Page 1

Assembly Instructions

Important

Before you begin, read and comply with all safety and operating instructions,

and ensure all parts and correct quantities are included.

Any parts damaged during shipment must be reported within 5 days of receipt. To

report information regarding missing parts or damage, to purchase parts or accessories, or if you have any questions, please contact us.

www.spectrumfurniture.com

800-235-1262, 715-723-6750

Thank you for purchasing Spectrum products!

Assembly Tips:

• Assemble the console in its nal location.

• To facilitate assembly, keep the fasteners nger-tight until the

console is completely together. Then tighten securely.

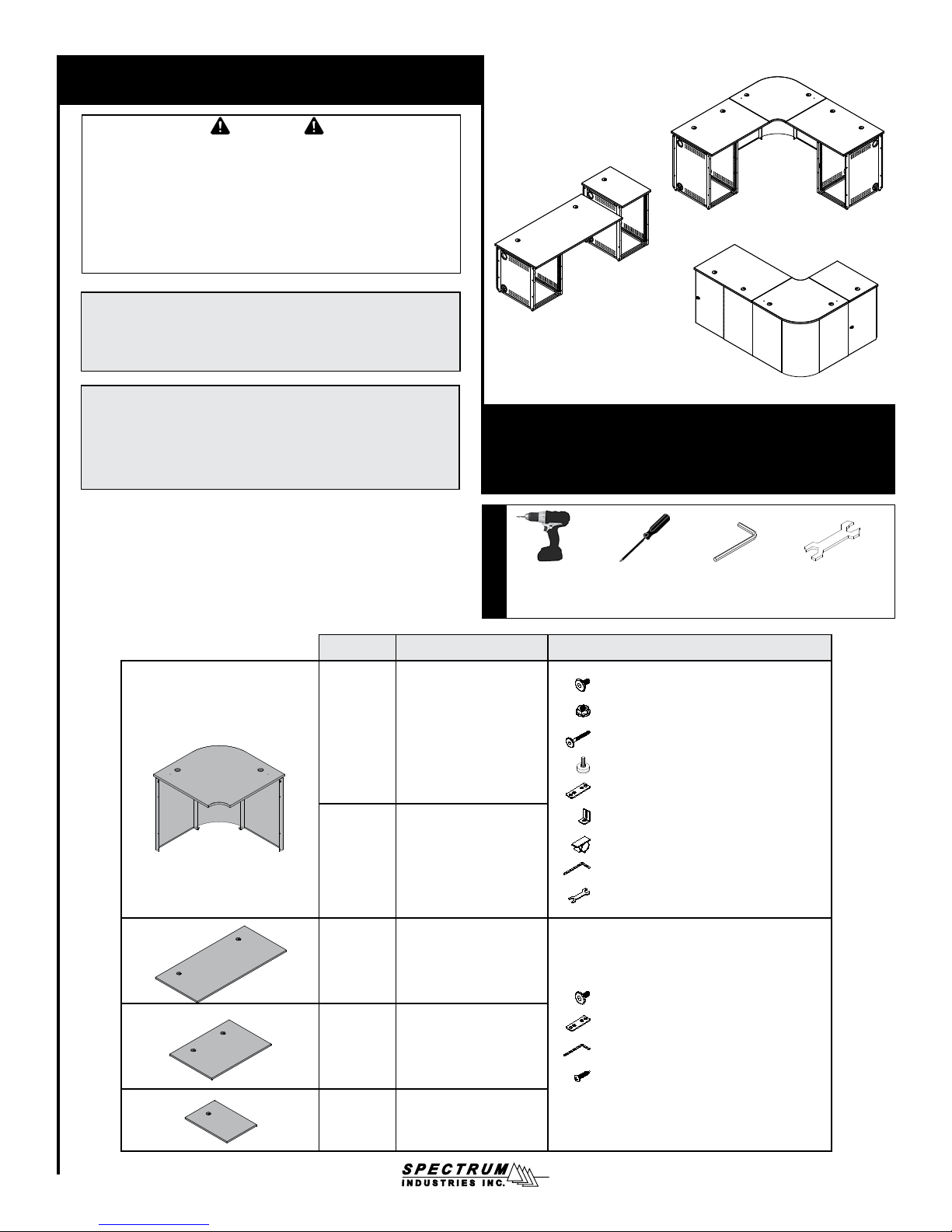

Note: The items below represent all the structural components

available for the Instructor Media Console. Due to the various

console congurations and order combinations available, some

of the items shown here may not be included with your particular

unit, and some assembly steps may not apply. Before beginning

assembly, please review these instructions.

Instructor Media Console

68XXX series

Drill with

Phillips driver

Tools Required

(best)

Product # Description Hardware

68156 36” Radius Corner

68106 29” Radius Corner

68202 Triple Worksurface

68201 Double Worksurface

Phillips

screwdriver

(26) 1/4-20 x 15mm JC bolt - 052605

(6) 1/4-20 Flanged locknut - 0108896

(2) 1/4-20 x 50mm JC bolt - 038047

(2) 5/16-18 x 1” Glide - 037779

(2) Unit-to-unit bracket - 037749

(2) Worksurface bracket - 044069

(3) Cord clip - 044207

(1) 4mm Hex wrench - 025039

(1) Glide wrench - 025069

(4) 1/4-20 x 15mm JC bolt - 052605

(2) Unit-to-unit bracket - 037749

(1) 4mm Hex wrench - 025039

(6) #6 x 5/8” PHSM screws - 025044

4mm Hex

Wrench

(included)

Glide Wrench

(included when

applicable)

68200 Single Worksurface

0108630R11 Page 1 of 10

Page 2

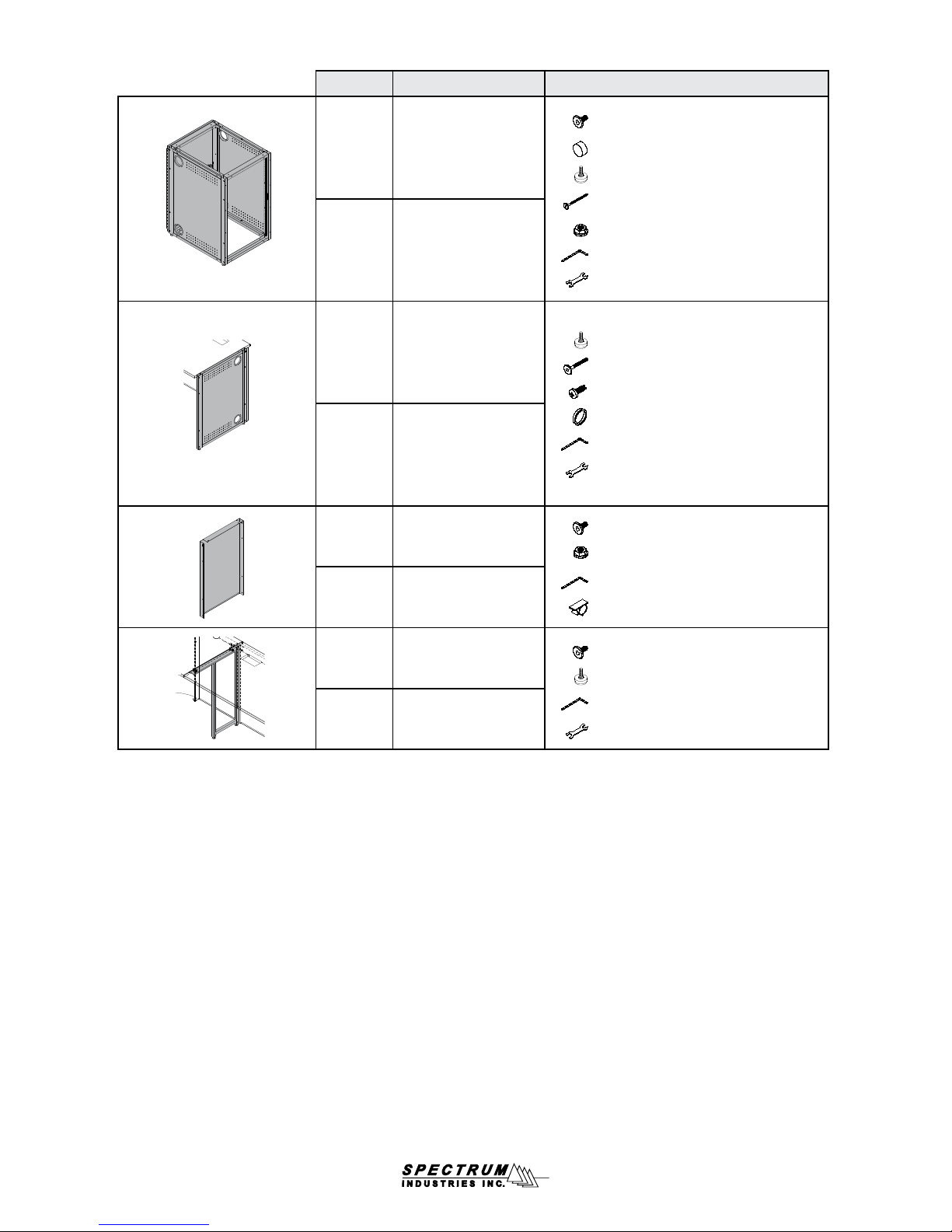

Product # Description Hardware

(4) 1/4-20 x 15mm JC bolt - 052605

68157 36” Equipment Rack

68107 29” Equipment Rack

(2) Adhesive bumper - 044573

(4) 5/16-18 x 1” Glide - 037779

(1) 1/4-20 x 90mm JC bolt - 039065

(1) 1/4-20 Flanged locknut - 0108896

(1) 4mm Hex wrench - 025039

(1) Glide wrench - 025069

68155 36” End Support Leg

68105 29” End Support Leg

68151 36” Wall Filler Panel

68101 29” Wall Filler Panel

68154 36” Mid-Support Leg

68104 29” Mid-Support Leg

(2) 5/16-18 x 1” Glide - 037779

(2) 1/4-20 x 40mm JC bolt - 021581

(6) 8-32 x 1/2” PH thread-cutting - 0100167

(2) 4” Snap-in grommet - 0104836

(1) 4mm Hex wrench - 025039

(1) Glide wrench - 025069

(10) 1/4-20 x 15mm JC bolt - 052605

(4) 1/4-20 Flanged locknut - 0108896

(1) 4mm Hex wrench - 025039

(2) Cord clip - 044207

(4) 1/4-20 x 15mm JC bolt - 052605

(2) 5/16-18 x 1” Glide - 037779

(1) 4mm Hex wrench - 025039

(1) Glide wrench - 025069

0108630R11 Page 2 of 10

Page 3

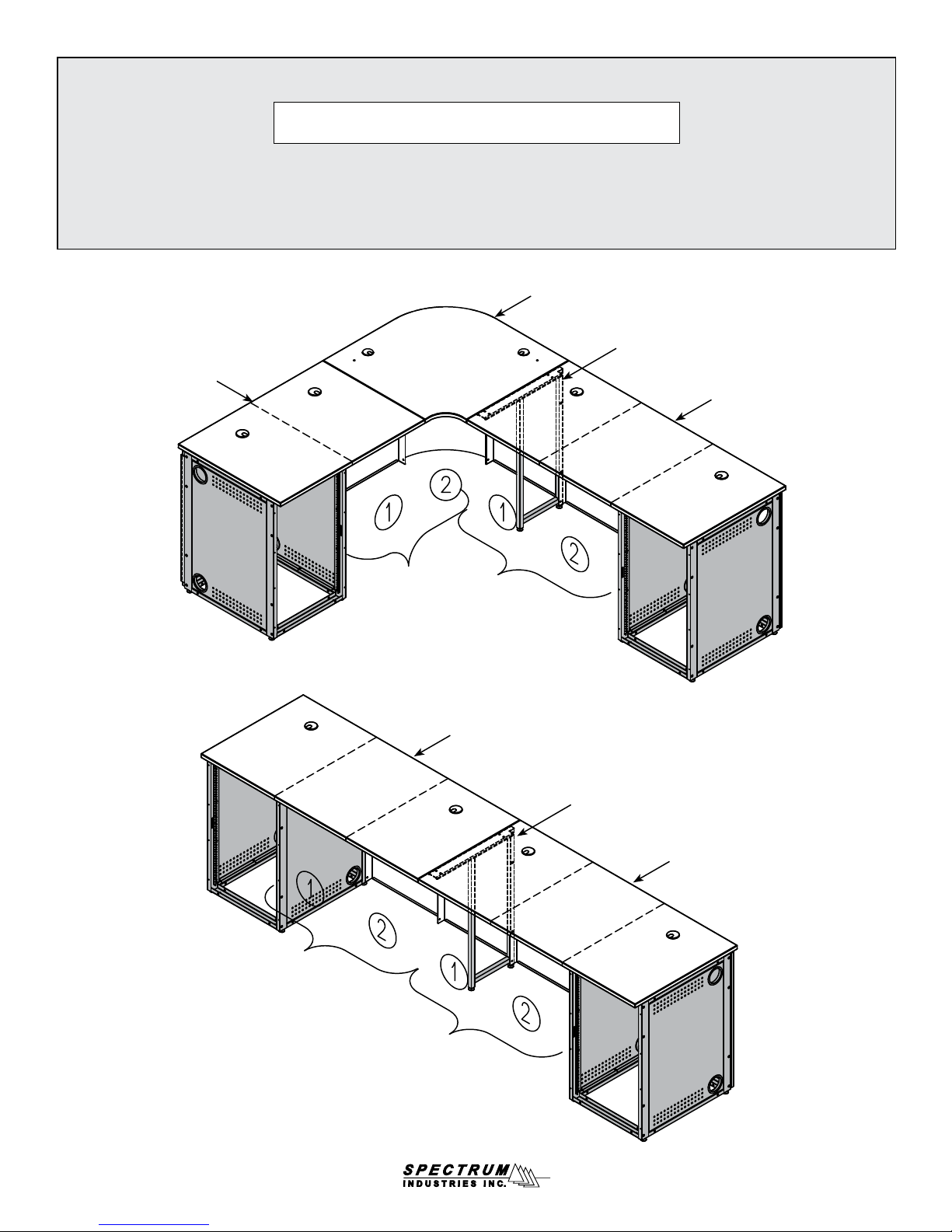

Worksurface Support Guidelines

For adequate support, areas under worksurfaces generally should not

exceed a span of more than 2 open spaces (or wall ller panels) wide.

• When a radius corner is used with two double worksurfaces that have equipment rack support, a mid-support leg usually is not necessary

• When a radius corner is next to a double worksurface, an equipment rack or mid-support leg should be used to support the double worksurface

• When a triple worksurface is specied, at least one equipment rack should be used underneath to provide adequate support

• Mid-support legs are used at the seam two worksurfaces

• End-support legs are used at the end of a worksurface

Radius corner worksurface

Mid-support leg at

Double

worksurface

worksurface connection

Triple worksurface

2 open

spaces

2 open

spaces

2 open

spaces

Triple worksurface

Mid-support leg at

worksurface connection

Triple worksurface

2 open

spaces

0108630R11 Page 3 of 10

Page 4

Assembly / Setup

Radius Corner Assembly

1. Install the (2) glides onto the corner panel. Figure 1A. The glides can be adjusted later to level the console.

2. Attach each wall ller panel to the corner panel with (4) 1/4-20 x 15mm JC bolts.

3. Align and attach the corner worksurface to the wall ller panels with (4) 1/4-20 x 15mm JC bolts. Figure 1B.

Corner panel

Wall ller panel Wall ller panel

Note: Do not tighten fasteners

completely until the unit is together.

3/8” monitor arm

mounting hole

1/4-20 x 15mm

JC bolts

Glides

Figure 1A

Corner worksurface

Note: Monitor arms can be mounted

to the corner worksurface using the

left or right 3/8” mounting holes.

3/8” monitor arm

mounting hole

Figure 1B

0108630R11 Page 4 of 10

Page 5

Equipment Rack Assembly

1. Tip the equipment rack onto its back.

2. Install the (4) glides onto the bottom as shown. Figure 2A. The glides

can be adjusted later to level the console.

3. Tip the unit back upright, and open the rear door to attach the (2)

adhesive bumpers to the equipment rack frame as shown. Figure 2B.

Glide

Adhesive

bumper

Rear door

Adhesive bumper

Figure 2A Figure 2B

Wall Filler Panel Assembly

Panel-to-Equipment Rack Attachment:

1. Align the wall ller panel mounting holes as shown. Figure 3A.

2. Attach with (4) 1/4-20 x 15mm JC bolts. (Locknuts not required.)

Equipment rack

Wall ller panel

1/4-20 x 15mm

JC bolt

(4 required per

connection)

Panel-to-Panel Attachment:

1. To attach two wall ller panels together, align the mounting holes.

2. Attach together with (4) 1/4-20 x 15mm JC bolts and (4) 1/4-20

anged locknuts. Figure 3B.

Wall ller panel

1/4-20 anged

locknut

(4 required per

connection)

1/4-20 x 15mm

JC bolt

(4 required per

connection)

Figure 3A Figure 3B

Wall ller panel

Note: The two holes on top of the

panel are for worksurface attachment.

0108630R11 Page 5 of 10

Page 6

End-Support Leg Assembly

1. Attach the side panel to the leg frame as shown with (6) 8-32 x 1/2” PH thread-cutting screws and tighten securely. Figure 4A.

Note: The 4” grommets will be at the rear of the console.

2. Install the (2) glides onto the bottom of the leg. (The glides can be adjusted later to level the console if necessary.)

3. Align the assembled end-support leg and wall ller panel mounting holes. Figure 4B.

Be sure the wall ller panel overlaps the end-support leg as shown.

4. Attach with (4) 1/4-20 x 15mm JC bolts.

5. Worksurface attaches to the end-support leg with (2) 1/4-20 x 40mm JC bolts.

4” Grommet

Note: End-support legs are used only

at the end of a worksurface (not on a

seam between two worksurfaces).

Side panel setup for

right-side installation

on console (this side

faces inside console, 4”

grommets toward rear)

Leg frame

Open area under

worksurface

Wall ller

panel

Be sure the wall ller

panel overlaps the

end-support leg here.

1/4-20 x 15mm

JC bolt

(4 required per

connection)

Glide

Glide

8-32 x 1/2” PH

thread-cutting screw

(6 required)

Figure 4A

Assembled endsupport leg

Equipment Rack-to-Equipment Rack Connection

1. Place the two equipment racks together as shown. Figure 5.

2. Install (2) 1/4-20 x 90mm JC bolts and (2) 1/4-20 anged locknuts.

3. Do not over-tighten fasteners.

1/4-20 x 90mm

JC bolt

1/4-20 anged locknut

Flush side of panel in endsupport leg facing outward. 4”

grommets toward rear of console.

Figure 4B

1/4-20 anged locknut

1/4-20 x 90mm JC bolt

Figure 5

0108630R11 Page 6 of 10

Page 7

Mid-Support Leg Assembly

1. Install the (2) glides onto the bottom of the leg. The

glides can be adjusted later to level the console.

2. Align the mid-support leg and wall ller panel mounting

holes as shown. Figure 6.

3. Attach the mid-support leg to the wall ller panels with

(4) 1/4-20 x 15mm JC bolts.

4. Set both worksurfaces onto console with the seam

centered over the mid-support leg.

5. Attach to worksurfaces with (4) 1/4-20 x 15mm JC bolts

Note: Mid-support legs are used at the joint connection of two worksurfaces to provide support for two

or more open spaces (or wall ller panels) wide.

Worksurfaces

1/4-20 x 15mm JC bolts

(4 required)

Wall ller

panel

Wall

ller

panel

Mid-support leg

Wall ller

panel

1/4-20 x

15mm JC bolt

(4 required per

connection)

Figure 6

Worksurface Assembly

Worksurface-to-Worksurface connection:

1. Attach the (2) unit-to-unit brackets to one installed worksurface (use inner holes)

with 1/4-20 x 15mm JC bolts. Do not tighten completely. Figure 7A.

2. Set the second worksurface onto the unit-to-unit brackets, and adjacent assembled wall ller panels.

3. Align the worksurface mounting holes with the wall ller panel mounting holes.

4. Attach with 1/4-20 x 15mm JC bolts.

Underside of

worksurface

Unit-to-unit

brackets

Wall ller

panel

Glides

Note: This is the connection between two worksurfaces with open area underneath (no equipment racks).

To provide adequate support, areas under worksurfaces generally should not exceed a span of more than

two open spaces (or wall ller panels) wide.

1/4-20 x 15mm JC bolt

(2 per bracket)

Worksurface

Wall ller

panel

Figure 7A

0108630R11 Page 7 of 10

Page 8

Worksurface-to-top of Equipment Rack:

Worksurface-to-Worksurface with Equipment Rack:

Note: This is the attachment of a worksurface to the top of an equipment rack.

1. Set the worksurface onto the equipment rack and any adjacent

assembled wall ller panels (if applicable). Figure 7B.

2. Align the worksurface and equipment rack mounting holes.

3. Attach worksurface with (4) 1/4-20 x 15mm JC bolts.

Worksurface

Note: This is the connection between a worksurface of equal

height to another worksurface above an equipment rack.

1. Attach each worksurface bracket to the equipment rack with (1)

1/4-20 x 50mm JC bolt and (1) 1/4-20 serrated anged locknut

(attached from inside eq rack). (The slotted side of the bracket will

attach to the worksurface.) Do not tighten completely. Figure 7C.

2. Set the worksurface onto the assembled wall ller panel(s) and

worksurface brackets and align the mounting holes.

3. Attach worksurface with 1/4-20 x 15mm JC bolts.

4. Align the tops of the worksurfaces and tighten all screws securely.

1/4-20 x 50mm JC bolt

(1 per bracket)

Underside of

worksurface

Worksurface

brackets

1/4-20 anged locknut

(1 per bracket-attach

from inside eq rack)

Equipment rack

1/4-20 x 15mm

JC bolt

(4 required)

Figure 7B

Cord Clips

1. Apply cord clips to underside of worksurface where needed

to route and secure cords. Figure 8.

(Clips only included with radius corner and wall ller panels.)

Note: The cord clips provide cord management when cords and

wires are to be routed to the worksurface from under the console.

1/4-20 x 15mm

JC bolt

(1 per bracket)

Wall ller

panel

Equipment rack

Figure 7C

Cord clip

Figure 8

0108630R11 Page 8 of 10

Page 9

Accessories

Not for use on endsupport legs or standalone equipment racks

Clear Acrylic Locking Door

36”H - 68153

29”H - 68103

• For instructor-side installation

• Can be installed to be hinged

from the left or right side

Equipment Rack Bottom Shelf - 68203

• Increases security

• Prevents static electricity and dust build-up

• Includes 4’ grommet at back

Solid Locking Door

36”H - 68152

29”H - 68102

• For instructor-side installation

• Can be installed to be hinged

from the left or right side

Stepped-Height Bracket - 68205

• Connects 29”H console to 36”H

console

Flip-up Shelf - 68204

• Shelf hinges lock into place in the upright position

• Shelf mounts level with worksurface

• Includes 2” grommet

• Mounting plate available in black or dark gray

Weight capacity: 35 lb [15.9 kg]

Dimensions: 21.1875”W [53.8 cm] x 30”D

[76.2 cm] x 1”H [2.54 cm]

Unit weight: N/A

Level-Height Bracket Kit - 68207

• Attaches a worksurface to another worksurface

of equal height over an equipment rack

Econo Keyboard Tray - 95520

• 18.375”W [46.7 cm] x 12”D [30.5 cm]

Wire Management Clips - 68206

• Mounts under worksurface

• Set of 3

Micro-Arm Keyboard Tray - 95506

• Slides in, out, up and down

• 19.75”W x 10”D

Rear Rack Rail Kit

36”H - 68150

29”H - 68100

• Adds 18RU or 14RU to

• Set of 2

rear of equipment rack

Cove Power Module - 99044

• Two power receptacles per module

• Two USB charge ports (not data-compatible)

• Thumbscrew clamps

• Requires worksurface cutout

• ETL listed

• Available in Black or Silver

Cutout required: 5.25”W [13.3 cm] x 2”D [5.1 cm]

Power cord:

Power receptacles: 12A, 120 VAC spill-resistant

USB charging ports: 2.1A (10.5W)

Dimensions:

Unit weight: 2.29 lb [1 kg]

(mounts to surface thicknesses

up to 1.5”)

9’ [274 cm] with 90° at plug with

45° rotation

6”W [15.2 cm] x 2.5”D [6.35 cm] x

3.18”H [8.1 cm]

See spectrumfurniture.com for the latest

accessories and detailed warranty information.

0108630R11 Page 9 of 10

Page 10

Warranty

DESIGNED AND ASSEMBLED IN

CHIPPEWA FALLS

WISCONSIN.USA

WE WILL MAKE IT RIGHT FOR YOU!

Spectrum is committed to provide complete customer satisfaction. Each of our products is manufactured from the best materials available and each

product is stringently monitored throughout the production process through our P.A.C.E. program (Product Assurance to meet Customer Expectations).

We expressly warrant that Spectrum products will be of good quality and workmanship and free from defect for the period set out in the warranty table below

from the date of delivery. This warranty shall not apply to defects or damage resulting from misuse, abuse, neglect, improper care, modifi cation or repair not

authorized by Spectrum, or any other cause outside the control of Spectrum. Spectrum will, at its sole option, either repair or replace the defective product.

This warranty is exclusive; no other warranty, written or oral, is expressed or implied. This warranty is given by Spectrum to Buyer and to no other per-

son or legal entity. No Spectrum dealer, distributor, agent or employee is authorized to make any modifi cation or addition to this warranty.

NOTWITHSTANDING ANYTHING TO THE CONTRARY, SPECTRUM WILL NOT UNDER ANY CIRCUMSTANCES BE LIABLE FOR INDIRECT OR LIQUIDATED DAMAGES, INCLUDING CONSEQUENTIAL, INCIDENTAL AND SPECIAL DAMAGES. IN NO EVENT SHALL SPECTRUM’S LIABILITY, WHETHER

UNDER CONTRACT OR WARRANTY, IN TORT OR OTHERWISE, EXCEED THE PURCHASE PRICE RECEIVED BY SPECTRUM FOR THE PRODUCT AT

ISSUE AND “RECALL ACTION” EXPENSES. SPECTRUM SHALL NOT BE SUBJECT TO ANY OTHER OBLIGATIONS OR LIABILITIES, WHETHER ARISING OUT OF BREACH OF CONTRACT, WARRANTY, TORT (INCLUDING NEGLIGENCE AND STRICT LIABILITY) OR OTHER THEORIES OF LAW, WITH

RESPECT TO PRODUCTS SOLD OR SERVICES RENDERED BY SPECTRUM, OR ANY UNDERTAKINGS, ACTS OR OMISSIONS RELATING THERETO.

Our Customer Service Department is ready to provide immediate attention to any questions, comments or concerns. They are available to answer your calls

Monday through Friday from 7 am to 5 pm CST. In addition your product comments or concerns are welcome via e-mail at: spectrum@spectrumfurniture.com.

Warranty Table

Item

Adjustable Crank / Electric Desk Legs

Flat Panel Desk Gas Cylinders

Chairs

• Adjustable Height Chair Parts – including frames, gas

cylinders, wood and plastic parts, control handles, casters

• Adjustable Height Chair Upholstery

• In-Stock Upholstery

• Graded-In Fabrics and Customer Owned Material

Height Adjustable Columns and Lifts

General Use Casters

Electrical (including timers and LINAK actuators) • 2 Years

Keyboard / Mouse Trays • 1 Year

Flat Panel Monitor Arms

• Flat Panel Monitor Arm – General Parts

• Flat Panel Monitor Arm – Gas Cylinders

Desks and Lecterns

• Computer Desk Chassis

• Cart Chassis

• Lectern Chassis

Warranty Period

effective 1/1/2015

• 1 Year

• 7 Years

• 2 Years

• 2 Years

• No Warranty

• 1 Year

• 5 Years

• 2 Years

• 10 Years

925 FIRST AVENUE, CHIPPEWA FALLS, WI 54729 / 800-235-1262 / 715-723-6750 / WWW.SPECTRUMFURNITURE.COM

© 2016 Spectrum Industries Inc., All rights reserved.

8

0108630R11 Page 10 of 10

Loading...

Loading...