Page 1

Page 2

ii MicroLogix™ 1200 8 Ch Output Module

User’s Manual Pub. 0300246-01 Rev. C

Important Notes

1. Please read all the information in this owner’s guide before installing the

product.

2. The information in this owner's guide applies to hardware Series A and

firmware version 1.00 or later.

3. This guide assumes that the reader has a full working knowledge of the

relevant processor.

Notice

The products and services described in this owner's guide are useful in a wide

variety of applications. Therefore, the user and others responsible for applying

the products and services described herein are responsible for determining their

acceptability for each application. While efforts have been made to provide

accurate information within this owner's guide, Spectrum Controls, Inc. assumes

no responsibility for the accuracy, completeness, or usefulness of the information

herein.

Under no circumstances will Spectrum Controls, Inc. be responsible or liable for

any damages or losses, including indirect or consequential damages or losses,

arising out of either the use of any information within this owner's guide or the

use of any product or service referenced herein.

No patent liability is assumed by Spectrum Controls, Inc. with respect to the use

of any of the information, products, circuits, programming, or services referenced

herein.

The information in this owner's guide is subject to change without notice.

Limited Warranty

Spectrum Controls warrants that its products are free from defects in material and

workmanship under normal use and service, as described in Spectrum Controls,

Inc. literature covering this product, for a period of 1 year. The obligations of

Spectrum Controls, Inc. under this warranty are limited to replacing or repairing,

at its option, at its factory or facility, any product which shall, in the applicable

period after shipment, be returned to the Spectrum Controls, Inc. facility,

transportation charges prepaid, and which after examination is determined, to the

satisfaction of Spectrum Controls, Inc., to be thus defective.

This warranty shall not apply to any such equipment which shall have been

repaired or altered except by Spectrum Controls, Inc. or which shall have been

subject to misuse, neglect, or accident. In no case shall the liability of Spectrum

Controls, Inc. exceed the purchase price. The aforementioned provisions do not

extend the original warranty period of any product which has either been repaired

or replaced by Spectrum Controls, Inc.

Page 3

iii

User’s Manual Pub. 0300246-01 Rev. C

Table of Contents

IMPORTANT NOTES ................................................................................................................. II

CHAPTER 1 MODULE OVERVIEW ........................................................................................... 1-1

SECTION 1.1 GENERAL DESCRIPTION ...................................................................................................... 1-1

SECTION 1.2 INPUT TYPES AND RANGES .................................................................................................. 1-1

SECTION 1.3 DATA FORMATS ............................................................................................................... 1-2

SECTION 1.4 HARDWARE FEATURES ...................................................................................................... 1-2

1.4.1 LED Indicator ......................................................................................................................... 1-3

SECTION 1.5 SYSTEM OVERVIEW ........................................................................................................... 1-3

1.5.1 Module Power-up ................................................................................................................. 1-3

1.5.2 Module Operation ................................................................................................................. 1-4

CHAPTER 2 INSTALLATION AND WIRING ............................................................................... 2-1

SECTION 2.1 COMPLIANCE TO EUROPEAN UNION DIRECTIVES ..................................................................... 2-1

2.1.1 EMC Directive ........................................................................................................................ 2-1

SECTION 2.2 POWER REQUIREMENTS .................................................................................................... 2-1

SECTION 2.3 GENERAL CONSIDERATIONS ................................................................................................ 2-2

2.3.1 Hazardous Location Considerations ...................................................................................... 2-2

2.3.2 Prevent Electrostatic Discharge ............................................................................................ 2-3

2.3.3 Remove Power ...................................................................................................................... 2-3

2.3.4 Selecting a Location .............................................................................................................. 2-3

2.3.5 Reducing Noise ...................................................................................................................... 2-3

SECTION 2.4 MOUNTING ..................................................................................................................... 2-4

2.4.1 Minimum Spacing ................................................................................................................. 2-4

2.4.1 DIN Rail Mounting................................................................................................................. 2-4

2.4.2 Panel Mounting .................................................................................................................... 2-5

SECTION 2.5 SYSTEM ASSEMBLY ............................................................................................................ 2-6

SECTION 2.6 FIELD WIRING CONNECTIONS .............................................................................................. 2-6

2.6.1 Wiring Diagram .................................................................................................................... 2-8

2.6.2 Wiring the Finger-Safe Terminal Block ................................................................................. 2-8

2.6.3 Terminal Door Label .............................................................................................................. 2-9

SECTION 2.7 MODULE INDICATORS ...................................................................................................... 2-10

CHAPTER 3 CONFIGURING THE 1762SC-OF8 USING RSLOGIX 500 ........................................... 3-1

SECTION 3.1 THINGS YOU SHOULD KNOW .............................................................................................. 3-1

SECTION 3.2 MODULE MEMORY MAP ................................................................................................... 3-1

SECTION 3.3 ADD MODULE TO LOGIX 500 .............................................................................................. 3-2

SECTION 3.4 MODULE CONFIGURATION ................................................................................................. 3-3

3.4.1 Output Data File (Command Mode)...................................................................................... 3-4

3.4.2 Output Data File (Normal Run Mode) ................................................................................... 3-8

SECTION 3.5 MODULE STATUS .............................................................................................................. 3-8

3.5.1 Input Data File (Command Mode) ........................................................................................ 3-8

3.5.2 Input Data File (Normal Run Mode) .................................................................................... 3-10

SECTION 3.6 CONFIGURATION LADDER SAMPLE ..................................................................................... 3-11

APPENDIX A MODULE SPECIFICATIONS ................................................................................. A-1

Page 4

iv MicroLogix™ 1200 8 Ch Output Module

User’s Manual Pub. 0300246-01 Rev. C

Preface

Read this preface to familiarize yourself with the rest of the manual. This preface

covers the following topics:

Who should use this manual

How to use this manual

Related publications

Conventions used in this manual

Rockwell Automation support

Who Should

Use This Manual

Use this manual if you are responsible for designing, installing, programming, or

troubleshooting control systems that use Allen-Bradley I/O and/or compatible

controllers, such as MicroLogix 1100 or 1200.

How to Use

This Manual

As much as possible, we organized this manual to explain, in a task-by-task

manner, how to install, configure, program, operate, and troubleshoot a control

system using the 1762sc-OF8.

Related

Documentation

The table below provides a listing of publications that contain important

information about Allen-Bradley PLC systems.

Document Title

Document Number

MicroLogix™ 1200 User Manual

1762-UM001

MicroLogix™ 1200 Technical Data

1762-TD001

MicroLogix 1200 and MicroLogix 1500

Programmable Controllers Instruction

Set Reference Manual

1762-RM001

Allen-Bradley Programmable Controller

Grounding and Wiring Guidelines

1770-4.1

Technical

Support

For technical support, please contact your local Rockwell Automation

TechConnect Office for all Spectrum products. Contact numbers are as follows:

USA 440-646-6900

United Kingdom 01908 635230

Australia 1800-809-929

Mexico 001-888-365-8677

Brazil (55) 11 3618 8800

Europe +49 211 41553 63

or send an email to

support@spectrumcontrols.com

Page 5

v

User’s Manual Pub. 0300246-01 Rev. C

Documentation

If you would like a manual, you can download a free electronic version from

the Internet at www.spectrumcontrols.com

Conventions

Used in This

Manual

The following conventions are used throughout this manual:

Bulleted lists (like this one) provide information, not procedural steps.

Numbered lists provide sequential steps or hierarchical information.

Italic type is used for emphasis.

Bold type identifies headings and sub-headings:

WARNING

Identifies information about practices or circumstances that can lead to

personal injury or death, property damage, or economic loss. These

messages help you to identify a hazard, avoid a hazard, and recognize the

consequences.

ATTENTION

Actions ou situations risquant d’entraîner des blessures pouvant être

mortelles, des dégâts matériels ou des pertes financières. Les messages «

Attention » vous aident à identifier un danger, à éviter ce danger et en

discerner les conséquences.

NOTE

Identifies information that is critical for successful application and

understanding of the product.

Page 6

vi MicroLogix™ 1200 8 Ch Output Module

User’s Manual Pub. 0300246-01 Rev. C

Page 7

User’s Manual Pub. 0300246-01 Rev. C

Chapter 1

Module Overview

This chapter describes the 1762sc-OF8 output module. The module provides 8

analog output channels that can be configured for current or voltage. Included is

information about:

General description

Input types and ranges

Data formats and filter frequencies

Hardware features

System overview and module operation

Section 1.1

General

Description

The output module supports current and voltage type outputs. The module

converts the digital value stored in each channel’s output command word to an

analog current or voltage signal. Each output channel is individually configured

via software for a specific output type, data format, and provides open-circuit or

short-circuit detection and indication.

Section 1.2

Input Types

and Ranges

The tables below list the output types and their associated ranges.

Voltage Selection

Range (VDC)

-10 V to +10 V

-11.0 to +11.0

0 to +5 V

0.0 to +5.5

0 to +10 V

0.0 to +11.0

1 to +5 V

0.0 to +5.5

Current Selection

Range (mA)

0 to 20 mA

0 to 20.4

4 to 20 mA

3.92 to 20.4

Page 8

1-2 Chapter 1: Module Overview

User’s Manual Pub. 0300246-01 Rev. C

Section 1.3

Data Formats

For each module, the data can be configured for:

Engineering units

Scaled-for-PID

Raw/proportional data

Percent of full range

Section 1.4

Hardware

Features

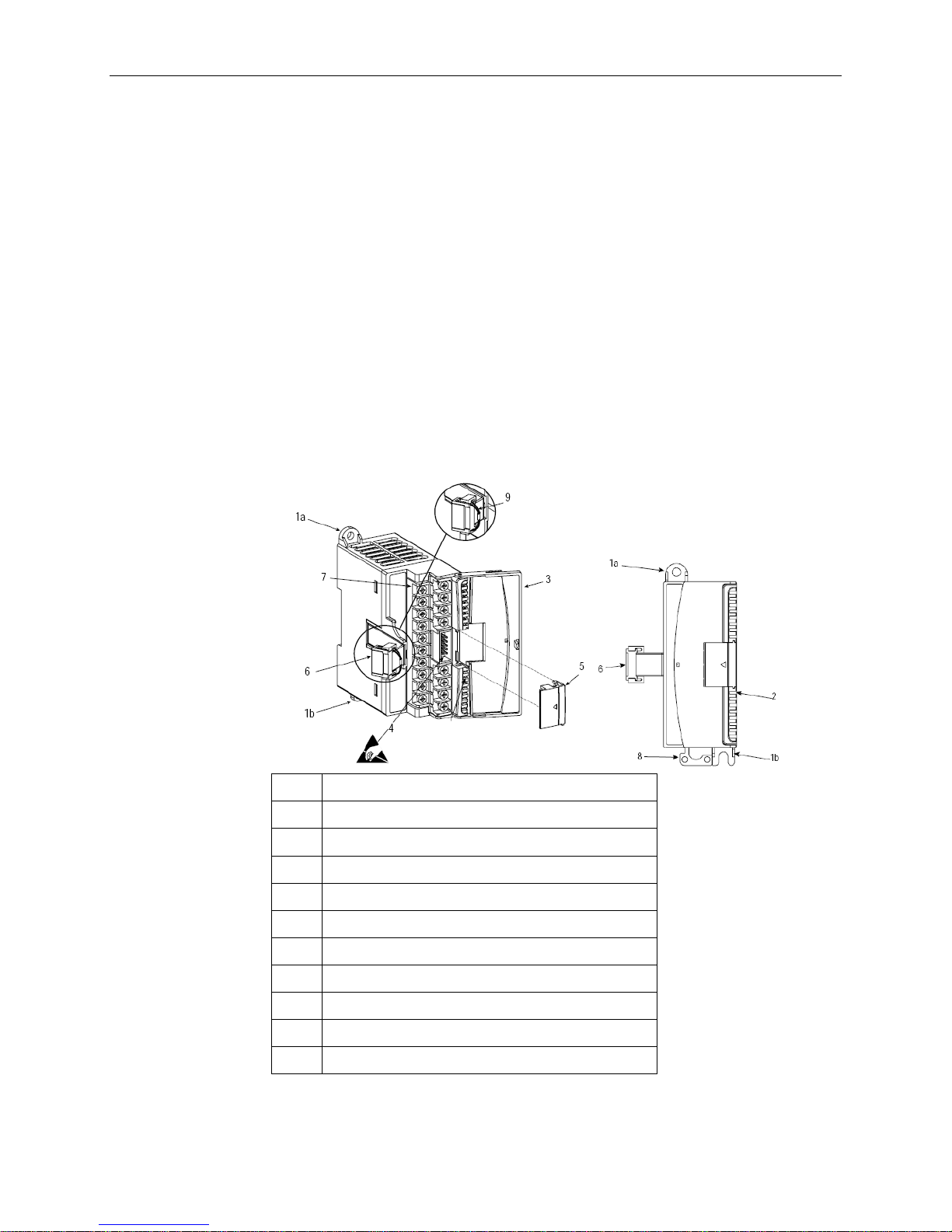

Module configuration is done via the controller’s programming software. The

module configuration is stored in the memory of the controller. Refer to your

controller’s user manual for more information. The illustration below shows the

module’s hardware features.

Item

Description

1a

Upper panel mounting tab

1b

Lower panel mounting tab

2

Power diagnostic LED

3

Module door with terminal identification label

4

Bus connector (male)

5

Bus connector cover

6

Flat ribbon cable with bus connector (female)

7

Terminal block

8

DIN rail latch

9

Pull loop

Figure 1-1

Page 9

Chapter 1: Module Overview 1-3

User’s Manual Pub. 0300246-01 Rev. C

1.4.1 LED Indicator

The 1762 output module uses a single green LED to show operational status of

the module. The LED will illuminate solid when the PLC is in run mode and the

module properly configured. If the module is not properly configured, or if the

PLC is not in run mode, the LED will blink rapidly. The following blink codes

are the only exception:

Table 1-1 (LED Blink Codes)

Blink Code

Description

Rapid Blink1

PLC not in run mode, or no valid module configuration present

Solid

Module is in run mode (Normal Operation)

3

Factory calibration in progress

4

Factory calibration invalid

5

Module is in command mode

Section 1.5

System

Overview

The module communicates to the controller through the bus interface. The

module also receives 5 VDC and 24 VDC power through the bus interface.

1.5.1 Module Power-up

At power-up, the module performs a check of its internal circuits, memory, and

basic functions. During this time, the module status LED remains off. If no

faults are found during power-up diagnostics, the module status LED blinks

rapidly waiting for command mode.

After power-up checks are complete, the module waits for command mode and

then valid channel configuration data. If an invalid configuration is detected, the

module generates a configuration error and remains in command mode. Once the

module is properly configured and enabled, it continuously converts the output

command value to a proportional analog output signal.

Each time a channel command value is read by the output module, that data value

is tested by the module for an over-range or under-range condition. If such a

condition is detected, a unique bit is set in the channel status word. The channel

status word is described in section 0 Input Data File.

Using the module image table, the controller reads the two’s complement binary

converted input data from the module. This typically occurs at the end of the

program scan or when commanded by the control program. If the controller and

the module determine that the data transfer has been made without error, the data

is used in the control program.

1

All outputs are disabled until the PLC goes into run mode, and the module receives a valid configuration.

Page 10

1-4 Chapter 1: Module Overview

User’s Manual Pub. 0300246-01 Rev. C

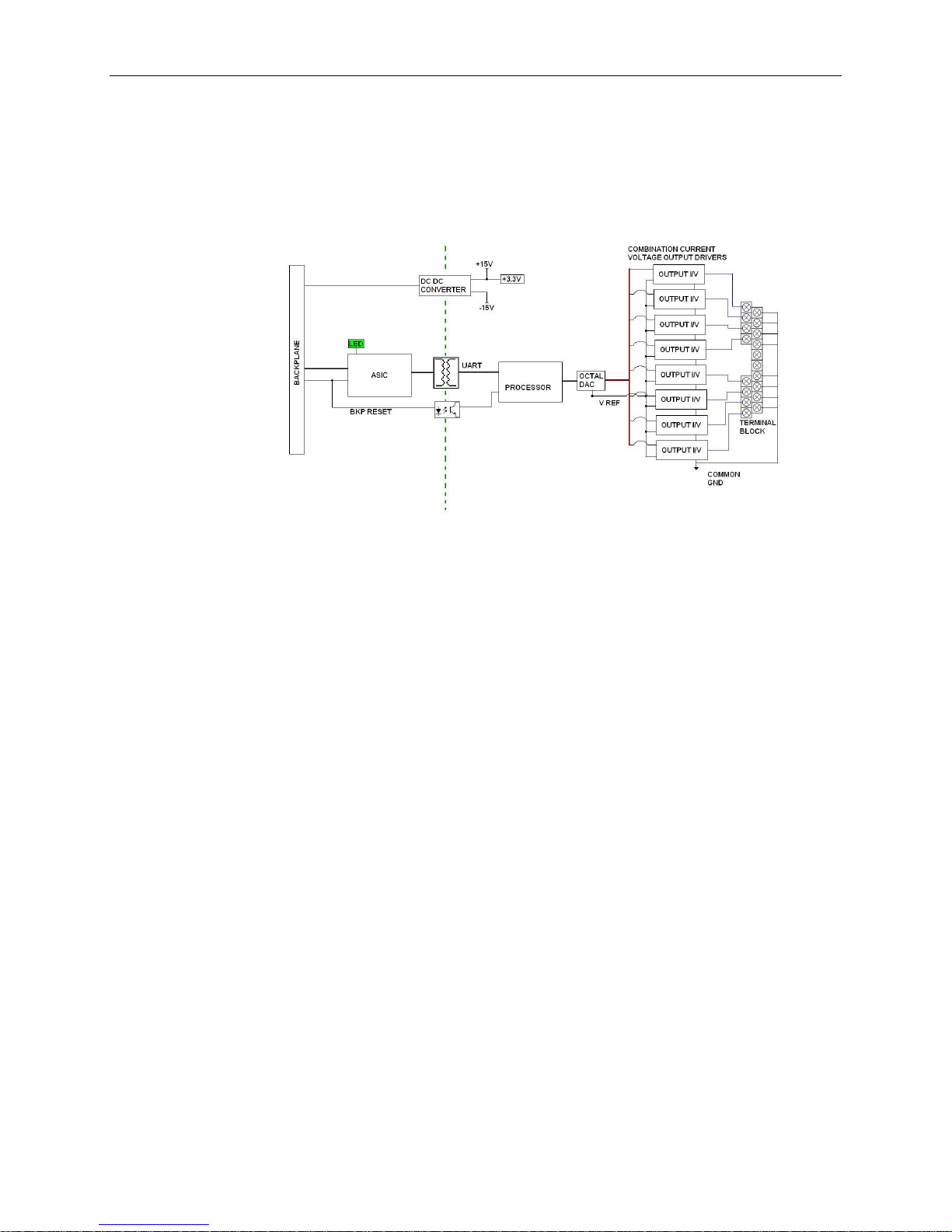

1.5.2 Module Operation

When the module receives a new command value from the output image, the

module’s circuitry converts the digital value to an analog current/voltage signal

using a DAC (Digital to Analog Converter). See the block diagram below.

Page 11

User’s Manual Pub. 0300246-01 Rev. C

Chapter 2

Installation and Wiring

This chapter will cover:

Compliance to European union directives

Power requirements

General considerations

Mounting

Field wiring connections

Module Indicators

Section 2.1

Compliance to

European

Union Directives

This product is approved for installation within the European Union and EEA

regions. It has been designed and tested to meet the following directives.

2.1.1 EMC Directive

The 1762sc-OF8 module is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards, in whole or

in part, documented in a technical construction file:

IEC 61000-6-4 Electromagnetic compatibility (EMC)–Part 6-4: Generic

standards–Emission standard for industrial environments

IEC 61000-6-2 Electromagnetic compatibility (EMC)–Part 6-2: Generic

standards–Immunity for industrial environments

This product is intended for use in an industrial environment.

Section 2.2

Power

Requirements

The module receives power through the bus interface from the +5 VDC/+24

VDC system power supply. The maximum current drawn by the module is

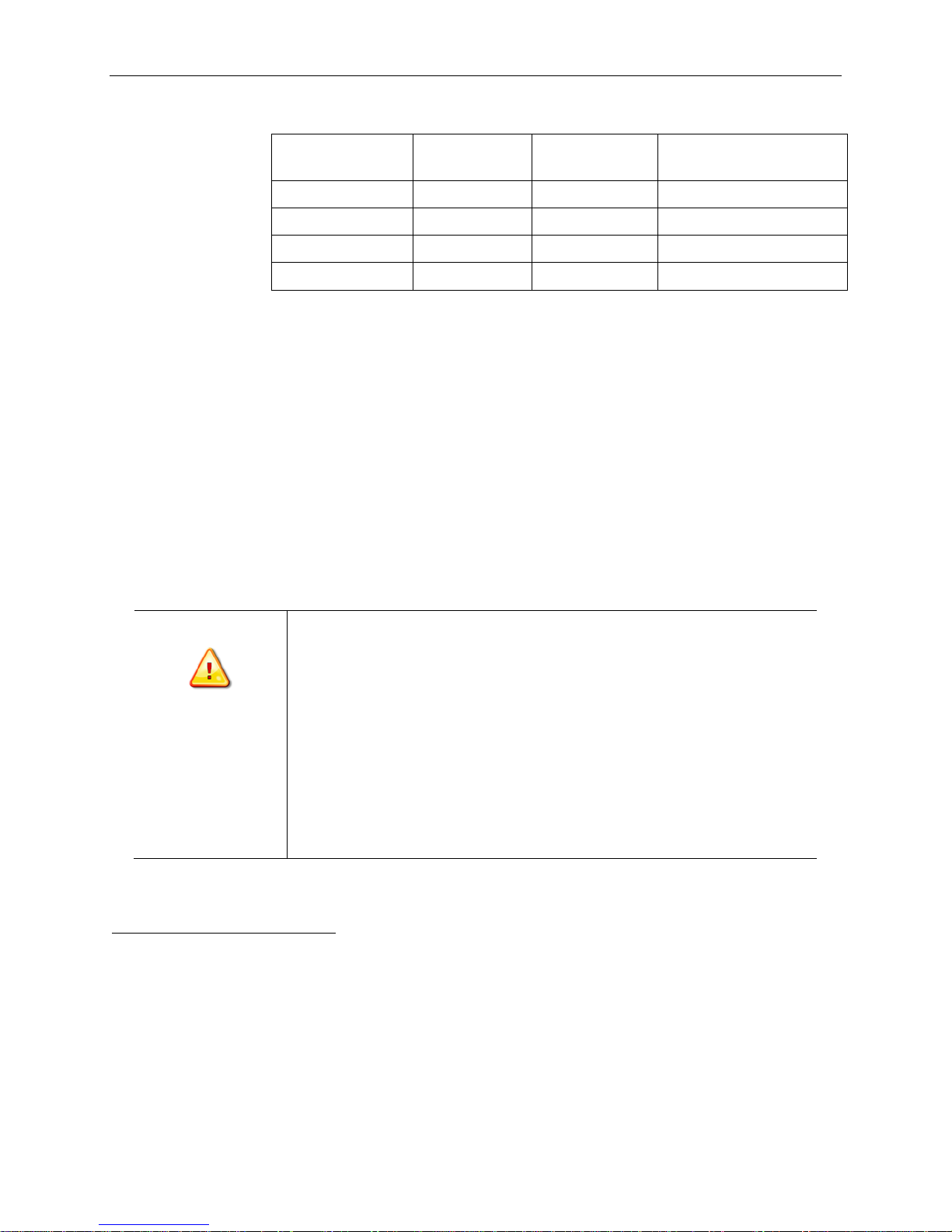

shown in the table below.

5 VDC

24 VDC

30 mA

250 mA at 18.7 V, 195 mA at 24 V

Use the table below to determine the maximum number of OF8 modules that can

be installed in a MicroLogix system.

Page 12

2-2 Chapter 2: Installation and Wiring

User’s Manual Pub. 0300246-01 Rev. C

Table 2-1

Controller

Max 5 V Bus

Current mA)

Max 24 V Bus

Current (mA)

Max # of OF8 Modules

ML1100

800

700

3

ML1200 (24 pt.)

400

350

1

ML1200 (40 pt.)

600

500 2 ML1400 (All)

1500

1500

6

Section 2.3

General

Considerations

1762 I/O is suitable for use in an industrial environment when installed in

accordance with these instructions. Specifically, this equipment is intended for

use in clean, dry environments Pollution degree 22 and to circuits not exceeding

Over Voltage Category II3(IEC 60664-1)4.

2.3.1 Hazardous Location Considerations

This equipment is suitable for use in Class I, Division 2, Groups A, B, C, D or

non-hazardous locations only. The following WARNING statement applies to

use in hazardous locations.

WARNING

EXPLOSION HAZARD

Substitution of components may impair suitability for Class I,

Division 2. Touch a grounded object to discharge static potential.

Do not replace components or disconnect equipment unless power

has been switched off or the area is known to be non-hazardous.

Touch a grounded object to discharge static potential.

This product must be installed in an enclosure. Touch a grounded

object to discharge static potential.

All wiring must comply with N.E.C. article 501-4(b). Touch a

grounded object to discharge static potential.

2

Pollution Degree 2 is an environment where, normally, only non-conductive pollution occurs except that

occasionally a temporary conductivity caused by condensation shall be expected.

3

Over Voltage Category II is the load level section of the electrical distribution system. At this level

transient voltages are controlled, and do not exceed the impulse voltage capability of the product’s

insulation.

4

Pollution Degree 2 and Over Voltage Category II are International Electrotechnical Commission (IEC)

designations.

Page 13

Chapter 2: Installation and Wiring 2-3

User’s Manual Pub. 0300246-01 Rev. C

2.3.2 Prevent Electrostatic Discharge

WARNING

Electrostatic discharge can damage integrated circuits or semiconductors if

you touch analog I/O module bus connector pins or the terminal block on

the module. Follow these guidelines when you handle the module:

Touch a grounded object to discharge static potential.

Wear an approved wrist-strap grounding device.

Do not touch connectors or pins on component boards.

Do not touch circuit components inside the module.

If available, use a static-safe work station.

When not in use, keep the module in its static-shield box.

2.3.3 Remove Power

WARNING

Remove power before removing or inserting this module. When you

remove, or insert, a module with power applied, an electrical arc may

occur. An electrical arc can cause personal injury or property damage by:

Sending an erroneous signal to your system’s field devices,

causing unintended machine motion.

Causing an explosion in a hazardous environment.

Electric arcing causes excessive wear to contacts on both the

module and its mating connector, and may lead to premature

failure.

2.3.4 Selecting a Location

2.3.5 Reducing Noise

Most applications require installation in an industrial enclosure to reduce the

effects of electrical interference. Analog inputs are highly susceptible to

electrical noise. Electrical noise coupled to the analog inputs will reduce the

performance (accuracy) of the module. Group your modules to minimize adverse

effects from radiated electrical noise and heat. Consider the following conditions

when selecting a location for the analog module. Position the module:

Away from sources of electrical noise such as hard-contact switches,

relays, and AC motor drives.

Away from modules which generate significant radiated heat. Refer to

the module’s heat dissipation specification.

In addition, route shielded, twisted-pair analog input wiring away from any high

voltage I/O wiring.

Page 14

2-4 Chapter 2: Installation and Wiring

User’s Manual Pub. 0300246-01 Rev. C

Section 2.4

Mounting

WARNING

Do not remove protective debris strip until after the module and all other

equipment near the module is mounted and wiring is complete. Once

wiring is complete, and the module is free of debris, carefully remove

protective debris strip. Failure to remove strip before operating can cause

overheating.

2.4.1 Minimum Spacing

Maintain spacing from enclosure walls, wireways, adjacent equipment, etc.

Allow 50.8 mm (2 in.) of space on all sides for adequate ventilation, as shown:

Figure 2-1

NOTE

1762 expansion I/O may only be mounted horizontally.

WARNING

During panel or DIN rail mounting of all devices, be sure that all debris

(metal chips, wire strands, etc.) is kept from falling into the module.

Debris that falls into the module could cause damage when power is

applied to the module.

2.4.1 DIN Rail Mounting

The module can be mounted using the following DIN rails: 35 × 7.5 mm (EN 50

022 - 35 × 7.5) or 35 × 15 mm (EN 50 022 - 35 × 15).

Before mounting the module on a DIN rail, close the DIN rail latch. Press the

DIN rail mounting area of the module against the DIN rail. The latch will

momentarily open and lock into place.

Page 15

Chapter 2: Installation and Wiring 2-5

User’s Manual Pub. 0300246-01 Rev. C

Use DIN rail end anchors (Allen-Bradley part number 1492-EA35 or 1492EAH35) for environments with vibration or shock concerns.

Figure 2-2

NOTE

For environments with extreme vibration and shock concerns, use the

panel mounting method described below, instead of DIN rail mounting.

2.4.2 Panel Mounting

Use the dimensional template shown below to mount the module. The preferred

mounting method is to use two M4 or #8 Pan Head screws per module. M3.5 or

#6 Pan Head screws may also be used, but a washer may be needed to ensure a

good ground contact. Mounting screws are required on every module.

Figure 2-3

Page 16

2-6 Chapter 2: Installation and Wiring

User’s Manual Pub. 0300246-01 Rev. C

Section 2.5

System

Assembly

The expansion I/O module is attached to the controller or another I/O module by

means of a ribbon cable after mounting as shown below.

Figure 2-4

NOTE

Use the pull loop on the connector to disconnect modules. Do not pull on

the ribbon cable.

WARNING

EXPLOSION HAZARD

In Class I, Division 2 applications, the bus connector must be fully

seated and the bus connector cover must be snapped in place.

In Class I, Division 2 applications, all modules must be mounted

in direct contact with each other as shown in the graphic. If DIN

rail mounting is used, an end stop must be installed ahead of the

controller, and after the last 1762 I/O module.

Section 2.6

Field Wiring

Connections

Consider the following when wiring your system:

General

Power and output wiring must be in accordance with Class 1, Division 2

wiring methods, Article 501-4(b) of the National Electric Code, NFPA

70, and in accordance with the authority having jurisdiction.

The analog common (COM) is not connected to earth ground inside the

module. All terminals are electrically isolated from the system.

Page 17

Chapter 2: Installation and Wiring 2-7

User’s Manual Pub. 0300246-01 Rev. C

To ensure optimum accuracy for voltage type outputs, limit overall cable

impedance by keeping all analog cables as short as possible. Locate the

I/O system as close to your voltage type sensors or actuators as possible.

Digital and analog power must be supplied by an Isolated Secondary

Limited Energy Low Voltage source.

Use Belden™ 8761, or equivalent, shielded wire.

WARNING

USE SUPPLY WIRES SUITABLE FOR 20 °C ABOVE

SURROUNDING AMBIENT TEMPERATURE.

WARNING

UTILISER DES FILS D’ALIMENTATION QUI CONVIENNENT A

UNE TEMPERATURE DE 20 °C AU-DESSUS DE LA

TEMPERATURE AMBIANTE.

Grounding

This product is intended to be mounted to a well-grounded mounting

surface such as a metal panel. Additional grounding connections from

the module’s mounting tabs or DIN rail (if used) are not required unless

the mounting surface cannot be grounded.

Under normal conditions, the drain wire (shield) should be connected to

the metal mounting panel (earth ground). Keep shield connection to earth

ground as short as possible.

Ground the shield drain wire at one end only. The typical location is at

the module end.

If it is necessary to connect the shield drain wire at the module end,

connect it to earth ground using a panel or DIN rail mounting screw.

Refer to Industrial Automation Wiring and Grounding Guidelines, Allen-

Bradley publication 1770-4.1, for additional information.

Noise Prevention

Route field wiring away from any other wiring and as far as possible

from sources of electrical noise, such as motors, transformers, contactors,

and ac devices. As a general rule, allow at least 15.2 cm (6 in.) of

separation for every 120 V of power.

Routing field wiring in a grounded conduit can reduce electrical noise.

If field wiring must cross ac or power cables, ensure that they cross at

right angles.

If noise persists for a device, try grounding the opposite end of the cable

shield or ground both ends of the shield.

Page 18

2-8 Chapter 2: Installation and Wiring

User’s Manual Pub. 0300246-01 Rev. C

2.6.1 Wiring Diagram

Refer to the following wiring diagrams for field wiring connections.

WARNING

All return terminals are electrically tied together, but each output should

use its own associated return terminal for best accuracy.

2.6.2 Wiring the Finger-Safe Terminal Block

Figure 2-6

OUT 0

Shield

OUT 2

OUT 3

OUT 4

OUT 5

OUT 6

OUT 7

RTN 0

RTN 1

RTN 2

RTN 3

RTN 4

RTN 5

RTN 7

NC

NC

RTN 6

+

-

OUT 1

Load

Figure 2-5 (Wiring Diagram)

Page 19

Chapter 2: Installation and Wiring 2-9

User’s Manual Pub. 0300246-01 Rev. C

WARNING

Be careful when stripping wires. Wire fragments that fall into a module

could cause damage when power is applied. Once wiring is complete,

ensure the module is free of all metal fragments.

When wiring the terminal block, keep the finger-safe cover in place.

1. Refer to section 2.6.1 for proper field wiring connections.

2. Route the wire under the terminal pressure plate. You can use the

stripped end of the wire or a spade lug. The terminals will accept a 6.35

mm (0.25 in.) spade lug. See Figure 2-6.

3. Tighten the terminal screw making sure the pressure plate secures the

wire. Recommended torque when tightening terminal screws is 0.904

Nm (8 in-lbs).

4. After wiring is complete, remove the debris shield.

2.6.3 Terminal Door Label

A removable, write-on label is provided with the module. Remove the label from

the door, mark your unique identification of each terminal with permanent ink,

and slide the label back into the door. Your markings (ID tag) will be visible

when the module door is closed.

See figure below.

Figure 2-7 (Door Label)

Page 20

2-10 Chapter 2: Installation and Wiring

User’s Manual Pub. 0300246-01 Rev. C

Section 2.7

Module Indicators

The 1762 output module uses a single green LED to show operational status of

the module. The LED will illuminate solid when the PLC is in run mode and the

module properly configured. If the module is not properly configured, or if the

PLC is not in run mode, the LED will blink rapidly. The following blink codes

are the only exception:

Table 2-2 (LED Blink Codes)

Blink Code

Description

Rapid Blink5

PLC not in run mode, or no valid module configuration present

Solid

Module is in run mode (Normal Operation)

3

Factory calibration in progress

4

Factory calibration invalid

5

Module is in command mode

5

All outputs are disabled until the PLC goes into run mode, and the module receives a valid configuration.

Page 21

User’s Manual Pub. 0300246-01 Rev. C

Chapter 3

Configuring the 1762sc-OF8

Using RSLogix 500

This chapter covers the following subjects:

Things you should know

Module memory map

Add module to Logix 500

Module configuration

Module status

Configuration Ladder Sample

Section 3.1

Things You

Should Know

This chapter describes how to configure the OF8 module for the MicroLogix

1100, 1200, and 1400 system using RSLogix 500 programming software.

Section 3.2

Module Memory

Map

The module uses 8 input words and 8 output words for input data and

configuration. The following figure describes the data mapping for the module.

Input Image

I:0 to I:7 (8 words)

(Input Data)

Output Image

O:0 to O:7 (8 words)

(Configuration or

Output Data)

1762sc-OF8

Read

Write

Figure 3-1 (Module Memory Map)

Page 22

3-2 Chapter 3: Configuring the 1762sc-OF8 for RSLogix 50

User’s Manual Pub. 0300246-01 Rev. C

Section 3.3

Add Module

to Logix 500

The following procedure describes how to add the OF8 module to the RSLogix

500 programming software.

1. Create a new RSLogix 500 project and select either a Micro 1100, 1200,

or 1400 processor.

2. Double-click I/O Configuration from the project tree.

3. Select the first empty slot and then double-click the Other—Requires

I/O Card Type ID option, from the I/O configuration screen.

Page 23

Chapter 3: Configuring the 1762sc-OF8 for RSLogix 500 3-3

User’s Manual Pub. 0300246-01 Rev. C

4. Enter the module profile data as shown in the figure below and click OK.

5. Repeat steps 1 through 4 for additional modules.

Section 3.4

Module

Configuration

The OF8 module is configured using a process that employs the input and output

files. The following flow chart describes the configuration process.

Transition

To

Run

Unlock

Command

Issued

Write

Configuration

Data

Issue Load

Configuration

Command

Issue

Exit

Command

600 ms

Delay

Module

Enters Run

Mode

Page 24

3-4 Chapter 3: Configuring the 1762sc-OF8 for RSLogix 50

User’s Manual Pub. 0300246-01 Rev. C

WARNING

Each command issued will have a corresponding module response in the

input data file. See Section 3.5.1 for more information.

WARNING

For proper operation, during the 600 ms delay, the output words should be

set to the correct command values to avoid sending erroneous analog

signals.

3.4.1 Output Data File (Command Mode)

The output data file is used to configure each channel for the OF8 as well as

control the output signal of each channel. Use the addressing scheme below to

locate the 8 output words needed to configure the module.

Figure 3-2 (Output Addressing Scheme)

1. I/O located on the controller (embedded I/O) is slot 0. I/O added to the

controller (expansion I/O) begins with slot 1.

The module enters a special mode called Command Mode when the PLC

transitions from Program mode to Run mode. When the module enters

Command Mode, the output file is used to send commands to the module and the

module responds via the input data file. The table below shows the layout for

each output word during both modes of operation. See Table 3-6 for command

mode response data.

Page 25

Chapter 3: Configuring the 1762sc-OF8 for RSLogix 500 3-5

User’s Manual Pub. 0300246-01 Rev. C

Table 3-1 (Normal Mode/Command Mode)

Output File

Output

Word

Normal Run Mode

Command Mode

O:e.0

Channel 0 Data Word

Command

O:e.1

Channel 1 Data Word

Data Word 1 (Ch0 & 1)6

O:e.2

Channel 2 Data Word

Data Word 2 (Ch2 & 3)6

O:e.3

Channel 3 Data Word

Data Word 3 (Ch4 & 5)6

O:e.4

Channel 4 Data Word

Data Word 4 (Ch6 & 7)6

O:e.5

Channel 5 Data Word

Fixed Word 1 (0×CDEF)

O:e.6

Channel 6 Data Word

Fixed Word 2 (0×FEDC)

O:e.7

Channel 7 Data Word

Fixed Word 3 (0×5A5A)

Once the module detects the transition from Program to Run it waits until the

Fixed Words and Command code are set to valid values. The first command

must be Unlock. If an error is detected, a non-zero response will be placed in the

Response Code (see Input Data File table).

Keep in mind the module is constantly polling the output file as it is updated by

the controller. The module will validate each command using the following three

step process:

1. Validate Fixed Words 1-3:

These words must always be valid during Command Mode. An error

will be posted in the Response Code until these are correct. Commands

will not be validated and processed until these words are set correctly.

The fixed words are posted above in Table 3-1.

2. Validate Command:

If the Fixed Words are valid, the Command word will be checked. If it is

not set to a valid command, an error will be reported. Initially the

module only checks for the Unlock command. After the Unlock

command is detected, the module must detect a transition in the

Command word to trigger a new command. The available commands are

listed in the table below.

6

See Table 3-3 (Data Words 1 through 4)

Page 26

3-6 Chapter 3: Configuring the 1762sc-OF8 for RSLogix 50

User’s Manual Pub. 0300246-01 Rev. C

Table 3-2 (Commands)

Command

Value

Description

Unlock

0×FFF0

This MUST be the first command issued after entering

Command Mode. If not, an error will be posted. Data

Words are ignored when the module enters command

mode.

The module does not need to detect a command

transition to Unlock. It simply waits for the Fixed

Words to be valid and Unlock command set. This

command is ignored if issued multiple times

(Response Code will be 0).

Once Command Mode is unlocked it remains unlocked

until it has been successfully configured and the Exit

command issued.

Clear

Command

0×FF00

Clears the command buffer to allow a command to be

re-issued. Since the module only knows a command is

issued when the Command word changes, the only

way to re-issue a command is to cause a transition.

This command gives the user a null command to do

that. The response is always 0. No other action is

taken with this command.

Load

Config

0×FFF1

Data Words 1-4 must contain valid channel

configuration data for all channels. See Data Words

table below.

Configuration will be validated. An error will be

posted for the first invalid channel configuration

found. If the configuration is invalid, the configuration

info in the Data Words may be modified but to re-issue

the Load Config, the Clear Command must be issued

first.

Exit

0×FF80

Delay 600 ms and then enter run state with

configuration. The delay begins after the response. If

configuration is not valid, the module will remain in

Command Mode until a valid configuration is entered.

1. Data Words 1-4:

If the command requires valid data in the Data Words, they are validated

and a response is placed in the Response Code register (i.e. Word I:e.1).

See section 3.5.1 for a description of each response code.

The following table lists the possible configuration settings for each of

the 8 channels. Each Data Word contains two channel configurations.

See Table 3-1 for Data Word layout.

Page 27

Chapter 3: Configuring the 1762sc-OF8 for RSLogix 500 3-7

User’s Manual Pub. 0300246-01 Rev. C

Table 3-3 (Data Words 1 through 4)

To Select

Channels 1, 3, 5, or 7

Channels 0, 2,4 or 6

15

14

13

12

11

10 9 8 7 6 5 4 3 2 1 0

Output Type

4 to 20 mA

0 0

0

0 0

0

0 to 20 mA

0 0 1 0 0

1

-10 to 10 V

0 1 0 0 1

0

0 to 10 V

0 1 1 0 1

1

1 to 5 V

1 0 0 1 0 0 0 to 5 V

1 0 1 1 0 1 Reserved

1 1 0 1 1 0 Channel Disabled

1 1 1 1 1

1

Data Format

Scaled for PID

0 0

0 0

Engineering Units

0 1 0 1 Percent Range

1 0 1 0 Raw/Proportional Data

1 1 1 1 Unused

0 0 0 0 0 0

Table 3-4 (Data Format)

Output Range

Output Value

Condition

Raw/Prop

EU

PID

% FS

4..20 mA

20.40 mA

High Limit

32767

20400

16793

10250

20.00 mA

High Range

31176

20000

16383

10000

4.00 mA

Low Range

-32450

4000

0

0

3.92 mA

Low Limit

-32768

3920

-82

-50

0..20 mA

20.40 mA

High Limit

32767

20400

16711

10200

20.00 mA

High Range

31482

20000

16383

10000

0.00 mA

Low Limit/Range

-32768

0 0 0

+/-10 V

11.00 VDC

High Limit

32767

11000

17202

11000

10.00 VDC

High Range

29788

10000

16383

10000

-10.00 VDC

Low Range

-29788

-10000

0

-10000

-11.00 VDC

Low Limit

-32768

-11000

-819

-11000

0 to 5 V

5.50 VDC

High Limit

32767

5500

18021

11000

5.00 VDC

High Range

26809

5000

16383

10000

0.00 VDC

Low Range

-32768

0 0 0

0.00 VDC

Low Limit

-32768

0 0 0

0 to 10 V

11.00 VDC

High Limit

32767

11000

18021

11000

10.00 VDC

High Range

26809

10000

16383

10000

0.00 VDC

Low Range

-32768

0 0 0

Page 28

3-8 Chapter 3: Configuring the 1762sc-OF8 for RSLogix 50

User’s Manual Pub. 0300246-01 Rev. C

Output Range

Output Value

Condition

Raw/Prop

EU

PID

% FS

0.00 VDC

Low Limit

-32768

0 0 0

1 to 5V

5.50 VDC

High Limit

32767

5500

18431

11250

5.00 VDC

High Range

26809

5000

16383

10000

1.00 VDC

Low Range

-20853

1000

0 0 0.00 VDC

Low Limit

-32768

000

-4096

-2500

3.4.2 Output Data File (Normal Run Mode)

The output data file is used to configure each channel for the OF8 as well as

control the output signal of each channel. Use the addressing scheme shown in

Figure 3-2 above.

In normal run mode, output words 0 through 7 control the analog output signal

for channels 0 through 7 respectively. See Table 3-1 above.

Section 3.5

Module Status

Input data for the OF8 consists of status information, channel configuration

information and module configuration status.

3.5.1 Input Data File (Command Mode)

In command mode, the input data file returns module configuration status used

during the configuration process. Refer to section 3.4.1 for more information

regarding command mode. Use the addressing scheme below to locate the 8

input words.

Figure 3-3 (Input Addressing Scheme)

1. I/O located on the controller (embedded I/O) is slot 0. I/O added to the

controller (expansion I/O) begins with slot 1.

The layout for the input data file is shown below.

Page 29

Chapter 3: Configuring the 1762sc-OF8 for RSLogix 500 3-9

User’s Manual Pub. 0300246-01 Rev. C

Table 3-5 (Input Data File)

Input Word

Normal Run Mode

Command Mode

I:e.0

General Status Word 0

Command Echo

I:e.1

Output Status Word 1 (Ch 0-3)

Response Code

I:e.2

Output Status Word 2 (Ch 4-7)

Response Channel

I:e.3

Echo Config (Ch 0-1)

I:e.4

Echo Config (Ch 2-3)

I:e.5

Echo Config (Ch 4-5)

I:e.6

Echo Config (Ch 6-7)

I:e.7

Not Used

The following table describes each of the input data words when in command

mode.

Table 3-6 (Input Words - Command Mode)

Word

Description

Command Echo (Word 0)

Matches Command Word 0 (that is, O:e.0).

When this word matches the Command Word, it

indicates the command is complete. The

Response Code is now valid.

Response Code (Word 1)

Non-zero is an error (see Response Codes). This

is valid only when Command Echo matches

Command Word.

Response Channel (Word 2)

If Response Code error, indicates which

channel. Only applies to commands that involve

channels.

Echo of Data (Word 1)

Chan 1 Config

Chan 0 Config

Echo of Data (Word 2)

Chan 3 Config

Chan 2 Config

Echo of Data (Word 3)

Chan 5 Config

Chan 4 Config

Echo of Data (Word 4)

Chan 7 Config

Chan 6 Config

Not Used (Word 7)

Page 30

3-10 Chapter 3: Configuring the 1762sc-OF8 for RSLogix 50

User’s Manual Pub. 0300246-01 Rev. C

Table 3-7 (Response Codes)

Name

Value

Description

Success

0×0000

The command was completed successfully.

Invalid

Command

0×F001

An invalid command code was issued.

Locked

0×F002

A command was issued before the Unlock was

given.

Invalid State

0×F003

One or more Fixed Words invalid. The module

will remain in its previous state until all of the

words are set correctly.

Invalid Config

0×F004

A configuration for one of the channels is

invalid. Check Response Channel to determine

which one. First error detected is displayed.

No Config

0×F005

An attempt was made to exit Command Mode

before a configuration was loaded. Either load

the default config or manually enter a

configuration for all channels.

Invalid Cal

0×F006

Calibration is invalid. Module requires factory

calibration before it can be configured.

NOTE

Response codes are not to be considered valid until the Command Echo

matches the issued command.

NOTE

Response codes will remain valid after the Exit command until the timeout

expires. After that, normal Input File operation takes over. Words 0-2 are

status.

3.5.2 Input Data File (Normal Run Mode)

In normal run mode, the input data file displays general module status, channel

status, and an echo of each channel configuration.

Use the addressing scheme in Figure 3-3 to locate the 8 input words.

Page 31

Chapter 3: Configuring the 1762sc-OF8 for RSLogix 500 3-11

User’s Manual Pub. 0300246-01 Rev. C

Table 3-8 (Input Words - Normal Run Mode)

Word

Bit

15

14

13

12

11

10 9 8 7 6 5 4 3 2 1 0

General Status

(Word 0)

I:e.0

- - - - - - - - S7

S6

S5

S4

S3

S2

S1

S0

Output Status

(Word 1)

I:e.1

-

LD3

U3

O3 - LD2

U2

O2 - LD1

U1

O1 - LD0

U0

O0

Output Status

(Word 2)

I:e.2

-

LD7

U7

O7 - LD6

U6

O6 - LD5

U5

O5 - LD4

U4

O4

Echo Config

(Word 3)

<Ch 1 Config>7

<Ch 0 Config>7

Echo Config

(Word 4)

<Ch 3 Config>7

<Ch 2 Config>7

Echo Config

(Word 5)

<Ch 5 Config>7

<Ch 4 Config>7

Echo Config

(Word 6)

<Ch 7 Config>7

<Ch 6 Config>7

Not Used (Word

7)

0x0000

- = Not used. Bit set to 0.

S<x> = General status bit.

If a bit is set (1) then there is an error associated with that channel (i.e.

under/over range).

When set to 1, indicates the output word value set by the user is below the

defined Low Range value (see Output Data Format table). The channel will

output voltage or current (depending on the range type) to the Low Limit value.

O<x> = Over range flag.

When set to 1, indicates the output word value set by the user is above the

defined High Range value (see Output Data Format table). The channel will

output voltage or current (depending on the range type) up to the High Limit

value.

LD<x> = Load Error. If the channel is configured for voltage mode, this bit

indicates a short circuit. If the channel is configured for current mode, open

circuit is indicated. The error bit is cleared (0) at the time the condition is

cleared.

Section 3.6

Configuration

Ladder Sample

The following ladder sample demonstrates how to configure the module when

the PLC transitions from Program to Run, using the process described in Section

3.4.

7

See Table 3-3 (Data Words 1 through 4)

Page 32

3-12 Chapter 3: Configuring the 1762sc-OF8 for RSLogix 50

User’s Manual Pub. 0300246-01 Rev. C

WARNING

Use the “Command” bit (B3:0/0) in the following ladder sample as a

condition before any instruction that writes data to one of the 8 module

output words. Failure to do so can result in the module rejecting the

configuration and not going into run mode (i.e. a rapid blinking module

status LED).

Page 33

Chapter 3: Configuring the 1762sc-OF8 for RSLogix 500 3-13

User’s Manual Pub. 0300246-01 Rev. C

Page 34

3-14 Chapter 3: Configuring the 1762sc-OF8 for RSLogix 50

User’s Manual Pub. 0300246-01 Rev. C

Getting Technical

Assistance

Note that your module contains electronic components which are susceptible to

damage from electrostatic discharge (ESD). An electrostatic charge can

accumulate on the surface of ordinary plastic wrapping or cushioning material.

In the unlikely event that the module should need to be returned to

Spectrum Controls, Inc., please ensure that the unit is enclosed in approved

ESD packaging (such as static-shielding / metalized bag or black conductive

container). Spectrum Controls, Inc. reserves the right to void the warranty on

any unit that is improperly packaged for shipment.

RMA (Return Merchandise Authorization) form required for all product returns.

For further information or assistance, please contact your local distributor, or call

the Spectrum Controls Technical Support at:

USA - 425-746-9481

Declaration of

Conformity

Available upon request

Page 35

User’s Manual Pub. 0300246-01 Rev. C

Appendix A

Module Specifications

General Specifications

Specification

Value

Dimensions

90 mm (height) × 87 mm (depth) × 40 mm (width)

height including mounting tabs is 110 mm

3.54 in. (height) × 3.43 in. (depth) × 1.58 in. (width)

height including mounting tabs is 4.33 in.

Approximate Shipping Weight (with

carton)

279 g (0.615 lbs.)

Storage Temperature

-40 °C to +85 °C (-40 °F to +185 °F)

Operating Temperature

-20 °C to +60 °C (-4 °F to +140 °F)

Operating Humidity

5% to 95% non-condensing

Operating Altitude

2000 meters (6561 feet)

Vibration

Operating: 10 to 500 Hz, 5 G, 0.030 in. max. peak-topeak

Shock

Operating: 30 G

Bus Current Draw (max.)

30 mA at 5 VDC Max

250 at 18.7 V, 195 mA at 24 V

Heat Dissipation

4.9 W Total Max

Maximum number of modules on the

bus

Distance rating of 6. Maximum number of modules by

controller type:

Controller

Max 5 V

Bus

Current

Max 24 V

Bus

Current

Max # of

Modules

ML1100

800

700 3 ML1200 (24 pt.)

400

350 1 ML1200 (40 pt.)

600

500 2 ML1400

1500

1500

6

Fusing

None

Wire Size

Up to two wires of size #14-#22 AWG (solid) or #16#22 AWG (stranded)

Wire Type

To ensure proper operation and high immunity to

electrical noise, always use Belden 8761 (shielded,

twisted pair) or equivalent wire for voltage and current

sensors

Page 36

A-2 Appendix A: Specifications

User’s Manual Pub. 0300246-01 Rev. C

Specification

Value

Isolation

Channel to Rack

707 VDC for 1 minute (withstand voltage)

Channel to Channel

Return lines are connected together. No isolation

between channels.

Module Power LED

On: indicates power is applied and module not faulted.

See Section 1.4.1 for more information.

Vendor I.D.

58

Product Type

10

Product Code

21

Agency Certification

C-UL listed (under CSA C22.2 No. 142) UL 508 listed

CE compliant for all applicable directives

Hazardous Environment

Class

Class I, Division 2, Hazardous Location, Groups A, B,

C, D (ISA 12.12.01, C-UL under CSA C22.2 No. 213)

Operating Temperature Code T6

Radiated and

Conducted Emissions

EN61131-2

Electrical /EMC:

The module has passed testing at the following levels:

ESD Immunity

(IEC61000-4-2)

4 kV contact, 8 kV air, 4 kV indirect

Radiated Immunity

(IEC61000-4-3)

10 V/m, 80 to 1000 MHz, 80% amplitude modulation,

+900 MHz keyed carrier

Fast Transient Burst

(IEC61000-4-4)

2 kV, 5 kHz

Surge Immunity

(IEC61000-4-5)

1 kV galvanic gun

Conducted Immunity

(IEC61000-4-6)

10 V, 0.15 to 80 MHz8

8

Conducted Immunity frequency range may be 150 kHz to 30 MHz if the Radiated Immunity frequency

range is 30 MHz to 2700 MHz.

Page 37

Appendix A: Specifications A-3

User’s Manual Pub. 0300246-01 Rev. C

Output Specifications

Specification

Description

Accuracy - Voltage

Outputs

System accuracy at 25 °C: ±20 mV maximum

System accuracy at -20-60 °C: ±50 mV maximum

Accuracy - Current

Outputs

System accuracy at 25 °C: ±0 uA maximum

System accuracy at -20-60 °C: ±75 uA maximum

Output Resolution

(at 25C)

In RAW mode

Voltage Output

400 µV per bit average when using RAW format in

±10 V range and 0-10 V range

185 µV per bit average when using RAW format in

0-5 or 1-5 V ranges

Current Output

380 nA per bit when using RAW format for all

current ranges

Differential

Nonlinearity

±1 LSB

Output Ripple

<15 mV ripple for voltage or current

Output Impedance

Current: >1 Mohm, Voltage: <1 ohm

Output Load

Current: 0 ohm min, 500 ohm max,

Voltage: >=1 kohm at 10 V output (10 mA), includes

wire resistance.

Maximum Output

Inductive and

Capacitive Load

0.1 mH

1 µF

Output Settling

Time

<1ms to 63% of full scale

Output Channel

glitch

Current mode = < ± 1 V for 20 ms at maximum load

Voltage mode = < ± 0.4 V for 20 ms and < ±- 1 V for

1.5 ms with 1 k ohm load

Output Protection

±24 V at 25 °C for 1 minute on any channel, with any

range and value

Short Circuit

Protection

Yes, continuous. (IEC 1131-2 requirement) with any

range and value

Page 38

A-4 Appendix A: Specifications

User’s Manual Pub. 0300246-01 Rev. C

Page 39

User’s Manual Pub. 0300246-01 Rev. C

A

Addressing · 3-4, 3-8, 3-10

B

block diagram · 1-4

C

Configuration · 3-4

Conventions

used in the manual · v

D

Data Format · 1-2

Door Label · 2-9

E

EMC Directive · 2-1

G

Grounding · 2-7

H

Hazardous Location · 2-2

I

Input Data · 3-8

L

LED · 1-3, 2-10

M

Memory Map · 3-1

Mounting

DIN · 2-4

Panel · 2-5

N

Noise · 2-3, 2-7

O

Output Type · 1-1

P

Power Requirements · 2-1

power-up · 1-3

S

Slot number · 3-4

Slot Number · 3-8

Spacing

Minimum · 2-4

T

Technical support

contact information · iv

W

Wiring Diagram · 2-8

Page 40

User’s Manual Pub. 0300246-01 Rev. C

Page 41

User’s Manual Pub. 0300246-01 Rev. C

Page 42

User’s Manual Pub. 0300246-01 Rev. C

©2009 to 2017, Spectrum Controls, Inc. All rights reserved. Specifications subject to change

without notice. The Encompass logo and ControlLogix are trademarks of Rockwell Automation.

Corporate Headquarters

Spectrum Controls Inc.

P.O. Box 6489

Bellevue, WA 98006 USA

Fax: 425-641-9473

Tel: 425-746-9481

Web Site: www.spectrumcontrols.com

E-mail: spectrum@spectrumcontrols.com

Loading...

Loading...