Page 1

D201-S-Q6055-E-BD

Explosion Camera Proof Network Camera

Installation Manual

1

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 2

This pageintentionallyleft blank

2105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 3

Information in this document is subject to change without notice. All terms

mentioned in this manual that are known to be trademarks have been

appropriately capitalized. Spectrum Camera Solutions LLC acknowledges

all trademark(s) and the rights of the trademark(s) owned by the company

referred to herein.

Release Date:08/30/2018

Document Name D201-S-Q6055-E-BD

© Copyright 2018 by Spectrum Camera Solutions LLC All rights

reserved

Revision Record

Rev. Description Date

0 Initial Release

Aug 30, 2018

1 Updated

Oct 10, 2018

3

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 4

Copyright Notice:

This document contains information proprietary to Spectrum Camera Solutions LLC

with all rights reserved worldwide. Any reproduction or disclosure of this publication,

or any part thereof, to persons other than Spectrum Camera Solutions, Inc.

personnel or customers is strictly prohibited, except by written permission of

Spectrum Camera Solutions, Inc. Unauthorized use, disclosure, reproduction, or

translation of this publication will result in Spectrum Camera Solutions, Inc.

exercising maximum possible legal action against all persons and / or organizations

involved.

Disclaimer:

Spectrum Camera Solutions LLC makes no representations or warranties with

respect to the contents hereof. Further, Spectrum Camera Solutions LLC reserves

the right to revise this publication and to make changes in the content hereof, without

obligation to notify any person or organization of such revision or changes.

Patent Notice:

Manufactured under United States US Patent 9917428

Trademark Information:

Spectrum Camera Solutions LLC and its logo(s) are trademark(s) of Spectrum

Camera Solutions LLC.

4

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 5

Table of Contents

Legal Notices and Revision History Inside front cover

5

Page

DESCRIPTION 6

MODEL MATRIX 7

LABELS 8

STANDARDS AND CERTIFICATIONS 9

DOCUMENT SYMBOLS 10

HOW TO USE THIS MANUAL 11

GENERAL SAFETY AND OPERATING INFORMATION 12-14

SPECIFICATIONS 15-17

INSTALLATION 18-24

DIMENTIONAL GENERAL ASSEMBLY 25

HARDWARE BOM 26

DISMANTLING & MAINTENANCE 27

MOUNTING OPTIONS 28-33

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 6

6

The “D” Series includes a full range of Stainless Steel or Anodized Aluminum camera stations

specifically designed for Hazardous Area Applications.

Spectrum’s D Series is the first Class I Division 1 rated dome style explosion proof housings,

and utilizes the most robust and advanced camera technologies available. The D Series was

designed with the integrator in mind and offers features never before seen in current camera

systems. The solution is Patented with features including a uniform constructed enclosure

consisting of an integrated junction box milled directly to the camera housing. This eliminates

the need for extra equipment, reduces installation time, reduces labor expenses, and increases

safety by lessening the potential for mismatched hazardous rated components. Additionally,

the D Series are constructed with a proprietary explosion resistant polymer blend offering

maximum clarity and enhance optical performance. To enhance optical performance, the

explosion proof lens is equipped with our Virtual Wiper Nano Technology. The series are

available in anodized aluminum or 316L Stainless steel ensuring protection against rain, dust

and corrosion within a wide temperature range between --20°C to 55°C. This feature

ensures operation under extreme weather conditions and hazardous environments. It is

suitable for monitoring wide open indoor/outdoor spaces such as refineries, wellheads,

pipelines, offshore installations, remote and harsh locations where high-level reliability and

precision are always required.

DESCRIPTION

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 7

Option A- Model Matrix- D100-D500*

D(N)(XX)-(1)-(CCCCCC)-BD

N=(1) HOUSING LENGTH=3.32 in

N=(2) HOUSING LENGTH=7.75 in

N=(3) HOUSING LENGTH=4.5 in

N=(4) HOUSING LENGTH=5 in

N=(5) HOUSING LENGTH= 5.5 in

XX= 01-99 IEC/EN/UL 60950-1, IEC/EN/UL 62368-1, IEC/EN/UL 60950-22 Internal

Equipment Manufacturer Code**

1= (A) Aluminum Housing with SS 316L Dome Ring

1= (S) Stainless Steel 316L Housing

C= Internal Equipment Part Number from Manufacturer***

BD= Optional Breather drain model****

*Internal components and D Series must be approved by Spectrum

**Internal Equipment Manufacturer Code below

***Must be approved and verified by Spectrum

****Models supplied with Breather Drains will have IP66 ingress protection level

CODE “XX”

Manufacture

01

AXIS COMMUNICATIONS

7105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 8

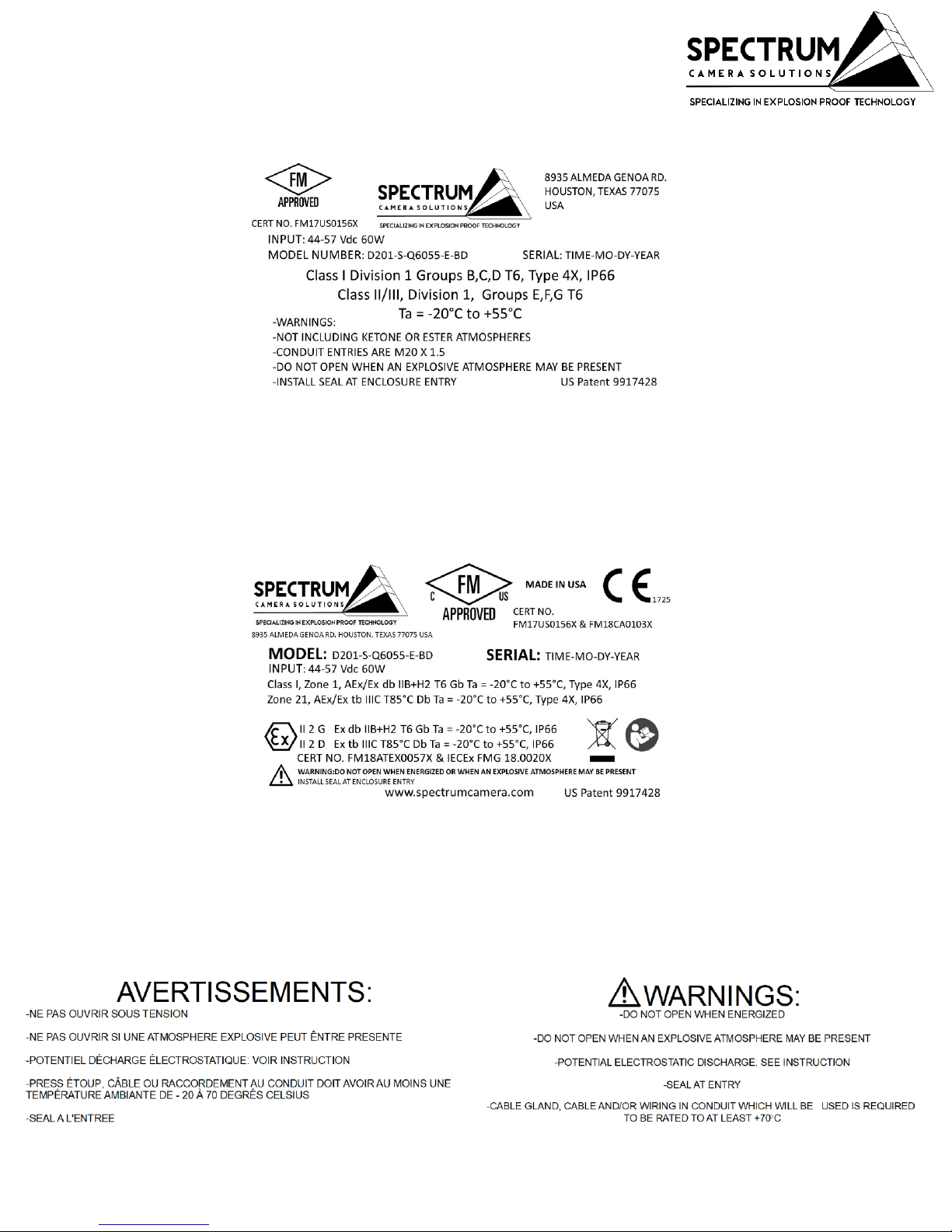

Labels

8

BREATHER DRAIN MODEL

BREATHER DRAIN MODEL

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 9

STANDARDS & CERTIFICATIONS

9

STANDARDS-

The equipment is manufactured in accordance with the IECEX scheme, the ATEX Directive 2014/34/EU and

with the following standards :

IEC 60079-0:2011

IEC 60079-1:2014

IEC 60079-31:2013

IEC 60529:2013

EN 60079-0:2012 + A11:2013

EN 60079-1:2014

EN 60079-31:2014

EN 60529:1991 + A1:2000 + A2:2013

ANSI/ISA 60079-0:2013

ANSI/UL 60079-1:2015

ANSI/ISA 60079-31:2015

ANSI/IEC 60529:2004

CAN/CSA-C22.2 No. 60079-0:2015

CAN/CSA-C22.2 No. 60079-1:2016

CAN/CSA-C22.2 No. 60079-31:2015

CAN/CSA-C22.2 No. 60529:2016

Specific Conditions of Use:

-The flameproof joints of the equipment are not intended to be repaired. Consult the manufacturer if dimensional

information on the flameproof joints is necessary.

-Follow the manufacturer’s instructions to reduce the potential of an electrostatic charging hazard on the surface

of the equipment in Group II and III environments.

-The equipment meets the requirements according to the low level risk of mechanical danger. Therefore, the

equipment shall be located and installed such that the risk of impact or other mechanical damage is reduced or

avoided.

NOTE: Use a clean cloth dampened with pure water for cleaning.

CERTIFICATIONS-

CERT NO. FM17US0156X & FM18CA0103X

Class I Division 1 Groups B,C,D T6, Ta = -20°C to +55°CType 4X, IP66/67

Class II/III, Division 1, Groups E,F,G T6 Type 4X, IP66/67 Ta = -20°C to +55°C

Class I, Zone 1, AEx/Ex db IIB+H2 T6 Gb Ta = -20°C to +55°C, Type 4X, IP66/67

Zone 21, AEx/Ex tb IIIC T85°C Db Ta = -20°C to +55°C, Type 4X, IP66/67

CERT NO. FM18ATEX0057X & IECEx FMG 18.0020X

II 2 G Ex db IIB+H2 T6 Gb Ta = -20°C to +55°C, IP66/67

II 2 D Ex tb IIIC T85°C Db Ta = -20°C to +55°C, IP66/67

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 10

The following symbols are used throughout this manual to alert users to potential

hazards or important information. Failure to heed the warnings and cautions listed

herein can lead to injury and equipment damage.

Symbol Label Description

WARNING:

Consists of conditions, practices, or procedures that

must be observed to prevent personal injury and/or

equipment damage.

CAUTION:

Risk of electric shock or high temperature parts may

result in injury if proper precautions are not taken.

NOTE:

Emphasizes important or essential information.

Locating Information:

NOTE: In the interest of completeness, manuals and drawings included with

the system may provide information pertaining to options not included with

your equipment. Information in application notes supersedes general

information in these documents. Information can be located in this manual

using any of the following aids.

10

DOCUMENT SYMBOLS

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 11

How to use this Manual

Safety Considerations:

This information that must be read and understood by all persons installing,

using, or maintaining this equipment. This manual is designed to aid

personnel in the correct and safe installation, operation, and maintenance of

the systems described. Personnel must consider all actions and procedures

for potential hazards or conditions that may not have been anticipated in the

written procedures. If a procedure cannot be performed safely, it must not be

performed until appropriate actions can be taken to ensure the safety of

equipment and personnel. The procedures in this manual are not designed to

replace or supersede required or common sense safety practices. All safety

warnings listed in any documents applicable to equipment and parts used in

or with the system described in this manual must be read and heeded before

commencing work on any part of the system.

NOTE: Refer to all ATEX, CSA, IECEx, NEC, NFPA and FM certificates

for any Special Conditions of Use. If the sign “X” is placed after the

certificate number, it indicates that the equipment or protective

system is subject to special conditions for safe use specified in the

schedule of the certificate.

NOTE: Review all material and safety information in this manual and

install in accordance with this document and all other applicable

ATEX, CSA, IECEx, NEC, NFPA70 Installation Methods and FM and

National standards.

Warning- Failure to follow appropriate safety procedures or

appropriate use of the equipment described in this manual can lead to

injury of personnel or equipment damage.

WARNING – EXPLOSION HAZARD – Do not open equipment

unless power has been removed or the area is known to be nonhazardous.

General Manual:

This manual is intended to be used in conjunction with installed equipment

manual from internal equipment manufacturer.

Note: In the event of a conflict between the requirements of this general

installation manual and the internal equipment manual, the safety and

installation procedures described in this manual shall take precedence.

11

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 12

General safety and operating information applicable to electrical equipment installed within

hazardous locations. This information must be understood by all persons installing, using, or

maintaining the electrical equipment. This information is designed to aid personnel in safe

installation, operation, and maintenance of the "D" Series equipment. It is not designed to replace or

limit appropriate safety measures applicable to work performed by personnel. Any additional safety

and operating measures that are required must be determined by and followed by personnel

performing work on the electrical equipment.

WARNING: Deviation from the specified instructions or procedure steps can result

in injury to personnel, equipment malfunction or equipment damage.

WARNING: Return unit to factory for any repairs or replacement of parts, customer

not permitted to repair. This will void all warranties and hazardous area

certification(s) if non-authorized repair occurs.

General Precautions:

Slip resistant gloves and protective eyewear (glasses with side shields or goggles as appropriate)

should be worn when installing and servicing any part of electrical equipment. Hot components

should be allowed to cool before servicing if possible. Other appropriate equipment or clothing must

be used as required by the type of work performed. All applicable regulations and procedures must

be followed for the work performed. Before beginning any work on the equipment, carefully consider

all the potential hazards and ensure that appropriate measures are taken to prevent injury to

personnel or equipment damage.

CAUTION: Electrical equipment components may be hot even when power is

not applied. Take appropriate precautions to prevent injury from contact with hot

items.

12

WARNING:

NEVER open the main housing of the "D" Series unless

authorized and trained and certified to do so

The main housing is manufactured in a controlled environment that eliminates

moister at the factory and is only to be opened by factory certified technicians at an

authorized repair facility. Opening of the main housing will void all warranties.

CAUTION: Failure to allow adequate cooling of electrical equipment components

with hot surfaces before opening the enclosure can lead to injury of personnel or

equipment damage.

General Safety and Operating Information:

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 13

Electrical Power:

The "D" Series IP cameras operate from a variety of power options including IEEE compliant POE devices.

• The power supply used with this product shall fulfill the requirements for Safety Extra Low

Voltage (SELV) and Limited Power Source (LPS) according to IEC/EN/UL 62368-1 or

IEC/EN/UL 60950-1 or Listed Class II Power Source Equipment. The product shall be

grounded either through a shielded network cable (STP) or other appropriate method.

Camera Location:

The "D" Series IP camera must be installed in a suitable location away from impacts, heavy vibration and

extreme heat. The "D" Series camera

must not be installed in an area classification for which it is not rated.

The "D" Series camera must be attached securely and appropriately to a wall or supporting structure.

CAUTION: The electrical cover should never be removed unless

power is removed (for at least 5 minutes) from the unit or the area is

known not to contain explosive materials.

13

WARNING

• The product shall be installed by a trained professional.

• The product shall be used in compliance with local laws and regulations.

• Store the product in a dry and ventilated environment.

• Avoid exposing the product to shocks or heavy pressure.

• Do not install the product on unstable brackets, surfaces or walls.

• Use only applicable tools when installing the product. Using excessive force with power tools

could cause damage to the product.

• Do not use chemicals, caustic agents, or aerosol cleaners.

• Use a clean cloth dampened with pure water for cleaning.

• Use only accessories that comply with the technical specification of the product. These can be

provided by Spectrum or a third party.

NOTE:

General Safety and Operating Information:

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 14

Installation:

The installation must be realized in accordance with IEC/EN 60079-14 and/or in accordance

with the national requirements. This equipment must be installed and used only by qualified

personnel, having knowledge concerning electrical equipment for use in potentially

explosive areas containing gas and/or dust. Qualified personnel must have knowledge

regarding the types of explosion protection. This equipment is intended to be used in zone 1,

2, 21 and 22 for groups IIB+H2 and IIIC with temperature class T6 or T85°C, it is necessary to

verify if this equipment is in accordance with the atmosphere where it is installed.

Connections:

Electric parameters power control unit Maximum supply voltage: POE+ IEEE 802.3at/af

The terminals are suitable to receive: Solid wires Stranded wires.- *See wiring Diagram

Page

Cable Glands:

The cable entry must be made in order not to alter the specific properties of terminal housing

compartment. The connection to the external circuits must be realized by cable glands or

pipe fittings covered by a separate certificate(s). If a cable gland is not used, or an entry is

open, the entry must be closed by a stopping plug covered by a separate certificate. The

diameter of the cable gland is cylindrical ISO M20 x 1.5.

This equipment can be used with different voltage and power, the nominal parameters are

specified in the manual.

Cable: cable must be tested and certified for temperatures of 70°C or higher.

Fiber Cable: Use a suitably certified optical fiber cable and internal connections shall comply

with requirements of IEC/EN 60079-15

Equipment Modifications:

This equipment must be installed and used in strict accordance with the instructions given in the

user documentation. This equipment contains no user-serviceable components. Unauthorized

equipment changes or modifications will invalidate all applicable regulatory certifications and

approvals.

14

General Safety and Operating Information:

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 15

SPECIFICATIONS

Environmental Conditions

(Equipment must be powered)

OPERATIONONAL CONDITIONS

USE

For Indoor and Outdoor Use

15

CERTIFICATIONS of Model- D201-S-Q6055-E-BD

CERT NO. FM17US0156 & FM18CA0103X

Class I Division 1 Groups B,C,D T6, Ta = -20°C to +55°C Type 4X, IP66

Class II/III, Division 1, Groups E,F,G T6 Type 4X, IP66/67 Ta = -20°C to +55°C

Class I, Zone 1, AEx/Ex db IIB+H2 T6 Gb Ta = -20°C to +55°C, Type 4X, IP66

Zone 21, AEx/Ex tb IIIC T85°C Db Ta = -20°C to +55°C, Type 4X, IP66

CERT NO. FM18ATEX0057X & IECEx FMG 18.0020X

II 2 G Ex db IIB+H2 T6 Gb Ta = -20°C to +55°C, IP66

II 2 D Ex tb IIIC T85°C Db Ta = -20°C to +55°C, IP66

ELECTRICAL REQUIREMENTS of Model- D201-S-Q6055-E-BD

POWER

INPUT/CONSUMPTION

CAMERA CONSUMPTION: TYPICAL 16W, MAX 60W

Voltage 44-57 Vdc 60W over 4-pairs

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 16

D201-S-Q6055-E-BD Series Casing Material Specifications

316L STAINLESS STEEL 62lbs

NOTE: Spectrum Camera Solutions, LLC is NOT responsible for any misuse

or improper installation of product, assumes no liability for special or

consequential damages caused by use or misuse or improper installation of

its products sold and assumes no liability for injury from use or misuse or

improper installation of its products or attached products.

D201-S-Q6055-E-BD Explosion Proof

Camera Hazardous Area

Voltage Material Model Number

IEEE 802.3bt / PoE++ / 60W

PoE Midspans/PoE Injectors

316L STAINLESS STEEL D201-S-Q6055-E-BD

16

SPECIFICATIONS

Power Source Specification For D201-S-Q6055-E-BD

AXIS T8154 60 W SFP Midspan

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 17

17

WIRING ENTRIES

Conduit Entries are M20 x 1.5 Use appropriate Adapter

With Nylon Washer or O-ring to keep ingress protection

CAUTION: Ensure the Ethernet cable is disconnected from power source prior to wiring to

the terminal block

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 18

CAUTION: Ensure the Ethernet cable is disconnected from power

source prior to wiring to the terminal block

18

Ensure that power is off before attempting to connect and wire the camera

1. Use supplied M6 Hex tool to unscrew bolts and lock washers supplied on camera

2. Make sure threads on camera and M10x 1.5 are free of dirt and debris. Place mount on camera

and align holes and tighten bolts

3. Attach the camera with wall mount to mounting surface. Use only installation methods and

materials capable of supporting four times the maximum specified load of the system

Figure 1. wall bracket installation

INSTALLATION

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 19

19

4. Use supplied M5 supplied Hex tool to loosen D1005 terminal cap by turning counterclockwise

5. Set D1005 terminal cap in safe place

6. Route cable(s) into D1006 terminal housing junction box through user-supplied cable gland and

seal using the recommended gland installation practices. There are two conduit entries on models

without the-BD Breather drain option.

Figure 2. Removing D1005 terminal cap

Conduit Entries are M20 x 1.5 Use appropriate Adapter with Nylon Washer

or O-ring to keep ingress protection follow guidelines of the manufacturer of

gland or adapter

INSTALLATION

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 20

20

Conduit Entries are M20 x 1.5 Use appropriate Adapter

With Nylon Washer or O-ring to keep ingress protection

Example of CMP M20 to

3/4NPT adapter with Nylon

Washer

INSTALLATION

CAUTION: Ensure the Ethernet cable is disconnected from power

source prior to wiring to the terminal block

Figure 3.

Figure 4.

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 21

21

7. Connect the wiring using installer supplied small screw driver to push the open terminal block

contact. Insert wires and remove screw driver. Adhere to local electrical codes/laws.

Power Connection To "D" Series Camera

TERMINAL NUMBER WIRE

Position - 1 White-Orange

Position - 2 Orange

Position - 3 White-Green

Position - 4 Blue

Position - 5 White-Blue

Position - 6 Green

Position - 7 White-Brown

Position - 8 Brown

Table 1.

Figure 5. Wire/Cable Connections

INSTALLATION

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 22

8. In addition to the internal ground connection, this equipment is also provided by an external

secondary ground connection. Both must be connected for the internal ground the section must be

equal to the active conductors. The external ground can receive a wire of 4 mm. The user/installer

must connect the internal and external earthing before powering. STP cable connection with earthing

in camera junction box. The earth wire is the screen of the cable, to be isolated in the wiring terminal

junction box size Green Thread-forming Bonding Screw, M5 x 15mm

22

External

Ground

Internal

Ground

Figure 6. Grounding

INSTALLATION

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 23

23

9. Ensure threads on D1005 terminal cap and D1006 Terminal housing are free of dirt and debris.

10. Ensure gasket is free of dirt and debris

11. Reinstall D1005 terminal cap using supplied M5 supplied Hex tool to tighten by turning

clockwise until hand tight and gasket is seated

12. In the following order install D2005 housing retainer clip, wedge lock washers, and nut. Ground

lug is at bottom of thread adapter See figure 8-9

Figure 7. Installing D1005 cap

Figure 8. Retaining clip order

Figure 9. Final assembly

INSTALLATION

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 24

24

NOTE: Do not install camera unless power is applied in near future.

13. Remove Protective film after installation. If protective film is not removed in timely manor

damage to dome is likely to occur with UV exposure

14. Apply power. For internal equipment startup procedures, setting changes, and troubleshooting

guides reference the camera manufacturer’s manual included with the "D" Series Cameras. If the

included copy is lost please contact https://www.spectrumcamera.com/support or To obtain

assistance, please go to https://www.axis.com/support

INSTALLATION

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 25

Dimensional General Assembly:

25105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 26

26

HARDWARE BOM

41

3

2

5

1- (QTY 1)EXTERNAL GROUND LUG

2- (QTY 3)M10 X 1.5 18-8 BOLT

3- (4 SETS) WEDGE LOCK WASHER

4- (QTY 1)D2005 Z-CLIP

5- SD-WM (WALL MNT. NOT INCLUDED)

6- M10X1.25 M10X1.5 ADAPTER

6

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 27

Dismantling:

It is not recommended to open the main camera housing. All repairs of explosion-proof

equipment must be made according the specified criteria of IEC/EN 60079-19 rule by qualified

personnel, having knowledge concerning electrical equipment for potentially explosive areas

containing gas and/or dust. Qualified personnel must have knowledge regarding the types of

explosion protection.

Maintenance:

The maintenance must be realized in accordance with IEC/EN 60079-17 and/or in accordance

with the national requirements. Contact Spectrum Camera for training program to properly

open and close the main camera housing.

Cleaning lens- Washdown dome with water first to avoid partials scratching the surface. Clean

lens with damp microfiber cloth with mild dish soap and water. Lastly, apply coating of Repel (by

Unelko corporation) surface cleaner. Never use harsh chemicals or abrasive towels.

Replacing the battery- The Axis Q6055-E product uses a *Panasonic 3.0 V BR2032 lithium

battery Lithium primary battery composed of cathode from carbon monofluoride anode from

lithium and electrolyte from organic solvent and lithium salt as the power supply for its internal

real-time clock (RTC). Under normal conditions this battery will last for a minimum of five years.

Low battery power affects the operation of the RTC, causing it to reset at every power-up. When

the battery needs replacing, a log message will appear in the product’s server report. For more

information about the server report, see the product´s setup pages or contact Spectrum support.

The battery should not be replaced unless required, but if the battery does need replacing,

contact Spectrum support at

www.spectrumcamera.com/support for assistance or To obtain

assistance, please go to https://www.axis.com/support.

This battery is not field replaceable*.

27

DISMANTLING & MAINTENANCE

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 28

SD-WM WALL MOUNT

28105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 29

SD-PMA POLE MOUNT ADAPTER

29

HARDWARE

QTY 4 7/8-20 18-8 Bolts

QTY 2 12in all thread with nuts and washers

QTY 2 A1612 sides

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 30

SD-CM CORNER MOUNT

30

HARDWAREQTY 4 7/8-20 18-8 Bolts

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 31

SD-VM VIBRATION MOUNT

31

HARDWAREQTY 4 7/8-20 18-8 Bolts

FRONT

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 32

SD-SO STANDOFF MOUNT

32

HARDWAREQTY 4 7/8-20 18-8 Bolts

FRONT

BACK

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 33

ASSEMBLY MOUNTS

33

SD-CM+SD-PMA

SD-CM+SD-VM+SD-SO+ SD-PMA

105607312018 D201-x-Q6055-E

INSTALLATION MANUAL REV-1

Page 34

EU Declaration of Conformity

Spectrum Camera Solutions,

LLC

Spectrum Camera Solutions declares that under our sole responsibility that the product (s)

listed below conform to the relevant provisions of 2014/34/EU of August 29, 2018

Doc No. 100108292018 2014/34/EU Spectrum Camera Solutions, LLC 8935 Almeda Genoa Rd. Houston, TX

77075

Notified Body

FM Approvals Ltd. 1 Windsor Dials,

Windsor, Berkshire, UK. SL4 1RS

Product(s) Network Ethernet Cameras

Model numbers D Series

Dab-c-d-e. Network Ethernet Camera.

a = Housing length 1, 2, 3, 4 or 5 (or any three digits from 084 to 196 representing custom housing

lengths in mm).

b = Camera manufacturer code (two digits) 01 to 99.

c = Material A or S.

d = Several characters representing the camera manufacturer’s part number (may contain additional

dashes).

e = Optional breather/drain BLANK or BD. (IP67 is not applicable when supplied with optional

breather/drain).

Markings II 2 G Ex db IIB+H2 T6 Gb Ta = -20°C to +55°C

II 2 D Ex tb IIIC T85°C Db Ta = -20°C to +55°C

Ratings The D Series Network Ethernet Cameras can be supplied with a variety of cameras (in accordance

with EN 60950 or EN 62368) complying with the IEEE 802.3af, 802.3at, 802.3at++ or 802.3bt PoE (Power

over Ethernet) standard (57Vdc max). Voltage and wattage shall not exceed the maximum tested

configuration of 57Vdc (60W). The D Series Network Ethernet Cameras are rated for use in an ambient

temperature range of -20°C to +55°C and are IP66/67 (IP67 is not applicable when supplied with optional

breather/drain). The camera within the enclosure may be placed in any arrangement provided that an area

of at least 40% of each cross-sectional area remains free to permit unimpeded gas flow and, therefore,

unrestricted development of an explosion. Separate relief areas may be aggregated provided each area has

a minimum dimension in any direction of 12.5mm.

Compliance with the Essential

Health and Safety Requirements

has been assessed by reference to

the following Standards

EN 60079-0:2012 + A11:2013, EN 60079-1:2014, EN 60079-31:2014,

EN 60529:1991 + A1:2000 + A2:2013

Factory/Manufacturing Location 8935 Almeda Genoa Rd. Building B Houston Texas 77075

Conformity has been

demonstrated with reference to

the following documentation:

EU Type Examination Certificate (FM18ATEX0057X - 0)

Quality Assurance Notification FM17ATEXQ0099

Hubert Lee Rice II

CEO

Date: August 29, 2018

Doc No. 100108292018

2014/34/EU

Page 35

Attestation of Conformity

Spectrum Camera Solutions,

LLC

Spectrum Camera Solutions declares that under our sole responsibility that the product (s)

listed below conform to the relevant provisions of 2014/34/EU of August 29, 2018

Doc No. 100108292018 2014/34/EU Spectrum Camera Solutions, LLC 8935 Almeda Genoa Rd. Houston, TX

77075

Notified Body

FM Approvals Ltd. 1 Windsor Dials,

Windsor, Berkshire, UK. SL4 1RS

Product(s) Network Ethernet Cameras

Model numbers D Series

Dab-c-d-e. Network Ethernet Camera.

a = Housing length 1, 2, 3, 4 or 5 (or any three digits from 084 to 196 representing custom housing

lengths in mm).

b = Camera manufacturer code (two digits) 01 to 99.

c = Material A or S.

d = Several characters representing the camera manufacturer’s part number (may contain additional

dashes).

e = Optional breather/drain BLANK or BD. (IP67 is not applicable when supplied with optional

breather/drain).

Markings II 2 G Ex db IIB+H2 T6 Gb Ta = -20°C to +55°C

II 2 D Ex tb IIIC T85°C Db Ta = -20°C to +55°C

Ratings The D Series Network Ethernet Cameras can be supplied with a variety of cameras (in accordance

with EN 60950 or EN 62368) complying with the IEEE 802.3af, 802.3at, 802.3at++ or 802.3bt PoE (Power

over Ethernet) standard (57Vdc max). Voltage and wattage shall not exceed the maximum tested

configuration of 57Vdc (60W). The D Series Network Ethernet Cameras are rated for use in an ambient

temperature range of -20°C to +55°C and are IP66/67 (IP67 is not applicable when supplied with optional

breather/drain). The camera within the enclosure may be placed in any arrangement provided that an area

of at least 40% of each cross-sectional area remains free to permit unimpeded gas flow and, therefore,

unrestricted development of an explosion. Separate relief areas may be aggregated provided each area has

a minimum dimension in any direction of 12.5mm.

Compliance with the Essential

Health and Safety Requirements

has been assessed by reference to

the following Standards

EN 60079-0:2012 + A11:2013, EN 60079-1:2014, EN 60079-31:2014,

EN 60529:1991 + A1:2000 + A2:2013

Factory/Manufacturing Location 8935 Almeda Genoa Rd. Building B Houston Texas 77075

Conformity has been

demonstrated with reference to

the following documentation:

EU Type Examination Certificate (FM18ATEX0057X - 0)

Quality Assurance Notification FM17ATEXQ0099

Hubert Lee Rice II

CEO

Date: August 29, 2018

Doc No. 100108292018

2014/34/EU

Loading...

Loading...