Page 1

REMARQUE : Le

manuel en fran_ais

figure _ la suite du

manuel en anglais.

Automatic

r_

Clothes Dryers

Electric and Gas Models

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

liance

Laundry Systems

www.comlaundry.com

Part No. 512023R2

June 2007

Page 2

WARNING

FOR YOUR SAFETY, the information in this manual must be followed to minimize the risk of

fire or explosion or to prevent property damage, personal injury or death.

W033

• Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

• WHAT TO DO IF YOU SMELL GAS:

- Do not try to light any appliance.

- Do not touch any electrical switch; do not use any phone in your building.

- Clear the room, building or area of all occupants.

- Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

- If you cannot reach your gas supplier, call the fire department.

• Installation and service must be performed by a qualified installer, service agency or the

gas supplier.

W052

IMPORTANT: Purchaser must consult the local gas supplier for suggested instructions to be followed if the

unit user smells gas. The gas utility instructions plus the SAFETY and WARNING note directly above must

be posted in a prominent location near the unit for customer use.

WARNING

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance,

Electric models are approved by CSA - International.

W053

512023 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 1

Page 3

Notes

2 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 512023

Page 4

Table of

Contents

Replacement Parts .............................................................................. 5

Installation ........................................................................................... 7

Dimensions and Specifications ............................................................. 7

Before You Start ................................................................................... 8

Tools ................................................................................................ 8

Gas ................................................................................................... 8

Location ........................................................................................... 8

Exhaust ............................................................................................. 8

Electrical .......................................................................................... 8

Installing the Dryer ............................................................................... 9

Step 1: Position and Level the Dryer ............................................... 9

Step 2: Connect Dryer Exhaust System ........................................... 9

Step 3: (Gas Dryer Only) Connect Gas Supply Pipe ....................... 10

Step 4: Wipe Out Inside of Dryer .................................................... 11

Step 5: Plug In the Dryer ................................................................. 11

Step 6: Check Installation ................................................................ 11

Heat Source Check ............................................................................... 12

Electric Dryers ................................................................................. 12

Gas Dryers ....................................................................................... 12

Reversing Door Procedure .................................................................... 13

Manufactured (Mobile) Home Installation ........................................... 14

Electrical Requirements ........................................................................ 15

Electric Dryers with 4-Wire Plug (Supplied with Dryer) ................ 15

Electric Dryers with 3-Wire Plug (Requires Conversion) ............... 16

Grounding Instructions .................................................................... 16

Gas Dryers ....................................................................................... 20

Gas Requirements ................................................................................. 22

Location Requirements ......................................................................... 24

Dryer Exhaust Requirements ................................................................ 25

Exhaust System Materials ................................................................ 25

Make-Up Air Requirements ............................................................. 25

Exhaust System ................................................................................ 26

Exhaust Direction ............................................................................. 26

Exhaust System Maintenance .......................................................... 27

Dryer Airflow ................................................................................... 27

Maintenance ........................................................................................ 29

User-Maintenance Instructions ............................................................. 29

Lubrication ....................................................................................... 29

Care of Your Dryer .......................................................................... 29

Exhaust System ................................................................................ 29

Information for Handy Reference ......................................................... 30

Installer Checklist ................................................................. Back Cover

(c)Copyright 2007, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

512023 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 3

Page 5

Notes

4 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 512023

Page 6

Replacement Parts

If replacement parts are required, contact the source

from which you purchased your dryer, or contact:

Alliance Laundry Systems LLC

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

U.S.A.

Phone: (920) 748-3950

for the name and address of the nearest authorized

parts distributor.

512023 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 5

Page 7

Notes

6 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 512023

Page 8

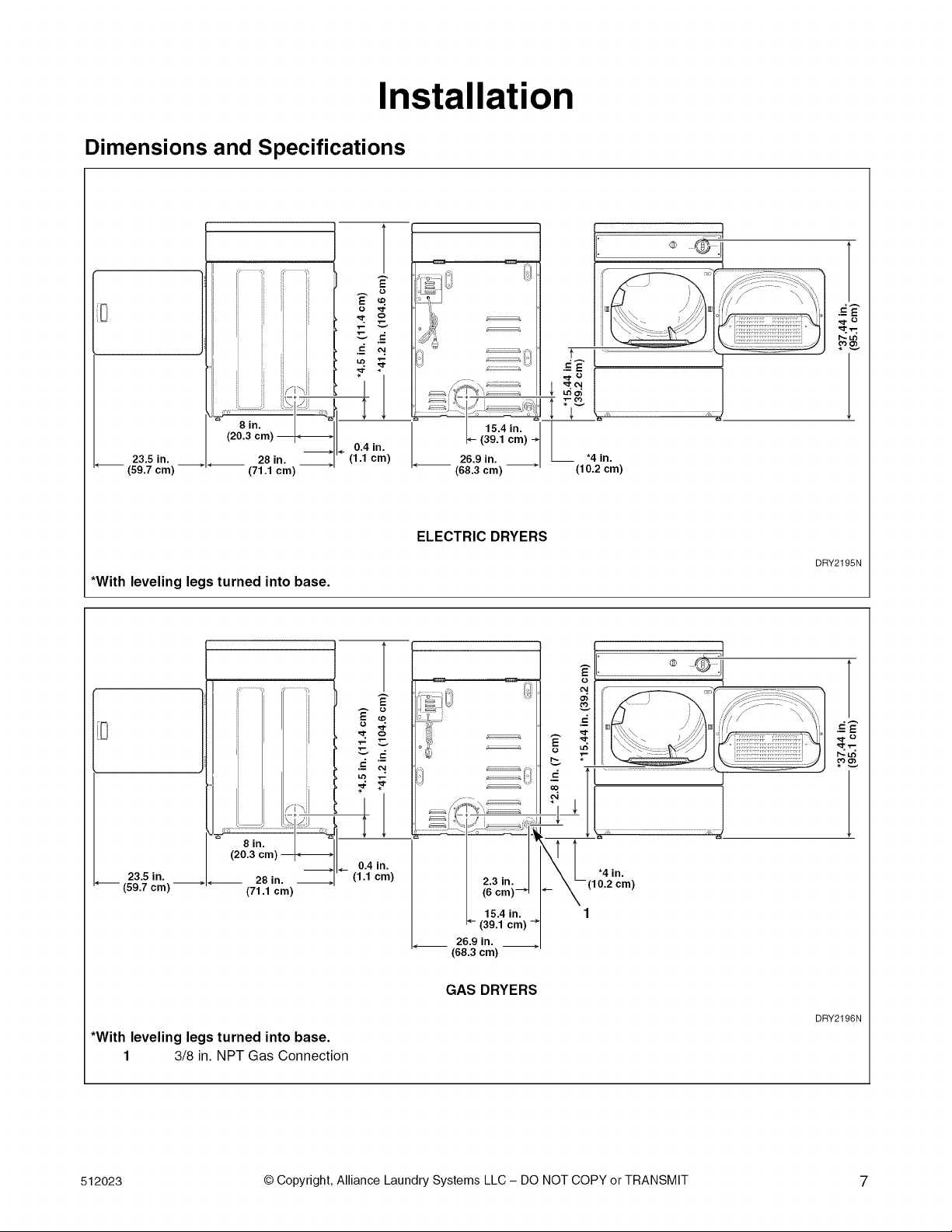

Dimensions and Specifications

Installation

23.5 in.

(59.7 cm) (71.1 cm)

*With leveling legs turned into base.

m

0.4 in.

(1.1 cm)

1

26.9 n. -_

(68,3 cm)

ELECTRIC DRYERS

1

15.4 in. I

(39,1 cm) ÷

®

*4 in.

(10.2 cm)

DRY2195N

®

• m

F_

8 in.

(20.3 cm) --

23.5 in.

(59.7 cm)

*With leveling legs turned into base.

1 3/8 in. NPT Gas Connection

512023 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 7

28 in. __

(71.1 cm)

0.4 in.

(1.1cm)

*4 in.

cm)

15.4 in.

(39.1

26.9 in.

(68.3 cm)

GAS DRYERS

DRY2196N

Page 9

Installation

Before You Start

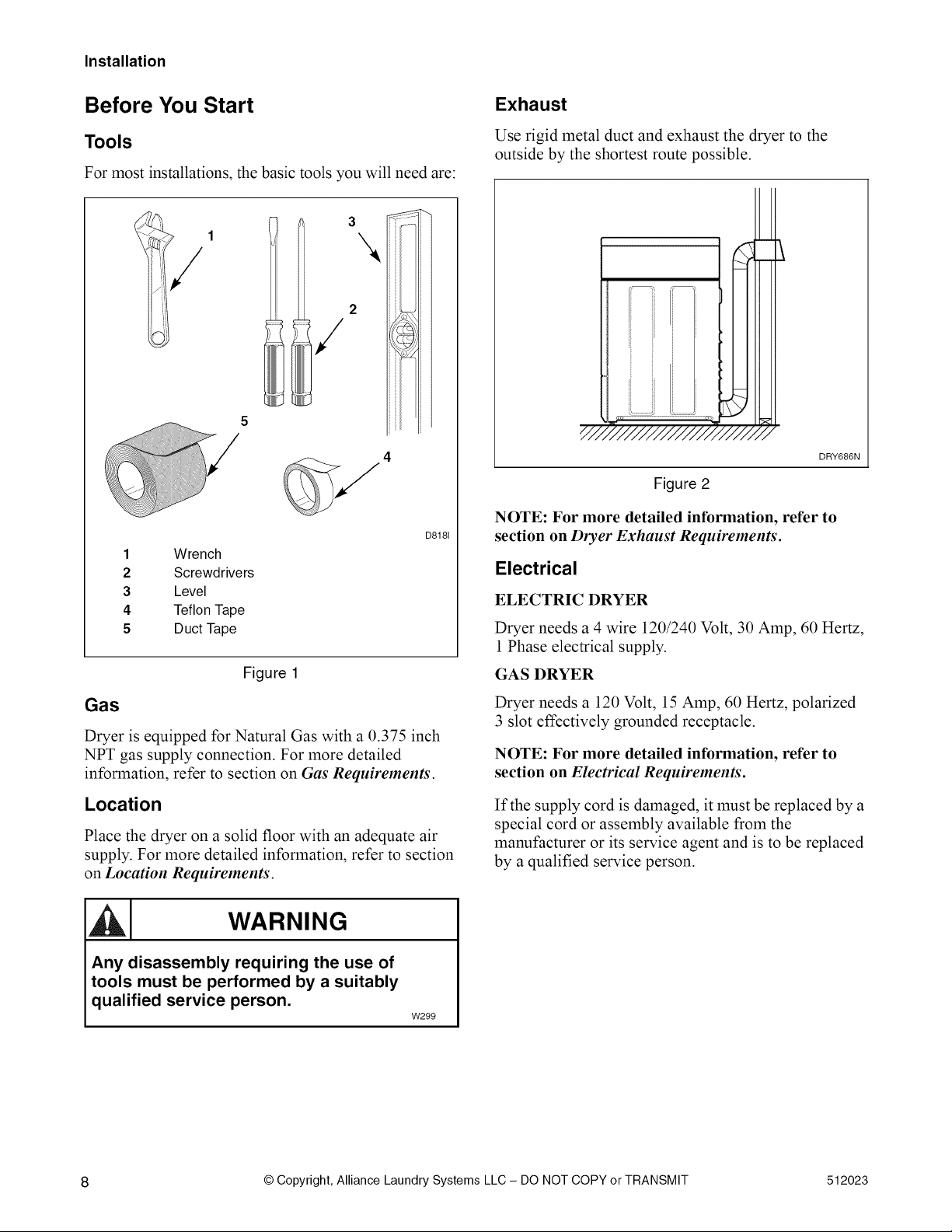

Tools

For most installations, the basic tools you will need are:

q ......

3

1

\

/

5

D8181

1 Wrench

2 Screwdrivers

3 Level

4 Teflon Tape

5 Duct Tape

Figure 1

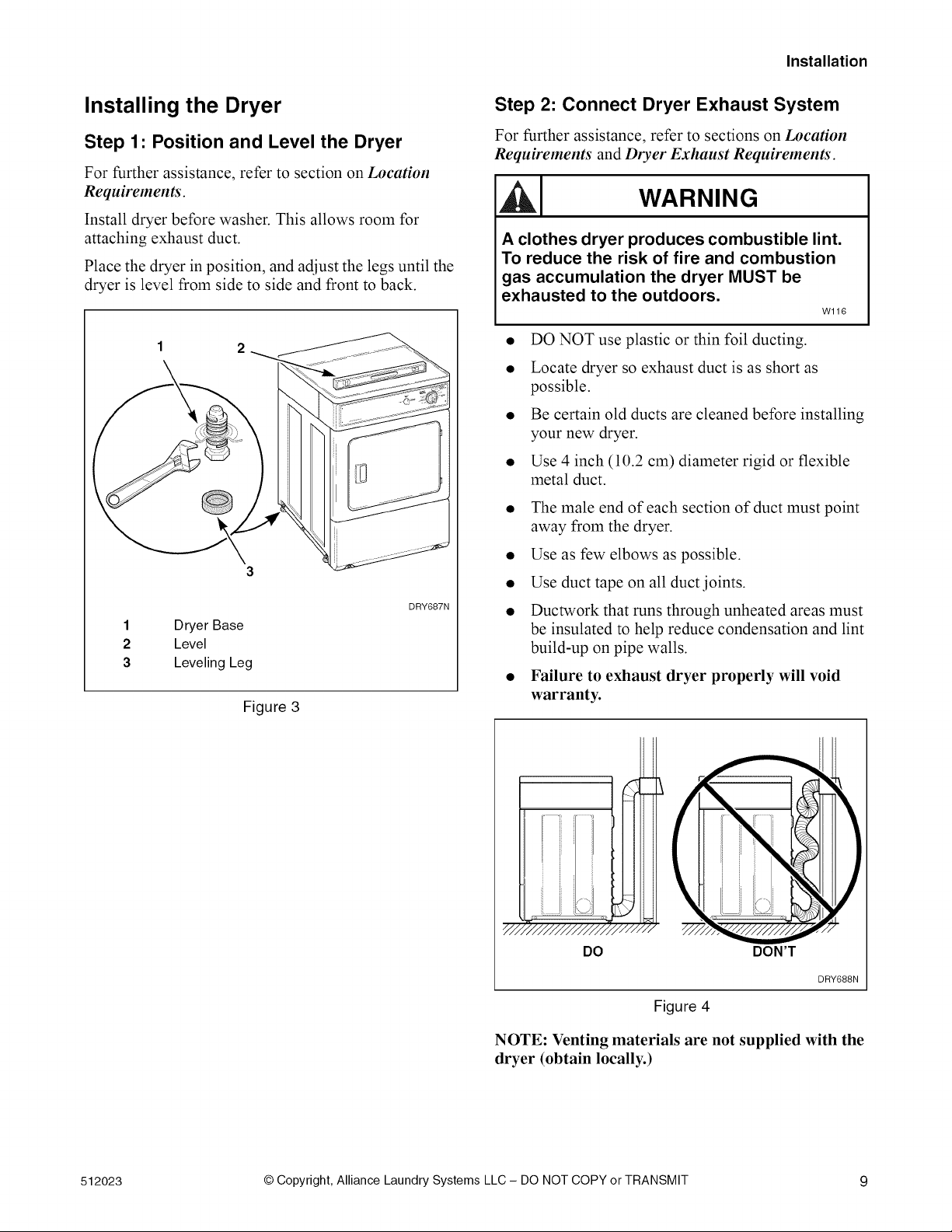

Exhaust

Use rigid metal duct and exhaust the dryer to the

outside by the shortest route possible.

i

//i"/////////////, U/l,

DRY686N

Figure 2

NOTE: For more detailed information, refer to

section on Dryer Exhaust Requirements.

Electrical

ELECTRIC DRYER

Dryer needs a 4 wire 120/240 Volt, 30 Amp, 60 Hertz,

1 Phase electrical supply.

GAS DRYER

Gas

Dryer is equipped for Natural Gas with a 0.375 inch

NPT gas supply connection. For more detailed

information, refer to section on Gas Requirements.

Location

Place the dryer on a solid floor with an adequate air

supply. For more detailed information, refer to section

on Location Requirements.

WARNING

Any disassembly requiring the use of

tools must be performed by a suitably

qualified service person.

W299

Dryer needs a 120 Volt, 15 Amp, 60 Hertz, polarized

3 slot effectively grounded receptacle.

NOTE: For more detailed information, refer to

section on Electrical Requirements.

If the supply cord is damaged, it must be replaced by a

special cord or assembly available from the

manufacturer or its service agent and is to be replaced

by a qualified service person.

8 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 512023

Page 10

Installation

Installing the Dryer

Step 1: Position and Level the Dryer

For further assistance, refer to section on Location

Requirements.

Install dryer before washer. This allows room for

attaching exhaust duct.

Place the dryer in position, and adjust the legs until the

dryer is level from side to side and front to back.

1 2

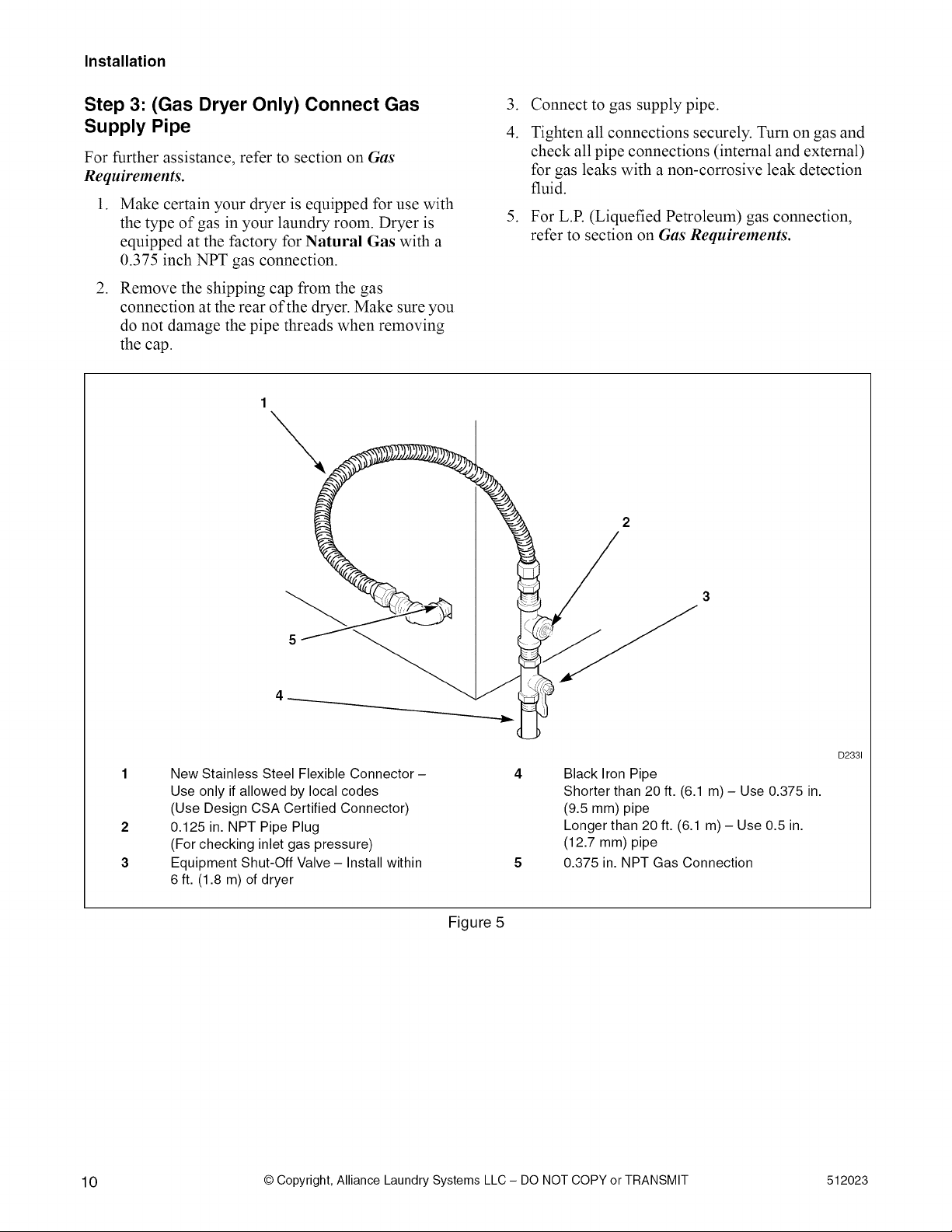

Step 2: Connect Dryer Exhaust System

For further assistance, refer to sections on Location

Requirements and Dryer Exhaust Requirements.

A clothes dryer produces combustible lint.

To reduce the risk of fire and combustion

gas accumulation the dryer MUST be

exhausted to the outdoors.

Wl16

• DO NOT use plastic or thin foil ducting.

• Locate dryer so exhaust duct is as short as

possible.

• Be certain old ducts are cleaned before installing

your new dryer.

• Use 4 inch (10.2 cm) diameter rigid or flexible

metal duct.

• The male end of each section of duct must point

away from the dryer.

• Use as few elbows as possible.

• Use duct tape on all duct joints.

DRY687N

1

2

3

Dryer Base

Level

Leveling Leg

• Ductwork that runs through unheated areas must

be insulated to help reduce condensation and lint

build-up on pipe walls.

• Failure to exhaust dryer properly will void

warranty.

Figure 3

Z_

DO DON'T

DRY688N

Figure 4

NOTE: Venting materials are not supplied with the

dryer (obtain locally.)

512023 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 9

Page 11

Installation

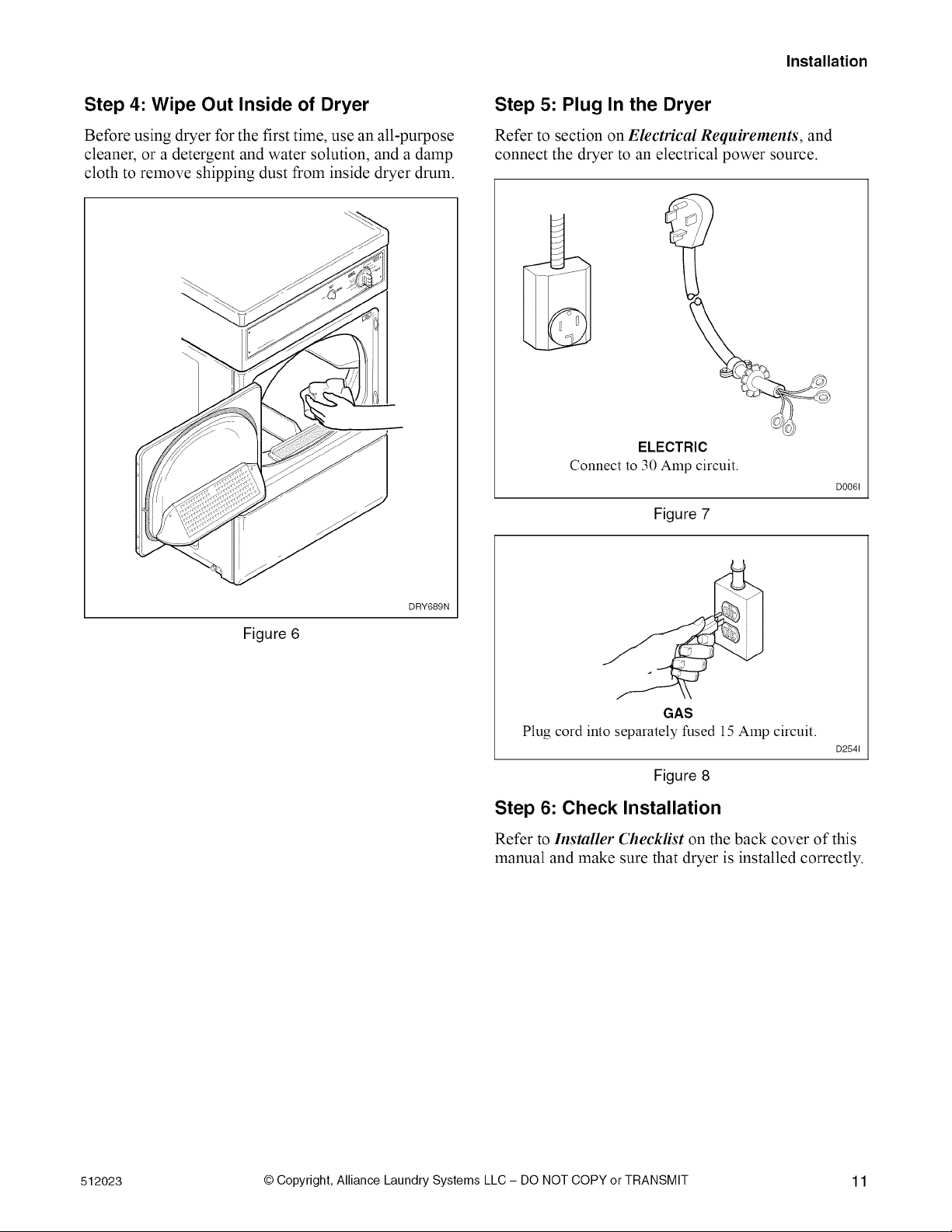

Step 3: (Gas Dryer Only) Connect Gas

Supply Pipe

For further assistance, refer to section on Gas

Requirements.

.

Make certain your dryer is equipped for use with

the type of gas in your laundry room. Dryer is

equipped at the factory for Natural Gas with a

0.375 inch NPT gas connection.

.

Remove the shipping cap from the gas

connection at the rear of the dryer. Make sure you

do not damage the pipe threads when removing

the cap.

.

Connect to gas supply pipe.

4.

Tighten all connections securely. Turn on gas and

check all pipe connections (internal and external)

for gas leaks with a non-corrosive leak detection

fluid.

.

For L.R (Liquefied Petroleum) gas connection,

refer to section on Gas Requirements.

2

3

4

D2331

New Stainless Steel Flexible Connector -

Use only if allowed by local codes

(Use Design CSA Certified Connector)

2

3

0.125 in. NPT Pipe Plug

(For checking inlet gas pressure)

Equipment Shut-Off Valve - Install within

6 ft. (1.8 m) of dryer

Black Iron Pipe

Shorter than 20 ft. (6.1 m) - Use 0.375 in.

(9.5 mm) pipe

Longer than 20 ft. (6.1 m) - Use 0.5 in.

(12.7 mm) pipe

0.375 in. NPT Gas Connection

Figure 5

10 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 512023

Page 12

Installation

Step 4: Wipe Out Inside of Dryer

Before using dryer for the first time, use an all-purpose

cleaner, or a detergent and water solution, and a damp

cloth to remove shipping dust from inside dryer drum.

Step 5: Plug In the Dryer

Refer to section on Electrical Requirements, and

connect the dryer to an electrical power source.

ELECTRIC

Connect to 30 Amp circuit.

D0061

Figure 7

Figure 6

DRY689N

GAS

Plug cord into separately fused 15 Amp circuit.

D2541

Figure 8

Step 6: Check Installation

Refer to Installer Checkfist on the back cover of this

manual and make sure that dryer is installed correctly.

512023 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 11

Page 13

Installation

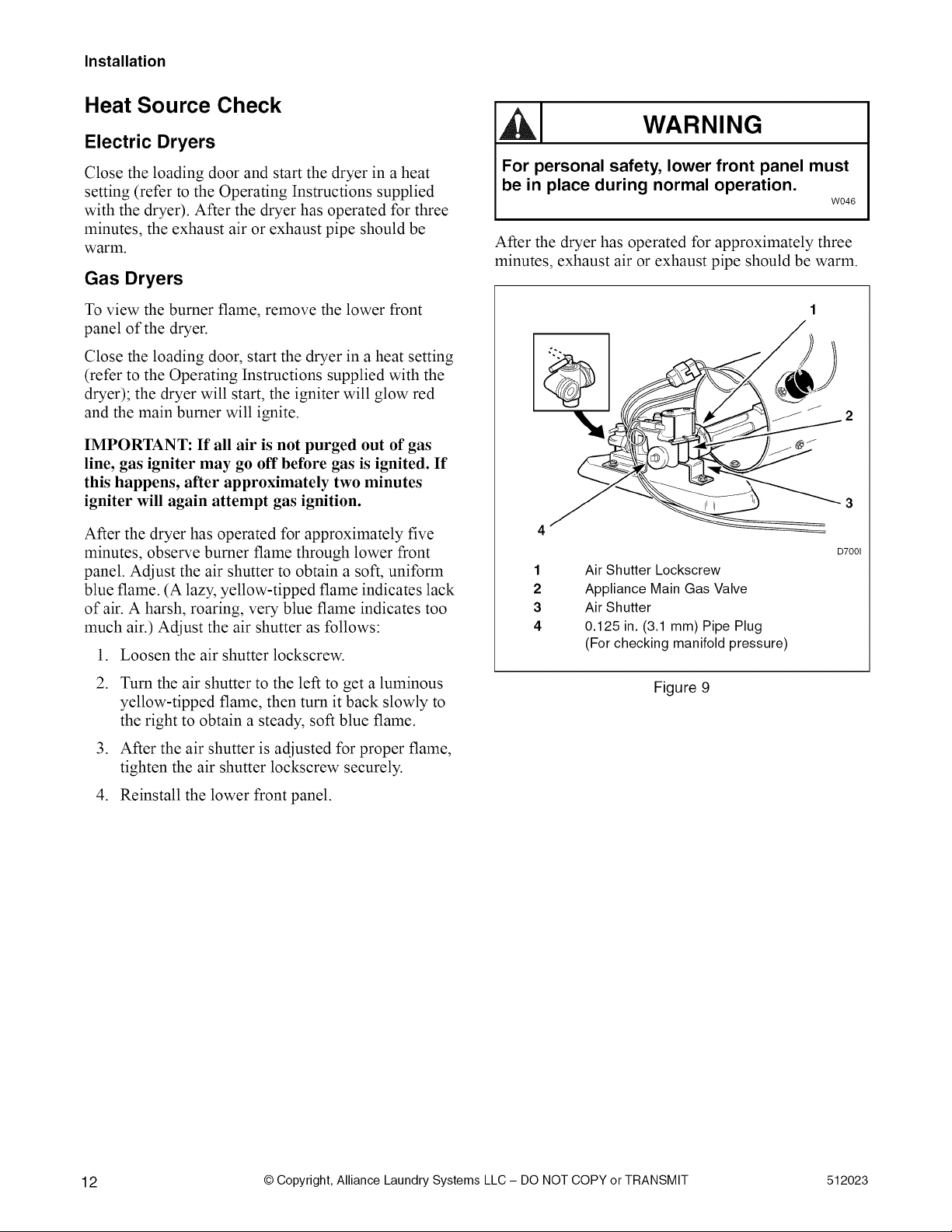

Heat Source Check

Electric Dryers

Close the loading door and start the dryer in a heat

setting (refer to the Operating Instructions supplied

with the dryer). After the dryer has operated for three

minutes, the exhaust air or exhaust pipe should be

warm.

Gas Dryers

To view the burner flame, remove the lower front

panel of the dryer.

Close the loading door, start the dryer in a heat setting

(refer to the Operating Instructions supplied with the

dryer); the dryer will start, the igniter will glow red

and the main burner will ignite.

IMPORTANT: If all air is not purged out of gas

line, gas igniter may go off before gas is ignited. If

this happens, after approximately two minutes

igniter will again attempt gas ignition.

WARNING

For personal safety, lower front panel must

be in place during normal operation.

W046

After the dryer has operated for approximately three

minutes, exhaust air or exhaust pipe should be warm.

After the dryer has operated for approximately five

minutes, observe burner flame through lower front

panel. Adjust the air shutter to obtain a soft, uniform

blue flame. (A lazy, yellow-tipped flame indicates lack

of air. A harsh, roaring, very blue flame indicates too

much air.) Adjust the air shutter as follows:

1. Loosen the air shutter lockscrew.

.

Turn the air shutter to the left to get a luminous

yellow-tipped flame, then turn it back slowly to

the right to obtain a steady, soft blue flame.

.

After the air shutter is adjusted for proper flame,

tighten the air shutter lockscrew securely.

4. Reinstall the lower front panel.

D7001

1

2

3

4

Air Shutter Lockscrew

Appliance Main Gas Valve

Air Shutter

0.125 in. (3.1 mm) Pipe Plug

(For checking manifold pressure)

Figure 9

12 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 512023

Page 14

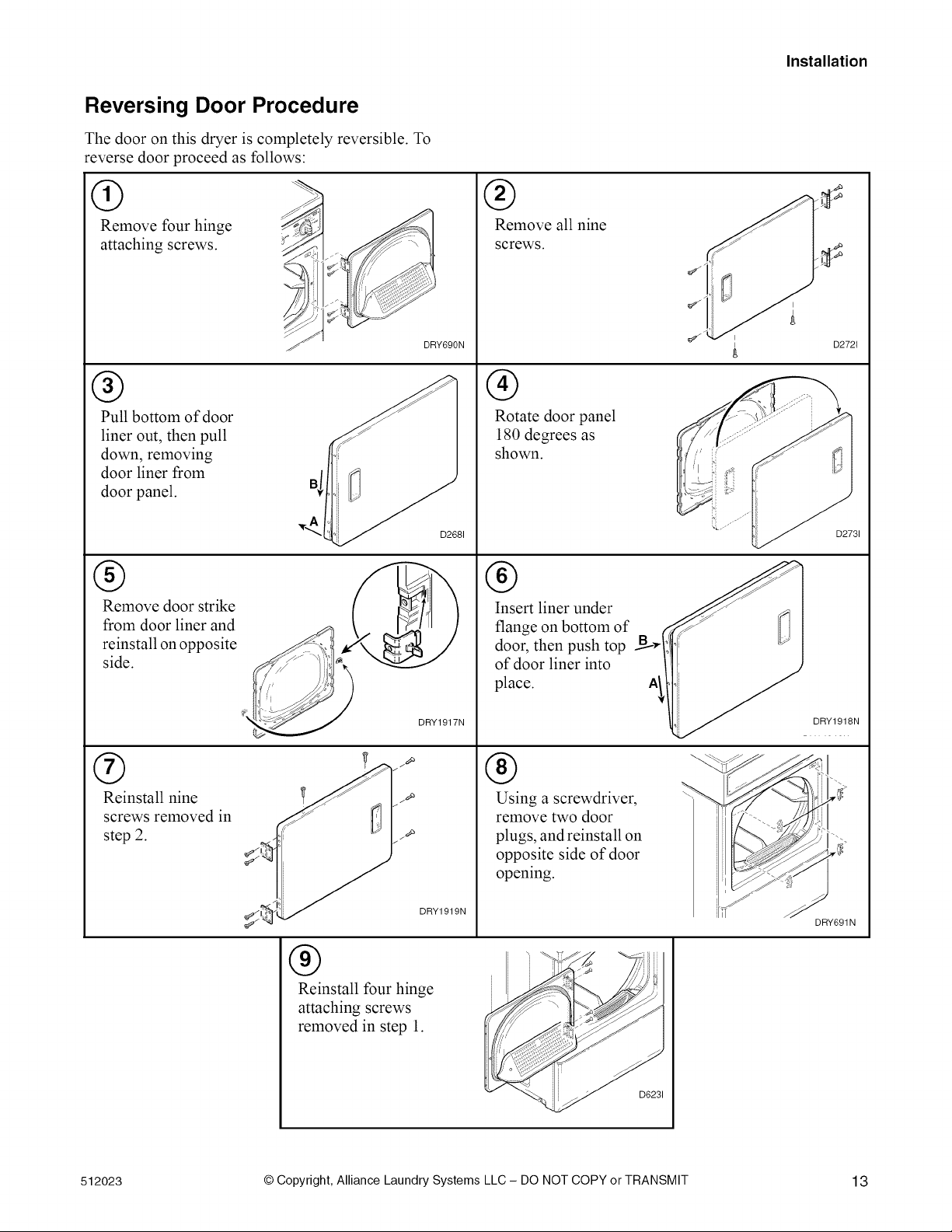

Reversing Door Procedure

The door on this dryer is completely reversible. To

reverse door proceed as follows:

Installation

(!)

Remove four hinge

attaching screws.

®

Pull bottom of door

liner out, then pull

down, removing

door liner from

door panel.

®

Remove door strike

from door liner and

reinstall on opposite

side.

DRY690N

D2681

®

Remove all nine

screws.

D2721

®

Rotate door panel

180 degrees as

shown.

D2731

®

Insert liner under

flange on bottom of

door, then push top B-ga'!

of door liner into

place.

®

Reinstall nine

screws removed in

step 2.

®

Reinstall four hinge

attaching screws

removed in step 1.

/,_

DRY1917N

DRY1919N

DRY1918N

®

Using a screwdriver,

remove two door

plugs, and reinstall on

opposite side of door

opening.

DRY691 N

D6231

512023 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 13

Page 15

Installation

Manufactured (Mobile) Home

Installation

IMPORTANT: Installation must conform to 1

the Manufactured Home Construction and 1

Safety Standards, Title 24 CFR, Part 32-80 |

Standard CAN/CSA-Z240

The dryer can be installed in a manufactured (mobile)

home by following these instructions:

.

IMPORTANT: Gas dryers MUST be

permanently attached to the floor at the time

of installation. Order No. 526P3 Dryer

Installation Kit for a manufactured (mobile)

home installation. Follow the instructions

supplied with the kit.

2. Venting - Dryer MUST be exhausted to the

outdoors.

The dryer exhaust duct must be secured to the

mobile home structure.

Exhaust ducts MUST NOT be connected with

sheet metal screws or fasteners which extend into

the duct.

Exhaust duct must not be connected to any other

duct, vent or chimney.

Dryer exhaust duct MUST NOT terminate under

the mobile home.

For proper operation, it is important that the dryer

has an ample amount of outside make-up air. The

free area of any opening for the introduction of

outside air must be at least 25 in2 (163 cm2).

When exhausting the dryer to the outdoors, the

dryer can be installed with "0" inch clearance at

the sides and rear. Clearance of the duct from

combustible construction must be a minimum of

2 inches (5.08 cm).

Venting materials are not supplied with the dryer

(obtain locally).

WARNING

To reduce the risk of fire and combustion

gas accumulation, the dryer MUST BE

EXHAUSTED TO THE OUTDOORS. Refer to

Section on Dryer Exhaust Requirements.

The dryer can be exhausted to the outdoors

through the back, left, right or bottom panel. Gas

dryers cannot be exhausted out the left side

because of the burner housing.

W047

WARNING

To reduce the risk of fire, the exhaust duct

and weather hood MUST be fabricated of a

material that will not support combustion.

Rigid or flexible metal pipe is

recommended for a clothes dryer.

W048

14 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 512023

Page 16

Installation

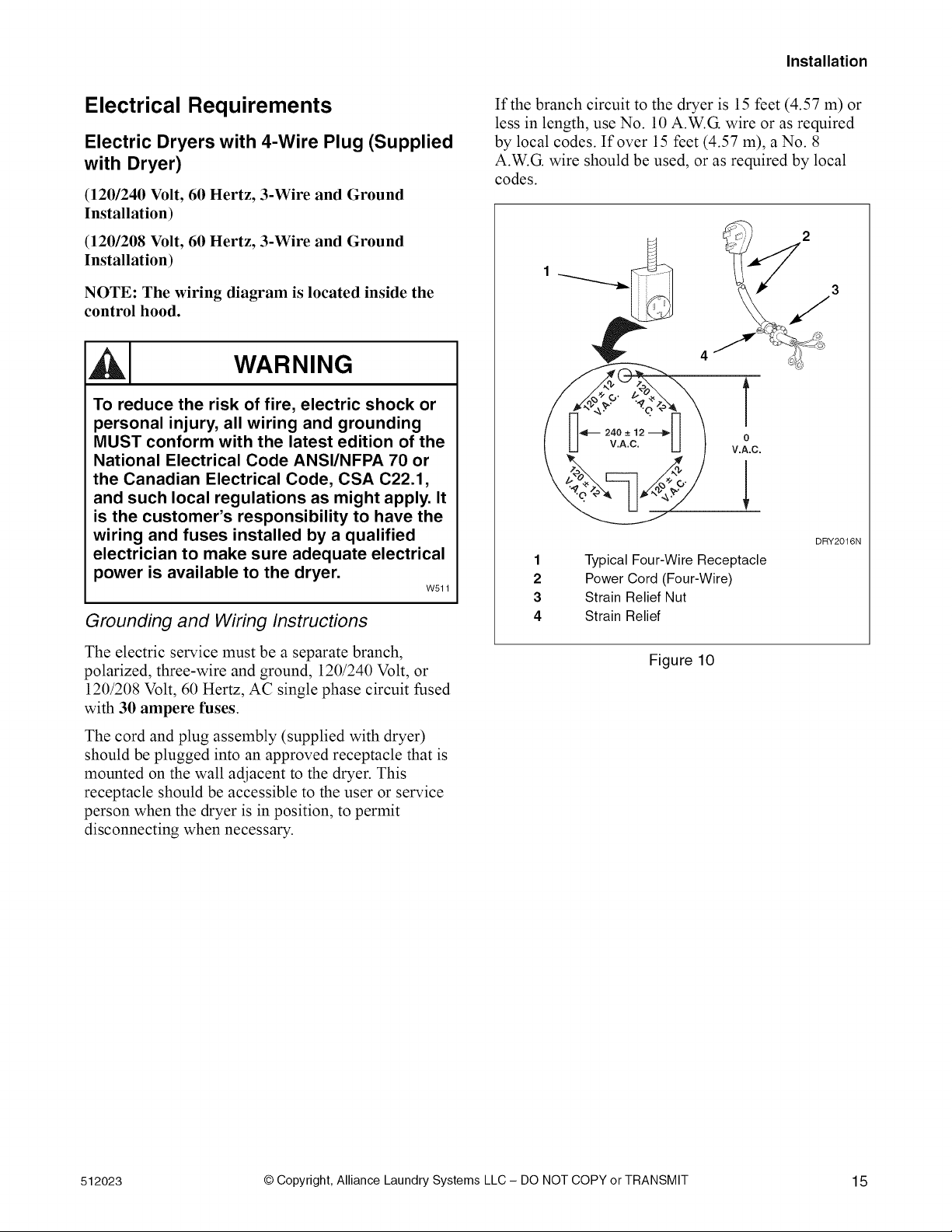

Electrical Requirements

Electric Dryers with 4-Wire Plug (Supplied

with Dryer)

(120/240 Volt, 60 Hertz, 3-Wire and Ground

Installation)

(120/208 Volt, 60 Hertz, 3-Wire and Ground

Installation)

NOTE: The wiring diagram is located inside the

control hood.

WARNING

To reduce the risk of fire, electric shock or

personal injury, all wiring and grounding

MUST conform with the latest edition of the

National Electrical Code ANSI/NFPA 70 or

the Canadian Electrical Code, CSA C22.1,

and such local regulations as might apply. It

is the customer's responsibility to have the

wiring and fuses installed by a qualified

electrician to make sure adequate electrical

power is available to the dryer.

W511

Grounding and Wiring Instructions

If the branch circuit to the dryer is 15 feet (4.57 m) or

less in length, use No. 10 A.W.G. wire or as required

by local codes. If over 15 feet (4.57 m), a No. 8

A.W.G. wire should be used, or as required by local

codes.

;

0

V.A.C.

DRY2016N

1 Typical Four-Wire Receptacle

2 Power Cord (Four-Wire)

3 Strain Relief Nut

4 Strain Relief

The electric service must be a separate branch,

polarized, three-wire and ground, 120/240 Volt, or

120/208 Volt, 60 Hertz, AC single phase circuit fused

with 30 ampere fuses.

The cord and plug assembly (supplied with dryer)

should be plugged into an approved receptacle that is

mounted on the wall adjacent to the dryer. This

receptacle should be accessible to the user or service

person when the dryer is in position, to permit

disconnecting when necessary.

Figure 10

512023 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 15

Page 17

Installation

Electric Dryers with 3-Wire Plug (Requires

Conversion)

(120/240 Volt, 60 Hertz, 3-Wire Installation)

(120/208 Volt, 60 Hertz, 3-Wire Installation)

NOTE: The wiring diagram is located inside the

control hood.

WARNING

To reduce the risk of fire, electric shock,

serious injury or death, all wiring and

grounding MUST conform with the latest

edition of the National Electrical Code,

ANSI/NFPA 70, or the Canadian Electrical

Code, CSA C22.1, and such local

regulations as might apply. It is the

customer's responsibility to have the wiring

and fuses installed by a qualified electrician

to make sure adequate electrical power is

available to the dryer.

W512

Grounding Instructions

If branch circuit to dryer is 15 feet (4.57 m) or

less in length, use No. l0 A.W.G. wire (copper

wire only), or as required by local codes. If over

15 feet (4.57 m), use No. 8 A.W.G. wire (copper

wire only), or as required by local codes. Allow

sufficient slack in wiring so dryer can be moved

from its normal location when necessary.

The power cord (pigtail) connection between

wall receptacle and dryer terminal block IS NOT

supplied with dryer. Type of pigtail and gauge

of wire must conform to local codes and with

instructions mentioned on the following pages.

The method of wiring the dryer is optional and

subject to local code requirements. Refer to

Figure 11.

This dryer must be connected to a grounded

metal, permanent wiring system; or an

equipment-grounding conductor must be run

with the circuit conductors and connected to the

equipment-grounding terminal or lead on the

dryer.

The dryer has its own terminal block that must be

connected to a separate branch, 60 Hertz, single

phase circuit, AC (alternating current) circuit,

fused at 30 Amperes (the circuit must be fused

on both sides of the line). Electrical service for

the dryer should be of maximum rated voltage

listed on the nameplate. Do not connect dryer

to 110, 115, or 120 Volt circuit. Heating

elements are available for field installation in

dryers which are to be connected to electrical

service of different voltage than that listed on

nameplate, such as 208 Volt.

16 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 512023

Page 18

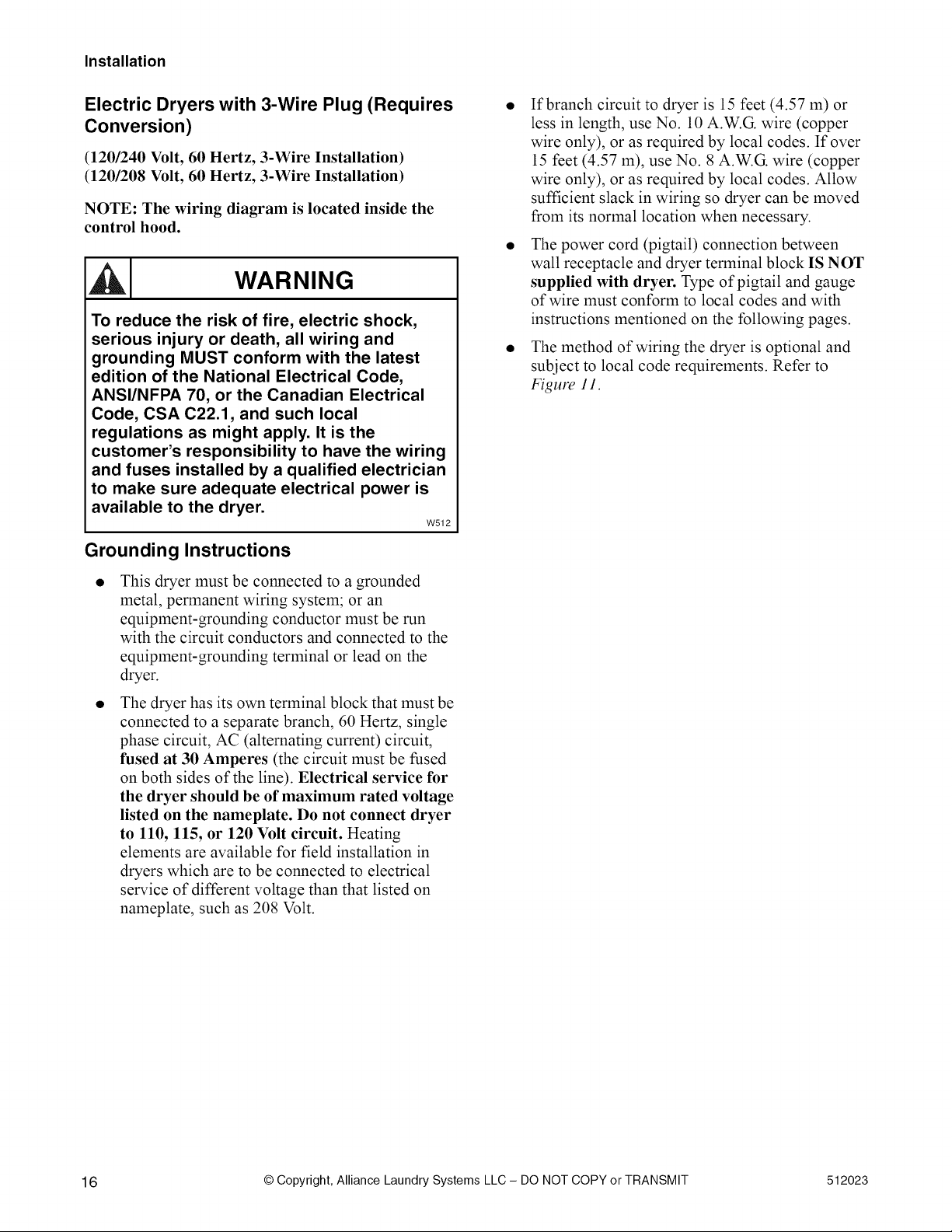

Three-Wire Plug

NOTE: The power cord (pigtail) is NOT supplied with the electric

dryer. Type of pigtail and gauge of wire must conform to local

codes and instructions.

The method of wiring the dryer is optional and subject to local

code requirements.

NOTE: Connect the dryer to the power supply with the

MAXIMUM RATED VOLTAGE listed on the nameplate.

POWER SUPPLY

Installation

POWER SUPPLY

_1_

2

A typical

30-Amp

Three-wire

Receptacle

NEMA Type

10-30R

240 -+12

V.A.C,

_ 120-+12

, V.A.C.

120-+12

V.A.C.

NOTE: Use COPPER WIRE only.

Shorter than 15 ft. (4.5 m) use 10 A.W.G.

Longer than 15 ft. (4.5 m) use 8 A.W.G.

INTERMEDIATE

FUSE BOX (May

be omitted if

service entrance

box is fused)

WALL RECEPTACLE

3-Wire Grounded Neutral 120/240 Volt, 60 Hertz

AC 1 Phase Service Entrance Switch Box

(Refer to NOTE above)

2

3

30 Ampere Fuses or Circuit Breaker

Neutral Wire

To Convert from 4-Wire Connection to 3-Wire

Connection

L1 L2

PIGTAIL CONNECTION

Figure 11

INTERMEDIATE

SHUT-OFF BOX

(May or may

r not be fused)

L1 L2

DIRECT CONNECTION

D8161

4

Metallic or Non-Metallic Sheathed Cable

(Copper wire only)

5

6

7

Pigtail to Dryer (Refer to NOTE above)

Neutral

Terminal Block in Dryer

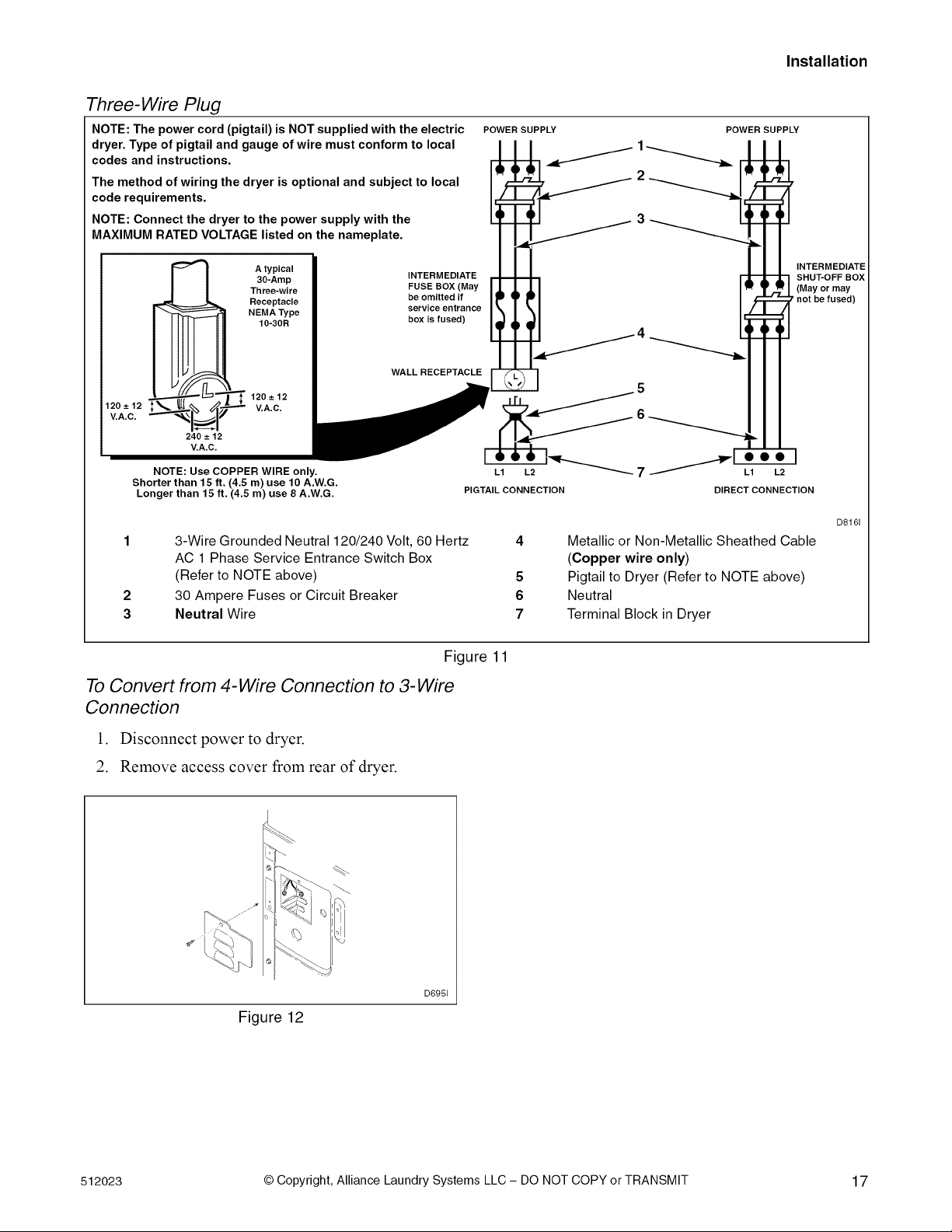

l. Disconnect power to dryer.

2. Remove access cover from rear of dryer.

D6951

Figure 12

512023 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 17

Page 19

Installation

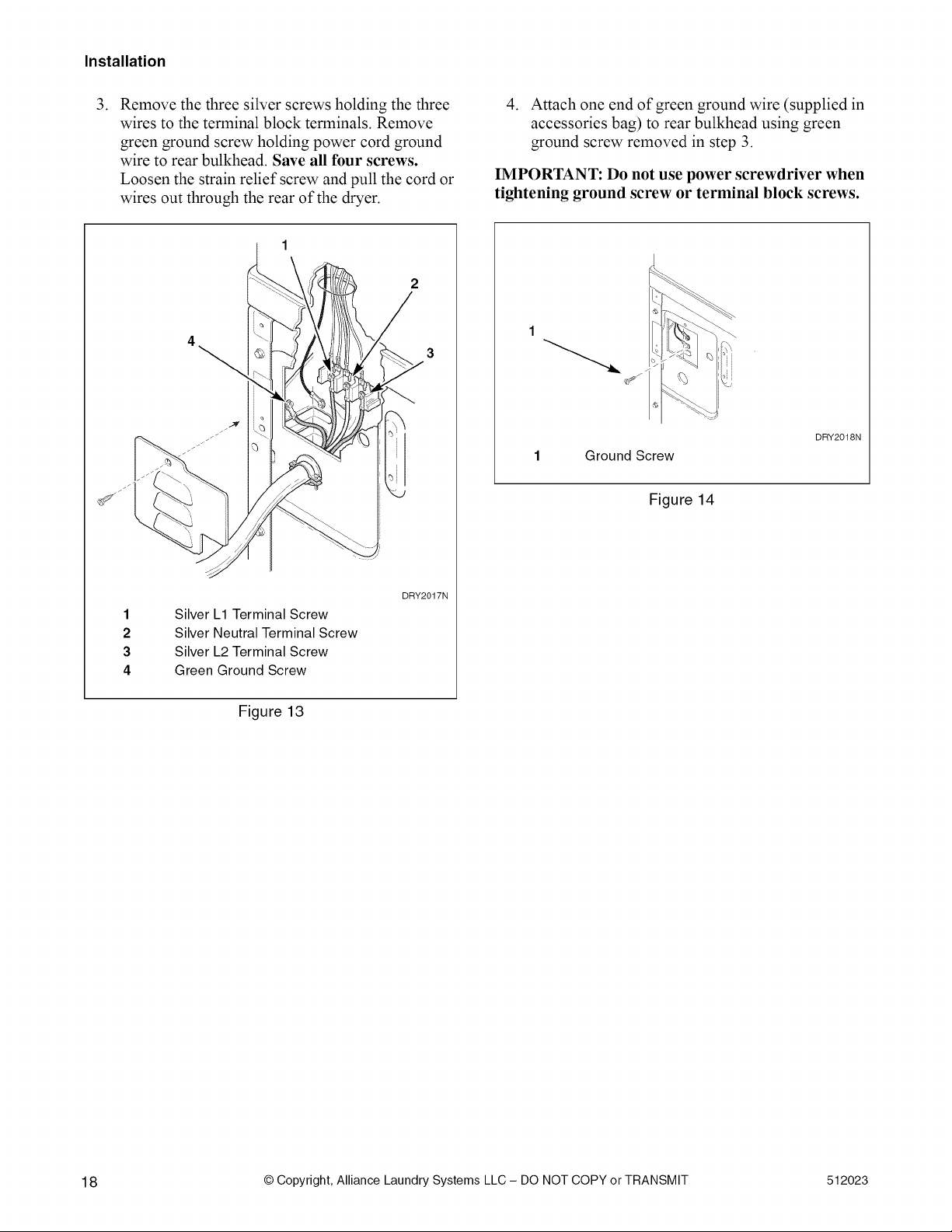

.

Remove the three silver screws holding the three

wires to the terminal block terminals. Remove

green ground screw holding power cord ground

wire to rear bulkhead. Save all four screws.

Loosen the strain relief screw and pull the cord or

wires out through the rear of the dryer.

4. Attach one end of green ground wire (supplied in

accessories bag) to rear bulkhead using green

ground screw removed in step 3.

IMPORTANT: Do not use power screwdriver when

tightening ground screw or terminal block screws.

1

DRY2018N

1 Ground Screw

Figure 14

DRY2017N

1

2

3

4

Silver L1 Terminal Screw

Silver Neutral Terminal Screw

Silver L2 Terminal Screw

Green Ground Screw

Figure 13

18 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 512023

Page 20

.

Use the three silver screws removed in step 3 to

attach the wires from the new power cord and the

other end of the green ground wire to the terminal

block as shown in Figure 15.

NOTE: Green ground wire must be connected to

center (neutral) terminal of terminal block.

8

Installation

6. Tighten all screws and reinstall access cover

removed in step 2.

IMPORTANT: Failure to tighten these screws

firmly may result in wire failure at the terminal

block.

.

Secure the strain relief to the power cord, or

wires, where they enter the dryer cabinet.

.

Check the continuity of the ground connection

before plugging the cord into an outlet. Use an

acceptable indicating device connected to the

center grounding pin of the plug and the green

screw on the back of cabinet.

.

Reinstall access cover and screw.

10.

Restore power to dryer.

5

DRY2015N

1

2

3

4

5

6

7

8

Ground to Neutral Wire

Neutral Terminal

L2 Terminal

Center (Neutral) Wire

Strain Relief (not supplied with dryer)

Green Ground Screw

L1 Terminal

Ground Wire

Figure 15

512023 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 19

Page 21

Installation

Gas Dryers

NOTE: The wiring diagram is located inside the

control hood.

WARNING

To reduce the risk of fire, electric shock,

serious injury or death, all wiring and

grounding MUST conform with the latest

edition of the National Electrical Code,

ANSI/NFPA 70, or the Canadian Electrical

Code, CSA C22.1, and such local

regulations as might apply. It is the

customer's responsibility to have the

wiring and fuses checked by a qualified

electrician to make sure your home has

adequate electrical power to operate the

dryer.

• DO NOT

OVERLOAD

CIRCUITS

• DO NOT

USE AN

ADAPTER

• DO NOT

USE AN

EXTENSION

CORD

Wl13

Do not modify the plug provided with the dryer - if it

will not fit the outlet, have a proper outlet installed by

a qualified electrician.

WARNING

This dryer is equipped with a three-prong

(grounding) plug for your protection

against shock hazard and should be

plugged directly into a properly grounded

three-prong receptacle. Do not cut or

remove the grounding prong from this

plug.

1 2

W036

DO091

Figure 16

Grounding Instructions

The dryer must be grounded. In the event of

malfunction or breakdown, grounding will reduce the

risk of electric shock by providing a path of least

resistance for electric current. The dryer is equipped

with a cord having an equipment-grounding conductor

and a 3 prong grounding plug. The three-prong

grounding plug on the power cord should be plugged

directly into a polarized three-slot effectively

grounded receptacle rated 110/120 Volts AC

(alternating current) 15 Amps.

WARNING

Improper connection of the equipment-

grounding conductor can result in a risk of

electric shock. Check with a qualified

electrician or service person if you are in

doubt as to whether the dryer is properly

grounded.

W038

STANDARD 120 VOLT, 60 HERTZ,

3 WIRE EFFECTIVELY

GROUNDED CIRCUIT

1

2

3

4

5

L1

Ground

Neutral

Round Grounding Prong

Neutral Side

Figure 17

D0901

20 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 512023

Page 22

NOTE: Have a qualified electrician check the

polarity of the wall receptacle. If a voltage reading

is measured other than that illustrated, the

qualified electrician should correct the problem.

Do not operate other appliances on the same circuit

when this appliance is operating.

WARNING

To reduce the risk of an electric shock or

fire, DO NOT use an extension cord or an

adapter to connect the dryer to the

electrical power source,

W037

Installation

512023 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 21

Page 23

Installation

Gas Requirements

Gas Dryers

NOTE: The gas service to a gas dryer must

conform with the local codes and ordinances, or in

the absence of local codes and ordinances, with the

latest edition of the National Fuel Gas Code ANSI

Z223.1/NFPA 54 or the CAN/CGA-B149, National

Gas Installation Code.

Natural Gas, 1000 Btu/ft 3 (37.3 MJ/m 3) service must

be supplied at 6.5 + 1.5 inch water column pressure.

For proper operation at altitudes above 2500 feet

(760 m) the natural gas valve spud orifice size must be

reduced to ensure complete combustion. Refer to

Table 1.

L.P. (Liquefied Petroleum) Gas, 2500 Btu/ft 3

(93.1 MJ/m 3) service must be supplied at 10 + 1.5 inch

water column pressure.

NOTE: DO NOT connect the dryer to L.P. Gas

Service without converting the gas valve. An LPK1

Sales Accessory (L.P. Gas Conversion Kit 649P3)

must be installed.

NOTE: The dryer and its appliance main gas valve

must be disconnected from the gas supply piping

system during any pressure testing of that system

at test pressures in excess of 0.5 psi (3.45 kPa).

The dryer must be isolated from the gas supply piping

system by closing the equipment shut-off valve during

any pressure testing of the gas supply piping system at

test pressures equal to or less than 0.5 psi (3.45 kPa).

NOTE: When connecting to a gas line, an

equipment shut-off valve must be installed within

6 feet (1.8 m) of the dryel. An 0.125 inch NPT pipe

plug must be installed as shown. Refer to Figure 18.

Natural Gas Altitude Adjustments

Altitude

Orifice Size

Part No.

feet m

3000 915

6000 1830

8000 2440

9000 2740

10000 3050

# inches mm

43 0.0890 2.26

44 0.0860 2.18

45 0.0820 2.08

46 0.0810 2.06

47 0.0785 1.99

503778

58719

503779

503780

503781

Table 1

WARNING

To reduce the risk of gas leaks, fire or

explosion:

• The dryer must be connected to the type

of gas as shown on nameplate located in

the door recess.

• Use a new flexible stainless steel

connector.

• Use pipe joint compound insoluble in L.P.

(Liquified Petroleum) Gas, or Teflon tape,

on all pipe threads.

° Purge air and sediment from gas supply

line before connecting it to the dryer.

Before tightening the connection, purge

remaining air from gas line to dryer until

odor of gas is detected. This step is

required to prevent gas valve

contamination.

• Do not use an open flame to check for

gas leaks. Use a non-corrosive leak

detection fluid.

W309

22 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 512023

Page 24

Installation

4

New Stainless Steel Flexible Connector -

Use only if allowed by local codes

(Use Design CSA Certified Connector)

2

0.125 in. NPT Pipe Plug

(For checking inlet gas pressure)

3

Equipment Shut-Off Valve - Install within

Black Iron Pipe

Shorter than 20 ft. (6.1 m) - Use 0.375 in.

(9.5 mm) pipe

Longer than 20 ft. (6.1 m) - Use 0.5 in.

(12.7 mm) pipe

0.375 in. NPT Gas Connection

3

D2331

6 ft. (1.8 m) of dryer

Figure 18

512023 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 23

Page 25

Installation

Location Requirements

Select a location with a solid floor. Dryers installed in

residential garages must be elevated 18 inches (46 cm)

above the floor.

No other fuel burning appliance should be installed in

the same closet with the dryer.

The dryer must not be installed or stored in an area

where it will be exposed to water and/or weather.

!iii!iii!illI

_ J

i; i

Leveling legs can be adjusted from inside the dryer

with a 1/4 inch driver. All four legs must rest firmly on

the floor so the weight of the dryer is evenly

distributed. The dryer must not rock.

The dryer needs sufficient clearance and an adequate

air supply for proper operation and ventilation, and for

easier installation and servicing. (Minimum clearances

are shown in Figure 19.)

i F

q E 2 (G)

F

- .-.

FRONT VIEW

(w/o Closet Door)

Area Description Installation

A Dryer sides and rear clearance 0 in. (0 cm) 0 in. (0 cm)

B Dryer top clearance 12 in. (30.5 cm) 12 in. (30.5 cm)

C Dryer front clearance Not Applicable 2 in. (5.1 cm)

D Exhaust duct clearance to 2 in. (5.1 cm) 2 in. (5.1 cm)

combustible material

E Weather hood to ground clearance 12 in. (30.5 cm) 12 in. (30.5 cm)

F Distance from floor or ceiling to Not Applicable 3 in. (7.6 cm)

hole edge

G* Area of centered air openings in Not Applicable 40 sq. in./open (260 sq. cm)

closet door

*Louvered door with equivalent air openings is acceptable. (Minimum clearances are shown.)

**NOTE: For new installations, locate top of wall vent 42 inches (106.7 cm) above floor to make venting easier to

connect.

1 Closet Door

2 Centered Air Openings (2 openings minimum)

3 Outer Wall of Enclosure

SIDE VIEW 3 FRONTVIEW

(Closet Door)

Free Standing/Alcove Closet Installation

DRY1991N

Figure 19

24 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 512023

Page 26

Installation

Dryer Exhaust Requirements

A clothes dryer produces combustible lint.

To reduce the risk of fire and combustion

gas accumulation the dryer MUST be

exhausted to the outdoors.

This gas appliance contains or produces a

chemical or chemicals which can cause

death or serious illness and which are

known to the State of California to cause

cancer, birth defects, or other reproductive

harm. To reduce the risk from substances

in the fuel or from fuel combustion, make

sure this appliance is installed, operated,

and maintained according to the

instructions in this manual.

To reduce the risk of fire and the

accumulation of combustion gases, DO

NOT exhaust dryer air into a window well,

gas vent, chimney or enclosed,

unventilated area, such as an attic, wall,

ceiling, crawl space under a building or

concealed space of a building.

To reduce the risk of fire, DO NOT use

plastic or thin foil ducting to exhaust the

dryer.

Wl16

Wl15

W045

W354

Exhaust System Materials

Exhaust duct must be 4 inches (10.2 cm) in diameter

having no obstructions. Rigid metal duct is

recommended. Non-combustible flexible metal duct is

acceptable. Do not use plastic pipe or thin foil ducting,

because it contributes to poor drying performance and

collects lint, which can lead to a fire hazard.

Never install flexible duct in concealed spaces, such as

a wall or ceiling.

DO NOT use sheet metal screws on exhaust pipe joints

or other fastening means which extend into the duct

that could catch lint and reduce the efficiency of the

exhaust system. Secure all duct joints with duct tape.

Make-Up Air Requirements

For proper operation it is important that you locate the

dryer in an area that has an ample amount of make-up

air to replace the amount exhausted by the dryer.

A dryer exhausts 220 cfm (measured at back of dryer).

Energy efficient homes with low air infiltration rates

should be equipped with an air exchanger that can

accommodate on demand make-up air needs in the

home. These devices can be obtained through your

building contractor or building material suppliers.

_//////////////,

/./,

DO DON'T

DRY688N

Figure 20

512023 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 25

Page 27

Installation

Exhaust System

IMPORTANT: Keep exhaust duct as short as

possible.

NOTE: Be certain old ducts are cleaned before

installing your new dryel.

For best drying results, recommended maximum

length of exhaust system is shown in Table 2.

To prevent backdraft when dryer is not in operation,

outer end of exhaust pipe must have a weather hood

with hinged dampers (obtain locally).

NOTE: Weather hood should be installed at least

12 inches (30.5 cm) above the ground. Larger

clearances may be necessary in areas where heavy

snowfall can occm.

Exhaust Direction

The dryer can be exhausted to the outdoors through the

back, left, right or bottom of the dryer. EXCEPTION:

Gas dryers cannot be vented out the left side

because of the burner housing.

Dryer is shipped from factory ready for rear exhaust;

no kits required.

Exhausting the dryer through sides or bottom can be

accomplished by installing a DK1 Sales Accessory

(Directional Exhaust Kit 528P3) available as optional

equipment at extra cost.

528P3 DIRECTIONAL EXHAUST KIT

D3711

Figure 21

Number of Weather Hood Type

90 ° Elbows Recommended Use only for short run installations

4 in. "_

(10.2 cm) (10.2 cm)

D6731 2.5 in.

(6.35 cm)

Maximum length of 4 in. (10.2 cm) diameter rigid metal duct

0 65 feet (19.8 m) 55 feet (16.8 m)

1 55 feet (16.8 m) 47 feet (14.3 m)

2 47 feet (14.3 m) 41 feet (12.5 m)

3 36 feet (11.0 m) 30 feet (9.1 m)

4 28 feet (8.5 m) 22 feet (6.7 m)

Maximum length of 4 in. (10.2 cm) diameter flexible metal duct

0 45 feet (13.7 m) 35 feet (10.7 m)

1 35 feet (10.7 m) 27 feet (8.2 m)

2 30 feet (9.1 m) 21 feet (6.4 m)

3 25 feet (7.6 m) 17 feet (5.2 m)

4 20 feet (6.1 m) 15 feet (4.5 m)

NOTE: Deduct 6 feet (1.8 m) for each additional elbow.

Table 2

D8021

26 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 512023

Page 28

Installation

Exhaust System Maintenance

The dryer interior and the complete exhaust system

should be inspected after one year of use and cleaned

if necessary. Inspect and clean exhaust duct every one

to two years as required thereafter. The weather hood

should be checked frequently to make sure the

dampers move freely, dampers are not pushed in and

that nothing has been set against them. This

maintenance work should be done by a qualified

service person.

WARNING

To reduce the risk of electric shock,

disconnect the electrical service to the

dryer before cleaning.

W043

Exhausting the dryer in hard-to-reach locations can be

accomplished by installing the 521 P3 Flexible Metal

Vent Kit, available as optional equipment at extra cost.

The kit comes in two halves that can be separately

attached to the dryer and wall outlet. Once attached,

the dryer can be slid back into position and the two

halves connected from the front.

Dryer Airflow

Efficient dryer operation requires proper dryer airflow.

Proper dryer airflow can be evaluated by measuring

the static pressure.

Static pressure in the dryer's exhaust duct should be no

greater than that shown in Figure 23. (Check with

dryer running and no load.)

NOTE: This can be measured with a manometer

placed on the exhaust duct approximately two feet

(61 cm) from the dryel. Refer to Figure 23.

MAXIMUM STATIC

PRESSURE IN

WATER COLUMN

0.6 in. (1.5 cm)

521P3 FLEXIBLE METAL VENT KIT

Figure 22

D6241

1

2

MEASURING STATIC PRESSURE

D0121

Manometer

Exhaust Duct

Figure 23

512023 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 27

Page 29

Notes

28 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 512023

Page 30

Maintenance

User-Maintenance Instructions

Lubrication

CAUTION

All moving parts are sealed in a permanent supply of

lubricant or are equipped with oilless bearings.

Additional lubrication will not be necessary.

Care of Your Dryer

Clean the lint filter after drying each load. The lint

filter may be washed if needed. Annually remove lint

filter and screw to vacuum the duct under it.

Ordinarily, the dryer cylinder will need no care.

Wipe the dryer cabinet as needed. If detergent, bleach

or other washing products have been spilled on the

dryer, wipe immediately. Some products will cause

permanent damage if spilled on the cabinet.

Use only a damp or sudsy cloth for cleaning the

control panel. Some spray prewash products may harm

the finish on the control panel.

NOTE: The wiring diagram is located inside the

control panel.

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation.

W049

Exhaust System

The exhaust duct should be inspected after one year of

use and cleaned if necessary. Inspect and clean exhaust

duct every one to two years as required thereafter.

The weather hood should be checked frequently to

make sure the dampers move freely, dampers are not

pushed in and that nothing has been set against them.

Keep dryer area clear and free from combustible

materials, gasoline and other flammable vapors and

liquids.

Do not obstruct the flow of combustion and ventilation

air.

NOTE: Verify proper operation after servicing.

512023 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 29

Page 31

Maintenance

Information for Handy Reference

Alliance Laundry Systems LLC

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

Date Purchased

Model Number

Dealer's Name

Dealer's Address

Service Agency

Service Agency Address

NOTE: Record the above information and keep your sales slip. Model and serial numbers are located

on the nameplate.

Serial Number

Phone Number.

Phone Number

30 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 512023

Page 32

Sdcheuses

automatlques

linge

Modbles dlectriques et _ gaz

r_

Brat

_o

Conserver ces instructions h titre de r6f6rence.

(Si la machine est vendue, le guide dolt _tre remis au nouveau propridtaire.)

liance

Laundry Systems

www.comlaundry.com

DRY683C

Rd£ 512023R2QU

Juin 2007

Page 33

MISE EN GARDE

POUR VOTRE SE_CURITE_, les informations de ce guide doivent 6tre respect6es afin de

r6duire les risques d'incendie, d'explosion ou d'6viter les dommages mat6riels, personnels

ou blessures mortelles.

W033R3QU

• Ne pas entreposer ou utiliser d'essence ou toutes autres vapeurs et liquides inflammables

proximit6 de cette machine ou de tout autre appareil.

• QUE FAIRE EN CAS D'ODEUR DE GAZ :

- Ne pas mettre d'appareil en marche.

- Ne pas toucher aux interrupteurs 61ectriques ; ne pas utiliser le t616phone des lieux.

- E_vacuer la pi6ce, le b&timent ou la zone de tousles occupants.

- Appeler imm6diatement le fournisseur de gaz de la maison d'un voisin. Respecter les

instructions communiqu6es par le fournisseur.

- Si vous ne pouvez pas joindre le fournisseur de gaz, appeler le service d'incendie.

• L'installation et rentretien doivent 6tre effectu6s par un installateur, service d'entretien

qualifi6s ou par le fournisseur de gaz.

IMPORTANT : L'acheteur veillera h s'informer auprbs de la compagnie de gaz locale de la d6marche

suivre au cas oh l'utilisateur de l'appareil d6tecte une odeur de gaz. Les instructions de la compagnie de gaz

ainsi que les avis SI_CURITI_ et AVERTISSEMENT ci-dessus doivent _tre affich6s de faqon bien visible prbs

de l'appareil h l'intention de ses utilisateurs.

W052R5QU

AI

I MISE EN GARDE

i

POUR VOTRE SE_CURITE_

Ne pas entreposer ou utiliser d'essence ou toutes autres vapeurs et liquides inflammables

proximit6 de cette unit6 ou de tout autre appareil.

Les moddles dlectriques sont approuvds par CSA - International.

W053R2QU

512023 (QU) © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 33

Page 34

Remarques

34 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 512023 (QU)

Page 35

Table de

mati res

Pi_ces de rechange .............................................................................. 37

Installation ........................................................................................... 39

Dimensions d'installation ..................................................................... 39

Avant de commencer ............................................................................ 40

Outils ................................................................................................ 40

Gaz ................................................................................................... 40

Emplacement .................................................................................... 40

t_vacuation ........................................................................................ 40

t_lectricit6 ......................................................................................... 40

Installation de la sdcheuse .................................................................... 41

t_tape 1 " Placer la sdcheuse et la mettre _ niveau ............................ 41

t_tape 2 " Raccorder le systbme d'dvacuation de la sdcheuse ........... 41

t_tape 3 " (Uniquement pour les sdcheuses _ gaz)

Raccorder le tuyau d'alimentation en gaz ...................................... 42

t_tape 4 " Nettoyer l'intdrieur de la sdcheuse ................................... 43

t_tape 5 " Brancher la sdcheuse ......................................................... 43

t_tape 6 " Vdrifier l'installation ........................................................ 43

Vdrification de la source de chaleur ..................................................... 44

Sdcheuse dlectrique .......................................................................... 44

Sdcheuse _ gaz ................................................................................. 44

Procddure d'inversion de la porte ......................................................... 45

Installation en maison prdabriqude (maison mobile) ............................ 46

Installation dlectrique ............................................................................ 47

Sdcheuses dlectriques avec fiche _ 4 fils

(fournie avec la sdcheuse) .............................................................. 47

Sdcheuses dlectriques avec fiche _ 3 ills

(ndcessite une conversion) .............................................................. 48

Instructions de mise _ la terre .......................................................... 48

Por les sdcheuses au gaz .................................................................. 52

Installation au gaz ................................................................................. 53

Dimensions de l'emplacement .............................................................. 55

Critbres d'dvacuation de la sdcheuse .................................................... 56

Matdriaux pour le systbme d'dvacuation ......................................... 56

Critbres pour l'air d'appoint ............................................................. 56

Systbme d'dvacuation ...................................................................... 57

Direction de l'dvacuation ................................................................. 57

Entretien du systbme d'dvacuation .................................................. 59

Flux d'air de la sdcheuse .................................................................. 59

Entretien .............................................................................................. 61

Instructions d'entretien destindes il l'utilisateur ................................... 61

Lubrification .................................................................................... 61

Prdcautions il prendre avecla sdcheuse ........................................... 61

Syst_me d'dvacuation ...................................................................... 61

Informations servant de rdfdrence rapide ............................................. 62

Vdrification de l'installation .................................... Courverture arri_re

(OCopyright 2007, Alliance Laundry Systems LLC

Tous droits rdservds. Toute reproduction, m_me partielle, de cet ouvrage est interdite. Une copie ou diffusion par

quelque procddd que ce soit sans le consentement dcrit de l'dditor constitue une contrefacon.

512023 (QU) © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 35

Page 36

Remarques

36 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 512023 (QU)

Page 37

Pi ces de rechange

En cas de besoins de pibces de rechange, contacter le

distributeur auprbs duquel vous avez achetd la machine

OU"

Alliance Laundry Systems LLC

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

T616phone : (920) 748-3950

pour obtenir les nom et adresse du distributeur de

pibces agrdd local.

512023 (QU) © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 37

Page 38

Remarques

38 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 512023 (QU)

Page 39

Dimensions d'installation

Installation

1

E

,2:i................

59,7 cm

(23,5 po)

*Avec les pieds de nivellement totalement viss_s dans la base.

71,1 cm *1 (0,4 po)

(28 po)

__ 68,3 cm -_

SI_CHEUSES I_LECTRIQUES

39,1 cm I

(15,4 po) ÷

(26,9 po)

1

®

2cm

(4 po)

DRY2195N

_°

co

F_

20,3 cm

(8 po) --

59,7 cm

(23,5 po)

*Avec les pieds de nivellement totalement viss_s dans la base,

1 Raccord gas NPT de 3/8 po

512023 (QU) © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 39

71,1 cm __

(28 po)

1,1 cm

(0,4 po)

39,1 cm

(15,4 po)

__ 68,3 cm __

(26,9 po)

SI_CHEUSES AU GAZ

"10,2 cm

(4 po)

DRY2196N

Page 40

Installation

Avant de commencer

Outils

Pour la plupart des installations, ces outils de base seront

ndcessaires •

3

\

D8181

1

2

3

4

5

CI6

Tournevis

Niveau

Ruban en t6flon

Ruban adh6sif en toile

I_vacuation

Utiliser un conduit mdtallique rigide et effectuer

l'dvacuation de la sdcheuse vers l'extdrieur selon un

acheminement le plus court possible.

Y/Ill//Ill/Ill U/l,

DRY686N

Figure 2

REMARQUE : Pour des plus amples informations,

se reporter h la section Critbres d'_vacuation de la

s_cheuse.

I_lectricit6

SI_CHEUSE I_LECTRIQUE

Figure 1

Gaz

Cette sdcheuse est munie d'un raccord pour

l'alimentation de gaz NPT de 0,375 po. Pour de plus

amples informations, se reporter g la section sur

Installation au gaz.

Emplacement

Installer la sdcheuse sur un sol solide dotd d'une

alimentation d'air addquate. Pour de plus amples

informations, se reporter g la section sur Dimensions

de l'emplacement.

MISE EN GARDE

Tout d6montage ndcessitant I'emploi

d'outils doit 6tre effectual par un

rdparateur qualifi&

W299QU

L'alimentation de la sdcheuse est effectude par un

cfible _ 4 ills, 120/140 volts, 30 A, 60 Hz monophasd.

SI_CHEUSE AU GAZ

L'alimentation de la sdcheuse est effectude par une

prise de courant efficacement mise _ la terre,

120 volts, 15 A, 60 Hz polarisd, _ 3 fentes.

REMARQUE : Pour des plus amples informations,

se reporter h la section Installation _lectrique.

Si le cordon d'alimentation est endommagd, il doit etre

remplacd par un cordon ou ensemble spdcial

disponible auprbs du fabricant ou de son reprdsentant

et doit _tre installd par un dparateur qualifid.

40 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 512023 (QU)

Page 41

Installation

Installation de la secheuse

I_tape 1 • Placer la secheuse et la mettre b

niveau

Pour de plus amples ddtails, se reporter g la section

Dimension de l'emplacement.

Installer la sdcheuse avant la machine g laver afin de

laisser suffisamment de place pour le branchement du

conduit d'dvacuation.

Mettre la sdcheuse en place et ajuster les pieds de

nivellement jusqu'g ce qu'elle soit _ niveau des deux

c6tes et d'avante et arri_re.

1 2

NE PAS utiliser de conduit en aluminium fin ou

en plastique.

Placer la sdcheuse de sorte que le conduit

d'dvacuation soit le plus court possible.

Veiller _ ce que les anciens conduits soient

propres avant de les installer sur la nouvelle

sdcheuse.

Utiliser un conduit en mdtal flexible ou rigide de

10,2 cm (4 po) de diam6tre.

L'extrdmitd mille de chaque section du conduit

doit pointer dans la direction opposde de la

sdcheuse.

• Utiliser le moins de coudes possible.

• Recouvrir tousles joints de ruban isolant.

• Le conduit qui passe par des zones non-chauffdes

doit &re isold afin de rdduire la condensation et

l'accumulation de charpie sur les parois.

• Ne pas installer de syst_me d'_vacuation

correct sur la s6cheuse annule la garantie.

DRY687N

1

2

3

I_tape 2 • Raccorder le systeme

d'evacuation de la secheuse

Pour de plus amples ddtails, se reporter aux sections

Dimension de l'emplacement et Critbres

d &acuation de la s_cheuse.

Base de la s6cheuse

Niveau

Pied de nivellement

Figure 3

MISE EN GARDE

Une sdcheuse produit de la charpie

combustible. Pour rdduire tout risque

d'incendie et d'accumulation de gaz de

combustion, la sdcheuse DOlT dvacuer

I'extdrieur.

W116R4QU

¸¸¸¸¸¸¸¸¸7/l

"/////////////%_"/,

A FAIRE A NE PAS FAIRE

DRY688N

Figure 4

REMARQUE : Les mat6riaux d'6vacuation ne sont

pas fournis avec la s6cheuse (se les procurer

localement).

512023 (QU) © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 41

Page 42

Installation

I_tape 3 •(Uniquement pour les secheuses

gaz) Raccorder le tuyau d'alimentation

en gaz

Pour de plus amples informations, se reporter 6.la

section sur Installation au gaz.

°

Veiller g ce que votre sdcheuse soit munie des

dldments ndcessaires au type de gaz de votre

buanderie. A l'usine, la sdcheuse est con9ue pour

un raccordement au gaz natm'el de 0,375 po NPT.

°

Enlever le bouchon d'expddition du raccord de

gaz sired _ l'arribre de la sdcheuse. Veiller _ ne

pas endommager le filetage du myau lors du

retrait du bouchon.

°

Effectuer le raccordement au tuyau

d' alimentation en gaz.

°

Resserrer tousles raccords fermement. Ouvrir le

gaz et vdrifier tousles raccords de myau (internes

et extemes) afin de ddtecter les fuites de gaz

l'aide d'un liquide de ddtection de fuite non

corrosif.

°

Pour les raccordements au gaz L.R (combustible

liquide du pdtrole), se reporter _ la section

Installation au gaz.

D2331

Nouveau connecteur d'acier inoxydable 4

flexible - & n'utiliser que si les codes Iocaux

I'autorisent

(utiliser un connecteur approv6 par la CSA)

2

3

Bouchon de tuyau de 0,125 po NPT

(pour v6rifier la pression du gaz & d'admission) 5

Robinet d'arr6t de circuit - Installer & 1,8 m (6 pi)

de la s6cheuse

Tuyau en fer noir

Plus court que 6,1 m (20 pi) - Utiliser un tuyau

de 9,5 mm (0,375 po)

Plus long que 6,1 m (20 pi) - Utiliser un tuyau

de 12,7 mm (0,5 po)

Raccord de gaz de 0,375 po NPT

Figure 5

42 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 512023 (QU)

Page 43

Installation

I_tape 4 • Nettoyer I'interieur de la

secheuse

Avant d'utiliser la sdcheuse pour la premibre fois,

nettoyer l'intdrieur du tambour recouvert de poussibre

accumulde au cours de l'expddition h l'aide d'un

chiffon imbibd d'un produit nettoyant non abrasif ou

un ddtergent mdlangd h l'eau.

I_tape 5 • Brancher la secheuse

Se reporter/_ la section Installation _lectrique et

connecter la sdcheuse _ la source d'dlectricitd.

I_LECTRIQUE

Connector & un circuit de 30 A.

D0061

Figure 7

Figure 6

DRY689N

GAZ

Brancher la prise dans un circuit & un fusible

de 15A.

D2541

Figure 8

I_tape 6 • Verifier I'installation

Se reporter _ la section V_rification de l'installation

sur la couverture arribre de ce guide et vdrifier que la

sdcheuse soit installde correctement.

512023 (QU) © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 43

Page 44

Installation

Verification de la source de chaleur

Secheuse electrique

Fermer la porte et mettre la sdcheuse en marche selon

un rdglage avec chaleur (se reporter aux instructions

stipuldes dans le guide d'utilisation de la sdcheuse

joint). Aprbs avoir fair fonctionner la sdcheuse pendant

3 minutes, l'air d'dvacuation ou le tuyau d'dvacuation

doit _tre chaud.

Secheuse a gaz

Pour voir les flammes du brfileur, enlever le panneau

infdrieur avant de la sdcheuse.

Fermer la porte, mettre la machine en marche selon un

rdglage avec chaleur (se reporter aux instructions

stipuldes dans le guide d'utilisation de la sdcheuse

joint) ; la sdcheuse se met en marche, l'allumeur est

rouge et le brfileur principal s'allume.

IMPORTANT : Si l'air engouffr6 dans le conduit

de gaz n'est pas purg6, l'allumeur de gaz risque de

s',_teindre avant que le gaz ne soit allum,_. Dans ce

cas, l'allumeur tentera d'allumer le gaz environ

deux minutes apr_s.

Lorsque la sdcheuse a fonctionnd pendant environ cinq

minutes, observer la flamme du brfileur h travers le

panneau infdrieur avant. Rdgler le volet d'air afin

d'obtenir une flamme bleue douce et uniforme (une

flamme paresseuse h pointe jaune indique un manque

d'air. Une flamme forte, bruyante, trbs bleue indique

par contre un excbs d'air). Rdgler le volet d'air comme

suit :

AI

MISE EN GARDE

Pour des raisons de s6curit6, le panneau

inf6rieur avant doit 6tre en place pendant le

fonctionnement normal de la s6cheuse.

W046R2QU

Lorsque la sdcheuse a fonctionnd pendant environ trois

minutes, l'air d'dvacuation ou le tuyau doit etre chaud.

1

3

D7001

1

2

3

4

Vis de blocage du volet d'air

Vanne de gaz principale

Volet d'air

Bouchon de tuyau de 3,1 mm (0,125 po)

(permettant de v6rifier la pression du

collecteur)

Figure 9

.

Desserrer les vis de blocage du volet d'air.

2.

Tourner le volet d'air vers la gauche afin

d'obtenir une flamme lumineuse aux pointes

jaunes, le tourner ensuite lentement vers la droite

afin d'obtenir une flamme bleue, douce et

rdgulibre.

.

Lorsque le volet d'air est rdgld it la flamme

appropride, serrer fermement la vis de blocage du

volet d'air.

4. Remettre le panneau infdrieur avant en place.

44 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 512023 (QU)

Page 45

Procedure d'inversion de la porte

La porte de cette sdcheuse est complbtement

rdversible. Pour l'inverser, procdder comme suit "

Installation

®

Enlever les quatre

vis de fixation de

chamibre.

®

Sdparer la contre-

porte du panneau de

la porte en tirant

d'abord sur la partie

infdfieure et en la

glissant ensuit vers

le bas.

®

Enlever la gache de

la contre-porte et la

rdinstaller sur le

c6td opposd.

DRY690N

D2681

DRY1917N

®

Enlever les neufvis

(toutes).

®

Tourner le panneau

de porte de 180

degrds selon

l'illustration.

®

Insdrer la contre-

porte dans le fentes

de la partie

infdrieure de la

porte en mettre la

partie supdrieure de

la porte en place.

D2721

D2731

DRY1918N

®

Resserrer le neuf

vis enlevdes au cors

de l'etape 2.

DRY1919N

®

)t l'aide d'un

tournevis, enlever les

deux bouchons de la

porte et les rdinstaller

sur la c6td opposd

l'ouvermre de la

porte.

DRY691 N

®

Rdinstaller les quatre

vis de fixation de

chamibre enlevdes

l'dtape 1.

D6231

512023 (QU) © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 45

Page 46

Installation

Installation en maison preabriqu6e

(maison mobile)

_sMPORTANT : L'installation doit _tre conforme_

ux normes de construction et de s6curit6 des 1

aisons pr6fabriqu6es, Titre 24 CFR, Section l

0 ou h la norme CAN/CSA-Z240-MH. I

La sdcheuse peut _tre installde dans une maison

prdfabriqude selon les instructions suivantes "

.

IMPORTANT : Les s6cheuses h gaz

DOIVENT fix6es au sol de faqon permanente

lors de l'installation. Commander le kit

d'installation pour s6cheuse, r6f. 526P3, pour

une installation en maison pr6fabriqu6e

(maison mobile). Se conformer aux

instructions fournies avec le kit.

2. t_vacuation - La sdcheuse DOIT dvacuer

l'extdrieur.

MISE EN GARDE

Le conduit d'dvacuation de la sdcheuse doit _tre

fixd _ la structure de la maison prdfabriqude.

Les conduits d'dvacuation NE DOIVENT PAS

t_TRE raccordds par des vis ou des brides

m&alliques pour t61es qui rentreraient dans le

conduit.

Le conduit d'dvacuation ne doit &re raccordd

aucun autre conduit, dvent ou cheminde.

Le conduit d'dvacuation de la sdcheuse NE DOIT

PASse terminer sous la maison prdfabriqude.

Pour un fonctionnement correct, il est important

que la sdcheuse ait une grande quantitd d'air

d'appoint de l'extdrieur. La partie libre de toute

ouverture servant _ l'introduction de l'air

extdrieur doit _tre au moins de 163 cm 2 (25 po2).

Lors d'une dvacuation vers l'extdrieur, la

sdcheuse peut _tre installd avec un espace de

0 cm sur les c6tds et _ l'arribre. L'espace entre le

conduit et la construction combustible doit _tre

au moins de 5,08 cm (2 po).

Les matdriaux d'dvacuation ne sont pas fournis

avec la sdcheuse (se les procurer localement).

Pour r6duire tout risque d'incendie et

d'accumulation de gaz de combustion, la

s6cheuse DOlT E_VACUER ,_,L'EXTE_RIEUR.

Se reporter _ la section relative aux

Criteres d'6vacuation de la s6cheuse.

W047R2QU

La sdcheuse peut dvacuer g l'extdrieur par le

panneau arribre, gauche, droite ou infdrieur. Les

s6cheuses _ gaz ne peuvent pas 6vacuer sur la

gauche oil se trouve le boitier du brfileul.

MISE EN GARDE

Pour r6duire tout risque d'incendie, le

conduit d'6vacuation et la hotte contre les

intemp6ries DOIVENT 6tre fabriqu6s dans

un mat6riau qui n'entretienne pas la

combustion. II est recommand6 d'utiliser

un tuyau en m6tal rigide ou flexible pour les

s6cheuses.

W048R3QU

46 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 512023 (QU)

Page 47

Installation

Installation electrique

Secheuses electriques avec fiche b 4 fils

(fournie avec la secheuse)

(Installation h 3 ills, h la terre, 120/240 volts, 60 Hz)

(Installation h 3 ills, h la terre, 120/208 volts, 60 Hz)

REMARQUE : Le sch6ma de cfiblage se trouve

l'int6rieur du tableau de commande.

MISE EN GARDE

Pour r6duire tout risque d'incendie, de

choc 61ectrique ou de blessures

corporelles, le c&blage et la mise a la terre

DOIVENT 6tre conformes b la dernibre

6dition du Code national de 1'61ectricit6

ANSI/NFPA 70, ou du code canadien de

1'61ectricit6, CSA C22.1, ainsi qu'aux

r6glementations locales. II appartient au

client de faire contr61er le c&blage et les

fusibles par un 61ectricien qualifi6 afin de

s'assurer que I'appareil dispose d'une

alimentation 61ectrique suffisante.

W511QU

Instructions relatives a la mise a la terre et au

cgblage

La sdcheuse doit _tre connectde fi un circuit de

ddrivation distinct, polarisd, fi 3 fils, mis _ la terre, de

120/240 volts ou de 120/208 volts, 60 Hz, C.a,

monophasd avec fusibles de 30 A.

Si le circuit de ddrivation _ la sdcheuse mesure 4,57 m

(15 pieds) ou moins, utiliser un fil de calibre

10 A.W.G. ou tel que requis par les codes locaux. Si le

circuit est supdrieur fi 4,57 m (15 pieds), utiliser le fil

de calibre 8 A.W.G. ou tel que requis par les codes

locaux.

4

0

V.A.C.

DRY2016N

1

2

3

4

Prise standard & quatre fils

Cordon 61ectrique (& quatre ills)

I_crou de serre-c&ble

Serre-c&ble

Figure 10

Le cordon dlectrique et la fiche (founis avec la

sdcheuse) doivent _tre branchds dans une prise

approuvde installde sur lemur adjacent il la sdcheuse.

Cette prise doit rester accessible _ l'utilisateur ou au

rdparateur une fois la sdcheuse en place afin de

pouvoir la ddbrancher facilement.

512023 (QU) © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 47

Page 48

Installation

Secheuses electriques avec fiche b 3 fils

(necessite une conversion)

(Installation h 3 ills, 120/240 volts, 60 Hz)

(Installation h 3 ills, 120/208 volts, 60 Hz)

REMARQUE : Le sch6ma de cfiblage se trouve

l'int6rieur du tableau de commande.

MISE EN GARDE

Pour r6duire tout risque d'incendie, de choc

61ectrique, de blessures corporelles ou de

mort, le c&blage et la mise a la terre

DOIVENT 6tre conformes b la dernibre

6dition du Code national de 1'61ectricit6,

ANSI/NFPA 70, ou du Code canadien de

1'61ectricit6, CSA C22.1, ainsi qu'aux

r6glementations locales. II incombe au

client la responsabilit6 de faire installer le

c&blage et les fusibles par un 61ectricien

qualifi6 afin de garantir que la s6cheuse

dispose d'une alimentation suffisamment

puissante.

W512QU

Instructions de mise b la terre

Si le circuit de ddrivation de la sdcheuse mesure

4,57 m (15 pieds) ou moins, utiliser un fil de

calibre 10 A.W.G. (ill de cuivre uniquement), ou

tel que requis par les codes locaux. Si le circuit

est supdrieur _ 4,57 m (15 pieds), utiliser du fil de

calibre 8 A.W.G. (ill de cuivre uniquement), ou

tel que requis par les codes locaux. Prdvoir

dgalement suffisamment de mou pour que la

sdcheuse puisse _tre dcartde de son emplacement

normal lorsque cela est ndcessaire.

Le cordon d'alimentation (spirale) de

raccordement entre la prise murale et le bomier

de la sdcheuse N'EST PAS fourni avee la

s6eheuse. Le type de spirale et le calibre du fil

doivent _tre conformes aux codes locaux et aux

instructions des pages suivantes.

La mdthode de cfiblage de la sdcheuse est

facultative et ddpend des exigences

rdglementaires locales. Se reporter _ la Figure 11.

La sdcheuse doit _tre connectde/_ un systbme de

cfiblage mdtallique permanent relid h la terre ; ou

un conducteur de mise h la terre d'appareil doit

_tre posd avec les conducteurs du circuit et

connectd _ la borne ou au fil de terre sur la

sdcheuse.

La sdcheuse comporte son propre bornier qui doit

_tre raccordd _ un circuit de ddrivation distinct

C.a. (courant altematif) monophasd 60 Hz, avec

fusible de 30 A (le circuit doit comporter un

fusible des deux c6tds de la ligne).

L'alimentation 61eetrique de la s6eheuse doit

correspondre it la tension nominale maximale

figurant sur la plaque signal6tique. Ne pas

raccorder la s6cheuse hun circuit de 110, 115

ou 120 volts. Des dldments chauffants sont

disponibles pour _tre installds dans des sdcheuses

qui sont branchds sur des alimentations

dlectriques de tension diffdrente que celle

figurant sur la plaque signaldtique, comme

208 volts par exemple.

48 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 512023 (QU)

Page 49

Fiche a 3 ills

Installation

REMARQUE : Le cordon d'alimentation (spirale) n'est PAS ALIMENTATiONI_LECTRIQUE

calibre du fil doivent _tre conformes aux codes Iocaux et aux

fourni avec la sdcheuse dlectrique. Le type de spirale et le _ _ 1

instructions.

des exigences r6glementaires locales.

REMARQUE : Raccorder la s_cheuse sur I'alimentation

La mdthode de c_blage de la sdcheuse est facultative at ddpend _.__ 2 _

61ectrique pr6sentant la TENSION NOMINALE MAXIMALE 3

figurant sur la plaque signal_tique.

ModUle - -

t i ue de BOITIER A

YP q

.... FUSIBLES

prise :Ju A

trois fils I

NEMA TVDe (facultatif si le

10-301¥ boftier d'arriv_e q 4_lectrique comporte

120 -+ 12 V,c.a.

v.c.a. 6

240 -+12

V.c.a,

REMARQUE : Utiliser exclusivement du FIL DE CUIVRE.

Moins de 4,5 m (15 pi), utiliser 10 A.W.G.

Plus de 4,5 m (15 pi), utiliser 8 A.W.G.

120-+12

INTERMEDIAIRE

des fusibles)

PRISE MURALE

RACCORDEMENT

Boftier de coupure d'arriv6e electrique 3 fils &

terre et neutre, 120/240 volts C.a. monophase

60 Hz (Se reporter & la REMARQUE ci-dessus)

2

3

Fusibles ou disjoncteur 30 A

Fil de neutre

L1 L2

SPIRALE

4

5

6

7

d

!

Cfible gaine m6tallique ou non m6tallique (fil de

cuivre seulement)

Spirale vers la s6cheuse (Se reporter & la

REMARQUE ci-dessus)

Neutre

Bornier dans la s6cheuse

ALIM ENTATION FtLECTRIQUE

BO|TIER

D'ARRET

INTERMFtDIAIRE

v(fusibles

facultatifs)

L1 L2

RACCORDEMENT

DIRECT

D8161

Pour convertir un raccordement a 4 ills en

raccordement a 3 ills

°

Ddbrancher l'alimentation dlectrique de la

sdcheuse.

°

Enlever le couvercle d'accbs de l'arribre de la

sdcheuse.

Figure 12

Figure 11

D6951

512023 (QU) © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 49

Page 50

Installation

°

Enlever les trois vis argentdes qui attachent les

trois ills aux bomes du bomier. Enlever la vis de

terre verte qui attache le fil de terre du cordon

d'alimentation h la paroi arribre. Conserver les

qnatre vis. Desserrer la vis du collier de serrage

et extraire le cordon ou les ills par l'arribre de la

sdcheuse.

4. Attacher l'un des bouts du fil de terre vert (foumi

dans le sac d'accessoires) sur la paroi arribre

l'aide de la vis de terre verte enlevde _ l'dtape 3.

IMPORTANT : Ne pas utiliser de tournevis

6lectrique pour serrer la vis de terre ou les vis du

borniel.

1

DRY2018N

1 Vis de terre

Figure 14

DRY2017N

1

2

3

4

Vis de bornier L1 argentee

Vis de bornier Neutre argentee

Vis de bornier L2 argentee

Vis de terre verte

Figure 13

50 © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 512023 (QU)

Page 51

Installation

.

Utiliser les trois vis argentde enlevde h l'dtape 3

pour attacher les fils du nouveau cordon

d'alimentation et l'autre bout du fil de terre vert

au bomier comme indiqud h la Figure 15.

REMARQUE : Le fil de terre vert doit _tre

raccord6 h la borne (neutre) centrale du borniel.

8

6. Serrer toutes les vis et remettre le couvercle

d'accbs ddmontd _ l'dtape 2.

IMPORTANT : Un serrage insuffisant de ces vis

peut entrainer une d6faillance du cfiblage au niveau

du borniel.

.

Fixer le collier de serrage au cordon

d'alimentation, ou aux fils, au point oil ils

pdnbtrent dans l'enveloppe de la sdcheuse.

.

Contr61er la continuitd du raccordement _ la terre

avant de brancher le cordon dans une prise.

Utiliser un dispositif indicateur acceptable

raccordd _ la broche de terre centrale de la fiche

et la vis verte _ l'arribre de la sdcheuse.

9. Remettre le couvercle d'accbs en place et visser.

10. Rdtablir l'alimentation dlectrique de la sdcheuse.

5

DRY2015N

1

2

3

4

5

6

7

8

Fil terre vers neutre

Borne Neutre

Borne L2

Fil du centre (Neutre)

Collier de serrage (non fourni avec la

s6cheuse)

Vis de terre verte

Borne L1

Fil de terre

Figure 15

512023 (QU) © Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT 51

Page 52

Installation

Por les secheuses au gaz

REMARQUE : Le sch6ma de cfiblage se trouve

l'int6rieur du tableau de commande.

AI

i

Pour r6duire tout risque d'incendie, de choc

61ectrique ou de dommages corporels voire

la mort, le cfiblage et la mise a terre

DOIVENT _tre conformes a la derni_re

6dition du Code national de r61ectricit6