatura para el agua fría entre

16° y 27° centígrados (60° y 80° Fahrenheit).

Caliente:

Se recomienda una temperatura para el agua caliente

entre 49° y 60° centígrados (120° y 140° Fahrenheit).

Tibia:

Es una mezcla de agua caliente y agua fría. (La

temperatura del agua tibia depende de la temperatura

del agua y de la presión de las tuberías de agua

caliente y agua fría).

IMPORTANTE: Cierre los grifos de suministro de

agua después de la revisión y demostración. El

dueño de la unidad debe cerrar los grifos de

suministro de agua siempre que no vaya a utilizarla

por un período de tiempo prolongado.

NOTA: Pueden adquirirse mangueras de

suministro de agua más largas (como equipo

opcional con un costo adicional), si las mangueras

(que vienen con la lavadora) no son lo

suficientemente largas para la instalación. Pida sus

mangueras de la manera siguiente:

Presión del agua

La presión estática del agua medida en el grifo deberá

estar entre 138 kPa la mínima y 827 kPa la máxima

(20 a 120 libras por pulgada cuadrada).

NOTA: Una presión del agua menor a las 138 kPa

(20 libras por pulgada cuadrada) causa un

aumento del tiempo de llenado de la lavadora y es

posible que no accione adecuadamente el surtidor

de detergente.

Tubos ascendentes

Quizá sea necesario instalar tubos ascendentes (o

cojines de aire), si entra aire en los tubos y los mismos

emiten un golpeteo cuando cesa el suministro de agua.

Los tubos ascendentes son más eficaces cuando se

instalan lo más cerca posible de los grifos de

suministro de agua (consulte la Figura 19).

2

1

Manguera de suministro No. 20617 (2,44 m) (8 pies)

Manguera de suministro No. 20618 (3,05 m) (10 pies)

FLW2008N

FLW2008N

1 Grifos de suministro de agua

2 Conexión de agua fría

3 Conexión de agua caliente

4 Mangueras de suministro de agua

Figura 18

W005I

1 Grifos de suministro de agua

2 Tubos ascendentes (cojines de aire)

Figura 19

801561 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

37

Page 40

Instalación

Información de referencia

Alliance Laundry Systems

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

U.S.A.

Fecha de compra

Número de modelo Número de serie

Nombre del distribuidor

Dirección del distribuidor Teléfono

Agencia de servicio

Dirección de la agencia de servicio Teléfono

NOTA: Registre la información anterior y guarde su recibo de compra. Los números de modelo y de serie

aparecen en la placa

.

38

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801561 (SP)

Page 41

Page 42

Installer Checklist

H091IE0A

FLW2010N

Fast Track for Installing the Washer

(Refer to the manual for more detailed information)

Lista de comprobación del instalador

Guía rápida para instalar la lavadora

(Consulte el manual para obtener una información más detallada)

➊

• Position Washer Near

Installation Area.

• Colocación de la

lavadora cerca del

área de instalación.

CHECK/

REALIZADO

• Connect Water Inlet Hoses.

➋

• Conexión de las mangueras de

suministro de

agua.

CHECK/

REALIZADO

• Connect Drain Hose

➌

to Drain Receptacle.

• Conexión de la

manguera de

desagüe al

receptáculo de

desagüe.

D772I

D772I

W004I

FLW2010N

➎

• Remove the

Shipping Brace and

Shock Sleeves.

• Saque los

manguitos de

amortiguador y el

tirante sujetador.

CHECK/

REALIZADO

• Wipe Out Inside

➏

➐

of Wash Drum.

• Limpie el interior

del tambor de la

lavadora.

CHECK/

REALIZADO

• Connect the Washer to

Electrical Power.

• Conecte la lavadora a la

corriente eléctrica.

H336I

H337I

H337I

W504SE3B

W504SE3B

➍

• Position and

• Coloque la

CHECK/

REALIZADO

Level the

Washer.

lavadora en su

lugar y nivélela.

CHECK/

REALIZADO

CHECK/

REALIZADO

H381I

Loading...

Loading...