Page 1

MI.61xx

fast 8 bit arbitrary waveform generator

D/A converter board

for PCI bus

Hardware Manual

Driver Manual

English version October 5, 2004

SPECTRUM SYSTEMENTWICKLUNG MICROELECTRONIC GMBH · AHRENSFELDER WEG 13-17 · 22927 GROSSHANSDORF · GERMANY

PHONE: +49 (0)4102-6956-0 · FAX: +49 (0)4102-6956-66 · E-MAIL: info@spec.de · INTERNET: http://www.spec.de

Page 2

(c) SPECTRUM SYSTEMENTWICKLUNG MICROELECTRONIC GMBH

AHRENSFELDER WEG 13-17, 22927 GROSSHANSDORF, GERMANY

SBench is a registered trademark of Spectrum Systementwicklung Microelectronic GmbH.

Microsoft, Visual C++, Visual Basic, Windows, Windows 98, Windows NT, Window 2000 and Windows XP are tradenarks/registered

trademarks of Microsoft Corporation.

LabVIEW, DASYLab, Diadem and LabWindows/CVI are tradenarks/registered trademarks of National Instruments Corporation.

MATLAB is a tradenark/registered trademark of The Mathworks, Inc.

Agilent VEE, VEE Pro and VEE OneLabare tradenarks/registered trademarks of Agilent Technologies, Inc.

FlexPro is a registered trademark of Weisang GmbH & Co. KG.

Page 3

Introduction....................................................................................................................... 6

Preface ............................................................................................................................................................................... 6

General Information ............................................................................................................................................................. 6

Different models of the MI.61xx series .................................................................................................................................... 7

Additional options................................................................................................................................................................ 8

Extra I/O (Option -XMF).................................................................................................................................................. 8

Extra I/O (Option -XIO)................................................................................................................................................... 8

Starhub ......................................................................................................................................................................... 9

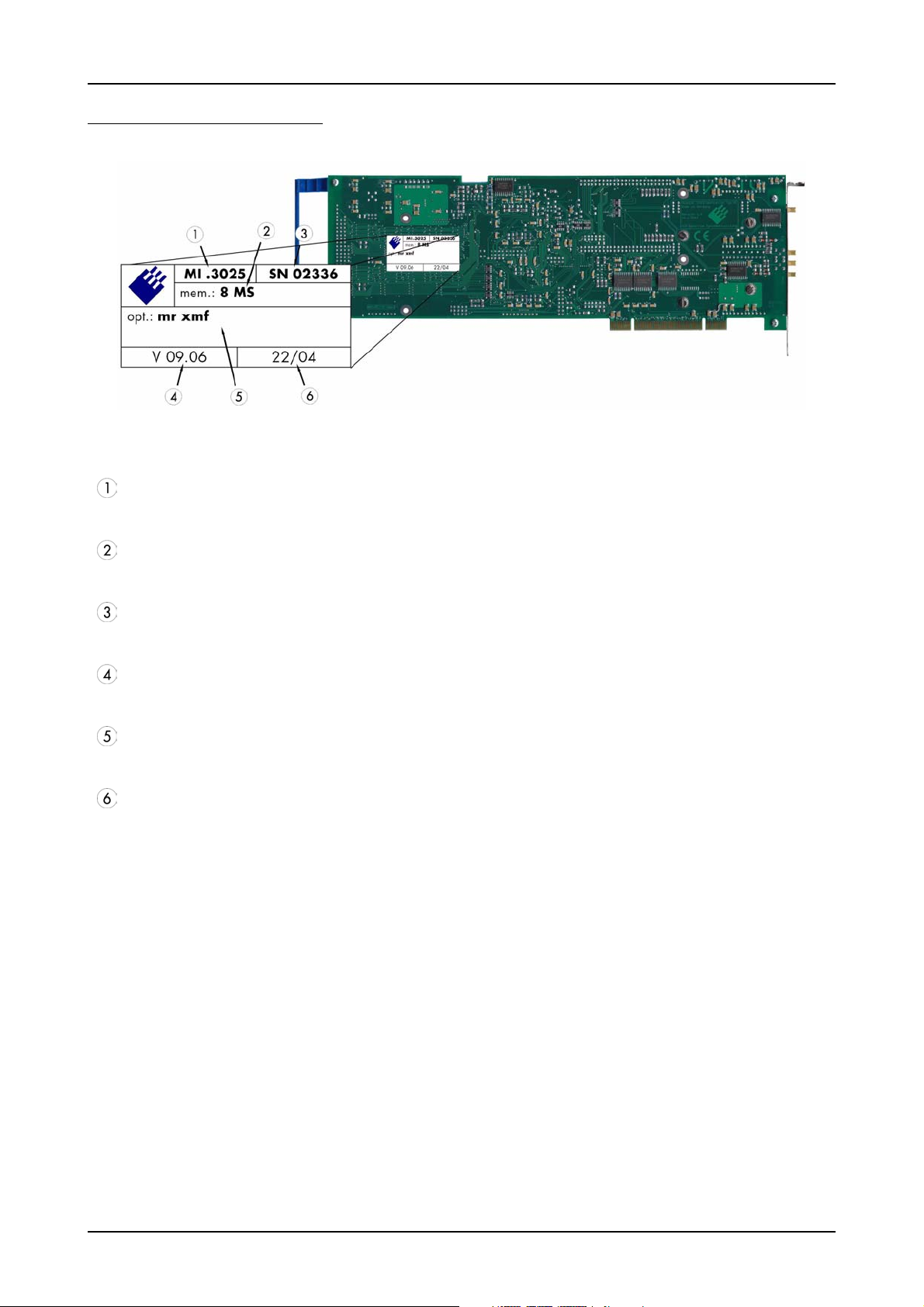

The Spectrum type plate ...................................................................................................................................................... 10

Hardware information......................................................................................................................................................... 11

Block diagram.............................................................................................................................................................. 11

Technical Data ............................................................................................................................................................. 11

Dynamic Parameters ..................................................................................................................................................... 12

Order information......................................................................................................................................................... 12

Hardware Installation ..................................................................................................... 13

System Requirements .......................................................................................................................................................... 13

Warnings.......................................................................................................................................................................... 13

ESD Precautions ........................................................................................................................................................... 13

Cooling Precautions...................................................................................................................................................... 13

Sources of noise ........................................................................................................................................................... 13

Installing the board in the system.......................................................................................................................................... 13

Installing a single board without any options.................................................................................................................... 13

Installing a board with digital inputs/outputs.................................................................................................................... 14

Installing a board with extra I/O (Option -XMF) ............................................................................................................... 14

Installing multiple boards synchronized by starhub............................................................................................................ 15

Installing multiple synchronized boards ........................................................................................................................... 16

Software Driver Installation............................................................................................. 17

Interrupt Sharing ................................................................................................................................................................ 17

Windows 98 ..................................................................................................................................................................... 18

Installation ................................................................................................................................................................... 18

Version control ............................................................................................................................................................. 18

Driver - Update............................................................................................................................................................. 19

Windows 2000 ................................................................................................................................................................. 20

Installation ................................................................................................................................................................... 20

Version control ............................................................................................................................................................. 20

Driver - Update............................................................................................................................................................. 21

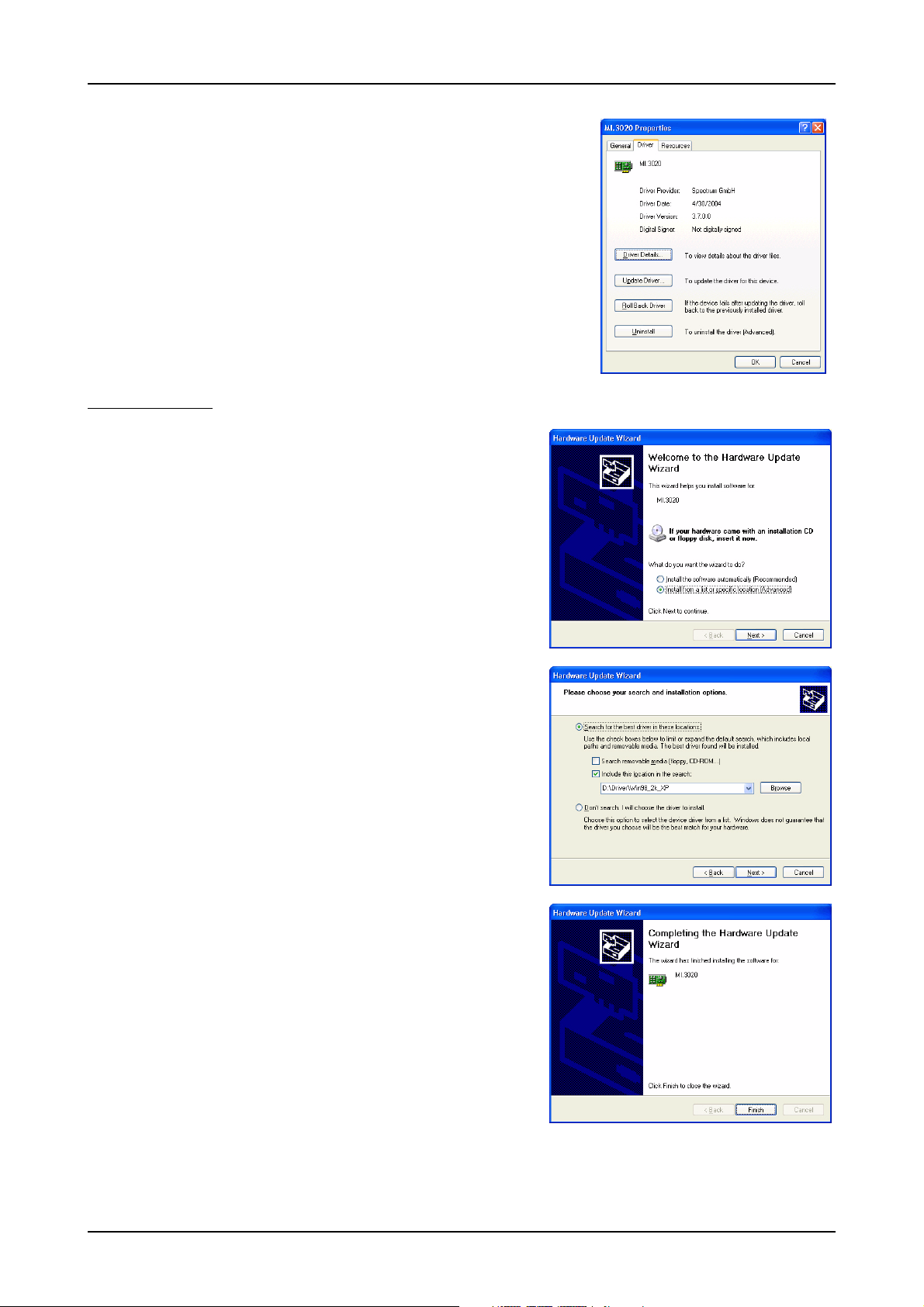

Windows XP...................................................................................................................................................................... 22

Installation ................................................................................................................................................................... 22

Version control ............................................................................................................................................................. 22

Driver - Update............................................................................................................................................................. 23

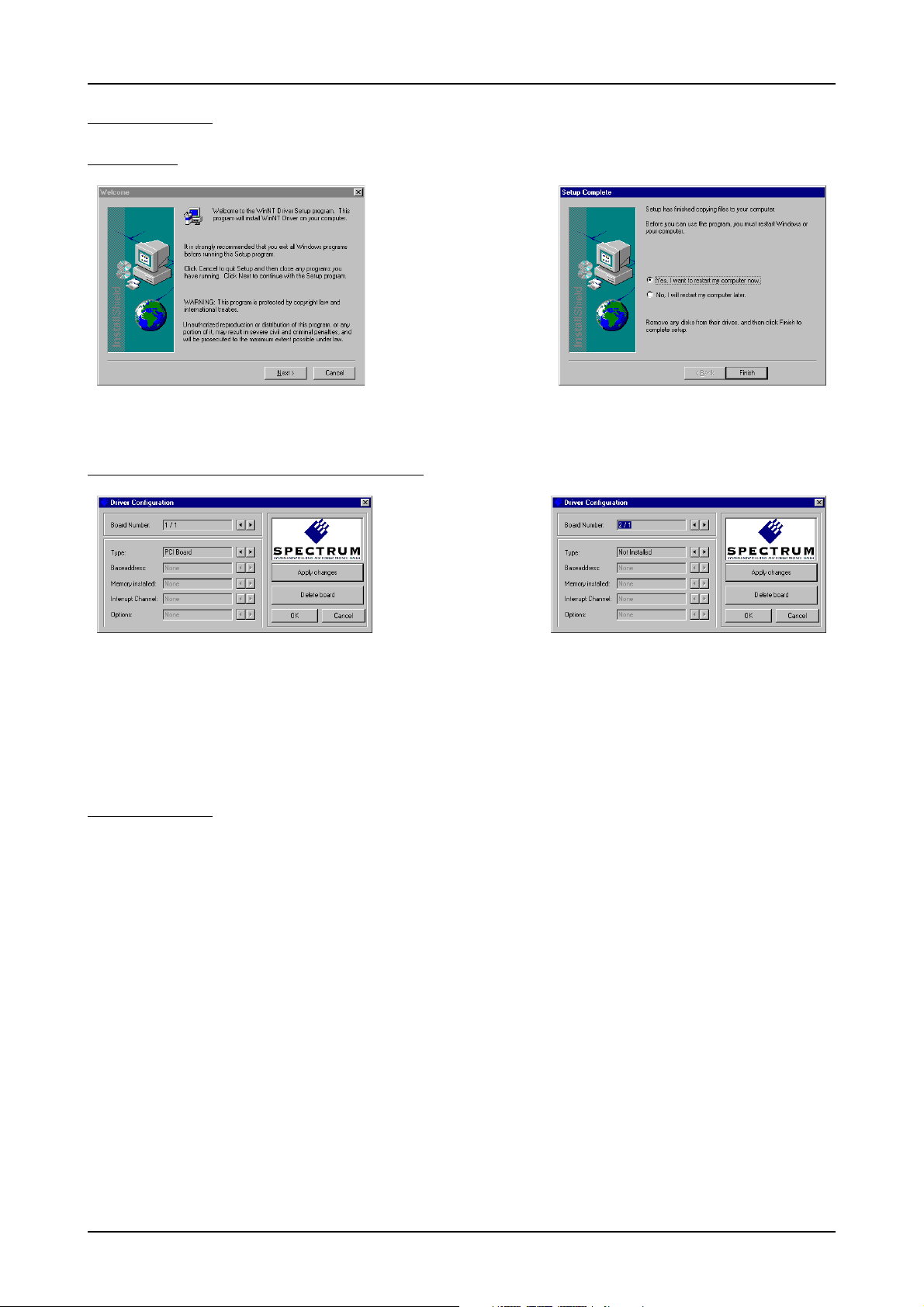

Windows NT..................................................................................................................................................................... 24

Installation ................................................................................................................................................................... 24

Adding boards to the Windows NT driver ....................................................................................................................... 24

Driver - Update............................................................................................................................................................. 24

Linux................................................................................................................................................................................. 25

Overview .................................................................................................................................................................... 25

Installation ................................................................................................................................................................... 25

Software ......................................................................................................................... 27

Software Overview............................................................................................................................................................. 27

First Test with SBench.......................................................................................................................................................... 27

C/C++ Driver Interface....................................................................................................................................................... 28

Header files ................................................................................................................................................................. 28

Microsoft Visual C++ .................................................................................................................................................... 28

Linux Gnu C................................................................................................................................................................. 28

Other Windows C/C++ compilers ................................................................................................................................. 29

National Instruments LabWindows/CVI........................................................................................................................... 29

Driver functions ............................................................................................................................................................ 29

Delphi (Pascal) Programming Interface .................................................................................................................................. 32

Type definition ............................................................................................................................................................. 32

Include Driver............................................................................................................................................................... 32

Examples..................................................................................................................................................................... 32

Driver functions ............................................................................................................................................................ 32

Visual Basic Programming Interface ...................................................................................................................................... 34

Include Driver............................................................................................................................................................... 34

Visual Basic Examples................................................................................................................................................... 34

VBA for Excel Examples ................................................................................................................................................ 34

Driver functions ............................................................................................................................................................ 34

3

Page 4

Programming the Board .................................................................................................. 36

Overview .......................................................................................................................................................................... 36

Register tables ................................................................................................................................................................... 36

Programming examples....................................................................................................................................................... 36

Error handling.................................................................................................................................................................... 36

Initialization....................................................................................................................................................................... 37

Starting the automatic initialization routine ...................................................................................................................... 37

PCI Register ................................................................................................................................................................. 37

Hardware version......................................................................................................................................................... 38

Date of production........................................................................................................................................................ 38

Serial number .............................................................................................................................................................. 38

Maximum possible sample rate ...................................................................................................................................... 38

Installed memory .......................................................................................................................................................... 38

Installed features and options ......................................................................................................................................... 39

Used interrupt line ........................................................................................................................................................ 39

Used type of driver ....................................................................................................................................................... 39

Powerdown and reset ......................................................................................................................................................... 40

Analog Outputs ............................................................................................................... 41

Channel Selection .............................................................................................................................................................. 41

Important note on channels selection............................................................................................................................... 41

Disabling the outputs..................................................................................................................................................... 41

Setting up the outputs.......................................................................................................................................................... 42

Output Amplifiers ......................................................................................................................................................... 42

Output offset ................................................................................................................................................................ 42

Maximum Output Range................................................................................................................................................ 43

Output Filters ............................................................................................................................................................... 43

Standard generation modes ............................................................................................ 44

General description............................................................................................................................................................ 44

Singleshot mode........................................................................................................................................................... 44

Continuous Mode ......................................................................................................................................................... 44

Posttrigger Mode.......................................................................................................................................................... 44

Programming..................................................................................................................................................................... 44

Partitioning the memory................................................................................................................................................. 44

Starting without interrupt (classic mode)........................................................................................................................... 46

Starting with interrupt driven mode ................................................................................................................................. 46

Data organization ........................................................................................................................................................ 47

Writing data with SpcSetData........................................................................................................................................ 47

Sample format.............................................................................................................................................................. 48

FIFO Mode....................................................................................................................... 49

Overview .......................................................................................................................................................................... 49

General Information...................................................................................................................................................... 49

Background FIFO Write................................................................................................................................................. 49

Speed Limitations.......................................................................................................................................................... 49

Programming..................................................................................................................................................................... 50

Software Buffers ........................................................................................................................................................... 50

Buffer processing.......................................................................................................................................................... 51

FIFO mode .................................................................................................................................................................. 52

Example FIFO generation mode ..................................................................................................................................... 52

Data organization ........................................................................................................................................................ 52

Sample format.............................................................................................................................................................. 53

Clock generation ............................................................................................................. 54

Overview .......................................................................................................................................................................... 54

Internally generated sample rate .......................................................................................................................................... 54

Standard internal sample rate ........................................................................................................................................ 54

Using plain quartz with no PLL........................................................................................................................................ 55

Direct external clock ..................................................................................................................................................... 56

External clock with divider ............................................................................................................................................. 57

Trigger modes and appendant registers .......................................................................... 58

General Description............................................................................................................................................................ 58

Software trigger ................................................................................................................................................................. 58

External TTL trigger ............................................................................................................................................................. 58

Edge triggers ............................................................................................................................................................... 59

Option Multiple Replay.................................................................................................... 61

Output modes .................................................................................................................................................................... 61

Standard Mode............................................................................................................................................................ 61

FIFO Mode .................................................................................................................................................................. 61

Trigger modes.................................................................................................................................................................... 61

4

Page 5

Option Gated Replay....................................................................................................... 63

Output modes .................................................................................................................................................................... 63

Standard Mode............................................................................................................................................................ 63

FIFO Mode .................................................................................................................................................................. 63

Trigger modes.................................................................................................................................................................... 63

General information and trigger delay ............................................................................................................................ 63

Allowed trigger modes .................................................................................................................................................. 64

Example program............................................................................................................................................................... 64

Option Extra I/O ............................................................................................................. 65

Digital I/Os....................................................................................................................................................................... 65

Channel direction ......................................................................................................................................................... 65

Transfer Data ............................................................................................................................................................... 65

Analog Outputs.................................................................................................................................................................. 66

Programming example ........................................................................................................................................................ 66

Synchronization (Option) ................................................................................................. 67

The different synchronization options .................................................................................................................................... 67

Synchronization with option cascading ........................................................................................................................... 67

Synchronization with option starhub ............................................................................................................................... 67

The setup order for the different synchronization options ......................................................................................................... 68

Setup Order for use with standard (non FIFO) mode and equally clocked boards ................................................................. 68

Setup synchronization for use with FIFO mode and equally clocked boards ......................................................................... 72

Additions for synchronizing different boards .................................................................................................................... 74

Additions for equal boards with different sample rates ...................................................................................................... 76

Resulting delays using different boards or speeds ............................................................................................................. 76

Appendix ........................................................................................................................ 77

Error Codes....................................................................................................................................................................... 77

Pin assignment of the multipin connector ............................................................................................................................... 78

Extra I/O with external connector(Option -XMF) ............................................................................................................... 78

Pin assignment of the multipin cable ..................................................................................................................................... 78

Pin assignment of the internal multipin connector .................................................................................................................... 79

Extra I/O with internal connector (Option -XIO)................................................................................................................ 79

5

Page 6

Preface Introduction

Introduction

Preface

This manual provides detailed information on the hardware features of your Spectrum instrumentation board. This information includes technical data, specifications, block diagram and a connector description.

In addition, this guide takes you through the process of installing your board and also describes the installation of the delivered driver package

for each operating system.

Finally this manual provides you with the complete software information of the board and the related driver. The reader of this manual will

be able to integrate the board in any PC system with one of the supported bus and operating systems.

Please note that this manual provides no description for specific driver parts such as those for LabVIEW or MATLAB. These drivers are provided by special order.

For any new information on the board as well as new available options or memory upgrades please contact our webside

http://www.spectrum-instrumentation.com. You will also find the current driver package with the latest bug fixes and new features on our site.

Please read this manual carefully before you install any hardware or software. Spectrum is not responsible

for any hardware failures resulting from incorrect usage.

General Information

The MI.61xx series contains 2 different versions of arbitrary waveform generators for the PCI bus. With these boards it is possible to generate

free definable waveforms on several channels synchronously. There are up to four channels on one board with a maximum sample rate of

125 MS/s. The internal standard Syncbus allows the setup of synchronous multi channel systems with higher channel numbers. It is also possible to combine the arbitrary waveform generator with other boards of the MI product family like analogue or digital acquisition boards.

With the up to 512 MSample (512 MByte) large on-board memory long waveform could be generated even with high sample rates. The

memory can also be used as a FIFO buffer to make continuous data transfer from PC memory or hard disk.

Application examples: Automatic test systems, Synthesizer, Supersonics, Signal generators.

6 MI.61xx Manual

Page 7

Introduction Different models of the MI.61xx series

Different models of the MI.61xx series

The following overwiew shows the different available models of the MI.61xx series. They differ in the number mounted generation modules

and the number of available channels. You can also see the model dependant allocation of the output connectors.

• MI.6110

• MI.6111

(c) Spectrum GmbH 7

Page 8

Additional options Introduction

Additional options

Extra I/O (Option -XMF)

With this simple-to-use enhancement

it is possible to control a wide range

of external instruments or other

equipment. Therefore you have 24

digital I/O and the 4 analog outputs

available.

The extra I/O option is useful if an

external amplifier should be controlled, any kind of signal source must

be programmed, an antenna must

be adjusted, a status information

from external machine has to be obtained or different test signals have

to be routed to the board.

The additional inputs and outputs

are mounted on an extra bracket.

The figure shows the allocation of

the two connectors. The shown option is mounted exemplarily on a board with two modules. Of course you can also combine this option as

well with a board that is equipped with only one module.

It is not possible to use this option together with the star hub or timestamp option, because there is just space for

one piggyback module on the on-board expansion slot.

Extra I/O (Option -XIO)

With this simple-to-use enhancement

it is possible to control a wide range

of external instruments or other

equipment. Therefore you have 16

digital I/O and the 4 analog outputs

available.

The extra I/O option is useful if an

external amplifier should be controlled, any kind of signal source must

be programmed, an antenna must

be adjusted, a status information

from external machine has to be obtained or different test signals have

to be routed to the board.

The additional inputs and outputs

are not mounted on an extra brakket, but are available on an internal

connector. The figure shows the position of this connector on the bottom side of the extra I/O piggy-back module. The shown option is mounted exemplarily on a board with two modules. Of course you can also combine this option as well with a board that is equipped with only

one module.

It is not possible to use this option together with the star hub or timestamp option, because there is just space for

one piggyback module on the on-board expansion slot.

8 MI.61xx Manual

Page 9

Introduction Additional options

Starhub

The star hub module allows the synchronisation of up to 16 MI boards.

It is possible to synchronise boards

of the same type with each other as

well as different types.

The module acts as a star hub for

clock and trigger signals. Each

board is connected with a small cable of the same length, even the master board. That minimises the clock

skew between the different boards.

The figure shows the piggyback module mounted on the base board

schematically without any cables to

achieve a better visibility.

Any board could be the clock master and the same or any other

board could be the trigger master. All trigger modes that are available on the master board are also available if the synchronisation star hub

is used.

The cable connection of the boards is automatically recognised and checked by the driver at load time. So no care must be taken on how to

cable the boards. The programming of the star hub is included in the standard board interface and consists of only 3 additional commands.

It is not possible to use this option together with the timestamp or extra I/O option, because the is just space for one

piggyback module on the on-board expansion slot.

(c) Spectrum GmbH 9

Page 10

The Spectrum type plate Introduction

The Spectrum type plate

The Spectrum type plate, which consists of the following components, can be found on all of our boards.

The board type, consisting of the two letters describing the bus (in this case MI for the PCI bus) and the model number.

The size of the on-board installed memory in MSamples. In this example there are 8 MS (16 MByte) installed.

The serial number of your Spectrum board. Every board has a unique serial number.

The board revision, consisting of the base version and the module version.

A list of the installed options. A complete list of all available options is shown in the order information. In this example the options

’Multiple recording’ and ’Extra I/O with external outputs’ are installed.

The date of production, consisting of the calendar week and the year.

Please always supply us with the above information, especially the serial number in case of support request. That

allows us to answer your questions as soon as possible. Thank you.

10 MI.61xx Manual

Page 11

Introduction Hardware information

Hardware information

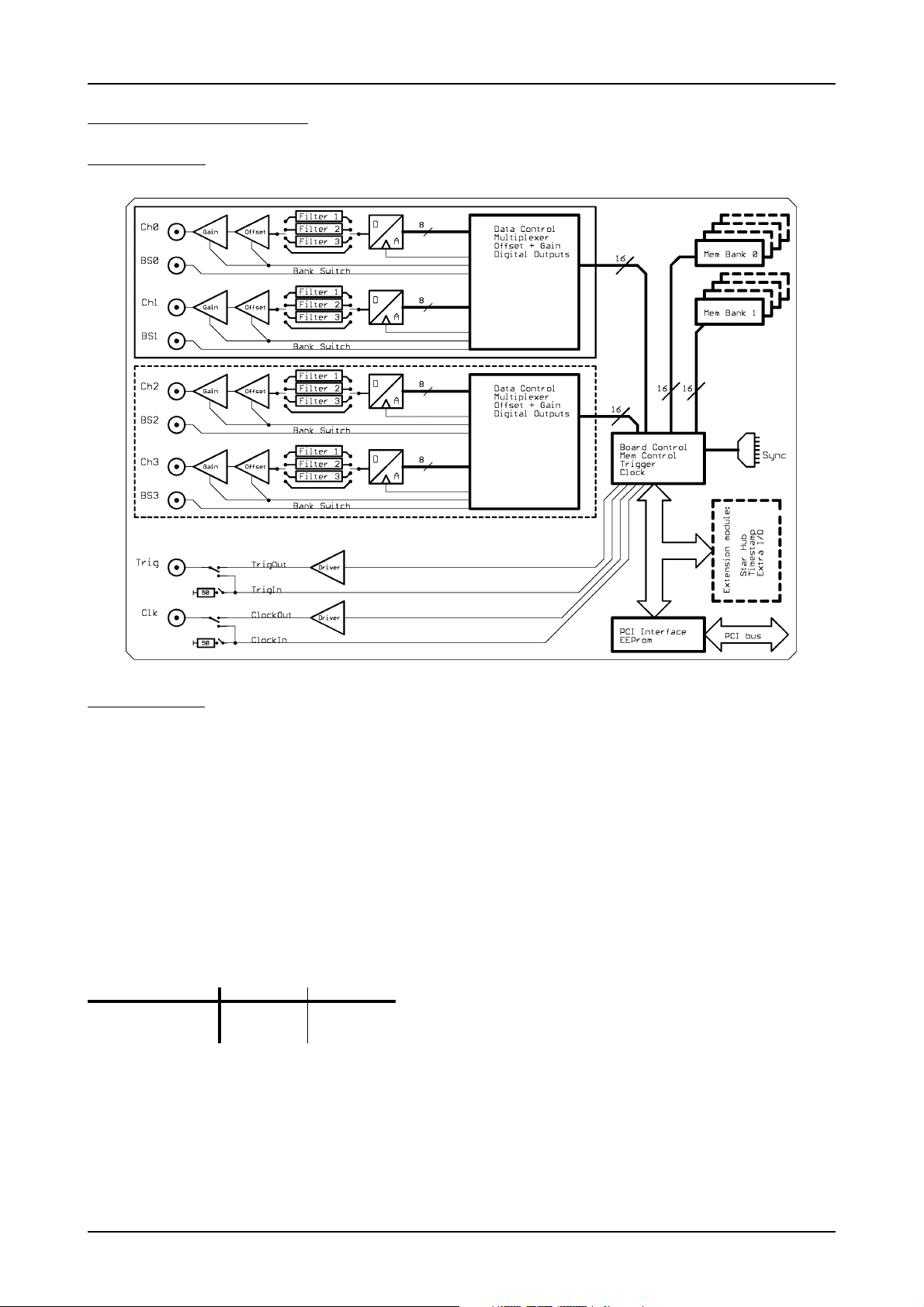

Block diagram

Technical Data

Resolution 8 Bit Dimension 312 mm x 107 mm

Integral linearity (DAC) ± 1.5 LSB typ. Width (Standard) 1 full size slot

Differential linearity (DAC) ± 1.0 LSB typ. Width (with star hub option) 2 full size slots

Output resistance < 1 Ohm Analogue connector 3 mm SMB male

Max output swing in 50 Ohm ± 3 V (offset + amplitude) Warm up time 10 minutes

Max slew rate (no filter) > 0.9 V/ns Operating temperature 0°C - 50°C

Multi: Trigger to 1st sample delay fixed Storage temperature -10°C - 70°C

Multi: Recovery time < 20 samples Humidity 10% to 90%

Ext. clock: delay to internal clock 42 ns ± 2 ns Offset stepsize < 2 mV

Trigger output delay 1 Sample Amplitude stepsize < 1 mV

Crosstalk @ 1 MHz signal ±3 V < -80 dB

Min internal clock 1 kS/s Power consumption 5 V @ full speed max 3.7 A (18.5 Watt)

Min external clock DC Power consumption 5 V @ power down max 2.3 A (11.5 Watt)

max internal clock 125 MS/s 125 MS/s

max external clock 125 MS/s 125 MS/s

-3 dB bandwidth no filter > 60 MHz > 60 MHz

MI.6110 MI.6111

(c) Spectrum GmbH 11

Page 12

Hardware information Introduction

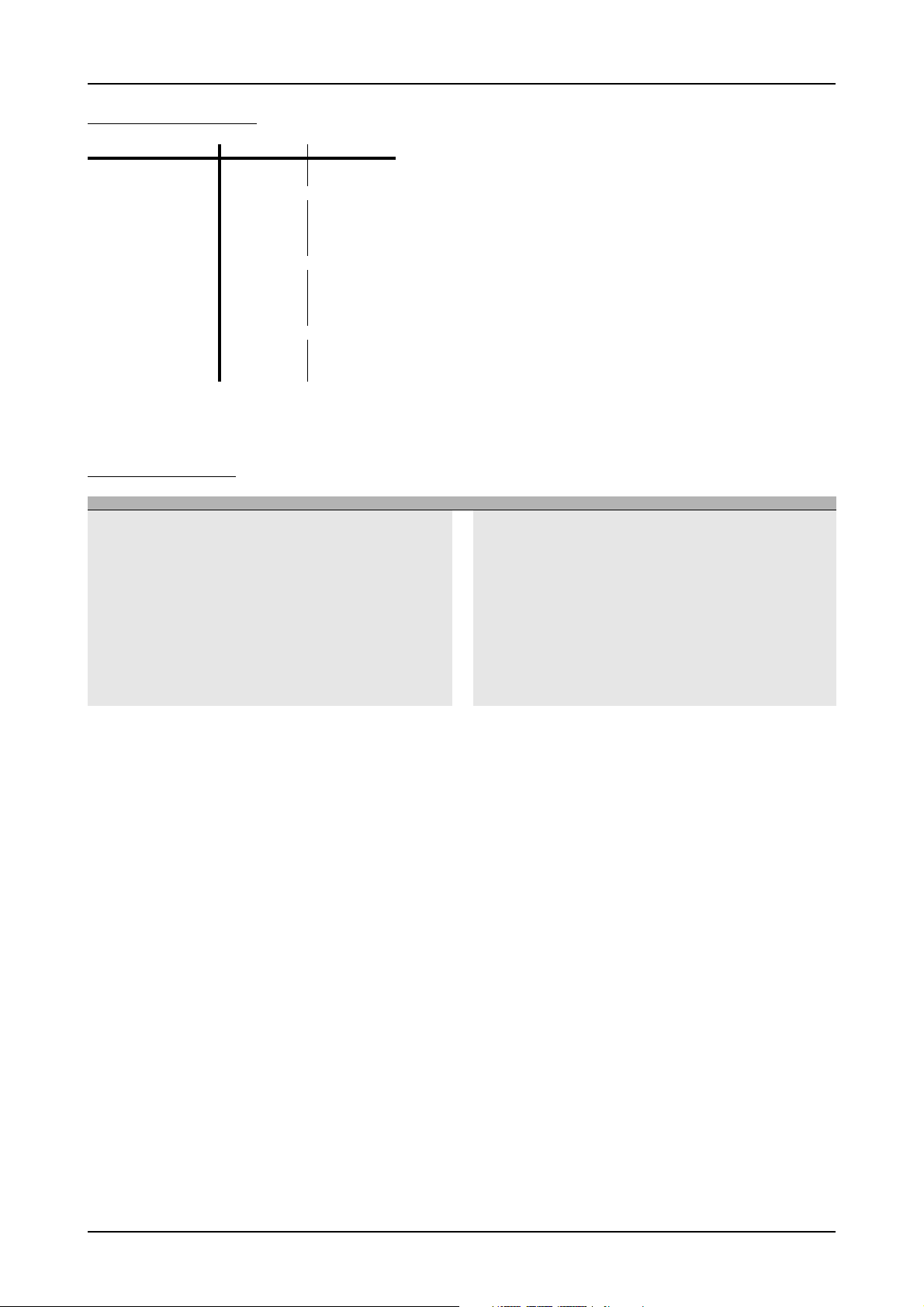

Dynamic Parameters

Test - Samplerate 125 MS/s 125 MS/s

Filter 3

Characteristics 5th order Butterworth

-3 dB bandwidth 25 MHz 25 MHz

SNR ±1 V in 50 ohm -49 dB

THD ±1 V in 50 ohm -42 dB

Filter 2

Characteristics 4th order Butterworth

-3 dB bandwidth 5 MHz 5 MHz

SNR ±1 V in 50 ohm -42 dB

THD ±1 V in 50 ohm -67 dB

Filter 1

Characteristics 4th order Butterworth

-3 dB bandwidth 500 kHz 500 kHz

SNR ±1 V in 50 ohm -72 dB

THD ±1 V in 50 ohm -54 dB

Dynamic parameters are measured at ± 1 V output level and 50 Ohm termination with a spectrum analyser. The samplerate selected is the maximum possible samplerate. Signal frequency is equal to the cut-off frequency of the filter. SNR and RMS noise parameters may differ depending on the quality of the used PC. SNR = Signal to Noise Ratio, THD = Total Harmonic Distortion

MI.6110 MI.6111

Order information

Order No Description Order No Description

MI6110 MI.6111 with 16 MSample memory and drivers/SBench 5.x MI61xx-32M Option: 32 MSample mem instead of 16 MSample standard mem

MI6111 MI.6111 with 16 MSample memory and drivers/SBench 5.x MI61xx-64M Option: 64 MSample mem instead of 16 MSample standard mem

MI6xxx-mr Option Multiple Replay: Memory segmentation MI61xx-256M Option: 256 MSample mem instead of 16 MSample standard mem

MI6xxx-gs Option Gated Sampling: Gate signal controls replay MI61xx-512M Option: 512 MSample mem instead of 16 MSample standard mem

MI6xxx-cs Synchronisation of 2 - 4 boards, one option per system MI61xx-up Additional handling costs for later memory upgrade

MI61xx-128M Option: 128 MSample mem instead of 16 MSample standard mem

MI6xxx-smod Star Hub: Synchronisation of 2 - 16 boards, one option per system MI61xx-dl DASYLab driver for MI.61xx series

MIxxxx.xio Extra I/O, internal connector: 16 DI/O, 4 Analog out MI61xx-hp VEE driver for MI.61xx series

MIxxxx-xmf Extra I/O, external connector: 24 DI/O, 4 Analog out, incl. cable MI61xx-lv LabVIEW driver for MI.61xx series

Cab-3f-9m-80 Adapter cable: SMB female to BNC male 80 cm Cab-3f-9f-80 Adapter cable: SMB female to BNC female 80 cm

Cab-3f-9m-200 Adapter cable: SMB female to BNC male 200 cm Cab-3f-9f-200 Adapter cable: SMB female to BNC female 200 cm

MATLAB MATLAB driver for all MI.xxxx, MC.xxxx and MX.xxxx series.

12 MI.61xx Manual

Page 13

Hardware Installation System Requirements

Hardware Installation

System Requirements

All Spectrum MI.xxxx instrumentation boards are compliant to the PCI standard and require in general one free full length slot. Depending

on the installed options additional free slots can be necessary.

Warnings

ESD Precautions

The boards of the MI.xxxx series contain electronic components that can be damaged by electrostatic discharge (ESD).

Before installing the board in your system or even before touching it, it is absolutely necessary to bleed of

any electrostatic electricity.

Cooling Precautions

The boards of the MI.xxxx series operate with components having very high power consumption at high speeds. For this reason it is absolutely

required to cool this board sufficiently. It is strongly recommended to install an additional cooling fan producing a stream of air across the

boards surface. In most cases professional PC-systems are already equipped with sufficient cooling power. In that case please make sure that

the air stream is not blocked.

During longer pauses between the single measurements the power down mode should be called to reduce the heat production.

Sources of noise

The boards of the MI.xxxx series should be placed far away from any noise producing source (like e.g. the power supply). It should especially

be avoided to place the board in the slot directly adjacent to another fast board (like the graphics controller).

Installing the board in the system

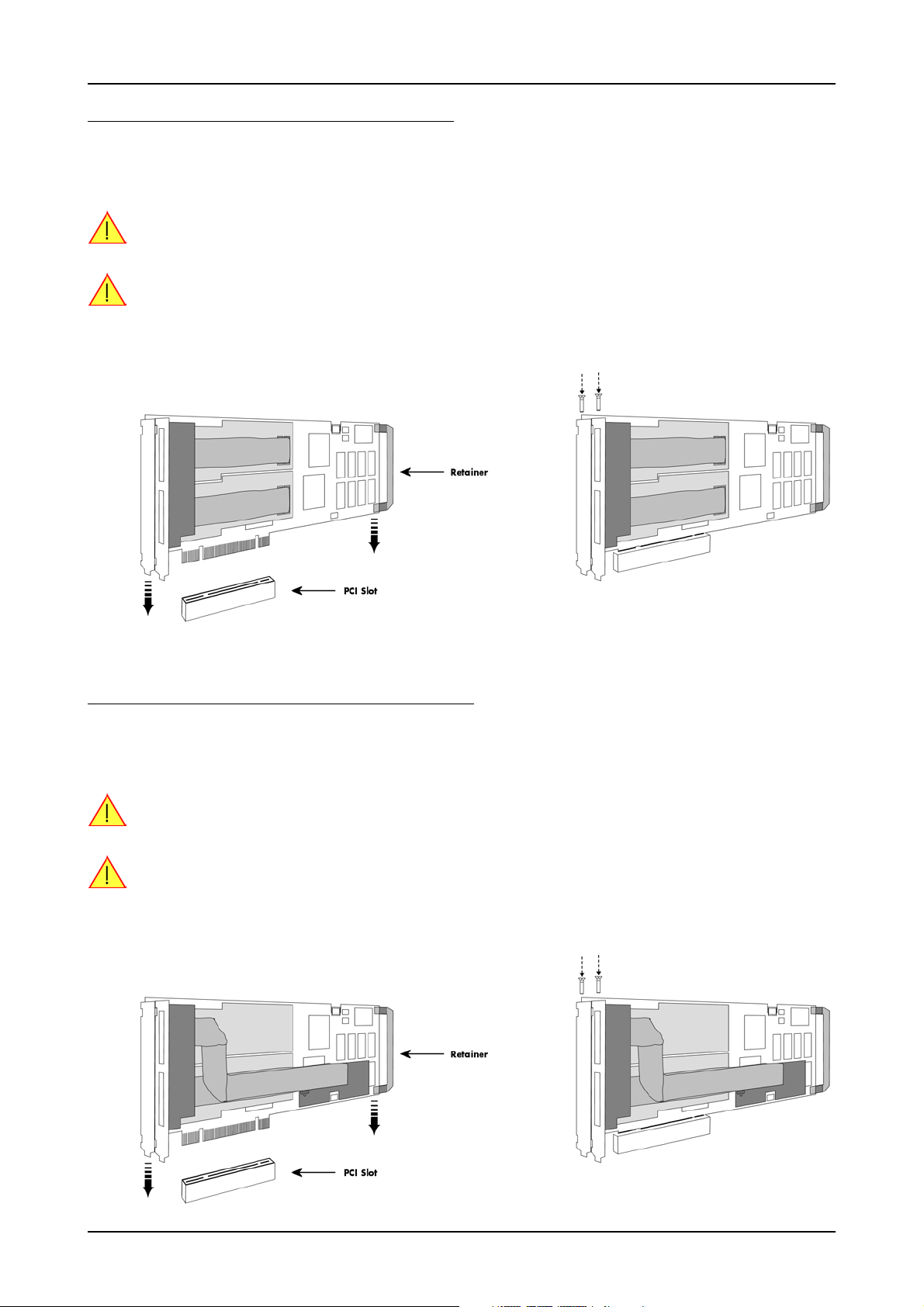

Installing a single board without any options

Before installing the board you first need to unscrew and remove the dedicated blind-bracket usually mounted to cover unused slots of your

PC. Please keep the screw in reach to fasten your Spectrum board afterwards. All Spectrum boards require a full length PCI slot with a track

at the backside to guide the board by it’s retainer. Now insert the board slowly into your computer. This is done best with one hand each at

both fronts of the board.

While inserting the board take care not to tilt the retainer in the track.

Please be very carefully when inserting the board in the PCI slot, as most of the mainboards are mounted

with spacers and therefore might be damaged if they are exposed to high preasure.

After the board’s insertion fasten the screw of the bracket carefully, without overdoing.

(c) Spectrum GmbH 13

Page 14

Installing the board in the system Hardware Installation

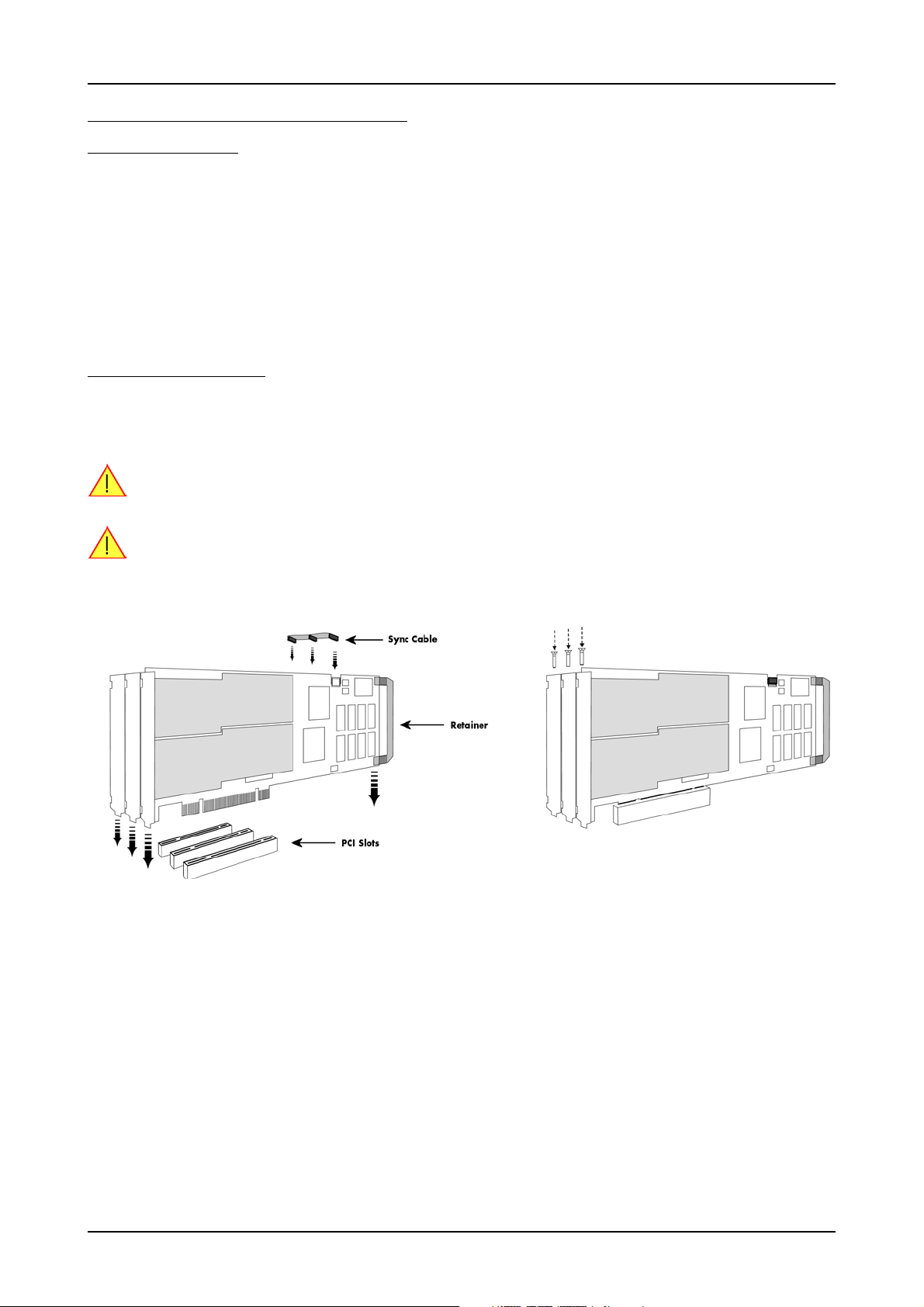

Installing a board with digital inputs/outputs

Before installing the board you first need to unscrew and remove the dedicated blind-brackets usually mounted to cover unused slots of your

PC. Please keep the screws in reach to fasten your Spectrum board and the extra bracket afterwards. All Spectrum boards require a full length

PCI slot with a track at the backside to guide the board by it’s retainer. Now insert the board and the extra bracket slowly into your computer.

This is done best with one hand each at both fronts of the board.

While inserting the board take care not to tilt the retainer in the track.

Please be very carefully when inserting the board in the PCI slot, as most of the mainboards are mounted

with spacers and therefore might be damaged they are exposed to high preasure.

After the board’s insertion fasten the screws of both brackets carefully, without overdoing. The figure shows an example of a board with two

installed modules.

Installing a board with extra I/O (Option -XMF)

Before installing the board you first need to unscrew and remove the dedicated blind-brackets usually mounted to cover unused slots of your

PC. Please keep the screws in reach to fasten your Spectrum board and the extra bracket afterwards. All Spectrum boards require a full length

PCI slot with a track at the backside to guide the board by it’s retainer. Now insert the board and the extra bracket slowly into your computer.

This is done best with one hand each at both fronts of the board.

While inserting the board take care not to tilt the retainer in the track.

Please be very carefully when inserting the board in the PCI slot, as most of the mainboards are mounted

with spacers and therefore might be damaged they are exposed to high preasure.

After the board’s insertion fasten the screws of both brackets carefully, without overdoing. The figure shows an example of a board with two

installed modules.

14 MI.61xx Manual

Page 15

Hardware Installation Installing the board in the system

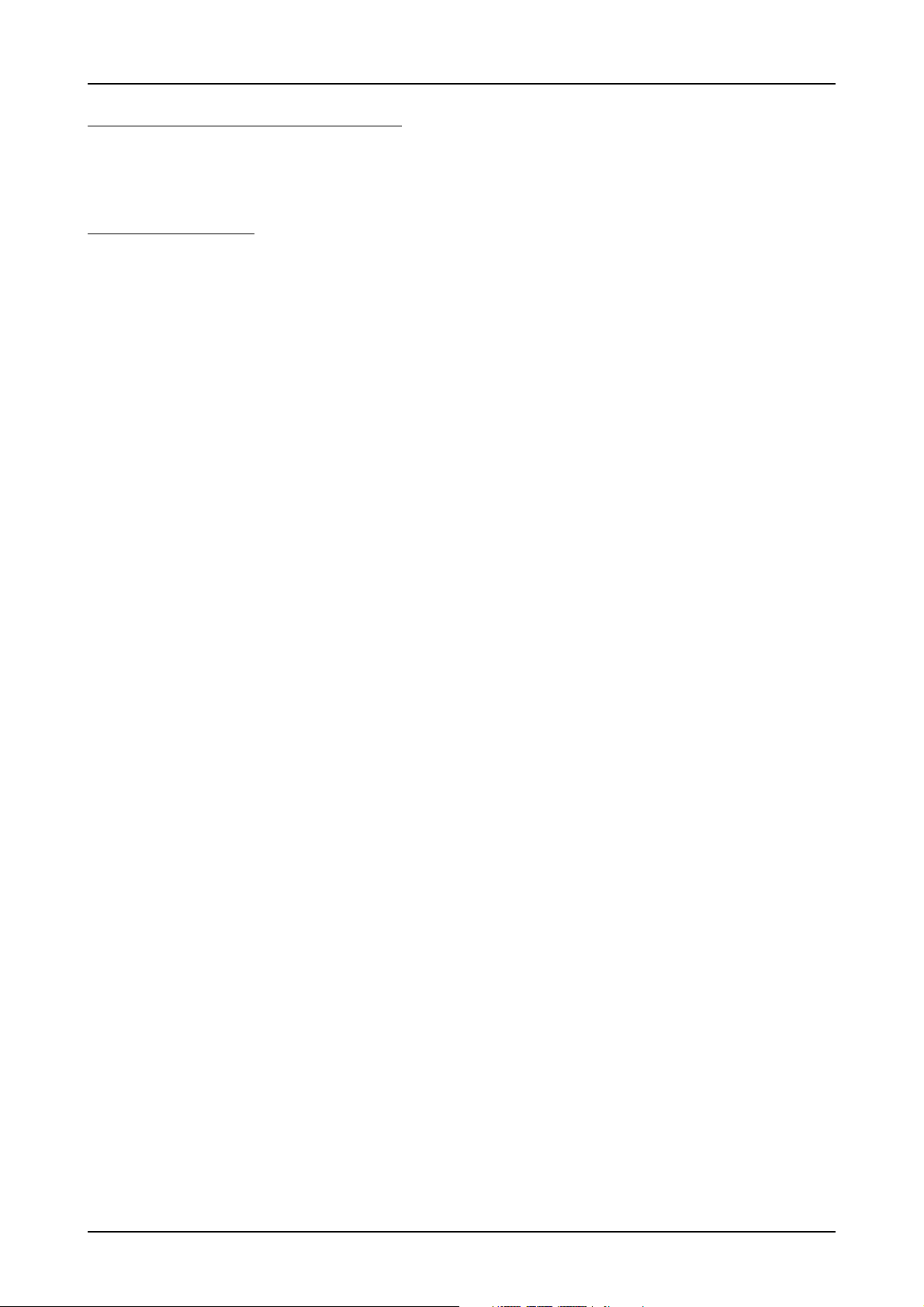

Installing multiple boards synchronized by starhub

Hooking up the boards

Before mounting several synchronized boards for a multi channel system into the PC you can hook up the boards with their synchronization

cables first. If there is enough space in your computer’s case (e.g. a big tower case) you can also mount the boards first and hook them up

afterwards. Spectrum ships the boards together with the needed amount of synchronization cables. All of them are matched to the same

length, to achieve a zero clock delay between the boards.

Only use the included flat ribbon cables.

All of the boards, including the board that carrys the starhub piggy-back module, must be wired to the starhub as the figure is showing exemplarily for three synchronized boards.

It does not matter which of the 16 connectors on the starhub module you use for which board. The software driver will detect the types and

order of the synchronized boards automatically. The figure shows the three cables mounted next to each other only to achieve a better visibility.

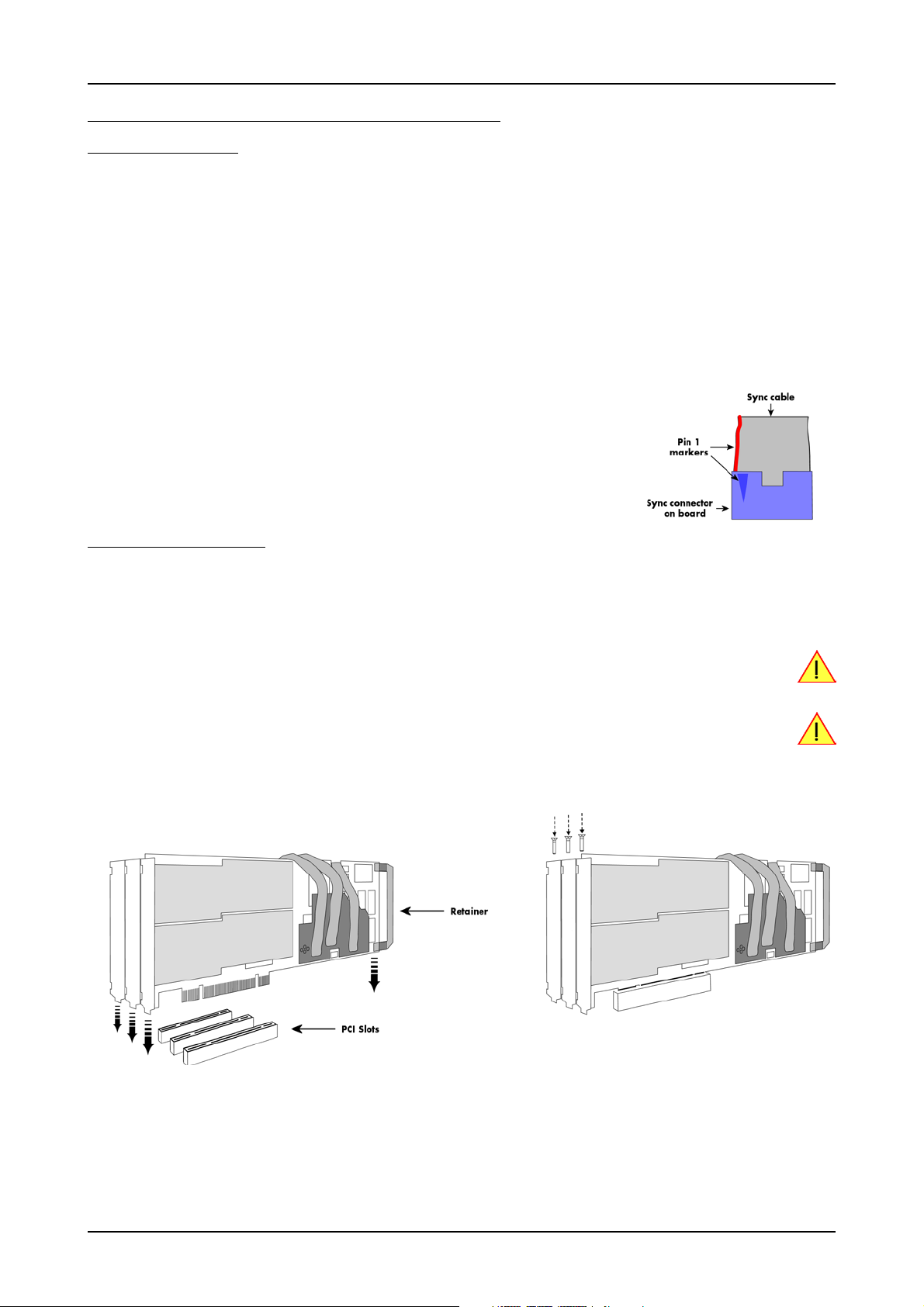

As some of the synchronization cables are not secured against wrong plugging you should take

care to have the pin 1 markers on the multiple connectors and the cable on the same side, as the

figure on the right is showing.

Mounting the wired boards

Before installing the boards you first need to unscrew and remove the dedicated blind-brackets usually mounted to cover unused slots of your

PC. Please keep the screws in reach to fasten your Spectrum boards afterwards. All Spectrum boards require a full length PCI slot with a track

at the backside to guide the board by it’s retainer. Now insert the board and the extra bracket slowly into your computer. This is done best

with one hand each at both fronts of the board. Please keep in mind that the board carrying the starhub piggy-back module requires the width

of two slots.

While inserting the boards take care not to tilt the retainers in the tracks.

Please be very carefully when inserting the boards in the PCI slots, as most of the mainboards are mounted

with spacers and therefore might be damaged if they are exposed to high preasure.

After the boards insertion fasten the screws of all brackets carefully, without overdoing. The figure shows an example of three boards with

two installed modules.

(c) Spectrum GmbH 15

Page 16

Installing the board in the system Hardware Installation

Installing multiple synchronized boards

Hooking up the boards

Before mounting several synchronized boards for a multi channel system into the PC you can hook up the boards with the synchronization

cable first. If there is enough space in your computer’s case (e.g. a big tower case) you can also mount the boards first and hook them up

afterwards. Spectrum ships the boards together with the needed synchronization cable.

All of the possible four boards must be wired with the delivered synchronization cable. The figure is showing an example of three synchronized boards.

The outer boards have a soldered termination for the sync bus. These boards are marked with an additional sticker.

Only mount the cluster of synchronized boards in a row with the dedicated boards on the outer sides.

Mounting the wired boards

Before installing the boards you first need to unscrew and remove the dedicated blind-brackets usually mounted to cover unused slots of your

PC. Please keep the screws in reach to fasten your Spectrum boards afterwards. All Spectrum boards require a full length PCI slot with a track

at the backside to guide the board by it’s retainer. Now insert the boards slowly into your computer. This is done best with one hand each

at both fronts of the board.

While inserting the boards take care not to tilt the retainers in the tracks.

Please be very carefully when inserting the boards in the PCI slots, as most of the mainboards are mounted

with spacers and therefore might be damaged if they are exposed to high preasure.

After the boards insertion fasten the screws of all brackets carefully, without overdoing. The figure shows an example of three boards with

two installed modules.

16 MI.61xx Manual

Page 17

Software Driver Installation Interrupt Sharing

Software Driver Installation

Before using the board a driver must be installed that matches the operating system. The installation is done in different ways depending on

the used operating system. The driver that is on CD supports all boards of the MI, MC and MX series. That means that you can use the same

driver for all boards of theses families.

Interrupt Sharing

This board uses a PCI interrupt for DMA data transfer and for controlling the FIFO mode. The used interrupt line is allocated by the PC BIOS

at system start and is normally depending on the selected slot. Because there is only a limited number of interrupt lines available on the PCI

bus it can happen that two or more boards must use the same interrupt line. This so called interrupt sharing must be supported by all drivers

of the participating equipment.

Most available drivers and also the Spectrum driver for your board can manage interrupt sharing. But there are also some drivers on the

market that can only use one interrupt exclusively. If this equipment shares an interrupt with the Spectrum board, the system will hang up if

the second driver is loaded (the time is depending on the operating system).

If this happens it is necessary to reconfigure the system in that way that the critical equipment has an exclusive access to an interrupt.

On most systems the BIOS shows a list of all installed PCI boards with their allocated interrupt lines directly after system start. You have to

check whether an interrupt line is shared between two boards. Some BIOS allow the manual allocation of interrupt lines. Have a look in your

mainboard manual for further information on this topic.

Because normally the interrupt line is fixed for one PCI slot it is simply necessary to use another slot for the critical board to force a new

interrupt allocation. You have to search a configuration where all critical boards have only exclusive access to one interrupt.

Depending on the system, using the Spectrum board with a shared interrupt may degrade performance a little. Each interrupt needs to be

checked by two drivers. For this reason when using time critical FIFO mode even the Spectrum board should have an exclusively access to

one interrupt line.

(c) Spectrum GmbH 17

Page 18

Windows 98 Software Driver Installation

Windows 98

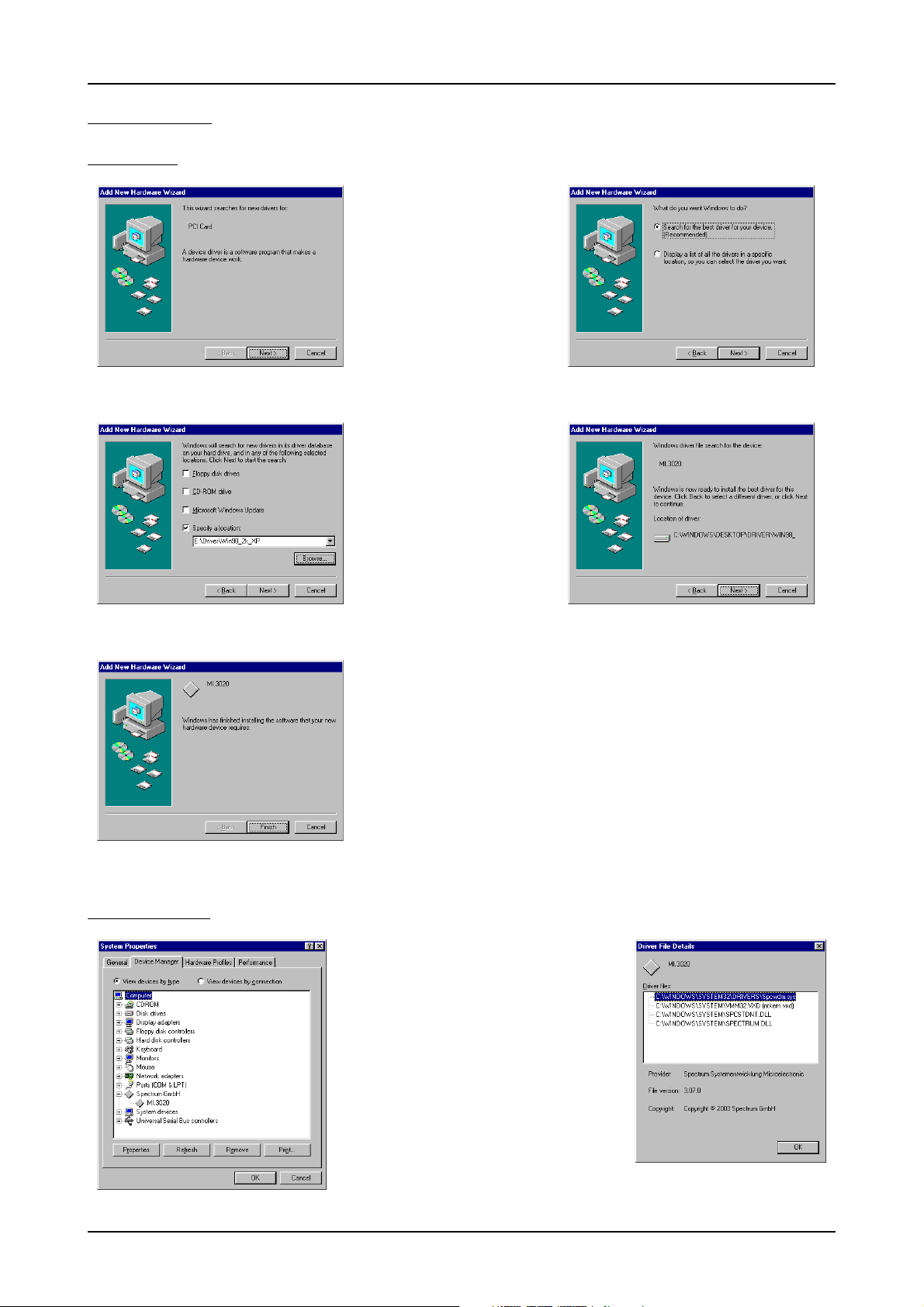

Installation

When installing the board in a Windows 98 system the Spectrum board

will be recognized automatically on

the next start-up.

The system offers the direct installation of a driver for the board.

Let Windows search automatically

for the best driver for your system.

Select the CD that was delivered

with the board as installation source.

The driver files are located on CD in

the directory

\Driver\Win98_2k_XP.

The hardware assistant shows you

the exact board type that has been

found like the MI.3020 in the example. Older boards (before june

2004) show „Spectrum Board“ instead.

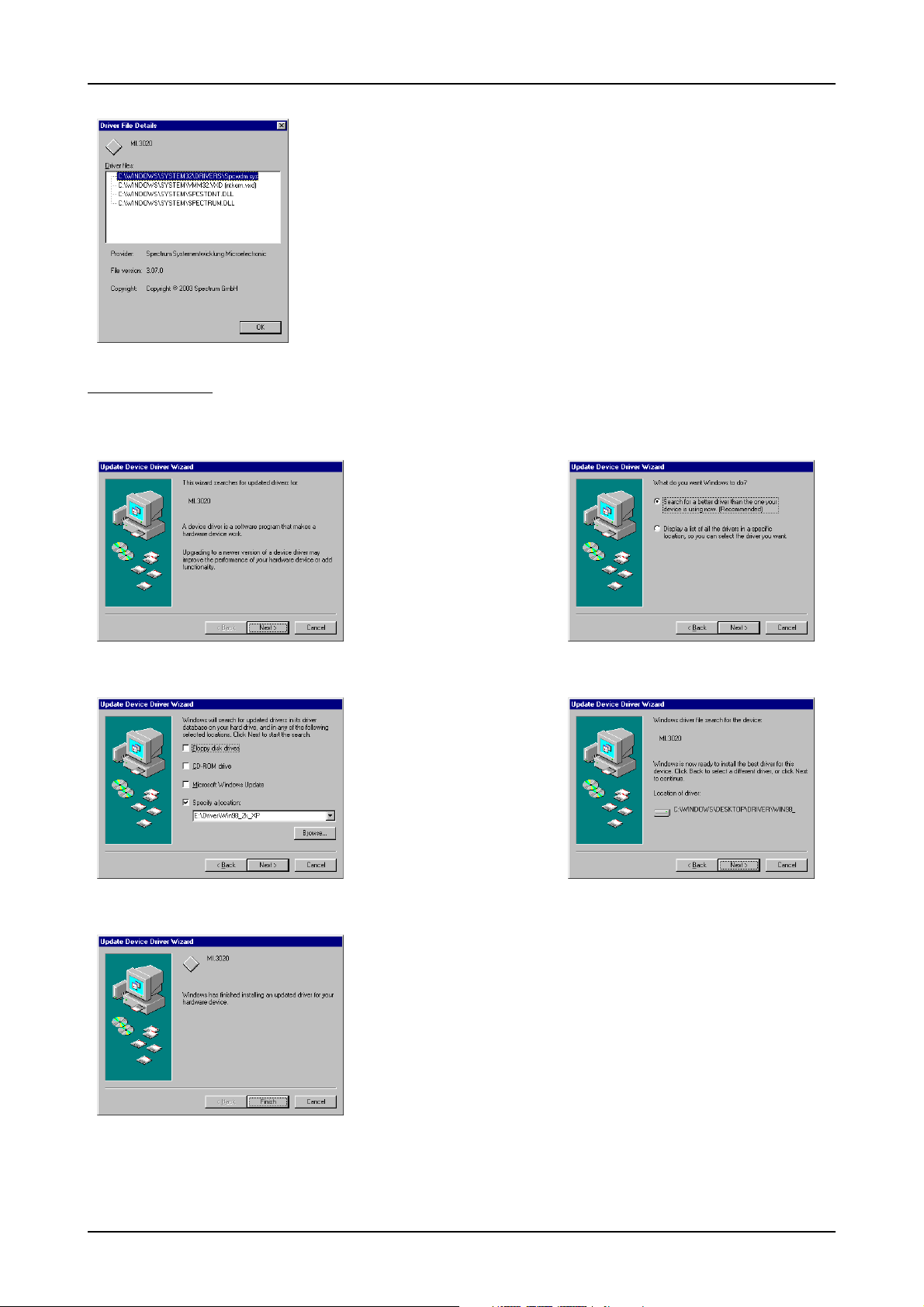

Version control

The drivers can be used directly after installation. It is not necessary to restart the system.

The installed drivers are linked in the device manager. Below you’ll see how to examine

the driver version and how to update the driver with a newer version.

If you want to check which driver version is installed

in the system this can be easily done in the device

manager. Therefore please start the device manager

from the control panel and show the properties of the

installed driver.

On the property page Windows 98 shows the date

of the driver.

18 MI.61xx Manual

Page 19

Software Driver Installation Windows 98

After clicking the driver info button the detailed version information of the driver is shown. In the case

of a support question this information must be presented together with the board’s serial number to

the support team to help finding a fast solution.

Driver - Update

If a new driver version is to be installed no Spectrum board should be in use. So please stop and exit all software that could access the boards.

New drivers are available at http://www.spectrum-instrumentation.com. After down loading the driver unzip it to a temporary folder.

A new driver version is directly installed from the device manager.

Therefore please open the properties

page of the driver as shown in the

section before. As next step click on

the update driver button and follow

the steps of the driver installation in

a similar way to the previous board

and driver installation.

Please select the path where the new

driver version was unzipped to. If

you’ve got the new driver version on

CD please select the

\Driver\Win98_2k_XP path on the

CD containing the new driver version.

The new driver version can be used directly after installation without restarting the system.

Please keep in mind to update the driver of all installed Spectrum boards.

(c) Spectrum GmbH 19

Page 20

Windows 2000 Software Driver Installation

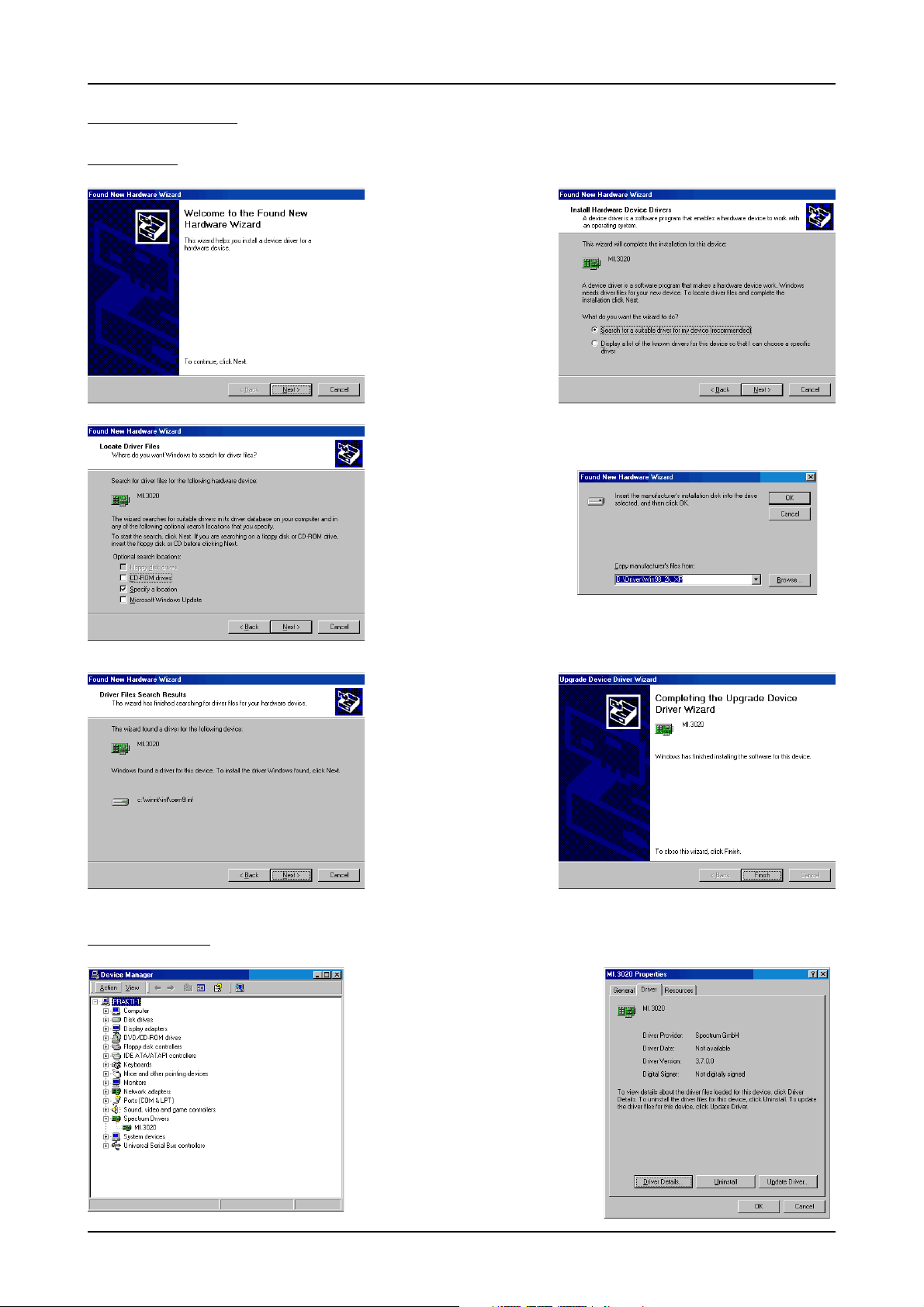

Windows 2000

Installation

When installing the board in

a Windows 2000 system the

Spectrum board will be recognized automatically on the

next start-up.

The system offers the direct installation of a driver for the

board.

Let Windows search automatically for the best driver for

your system.

Select the CD that was delivered with the board as installation source. The driver files

are located on CD in the directory

\Driver\Win98_2k_XP.

Version control

The hardware assistant

shows you the exact board

type that has been found like

the MI.3020 in the example.

Older boards (before june

2004) show „Spectrum

Board“ instead.

The drivers can be used directly after installation. It is

not necessary to restart the

system. The installed drivers

are linked in the device manager.

Below you’ll see how to examine the driver version and

how to update the driver with

a newer version.

If you want to check which driver version

is installed in the system this can be easily done in the device manager. Therefore please start the device manager

from the control panel and show the

properties of the installed driver.

On the property page Windows 2000

shows the date and the version of the installed driver.

After clicking the driver details button the

detailed version information of the driver

is shown. In the case of a support question this information must be presented together with the board’s serial number to

the support team to help finding a fast solution.

20 MI.61xx Manual

Page 21

Software Driver Installation Windows 2000

Driver - Update

If a new driver version should be installed no Spectrum board is allowed to be in use by any software. So please stop and exit all software

that could access the boards.

A new driver version is directly installed from the device

manager. Therefore please

open the properties page of

the driver as shown in the section before. As next step click

on the update driver button

and follow the steps of the

driver installation in a similar

way to the previous board

and driver installation.

Please select the path where

the new driver version was

unzipped to. If you’ve got the

new driver version on CD

please select the

\Driver\Win98_2k_XP path

on the CD containing the new

driver version.

The new driver version can

be used directly after installation without restarting the system. Please keep in mind to

update the driver of all installed Spectrum boards.

(c) Spectrum GmbH 21

Page 22

Windows XP Software Driver Installation

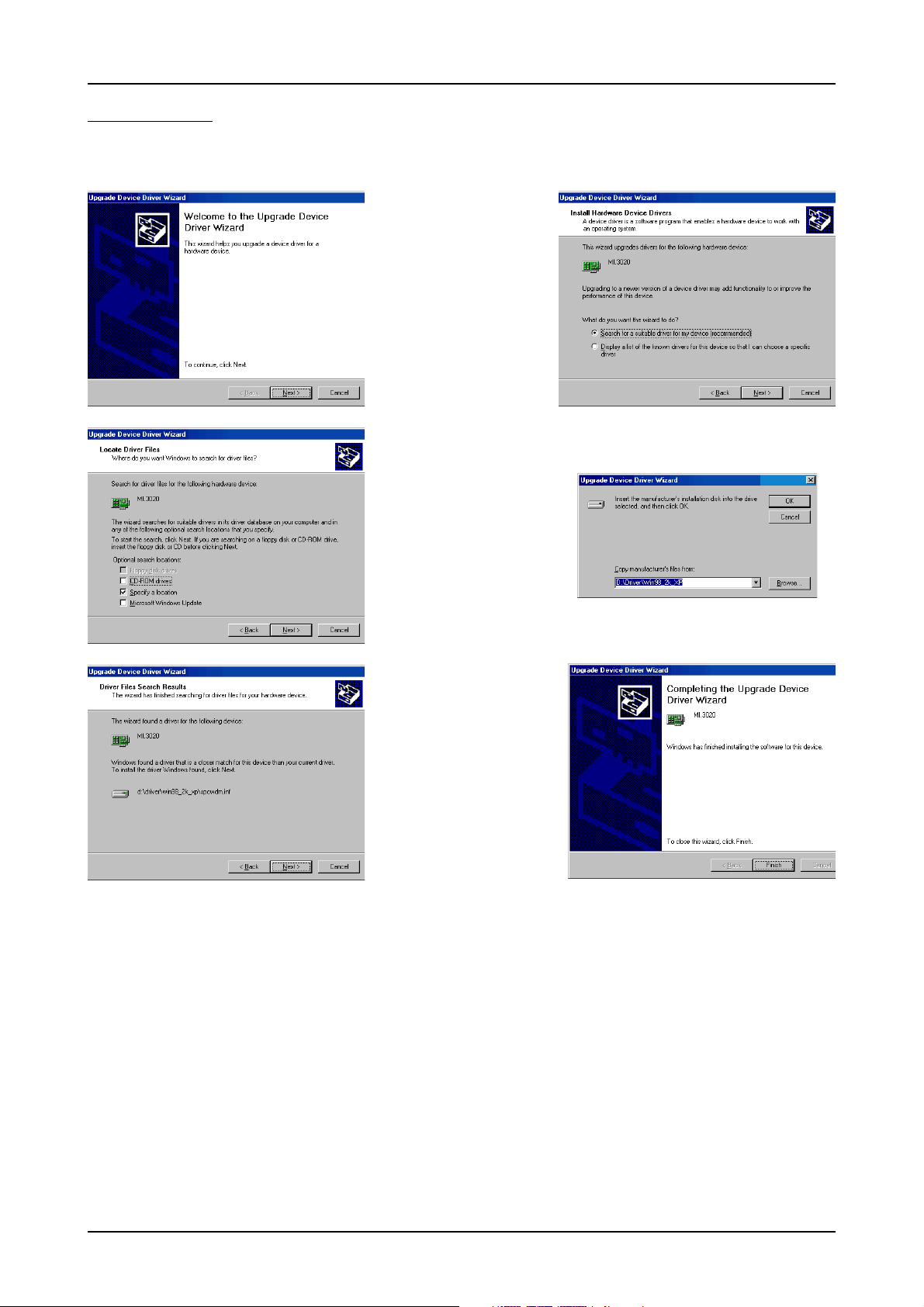

Windows XP

Installation

When installing the board in a Windows XP system the Spectrum board will be recognized automatically on the next start-up.

The system offers the direct installation of a driver for the board.

Do not let Windows automatically search for the best driver, because sometimes the driver will not be found on the CD. Please take the

option of choosing a manual installation path instead.

Allow Windows XP to search for the most suitable driver in a specific directory. Select the CD that was delivered with the board as installation source. The driver files

are located on CD in the directory \Driver\Win98_2k_XP.

The hardware assistant shows you the exact board type that has been found like

the MI.3020 in the example. Older boards (before june 2004) show „Spectrum

Board“ instead.

The drivers can be used directly after installation. It is not necessary to restart the

system. The installed drivers are linked in the device manager.

Below you’ll see how to examine the driver version and how to update the driver

with a newer version.

Version control

If you want to check which driver version is installed in the system this

can be easily done in the device manager. Therefore please start the

device manager from the control panel and show the properties of

the installed driver.

22 MI.61xx Manual

Page 23

Software Driver Installation Windows XP

On the property page Windows XP shows the date and the version of the installed driver.

After clicking the driver details button the detailed version information of the driver is shown.

In the case of a support question this information must be presented together with the

board’s serial number to the support team to help finding a fast solution.

Driver - Update

If a new driver version should be installed no Spectrum board is allowed to be in

use by any software. So please stop and exit all software that could access the

boards.

A new driver version is directly installed from the device manager. Therefore please

open the properties page of the driver as shown in the section before. As next step

click on the update driver button and follow the steps of the driver installation in a

similar way to the previous board and driver installation.

Please select the path where the new driver version was unzipped to. If you’ve got

the new driver version on CD please select the \Driver\Win98_2k_XP path on the

CD containing the new driver version.

The new driver version can be used directly after installation without restarting the

system. Please keep in mind to update the driver of all installed Spectrum boards.

(c) Spectrum GmbH 23

Page 24

Windows NT Software Driver Installation

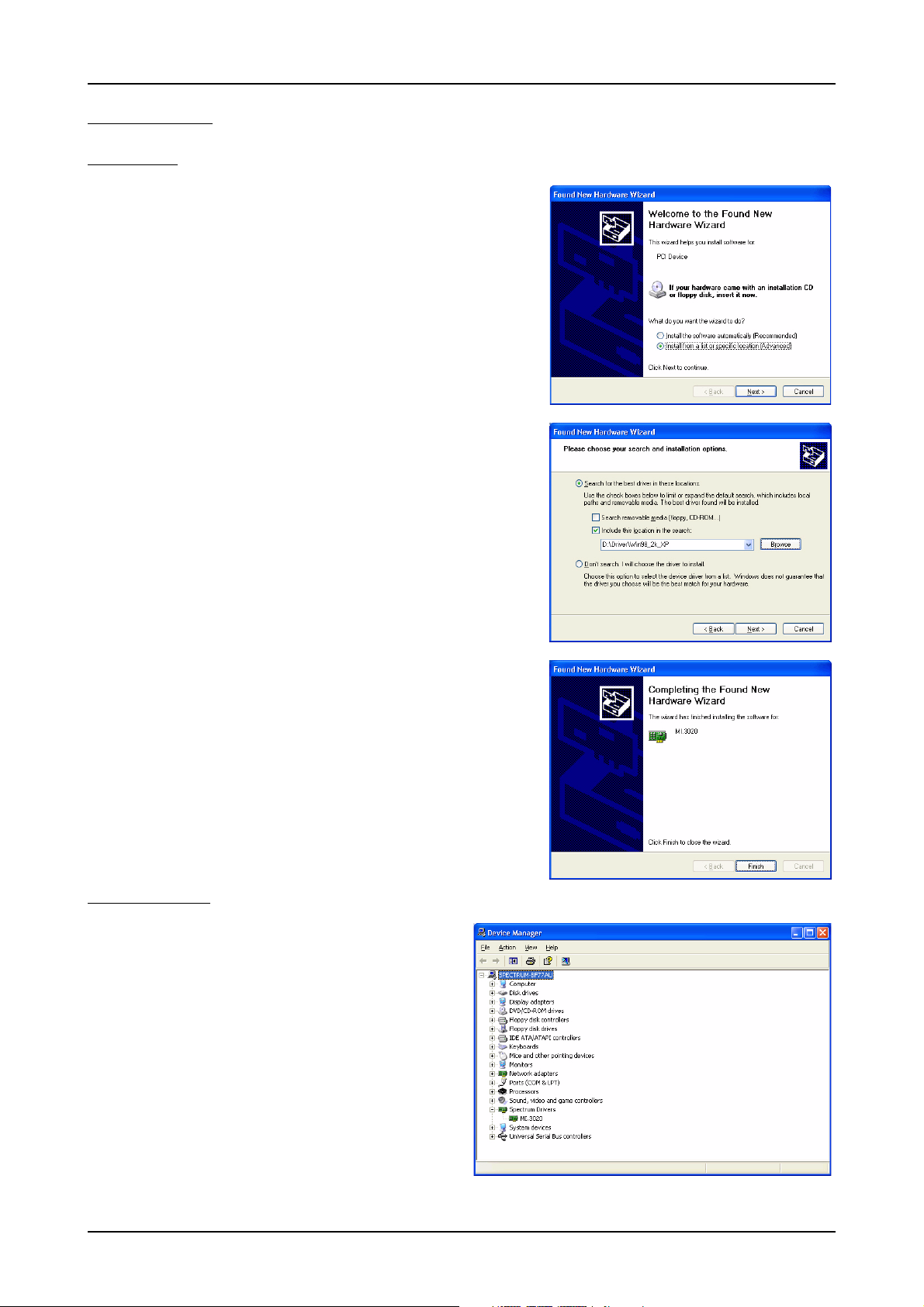

Windows NT

Installation

Under Windows NT the

Spectrum driver must be installed manually. The driver is

found on CD in the directory

\Install\WinNTDrv. Please

start the „Setup.exe“ program. The installation is performed totally automatically,

simply click on the „Next“

button. After installtion the system must be rebooted once

(see picture on the right side).

The driver is install to support

device. If more boards are installed in the system the configuration of the driver has to be changed. Please see the following chapter for this

topic.

Adding boards to the Windows NT driver

one PCI/PXI or CompactPCI

The Windows NT driver

must be configured by the

Driver Configuration utility

to support more than one

board. The Driver Configuration utility is automatically installed with the driver.

The Utility can be found in

the start menu as „DrvConfig“.

To add a new card please follow these steps:

• Increase the board number on top of the screen by pressing the right button

• Change the board type from „Not Installed“ to „PCI Board“

• Press the „Apply changes“ button

• Press the „OK“ button

• Restart the system

Driver - Update

If a new driver version should be installed no Spectrum board is allowed to be in use by any software. So please stop and exit all software

that could access the boards.

When updating a system please simply execute the setup file of the new driver version. Afterwards the system has to be rebooted. The driver

configuration is not changed.

24 MI.61xx Manual

Page 25

Software Driver Installation Linux

Linux

Overview

The Spectrum boards are delivered with drivers for linux. It is necessary to install them manually following the steps explained afterwards.

The linux drivers can be found on CD in the directory /Driver/linux. As linux is an open source operating system there are several distributions

in use world-wide that are compiled with different kernel settings. As we are not able to install and maintain hundreds of different distributions

and versions we had to focus on some common used linux distributions.

However if your distribution does not work with one of these pre-compiled kernel modules or you have a specialized kernel installed (like a

SMP kernel) you can get the linux driver sources directly from us. With this sources it’s no problem to compile and use the linux driver on your

system. Please contact your local distributor to get the sources. The Spectrum linux drivers are compatible with kernel versions 2.4 and 2.6.

On this CD you’ll find pre-compiled linux kernel modules for the following versions:

SuSE version 8.0 Kernel 2.4.18 directory /Driver/linux/suse80 SuSE version 8.2 Kernel 2.4.20 directory /Driver/linux/suse82

SuSE version 9.0 Kernel 2.4.21 directory /Driver/linux/suse90 SuSE version 9.1 Kernel 2.6.4 directory /Driver/linux/suse91

Redhat version 9.0 Kernel 2.4.20 directory /Driver/linux/redhat90

Installation

Login as root.

It is necessary to have the root rights for installing a driver.

Select the right driver from the CD.

Refer to the list shown above. If your distribution is not listed there please select the module that most closely matches your installed kernel

version. Copy the driver kernel module spc.o from the CD directory to your hard disk. Be sure to use a hard disk directory that is a accessible

by all users who should work with the board.

First time load of the driver

The linux driver is shipped as the loadable module spc.o. The driver includes all Spectrum PCI, PXI and CompactPCI boards. The boards are

recognized automatically after driver loading.Load the driver with the insmod command:

linux:~ # insmod spc.o

The insmod command may generate a warning that the driver module was compiled for another kernel version. In that case you may try to

load the driver module with the force parameter and test the board very carefully.

linux:~ # insmod -f spc.o

If the kernel module could not be loaded in your linux installation it is necessary to compile the driver directly on your system. Please contactSpectrum to get the needed source files including the compilation description.

Depending on the used linux distribution the insmod command generates a message telling the driver version and the board types and serial

numbers that have been found. If your distribution does not show this message it is possible to view them with the dmesg command:

linux:~ # dmesg

... some other stuff

spc driver version: 3.07 build 0

sp0: MI.3020 sn 01234

In the example we show you the output generated by a MI.3020. All other board types are similar to this output but showing the correct

board type.

Examine the major number of the driver

For accessing the device driver it is necessary to know the major number of the device. This number is listed in the /proc/devices list. The

device driver is called "spec" in this list. Normally this number is 254 but this depends on the device drivers that have been installed before.

linux:~ # cat /proc/devices

Character devices:

...

171 ieee1394

180 usb

188 ttyUSB

254 spec

Block devices:

1 ramdisk

2 fd

...

(c) Spectrum GmbH 25

Page 26

Linux Software Driver Installation

Installing the device

You connect a device to the driver with the mknod command. The major number is the number of the driver as shown in the last step, the

minor number is the index of the board starting with 0. This step must only be done once for the system where the boards are installed in.

The device will remain in the file structure even if the board is de-installed from the system.

The following command makes a device for the first Spectrum board the driver has found:

linux:~ # mknod /dev/spc0 c 254 0

Make sure that the users who work with the driver have full rights access for the device. Therefore you should give all persons all rights to the

device:

linux:~ # chmod a+w /dev/spc0

Now it is possible to access the board using this device.

Driver info

Information about the installed boards could be found in the /proc/spectrum file. All PCI, PXI and CompactPCI boards show the basic information found in the EEProm there. This is an example output generated by a MI.3020:

linux:~ # cat /proc/spectrum

Spectrum driver information

--------------------------Driver Version: 3.07 build 0

Board#0: MI.3020

serial number: 01234

production month: 05/2004

version: 9.6

samplerate: 100 MHz

installed memory: 16 MBytes

Automatic load of the driver

It is necessary to load the kernel driver module after each start of the system before using the boards. Therefore you may add the „insmod

spc.o“ command in one of the start-up files. Or you may load the kernel driver module manually whenever you need access to the board.

26 MI.61xx Manual

Page 27

Software Software Overview

Software

This chapter gives you an overview about the structure of the drivers and the software, where to find and how to use the examples. It detailed

shows how the drivers are included under different programming languages and where the differences are when calling the driver functions

from different programming languages.

This manual only shows the use of the standard driver API. For further information on programming drivers

for third-party software like LabVIEW, MATLAB, DASYLab or VEE an additional manual is required that is delivered with the ordered driver option.

Software Overview

The Spectrum drivers offer you a common and fast API for using all of the board hardware features. This API is nearly the same on all operating

systems. Based on this API one can write your own programs using any programming language that can access the driver API. This manual

detailed describes the driver API allowing you to write your own programs.

The optional drivers for third-party products like LabVIEW or DASYLab are also based on this API. The special functionality of these drivers

is not subject of this manual and is described on separate manuals delivered with the driver option.

First Test with SBench

After installation of the board and the drivers it can be useful to first test the board function with

a ready to run software before starting with programming. A full version of SBench 5.x is delivered with the board on CD. The program supports all actual acquisition, generator and digital I/O boards from Spectrum. Depending on the used board and the software setup, one

could use SBench as a digital storage oscilloscope, a spectrum analyser, a logic analyser or

simply as a data recording front end. Different export and import formats allow the use of

SBench together with a variety of other programs.

On the CD you’ll find an install version of SBench in the directory /Install/SBench. There’s also

a pre-installed program version on CD that can be started directly from CD without installing

to hard disk. This file can be found in the /Programs/SBench5 directory. Also on CD is a program description that shows in detail how SBench works and what settings have to be done to

use SBench in one of the different modes. The manual is found in the path /Internet/english/

swmanuals/SBench.

The current version of SBench can be down loaded free of charge directly from the Spectrum

website http://www.spectrum-instrumentation.com. Please go to the download section and get the latest version there.

SBench is designed to run under Windows 98, Windows ME, Windows NT, Windows 2000 and Windows XP.

It does not run under Linux. At the moment there is no graphical ready-to-run software for Linux available.

Please use the driver examples to examine whether the board is correctly installed under Linux.

(c) Spectrum GmbH 27

Page 28

C/C++ Driver Interface Software

C/C++ Driver Interface

C/C++ is the main programming language for which the drivers have been build up. Therefore the interface to C/C++ is the best match. All

the small examples of the manual showing different parts of the hardware programming are done with C.

Header files

The basic task before using the driver is to include the header files that are delivered on CD together with the board. The header files are

found in the directory /Driver/header_c. Please don’t change them in any way because they are updated with each new driver version to

include the new registers and new functionality.

dlltyp.h Includes the platform specific definitions for data types and function declarations. All data types are based on this definitions. The use of this typ definition file

regs.h Defines all registers and commands which are used in the Spectrum driver for the different boards. The registers a board uses are described in the board spe-

spectrum.h Defines the functions of the driver. All definitions are taken from the file dlltyp.h. The functions itself are described below.

spcerr.h Lists all and describes all error codes that can be given back by any of the driver functions. The error codes and their meaning are described in detail in the

errors.h Only there for backward compatibility with older program versions. Please use spcerr.h instead.

allows the use of examples and programs on different platforms without changes to the program source.

cific part of the documentation.

appendix of this manul.

Example for including the header files:

// ----- driver includes ----#include "dlltyp.h"

#include "spectrum.h"

#include "spcerr.h"

#include "regs.h"

Microsoft Visual C++

Include Driver

The driver files can be easily included in Microsoft C++ by simply using the library file that is delivered together with the drivers. The library

file can be found on the CD in the path /Driver/Win98_2k_XP. Please include the library file Spectrum.lib in your Visual C++ project. All

functions described below are now available in your program.

Examples

Examples can be found on CD in the path /Examples/vc. There is one subdirectory for each board family. You’ll find board specific examples

for that family there. The examples are bus type independent. As a result that means that the MI30xx directory contains examples for the

MI.30xx, the MC.30xx and the MX.30xx families. The example directories contain a running project file for Microsoft Visual C++ that can

be directly loaded and compiled.

There are also some more board independent examples in the directory MIxxxx. These examples show different aspects of the boards like

programming options or synchronization and have to be combined with one of the board specific example.

Linux Gnu C

Include Driver

The interface of the linux drivers is a little bit different from the windows interface. To make the access easier and to have more similar examples we added an include file that re maps the standard driver functions to the linux specific functions. This include file is found in the path /

Examples/linux/spcioctl.inc. All examples are based on this file.

Example for including Linux driver:

// ----- driver includes ----#include "dlltyp.h"

#include "regs.h"

#include "errors.h"

// ----- include the easy ioctl commands from the driver ----#include "../spcioctl.inc"

Examples

Examples can be found on CD in the path /Examples/linux. There is one subdirectory for each board family. You’ll find board specific examples for that family there. The examples are bus type independent. As a result that means that the MI30xx directory contains examples for

the MI.30xx, the MC.30xx and the MX.30xx families. The examples are simple one file programs and can be compiled using the Gnu C

compiler gcc. It’s not necessary to use a makefile for them.

28 MI.61xx Manual

Page 29

Software C/C++ Driver Interface

Other Windows C/C++ compilers

Include Driver

To access the driver, the driver functions must be loaded from the driver dll. This can be easily done by standard windows functions. There

is one example in the directory /Examples/other that shows the process. After loading the functions from the dll one can proceed with the

examples that are given for Microsoft Visual C++.

Example of function loading:

// definition of external function that has to be loaded from DLL

typedef int16 (SPCINITPCIBOARDS) (int16* pnCount, int16* pnPCIVersion);

typedef int16 (SPCSETPARAM) (int16 nNr, int32 lReg, int32 lValue);

typedef int16 (SPCGETPARAM) (int16 nNr, int32 lReg, int32* plValue);

...

SPCINITPCIBOARDS* pfnSpcInitPCIBoards;

SPCSETPARAM* pfnSpcSetParam;

SPCGETPARAM* pfnSpcGetParam;

...

// ----- Search for dll ----hDLL = LoadLibrary ("spectrum.dll");

// ----- Load functions from DLL ----pfnSpcInitPCIBoards = (SPCINITPCIBOARDS*) GetProcAddress (hDLL, "SpcInitPCIBoards");

pfnSpcSetParam = (SPCSETPARAM*) GetProcAddress (hDLL, "SpcSetParam");

pfnSpcGetParam = (SPCGETPARAM*) GetProcAddress (hDLL, "SpcGetParam");

National Instruments LabWindows/CVI

Include Drivers

To use the Spectrum driver under LabWindows/CVI it is necessary to first load the functions from the driver dll. This is more or less similar to

the above shown process with the only difference that LabWindows/CVI uses it’s own library handling functions instead of the windows

standard functions.

Example of function loding under LabWindows/CVI:

// ----- load the driver entries from the DLL ----DriverId = LoadExternalModule ("spectrum.lib");

// ----- Load functions from DLL ----SpcInitPCIBoards = (SPCINITPCIBOARDS*) GetExternalModuleAddr (DriverId, "SpcInitPCIBoards", &Status);

SpcSetParam = (SPCSETPARAM*) GetExternalModuleAddr (DriverId, "SpcSetParam", &Status);

SpcGetParam = (SPCGETPARAM*) GetExternalModuleAddr (DriverId, "SpcGetParam", &Status);

Examples

Examples for LabWindows/CVI can be found on CD in the directory /Examples/cvi. Theses examples show mainly how to include the driver

in a LabWindows/CVI environment and don’t use any special functions of the boards. The examples have to be merged with the standard

windows examples described under Visual C++.

Driver functions

The driver contains five functions to access the hardware.

Function

This function initializes all installed PCI, PXI and CompactPCI boards. The boards are recognized automatically. All installation parameters

are read out from the hardware and stored in the driver. The number of PCI boards will be given back in the value Count and the version of

the PCI bus itself will be given back in the value PCIVersion.

SpcInitPCIBoard

Function SpcInitPCIBoards:

int16 SpcInitPCIBoards (int16* count, int16* PCIVersion);

Under Linux this function is not available. Instead one must open and close the driver with the standard file

functions open and close. The functionality behind this function is the same as the SpcInitPCIBoards function.

Using the Driver under Linux:

hDrv = open ("/dev/spc0", O_RDWR);

...

close (hDrv);

(c) Spectrum GmbH 29

Page 30

C/C++ Driver Interface Software

Function SpcSetParam