Page 1

Installation Instructions

for Frontload Washers

Inside ......................................

Washer Dimensions ........................................................... 2

Before You Start ................................................................ 2

Installation ......................................................................... 3

Installer Checklist .............................................. Back Cover

Date Purchased

Model Number

Serial Number

REMARQUE : Le guide est r_dig_ en anglais et en fran_ais. La version fran_aise figure A la

suite de la version anglaise.

Keep these instructions for future reference.

(If this machine changes ownership, this manual must accompany machine.)

liance

Laundry Systems www.comlaundry.com

Part No. 802754R3

May 2011

Page 2

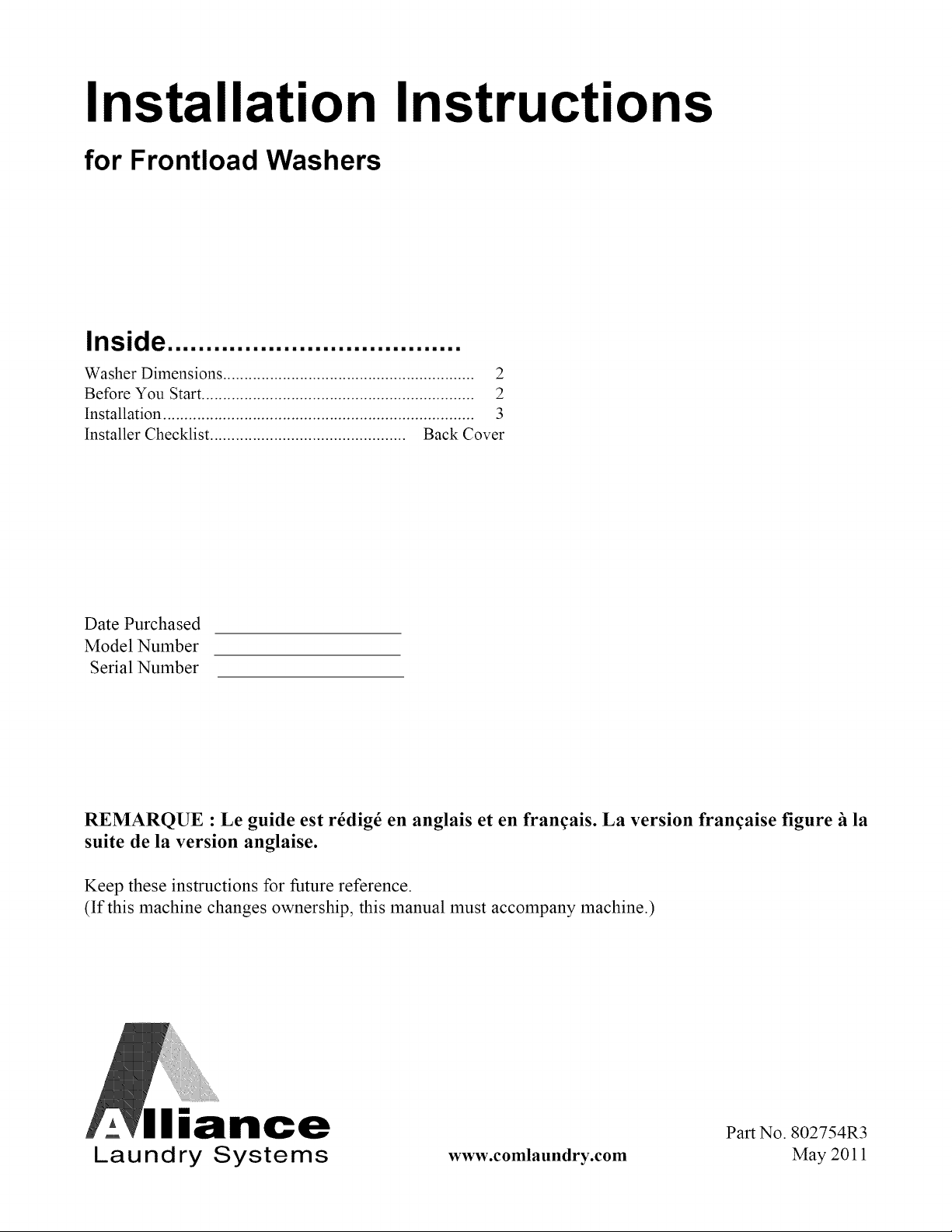

Washer Dimensions

61 cm

3.8 cm (1.5 in.)

.....................................................................................................................................,_

1

A

E

_ L

!

cm

5.1 cm (2 ir .)

FLW2222N

Figure 1

Before You Start

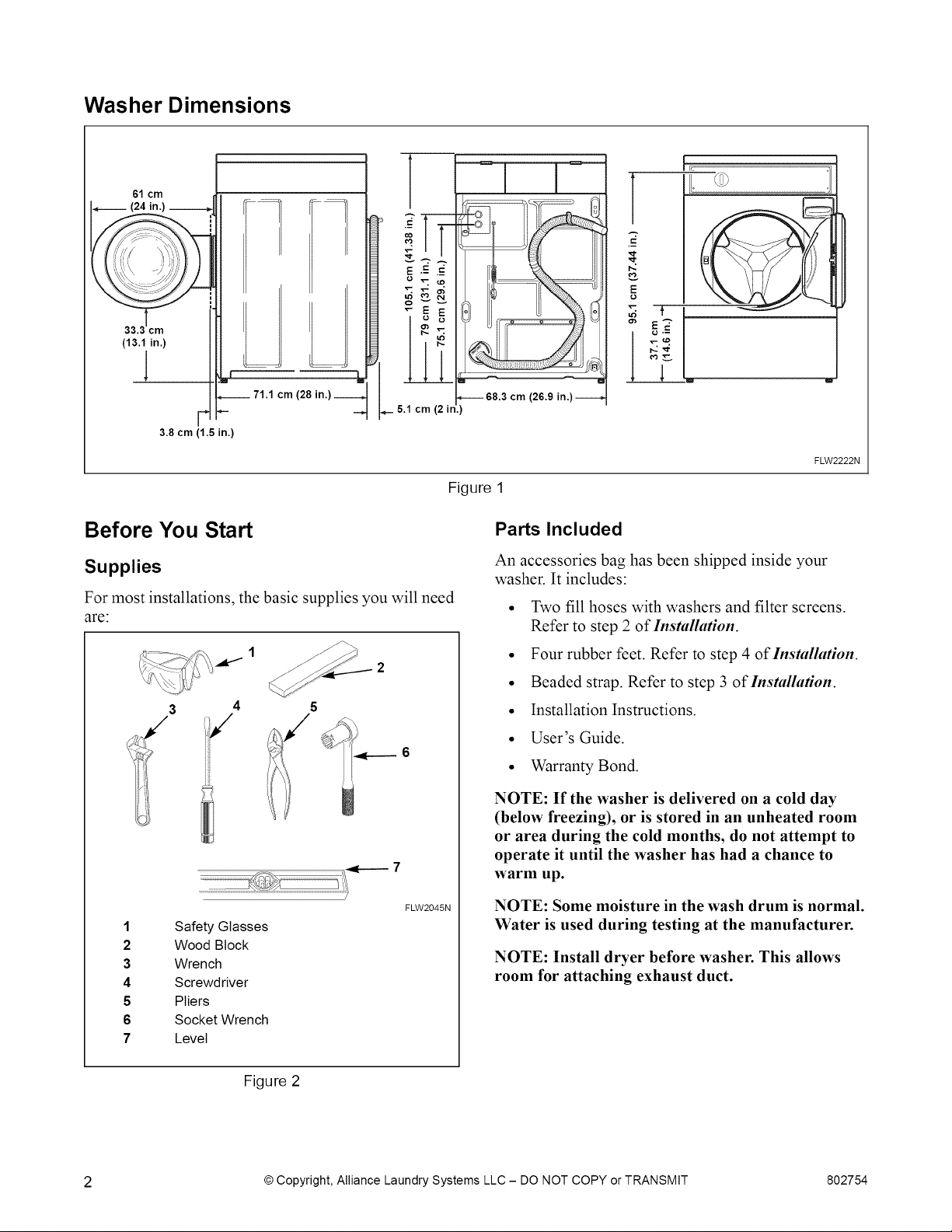

Supplies

For most installations, the basic supplies you will need

are:

2

5

FLW2045N

1

2

3

4

5

6

7

Safety Glasses

Wood Block

Wrench

Screwdriver

Pliers

Socket Wrench

Level

Parts Included

An accessories bag has been shipped inside your

washer. It includes:

• Two fill hoses with washers and filter screens.

Refer to step 2 of Installation.

• Four rubber feet. Refer to step 4 of Installation.

• Beaded strap. Refer to step 3 of Installation.

• Installation Instructions.

• User's Guide.

• Warranty Bond.

NOTE: If the washer is delivered on a cold day

(below freezing), or is stored in an unheated room

or area during the cold months, do not attempt to

operate it until the washer has had a chance to

warm up.

NOTE: Some moisture in the wash drum is normal.

Water is used during testing at the manufacturer.

NOTE: Install dryer before washer. This allows

room for attaching exhaust duct.

Figure 2

2 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 802754

Page 3

Installation

Step 1: Position Washer Near Installation

Area

Move washer as close to the desired area of

installation as possible.

NOTE: For best performance and to minimize

vibration or movement, install washer on a solid,

sturdy and level floor. Some floors may need to be

reinforced, especially on a second floor or over a

basement. Do not install the washer on carpeting,

soft tile, a platform or other weakly supported

structures.

Step 2: Position and Level the Washer

WARNING

Washers elevated above floor level must

be anchored to that elevated surface,

base or platform. The material used to

elevate the washer should also be

anchored to the floor to ensure that the

washer will not walk or that the washer

can not be physically pulled, tipped or

slid from its installed position. Failure to

do so may result in conditions which can

produce serious injury, death and/or

property damage.

W306

Position washer so it has sufficient clearance for

installation and servicing.

NOTE: Use of the dispenser drawer or washer door

as a handle in the transportation of the washer may

cause damage to the dispenser or door.

Make sure that the washer does not rock. When

washer is level and does not rock, tighten locknuts

securely against bottom of washer base. If these

locknuts are not tight, washer will move out of

position during operation.

Do not slide washer across floor once the leveling legs

have been extended. Legs and base could become

damaged.

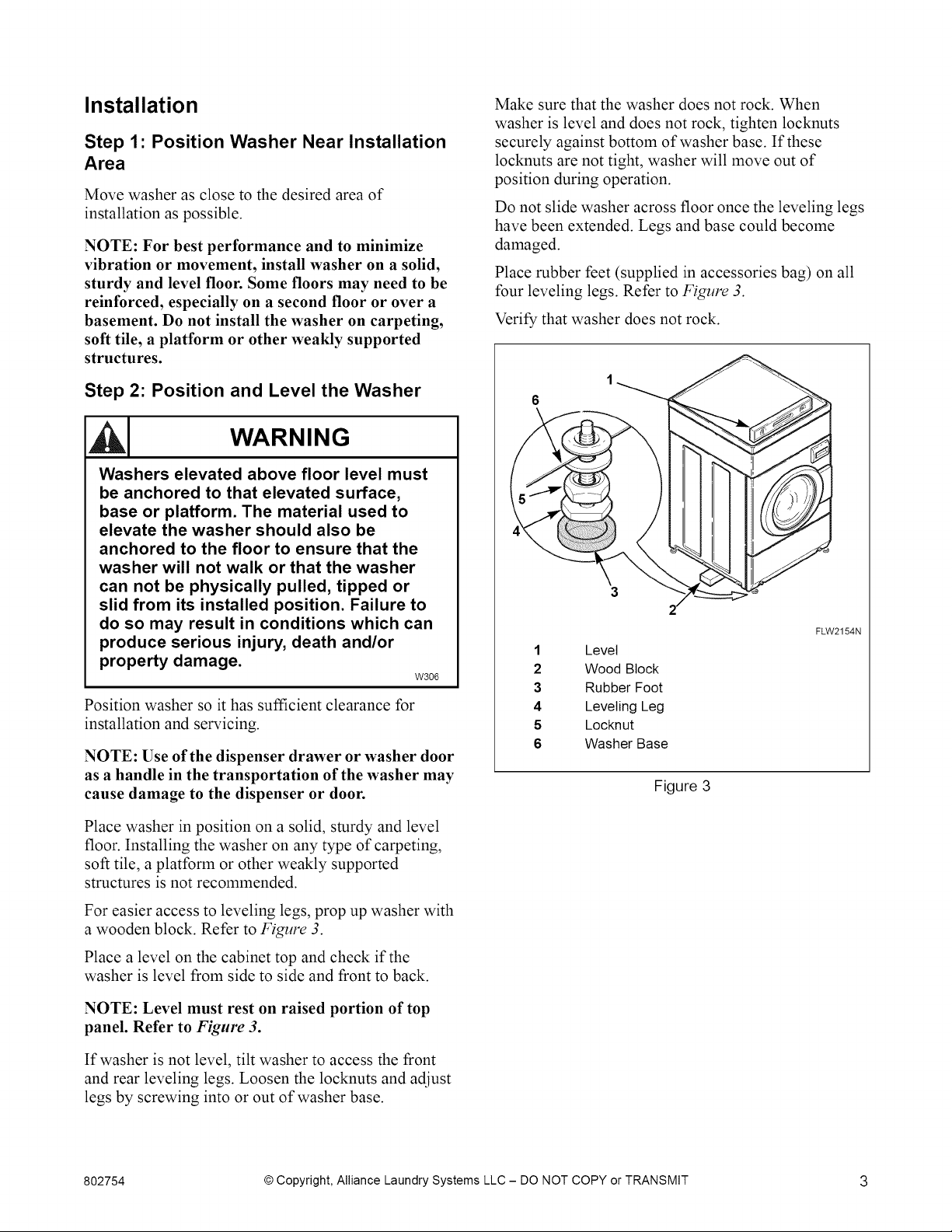

Place rubber feet (supplied in accessories bag) on all

four leveling legs. Refer to Figure 3.

Verify that washer does not rock.

1

6

FLW2154N

1

2

3

4

5

6

Level

Wood Block

Rubber Foot

Leveling Leg

Locknut

Washer Base

Figure 3

Place washer in position on a solid, sturdy and level

floor. Installing the washer on any type of carpeting,

soft tile, a platform or other weakly supported

structures is not recommended.

For easier access to leveling legs, prop up washer with

a wooden block. Refer to Figure 3.

Place a level on the cabinet top and check if the

washer is level from side to side and front to back.

NOTE: Level must rest on raised portion of top

panel. Refer to Figure 3.

If washer is not level, tilt washer to access the front

and rear leveling legs. Loosen the locknuts and adjust

legs by screwing into or out of washer base.

802754 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 3

Page 4

Step 3: Connect Fill Hoses

WARNING

NOTE: When installing in newly constructed or

renovated buildings, it is very important to flush

the lines since build-up may have occurred during

construction.

Under certain conditions, hydrogen gas

may be produced in a hot water system

that has not been used for two weeks or

more. HYDROGEN GAS IS EXPLOSIVE. If

the hot water system has not been used

for such a period and before using the

washer, turn on all hot water faucets and

let the water flow from each for several

minutes. This will release any

accumulated hydrogen gas. The gas is

flammable. Do not smoke or use an open

flame during this time.

Water Supply

Water supply faucets must fit standard 19.1 mm

(3/4 inch) female garden hose couplings. DO NOT

USE SLIP-ON OR CLAMP-ON CON_ECTIONS.

Water supply faucets should be readily accessible to

permit turning them off when washer is not being

used.

Recommended cold water temperature is 16° to 27 °

Celsius (60 ° to 80° Fahrenheit). Recommended

maximum hot water temperature is 51 ° Celsius

(125 ° Fahrenheit). Warm water is a mixture of hot and

cold water. Warm water temperature is dependent

upon water temperature and pressure of both the hot

and cold water supply lines.

W029

WARNING

Connecting Hoses

Remove the two plain rubber washers and two filter

screens from the accessories bag. Install them into

each end of the fill hoses as shown in Figure 4. The

screen must be facing outward.

Screw hose couplings with the filter screens onto the

water faucets until they are finger-tight. Then, using a

pliers, screw approximately 1/4 turn.

Screw hose couplings from other end of hoses onto the

water mixing valve until they are finger-tight. Then,

using a pliers, screw approximately 1/4 turn. Refer to

Figure 5.

IMPORTANT: Do not cross thread or overtighten

couplings. This will cause them to leak.

Turn water on and check for leaks. If leaks are found,

turn off the water, unscrew hoses and reinstall them

until there are no leaks.

IMPORTANT: Turn off water supply whenever

there will be an extended period of non-use.

NOTE: Longer fill hoses are available (as optional

equipment at extra cost) if the hoses supplied with

the washer are not long enough for the installation.

Order hoses as follows:

No. 20617 Fill Hose 2.44 m (8 feet)

No. 20618 Fill Hose 3.05 m (10 feet)

To prevent personal injury, avoid contact

with inlet water temperatures higher than

51 ° Celsius (125 ° Fahrenheit) and hot

surfaces.

W750

Water pressure must be a minimum of 138 to a

maximum of 827 kPa (20 to 120 psi) static pressure

measured at the faucet.

NOTE: Water pressure under 138 kPa (20 psi) will

cause an extended fill time in the washer and may

not properly flush out the detergent dispenser.

Turn on the water faucets and flush the lines for

approximately two minutes to remove any foreign

material that could clog the screens in the water

mixing valve.

4 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 802754

Page 5

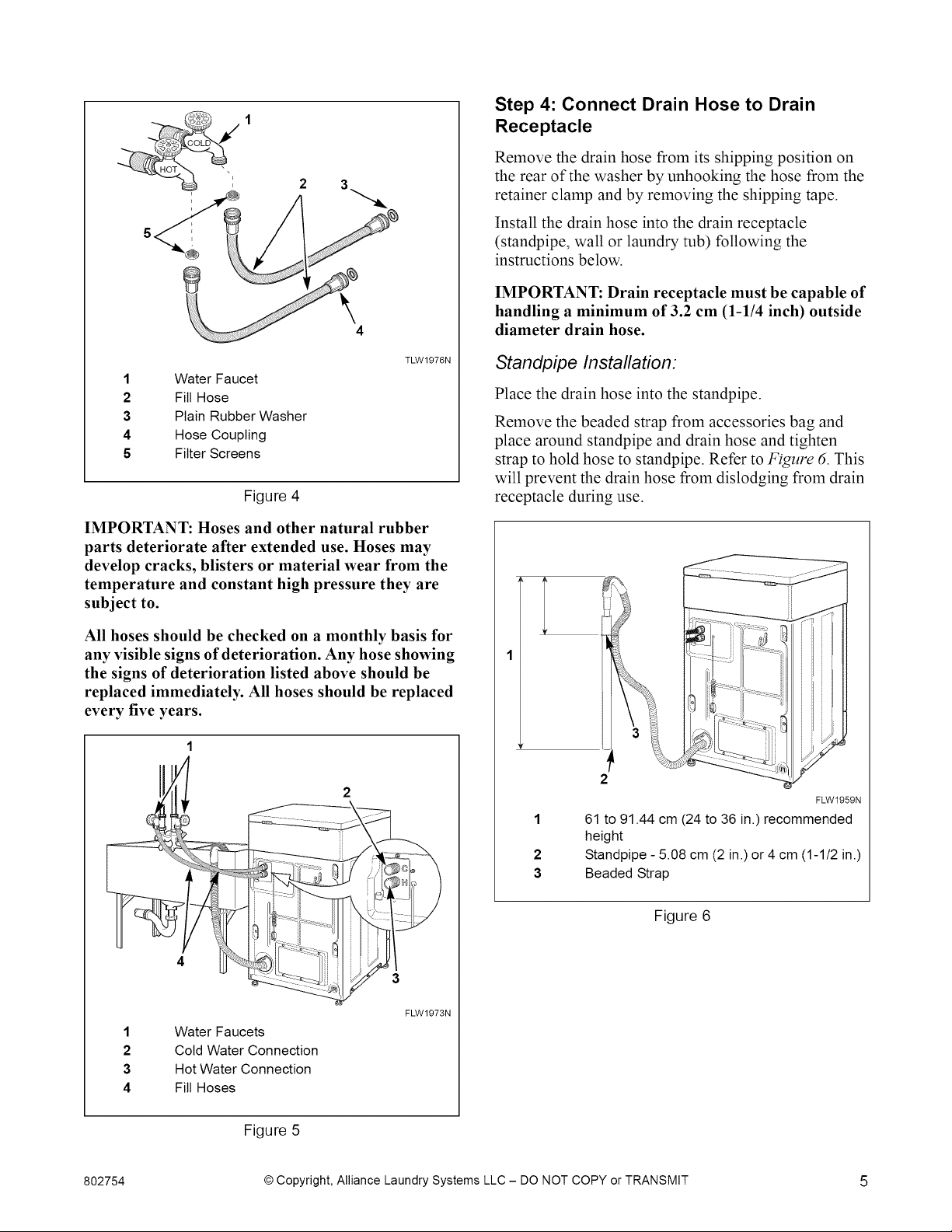

Step 4: Connect Drain Hose to Drain

Receptacle

Remove the drain hose from its shipping position on

the rear of the washer by unhooking the hose from the

retainer clamp and by removing the shipping tape.

Install the drain hose into the drain receptacle

(standpipe, wall or laundry tub) following the

instructions below.

IMPORTANT: Drain receptacle must be capable of

handling a minimum of 3.2 cm (1-1/4 inch) outside

diameter drain hose.

TLW1976N

1

2

3

4

5

Water Faucet

Fill Hose

Plain Rubber Washer

Hose Coupling

Filter Screens

Figure 4

IMPORTANT: Hoses and other natural rubber

parts deteriorate after extended use. Hoses may

develop cracks, blisters or material wear from the

temperature and constant high pressure they are

subject to.

All hoses should be checked on a monthly basis for

any visible signs of deterioration. Any hose showing

the signs of deterioration listed above should be

replaced immediately. All hoses should be replaced

every five years.

2

Standpipe Installation:

Place the drain hose into the standpipe.

Remove the beaded strap from accessories bag and

place around standpipe and drain hose and tighten

strap to hold hose to standpipe. Refer to Figz_re 6. This

will prevent the drain hose from dislodging from drain

receptacle during use.

1

2

FLW1959N

1

2

3

61 to 91.44 cm (24 to 36 in.) recommended

height

Standpipe - 5.08 cm (2 in.) or 4 cm (1-1/2 in.)

Beaded Strap

Figure 6

3

FLW1973N

1

2

3

4

Water Faucets

Cold Water Connection

Hot Water Connection

Fill Hoses

Figure 5

802754 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 5

Page 6

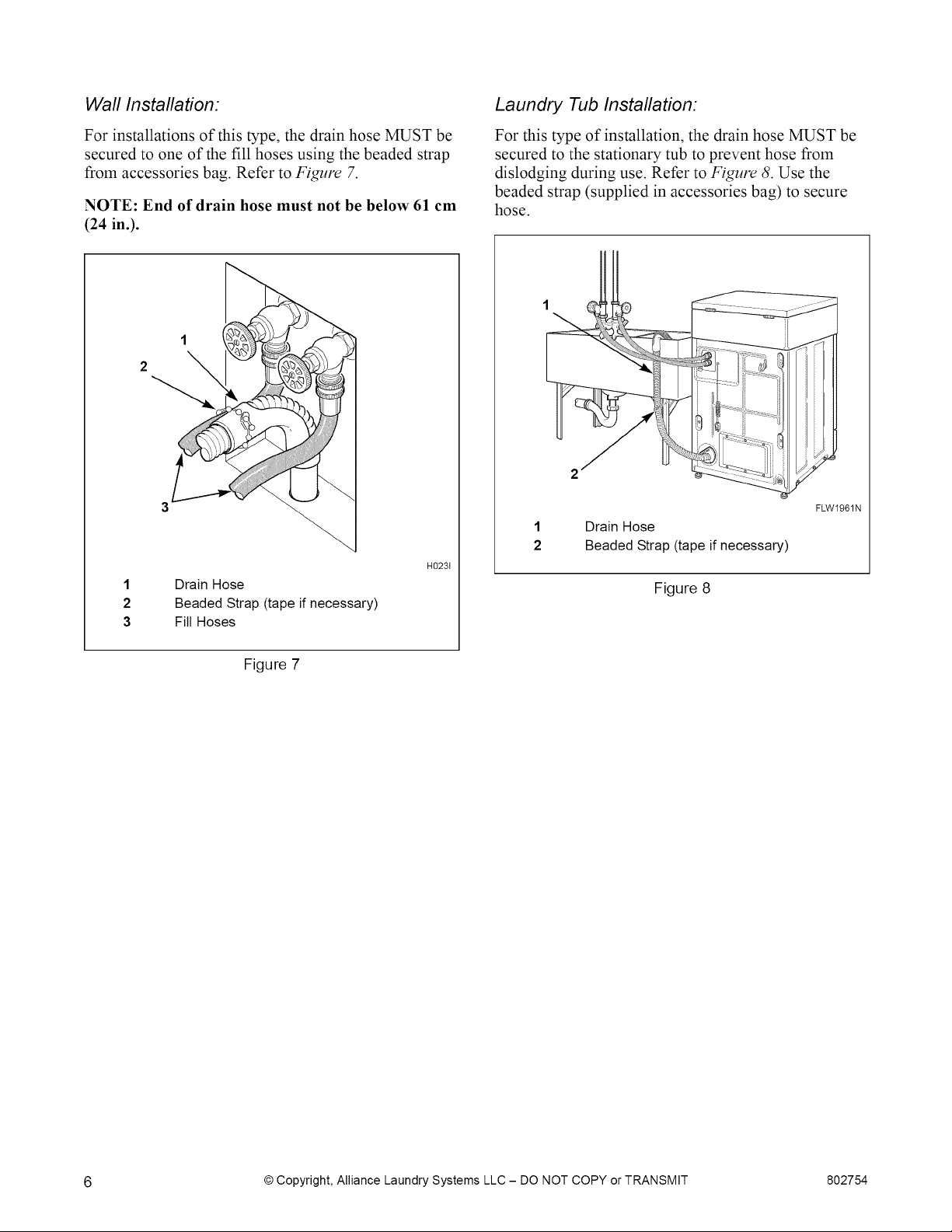

Wall Installation:

Laundry Tub Installation:

For installations of this type, the drain hose MUST be

secured to one of the fill hoses using the beaded strap

from accessories bag. Refer to Figure 7.

NOTE: End of drain hose must not be below 61 cm

(24 in.).

2

H023t

1

2

3

Drain Hose

Beaded Strap (tape if necessary)

Fill Hoses

For this type of installation, the drain hose MUST be

secured to the stationary tub to prevent hose from

dislodging during use. Refer to FJg_re 8. Use the

beaded strap (supplied in accessories bag) to secure

hose.

f

FLW1961N

1

2

Drain Hose

Beaded Strap (tape if necessary)

Figure 8

Figure 7

6 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 802754

Page 7

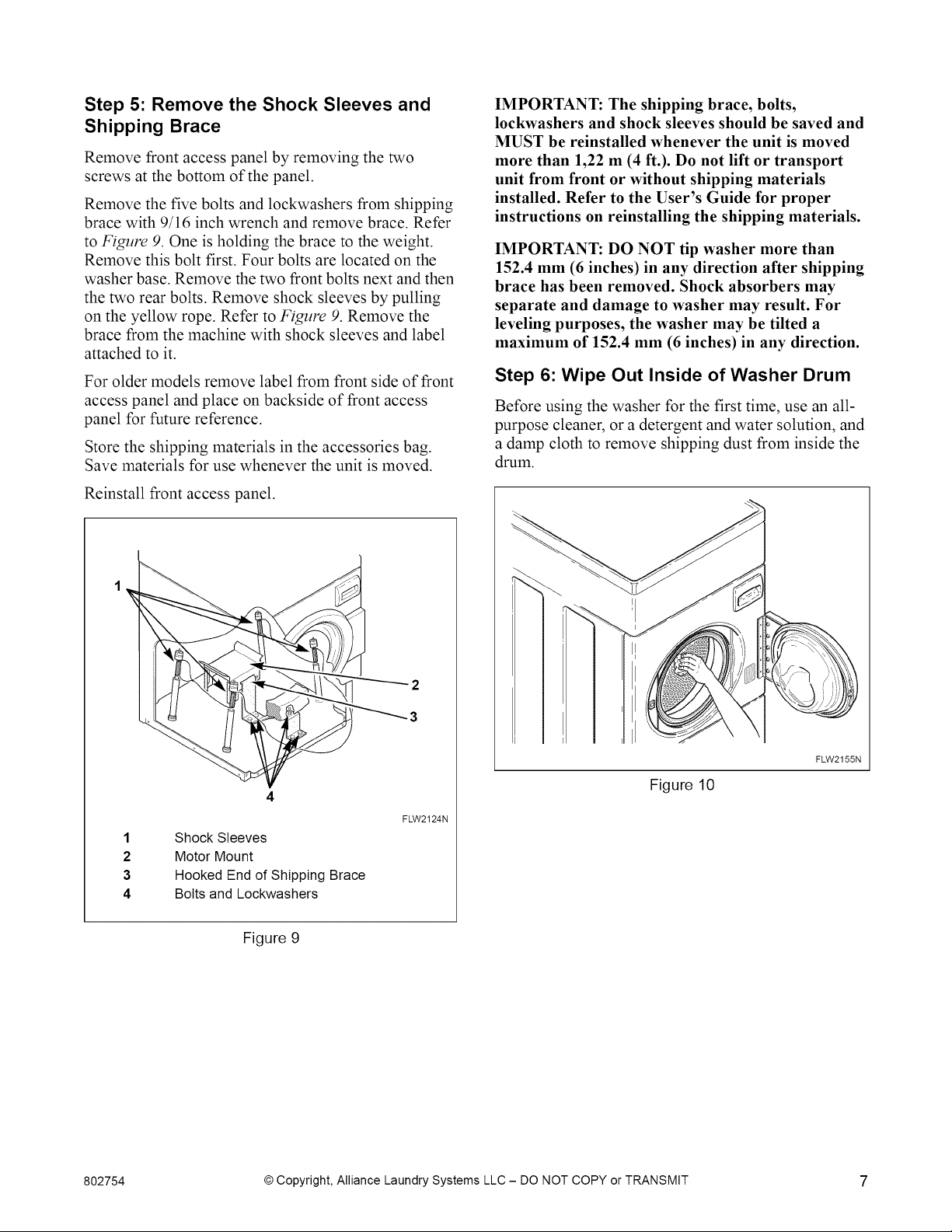

Step 5: Remove the Shock Sleeves and

Shipping Brace

Remove front access panel by removing the two

screws at the bottom of the panel.

Remove the five bolts and lockwashers from shipping

brace with 9/16 inch wrench and remove brace. Refer

to Figure 9. One is holding the brace to the weight.

Remove this bolt first. Four bolts are located on the

washer base. Remove the two front bolts next and then

the two rear bolts. Remove shock sleeves by pulling

on the yellow rope. Refer to Figure 9. Remove the

brace from the machine with shock sleeves and label

attached to it.

For older models remove label from front side of front

access panel and place on backside of front access

panel for future reference.

Store the shipping materials in the accessories bag.

Save materials for use whenever the unit is moved.

Reinstall front access panel.

IMPORTANT: The shipping brace, bolts,

lockwashers and shock sleeves should be saved and

MUST be reinstalled whenever the unit is moved

more than 1,22 m (4 ft.). Do not lift or transport

unit from front or without shipping materials

installed. Refer to the User's Guide for proper

instructions on reinstalling the shipping materials.

IMPORTANT: DO NOT tip washer more than

152.4 mm (6 inches) in any direction after shipping

brace has been removed. Shock absorbers may

separate and damage to washer may result. For

leveling purposes, the washer may be tilted a

maximum of 152.4 mm (6 inches) in any direction.

Step 6: Wipe Out Inside of Washer Drum

Before using the washer for the first time, use an all-

purpose cleaner, or a detergent and water solution, and

a damp cloth to remove shipping dust from inside the

drum.

FLW2155N

Figure 10

FLW2124N

1

2

3

4

Shock Sleeves

Motor Mount

Hooked End of Shipping Brace

Bolts and Lockwashers

Figure 9

802754 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 7

Page 8

Step 7: (Supply Injection Models Only)

Connect External Supplies to Washer

IMPORTANT: Undiluted chemical dripping can

damage the washer.

1. Remove two nozzles from accessories bag. Use

either the 3/8 inch or 1/4 inch nozzles, depending

on the diameter of the dispenser tubing used.

2. Attach nozzles to rear of machine. Connection

point located on cabinet, above water mixing

valve. Refer to Figure 11.

3. Connect supply hoses to nozzles and secure with

hose clamps (obtain locally). Refer to Figure 11.

NOTE: Hoses can be connected to either nozzle.

.

Refer to supply iniection system instructions and

label inside washer junction box cover

(Figure 12) for electrical connection.

Do not attempt to make supply iniection

electrical connections to points other than those

provided specifically for that purpose by the

factory.

.

Refer to supply iniection system instructions for

details on operation.

Supply Injection System

Number of liquid supply connections 2

(l-Detergent and 2-Softener)

3

2

FLW2162N

1

2

3

Injection Point

Nozzle

Supply Dispenser Pump Outlet

Figure 11

A junction box on the rear panel houses a terminal

strip which furnishes supply output signals for the

supply injection pumps. Refer to Figure 12 for the

injection interface label.

Liquid supply connection size, 9.52 (3/8)

mm (in.) or

6.35 (1/4)

WARNING

Wear eye and hand protection when

handling chemicals; always avoid direct

contact with raw chemicals. Read the

manufacturer's directions for accidental

contact before handling chemicals. Ensure

an eye-rinse facility and an emergency

shower are within easy reach. Check at

regular intervals for chemical leaks.

SW016

CHEMICAL INJECTION

ELECTRICAL INTERFACE

YELLOW

DISPENSER

CONNECTION

SOFTENER

DISPENSER

DETERGENT [_

CONNECTION

NO CONNECTION

NOTE: Normally Open Contacts.

_ ----O

---O

---O

--O

YELLOW/BLACK

RED

_ _DETERGENT

RED/BLACK _ _ RELAY

O

TERMINAL

BLOCK

Contacts Close to Start Chemical injection.

Maximum Load Connection per Contact:

1A @ 120VAC/240VAC

Figure 12

gSOETENER

801653R1

FLW2028N

8 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 802754

Page 9

These terminals may be used to provide signals to the

supply injection system but must not be used to

provide power to the actual pump.

Any injection system pump which requires

110 VAC must be powered by a separate external

power source.

Control Function Test

The washer should be cleaned after the installation is

complete. A function test should then be executed on

the unloaded machine:

.

Check the power supply for such characteristics

as correct voltage, phase, and cycles to be certain

they are correct for the washer.

.

Open manual shut-off valves to the washer.

3.

Apply power to the washer.

WARNING

To reduce the risk of fire, electrical shock

or personal injury, all wiring and

grounding MUST conform with the latest

edition of the Canadian Electrical Code,

Parts I and II, and such local regulations

as might apply. It is the customer's

responsibility to have the wiring and

fuses checked by a qualified electrician to

make sure the laundry room has adequate

electrical power to operate the washer.

When plugging in the washer:

• DO NOT overload circuits.

• DO NOT use an extension cord.

Wl10

Step 8: Plug in the Washer

Washer requires 120 Volt, 60 Hertz electrical supply

and comes equipped with a 3-prong grounding plug.

Refer to serial plate for specific electrical

requirements.

4 5

Standard 120 Volt, 60 Hertz _

Grounded Circuit

3-Wire Effectively

DRY2022N

1

2

3

4

5

L1

Ground

Neutral Side

Round Grounding Prong

Neutral

DO NOT use an adapter.

DO NOT operate both a washer and gas dryer on

the same circuit. Use separately fused 15 Amp

circuits.

The washer is designed to be operated on a separate

branch, polarized, three-wire, effectively grounded,

120 Volt, 60 Hertz, AC (alternating current) circuit

protected by a 15 Amp fuse, equivalent fusetron or

circuit breaker.

The three-prong grounding plug on the power cord

should be plugged directly into a polarized three-slot

effectively grounded receptacle rated 110/120 Volts

AC (alternating current) 15 Amps. Refer to Figzlre 13

to determine correct polarity of the wall receptacle.

WARNING

To reduce the risk of an electric shock or

fire, DO NOT use an extension cord or an

adapter to connect the washer to the

electric power source.

W082

Figure 13

802754 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 9

Page 10

Grounding Information

The washer must be grounded. In the event of

malfunction or breakdown, grounding will reduce the

risk of electric shock by providing a path of least

resistance for electric current.

The washer is equipped with a cord having an

equipment-grounding conductor and a 3-prong

grounding plug. The plug must be plugged into an

appropriate outlet that is properly installed and

grounded in accordance with all local codes and

ordinances.

WARNING

Improper connection of the equipment-

grounding conductor can result in a risk

of electric shock. Check with a qualified

electrician or service person if you are in

doubt as to whether the washer is

properly grounded.

W216

Do not modify the plug provided with the washer - if it

will not fit the outlet, have a proper outlet installed by

a qualified electrician.

WARNING

This unit is equipped with a three-prong

(grounding) plug for your protection

against shock hazard and should be

plugged directly into a properly grounded

three-prong receptacle. Do not cut or

remove the grounding prong from this

plug.

NOTE: The wiring diagram is located behind the

control panel, inside the control cabinet.

Step 9: Check Installation

Refer to Installer Checklist on the back cover of this

manual and make sure that washer is installed

correctly.

Run washer through one complete cycle to make sure

it is operating properly.

W213

NOTE: Have a qualified electrician check the

polarity of the wall receptacle. If a voltage reading

is measured other than that in Figure 13, the

qualified electrician should correct the problem.

10 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 802754

Page 11

Instructions d'installation

Machine & laver & chargement frontal

Contenu .....................................

Dimensions de la machine _ laver ..................................... 12

Avant de commencer ......................................................... 12

Installation ......................................................................... 13

Liste de vdrification de l'installateur ....... Couvercle arribre

Date d'achat

Numdro de modble

Numdro de sdrie

Conserver ces instructions fi titre de rdfdrence.

(Si la machine est vendue, le guide doit &re remis au nouveau propridtaire.)

liance

Laundry Systems www.comlaundry.com

R_f. 802754R3QU

Mai 2011

Page 12

Dimensions de la machine a laver

61 cm

__ (24 po)

I i,.

V

33,3 cm

(13,1 po)

1

cm (28 po) __

,- 5,1 cm (2 po)

3,8 cm (1,5 po)

Avant de commencer

Fournitures

Pour la plupart des installations, ces outils de base

seront ndcessaires :

_6

u_

cm (26,9 po)

FLW2222N

Figure 1

Pi_ces incluses

La machine g laver est expddide avec un sac

d'accessoires qui comprend "

• Deux tuyaux de remplissage avec rondelles et

filtres. Se reporter g l'dtape 2 de la section

Installation.

• Quatre pieds en caoutchouc. Se reporter _ l'dtape

4 de la section Installation.

• Courroie perlde. Se reporter _ l'dtape 3 de la

section Installation.

• Instructions d'installation.

• Guide d'utilisation et d'entretien.

• Bon de garantie.

FLW2145N

1

2

3

4

5

6

7

Lunettes de s6curite

Cale en bois

Cle

Tournevis

Pinces

Cle & douilles

Niveau

REMARQUE : Si le jour livraison de la machine la

temp6rature est particuli6rement basse (inf6rieure

0 °C), ou si la machine doit 6tre entrepos6e darts

un endroit sans chauffage pendant les mois froids,

ne l'utiliser pas tant qu'elle ne s'est pas r6chauff6e.

REMARQUE : Une certaine humidit6 dans le

tambour est normale. De l'eau est utilis6e pendant

les essais en usine.

REMARQUE : Installer la s6cheuse avant la

Figure 2

machine _ laver. II y a ainsi suffisamment de place

pour fixer le tuyau d'6chappement.

12 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 802754 (QU)

Page 13

Installation

l_tape 1 • Placer la machine b laver pros de

I'emplacement de I'installation

Placer le lave-linge aussi prbs que possible de

l'emplacement choisi pour l'installation.

REMARQUE : Pour obtenir le meilleur rendement

possible et minimiser les vibrations ou les

d_placements, installer la machine _ laver sur un

plancher solide et bien droit. Il peut 6tre n_cessaire

de renforcer certains planchers, en particulier les

planchers _ l'_tage ou les faux-planchers d'un

sous-sol. Ne pas installer la machine _ laver sur de

la moquette, sur un couvre-sol souple, sur une

plate-forme ni sur une structure instable.

l_tape 2 • Placer et mettre la machine

niveau

I

Si la machine est install6e sur une plate-

forme quelconque, il faut I'ancrer sur cette

plate-forme. Cette plate-forme utilis6e pour

61ever la machine b laver doit aussi _tre

ancr6e au sol pour assurer que la machine

ba laver ne se d6place pas et pour qu'il ne

soit pas possible de tirer sur la machine, la

faire basculer ou glisser de sa position

d'installation. Si cette prdcaution n'est pas

respect6e, il existe des risques de blessures

graves, de mort ou de dommages.

MISE EN GARDE

W306QU

REMARQUE : Le niveau doit se trouver sur une

portion sur_lev_e du panneau sup_rieur tel. Se

reporter/_ la Figure 3.

Si la laveuse n'est pas _ niveau, l'incliner pour avoir

accbs aux pattes de mise il niveau avant et arribre.

Ddserrer les dcrous de blocage et visser ou ddvisser les

pattes pour les aiuster.

Vdrifier que la machine _ laver est stable. Une fois la

machine _ laver de niveau et stable, resserrer

fermement les dcrous contre le socle de la machine. Si

les dcrous de blocage ne sont pas serrds, l'aiustement

des pattes ne tiendra pas durant le fonctionnement de

la machine _ laver.

Ne pas glisser la machine sur le plancher aprbs que les

pattes de mise _ niveau sont ddvissdes. Les pattes et le

socle peuvent _tre endommagds.

Placer les embouts en caoutchouc (qui se trouvent

dans le sac d'accessoires) sur les quatre pattes de mise

niveau. Se reporter _ la Figure 3.

S'assurer que l'appareil ne bouge pas.

6

Placer la machine _ laver _un endroit off il y a un

ddgagement suffisant pour pouvoir l'installer et

3 2

l'entretenir.

FLW2154N

REMARQUE : L'utilisation du tiroir du

distributeur ou de la porte de la machine _ laver

comme une poign_e lors du transport de la machine

peut endommager le distributeur ou la porte.

Placer la machine _ laver sur un plancher solide et bien

droit. I1n'est pas recommandd d'installer la machine

1 Niveau

2 Cale en bois

3 Pied en caoutchouc

4 Pied de niveau

5 Contre-ecrou

6 Base de la machine

laver sur de la moquette de quelque type que ce soit,

sur un couvre-sol souple, sur une plate-forme ou sur

Figure 3

une structure instable.

Pour faciliter l'accbs aux pattes de mise _ niveau,

placer une cale en bois sous la machine. Se reporter

la Figure 3.

Vdrifier, _ l'aide d'un niveau placd prbs de la plaque

supdrieure de la machine _ laver, si cette dernibre est

totalement stable.

802754 (QU) © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 13

Page 14

#tape 3 • Connecter les tuyaux de

remplissage

|1 MISE EN GARDE

I

Dans certaines conditions, de I'hydrog_ne

peut _tre produite dans un circuit _ eau

chaude qui ne serait pas utilisd pendant

deux semaines ou plus. L'HYDROGENE EST

UN GAZ EXPLOSIF. Si le circuit _ eau

chaude n'est pas utilisd pendant une telle

pdriode et avant de mettre la machine en

marche, ouvrir tous les robinets d'eau

chaude et laisser couler I'eau de chacun

d'eux pendant plusieurs minutes afin de

laisser I'hydrog_ne accumuld s'dchapper.

Le gaz est inflammable, ne pas fumer ou

utiliser de flamme nue pendant I'opdration.

W029R2QU

Approvisionnement en eau

Les robinets d'approvisionnement en eau doivent

s'ajuster fi des raccords femelles de tuyau d'arrosage de

19,1 mm (3/4 po). NE PAS UTILISER DE

RACCORDS A ASSEMBLAGE COULISSANT OU

ANNEAU DE SERRAGE.

Les robinets d'approvisionnement en eau doivent _tre

faciles d'acc_s pour qu'il soit possible de les fermer

lorsque la machine filaver n'est pas utilisde.

La tempdrature recommandde pour l'eau froide est 16°

27 ° Celsius (60 ° _ 80 ° Fahrenheit). La tempdrature

maximale recommandde pour l'eau chaude est

51 ° Celsius (125 ° Fahrenheit). L'eau tilde est un

mdlange d'eau chaude et d'eau froide. La tempdrature

de l'eau tilde ddpend de la tempdrature de l'eau et de

la pression des conduites d'alimentation en eau chaude

et froide.

Ouvrir les robinets d'approvisionnement en eau et

laisser couler pendant environ deux minutes pour

ddloger toutes les particules dtrang_res qui pourraient

bloquer les filtres du robinet mdlangeur d'eau.

REMARQUE : Lorsque l'appareil est install6 dans

un immeuble neuf ou r6nov6, il est trbs important

de vidanger les tuyaux puisque des particules

peuvent s'6tre accumul6es pendant les travaux de

construction.

Tuyaux de raccordement

Retirer les deux filtres et les deux rondelles en

caoutchouc du sac d'accessoires. Les placer dans

chaque extrdmitd des tuyaux de remplissage comme

illustrd dans Figure 4. Le filtre doit _tre tournd vers

l'extdrieur.

Serrer _ la main les raccords de tuyau dotds de filtres

sur les robinets. Puis, avec des pinces, resserrer le

montage d'environ 1/4 de tour.

Serrer _ la main les raccords situds aux autres

extrdmitds des tuyaux sur le robinet mdlangeur. Puis,

avec des pinces, resserrer le montage d'environ 1/4 de

tour. Se reporter il la Figure 5.

IMPORTANT : Ne pas fausser le filetage ni trop

serrer les raccords. Cela provoquera des fuites.

Ouvrir l'alimentation en eau et s'assurer qu'il n'y a pas

de fuite. En cas de fuite, couper l'alimentation en eau,

ddvisser les tuyaux et les rdinstaller de mani_re _ ce

qu'il n'y ait plus de fuite.

IMPORTANT : Couper l'alimentation en eau si la

machine fi laver n'est pas utilis_e pendant

longtemps.

AI

I

MISE EN GARDE

Pour prdvenir les blessures corporelles,

dviter tout contact avec I'arrivde d'eau _ des

tempdratures plus dlevdes que 51° Celsius

(125 ° Fahrenheit) et avec les surfaces

chaudes.

W750QU

La pression statique minimale doit _tre entre 138 et

827 kPa (20 et 120 psi) au robinet.

REMARQUE : Une pression d'eau inf6rieure _ 138

kPa (20 psi) prolongera le temps de remplissage et

ne rincera pas correctement le distributeur de

savon.

14 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 802754 (QU)

Page 15

REMARQUE : De plus longs tuyaux sont

disponibles (en 6quipement livr6 en option 5_cofit

suppl6mentaire) si ceux livr6s avec la machine

laver ne sont pas assez longs pour l'installation.

Commander les tuyaux de la mani6re suivante :

No. 20617 tuyau de remplissage

(Fill Hose) 2,44 m (8 pi.)

No. 20618 tuyau de remplissage

(Fill Hose) 3,05 m (10 pi.)

TLW1976N

1

2

3

4

5

Robinets d'eau

Tuyau de remplissage

Tuyaux de caoutchouc ordinaires

Raccord de tuyau

Filtres

Figure 4

1 2

4

FLW1973N

1

2

3

4

Robinets d'eau

Raccordement & l'eau froide

Raccordement & t'eau chaude

Tuyaux d'entree d'eau

Figure 5

I_tape 4 • Connecter le tuyau de vidange

la vidange

Ddgager le tuyau de vidange de sa position

d'expddition g l'arribre de la machine en ddcrochant le

tuyau de la bride de retenue et en enlevant l'adhdsif

d'emballage.

Brancher le tuyau de vidange sur la conduite de

vidange (conduite verticale, lemur ou un bac

lessive) en suivant les instructions ci-dessous.

IMPORTANT : Les tuyaux et les autres pi6ces en

caoutchouc se d6t6riorent apr6s un usage prolong6.

Les tuyaux peuvent se fendiller, cloquer ou s'user

cause de la temp6rature et des pressions 61ev6es

auxquelles ils sont soumis.

Tous les tuyaux doivent 6tre v6rifi6s une fois par

mois pour y d6celer les signes visibles de

d6t6rioration. Remplacer imm6diatement un tuyau

montrant les signes d'usure mentionn6s ci-dessus.

Tous les tuyaux doivent 6tre remplac6s tousles cinq

ans.

IMPORTANT : La vidange doit permettre le

raccordement d'un tuyau de vidange au diam_tre

ext6rieur de 3,2 cm (1-1/4 po) minimum.

802754 (QU) © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 15

Page 16

Installation de la colonne montante

Installation murale

Placer l'adaptateur dans la colonne montante.

Retirer la courroie perlde du sac d'accessoires. La

placer autour de la conduite verticale et du myau de

vidange et la resserrer pour fixer le myau _ la conduite

verticale. Se reporter _ la Figure 6. Le tuyau de

vidange ne pourra ainsi passe ddloger de la vidange

pendant l'utilisation.

2 3

FLW1959N

1

2

3

61 et 91,44 cm (24 et 36 po) Hauteur

recommandee

Colonne montante 5,08 cm (2 po) ou

4 cm (1-1/2 po)

Courroie perlee

Pour les installations de ce type, le myau de vidange

DOIT _tre bloqud il l'un des tuyaux de remplissage

l'aide d'une sangle incluse dans le sac d'accessoires.

Se reporter fi la Figure 7.

REMARQUE : L'extr_mit_ du tuyau de vidange ne

doit pas 6tre _ une hauteur inf_rieure _ 61 cm

(24 po).

1

....._iii!!iii_¸'j_

H0231

1

2

3

Tuyau de vidange

Sangle (Utiliser un ruban adhesif si besoin)

Tuyaux de remplissage

Figure 6

Figure 7

16 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 802754 (QU)

Page 17

Installation au bacb laver

Pour ce type d'installation, le tuyau de vidange DOIT

_tre bloqud au bac fixe afin d'emp_cher le tuyau de se

ddplacer pendant l'utilisation de la machine. Se

reporter fi la Figure 8. Fixer le tuyau fil'aide de la

courroie perlde (fournie dans le sac d'accessoires).

2,

l_tape 5 • Enlever les manchons

anti-chocs et I'attache d'expddition

Retirer le panneau d'acc_s avant en desserrant les deux

vis au bas du panneau.

l'aide d'une cld _ douilles (9/16 po), retirer les cinq

dcrous et les contre-dcrous de l'attache d'expddition, et

retirer l'attache. Se reporter au Figure 9. L'un des

boulons retient l'attache au poids. Retirer d'abord ce

boulon. I1y a quatre boulons sur la base de la machine

laver. Retirer d'abord les deux boulons avant, puis les

deux boulons arri_re. Retirer les manchons antichocs

en tirant sur le cfible jaune. Se reporter au Figure 9.

Retirer l'attache de la machine en veillant _ ce que les

manchons antichocs et la vignette y restent attachds.

Sur les modules plus anciens, retirer l'dtiquette de

l'avant du panneau d'acc_s avant et de la plaque

l'arri_re du panneau pour consultation future.

Ranger les accessoires d'expddition dans le sac

d'accessoires. Conserver les matdriaux et le remplacer

chaque fois que la machine doit _tre ddplacde.

FLW1961 N

1

2

Tuyau de vidange

Courroie pertee (au besoin, coller avec du

ruban adhesif)

Rdinstaller le panneau d'acc_s avant.

Figure 8

4

FLW2124N

1

2

3

4

Manchon anti-chocs

Support du moteur

Boulons

Extre mite crochue de l'attache d'expedition

Figure 9

802754 (QU) © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 17

Page 18

REMARQUE : Conserver l'attache d'exp6dition,

les 6crous, les contre-6crous et les manchons et les

INSTALLER d6s que la machine est d6plac6e de

plus de 1,22 m_tre (4 pi.). Ne pas soulever ou

transporter la machine sans que le panneau avant

et tout le mat6riel d'exp6dition ne soient install6s.

Se reporter au Guide de l'utilisateur pour y trouver

les instructions sur la mani6re de reinstaller le

mat6riel d'exp6dition.

IMPORTANT : Ne pas incliner la machine h laver

de plus de 152,4 mm (6 pouces) dans quelque

direction que ce soit une fois l'attache d'exp6dition

enlev6e. Les manchons antichocs pourraient se

d6tacher, ce qui risquerait d'endommager la

machine h laver. Il est possible d'incliner la

machine h laver d'au plus 152,4 mm (6 pouces)

dans quelque direction que ce soit pour la mettre h

niveau.

I_tape 6 • Nettoyer I'int6rieur de la machine

Avant la premibre utilisation du lave-linge, nettoyer

l'intdrieur du tambour h l'aide d'un chiffon humide et

d'un produit nettoyant universel ou d'une solution

d'eau et de ddtergent pour dliminer la poussibre

ddposde durant l'expddition.

l_tape 7 • (Mod61es b dispositif de

distribution automatique des produits de

lessive uniquement) Connecter les

produits (d6tergent et adoucisseur)

externes b la machine b laver

IMPORTANT : Les fuites de produits chimiques

non dilu6s peuvent endommager la machine h

laver.

. Prendre deux buses dans le sac d'accessoires.

Utiliser les buses de 9,52 mm (3/8 po) ou de

6,35 mm (1/4 po), selon le diambtre du tuyau

distributeur utilisd.

.

Fixer les buses h l'arribre de la machine _ laver.

Point de connexion situd sur le chfissis, au-dessus

du robinet mdlangeur d'eau. Se reporter _ la

Figure 11.

.

Connecter les tuyaux de distribution aux buses et

les fixer _ l'aide de colliers de serrage (_ se

procurer chez un fournisseur local). Se reporter

la Figure 11.

REMARQUE : Les tuyaux peuvent 6tre connect6s

h l'une ou h l'autre buse.

Figure 10

FLW2155N

.

Se reporter aux instructions sur le dispositif de

distribution automatique des produits de lessive

et _ la vignette _ l'intdrieur du couvercle de la

boite de jonction de la machine _ laver

(Figure 12) pour ce qui est du raccordement

dlectrique.

Ne pas tenter de faire le raccordement dlectrique

du dispositif de distribution automatique des

produits de lessive _ d'autres points que ceux qui

sont prdvus spdcifiquement h cette fin par le

fabricant.

.

Se reporter aux instructions du dispositif de

distribution automatique des produits de lessive

pour des renseignements ddtaillds sur le

fonctionnement.

Dispositif de distribution automatique des

produits de lessive

Nombre de connexions de produits liquides

(1 - d_tergent; 2 - adoucisseur)

Taille de la connexion de

l'approvisionnement en liquide, en mm (po)

2

9,52 (3/8)

OU

6,35(1/4)

18 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 802754 (QU)

Page 19

6-1 MISE EN GARDE

I

Utiliser des dispositifs de protection des

yeux et des mains pour manipuler les

produits chimiques; toujours 6viter les

contacts avec des produits chimiques non

dilu6s. Avant de manipuler des produits

chimiques, lire les instructions du fabricant

relatives aux contacts accidentels avec les

produits. S'assurer qu'une douche oculaire

et une douche d'urgence se trouvent

proximit6. Faire des v6rifications

intervalles r6guliers pour s'assurer qu'il n'y

a pas de fuite de produits chimiques.

SW016QU

3

2

CHEMICAL INJECTION

ELECTRICAL INTERFACE

YELLOW

DISPENSER

CONNECTION

i OFTENER

DISPENSER

i ETERGENT

CONNECTION

NO CONNECTION

NOTE: Normally Open Contacts.

---O

---O

----O

--O

YELLOW/BLACK _2_ RELAY

RED

RED/BLACK

O

TERMINAL

BLOCK

Contacts Close to Start Chemical injection.

Maximum Load Connection per Contact:

1A @ 120VAC/240VAC

Figure 12

Les bornes peuvent servir _ envoyer des signaux au

dispositif de distribution automatique mais elles ne

doivent pas 8tre utilisdes pour fournir l'alimentation

dlectrique il la pompe.

SOETENER

gDETERGENT

_, _ RELAY

801653R1

FLW2028N

FLW2162N

1

2

3

Entree des produits

Buse

Prise de la pompe du distributeur de produits

Figure 11

Dans la bo_te de jonction situde sur le panneau arribre,

une plaque h borne envoie des signaux aux pompes du

dispositif de distribution automatique des produits de

lessive. Se reporter h la Figure 12 qui montre la

vignette d'interface du dispositif de distribution

automatique.

Toute pompe de dispositif de distribution

automatique fonctionnant sur 110 VAC doit 6tre

branch6e fi une source d'alimentation 61ectrique

externe.

Test de fonctionnement

I1faut nettoyer la machine _ laver une fois

l'installation terminde. Un test de fonctionnement dolt

ensuite 8tre fait sur la machine non chargde "

.

Inspecter l'alimentation en courant pour vdrifier

la tension, la phase et les cycles et s'assurer qu'ils

sont approprids pour la machine _ laver.

.

Ouvrir les robinets d'alimentation.

3.

Mettre la machine h laver sous tension.

802754 (QU) © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 19

Page 20

l_tape 8 • Brancher la machine

Lors du branchement de la machine _ laver "

La machine h laver doit 8tre branchde h une

alimentation dlectrique de 120 V, 60 Hz, et elle est

munie d'une prise de mise _ la terre _ trois broches.

Consulter la plaque de sdrie pour conna_tre la

configuration dlectrique spdcifique.

Standard

efficacement mis

las terre de

120 volts, 60 hertz,

a trios fil

DRY2022N

1

2

3

5

5

L1

Mise & ta terre

CSte neutre

Fiche de terre ronde

Neutre

Figure 13

A]

I

MISE EN GARDE

Pour rdduire les risques d'incendie, chocs

dlectriques ou de lesions corporellas, le

c_blage et la mise _ la terre DOIVENT _tre

entierement conformds _ la toute dernidre

ddition du code electrique canadien, Parties

I et II, et aux rdglements Iocaux applicables.

II incombe au client de faire vdrifier le

cablage et les fusibles par un electricien

qualifie pour s'assurer que le salle de

lavage a suffisament de puissance

electrique pour faire fonctionner la machine

a laver.

W110QU

• NE PAS surcharger les circuits.

• NE PAS utiliser une rallonge.

• NE PAS utiliser un adaptateur

• NE PAS brancher la machine _ laver et la

sdcheuse sur le mSme circuit dlectrique. Utiliser

des circuits de 15 A h fusibles diffdrents.

La machine _ laver doit fonctionner sur un circuit

diffdrent, polarisd, _ trois ills, correctement mis _ la

terre, de 120 V, 60 Hertz, _ c.a. (courant alternatif) et

protdgd par un fusible de 15 A, un fusible temporisd

dquivalent ou un disjoncteur.

La fiche bipolaire avec terre du cordon d'alimentation

doit 8tre branchde directement dans une prise murale

polarisde h 3 fentes, correctement mise il la terre et

calibrde sur 110/120 V c.a. (courant alternatif) de

15 A. Se reporter au Fig_re 13 pour ddterminer la

polaritd exacte de la prise murale.

A[

I

MISE EN GARDE

Pour rdduire les risques d'incendie ou de

chocs dlectriques, NE PAS utiliser de

rallonge ou d'adaptateur pour brancher la

machine _ la source dlectrique.

W082QU

20 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 802754 (QU)

Page 21

Informations concemant la mise b la terre

La machine h laver doit _tre mise il la terre. En cas de

mauvais fonctionnement ou de claquage, la mise _ la

terre rdduira les risques de choc dlectrique en

fournissant un chemin de rdsistance moindre pour le

courant.

La machine il laver est munie d'un cordon avec

conducteur de mise _ la terre et d'une fiche _ trois

broches avec mise il la terre. La fiche doit _tre

branchde dans une prise murale addquate installde et

mise/_ la terre conformdment aux codes et aux

rbglements locaux.

AI

I

MISE EN GARDE

Une connexion incorrecte du conducteur de

mise _ la masse de la machine peut

entrainer des chocs 61ectriques. Consulter

un 61ectricien qualifi6 ou un rdparateur si

vous avez des doutes quant _ la mise _ la

masse de la machine.

W216QU

Ne pas modifier la fiche fournie avec la machine -- sl

elle ne se branche pas dans la prise murale, faire

installer une prise addquate par un dlectricien qualifid.

I

MISE EN GARDE

Cette unit6 est dot6e d'une fiche _ trois

broches (mise _ la terre) pour votre

protection contre tout risque d'61ectrocution

et doit 6tre branch6e directement dans la

prise _ trois fentes correctement mises _ la

terre.

W213QU

REMARQUE : Le diagramme de cfiblage est situ6

derri6re le panneau de commande, fi l'int6rieur du

boltier de commande.

l_tape 9 • V6rifier I'installation

Se reporter _ la Liste de vdrif!eation de l'installateur

sur la couverture arribre du manuel pour s'assurer que

la machine est correctement installde.

Lancer un cycle de lavage complet pour vdrifier que la

machine fonctionne correctement.

REMARQUE : Demander fi un 61ectricien qualifi6

de v6rifier la polarit6 de la prise murale. Si la

lecture de tension est diff6rente de celle du

Figure 13, un 61ectricien qualifi6 doit r6soudre le

probl+me.

802754 (QU) © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 21

Page 22

Installer Checklist

Fast Track for Installing the Washer

(Refer to the manual for more detailed information)

Liste de v6rification de I'installateur

Liste permettant de v6rifier rapidement I'installation de la machine

(Se reporter au manuel pour de plus amples informations)

O • Position Washer Neat"

• Placer la machine '_laver

pros de l'emplacement de

l'installation.

Installation Area.

CHECK

VE'RIFIE"

• Position and

Level the Washer.

• Placer et mettre la

machine '_ niveau.

_ CHECK

VE'RIFIE"

Connect Fill

• Connecter les

tuyaux de

remplissage

Hoses.

CHECK

VE'RIFIE"

Filter Screens Cold Valve Connection

Filtres Raccord de robinet

d'eau froide /

I I_ j II

Rondelles ! r

plates Hot VaIve Connection

Raccord de robinet

d'eau chaude

Remove the Shock Sleeves

and Shipping Brace.

Enlever les manchons

anti-chocs et l'attache

d'exp6dition.

CHECK

VE'RIFIE"

Washer Drum

Nettoyer l'int6rieur

de la machine.

Wipe Out Inside of

CHECK

VE'RIFIE"

, (Supply Injection Models Only)

O (Mod+les h de distribution automatique_

des produits de lessive uniquement)

L"

, J

dispositif

Connect External

Supplies to Washer

Connecter les produits

(d6tergent et

adoucisseur) externes '_

la machine '_ laver.

CHECK

v#iclH#

FLW2124N

FLW2155N

FLW2162N

/

O • Connect Drain

Receptacle.

• Connecter le

tuyau de

h Hose to Drain

_ CHECK

vidange '_la

vidange.

VE'RIFIE"

_ • Plug in the Washer.

• Brancher la machine.

D2541#

CHECK

VE'RIFIE"

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

Loading...

Loading...