Page 1

2011 Emission Certified

LPG Fuel System

3.0L GM Engine

Parts & Service Manual

Including Labor Time Guide

Revision A/March, 2011

Page 2

2011 Emission Certified

LPG Fuel System

3.0L GM Engine for

Parts & Service Manual

Table of Contents

General Information ................................................................................................ 5

An overview of this Service Manual

Maintenance ............................................................................................................ 9

General maintenance and maintenance interval information

Fuel System ........................................................................................................... 17

An overview of the LPG fuel system and its components

LPG Fuel System Diagnosis ................................................................................ 27

How to identify a general problem

LPG Symptom Diagnostics .................................................................................. 35

How to correct a specific problem

Electrical Section .................................................................................................. 51

Diagnostic Scan Tool ...................................................................................... 53

Using the DST for testing and trouble shooting

Page 3

Wire Schematic ................................................................................................... 81

Engine wiring schematics

Engine Wire Harness Repair ............................................................................. 85

Repairing a wire harness on the vehicle

Diagnostic Trouble Codes (DTCs) .................................................................... 89

Application, schematic and DTC specific code information

Servicing the Fuel System .................................................................................... 237

Step by step instructions on how repair and/or replace fuel related Components

LPG Parts Diagram ................................................................................................ 255

Illustrations and part views

Labor Time Guide .................................................................................................. 299

The labor reimbursed by IMPCO for warrantable service and repairs

Definitions .............................................................................................................. 317

Definitions of phrases and acronyms used throughout this Service Manual

Appendix ................................................................................................................ 323

Supplemental charts and tables

Page 4

4

Page 5

General Information

5

Page 6

INTRODUCTION

This service manual supplement has been developed to provide the service technician with the

basic understanding of the IMPCO certified fuel

and emission systems for the 3.0L GM engine.

This manual should be used in conjunction with

the base engine manual and the OEM service

manual when diagnosing fuel or electrical problems.

HOW TO IDENTIFY THE ENGINE YEAR

The emission label on the engine will identify the

specific model year.

SERVICING YOUR EMISSIONS

CERTIFIED ENGINE

Any maintenance and repair should be performed

by trained and experienced service technicians.

Proper tools and equipment should be used to

prevent injury to the servicing technician and

damage to the vehicle or components. Service

repairs should always be performed in a safe environment and the technician should always wear

protective clothing to prevent injury.

For parts or labor to be reimbursed under the

IMPCO Technologies Inc. emission warranty, only

work performed by IMPCO or OEM trained technicians using only IMPCO specified parts will qualify

for reimbursement. Refer to the IMPCO Labor

Time Guide for additional information.

For parts or labor not reimbursed under warranty,

a repair shop or person of the owner’s choosing

may maintain, replace, or repair emission-control

devices and systems. It is highly recommended

that any replacement parts used for maintenance

or for the repair of emission control systems be

new OEM replacement parts. The use of other

than genuine IMPCO replacement parts may impair the effectiveness of emission control systems,

therefore, the owner should assure that such parts

are warranted by their manufacturer to be equivalent to genuine IMPCO OEM parts in performance

and durability.

Fuel other than HD-5 or HD-10 may cause harm

to the engine’s emission control system and a

warranty claim may be denied on this basis if operators can readily find the proper fuel.* Use of

any other fuel may result in your engine no longer

operating in compliance with CARB or EPA emissions requirements.

*Not Applicable in the state of California.

FUEL LINE CONNECTIONS

Loctite® 567 is recommended for all NPT connections.

Do not use Teflon tape to seal any fuel fittings. Fragments of the tape may enter into

the fuel system, causing damage or malfunction of critical fuel system components.

AIR FILTRATION REQUIREMENTS

Dry filtration is required with maximum recommended 4” W.C. restriction @ 75 cfm. IMPCO

strongly recommends the use of OEM or factory

replacement parts.

WASHING

Caution should be used when pressure washing

near or on an engine’s electrical system. Avoid

direct pressure spray on the system electrical

connectors. The electrical connectors are splash

resistant, but if high pressure water or steam is

sprayed directly at the connectors, moisture can

become trapped behind the connector seal and

cause serious system problems, many of them

showing up as intermittent.

FUEL QUALITY

LPG engines and fuel systems are designed to

operate on HD-5 or HD-10 specification LPG fuel.

6

Page 7

FUEL SYSTEM CAUTIONS

Do not use Teflon tape to seal any fuel

fittings. Fragments of the tape may en-

ter into the fuel system, causing

damage or malfunction of critical fuel

system components.

Do not smoke, carry lighted tobacco or

use a lighted flame of any type when

working on or near any fuel related

component. Highly flammable air-fuel

mixtures may be present and can be

ignited causing personal injury.

Do not allow LPG to contact the skin.

LPG is stored in the fuel tank as a liq-

uid. When LPG contacts the

atmosphere, it immediately expands in-

to a gas, resulting in a refrigeration

effect that can cause severe burns to

the skin.

Do not allow LPG to accumulate in

areas below ground level such as in a

service pit or underground ventilation

systems. LPG is heavier than air and

can displace oxygen, creating a dan-

gerous condition.

Unlike gasoline or propane vapors that

sink downward. Highly flammable

air/fuel mixtures may be present and

can be ignited causing personal injury.

Always work in well ventilated areas.

WARNINGS, CAUTIONS AND NOTES

This manual contains several different Warnings,

Cautions, and Notes that must be observed to

prevent personal injury and or damage to the engine, the fuel system or personal property.

A “WARNING“ is an advisement that by performing a process or procedure listed in this manual

improperly may result in serious bodily injury,

death and/or serious damage to the engine or

property.

Typical Warning Label:

A “WARNING” is an advisement that

by performing a process or procedure

listed in this manual improperly may

result in serious bodily injury, death

and/or serious damage to the engine

or property.

A “CAUTION” label or statement is used when it

has been determine that by performing a process

or procedure defined in the manual improperly a

less severe result may occur. It could however,

result in serious bodily injury, and or serious damage to the engine or property damage.

Do not make repairs to the fuel system

if you are not familiar with or trained to

service Propane fuel systems. Contact

the dealer who sold you the engine to

locate a repair facility with trained

technicians to repair your fuel system.

Less severe than WARNING but has

the potential to cause injury or damage. Also used to notify of situations

that could lead to eventual failure, injury or damage.

This caution label may also appear in area of this

manual that applies to service and repair proce-

7

Page 8

dures. In addition it may also be used to indicate

a failure to observe which may influence the terms

of the warranty.

An “IMPORTANT” statement generally denotes a

situation that requires strict adherence to the assembly, tightening, or service procedure. Failure

to observe this procedure could result in an unsafe condition or improper performance of the

engine or a component.

A “NOTE” statement applies to a specific item or

procedure that is to be followed during the servicing of the engine or its components.

PROPER USE OF THIS SERVICE MANUAL,

TOOLS AND EQUIPMENT

To reduce the potential for injury to the technician

or others and to reduce damage to the engine during service repairs the technician should observe

the following Steps:

The service procedures defined in this ma-

nual, when followed, have been found to be a

safe and efficient process to repair the fuel

system. In some cases special tools may be

required to perform the necessary procedures

to safely remove and replace a failed component.

Tools identified in this manual with the prefix

“J” or “BT” can be procured through SPX in

Warren, Michigan.

IMPCO tools identified in this manual with a

prefix “ITK” can be acquired through OEM

Parts Distribution.

IMPORTANT

It is important to remember that there may be a

combination of Metric and Imperial fasteners used

in the installation of the IMPCO fuel system.

Check to insure proper fit when using a socket or

wrench on any fastener to prevent damage to the

component being removed or injury from “slipping

off” the fastener.

The fuel system utilizes fuel lines and hoses with

high pressure connectors. Always use a wrench

of the proper size and torque to the correct value.

For hoses with swivel fittings, be sure not to turn

the fixed fitting which may cause a twisting or

kinking of the hose, possibly resulting in fuel line

restriction and/or leak.

Always leak check any fuel system connection after servicing! Use an

electronic leak detector and/or a liquid

leak detection solution. Failure to leak

check could result in serious bodily injury, death, or serious property damage.

8

Page 9

Maintenance

9

Page 10

MAINTENANCE

The maintenance of an engine and related components are critical to its operating performance

and lifespan. Industrial engines operate in environments that often include hot and cold

temperatures and extreme dust. The recommended maintenance schedule is listed in this

section, however, environmental operating conditions and additional installed equipment may

require more frequent inspection and servicing.

The owner and/or service agent should review the

operating conditions of the equipment to determine the inspection and maintenance intervals.

When performing maintenance on the engine,

turn the ignition OFF and disconnect the battery negative cable to avoid injury or damage

to the engine.

ENGINE BELTS

The engine installed in this equipment uses a serpentine drive belt configuration that drives the

water pump, alternator and additional pumps or

devices. It is important to note that the drive belt

is an integral part of the cooling and charging system and should be inspected according to the

maintenance schedule in this section. When inspecting the belts check for:

Cracks

Chunking of the belt

Splits

Material hanging loose from the belt

Glazing, hardening

If any of these conditions exist the belt should be

replaced with the recommended OEM replacement belt.

Alcohol or Methanol based anti-freeze or

plain water are not recommended for use in

the cooling system at anytime.

SERPENTINE BELT SYSTEM

Serpentine belts utilize a spring-loaded tensioner

to keep the belt properly adjusted. Serpentine

belts should be checked according to the maintenance schedule in this section.

IMPORTANT:

The use of “belt dressing” or “anti-slipping

agents” on belts is not recommended.

COOLING SYSTEM

It is important that the cooling system of the engine be maintained properly to ensure proper

performance and longevity.

Alcohol or Methanol based anti-freeze or

plain water are not recommended for use

in the cooling system at anytime.

Do not remove the cooling system pressure cap (radiator cap) when the engine is

hot. Allow the engine to cool and then

remove the cap slowly to allow pressure

to vent. Hot coolant under pressure may

discharge violently.

NOTE that the LPG vaporizer is connected to the

cooling system and the fuel system may be adversely affected by low coolant levels and

restricted or plugged radiator cores. Therefore,

the cooling system must be maintained according

to the recommend maintenance schedule in this

section and also include:

The regular removal of dust, dirt and debris

from the radiator core and fan shroud.

Inspection of coolant hoses and components

for leaks, especially at the radiator hose connections. Tighten hose clamps if necessary.

Check radiator hoses for swelling, separation,

hardening, cracks or any type of deterioration.

10

Page 11

If any of these conditions exist the hose

should be replaced with a recommended OEM

replacement part.

Inspect the radiator cap to ensure proper seal-

ing.

COOLANT

Check coolant level in coolant recovery tank and

add coolant as required. Add 50/50 mixture of

GM Dexcool antifreeze and water or coolant per

engine manufacturer’s instructions. Do not add

plain water. Replace coolant per the recommended schedule.

IMPORTANT:

The manufacturers of the engine and fuel system

do not recommend the use of “stop leak” additives

to repair leaks in the cooling system. If leaks are

present the radiator should be removed and repaired or replaced.

ENGINE ELECTRICAL SYSTEM MAINTNANCE

The engine’s electrical system incorporates computers to control various related components. The

electrical system connections and ground circuits

require good connections. Follow the recommended maintenance schedule in this section to

maintain optimum performance. When inspecting

the electrical system check the following:

Check Positive and Negative cables for corro-

sion, rubbing, chafing, burning and to ensure

tight connections at both ends.

Check battery for cracks or damage to the

case and replace if necessary.

Inspect engine wire harness for rubbing, chaf-

ing, pinching, burning, and cracks or breaks in

the wiring.

Verify that engine harness connectors are cor-

rectly locked in by pushing in and then pulling

the connector halves outward.

Inspect ignition coil wire for hardening, crack-

ing, arcing, chafing, burning, separation, split

boot covers.

Check spark plug wires for hardening, crack-

ing, chafing, arcing or burning, separation, and

split boot covers.

Replace spark plugs at the required intervals

per the recommended maintenance schedule.

Verify that all electrical components are se-

curely mounted to the engine or chassis.

Verify that any additional electrical services

installed by the owner are properly installed in

the system.

Verify that the MIL, charging, and oil pressure

lights illuminate momentarily during engine start.

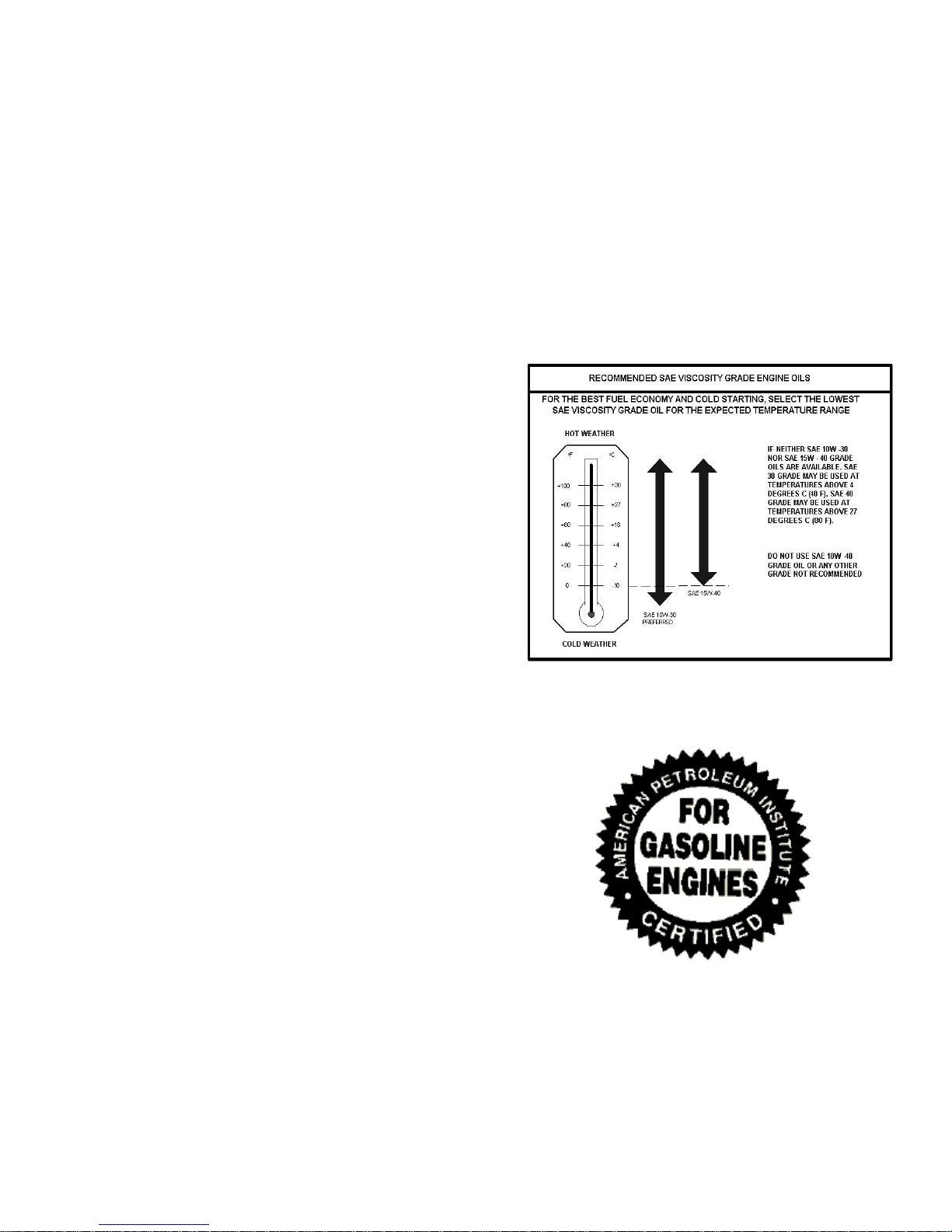

ENGINE CRANKCASE OIL

OIL RECOMMENDATION

Select an engine oil viscosity that will best match

the prevailing daytime temperature:

The oil must meet GM specification 9986231. Motor oils meeting this spec receive the API

(American Petroleum Institute) starburst symbol:

ILSAC GF-4 oils are highly recommended. Oils

meeting the SL-4 spec are improved over the previous generation GF-3 oils in many ways

Reduced Phosphorous levels (20%) for re-

duced catalyst poisoning

Improved oxidation resistance (4X oxidation

inhibitor treat level = 100% improvement)

11

Page 12

Improved hi temp deposit control (1.5X deter-

gents = 25% improvement)

It is noted that the GF-4 oils are also “backward

compatible” and are equal or better than previous

grades of oil in all aspects.

OEM’s may opt for higher viscosity oils based on

their application experience however GF-4 oils

may not be available in these viscosity ranges. In

this case it is recommended the OEM utilize high

quality oil (API rating SM).

CAUTION: Do not to operate your engine with an

oil level below the normal operating range. Severe engine damage could occur.

SYNTHETIC OILS

Synthetic oils have been available for use in industrial engines for a relatively long period of

time and may offer advantages in cold and hot

temperatures. However, it is not known if synthetic oils provide operational or economic

benefits over conventional petroleum-based oils

in industrial engines. Use of synthetic oils does

not permit the extension of oil change intervals.

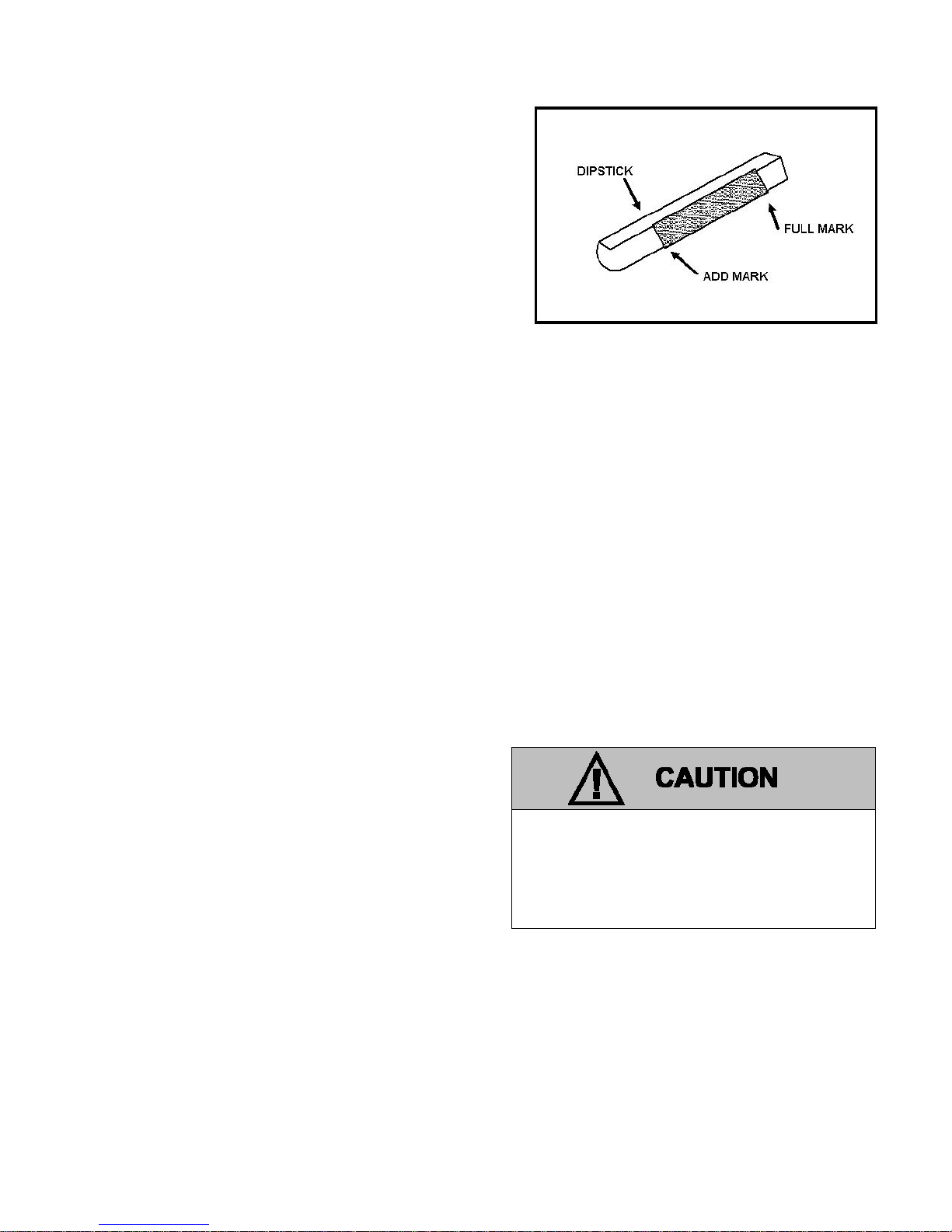

CHECKING/FILLING ENGINE OIL LEVEL

IMPORTANT:

Care must be taken when checking engine oil level. Oil level must be maintained between the

“ADD” mark and the “FULL” mark on the dipstick.

To ensure that you are not getting a false reading,

make sure the following steps are taken before

checking the oil level.

1. Stop engine.

2. Allow approximately five minutes for the oil to

drain back into the oil pan.

3. Remove the dipstick. Wipe with a clean cloth

or paper towel and reinstall. Push the dipstick

all the way into the dipstick tube.

4. Remove the dipstick and note the amount of

oil on the dipstick. The oil level must be between the “FULL” and “ADD” marks.

Engine Oil Dip Stick (Typical)

5. If the oil level is below the “ADD” mark reinstall

the dipstick into the dipstick tube and proceed

to Step 6.

6. Remove the oil filler cap from the valve cover.

7. Add the required amount of oil to bring the

level up to, but not over, the “FULL” mark on

the dipstick. Reinstall the oil filler cap to the

valve rocker arm cover and wipe any excess

oil clean.

CHANGING THE ENGINE OIL

IMPORTANT:

When changing the oil, always change the oil

filter.

1. Start the engine and run until it reaches normal operating temperature.

An overfilled crankcase (oil level being too

high) can cause an oil leak, a fluctuation

or drop in oil pressure. When overfilled,

the engine crankshafts splash and agitate

the oil, causing it to aerate or foam.

IMPORTANT:

Change oil when engine is warm and the old oil

flows more freely.

2. Stop engine

12

Page 13

Engine oil will be hot. Use protective

gloves to prevent burns. Engine oil contains chemicals which may be harmful to

your health. Avoid skin contact.

3. Remove drain plug and allow the oil to drain.

4. Remove and discard oil filter and its sealing

ring.

5. Coat sealing ring on the new filter with clean

engine oil, wipe the sealing surface on the filter

mounting surface to remove any dust, dirt or

debris. Tighten filter securely (follow filter manufacturer’s instructions). Do not over tighten.

6. Check sealing ring on drain plug for any damage, replace if necessary, wipe plug with clean

rag, wipe pan sealing surface with clean rag

and re-install plug into the pan. Tighten to the

OEM specification.

7. Fill crankcase with oil.

8. Start engine and check for oil leaks.

9. Dispose of oil and filter in a safe and responsible manner.

FUEL SYSTEM INSPECTION AND

LPG FUEL SYSTEM

The LPG fuel system installed on this industrial

engine has been designed to meet the emission

standard applicable for the 2011 model year. To

ensure compliance to these standards, follow the

recommended maintenance schedule contained in

this section.

INSPECTION AND MAINTENANCE OF THE

FUEL STORAGE CYLINDER

The fuel storage cylinder should be inspected

daily or at the beginning of each operational shift

for any leaks, external damage, adequate fuel

supply and to ensure the manual service valve is

open. Fuel storage cylinders should always be

securely mounted, inspect the securing straps or

retaining devices for damage ensure that all locking devices are closed and locked. Check to

ensure that the fuel storage cylinder is positioned

with the locating pin in the tank collar on all horizontally mounted cylinders this will ensure the

proper function of the cylinder relief valve.

MAINTENANCE

When refueling or exchanging the fuel cylinder,

check the quick fill valve for thread damage. Also

verify O-ring is in place and inspect for cracks,

chunking or separation. If damage to the o-ring

is found, replace prior to filling. Check the service line quick coupler for any thread damage.

IMPORTANT:

When refueling the fuel cylinder, wipe both the

female and male connection with a clean rag prior

to filling to prevent dust, dirt and debris from being

introduced to the fuel cylinder.

INSPECTION OF THE FUEL FILTER

The LPG system on this emission certified engine

utilizes an in-line replaceable fuel filter element.

This element should be replaced, at the intervals

specified in the recommended maintenance schedule. When inspecting the fuel filter check the

following:

Check for leaks at the inlet and outlet fittings,

using a soapy solution or an electronic leak

detector and repair if necessary.

Check to make sure filter is securely mounted.

Check filter housing for external damage or

distortion. If damaged replace fuel filter.

AIR FUEL MIXER/THROTTLE CONTROL

DEVICE MAINTENANCE AND INSPECTION

IMPORTANT:

The Air Fuel Mixer components have been

specifically designed and calibrated to meet the

fuel system requirements of the emission certified

engine. The mixer should not be disassembled or

rebuilt. If the mixer fails to operate or develops a

leak the mixer should be replaced with the OEM

recommended replacement parts.

When inspecting the mixer check for the following

items:

Leaks at the inlet fitting.

Fuel inlet hose for cracking, splitting or chaff-

ing, replace if any of these condition exist.

Ensure the mixer is securely mounted.

Inspect air inlet hose connection and clamp.

Also inspect inlet hose for cracking, splitting or

chafing. Replace if any of these conditions exist.

13

Page 14

Inspect Air cleaner element according to the

Recommended Maintenance Schedule found

in this section.

Check Fuel lines for cracking, splitting or chaf-

ing. Replace if any of these conditions exist.

Verify Throttle body return action to ensure

throttle shaft is not sticking. Repair if necessary.

Check for leaks at the throttle body and intake

manifold.

PRESSURE REGULATOR MAINTENANCE AND

INSPECTION

IMPORTANT:

The Pressure Regulator components have been

specifically designed and calibrated to meet the

fuel system requirements of the emission certified

engine.

If the Regulator fails to operate or develops a

leak, it should be repaired or replaced with the

OEM recommended replacement parts. When

inspecting the regulator check for the following

items:

Check for any fuel leaks at the inlet and outlet

fittings.

Check for any fuel leaks in the regulator body.

Check the inlet and outlet fittings of the coo-

lant supply lines for water leaks.

Check the coolant supply lines for hardening,

cracking, chafing or splits. If any of these conditions exist replace coolant lines.

Check coolant supply hose clamp connec-

tions, ensure they are tight.

Check to ensure the Regulator is securely

mounted and the mounting bolts are tight.

Check the Regulator for external damage.

Check the Regulator electrical connections to

ensure the connector is seated and locked.

EXHAUST SYSTEM AND CATALYTIC

CONVERTER INSPECTION AND

MAINTENANCE

IMPORTANT:

The exhaust system on this emission certified engine contains Heated Exhaust Gas Oxygen

Sensors (HEGOs) which provide feedback to the

ECM on the amount of oxygen present in the exhaust stream after combustion.

The measurement of oxygen in the exhaust

stream is measured in voltage and sent to the

ECM. The ECM then makes corrections to the

fuel air ratio to ensure the proper fuel charge and

optimum catalytic performance. Therefore, it is

important that the exhaust connections remain

secured and air tight.

Contamination of the HEGO sensor can result from the use of an inappropriate RTV

sealer or silicone spray products. Do not use

silicone sprays or hoses which are assembled using silicone lubricants. Always use

“oxygen sensor safe” RTV sealant for repair

procedures. Silicon contamination will cause

a high but false HEGO signal voltage (rich

exhaust indication). The ECM will then reduce the amount of fuel delivery to the

engine, causing a severe driveability problem. If silicone contamination is suspected,

remove and visually inspect the sensor element. If contaminated, the portion of the

sensor exposed to the exhaust stream will

have a white powdery coating. Always be

sure to eliminate the cause of contamination

before replacing the sensor.

When inspecting the Exhaust system check the

following:

Exhaust manifold at the cylinder head for

leaks and that all retaining bolts and shields (if

used) are in place.

Manifold to exhaust pipe fasteners to ensure

they are tight and that there are no exhaust

leaks repair if necessary.

HEGO electrical connector to ensure connec-

tor is seated and locked, check wires to

ensure there is no cracking, splits chafing or

“burn through. Repair if necessary.

Exhaust pipe extension connector for leaks

tighten if necessary.

Visually inspect converter to ensure muffler is

securely mounted and tail pipe is properly

aimed.

Check for any leaks at the inlet and outlet of

the converter.

14

Page 15

V

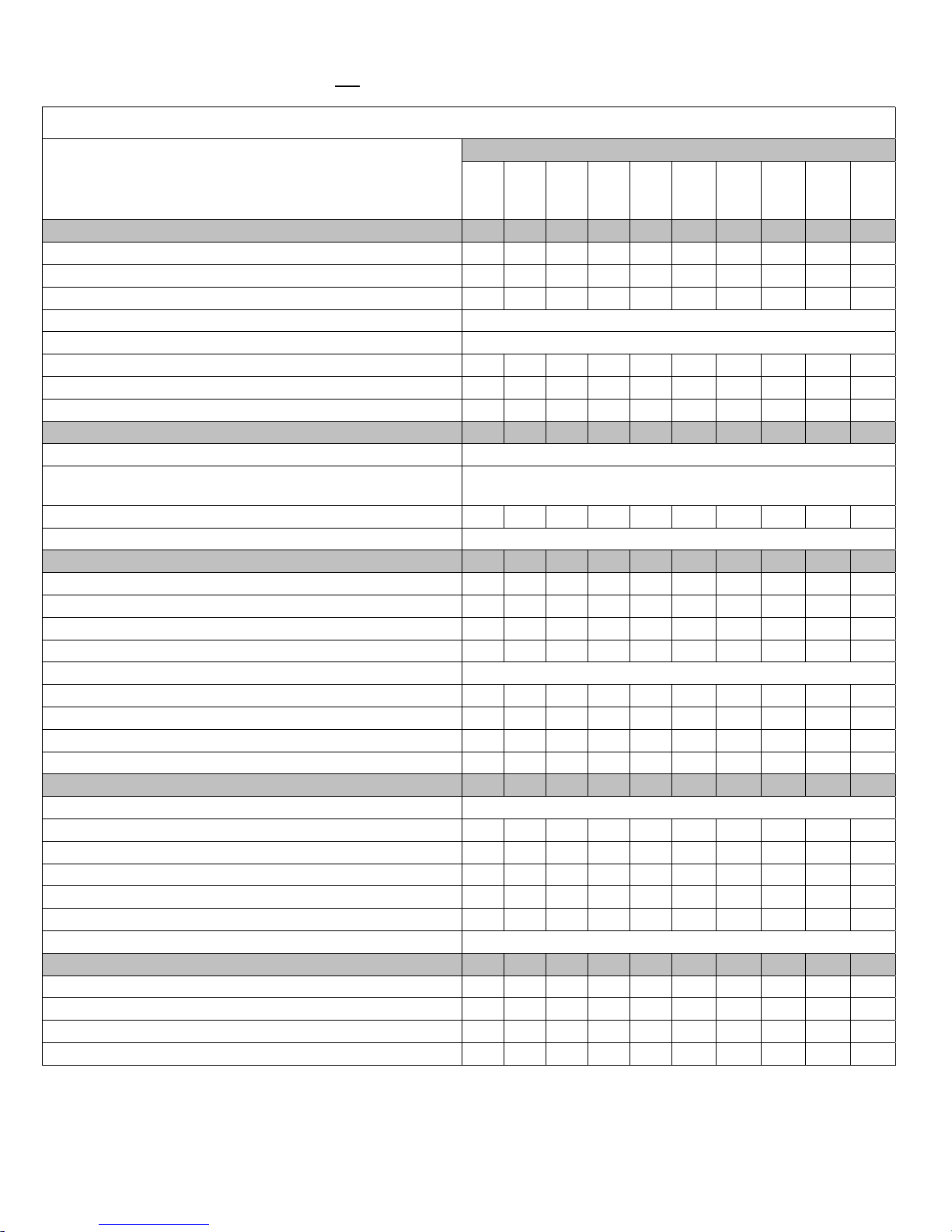

LPG CERTIFIED ENGINE MAINTENANCE REQUIREMENTS

For maintenance or other work that is not

the emission control devices and systems may be performed by any engine repair establishment or individual.

Perform the following maintenance on the engine at the hours indicated and at equivalent hour intervals thereafter.

This maintenance schedule represents the manufacturer’s recommended maintenance intervals to maintain proper engine/equipment

function. Federal, State, or Local regulations may require additional or

more frequent inspection or maintenance intervals than those specified above. Check with the authority having jurisdiction for details.

General Maintenance Section

isual check for fluid leaks X

Check engine oil level X

Check coolant level X

Change engine oil and filter

Check LPG system for leaks Prior to any service or maintenance activity

Inspect accessory drive belts for cracks, breaks, splits or glazing X X X X X

Inspect electrical system wiring for cuts, abrasions or corrosion X X

Inspect all vacuum lines and fittings for cracks, breaks or hardening X X

Engine Coolant Section

Clean debris from radiator core

Change coolant--GM 6277M specification (Dexcool) 50-50

mixture with distilled water

Inspect coolant hoses for cracks, swelling or deterioration X X X X X

Replace coolant hoses and accessory drive belt

Engine Ignition System

Inspect Battery case for leaks or damage X X X X X

Inspect battery cables for damage corrosion or contamination X X X X X

Check all electrical connector retainer locks X X X X X

Replace spark plugs X X X

Inspect crank sensor timing wheel for debris or damage

Clean ignition coil X X X X X

Check spark plug wires for cuts abrasions or hardening X

Replace distributor cap and rotor X

Replace spark plug wires X

Fuel System Maintenance

Inspect air cleaner

Replace fuel filters X X X X X

Inspect Shut-off Valve for leaks and closing X X

Leak check fuel lines, regulator, fuel rail and injectors X X

Check air induction and intake manifold for leaks X X

Check manifold for vacuum leaks X X

Drain Regulator oil build up

Engine Exhaust System

Inspect exhaust manifold for leaks X X

Inspect exhaust piping for leaks X X

Check HEGO sensor connectors and wires for burns, cuts or damage X X

Inspect catalyst for mechanical damage X X

Note that propane engines are designed to operate on HD–5 or HD–10 specification LPG fuel. Fuel other than HD–5 or HD–

10 may cause harm to the engine’s emission control system and a warranty claim may be denied on this basis if operators

can readily find the proper fuel*. Use of any other fuel may result in your engine no longer op erating in compliance with CARB

or EPA emissions requirements. * Not Applicable in the state of California.

performed under warranty, maintenance, replacement, or repair of

Interval Hours

Daily 1000 1500 2000 2500 3000 3500 4000 4500 5000

Every 100 hours or 60 days of operation

Every 100 hours or 60 days of operation

Every 5000 hours or five years

Every 2,000 hours or two years, whichever occurs first

Every 100 hours or 60 days of operation

Every 200 hours, or every 100 hours in dusty environment

Every 100 hours or 60 days of operation

15

Page 16

16

Page 17

LPG Fuel System

17

Page 18

LPG FUEL SYSTEM OPERATION

18

Page 19

DESCRIPTION AND OPERATION OF THE FUEL

SYSTEMS

LPG FUEL SYSTEM

The primary components of the LPG fuel system

are the fuel storage tank, regulator, throttle control

device, fuel injectors, engine control module (ECM),

catalytic converter and Heated Exhaust Gas Oxygen (HEGO) Sensor.

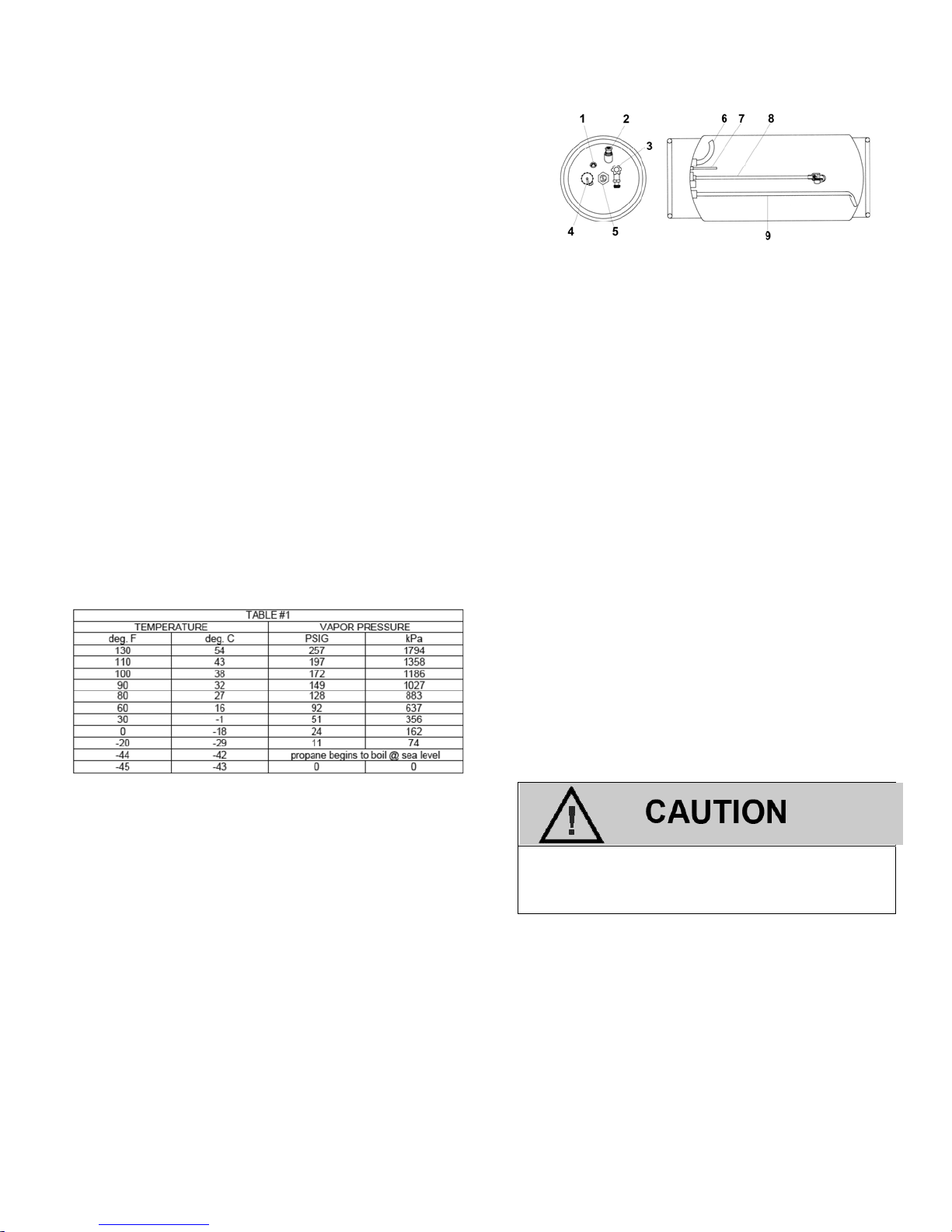

LPG FUEL TANK

LPG is stored in the fuel tank as a liquid. The approximate pressure of the fuel in the tank is 16.5

bar (240 psi) when the tank is full at an ambient

temperature of 27° C (81°F). The boiling point,

(temperature at which the liquid fuel becomes vapor) is approximately -40° C (-40° F). When the

fuel changes from liquid to vapor the fuel expands

and creates pressure inside the tank. When the

tank service valve is opened the pressure inside

the tank forces the liquid fuel out though the pickup

tube located near the bottom of the fuel cylinder.

The service valve mounted in the end of the cylinder controls the flow of fuel from the tank. By turning

the handle to its “open” position, fuel flows out of

the tank and into the service line. The service

valve is also equipped with a safety feature called

an excess flow check valve. This feature reduces

the flow from the service valve in the event of a rupture of the fuel line or any downstream fuel

transport components. A safety valve is built into

the tank. Normally set at 25.8 bar (375 psi), it will

release pressure to prevent tank rupture due to

over-pressurization of the cylinder

Typical LPG Cylinder

1. Liquid Outage Fill Check Valve

2. Pressure Relief Valve

3. Liquid Outage valve w/quick disconnect coupling

4. Filler Valve

5. Fuel Gauge

6. Vapor Withdrawal Tube (when applicable)

7. 80% Limiter Tube

8. Fuel Level Float

9. Liquid Withdrawal Tube

SERVICE LINE

LPG flows from the fuel tank to the Regulator via

the service line connected to the tank utilizing a

quick coupler. The other end of the service line is

connected to a bulkhead connector, allowing for a

safe means of passing through the sheet metal

and into the engine compartment. The service

line is made of high pressure hose with special

material or possibly tubing which is compatible

with the LPG fuel and should always be replaced

with an OEM supplied part.

The bulkhead assembly should never be

removed. Never run a service line through

the sheet metal.

FUEL FILTER

LPG, fuel like all other motor fuels is subject to

contamination from outside sources. Refueling of

the equipment tank and removal of the tank from

the equipment can inadvertently introduce dirt,

rust and other foreign matter into the fuel system.

It is therefore necessary to filter the fuel prior to

entering the fuel system components downstream

19

Page 20

of the tank. A replaceable, high pressure, inline

fuel filter is built into regulator and another is in

line between the regulator and fuel rail. Maintenance of the filters is critical to proper operation of

the fuel system and should be replaced according

to the maintenance schedule or more frequently

under severe operating conditions.

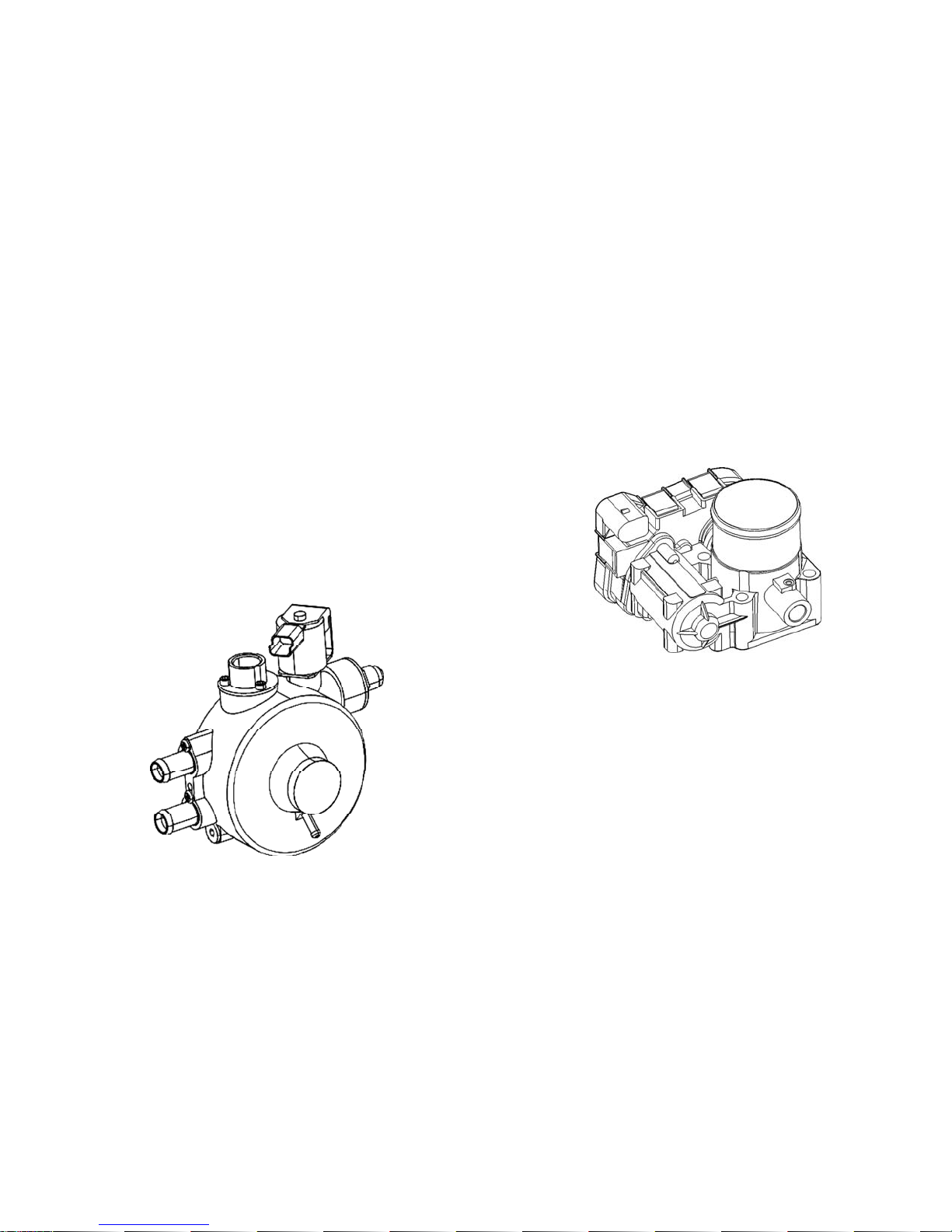

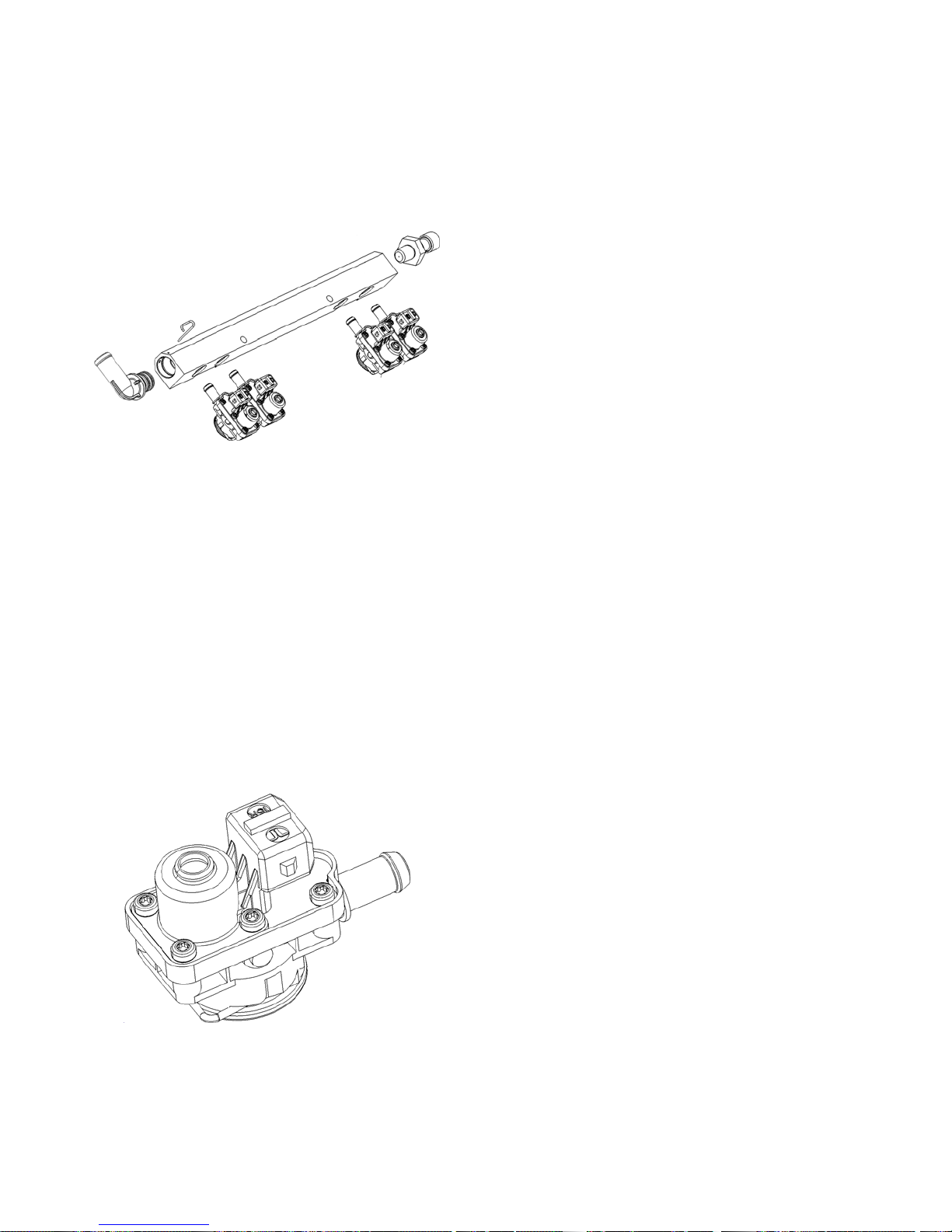

REGULATOR

The Regulator is a combination vaporizer and pressure regulating device with a built-in LPG shut-off

solenoid valve. The fuel shutoff is a normally

closed valve on the vaporizer, controlled by the

ECM. The valve is opened is opened momentarily

when the ignition is first turned on to allow the system to pressurize and when the engine is running.

When open, LPG passes into the regulator and any

liquid LPG is vaporized by heat provided by the engine coolant. The fuel vapor pressure is then

reduced to approximately 88 kPa (12.6 psi) and

delivered to the fuel rail and fuel injectors. The outlet fuel pressure is referenced to the manifold

pressure for a more stable idle.

connection with the throttle and there is no direct

mechanical (cable) connection between the pedal

and the throttle shaft.

The ECM monitors the foot pedal position sensor

when the engine is running. When the operator

depresses or releases the foot pedal, the ECM

sends an electrical signal to the motor on the

electronic throttle to increase or decrease the angle of the throttle blade thereby increasing or

decreasing the volume of air delivered to the engine. Two internal Throttle Position Sensors

(TPSs) provide feedback to the ECM indicating

the position of the throttle shaft and blade. Defaults programmed into the ECM software ensure

correct speed, load and emission control for all

throttle ranges.

Regulator

The regulator and some of components are serviceable.

THROTTLE CONTROL DEVICE—DRIVE BY

WIRE

S

peed control is maintained by the amount of pressure applied to the foot pedal located in the engine

compartment, however, in this Drive By Wire

(DBW) application, the foot pedal has an electronic

A throttle related failure will cause a “LIMP

HOME” mode of operation, where the engine has

no response to the pedal.

THREE WAY CATALYTIC CONVERTER

The Catalytic Converter is a component of the

emissions system which is designed and calibrated to meet the emission standards in effect

for 2011 model year.

The exhaust gases pass through the honeycomb

catalyst which is coated with a mixture of metals

(such as platinum, palladium, and rhodium) to

oxidize and reduce CO, HC and NOx emission

gases.

20

Page 21

Three Way Catalytic Converter

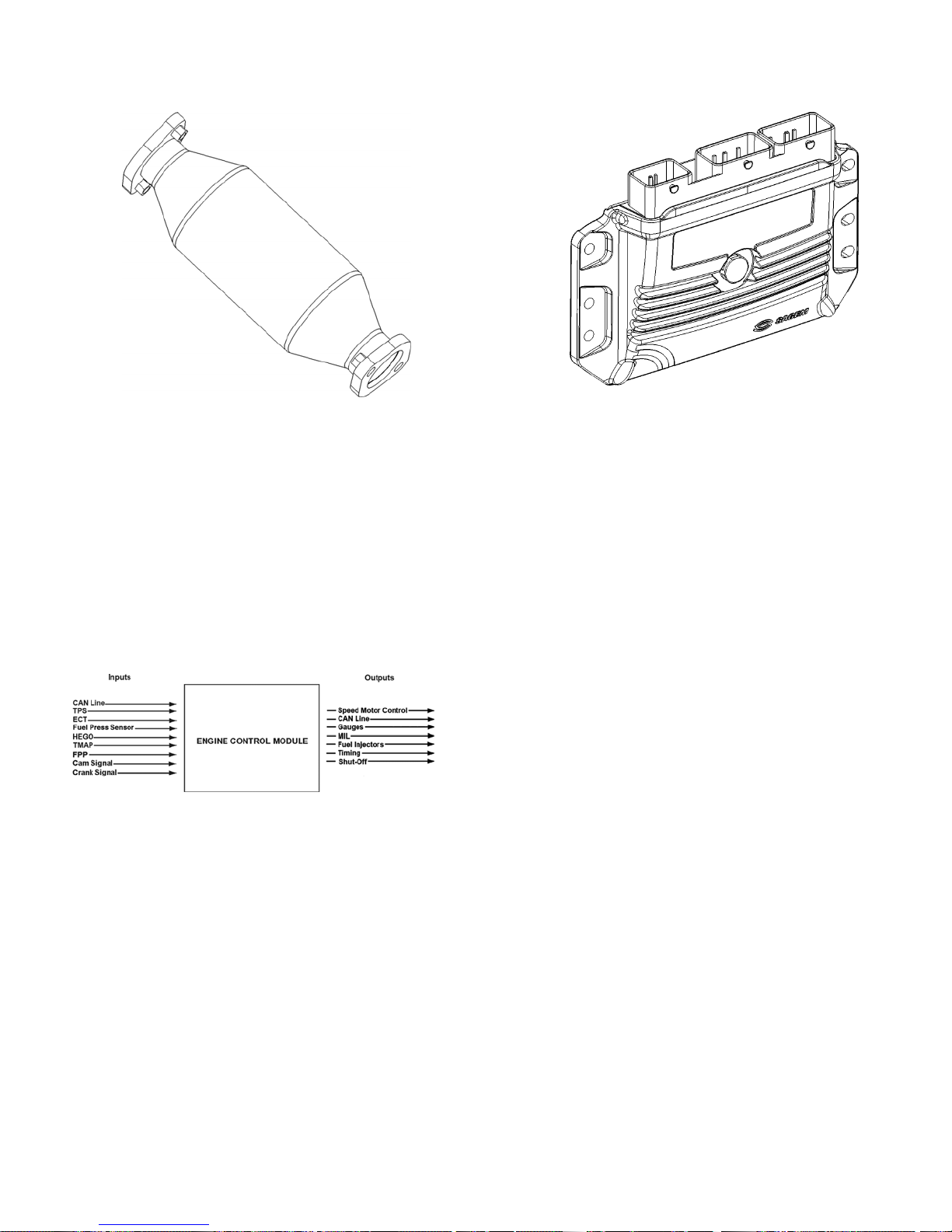

ENGINE CONTROL MODULE

To obtain maximum effect from the catalyst and

accurate control of the air fuel ratio, the emission

certified engine is equipped with an onboard

computer or Engine Control Module (ECM). The

ECM is a controller which receives input data

from sensors mounted to the engine and fuel system and then outputs various signals to control

engine operation.

One specific function of the controller is to maintain a closed loop fuel control which is

accomplished by use of the Heated Exhaust Gas

Oxygen Sensors (HEGOs) mounted in the exhaust system. The HEGO sensors send a

voltage signal to the ECM which then changes

the amount of fuel being delivered from the injectors to the engine.

Engine Control Module (ECM)

The ECM also performs diagnostic functions on

the fuel system and notifies the operator of engine malfunctions by turning on a Malfunction

Indicator Light (MIL) mounted in the dash. Malfunctions in the system are identified by a

Diagnostic Trouble Code (DTC) number. In addition to notifying the operator of the malfunction in

the system, the controller also stores the information about the malfunction in its memory. A

technician can than utilize a computerized diagnostic scan tool to retrieve the stored diagnostic

code and by using the diagnostic charts in this

manual to determine the cause of the malfunction. In the event a technician does not have the

computerized diagnostic tool.

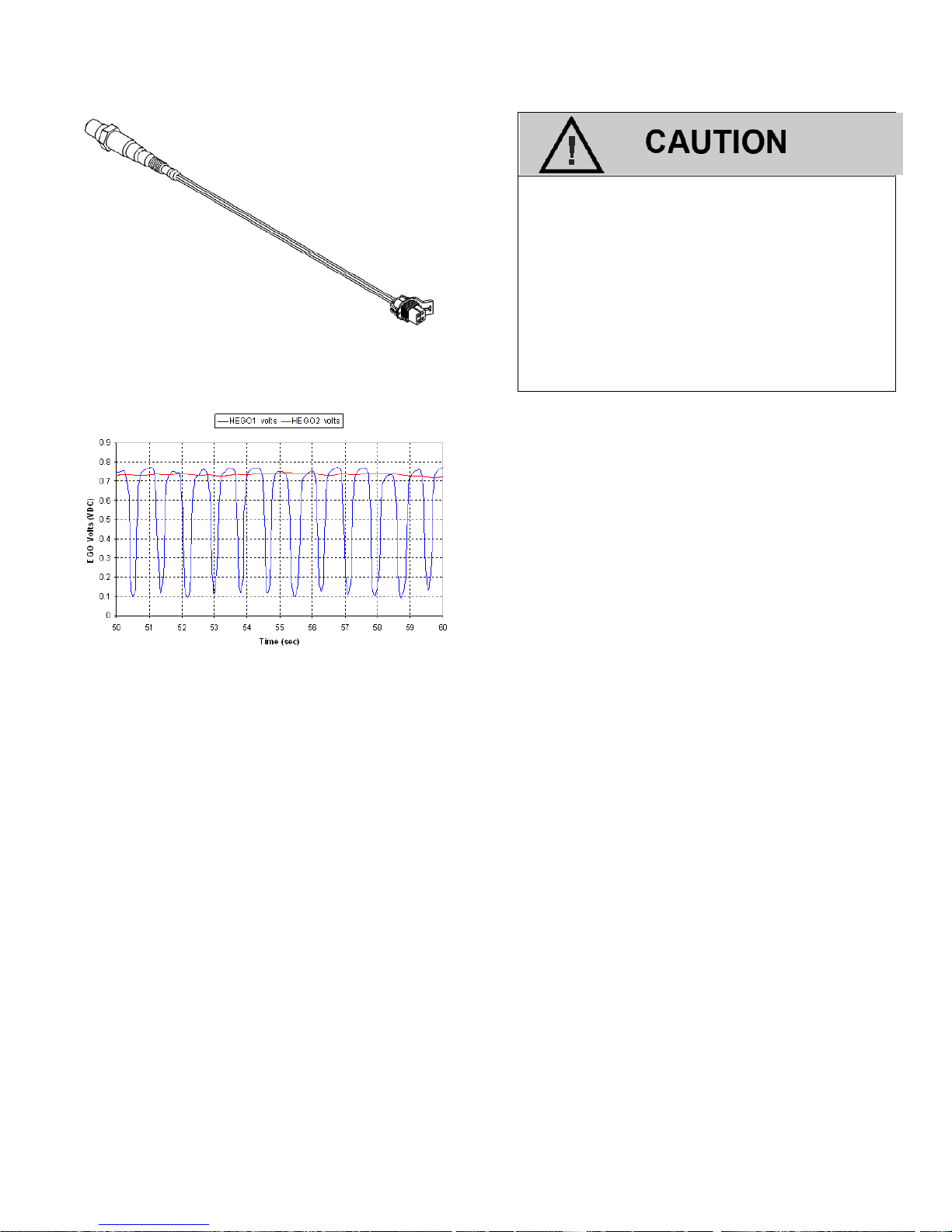

HEATED EXHAUST GAS OXYGEN SENSOR

The Heated Exhaust Gas Oxygen (HEGO) Sensor is mounted in the exhaust system to measure

the amount of oxygen present in the exhaust

stream. The ECM continuously monitors the

HEGO measurement to determine whether the

fuel air ratio is too rich, too lean and richen or

lean the mixture of fuel delivered to the engine. If

the ECM determines that a rich or lean condition

is present for an extended period of time which

cannot be corrected, the ECM will set a diagnostic code and turn on the MIL light in the dash.

21

Page 22

The Heat Exhaust Gas Oxygen (HEGO) Sensor

HEGO voltage output.

The Heated Exhaust Gas Oxygen Sensor

(HEGO) is an emissions control component. In the event of a failure, the HEGO

should only be replaced with the recommended OEM replacement part. The

HEGO is sensitive to silicone based products and can become contaminated.

Avoid using silicone sealers or air or fuel

hoses treated with a silicone based lubricant.

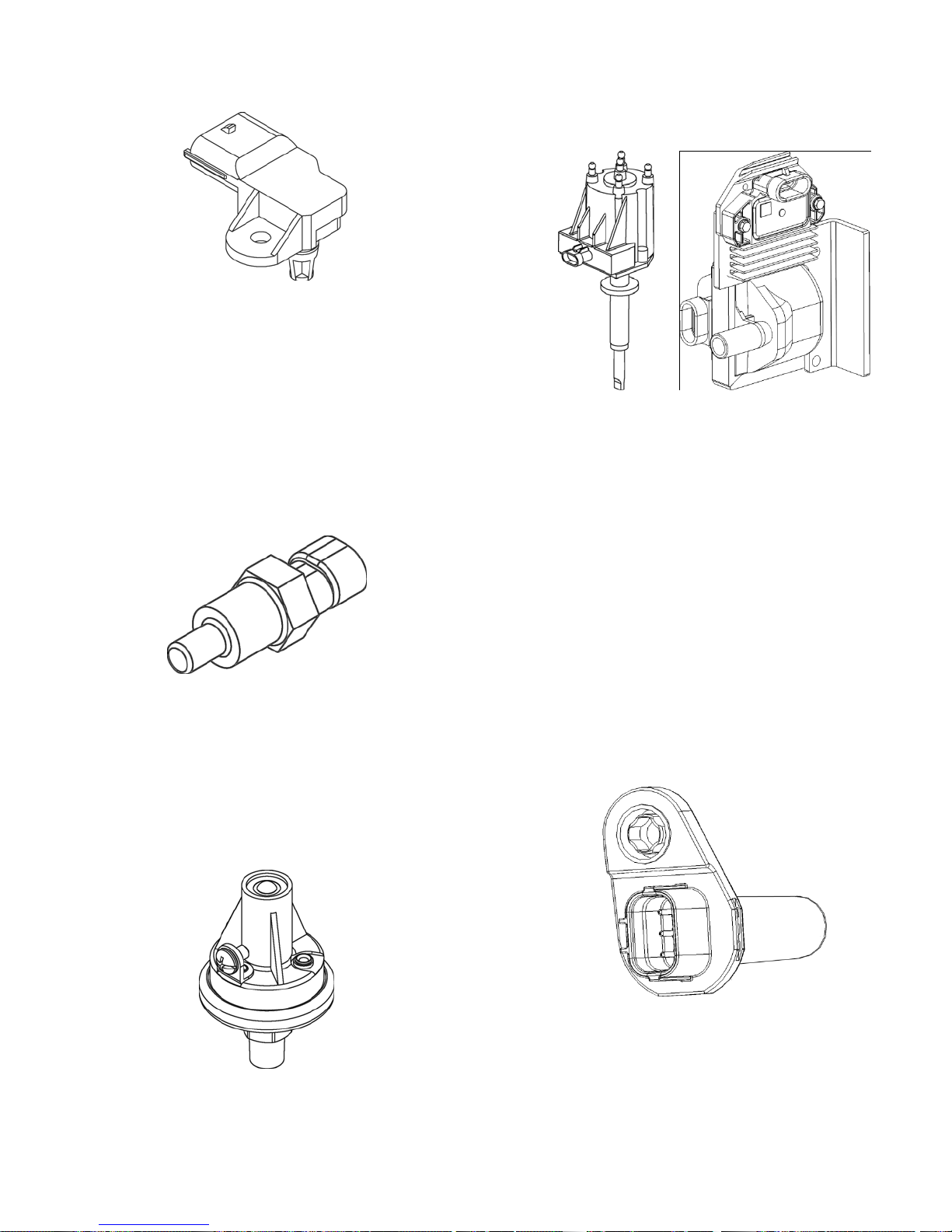

TMAP SENSOR

The Air Temperature/Manifold Absolute Pressure

or TMAP sensor is a combination of two sensors:

1) A variable resistor used to monitor the difference in pressure between the intake manifold

and outside or atmospheric pressure. The

ECM monitors the resistance of the sensor to

determine engine load (the vacuum drops

when the engine is under load or at wide

open throttle) and may alter the fuel mixture

to improve performance and emissions.

2) The Manifold Air Temperature (MAT or IAT)

sensor is a variable resistance thermistor located in the air intake passage which

measures the temperature of the incoming air.

The ECM uses the resistance value to monitor

incoming air temperature and calculate the engine’s airflow requirement. The ECM provides

a voltage divider circuit so that when the air is

cool, the signal reads a higher voltage, and

lower when warm. On cold starts, the ECM richens the fuel/air mixture.

22

Page 23

TMAP Sensor

COOLANT TEMPERATURE SENSOR

The Engine Coolant Temperature sensor or ECT is

a variable resistance thermistor that changes resistance as the engine's coolant temperature

changes. The sensor's resistance is monitored by

the ECM to determine a cold start condition and to

regulate various fuel and emission control functions

via a closed loop emission system.

Coolant Temperature Sensor

OIL PRESSURE SENDER

The Engine Oil Pressure Sender is designed to ensure adequate lubrication throughout the engine. It

is monitored by the ECM. If the pressure drops, a

MIL will occur.

IGNITION SYSTEM

The ignition system spark system uses a Crank

Position and Camshaft Position sensor for engine

timing. A coil assembly contain an ignition coil

and an ignition module supplies the ignition spark

for the system. The coil is fired for each cylinder

over two engine revolutions. The distributor

routes each spark event to the appropriate cylinder spark plug. The plug is fired near the top of

the compression stroke to ignite the fuel and air

mixture.

CAM SENSOR

In the 2011 engine the CAM sensor and a cam

signal wheel are incorporated into the ignition distributor mounted on the side of the engine block.

CRANK SENSOR

Oil Pressure Sender

Crank Sensor

The crank position sensor is a Hall effect sensor

that is triggered by a reluctor wheel on the crankshaft. Two missing teeth are used to determine

23

Page 24

engines rotational position. The crank sensor is the

source of all other ECU functions if this sensor is

not functioning the ECU will not see an engine

speed and will not provide fuel or spark to the engine.

Fuel Rail Assembly and LPG Injectors.

The gaseous LPG flows into the fuel rail where it is

distributed to the four LPG injectors. At the opposite end of the fuel rail to the inlet port there is a

Fuel Absolute Pressure (FAP) sensor (also known

as a Fuel Rail Pressure Sensor) this sensor allows

the ECU to lengthen or shorten the fuel injector

pulse width to compensate for variations in the absolute fuel pressure supplied to the injectors. This

injector assembly has one end inserted into the

manifold ports and the other end inserted into the

fuel rail ports. There is an o-ring seal on the manifold side and an o-ring and split spacer seal on the

fuel rail side. The fuel rail holds the injectors in

place.

stage, pilot actuated principal. When the coil is actuated it pulls the primary seal off the primary orifice

against the force of the flat return spring. This allows gas to flow out of the upper chamber of the

injector. Because the orifice supplying the upper

chamber is smaller than the primary orifice which is

now allowing fuel to flow out of the upper chamber,

the pressure drops in this chamber and the now

higher pressure in the lower chamber pushes the

main secondary seal off the secondary orifice and

allows full flow of the injector (this occurs in about 1

to 2 ms). When the coil is de-energized the primary

seal is returned to cover the primary orifice by the

force of the flat spring and pressure builds in the

upper chamber forcing the secondary seal down to

seal the secondary orifice and shutting off all flow of

gas.

A Spectrum IV Gaseous Fuel Injector

The 2011 saturated drive injectors operate on a two

24

Page 25

LPG Closed Loop Schematic

25

Page 26

26

Page 27

LPG System Diagnosis

27

Page 28

LPG FUEL SYSTEM DIAGNOSIS

Regulator Assembly

FUEL SYSTEM DESCRIPTION

The Engine Control Module (ECM) receives

information from various engine sensors in

order to control the operation of the engine.

LPG is stored in the tank as a liquid and delivered under pressure up to 21.5 BAR (312

psi). At Key ON the Regulator allows LPG to

flow from the tank through the fuel filter and

inside, where fuel is vaporized and reduced in

pressure.

DIAGNOSTIC AIDS

This procedure is intended to diagnose a vehicle operating on LPG. If the vehicle will not

continue to run refer to Hard Start for preliminary checks. Before starting this procedure,

complete the following tasks to verify that liquid fuel is being delivered to the EPR:

Inspect fuel tank to verify it has a sufficient

amount of fuel.

Verify the manual shut off valve on the

LPG tank is fully opened.

Verify that the excess flow valve has not

been activated.

Inspect fuel tank to ensure it is properly

mounted and rotated to the correct position.

Inspect the hoses leading from the tank

ensuring they are properly connected and

do not have any kinks or damage.

TOOLS REQUIRED:

7/16” Open end wrench (for test port

plugs)

Test port adapter

DST

Diagnostic Scan Tool (DST)

PRESSURE GAUGES

0-15 PSI Gauge

28

Page 29

FUEL SYSTEM DESCRIPTION

The Engine Control Module (ECM) receives information from various engine sensors in

order to control the operation of the Pressure Regulator and Shut-Off Valve. The ShutOff Valve solenoid prevents fuel flow unless the engine is cranking or running.

LPG is stored in the tank as a liquid and delivered under pressure of up to 21.5 BAR

(312 psi). At Key ON the Regulator allows LPG to flow from the tank through the fuel

filter and inside, where fuel is vaporized and reduced in pressure.

DIAGNOSTIC AIDS

This procedure is intended to diagnose a vehicle operating on LPG. If the vehicle will not

continue to run on LPG, refer to Hard Start for preliminary checks. Before starting this

procedure, complete the following tasks to verify that liquid fuel is being delivered to the

Regulator:

Inspect fuel tank to verify it has a sufficient amount of fuel.

Verify manual Shut Off valve on the LPG tank is fully opened.

Verify that the excess flow valve has not been activated.

Inspect fuel tank to ensure it is properly mounted and rotated to the correct position.

Inspect the hoses leading from the tank ensuring they are properly connected and do

not have any kinks or damage.

29

Page 30

LPG FUEL SYSTEM DIAGNOSTICS

Step Action Value(s) Yes No

Were you referred to this procedure by a DTC diagnostic

1

Chart?

Connect the Diagnostic Scan Tool (DST) to the ECM Data Link

Connector (DLC) and check for any DTCs.

2

Are any DTCs present in the ECM?

Perform the following visual and physical preliminary checks:

Check all ECM system fuses and circuit breakers (refer to

Engine Wiring Schematic).

Check the ECM grounds for being clean, tight and in their

proper locations (refer to Engine Wiring Schematic).

Check the vacuum hoses for damage, splits, kinks and prop-

er connections.

Check the fuel system for any type of leak or restriction from

the supply tank.

Check for air leaks at all mounting areas of the intake mani-

fold sealing surfaces.

Check for air leaks at all intake ducting between intake mani-

fold and air cleaner.

Check air cleaner and all vehicle intake ducting for restric-

3

4 Does the vehicle start and run?

5

tions.

Check exhaust system for flow obstructions or leaks.

Check the ignition wires for the following conditions:

Cracking or hardening

Proper routing

Bare or shorted wires

Carbon tracking

Check the wiring harness for the following conditions:

Proper connections

Pinches

Cuts or abrasions

Were any faulty conditions found in the preliminary checks?

Check the fuel system for the following conditions:

Verify the LPG fuel tank is at least ¼ full.

Verify the manual fuel shut-off valve is open and operating

correctly.

Verify the high-flow valve has not tripped.

Verify the quick disconnect is fully engaged and there are no

kinks or obstructions in the high pressure LPG supply hose.

Verify the LPG fuel filter is clean and unobstructed.

Were any faulty conditions found in the fuel supply system?

Go to Step

(3)

Go to appli-

cable DTC

Table

Correct

the faulty

condition

and Go to

Step 20

Go to Step

(9)

Correct

the faulty

condition

and Go to

Step 20

Go to

Step (2)

Go to

Step (3)

Go to

Step (4)

Go to

Step (5)

Go to

Step (6)

30

Page 31

Step Action Value(s) Yes No

Connect a calibrated 0-5” PSI pressure gauge to the pri-

mary pressure test port of the Regulator.

Make sure the manual shut-off valve is open and turn the

ignition to ON.

Crank the engine and observe the pressure gauge.

Does the pressure gauge indicate the proper primary fuel

6

pressure?

LPG is a gaseous fuel and requires higher secondary ignition voltages than gasoline fueled engines. Check the

ignition system for proper ignition secondary voltage output

with J 26792 or equivalent.

Remove the spark plugs and check for the following:

Correct plug type for LPG application.

Wet electrodes (oil fouling)

7

Cracks

Wear

Improper gap

Burned electrodes

Heavy deposits

Were any faulty conditions found in the ignition system

check?

Perform a leak-down test on the engine.

Are all cylinder leak-down test results within specification?

8

Turn OFF the manual fuel shut-off valve.

Start the engine and let it run until it dies.

Remove the LPG Temperature Sensor from the Regula-

tor (DO NOT disconnect the electrical connector).

9

Inspect the inside of the low-pressure fuel supply hose

for heavy-end deposits.

Are there any deposits built-up in the low-pressure fuel

supply hose?

2.0–4.0

PSI

<10%

leakage

Go to Step

(7)

Correct

the faulty

condition

and

Go to Step

(20)

Go to Step

(12)

Go to Step

(16)

If NO

pressure

was indi-

cated, Go

to Step

(14)

If LOW

or HIGH

pressure

was in-

dicated,

Go to

Step

(15)

Go to

Step (8)

Repair

the engine as

neces-

sary and

Go to

Step

(20)

Go to

Step

(10)

31

Page 32

Step Action Values Yes No

Remove the FAP sensor from the Fuel Rail and insert the

Pressure Test Adapter and connect to 103 kPa (15 PSI)

10

11

12

13

14

15

pressure gauge.

Connect the DST to the vehicle DLC connector and open the

DST software.

Turn the manual shut-off valve ON. Start the engine and

allow it to reach operating temperature.

Compare the gauge secondary pressure reading to the actual

pressure on the DST.

Is the gauge secondary pressure within the specified percentage of the actual pressure indicated on the DST?

Turn OFF the manual shut-off valve and let the engine run

until it dies.

Turn the ignition OFF.

If turned OFF, turn ON the manual shut-off valve.

Disconnect the Lock-off valve electrical connector.

Apply 12V to the lock-off valve terminals and observe the

pressure gauge.

Does the pressure gauge indicate pressure?

Repair or replace the Shut Off Valve (refer to Repair Instructions).

Is the action complete?

+/-15 kPa

(2.2 PSI)

Go to Step

19

Go to Step

(14)

Go to

Step (11)

Go to

Step (13)

Above

1.0 PSI

Go to Step

17

Go to Step

20

Go to

Step 18

NA

32

Page 33

Step Action Values Yes No

Inspect the following for heavy-end deposits:

16

17

18

19

20

21

22

23

Pressure Regulator. Inspect, clean and/or repair as neces-

sary (refer to Regulator Repair Instructions).

Are all actions complete?

Replace the ECM.

Is the action complete?

Replace the Shut Off Valve.

Is the action complete?

System working correctly at this time. Vehicle may have

intermittent electrical connection conditions.

Return vehicle to original condition (but leave the diagnostic

equipment connected).

Start the engine and wiggle test the harness while observing

the DST Faults Screen and the pressure gauge readings.

Repair any conditions encountered.

Is the action complete?

Clear any active or historic DTCs (DST Service or Faults

Screen).

Clear Adaptive from memory (DST Service Screen).

Return the vehicle to original condition.

Operate the vehicle under all load and driving conditions for

at least 10 minutes.

Park the vehicle with the engine running and connect the

DST to the vehicle’s DLC connector.

Open the DST software and switch to the Faults Screen.

Let the vehicle idle with no load for at least 30 seconds and

observe the Adaptive 1 fuel correction.

Did the Adaptive 1 fuel correction remain within the specified

values?

With engine still idling, apply a load with the hydraulic system

for at least 10 seconds and observe the Adaptive 1 value.

Did the Adaptive 1 fuel correction remain within the specified

values?

Raise the engine rpms to 75-90% of maximum full governed

speed with no load for at least 10 seconds and observe the

Adaptive 1 fuel correction.

Did the Adaptive 1 fuel correction remain within specified values?

With the engine still running at 75-90% of full governed

speed, apply a moderate load with the hydraulic system.

Observe the Adaptive 1 fuel correction.

Did the Adaptive 1 fuel correction remain within specified values?

-15% to

+15%

-15% to

+15%

-15% to

+15%

-15% to

+15%

Go to Step

20

Go to Step

20

Go to Step

20

Go to Step

20

Go to Step

21

Go to Step

22

Go to Step

23

Go to Step

29

33

NA

NA

NA

NA

Go to

Step 24

Go to

Step 24

Go to

Step 24

Go to

Step 24

Page 34

Step Action Values Yes No

24 Was the Adaptive 1 fuel correction less than -15%?

Go to Step

(26)

Go to

Step (25)

25 Was the Adaptive 1 fuel correction more than +15%?

Engine is running RICH (system is trying to compensate by decreasing the amount of fuel). Check the following for any

condition which may cause the engine to run RICH:

Ignition system (See Step 7).

26

Air cleaner and intake system (including vehicle intake

ducting) for airflow obstructions.

Exhaust system for flow obstructions.

HEGO for correct switching characteristics.

Are all actions complete?

Engine is running LEAN (system is trying to compensate by

increasing the amount of fuel). Check the following for any

condition which may cause the engine to run LEAN:

Intake manifold for leaks.

All throttle body gaskets or o-rings for leaks.

All vacuum hoses and fittings for leaks.

Exhaust system for leaks

27

NOTE: Exhaust system leaks allow for excess O

to dilute the

2

HEGO sensor giving a false reading. Engine may exhibit signs

of a rich running condition but the Adaptive 1 corrections will

indicate an excessive positive fuel adjustment.

HEGO for correct switching characteristics.

Are all actions complete?

Go to Step

(27)

Go to Step

(28)

Go to Step

(28)

NA

NA

NA

28 Repeat Step 20. NA NA

Remove all test equipment except the DST.

Connect any disconnected components, fuses, etc.

Using the DST clear DTC information from the ECM.

Turn the ignition OFF and wait 30 seconds.

Start the engine and operate the vehicle to full operating

29

temperature

NA NA

Observe the MIL

Observe engine performance and driveability

Does the engine operate normally with no stored codes?

Remove all diagnostic equipment and return vehicle to original

condition. Return vehicle to customer.

34

Page 35

Fuel Symptom Diagnostics

35

Page 36

FUEL SYMPTOM DIAGNOSTICS

Checks Action

Before using this section, you should have performed On Board Diagnostic

(OBD) Check and determined that:

1. The ECM and MIL are operating correctly.

Before Using This

Section

Fuel System Check

2. There are no Diagnostic Trouble Codes (DTCs) stored, or a DTC exists

but without a MIL.

Several of the following symptom procedures call for a careful visual and

physical check. These checks are very important as they can lead to prompt

diagnosis and correction of a problem.

1. Verify the customer complaint.

2. Locate the correct symptom table.

3. Check the items indicated under that symptom.

4. Operate the engine under the conditions the symptom occurs. Verify

HEGO switching between lean and rich (cycling of voltage).

IMPORTANT! Normal HEGO switching indicates the fuel system is

in closed loop and operating correctly at that time.

5. Take a data snapshot using the DST under the condition that the symptom occurs to review at a later time.

Visual and Physical

Checks

Check all ECM system fuses and circuit breakers.

Check the ECM ground for being clean, tight and in its proper location.

Check the vacuum hoses for splits, kinks and proper connections.

Check thoroughly for any type of leak or restriction.

Check for air leaks at all the mounting areas of the intake manifold sealing

surfaces.

Check for proper installation and leakage around the Regulator and Throt-

tle body.

Check the ignition wires for the following conditions:

Cracking

Hardening

Proper routing

Carbon tracking

Check the wiring for the following items: proper connections, pinches or

cuts.

The following symptom tables contain groups of possible causes for each

symptom. The order of these procedures is not important. If the DST readings do not indicate a problem, then proceed in a logical order, easiest to

check or most likely to cause the problem.

36

Page 37

INTERMITTENT

Checks Action

DEFINITION: The problem may or may not turn ON the (MIL) or store a Diagnostic Trouble Code

(DTC).

Preliminary Checks

Faulty Electrical Con-

nections or Wiring

Operational Test

Intermittent MIL

Illumination

Do not use the DTC table if a fault is an intermittent, the use of the DTC

tables with this condition may result in the replacement of good parts.

Faulty electrical connections or wiring can cause most intermittent problems.

Check the suspected circuit for the following conditions:

Faulty fuse or circuit breaker, connectors poorly mated, terminals not fully

seated in the connector (backed out). Terminals not properly formed or

damaged.

Wire terminals poorly connected.

Terminal tension is insufficient.

Carefully remove all the connector terminals in the problem circuit in or-

der to ensure the proper contact tension.

If necessary, replace all the connector terminals in the problem circuit in

order to ensure the proper contact tension (except those noted as “Not

Serviceable”). See section Wiring Schematics.

Checking for poor terminal to wire connections requires removing the

terminal from the connector body.

If a visual and physical check does not locate the cause of the problem, operate the engine with the DST connected. When the problem occurs, an

abnormal voltage or scan reading indicates a problem circuit.

The following components can cause intermittent MIL and no DTC(s):

A defective relay.

Switch that can cause electrical system interference. Normally, the prob-

lem will occur when the faulty component is operating.

The improper installation of add on electrical devices, such as lights, 2-

way radios, electric motors, etc.

The ignition secondary voltage shorted to a ground.

The MIL circuit or the Diagnostic Test Terminal intermittently shorted to

ground.

The MIL wire grounds.

To check for the loss of the DTC Memory:

1. Disconnect the TMAP sensor.

Loss of DTC Memory

2. Run engine under no load until the MIL illuminates.

3. The ECM should store a TMAP DTC which should remain in the memory

when the ignition is turned OFF. If the TMAP DTC does not store and

remain, the ECM is faulty.

37

Page 38

NO START

Checks Action

DEFINITION: The engine cranks OK but does not start.

Preliminary Checks None

Use the DST to :

Check for proper communication with both the ECM

ECM Checks

Sensor Checks

Fuel System Checks

Ignition System Checks

Check all system fuses engine fuse holder. Refer to Engine Controls

Schematics.

Check battery power, ignition power and ground circuits to the ECM. Re-

fer to Engine Control Schematics. Verify voltage and/or continuity for

each.

Check the TMAP sensor.

Check the cam/crank sensors for output (rpm). This can be verified by an

RPM signal on the DST.

Check the cam angle sensor for output (rpm).

Verify proper operation of the Shut-off solenoid Valves.

Important: A closed Gas supply valve will create a no start condition.

Check for air intake system leakage around the Regulator and throttle

body.

Check the fuel system pressures.

Refer to the Fuel System Diagnosis.

NOTE: Natural Gas and Propane require higher secondary ignition system

voltages for the equivalent gasoline operating conditions.

1. Check for the proper ignition voltage output with J 26792 or the equiva-

lent.

2. Verify that the spark plugs are correct.

Check the spark plugs for the following conditions:

Wet plugs (Oil Fouling)

Cracks.

Wear.

Improper gap.

Burned electrodes.

Heavy deposits.

Check for bare or shorted ignition wires.

Check for loose ignition coil connections at the coil.

38

Page 39

Checks Action

Engine Mechanical

Checks

Exhaust System Checks

Important: The LPG Fuel system is more sensitive to intake manifold lea-

kage than the gasoline fuel system.

Check for the following:

Manifold vacuum leaks.

Venturi vacuum leaks.

Engine Vacuum leaks.

Improper valve timing.

Low compression.

Improper valve clearance.

Worn rocker arms.

Broken or weak valve springs.

Worn camshaft lobes.

Check the exhaust system for a possible restriction:

Inspect the exhaust system for damaged or collapsed pipes.

Inspect the muffler for signs of heat distress or for possible internal fail-

ure.

39

Page 40

HARD START

Checks Action

DEFINITION: The engine cranks OK, but does not start for a long time. The engine does eventually run,

or may start but immediately dies.

Preliminary Checks Make sure the engine’s operator is using the correct starting procedure.

Check the Engine Coolant Temperature sensor with the DST. Compare

the engine coolant temperature with the ambient air temperature on a

cold engine. If the coolant temperature reading is more than 10 degrees

Sensor Checks

Fuel System Checks

greater or less than the ambient air temperature on a cold engine, check

for high resistance in the coolant sensor circuit. Check the cam/crank

sensors.

Check the Throttle Position (TPS) and Foot Pedal Position (FPP) sensor

connections.

Important: A closed LPG manual fuel shut off valve will create a no start

condition.

Check Venturi assembly for proper installation and leakage.

Verify proper operation of the Shut-off solenoid Valves.

Verify proper operation of the system low pressure Regulator.

Check for air intake system leakage between the Throttle Body and Air

Filter Assembly. Check the fuel system pressures. Refer to the Fuel

System Diagnosis.

Ignition System Checks

NOTE: LPG requires higher secondary ignition system voltages for the

equivalent gasoline operating conditions.

Check for the proper ignition voltage output with J 26792 tool or the

equivalent.

Verify that the spark plugs are the correct type and properly gapped.

Check the spark plugs for the following conditions:

Wet plugs (oil fouling).

Cracks.

Wear.

Burned electrodes.

Heavy deposits.

Check for bare or shorted ignition wires.

Check for moisture in the distributor cap.

Check for loose ignition coil connections.

Important:

1. If the engine starts but then immediately stalls, check the cam/crank sensor.

2. Check for improper gap, debris or faulty connections.

40

Page 41

Checks Action

Engine Mechanical

Checks

Exhaust System Checks

Important: The LPG Fuel system is more sensitive to intake manifold lea-

kage than the gasoline fuel supply system.

Check for the following:

Engine vacuum leaks

Manifold vacuum leaks.

Venturi Vacuum Leaks

Improper valve timing-how?

Low compression

Improper valve clearance.

Worn rocker arms

Broken or weak valve springs

Worn camshaft lobes.

Check the exhaust system for a possible restriction:

Inspect the exhaust system for damaged or collapsed pipes.

Inspect the muffler for signs of heat distress or for possible internal fail-

ure.

Check for possible plugged catalytic converter. Refer to Restricted Exhaust

System Diagnosis.

41

Page 42

CUTS OUT, MISSES

Checks Action

DEFINITION: A surging or jerking that follows engine speed, usually more pronounced as the engine load

increases, but normally felt below 1500 rpm. The exhaust has a steady spitting sound at low speed, or

hard acceleration for the fuel starvation that can cause the engine to cut-out.

Preliminary Checks None

1. Start the engine.

2. Check for proper ignition output voltage with spark tester J 26792.

3. Check for a cylinder misfire.

4. Verify that the spark plugs are the correct type and properly gapped.

Remove the spark plugs and check for the following conditions:

Insulation cracks.

Ignition System Checks

Engine Mechanical

Checks

Fuel System Checks

Wear.

Improper gap.

Burned electrodes.

Heavy deposits.

Visually/Physically inspect the secondary ignition for the following:

Ignition wires for arcing and proper routing.

Cross-firing.

Ignition coils for cracks or carbon tracking.

Perform a cylinder compression check. Check the engine for the following:

Improper valve timing.

Improper valve clearance.

Worn rocker arms.

Worn camshaft lobes.

Broken or weak valve springs.

Check the intake and exhaust manifold passages for casting flash.

Check the fuel system:

Plugged fuel filter (if equipped).

Low fuel pressure, etc. Refer to Fuel System Diagnosis.

Check the condition of the wiring to the Shut-off Valves.

Check for Electromagnetic Interference (EMI), which may cause a misfire condition. Using the DST, monitor the engine rpm and note sudden increases in

Additional Check

rpm displayed on the scan tool but with little change in the actual engine rpm.

If this condition exists, EMI may be present. Check the routing of the secondary wires and the ground circuit.

42

Page 43

HESITATION, SAG, STUMBLE

Checks Action

DEFINITION: The engine has a momentary lack of response when accelerating the engine. The condition can occur at any engine speed. The condition may cause the engine to stall if it’s severe enough.

Preliminary Checks None.

Check the fuel pressure. Refer to Fuel System Diagnosis.

Check for low fuel pressure during a moderate or full throttle accelera-

tion. If the fuel pressure drops below specification, there is possibly a

Fuel System Checks

Ignition System Checks

faulty low pressure regulator or a restriction in the fuel system.

Check the TMAP sensor response and accuracy.

Check Shut-Off electrical connections.

Check the Regulator, Venturi and Throttle body for proper installation

and leakage.

NOTE: Natural Gas and Propane require higher secondary ignition system

voltages for the equivalent gasoline operating conditions.

Check for the proper ignition voltage output with J 26792 or the equiva-

lent. Verify that the spark plugs are the correct type and properly gapped.

Check for faulty spark plug wires.

Check for oil fouled spark plugs.

Additional Check

Check for manifold vacuum or air induction system leaks.

Check the alternator output voltage.

43

Page 44

BACKFIRE

Checks Action

DEFINITION: The fuel ignites in the intake manifold, or in the exhaust system, making a loud popping

noise.

Preliminary Check None.

NOTE: LPG requires higher secondary ignition system voltages for the

equivalent gasoline operating conditions.

Check for the proper ignition coil output voltage using the spark tester

J26792 or the equivalent.

Check the spark plug wires by connecting an ohmmeter to the ends of

each wire in question. If the meter reads over 30,000 ohms, replace the

wires.

Check the connection at ignition coil.

Ignition System Checks

Engine Mechanical

Check

Fuel System Checks Perform a fuel system diagnosis. Refer to Fuel System Diagnosis.

Check for deteriorated spark plug wire insulation.

Remove the plugs and inspect them for the following conditions:

Wet plugs (oil fouling).

Cracks.

Wear.

Improper gap.

Burned electrodes.

Heavy deposits.

Important! The LPG Fuel system is more sensitive to intake manifold

leakage than a gasoline fuel supply system.

Check the engine for the following:

Improper valve timing.

Engine compression.

Manifold vacuum leaks.

Intake manifold gaskets.

Sticking or leaking valves.

Exhaust system leakage.

Check the intake and exhaust system for casting flash or other restric-

tions.

44

Page 45

LACK OF POWER, SLUGGISHNESS, OR SPONGINESS

Checks Action

DEFINITION: The engine delivers less than expected power. There is little or no increase in speed

when throttling the engine.

Refer to the Fuel system OBD System Check.

Compare the customer’s engine with a similar unit to verify customer has

an actual problem. Do not compare the power output of the engine op-

Preliminary Checks

Fuel System Checks

erating on Natural Gas and Propane to one operating on gasoline as the

fuels do have different performance characteristics.

Remove the air filter and check for dirt or restriction.

Check the vehicle transmission.

Refer to the OEM transmission diagnostics.

Check for a restricted fuel filter, contaminated fuel, or improper fuel pres-

sure. Refer to LPG Fuel System Diagnosis.

Check for the proper ignition output voltage with the spark tester J 26792

or the equivalent.

Check the Regulator and Throttle body for proper installation and lea-

kage. Check all air inlet ducts for condition and proper installation.

Check all air inlet ducts for condition and proper installation.

Check for fuel leaks in supply lines.

Verify that the Fuel Supply Valve on the supply line is open.

Verify that liquid fuel (not vapor) is being delivered to the Regulator.

Sensor Checks

Exhaust System Checks

Engine Mechanical

Check

Additional Check

Check the Heated Exhaust Gas Oxygen Sensor (HEGO) for contamina-

tion and performance. Check for proper operation of the TMAP sensor.

Check for proper operation of the TPS and FPP sensors.

Check the exhaust system for a possible restriction:

Inspect the exhaust system for damaged or collapsed pipes.

Inspect the muffler for signs of heat distress or for possible internal fail-

ure.

Check for possible plugged catalytic converter.

Check the engine for the following:

Engine compression.

Valve timing.

Improper or worn camshaft.

Refer to Engine Mechanical in the Service Manual.

Check the ECM grounds for being clean, tight, and in their proper loca-

tions.

Check the alternator output voltage.

If all procedures have been completed and no malfunction has been found,

review and inspect the following items:

Visually and physically, inspect all electrical connections within the sus-

pected circuit and/or systems.

Check the DST data.

45

Page 46

POOR FUEL ECONOMY

Checks Action

DEFINITION: Fuel economy, as measured by refueling records, is noticeably lower than expected.

Also, the economy is noticeably lower than it was on this vehicle at one time, as previously shown by

refueling records.

Check the air cleaner element (filter) for dirt or being plugged.

Visually check the vacuum hoses for splits, kinks, and proper connec-

tions.

Properly inflated tires.

Preliminary Checks

Fuel System Checks

Sensor Checks

Ignition System

Checks

Cooling System

Checks

Check the operators driving habits for the following:

Excessive idling or stop and go driving.

Carrying of very heavy loads.

Rapid acceleration.

Suggest to the owner to fill the fuel tank and to recheck the fuel economy

and/or suggest that a different operator use the equipment and record the

results.

Check the Regulator fuel pressure. Refer to Fuel System Diagnosis.

Check the fuel system for leakage.

Check the TMAP sensor.

Verify that the spark plugs are the correct type and properly gapped.

Remove the plugs and inspect them for the following conditions:

Wet plugs (oil fouling).

Cracks.

Wear.

Improper gap.

Burned electrodes.

Heavy deposits.

Check the ignition wires for the following items:

Cracking.

Hardness.

Proper connections.

Check the engine thermostat to see if it is stuck open or for the wrong heat

range.

46

Page 47

ROUGH, UNSTABLE, OR INCORRECT ENGINE SPEED, STALLING

Checks Action

DEFINITION: The engine runs unevenly at under no load. If severe enough, the engine may shake.

The engine speed may vary in rpm. Either condition may be severe enough to stall the engine.

Preliminary Check None.

Check the Heated Exhaust Gas Oxygen Sensor (HEGO) performance:

Check for silicone contamination from fuel or improperly used sealant. If

contaminated, the sensor may have a white powdery coating result in a high

Sensor Checks

Fuel System Checks

but false signal voltage (rich exhaust indication). The ECM will reduce the

amount of fuel delivered to the engine causing a severe performance problem.

Check the Temperature Manifold Absolute Pressure (TMAP) sensor response

and accuracy.

Check for rich or lean symptom that causes the condition.

Run the engine at the speed of the complaint.

Monitoring the oxygen sensor will help identify the problem.

Verify proper operation of the Regulator.

Perform a cylinder compression test. Refer to Engine Mechanical in the

Service Manual.

Check the Regulator fuel pressure. Refer to the Fuel System Diagnosis.

Check the Regulator, Venturi and Throttle body for proper installation and

leakage.

Ignition System