Page 1

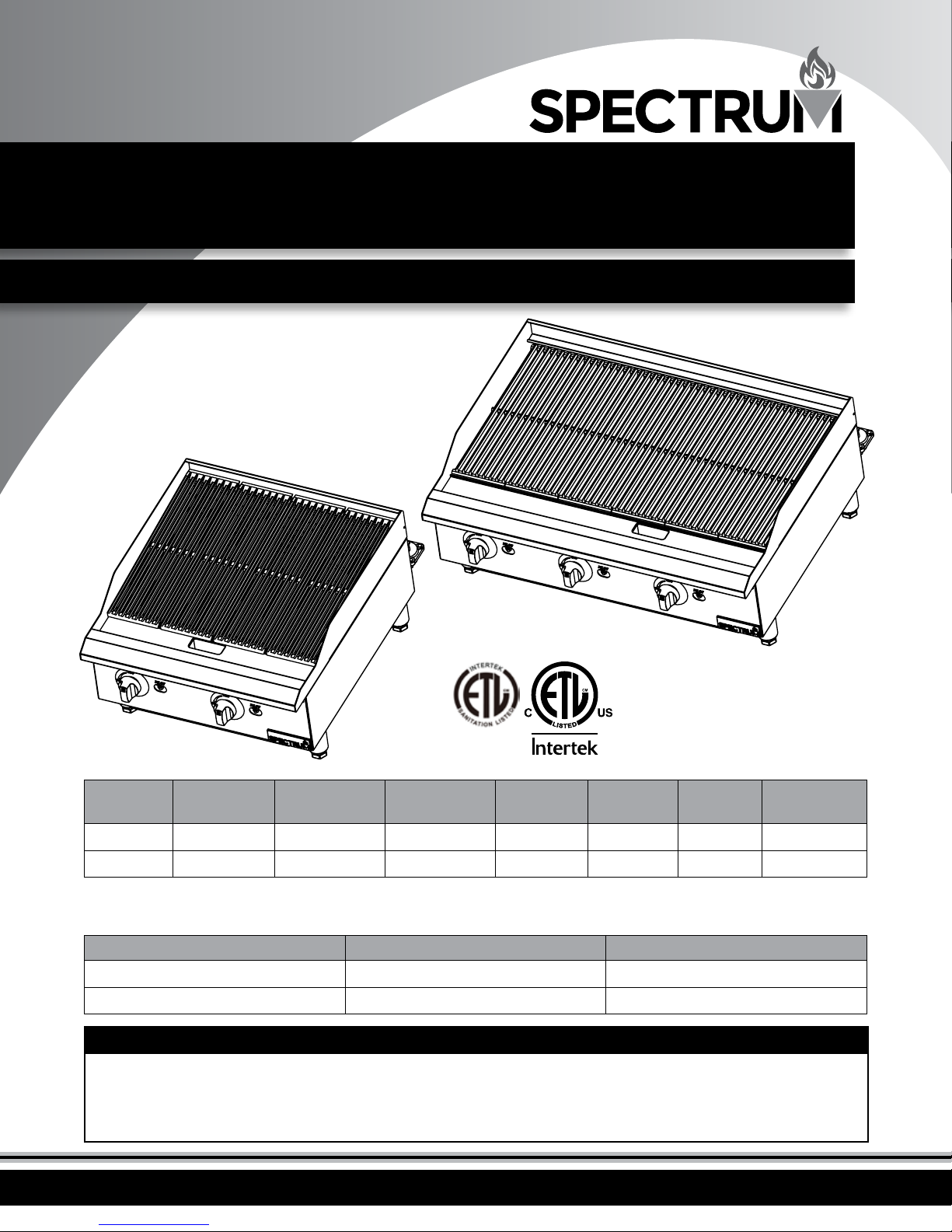

GCB-36R

Conforms to ANSI STD

Z83.11b-2009(R2012)

Certied to CSA

STD 1.8b-2009(R2012)

GCB-24R

3182799

MODEL

GCB-24R

GCB-36R

Note: Depth direction includes the regulator size.

CHAR BROILER SURFACE DIMENSIONS

WIDTH

IN. (MM)

24" (610 mm) 26.8" (680 mm) 15.6" (398 mm)

36" (915 mm) 26.8" (680 mm) 15.6" (398 mm)

MODEL WIDTH - IN. (MM) DEPTH - IN. (MM)

GCB-24R 24" (610 mm) 20" (510 mm)

GCB-36R 36" (915 mm) 20" (510 mm)

BEFORE OPERATING ANY EQUIPMENT, READ AND FAMILIARIZE YOURSELF WITH THESE USE AND SAFETY INSTRUCTIONS

Congratulations on your purchase of SPECTRUM commercial cooking equipment. SPECTRUM takes pride in the design

and quality of our products. When used as intended and with proper care and maintenance, you will experience years of

reliable operation from this equipment. To ensure best results, it is important that you read and follow the instructions in

this manual carefully. It’s important to save these instructions for future reference.

DEPTH

IN. (MM)

HEIGHT

IN. (MM)

# OF

BURNERS

2 40,000 80,000 6 / 10

3 40,000 120,000 6 / 10

BTU/PER

NAT/LP

TOTAL

BTU/HR

PRESSURE

IN. W.C

Page 2

Important For Future Reference

Please complete this information and retain this manual for the life of the equipment. For

Warranty Service and/or parts, this information is required.

Model Number Serial Number Date Purchased

WARNING: For your safety, do not store or use gasoline

or other ammable vapors or liquids in the vicinity of

! !

this or any other appliances. Keep the area free and

clear of combustibles. (See ANSI Z83. 14B, 1991).

WARNING: Improper installation, adjustment,

alteration, service or maintenance can cause property

! !

damage, injury, or death. Read the installation

operating and maintenance instructions thoroughly

before installing, or servicing this equipment.

WARNING: Instructions must be posted in a prominent

location. All safety precautions must be taken in the

! !

event the user smells gas. Safety information can be

obtained from your local gas supplier.

CAUTION: These models are designed, built, and sold for

commercial use only. If these models are positioned so

! !

the general public can use the equipment, make sure

that cautions, warnings, and operating instructions

are clearly posted near each unit so that anyone using

the equipment will use it correctly and not injure

themselves or harm the equipment.

AVERTISSEMENT: Pour votre sécurité, ne pas stocker ni

utiliser d'essence ou d'autres vapeurs ou liquides

inammables à proximité de cet appareil ou d'autres

appareils. Garder la zone libre de combustible.

(Voir la norme ANSI Z83. 14B, 1991).

AVERTISSEMENT: Une installation, un réglage, une

modication, un entretien ou peut causer des dommages

matériels, des blessures ou la mort. Lisez les

instructions d' exploitation et de maintenance d'installation

avant d'installer, ou sauvegarder cet équipement.

AVERTISSEMENT: Les instructions doit être achées dans

un endroit bien en vue. Toutes les mesures de sécurité

doit être prises en cas d'odeur de gaz. Les consignes

de sécurité peut être obtenue auprès de votre fournisseur

de gaz local.

ATTENTION: Ces modèles sont conçus, fabriqués et vendus

pour un usage commercial seulement. Si ces modèles

sont positionnés de sorte que le grand public peut

utiliser l'équipement, assurez-vous que mises en garde, les

avertissements et les instructions sont clairement achés unité

de sorte que toute personne utilisant l'équipement va l'utiliser

correctement et de ne pas nuire à injurethemselves

ou l'équipement.

WARNING: A factory authorized agent should handle

all maintenance and repair. Before doing any

! !

maintenance or repair, contact your authorized service

representative.

GAS PRESSURE

The appliance and its individual shuto valve (to be supplied by

user) must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures in

excess of ½ psi (3.45 kPa).

The appliance must be isolated from the gas supply piping

system by closing its individual manual shut-o valve during any

pressure testing of the gas supply piping system at test pressures

equal to or less than ½ psi (3.45 kPa).

2

AVERTISSEMENT: Un agent autorisé de l'usine doit traiter

tout l'entretien et la réparation. Avant de faire tout

entretien ou réparation, contactez votre représentant

de service autorisé.

PRESSION DE GAZ

L'appareil et la vanne d'arrêt individuel (à fournir par

l'utilisateur) doit être débranchés de la tuyauterie d'alimentation

en gaz pendant tout test de pression de ce système à des

pressions d' essai supérieures à ½ psi (3.45 kPa).

L'appareil doit être isolé du système de conduites d'alimentation

en gaz en fermant son robinet manuel d'arrêt individuel durant

tout test de pression du système de tuyauterie d'alimentation en

gaz à des pressions inférieures à ½ psi (3.45 kPa).

Page 3

Table of Contents

Specications .............................................................................. 1

Warnings ..................................................................................... 2

Table of Contents ....................................................................... 3

Introduction ................................................................................ 3

Safety Precautions ...................................................................... 4

Packaging .................................................................................... 4

Installation .................................................................................. 5

Conversion ................................................................................... 6

Lighting ....................................................................................... 7

Operation .................................................................................... 8

Cleaning, Care & Maintenance ................................................. 8

Troubleshooting ......................................................................... 9

Safety ............................................................................................ 9

Service & Repair ......................................................................... 9

Exploded View ......................................................................... 10

Spare Parts List ..........................................................................11

Limited Warranty ..................................................................... 12

Introduction

Congratulations on the purchase of your SPECTRUM machine. Please take

time to carefully read through this manual to ensure the machine is operated

and maintained properly, to ensure the best possible performance from the

product for many years.

SPECTRUM will not accept liability for the following if:

• The instructions in this manual have not been followed correctly.

• Non-authorized personnel have tampered with the machine.

• Non-original spare parts are used.

• The machine has not been handled and cleaned correctly.

• There is any use damage to the unit.

LOCATION OF DATA PLATE

The data plate is located on the side panel.

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

All containers should be examined for damage before and during unloading.

The freight carrier has assumed responsibility for its safe transit and delivery.

If equipment is received damaged, either apparent or concealed, a claim

must be made with the delivering carrier.

A. Apparent damage or loss must be noted on the freight bill at the time of

delivery. It must then be signed by the carrier representative (Driver). If

this is not done, the carrier may refuse the claim. The carrier can supply

the necessary forms.

B. If concealed damage or loss is not apparent until after equipment is

uncrated, a request for inspection must be made to the carrier within

15 days. The carrier should arrange an inspection. Be certain to keep all

contents and packaging material.

Installation should be performed by a qualied installer who thoroughly

read, understands and follows these instructions.

If you have questions concerning the installation, operation, maintenance or

service of this product, please contact WINCO.

Please keep this manual in a safe place for future use!

3

Page 4

Safety Precautions

DANGER: This symbol warns of imminent hazard which

will result in serious injury or death.

! !

WARNING: This symbol refers to a potential hazard

or unsafe practice, which could result in serious injury

! !

or death.

CAUTION: This symbol refers to a potential hazard

or unsafe practice, which could result in minor or

! !

moderate injury or product or property damage.

NOTICE: This symbol refers to information that needs

special attention or must be fully understood even

! !

though not dangerous.

NOTICE: This product is intended for commercial use

only. Not for household use.

! !

NOTICE: Local codes regarding installation vary greatly

from one area to another. The National Fire Protection

! !

Association, Inc., states in its NFPA96 latest edition that

local codes are “Authority Having Jurisdiction” when it

comes to requirement for installation of equipment.

Therefore, installation should comply with all local

codes.

Risque: Ce symbole avertit du danger imminent qui peut

entraîner des blessures graves ou la mort.

AVERTISSEMENT: Ce symbole indique un danger potentiel

ou une pratique dangereuse, qui peut entraîner des

blessures graves ou la mort.

ATTENTION: Ce symbole indique un danger potentiel ou une

pratique dangereuse, qui peut entraîner des blessures

mineures ou modérées ou des dommages matériels.

AVIS: Ce symbole renvoie à des informations qui nécessite

une attention particulière ou doit être pleinement

compris, même si pas dangereux.

AVIS: Ce produit est destiné à un usage commercial.

Pas pour usage domestique.

AVIS: Les codes locaux concernant l'installation varient

grandement d'une région à l'autre. La National Fire

Protection Association, Inc., déclare dans sa dernière

édition que NFPA96 codes locaux sont “Autorité Compétente”

lors de l'exigence pour l'installation d'équipements.

Par conséquent, l'installation doit être conforme à tous les

codes locaux.

Package Contents

All units come with Installation & Operation Instructions

and the following:

• Char Broiler

• Waste Tray

SPECTRUM prides itself on quality and service, ensuring that at the time

of packing, all products are supplied fully functional and free of damage.

Should you nd any damage as a result of freight, please contact your

SPECTRUM dealer immediately.

NOTE

Please remember that this manual and the warning labels do not replace the need to be alert, to properly train and supervise operators, and to use

common sense when using this equipment.

4

Unpacking the Equipment

DISPOSE OF ALL PACKAGING MATERIALS IN AN

ENVIRONMENTALLY RESPONSIBLE MANNER.

1. Remove all packing materials and tape, as well as any protective plastic

and cardboard, from the unit.

2. Clean any glue residue left over from the plastic or tape.

3. Place the unit in the desired position and height.

SAVE THE ORIGINAL BOX AND PACKAGING FOR USE IN

PACKAGING AND SHIPPING THE EQUIPMENT IF SERVICES

ARENEEDED.

Page 5

Installation

These instructions should be followed at all times. Failure to follow these

instructions could result in injury to yourself and others.

TO REDUCE RISK OF INJURY OR DAMAGE TO THE UNIT:

1. Read this manual thoroughly before installation and operation. DO NOT

proceed with installation and operation if you have any questions or do

not understand anything in this manual. Contact your representative or

the manufacturer rst.

WARNING

Fire Hazar d.

Correc t installation p recautions,

procedu res and regulatio ns

must be fo llowed. Operati on

and safe ty training is ne cessary

for all use rs of this equipme nt.

The equip ment must be

install ed by qualied per sonnel

only. Correc t installatio n

precau tions, procedur es and

regulati ons must be followe d

in order to re duce the risk of

re. Hood an d re suppression

system s must be maintaine d

per manuf acturer's guid elines.

Only quali ed and trained

person nel are to use this

equipme nt.

2. Remove the SPECTRUM Gas Char Broiler from the packaging. Be certain

that all protective plastics and residues are thoroughly cleaned from its

surface.

3. Place the SPECTRUM Gas Char Broiler on a rm level surface. Local

standards and regulations should be consulted in order to abide by

standards set in relation to positioning, spacing, and ventilation.

4. Ensure gas supply and gas type, as shown on unit nameplate, agree.

5. Unit installation must conform with the National Fuel Gas Code, ANSI

Z223.1/NFPA 54, the National Gas Installation Code, CSA-B149.1, or the

Propane Installation Code, CSA-B149.2 as applicable and in accordance

with local codes.

6. Screw legs into the permanently fastened nuts on the four corners of

the unit and tighten by hand. Level the unit by turning the adjustment

screw at the bottom of each leg. Do not slide unit with legs mounted;

lift if necessary to move unit.

7. Pipe threading compound must be resistant to the action of liqueed

petroleum gases.

CAUTION • ATTENTION

DO NOT use an open ame to check for leaks. Check all gas piping

for leaks with a soap and water solution before operating unit.

NE PAS utiliser une amme nue pour vérier les fuites. Vériez tous les

tuyaux de gaz pour les fuites avec de l'eau savonneuse avant de l'unité

d'exploitation.

AVERTISSEMENT

Risque d'incendie

La surcha ue des vapeurs d' huile ou de

l'huile peu t s'enamm er et provoquer

un incendi e. Surveillez la temp érature,

la qualité et l e niveau d’huile. Uti lisez et

entrete nez le système d'élimi nation des

vapeur s d'huile.

Faire chau er l'huile avec précau tion. Si

l'huile fum e, réduire le feu. Ne p as laisser

l'appareil s ans surveillance. Si l e feu se

produit , éteindre l'apparei l, couvrir jusqu'à

refroi dissement. Ne pa s mettre l'eau dans

l'huile chau de ou enammée. Ne fa ites pas

fonct ionner avec de l'huile s ous la barre

d'huile. L’huile sal e a un point d'éclair

plus bas. Re mplacer l'huile sur un e base

régulièr e. Maintenir le niveau d'h uile

correc t. Utiliser un sy stème d'évacuation

de la vapeur d' huile (capot) pour réd uire

l'accumulati on de graisse et d'hu ile sur les

surfa ces de paroi ou de plaf ond.

THESE UNITS ARE SUITABLE FOR INSTALLATION ON

NONCOMBUSTIBLE SURFACES ONLY.

Combustible clearances:

6" sides (152 mm) 6" rear (152 mm) 4" oor (102 mm)

Noncombustible clearances:

0" sides (0 mm) 0" rear (0 mm) 4" oor (102 mm)

THIS EQUIPMENT GETS EXTREMELY HOT. DO NOT POSITION AND OPERATE

NEAR COMBUSTIBLE MATERIALS/FLAMMABLE OBJECTS.

Do not obstruct the ow of combustion and ventilation air, under the unit by

the legs or behind the unit by the ue.

Ne pas obstruer le ux de combustion et de ventilation, sous l'unité par les jambes ou

derrière l'appareil par la cheminée.

Adequate clearance for air openings into the combustion chamber is

required. Do not place objects between the bottom of the unit and the

counter top.

Un dégagement adéquat pour des ouvertures d'air dans la chambre de combustion

est nécessaire. Ne pas placer d'objets entre le bas de l'appareil et le comptoir.

There must be adequate clearance for removal of the front panel. All major

parts except the burners are removable through the front if the gas line is

disconnected.

Il doit y avoir un espace susant pour le retrait de la face avant. Toutes les parties

principales à l'exception des brûleurs sont amovibles à travers l'avant si la conduite

de gaz est coupée.

WARNING AVERTISSEMENT

Burn Hazard.

When in ope ration, the

Conveyor Toaste r will be hot at

the entra nce to the conveyor

HOT

cavit y.

Please take e xtreme ca ution.

USE CAUTION WHEN

TOUCHING THE UNIT.

TO AVOID SERIOUS PERSONAL INJURY:

• ALWAYS install equipment in a work area with adequate light

and space.

• ONLY operate on a solid, level, nonskid surface.

• NEVER bypass, alter or modify this equipment in any way from

its original condition. Doing so can create hazards and will

void warranty.

• NEVER operate the char broiler without all warnings attached to it.

Risque de brûlure.

Ne touche z pas les surface s chaudes ou

chaué es liguid tout appar eil chaue ou

en fonc tionnement.

Ne touchez pas le liquide chaud

ou les sur faces de chauage

lorsque l’appareil chaue ou en

fonctionnement.

5

Page 6

Conversion

These instructions are for the conversion from Natural Gas to Propane (L.P.)

on all models. The conversion should be done before connecting the unit to

the gas supply.

Units are shipped from the factory equipped for use on natural gas. Orices

necessary for Propane (L.P.) are included with the unit.

1. Shut-o the main isolation gas valve and

follow the lock-out/tag-out procedure.

2. Pull-out and remove all the knobs. Remove the Tray, Grates

and Radiants.

4. Remove the nuts for U Burners.

Nut

5. Remove the U Burners.

U Burner

Knob

Tray

3. Remove the screws of the control panel.

Screw

Radiants

Grate

6. Remove the orice and replace it. Use a 1/2” spanner. See the list of

orice numbers for the appropriate gas type.

Main Burner

Valve

Pilot Valve Orice

6

Page 7

Conversion

7. Converting the gas regulator:

A. Remove the converter cover from the regulator. Use a 7/8” spanner.

B. Pull-out the converter from the cover.

C. Position of converter when using Propane (L.P.).

D. Install the converter cover to the regulator.

A B

8. Re-install the U burners.

9. Check leakage and re-install

other parts.

10. Ignite the pilot burner and check

ame state.

11. Turn the knobs to “High”.

• If the U burner does not ignite,

open the pilot valve more.

• If the pilot ame appears larger than necessary, turn it down and reset

burner ignition.

• The pilot ame should be as small as possible but large enough to

guarantee reliable ignition of the burners when the knobs are turned

to “|”.

C-D

Note:

The arrow in the

regulator indicates

the ow direction

of the gas.

Note

PLEASE CHECK LEAKAGE BEFORE REINSTALLING THE CONTROL PANEL.

Lighting Instructions

LIGHTING PILOT

The pilot light on the appliance has been set at the factory. A screwdriver

may be required for the rst lighting to adjust the ame for your elevation.

1. Turn o the manual valve and wait 5 minutes to clear the gas.

2. Turn all knobs to the "OFF" position.

3. Hold an ignition source (e.g. a match) at the pilot. When the ame is

established, remove the ignition source.

4. Turn the burner knobs to "ON". If the burner does not ignite, promptly

open the pilot valve more. If the pilot ame appears larger than

necessary, turn it down and reset burner ignition. The pilot ame should

be as small as possible but large enough to guarantee reliable ignition of

the burners when the knobs are turned to "ON".

LIGHTING MAIN BURNER

To light burner, turn knob to “ON”. Then back o to the desired ame level. The

range of adjustment is virtually innite between “ON” and “OFF”.

MAIN BURNER AIR SUPPLY

5. For ecient burner operation, a proper balance of gas volume and

primary air supply must be maintained, which will result in complete

combustion. Insucient air supply results in a yellow streaming ame.

Primary air supply is controlled by an air shutter on the front of the burner.

6. Loosen the screws on the front of the burner and adjust the air shutter

to just eliminate the yellow tips of the burner ame. Lock the air shutter

in place by tightening the screws.

CAUTION • ATTENTION

NEVER ATTEMPT TO MOVE A GRILL SECTION WHILE COOKING.

An unexpected are could cause severe injury. Turn o the unit, let it cool

and use potholders and/or gloves to reposition or remove.

The space between the legs at the bottom admits combustion air.

DO NOT BLOCK THIS SPACE.

Ne tentez jamais de déplacer une section de la grille pendant la cuisson. Une fusée

inattendu pourrait causer des blessures graves. Eteignez l'appareil, le laisser refroidir

et employer des gants isolants et/ou des gants pour repositionner ou supprimer.

L'espace entre les jambes en bas admet l'air de combustion.

NE PAS BLOQUER CET ESPACE.

All burners are lit from constantly burning pilots. Turning the valve to the

desired ame height is all that is required to put the unit in service.

Do not permit fans to blow directly at the unit. Wherever possible, avoid

open windows next to the unit's sides or back. Avoid wall type fans which

create air cross-currents within a room.

Tous les brûleurs sont allumés de pilotes brûlant constamment. Tourner la vanne à

la hauteur de amme désirée est tout ce qui est nécessaire pour mettre l'appareil en

service.

Ne pas permettre aux fans de souer directement à l' unité. Autant que possible,

éviter les fenêtres ouvertes à côté des côtés ou à l'arrière des unités. Évitez les fans de

type mur qui créent air contre-courants au sein d'une chambre.

It is also necessary that sucient air be allowed to enter the room to

compensate for the amount of air removed by any ventilating system.

Otherwise, a subnormal atmospheric pressure will occur, aecting operation

and causing undesirable working conditions.

Il est également nécessaire que l'air susant doit être autorisé à entrer dans la salle

pour compenser la quantité de l'air extrait par un système de ventilation. Sinon, une

pression atmosphérique inférieure à la normale aura lieu, aecter le fonctionnement

et causer des conditions de travail indésirables.

A properly designed and installed hood will act as the heart of the ventilating

system for the room or area in which the unit is installed, and will leave the

unit independent of changing draft conditions.

Un capot correctement conçu et installé agira comme le cœur du système de

ventilation pour la salle ou une zone dans laquelle l'appareil est installé, et laisser

l'unité indépendante de l'évolution des conditions de tirage.

All valves must be checked and lubricated periodically. This must be

done by an authorized service representative in your area.

Toutes les vannes doit être vériés et lubriés périodiquement. Cela

doit être fait par un technicien de maintenance agréé dans votre

région.

7

Page 8

Operation

Cleaning, Care & Maintenance

Before operating the char broiler, it must be checked to see that it

is sitting level. Adjust the feet to level the char broiler. Be sure the

waste tray has been assembled correctly.

OPERATION

Turn the burners on about 15-20 minutes before cooking for preheating.

Set the knobs to the desired ame height or temperature. Each valve will

control the gas ow to the burner to bring that area of the unit up to the

set temperature. If dierent temperature settings are to be used, adjoining

areas should be set at progressively higher temperatures using the lowest

temperatures on the outside burners. A uniform and systematic approach to

the loading of the unit will produce the most consistent product results.

Radiants

CAUTION • ATTENTION

CHAR BROILER SURFACE WILL BE HOT

Surface sera chaud

Place all the radiants in their position. Make sure that the radiants are setting

properly into the slots on the front and rear supports. Radiants should be

centered over straight section of the burners.

Radiant

Slots

INITIAL CLEANING

Prior to operating your new char broiler, thoroughly wash the exterior with

a mild detergent or soap solution. Do not use abrasive cleaners, since this

might damage the cabinet nish. If the stainless steel surfaces become

discolored, scrub by rubbing only in the direction of the nished grain.

When the char broiler is rst heated, it will smoke until oil used in

manufacturing, and preservation and dust from storage and shipping are

burned o. An hour at "max" on all burners is usually sucient.

DAILY CLEANING

Remove the grease pan, empty and wash it. The grease buildup on the grates

should be cleaned daily (more often as needed).

CAUTION • ATTENTION

When handling grates or radiants, always use insulated

gloves to prevent burns.

Lors de la manipulation des grilles ou radiants, utilisez

toujours des gants isolants pour éviter les brûlures.

WARNING • ADVERTISSEMENT

Do not cover the top of the grid grates during a burn o

operation. Restricting the airow by covering the grid

grates may cause them to warp. It will also cause damage

to the valves, the knobs and the front panel decal.

Ne couvrez pas le haut des grilles de la grille lors d'une

opération brûler. Le manque de ventilation en couvrant les

grilles de la grille peut causer les amener à se déformer. Il

sera également endommager les soupapes, les boutons et

l'autocollant du panneau avant.

Cooking Grates

Install the top cooking grates.

NOTE

When cooking grates are placed sloping toward the front, the grooves on top

will guide the excess fat drippings into the grease trough.

Grate

8

1. Place grates on broiler, with grid bars horizontal, facing down.

2. Turn the char broiler on for approximately 45 minutes.

3. Turn o the char broiler and allow it to cool for 20 Minutes.

4. Clean top and bottom surfaces of grate with a wire brush to remove

animal fats and carbonized grease.

5. Clean channels on grates with a scraper.

6. Remove grates from char broiler. Clean top surface of radiants with the

wire brush. They may be cleaned in place.

NOTE • AVIS

Parts protected by the manufacturer or its agent are not to be

adjusted by the installer, unless the installer is an authorized

service agent.

Les pièces protégées par le fabricant ou son mandataire ne doit pas

être réglés par l'installateur, à moins que l'installateur est un agent de

service autorisé.

Page 9

Troubleshooting

If your SPECTRUM Gas Char Broiler does not operate, please check the following before placing a service call.

ISSUE MIGHT BE CAUSED BY RECOMMENDED SOLUTION

Heat does not come on when valve

is turned on

Pilot burner will not light

Pilot burner will not stay lit

Fat appears to smoke excessively

Food sticks to grates

Food is undercooked inside

Food tastes greasy or has

objectionable o-avor.

Pilot burner not lit. Turn-ON pilot burner, then light up the main burner.

Gas valve is bad. Replace the gas valve.

Obstructed pilot orice. Check and clean the pilot head, or replace the pilot head

if necessary.

Pilot valve turned o. Turn-ON the pilot valve, then light up the pilot.

Obstructed pilot orice. Check and clean the pilot head, or replace the pilot head

if necessary.

Gas supply is not purged of air. Purge the gas supply line rst by continuing to light up

the pilot.

Air is blowing pilot light out. Check for drafts and increase the size of pilot ame by

adjusting the pilot valve.

Heat is set too high. Decrease the burner ame.

Moisture in the food may be turning into steam. Make sure to thaw the food before cooking.

Heat is set too high. Decrease the burner ame.

Char Broiler surface needs cleaning and/or seasoning. Clean the grates frequently.

Surface under food may not have been covered with

enough cooking oil.

Heat is set too high. Decrease the burner ame.

Food may not have been cooked for long enough time. Provide enough time for the food to cook.

Food itself may have o avor. Make sure to check the expiration date of the food before

Food may have been stored improperly before cooking. Make sure to store the food properly and with correct

Too much fat used. Remove excess fat/oil from food before cooking.

Heat is set too low. Increase the burner ame.

Cover the food with enough oil to prevent sticking to the

grates.

cooking

temperature to prevent spoilage.

Safety

A WINCO Approved Service Technician should carry out repairs if necessary.

Do not remove any components or service panels on this product. Allow Char

Broiler to cool down after use before dismantling for cleaning; the unit will

be too hot to handle immediately after use.

When cleaning, turn o gas and let machine cool.

Do not use hose to clean.

If the machine is damaged, it must be repaired by a WINCO Approved

Qualied Service Technician in order to avoid a hazard.

Service and Repair

THIS APPLIANCE MUST ONLY BE SERVICED BY AN AUTHORIZED AGENT.

NOTE

Parts protected by the manufacturer or its agent are not to be adjusted by

the installer unless the installer is an authorized service agent.

If you have any questions or problems DO NOT send unit to WINCO without

rst contacting our customer service department.

See "Limited Warranty" section on page 12 for details.

9

Page 10

Exploded View

MODEL GCB36R

10

Page 11

Exploded View & Spare Parts List

MODEL GCB24R

MODEL GCB36R MODEL GCB24R

NO. DESCRIPTION PART # QTY PART # QTY

1 Cooking Grate GCB-P1 6 GCB-P1 4

S/S radiant GCB-P2 6 GCB-P2 4

2

12” Cast Radiant Kit

(Optional)

3 Regulator GHP-P3 1 GHP-P3 1

4 Burner GCB-P5 3 GCB-P5 2

5 Foot GHP-P5 4 GHP-P5 4

6 Tray GCB-P7-36 1 GGD-P4 1

7 Pilot Pipe GCB-P8 3 GCB-P8 2

8 Pilot valve GCB-P9 3 GCB-P9 2

9 Valve for Manual GHP-P11 3 GHP-P11 2

10 Dial GHP-P12 3 GHP-P12 2

Orice for Natural Gas GCB-P12 3 GCB-P12 2

11

Orice for LPG GCB-P13 3 GCB-P13 2

12 12” Cast Lava Rock Kit

(Optional

GCB-P3 3 GCB-P3 2

GCB-LRRC 3 GCB-LRRC 2

11

Page 12

Limited Warranty

WINCO warrants to the original purchaser of new equipment that said

equipment, when installed in accordance with our instructions within

North America and subjected to normal use, is free from defects in

material or workmanship for a period of 1 year. The labor warranty is

one year from original installation or 18 months from actual factory

shipment date, whichever date occurs rst. Warranty includes on site

service calls within 60 miles of an authorized service company. End user

is responsible for all extra travel and mileage at prevailing rates.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES,

WHETHER EXPRESSED OR IMPLIED. WINCO EXPRESSLY DISCLAIMS

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR EXPRESSED

OR IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

WINCO’S OBLIGATION AND LIABILITY UNDER THIS WARRANTY

IS EXPRESSLY LIMITED TO REPAIRING AND REPLACING

EQUIPMENT WHICH PROVES TO BE DEFECTIVE IN MATERIAL OR

WORKMANSHIP WITHIN THE APPLICABLE WARRANTY PERIOD.

All repairs pursuant to this Warranty will be performed by an

Authorized Designated WINCO Service Location during normal working

hours. This warranty does not cover services performed at overtime or

premium labor rates. End user is responsible for the dierence between

normal service rates and premium service rates.

IN NO EVENT SHALL WINCO BE LIABLE FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES TO BUYER OR ANY THIRD PARTY,

INCLUDING, WITHOUT LIMITATION, LOSS OF PROPERTY,

PERSONAL INJURY, LOSS OF BUSINESS OR PROFITS OR OTHER

ECONOMIC LOSSES, OR STATUTORY OR EXEMPLARY DAMAGES,

WHETHER IN NEGLIGENCE, WARRANTY, STRICT LIABILITY, OR

OTHERWISE.

This warranty is given only to the rst purchaser from a retail dealer.

No warranty is given to subsequent transferees.

REGISTER ONLINE AT:

http://support.wincous.com

Proof of purchase is required to extend warranty more than 1 year from

date of shipment from the factory.

THE FOREGOING WARRANTY PROVISIONS ARE A COMPLETE AND

EXCLUSIVE STATEMENT BETWEEN THE BUYER AND SELLER. WINCO

NEITHER ASSUMES NOR AUTHORIZES ANY PERSONS TO ASSUME

FOR IT ANY OTHER OBLIGATION OR LIABILITY IN CONNECTION

WITH SAID EQUIPMENT.

Examples of items not covered under warranty, but not limited to just

these items:

1. Acts of God, re, water damage, burglary, accident, theft.

2. Freight damage.

3. Improper installation or alteration of equipment.

4. Use of generic or after market parts.

5. Repairs made by anyone other than a WINCO designated

service provider.

6. Lubrication.

7. Expendable wear parts, adjustable feet, blown fuses, lamps, etc.

8. Cleaning of equipment.

9. Misuse or abuse.

WARRANTY REGISTRATION

SCAN THE QR CODE WITH YOUR MOBILE DEVICE

Warranty does not cover product failures caused by: failure to maintain,

neglect, abuse, damage due to excess water, re, normal wear,

improper set up and use. Periodic maintenance is not covered.

This warranty is not in force until such time as a properly completed

and digitally signed Installation/Warranty Registration has been

received by WINCO within 30 days from the date of installation.

WARRANTY SERVICE

To initiate warranty service contact: support@wincous.com

or call: 973-295-3899

DO NOT send unit to WINCO without rst contacting our customer

service department.

12

or go to

http://support.wincous.com

TO FILL OUT AND SUBMIT YOUR WARRANTY REGISTRATION.

Loading...

Loading...