Page 1

de

quant® Pharo 300

Spectroquant

®

Pharo 300

Page 2

Operating manual

en

Spectroquant

®

UV/VIS Spectrophotometer

Pharo 300

Spectroquant

®

Pharo 300

Page 3

Spectroquant

®

UV/VIS Spectrophotometer

Pharo 300

General Information

Spectroquant

®

Pharo 300

Page 4

Spectroquant® photometers

Contents

1 Photometers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Photometry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 The Photometers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Photometric Test Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Basic Principle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.1 Spectroquant® Cell Tests . . . . . . . . . . . . . . . . . . . . 7

2.1.2 Spectroquant® Reagent Tests . . . . . . . . . . . . . . . . . 7

2.2 Notes for Practical Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2.1 Measuring Range . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2.2 Influence of pH . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.3 Influence of Temperature . . . . . . . . . . . . . . . . . . . . 10

2.2.4 Time Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.5 Influence of Foreign Substances. . . . . . . . . . . . . . . 11

2.2.6 Dosing of Reagents . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2.7 Shelf-life of the Reagents . . . . . . . . . . . . . . . . . . . . 12

3 Sample Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1 Taking Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 Preliminary Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3 Dilution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4 Filtration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.5 Homogenization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.6 Decomposition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 Pipetting System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5

Analytical Quality Assurance (AQA)

5.1 Quality Control at the Manufacturer . . . . . . . . . . . . . . . . . . 18

5.2 Quality Control for the User. . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.1 Checking the Photometer . . . . . . . . . . . . . . . . . . . . 20

5.2.2 Checking the Overall System . . . . . . . . . . . . . . . . . 20

5.2.3 Checking the Pipettes . . . . . . . . . . . . . . . . . . . . . . . 21

5.2.4 Checking Thermoreactors. . . . . . . . . . . . . . . . . . . . 21

5.2.5 Testing for Handling Errors . . . . . . . . . . . . . . . . . . . 22

5.3 Determination of Sample Influences . . . . . . . . . . . . . . . . . . 22

5.4 Definition of Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . 18

4

Release 06/2014

Page 5

1 Photometers

1.1 Photometry

Spectroquant® photometers

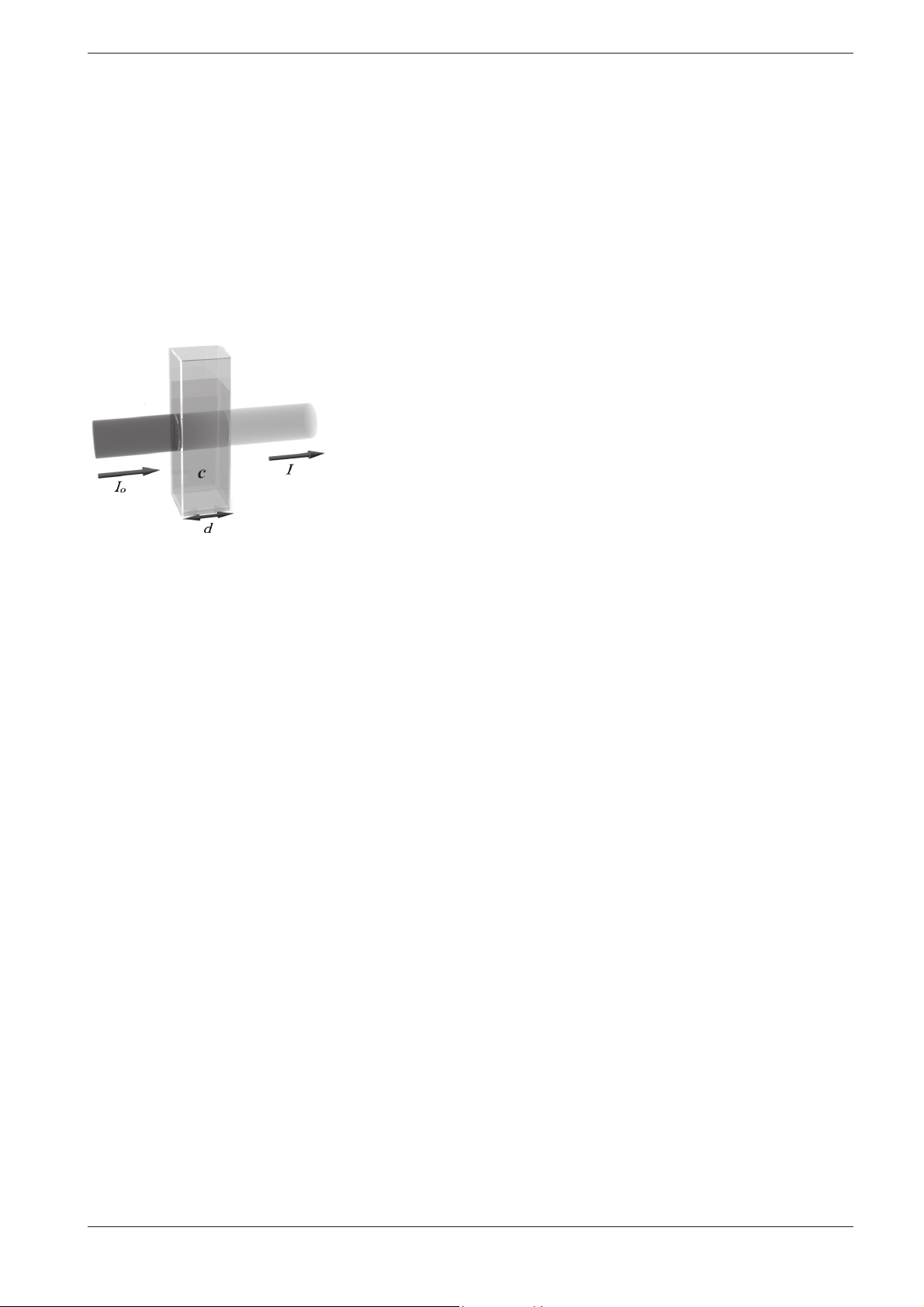

When a beam of light is transmitted through a colored solution, then this

beam loses its intensity, in other words a part of the light is absorbed by

the solution. Depending on the substance in question, this absorption

occurs at specific wave lengths.

Monochromators (e. g. narrow-band interference filters, lattices) are used

to select the wavelength from the total spectrum of a tungsten-halogen

lamp (VIS spectrum), a deuterium lamp (UV spectrum) or, respectively, a

xenon lamp.

The intensity of the absorption can be characterized using the transmittance T (or, respectively, T in percent).

T = I/I

0

I0 = Initial intensity of the light

I = Intensity of the transmitted light

If the light is not absorbed at all by a solution, then this solution has a

transmittance of 100 %; a com plete absorption of the light in the solution

means 0 % transmittance.

The measure generally used for the absorption of light is the absorbance

(A), since this correlates directly with the concentration of the absorbing

substance. The fol lowing connection exists between absorbance and

transmittance:

A = – log T

Experiments by BOUGUER (1698–1758) and LAMBERT (1728 –1777)

showed that the absorbance is dependent on the thickness of the absorbing layer of the cell used. The relationship between the absorbance

and the concentration of the analyte in ques

(1825–1863). The com

bination of these two natu ral laws led to the deri va-

tion was discovered by BEER

tion of Lambert-Beer’s law, which can be described in the form of the following equation:

A = · c · d

=

Molar absorptivity, in l/mol x cm

d = Path length of the cell, in cm

c = Concentration of the analyte, in mol/l

Release 06/2014

5

Page 6

Spectroquant® photometers

1 Photometers

1.2 The Photometers

The photometers that belong to the Spectroquant® Analysis System differ

from con ven tional photo meters in the following important aspects:

The calibration functions of all test kits are electronically stored.

•

The measurement value can be immediately read off from the display

•

in the de sired form.

The method for the test kits (Cell Tests and reagent tests) belonging to

•

the Spectroquant® analysis system is automatically selected via the

scanning of the bar code

All cells formats used are automatically identified and the correct meas-

•

uring range is selected automatically

Instrument-supported AQA ensures that measurement results can be

•

used as secure, reproducible, and recognized analytical results.

New methods can be downloaded from the internet site

•

www.service-test-kits.com and permanently stored in the instrument.

.

.

For technical data and instructions for use please refer to the section

“Function description” or can also be found on the internet.

2 Photometric Test Kits

2.1 Basic Principle

By means of reagents, the component of a sample to be analyzed is converted into a colored compound in a specific reaction. The reagents or

reagent mix tures contain – in addition to the reagent selective for a parameter to be determined – a number of auxi liary substances that are

essential for the course of the reaction. These include, for example, buffers

for adjusting the pH to the optimal value for the reaction, and masking

agents that suppress or mini mize the influence of interfering ions.

The color reactions are in most cases based on standardized analytical

methods specifically optimized in terms of ease of use, a low working

effort, and shorter reaction times. Furthermore, methods cited in the literature or developed by ourselves are also used

erence procedures are stated in the package insert or else in the parameter overview.

. Details on the respective ref-

6

Release 06/2014

Page 7

2 Photometric Test Kits

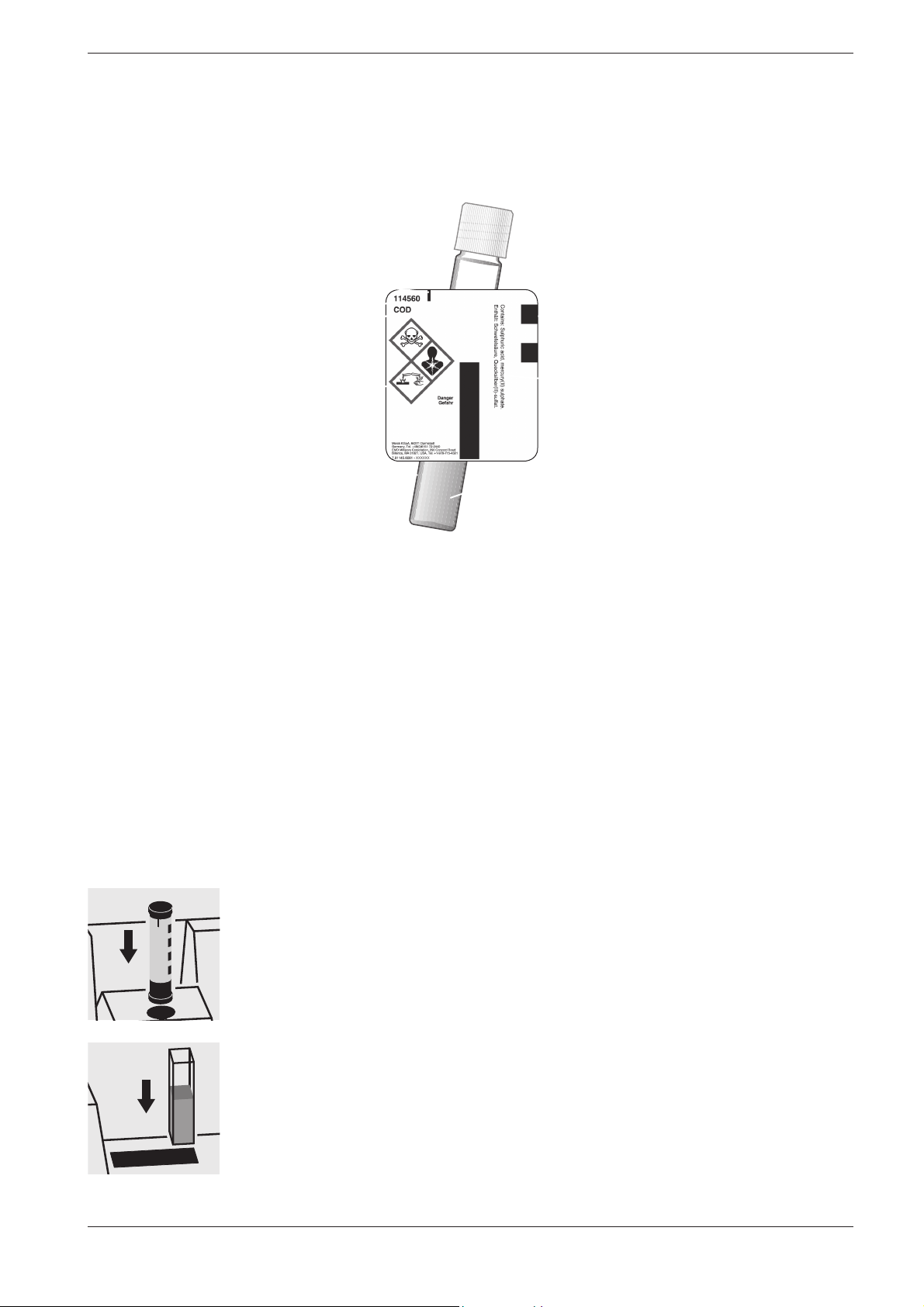

2.1.1 Spectroquant® Cell Tests

Identification mark for the

correct insertion into the cell

compartment of the photometer

Cat. No. of test kit

Spectroquant® photometers

Leakproof cap

Bar code for identification

in the photometer

Designation of test kit

Risk phrases

Special cell in

optical quality

Additional reagent(s)

Certain cell tests, e. g. COD or nitrite, already contain all necessary reagents in the cells, and the sample must merely be added with a pipette.

In other tests, however for reasons of chemical compatibility it is necessary to separate the test into two or three different reagent mixtures. In

such cases, besides the sample a metered reagent must also be added.

2.1.2 Spectroquant® Reagent Tests

The principle behind the reagent tests is that the reagents necessary for the

color reaction are com bined in the form of liquid concentrates or solid-substance mixtures

sample.

enhances the sensitivity of the detection

classical photometry by which the sample is made up to a defined volume

in a volumetric flask is dispensed with.

Details regarding contents

Highly precise dosage of

the reagent

. A few drops of the reagent concentrate are added to the

This means that there is no need to dilute the sample, which in turn

. The procedure generally used in

Release 06/2014

The method is selected automatically by means of the scanning of the bar

code by the AutoSelector.

All cells formats used are automatically identified and the correct measuring range is selected automatically.

Subsequently the result is automatically shown on the display

.

7

Page 8

Spectroquant® photometers

2 Photometric Test Kits

2.2 Notes for Practicle Use

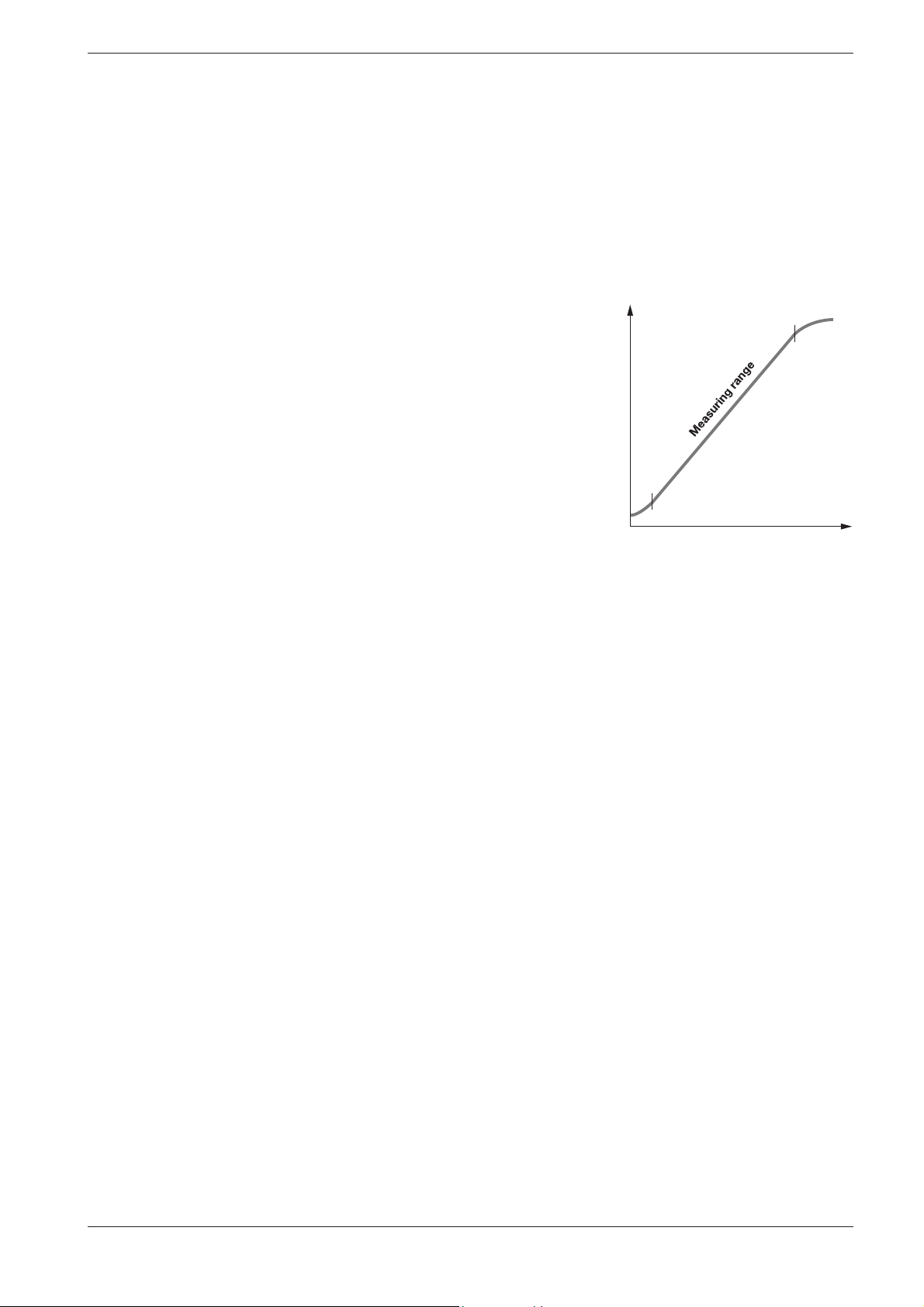

2.2.1 Measuring range

The intensity of the color of a solution, measured as the absorbance, is

proportional to the concentration of the respective analyte only within a

specific range. This mea sur ing range (effective range) is electro nically

stored in the photometers for each in di vidual test kit .

Below the specified measuring range, either a different cell or else another

procedure must be used. The lower limit of the measuring range either

takes the form of non linearity of the calibration curve, as shown in the

figure, or else is given by the method detection limit. The method detec-

tion limit of an analytical method is the lowest concentration of the analyte in question that can be measured quantitatively with a defined degree

of probability (e. g. 99 %).

The upper limit of the measuring range is the point at which the linear

correlation between the concentration and the absorbance ends. In such a

case the sample must be diluted accordingly so that it lies ideally in the

middle of the ef fective range (least-error measurement).

Absorbance

In photometry it is conventional practice to measure against the reagent

blank va lue. Here the analysis is carried out “blind”, i.e. without any analyte added. In stead of the sample volume, the corresponding quantity of

distilled or DI water is used. This reagent blank value is prestored in the

photometers belonging to the Spectroquant® analysis system, which

means that - due to the high batch reproducibility - it is possible to dispense with a separate measurement of the reagent blank. At the lower

limit of the measuring range, the accuracy of the determination can be

enhanced by performing the measurement against a separately prepared

reagent blank.

In some cases the intensity of the color of the solution and thus the absorbance can drop again when very high concentrations of the analyte

are present (see package insert).

Concentration

8

Release 06/2014

Page 9

2 Photometric Test Kits

2.2.2 Influence of pH

Chemical reactions follow an optimal course only within a certain pH

range. The rea gents contained in the test kits produce an adequate buffering of the sample sol u tions and ensure that the pH optimal for the reaction in question is obtained.

Strongly acidic (pH < 2) and strongly alkaline (pH >12) sample solutions

can prevent the pH from being adjusted to an optimal range, since under

certain circumstances the buffering capacity of the test-kit reagents may

not be sufficient. Any necessary correction is made by the dropwise addition of diluted acid (reduces the pH) or diluted lye (raises the pH), testing

the pH with suitable indicator strips after each drop is added. The addition

of the acid or lye results in a dilution of the test solution. When up to five

drops are added to 10 ml of sample, the change in the volume can be

neglected, since the resultant error is lower than 2 %. The addition of larger quantities should be duly con sidered by adjusting the sample volume

accordingly.

The specified pH values for the sample solution and, wherever applicable,

for the measurement solution are defined in the respective package

inserts and in the analy sis instruc tions in chapter 3 of the manual.

Spectroquant® photometers

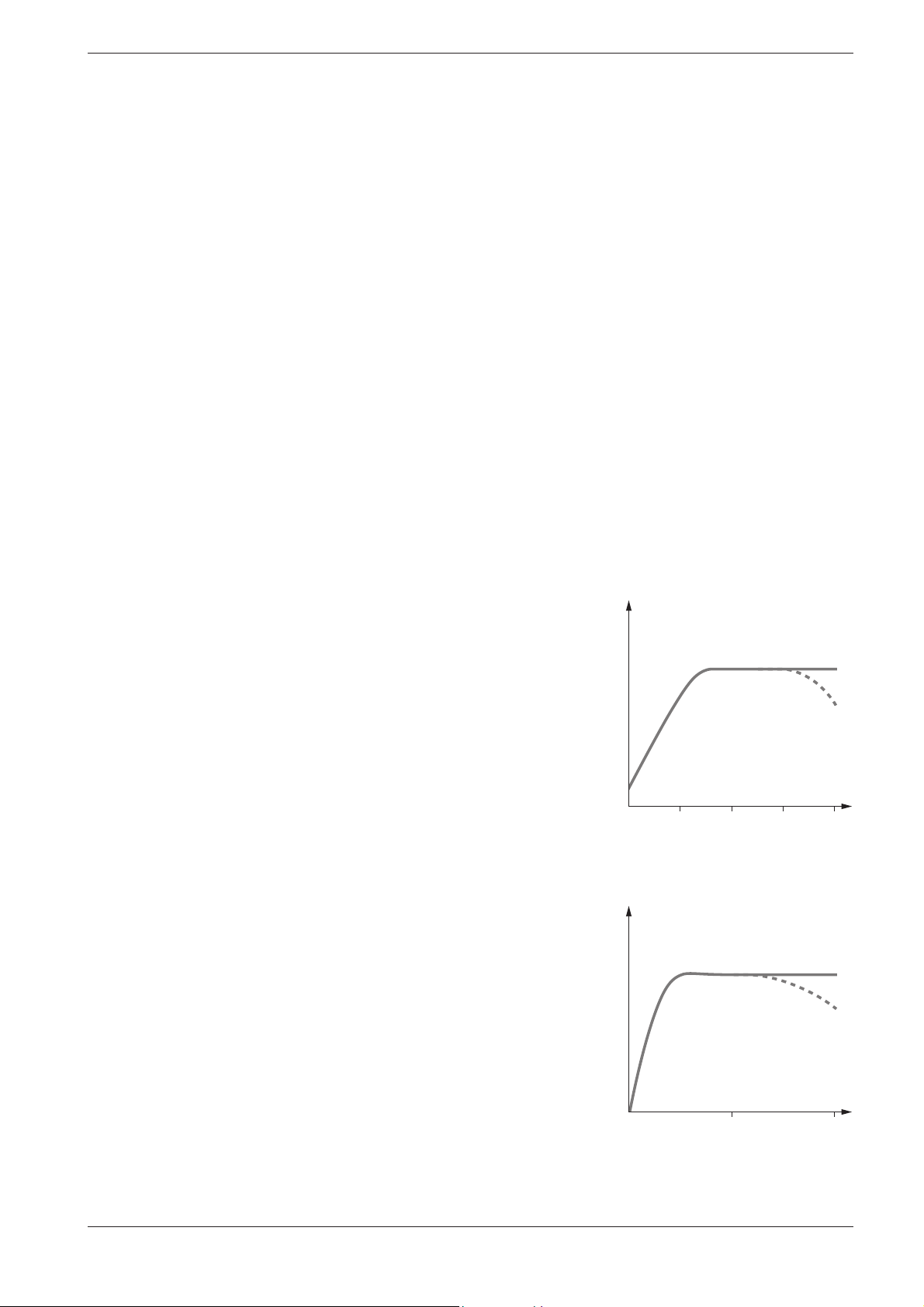

2.2.3 Influence of Temperature

The temperature of the sample solution and the reagents may have an

effect on the color reaction and thus on the measurement result. The typical tempe ra ture course is illustrated in the figure.

If the sample temperature is lower than 15 °C, false-low results must be

reckoned with. Temperatures exceeding 30°C generally influence the stability of the com pound that is formed in the reaction. The optimal temperature for the color reaction is stated in the package inserts of the

respective Spectro quant® test kits.

Attention! After thermic decomposition proce dures, the de termination of COD or total contents of nitro gen, phos pho rus, or metal, a

sufficient wait ing time must be allowed for to permit the solution

cool to room temperature.

2.2.4 Time Stability

Most of the color reactions require a certain time to reach the maximum

color in ten sity. The solid curve in the figure at the right gives a schematic

impression of a typical time course. The behavior of relatively instable color reactions with time is shown by the dotted curve.

The reaction time specified in the working instruc tions refers to the period

of time from the addition of the last reagent until the actual measurement.

In addition, the package inserts for the individual test kits also state the

time interval in which the mea sure ment value does not change. The maximum time inter val is 60 minutes; this time should not be ex ceeded, even in

the case of stable color reactions.

Absorbance

Absorbance

10 30

20 40

Temperature (°C)

Release 06/2014

30 60

Reaction time (minutes)

9

Page 10

Spectroquant® photometers

2 Photometric Test Kits

2.2.5 Influence of Foreign Substances

Foreign substances in the sample solution can

raise the measurement value as a result of an amplification of the

•

reaction

lower the measurement value as a result of a prevention of the reaction.

•

A quantification of this effects is stated in tabular form in the respective

package inserts for the most important foreign ions. The tolerance limits

have been deter mined for the indi vidual ions; they may not be evaluated

cumulatively.

Suitability for use in seawater

A tabular survey (see appendix 1) provides infor mation on the suitability of

the tests in connection with seawater and also on the tolerances for salt

concentrations.

2.2.6 Dosing the Reagents

Small amounts of liquids are dosed by counting the number of drops from

a leak proof bottle

bottle be held vertically and that the drops be added slowly

(approx. 1 drop per second). If this is not observed, the cor-

m

achieved.

A positive-displacement pipette should be used for larger quantities of liquid or for the exact dosage of smaller reagent quantities. In these cases

the reagent bottles are not fitted with a dropper insert.

Solid substances are dosed either with the dose-metering cap or with

microspoons that are integrated into the screw cap of the respective reagent bottle. The dose-metering cap is used for solid reagents or reagent

mixtures that are free-flowing.

In all other cases the substances are dosed with the microspoon.

In this case it is necessary to add only level microspoonfuls. To this end

the spoon must be drawn over the brim of the reagent bottle

When using dropper bottles it is extremely important that the

rect drop size and thus the correct amount of reagent are not

.

.

10

At the first use replace the black screw cap of the reagent bottle by the

dose-metering cap.

Hold the reagent bottle vertically and, at each dosage, press the slide all

the way into the dose-metering cap. Before each dosage ensure that the

slide is completely retracted.

end of the measurement series, since the function of the rea-

m

Reclose the reagent bottle with the black screw cap at the

gent is impaired by the absorption of atmospheric moisture.

Release 06/2014

Page 11

2 Photometric Test Kits

2.2.7 Shelf-life of the Reagents

The Spectroquant

stored in a cool, dry place. A few test kits have a lower shelf-life of 18 or

24 months or must else be stored in a refrigerator.

COD Cell Tests must be stored protected from light.

The expiry date of the package unit is printed on the outer label. The shelflife may become reduced when the reagent bottles are not reclosed tightly

after use or when the test kit is stored at temperatures higher than those

specified.

®

test kits are in most cases stable for 3 years when

3 Sample Preparation

Sample preparation covers all the steps necessary before the actual analysis can be performed.

3.1 Taking Samples

Spectroquant® photometers

The taking of samples is the first and most impor tant step on the way to

obtaining the correct ana lysis result. Not even the most exact method of

analysis can correct any mistakes made in the taking of the sample. The

objective of the sampling proce dure is to gain a sample with a representative com position. The most important pre condition for gain ing a re-

presentative sample is the identification of the suitable sampling site.

Here it must be borne in mind that the solution to be investigated can display varying con centrations in different places at different times.

In sampling, a distinction is made between manual and automatic methods. In many cases a true picture of the average composition of the sample can be obtained only once several individual samples have been collected; this can be done manually or with an automatic sampler.

Clean plastic containers with a volume of 500 or 1000 ml are suitable for

collecting samples. They should be rinsed several times, under vigorously

shaken, with the water to be investigated, and then filled free of air bubbles and immediately closed tightly. The containers must be protected

against the effects of air and heat and then be forward ed for the further

analytical steps as soon as possible. In ex ceptional cases, preserva tion

measures in the form of short-term refrigeration at +2 to + 5 °C and

chemical conservation can be taken.

Parameter Preservation

COD +2 to + 5 °C max. 24 h or

–18 °C max. 14 days

N compounds: analyze immediately, only in exceptional case

NH4-N, NO3-N, NO2-N

P compounds: short-term storage, no preservation;

PO

-P, P total with nitric acid to

4

Heavy metals short-term storage, no preservation;

with nitric acid to

+2 to + 5 °C max. 6 h

pH 1, max. 4 weeks

pH 1, max. 4 weeks

Release 06/2014

11

Page 12

Spectroquant® photometers

3 Sample Preparation

3.2 Preliminary Tests

Correct measurement results can be obtained only within the measuring

range spe ci fied for each indi vi dual parameter. When dealing with sample

solutions of an un known concentration, it is advisable to establish whether

the sample concentration is indeed within the specified measuring range,

ideally roughly in the middle of the range.

Preliminary tests enhance the analytical reliability and make the determination of the necessary dilution ratios in the case of high concentrations

easier. MQuantTM Test Strips are very well suited for preliminary tests.

3.3 Dilution

Dilution of samples is necessary for two reasons:

The concentration of the parameter under investigation is too high, i. e.

•

it lies out side the measuring range.

Other substances contained in the sample interfere with the determina-

•

tion (matrix interference); false-high or false-low results may ensue.

The following auxiliaries are absolute prerequisites for the dilution of the

sample:

Volumetric flasks of varying sizes (e. g. 50, 100 and 200 ml)

•

Positive-displacement pipette

•

Distilled or DI water.

•

Only dilutions carried out with these auxiliary pro ducts are of sufficient reliability in the area of trace analysis, to which photometry belongs (for the

sim pli fied procedure see page 14).

An important aspect here is that once the volumetric flask has been filled

up to the mark with distilled water the flask is closed and the contents are

thoroughly mixed.

The dilution factor (DF) resulting from the dilution procedure is calculated

as follows:

D

Initial volume (sample volume)

The analytical result is subsequently multiplied by the dilution factor.

A calculation can be dispensed with when the dilu tion is programmed into

the pho tometer. The dilution number (see the table on page 14) is

entered and the measure ment value is subsequently calculated cor rectly

and immediately displayed.

Final volume (total volume)

=

F

12

Release 06/2014

Page 13

3 Sample Preparation

All dilutions should be made in such a way that the measurement value

lies in the middle of the measur ing range. As a rule, the dilution factor

should never be higher than 100. In the event that yet higher dilu tions

become necessary all the same, then this must be done in two separate

steps.

Example

Step 1: Make up 2 ml of sample to 200 ml with distilled water;

D

Step 2: Take 5 ml of the above solution and make up to 100 ml;

D

The dilution factor for the total dilution is calcu lated by multiplying the

individual dilutions:

D

Simplified procedure

Dilutions up to 1:10 can also be prepared without volumetric flasks in a

glass bea ker, measuring the volumes of the sample and the dilution water

using a pre viously calibrated positive-displacement pipette (see table for

instructions).

= 100, dilution number 1+ 99

F

= 20, dilution number 1+19

F

= DF1 x DF2 = 100 x 20 = 2000, dilution number 1+1999

F total

Spectroquant® photometers

Desired Volume of Volume of Dilution Dilution

dilution sample

[ml] [ml]

distilled water

factor number

1:2 5 5 2 1+ 1

1:3 5 10 3 1+ 2

1:4 2 6 4 1 +3

1:5 2 8 5 1 +4

1:10 1 9 10 1 +9

3.4 Filtration

Strongly turbid samples require pretreatment before they can determined

in a photometer, since the effect of turbidity can result in considerable

variations in the measurement values and in false-high readings. Care

must be taken here to ensure that the sub stance to be deter mined is not

contained in the sus pended material, in which case a sample decompo si tion must be carried out.

Compounds that always occur in dissolved form (for example ammonium,

nitrate, nitrite, chlorine, chlo ride, cyanide, fluoride, orthophosphate, and

sulfate) permit a previous filtration, even when the sample solution is

strongly turbid.

Weak turbidity is eliminated by the automatic turbi dity-correction

feature built into the photo meter (see Function description, “Device set-up/

Correction function”); in such cases it is not necessary to filter the sample

before analysis.

As a measure to distinguish between dissolved and undissolved waterborne sub stances, the water sample can be filtered through a simple

paper filter. Following the recommendations stated in the refe rence methods, membrane filters with a pore size of 0.45 µm are required for fine

filtration.

Release 06/2014

13

Page 14

Spectroquant® photometers

3 Sample Preparation

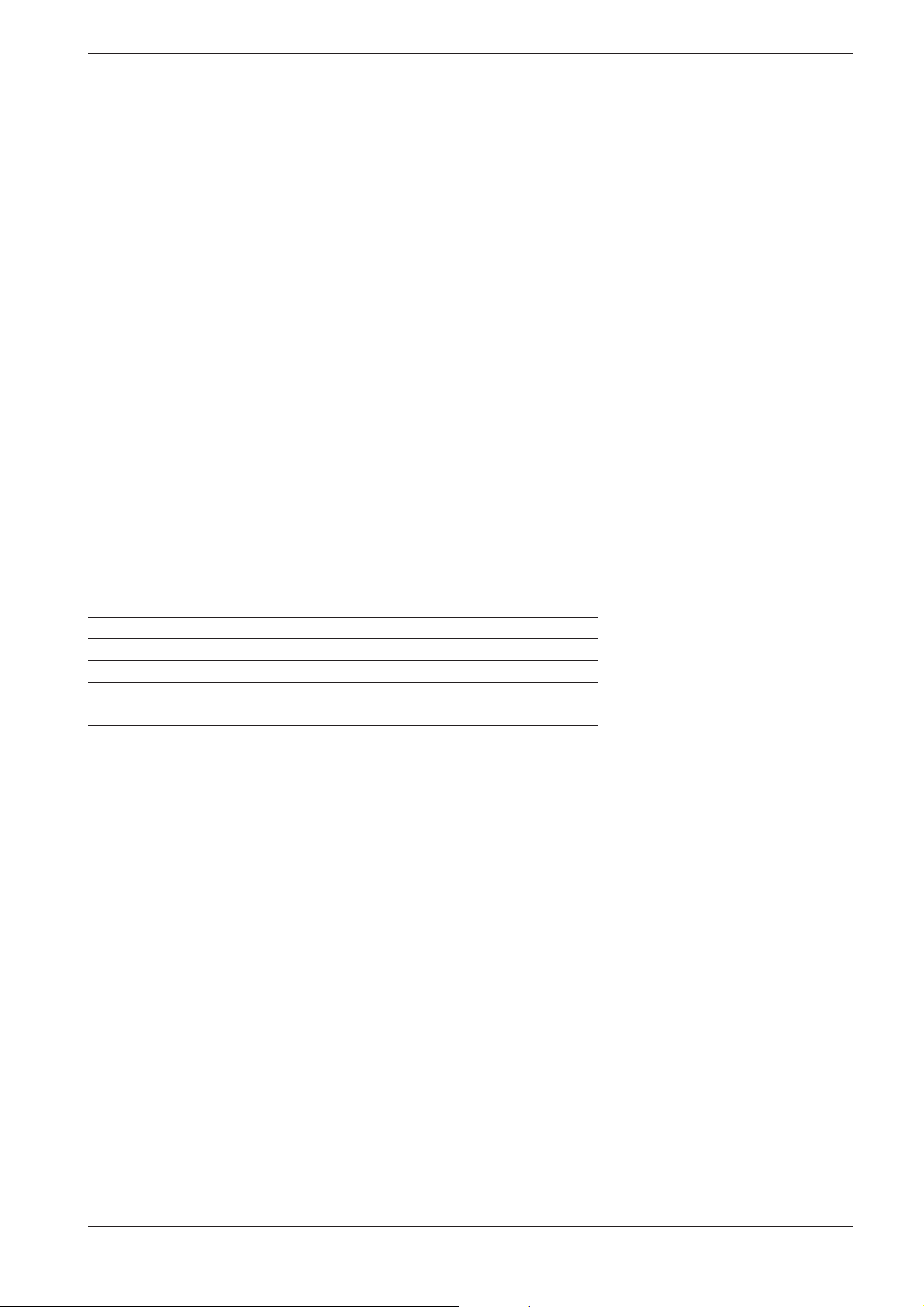

Procedure for microfiltration

Draw out the liquid

to be filtered with

the syringe.

3.5 Homogenization

3.6 Decomposition

Ion

Screw the syringe

tightly into the front

side of the mem brane-filter attachment.

As a measure to ensure that a representative sample can be taken in the

presence of suspended matter in the water sample in question, for certain

parameters - e. g. COD and the total content of heavy metals - the sample

must be homogenized. This must be carried out using a high-speed blender (2 minutes at 5000 –20 000 rpm and taking the sample while stirring.

Water-borne substances can be present in the sample for investigation in

a variety of forms: as the ion, bound more or less solidly in a complex, or

as a solid substance.

Hold the syringe

upright and slowly

depress the piston

upwards until the

membrane- filter is

fully wetted free of

air bubbles.

Filter the contents

of the syringe into

the intended glass

vessel.

14

Complex

Solid

substance

Release 06/2014

Page 15

3 Sample Preparation

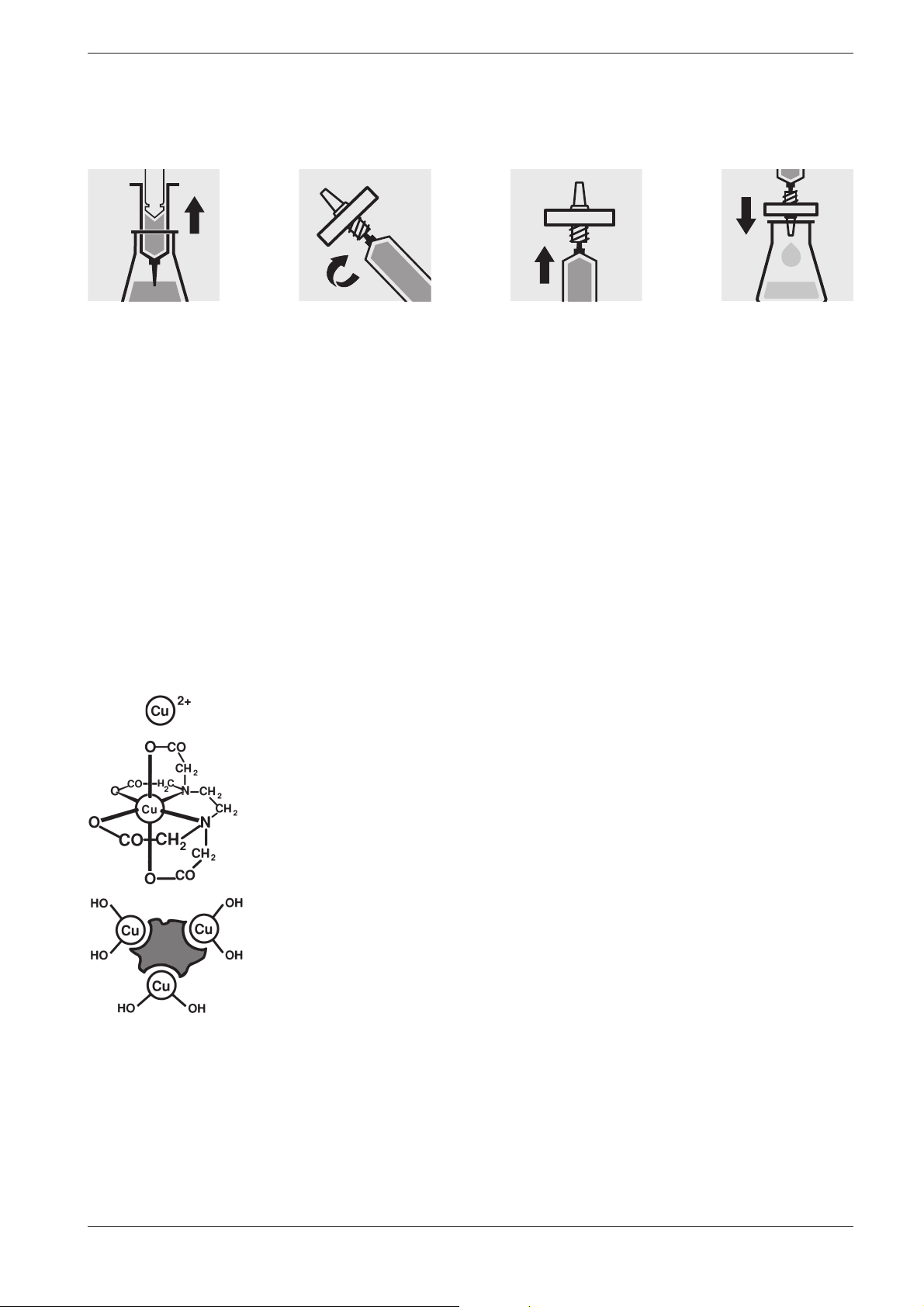

The manner in which the sample is pretreated en ables the three proportions to be dis tinguished from each other. This can be illustrated using

a copper-containing waste water sample as an example.

Example

Filtration

Spectroquant® photometers

Decomposition

Total content Dissolved proportion Dissolved proportion

Solid Substances

Cu(OH)

2

Complexes Cu-EDTA Complexes Cu-EDTA

2+

Ions Cu

Result A Result B Result C

Proportion:

Ionogenic = C

Complex = B–C

Solid Substances = A – B

Total content = A

Decomposition

2+

Ions Cu

Filtration

Ions Cu

2+

Decomposition converts the substance to be deter mined into an analyzable form. In most cases, de composition agents take the form of acids

in com bination with oxidiz ing agents; in exceptional cases (e. g. in the

determination of total nitrogen) an alka line decomposition is more effective. The type of decomposition procedure used de pends on the analyte to

be determined and the sample matrix.

The ready-to-use sample-decomposition products

Spectro

quant® Crack

Set 10 and 20 are suited for the preparation of the sample materials for

the determinations stated in the table.

The decomposition processes are carried out in the

Spectro

quant® ther-

moreactor (capacity: 12 or 24 decomposition cells) at 120°C or, respec-

tively, 100 °C. Details regarding the heating times and further treatment

can be found in the package inserts contained in the Spectroquant®

Crack Set packs.

Determination of Sample preparation with

Total phosphorus* Crack Set 10 / 10C**

Total chromium* Crack Set 10 / 10C

[= sum of chromate and chromium(III)]

Total metal Crack Set 10 / 10C

[= sum of free and complex-bound metal]

Total nitrogen* Crack Set 20

* The decomposition reagents are already contained in the packs of the respective cell tests.

** Decomposition cells are included in the pack; empty cells are required for the decomposition for

Crack Sets 10 and 20.

Release 06/2014

15

Page 16

Spectroquant® photometers

3 Sample Preparation

In the event that the sample to be analyzed is a highly contaminated material (high proportion of organic substances) or water-insoluble samples,

decomposition using concentrated acids and other agents is in dispensible

Corresponding examples from the collection of applications for real samples are available on request.

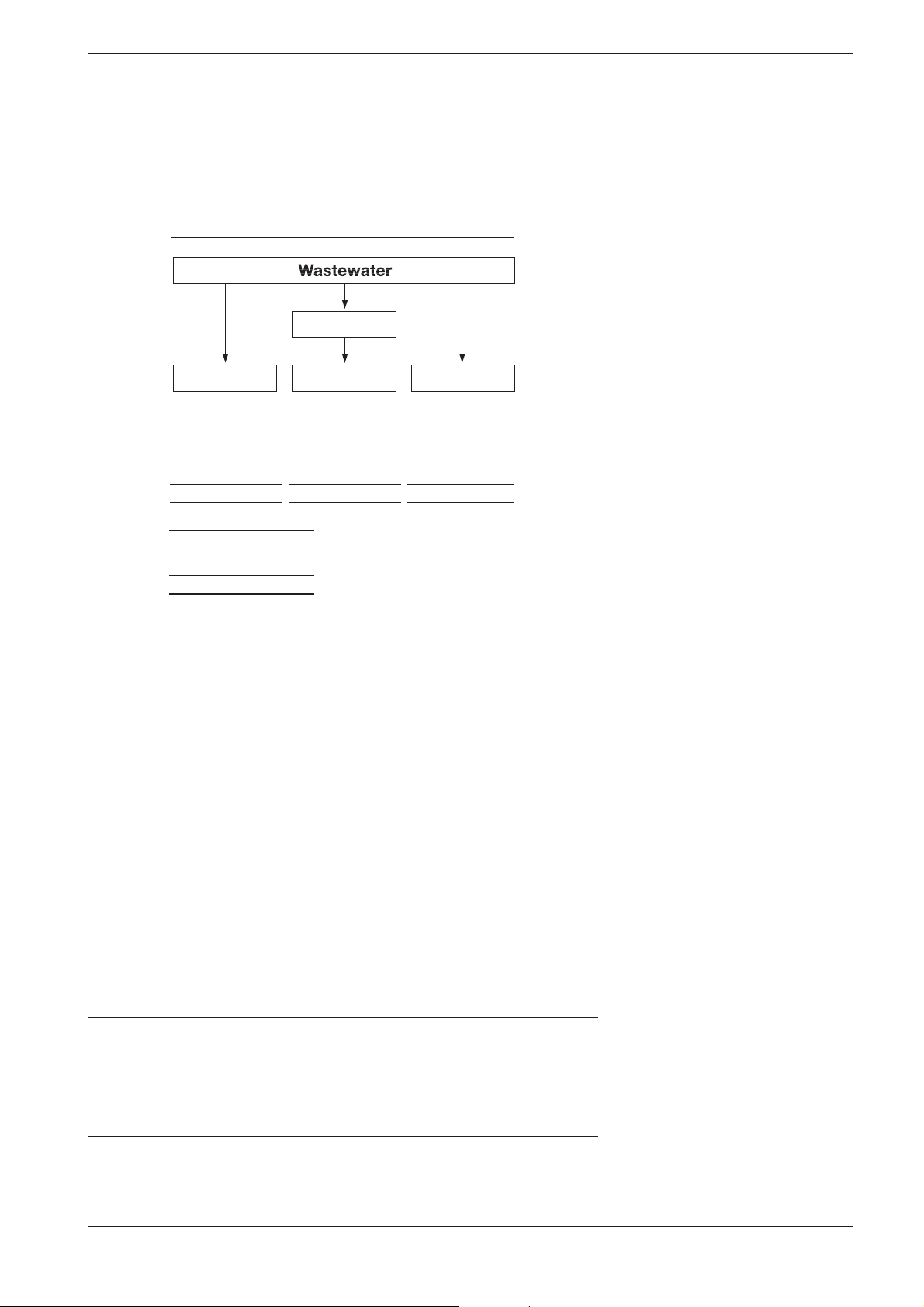

The necessity for decomposition can be checked according to the following diagram:

Decomposition

.

Procedure

Measurement

Result A

Decomposition

necessary

For wastewater with a consistent composition, this check as a rule need

be carried out only once. It is, however, advisable to check the result periodically.

No

A and B

idential?

Yes

Procedure

Measurement

Result B

No decomposition

necessary

4 Pipetting System

Positive-displacement pipettes permit

an exact dosage of the sample volume

•

a precise measurement of sample and reagent volumes and of the

•

volumes of water for dilution purposes

.

Pipettes of varying volumes and also ones with a fixed volume are available.

Sources of error and hints on how to avoid them:

Closely follow the instructions for use contained with the pipette in

•

question.

Check the pipetted volumes

•

a)

1 ml of water at 20°C = 1.000 g ±1 mg

b) using Spectroquant® PipeCheck;

this is a pho tometric check of the pipette, and scales are not

necessary (see section “AQA”).

Avoidance of spread effects by rinsing the pipette several times with

•

the solution to be pipetted.

Always exchange the pipette tip.

•

Draw up the liquid slowly and depress piston completely to discharge

•

the liquid.

16

by weighing using analytical scales (weighing ac cu racy ±1 mg),

Release 06/2014

Page 17

5 Analytical Quality Assurance (AQA)

The objective of analysis must always be to determine the true content of

the analyte in question as accurately and precisely as possible.

Analytical Quality Assurance represents a suitable and indispensible

method by which the quality of the user's own work can be assessed,

errors in the measurement system diagnosed, and the comparability with

the results obtained using the respec tive refe rence methods demonstrated.

Spectroquant® photometers

Details regarding the necessity of AQA can be found

dum A 704 of the German Association for the Water Sector, Wastewater,

and Waste Materials (Deutsche Vereinigung für Wasserwirtschaft, Abwasser und Abfall e.V., DWA)

toring regulations of the Ger man federal states (available in english).

Causes for errors can include:

the working materials used

•

the handling

•

the sample under investigation.

•

These errors have effects on both the accuracy and precision of the

results obtained.

and in the corresponding self-con trol/self-moni-

in the in Memoran-

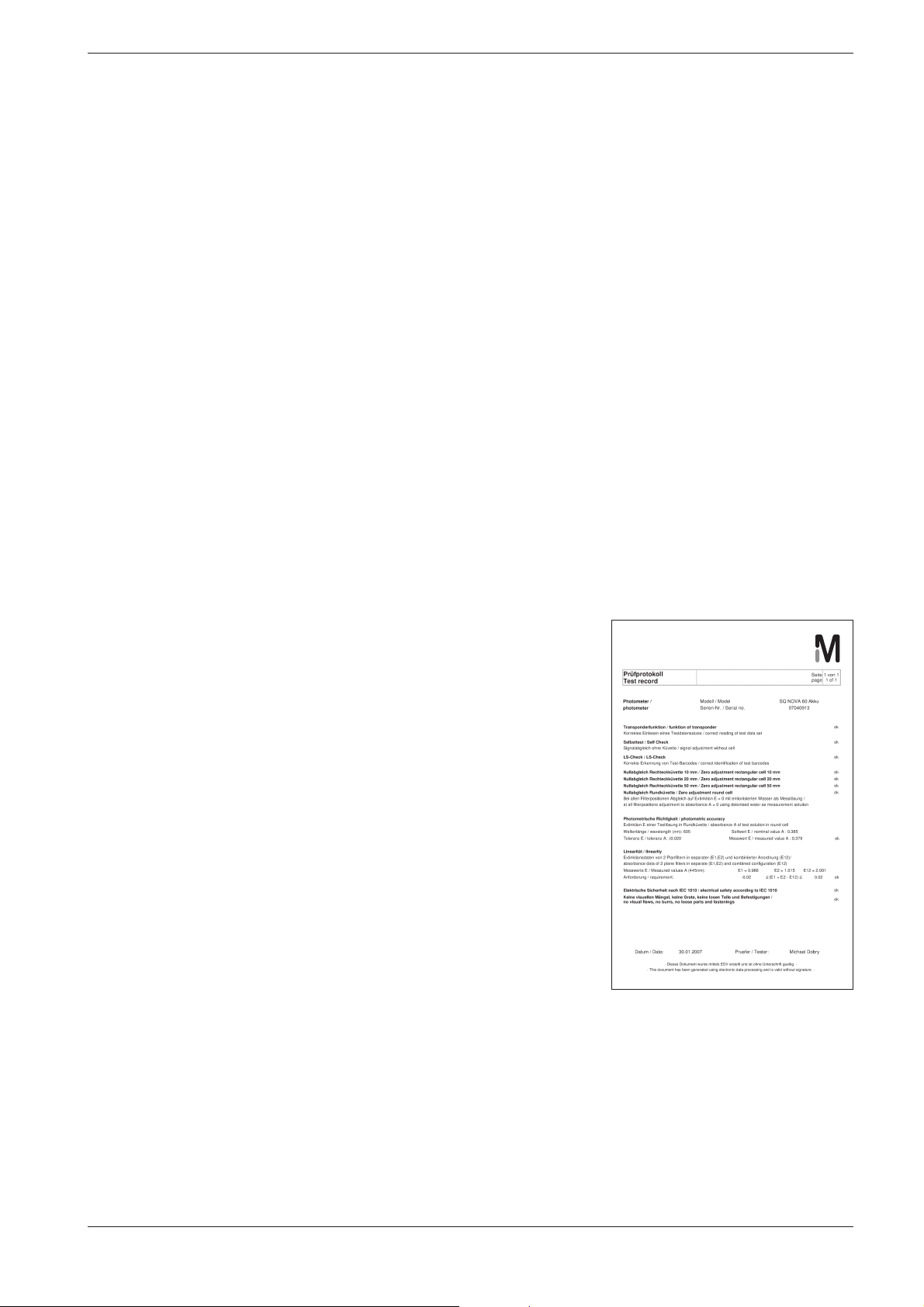

5.1 Quality Control at the Manufacturer

Photometers and photometric test kits possess specifications that are

adhered to and above all else also documented by the manufacturer.

The certificate for the photometer enclosed with each device documents the quali ty of the measuring device.

Release 06/2014

17

Page 18

Spectroquant® photometers

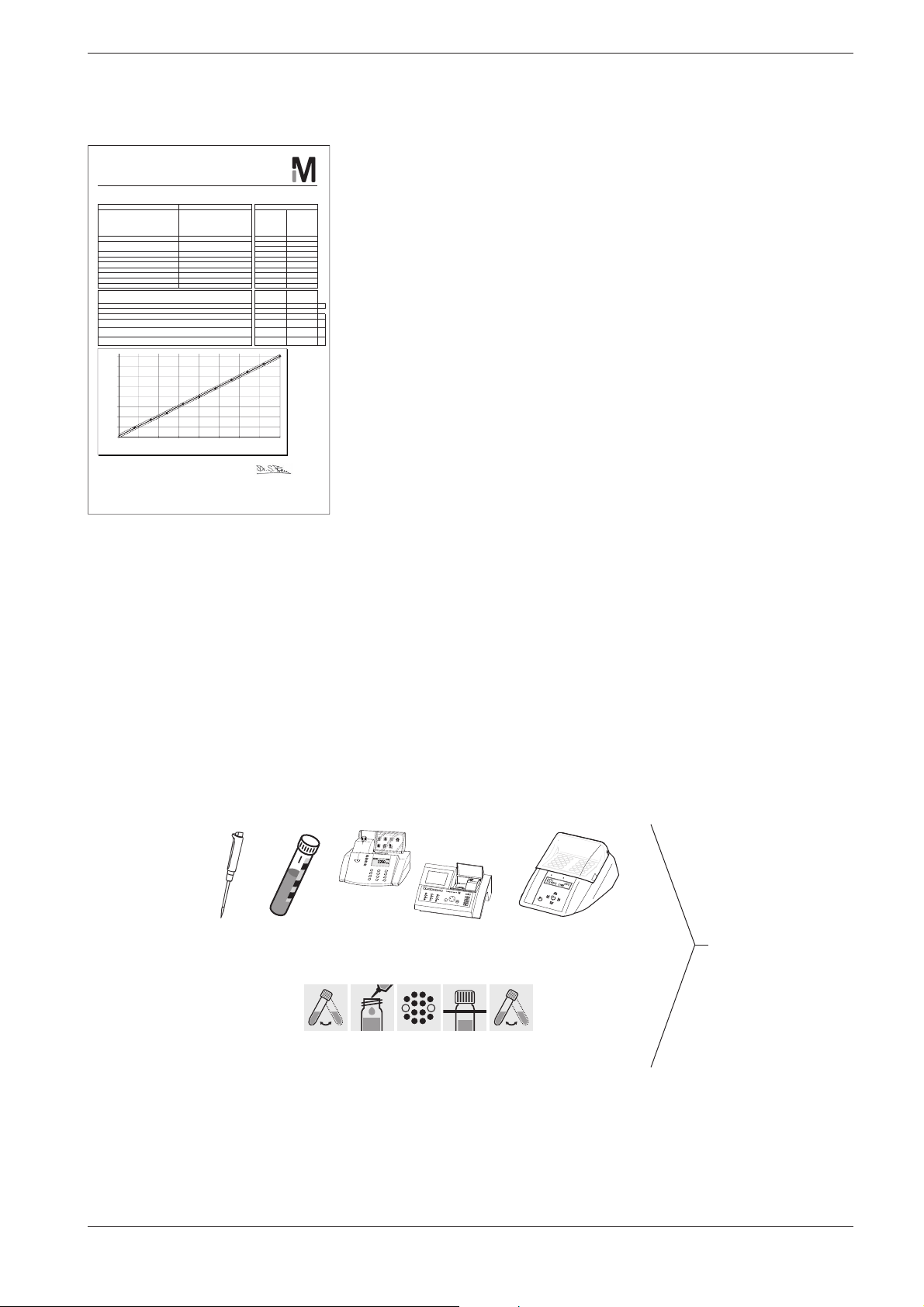

CSB/COD/DQO

Datum / Date / Fecha

Sollwert

Valor nominal

Chargenwert

Valor del lote

99

99

99

99

99

Merck KGaA

Chargenzertifikat

5 Analytical Quality Assurance (AQA)

The certificate for the test kit, available for each lot produced, docu-

Lot Certificate / Certificado del lote

Spectroquant® CSB-Küvettentest

®

Spectroquant

COD Cell Test / Spectroquant® Test en cubetas DQO

Art.Nr. / Cat.No. / Art. Nro. 1.14560.0001

Messbereich

Measuring Range / Intervalo de medida

Charge-Nr. / Lot no. / Lote nro. HC119527 4,0 4,7

Verwendbarkeit

Expiry date / Fecha de caducidad

Standard / Standard / Patrón Potassium hydrogen phthalat e 1.02400 16,0 16,4

Photometer / Photometer / Fotómetro Referenz / Reference / Referencia 20,0 19,9

Wellenlänge / Wavelength / Longitud de onda 340 nm 24,0 24,1

Küvette / Cell / Cubeta 16 mm rund / round / redonda 28,0 28,4

Prüfer / Tester / Verificador Fr. Brandner 32,0 32,4

Datei / File / Fichero 1145600001_HC119527_EN 40,0 40,2

Kalibrierfunktion / Calibration Function / Función de calibración

DIN 38402 A51 / ISO 8466-1

Steigung / Slope / Pendiente +/- Tolerance / Tolerancia

Ordinatenabschnitt / Ordinate segment / Interse cto en ordenadas

Reag.blindwert / Reagent blank / Valor en blanco del react +/- Tolerance / Tolerancia

Vertrauensbereich (95% Wahrscheinlichkeit )

Confidential interval (P=95%) / Intervalo de confianza (95 % de probabilidad)

Verfahrensstandardabweichung

Standard Deviation of the Method / Desviación estándar del procedimiento

Verfahrensvariationskoeffizient

Variation Coefficient of the Method / Coeficiente de variación del procedimiento

40,0

35,0

30,0

25,0

20,0

15,0

10,0

5,0

Messergebnis / Result / Resultado (mg/l)

0,0

0,0 5,0 10,0 15,0 20,0 25,0 30,0 35,0 40,0

Qualitätskontrolle Laborleiter / Head of Lab.

Quality control / Control de calidad Jefe de laboratorio

4,0 - 40,0 mg/l CSB/COD/DQO

31.10.2012

20.09.2011 36,0 36,3

Sollwert / Target value / Valor nominal (mg/l)

n = 10

Sollwert

Target value

Result / Resultado

Valor nominal

(Standard / Patrón)

(Standard / Patrón)

mg/l

8,0 8,7

12,0 11,8

Target value

1,00 ± 0,03 0,99

1,410 ± 0,020 A 1,403 A

± 1,0 mg/l ± 0,8 mg/l

± 2,5 % ± 1,4%

Messergebnis

CSB/COD/DQO

Lot value

± 0,3 mg/l

ments the quality of the reagents contained in the test kit.

Calibration function:

mg/l

The calculated function must agree, within specified tolerances, with the

function electronically stored in the photometer.

Confidence interval:

Maximum deviation from the desired value over the entire mea suring

0,4

range; every measurement value can be affected by this deviation; this

parameter is a measure for the accuracy.

Standard deviation for the procedure:

Measurement for the dispersion of the measurement values over the

entire measuring range, ex pressed in ±mg/l.

Coefficient of variation for the procedure:

Measurement for the dispersion of the measurement values over the

entire measuring range, ex pressed in %. The smaller the standard deviation/ coefficient of variation for the procedure, the more pronounced the

linearity of the calibration curve.

5.2 Quality Control for the User

A complete check comprises the entire system, i. e. the working equipment

and the mode of operation. The photometer offers an optimum degree of

support in this re gard, in the form of the different quality mode. The instrument, or the whole system (includ ing reagents and all accessories) will be

checked, depending on which quality mode selected. All of checking operations can thus be supported by the pho tometer and the check values

accordingly docu mented as per GLP (Good Laboratory Practice) recommendations (see Function description, “Analytical Quality Assurance”).

The following diagram provides an overview regarding internal qualityassurance aspects:

Checking the

working equipment

Pipette Test kit Photometer Thermoreactor

Checking the

handling

operations

Suspend the bottom

sediment in the cell by

swirling.

Carefully pipette 3.0 ml

of the sample into a

reaction cell, close tightly with the screw cap ,

and m ix vigorously.

Caution, the cell

becomes very hot!

1

4

7

.

C2/25 CSB

1500 Chemischer

Me§bereich

100 1500 mg/l CSB

2 ml Prob

elösung

Mischen

in ein Reaktions-

Küvette wird heiß,

küvette geben

am Verschluss

anfassen

Mischen

Abkühlen auf

Raumtem

peratur

(mind. 30 min)

2

3

5

6

8

9

0

C

Sauerst

offbedarf

14 mm

im Thermoreaktor

mind. 10 min

erhitzen

abkühlen

148 C, 120 min

Messen

Heat the reaction cell in

the thermoreactor at

148 °C for 2 hours.

Remove the reaction

cell from the thermoreactor and place in a

test-tube rack to cool.

Swirl the cell after

10 minutes.

= Test for the

overall system

Influence of the sample

18

Test for recovery

Release 06/2014

Page 19

5 Analytical Quality Assurance (AQA)

5.2.1 Checking the Photometer

As soon as the photometer is activated it is running a Self-Check. This

means the hardware and the soft ware of the photometer is checked and

compared with internal standards.

As soon as the photometer is activated it is running a Self-Check. This

means the hardware and the soft ware of the photometer is checked and

compared with internal standards.

The photometer itself is checked in the AQA 1 mode with the

Spec tro quant® Photo Check: the pack in cludes round cells con tain ing

stable

test solu tions (secondary

at the

445, 525, and 690 nm wave lengths. The test solutions

in a refe rence photo me ter monitored with primary standards, and the

certificate stating the absorbance values is enclosed with the package

unit. These desired values with the per missible tolerances are entered into

the pho tometer or else handwritten into the control chart. For the measure ment the cell is placed in the compartment for the round cell and identified by the photometer via the bar code, and the measured absorbance is

com pared with the de sired value. The ab sorbance is shown on the display

and can be entered into the corresponding control chart.

The measurement of four cells for a given wavelength tests – in addition to

the wavelength accuracy – also the linearity of the absorbance over the

effective range.

The verification of the instrument, as it is required by DIN/ISO 9000 or

GLP, can be easily performed by using the Spec tro quant

The PhotoCheck hence offering the possibility to check the instrument. All

of the corresponding documentation, required by these certifi cation guidelines, is done by the photometer auto ma tically.

stan dards) for checking the photo meter

are measured

®

PhotoCheck.

Spectroquant® photometers

C2/25 CSB 1500 Chemischer

Sauerst

offbedarf

Me§bereich

100 1500 mg/l CSB

14 mm

2 ml Probelösung

Mischen

in ein Reaktions-

im Thermoreaktor

Küvette wird heiß,

mind. 10 min

küvette geben

erhitzen

am Verschluss

abkühlen

148 C, 120 min

anfassen

Mischen

Abkühlen auf

Messen

Raumtemperatur

(mind. 30 min)

1

2

3

4

5

6

7

8

9

.

0

C

5.2.2 Checking the Overall System

Test for the overall system includes checking the working equipment and

checking the handling operations.

The overall system can be checked using standard solutions of a known

content, preferably with the Spectroquant® CombiCheck; this corres ponds

with the AQA 2 mode in the photometer.

Spectroquant® CombiCheck are ready-to-use standard solutions that in

terms of the analyte concentration are finely adjusted to the individual test

kits. They contain a mixture of several analytes that do not interfere with

each other. The stan dard solution (R -1) is used in the same way as a

sample. A double determination is recommended as a measure to

diagnose any random errors.

Standard solutions for photometric applications (CRM) are ready-touse standard solutions that in terms of the analyte concentration are finely

adjusted to the individual test kits. The standard solution is used in the

same way as a sample. A double determination is recommended as a

measure to diagnose any random errors.

In addition to the CombiCheck and the standard solutions for photometric

applications, it is also possible to use CertiPUR® stan dard solutions for

this checking procedure. These contain 1000 mg of the respective analyte

per liter of solution.

They can be diluted to different final con cen trations, which should preferably lie approxi mately in the middle of the mea sur ing range of the re spective test kit. The table presented in Appendix 2 pro vides an over-view of

the available CombiCheck and ready-to-use standard solu tions.

Release 06/2014

19

Page 20

Spectroquant® photometers

5 Analytical Quality Assurance (AQA)

Due to li mited shelf-life characteristics, there are no CombiCheck or

ready-to-use standard solutions for certain parameters. Appendix 3 is a

compilation of standard working procedures necessary to make your

own solutions of a defined concentration. This allows the control of parameters where there are no simple to prepare solutions available.

If the test for the overall system shows that all requirements are fulfilled,

the individual results are flagged as AQA2. If not, an error message is given and the individual components of the instrument have to be checked in

detail.

5.2.3 Checking the Pipettes

The Spectroquant

contains cells filled with color-dye concentrates. After the addition of a

predefined volume

ured against a corre sponding reference cell also contained in the pack.

The difference in the absorbance values of the measurement cell and reference cell may not exceed the tolerances given in the package insert.

If the tolerances are exceeded, the instructions given in the section

“Pipetting system” must be followed accordingly.

®

PipeCheck is used to check the pipettes. The pack

of water using the pipette in question, the

cell is meas-

5.2.4 Checking Thermoreactors

This is checked by means of the thermosensor. The thermoreactor is preheated as described in the Instructions for use. When the control lamp

goes out, the temperature is measured in any one of the bores of the thermoreactor. The following desired temperatures must be achieved:

Block temperature 100 °C = desired temperature 100 ±3 °C

Block temperature 120 °C = desired temperature 120 ±3 °C

Block temperature 148 °C = desired temperature 148 ±3 °C

The even distribution of the temperature over all bores can also be documented using the thermosensor.

20

Release 06/2014

Page 21

5 Analytical Quality Assurance (AQA)

5.2.5 Testing for Handling Errors

The user’s own mode of operation must also be subjected to an exact

analysis.

The following questions may serve as a guide in this regard:

Is the test kit optimal for the measurement assignment in question?

•

Is the test kit’s measuring range suitable?

•

Were the operating instructions for the test followed

•

Was the sample volume correct?

•

Was the pipette handled properly?

•

Was a new pipette tip used?

•

Is the pH of the sample and measurement solution correct?

•

Was the reaction time adhered to?

•

Does the sample and reagent temperature lie within the correct range?

•

Is the cell clean and free from scratches?

•

Has the expiry date for the test kit been exceeded?

•

?

Spectroquant® photometers

5.3 Determination of Sample Influences (matrix effects)

The influence of other substances contained in the sample may, under

certain cir cumstances, be so great that their recovery rates lie in the region

of several percent. It is recommended to check for any influence by using

the addition solution contain ed in the Spectroquant

A defined quantity of the addition solution (R-2), which contains a known

concen tration of the respective analyte, is added to the sample and the

recovery rate is de termined. The following difference is then calculated:

Result (sample + addition solution) – Result (sample)

If the calculated difference is equal to the concen tration of analyte of addition solution that was add ed, the recovery rate is 100 %. If the difference

is less than 90 %, then a matrix inter ference is present.

®

CombiCheck pack.

Release 06/2014

21

Page 22

Spectroquant® photometers

5 Analytical Quality Assurance (AQA)

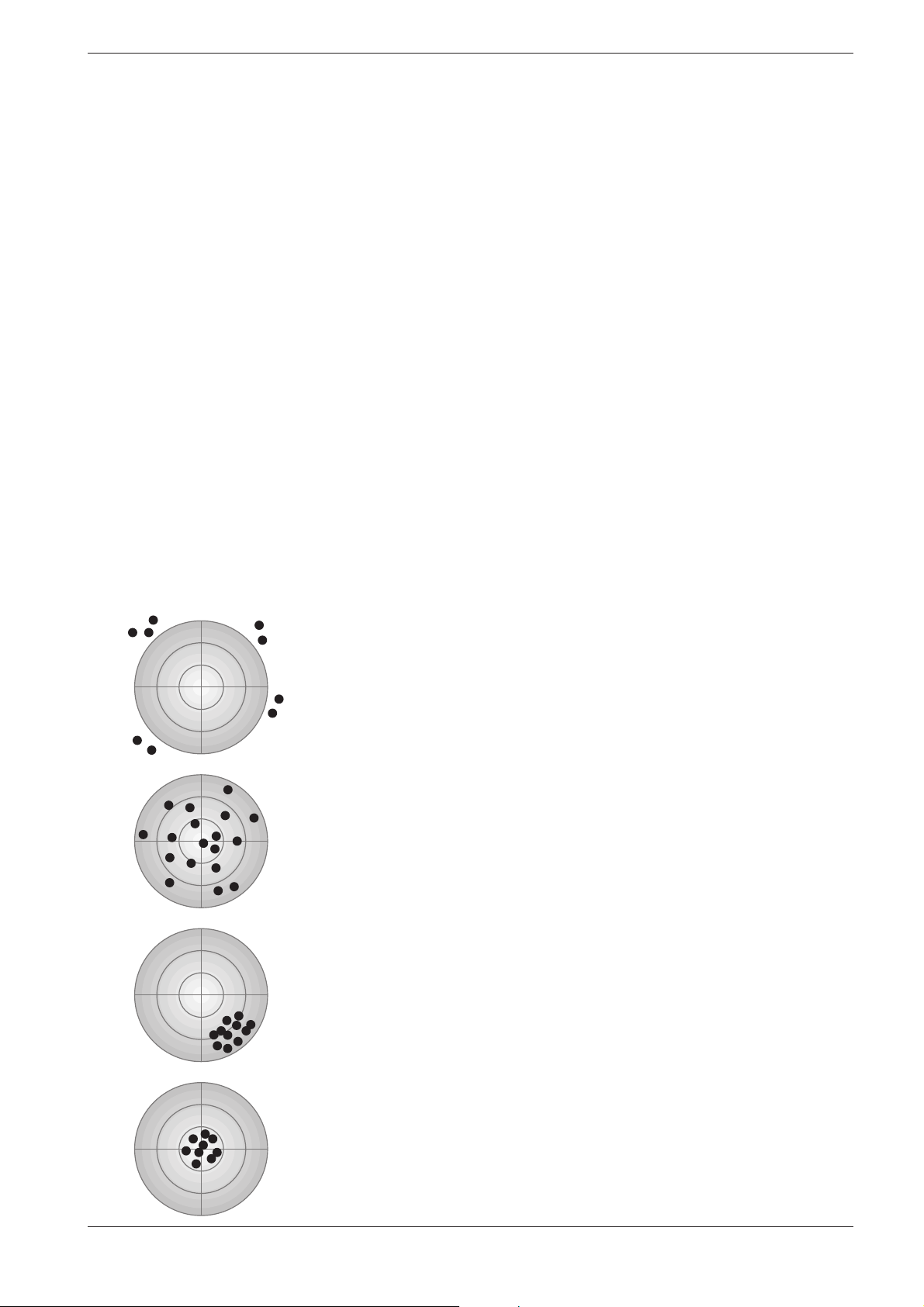

5.4 Definition of Errors

It is obvious that measurement results as a rule may be associated with

errors. This applies equally to standardized methods of analysis (reference

methods) and to rou tine analysis. The discovery and the minimization of

errors must be the objective here.

A distinction is made between systematic errors and random errors.

Systematic errors are present when all the results of an analysis deviate

from the true value with the same algebraic sign. Examples here include:

a wrong sample volume, a wrong pH, a wrong reaction time, a samplematrix influence, etc. Systematic errors thus affect the accuracy of the

method of analysis.

Accuracy = Deviation of the measured concentration from the true concentration

Random errors manifest themselves in the form of a wide range of deviation of the results of a given sample. These can be kept to a minimum by

ensuring good operat ing techniques and multiple determina tion with calculation of the mean values. Ran dom errors make the result of the analysis unreliable; they influence the precision.

Precision = Dispersion of the results among each other

The following diagram illustrates the aspects of accuracy and precision:

Accuracy: poor

Precision: poor

Major errors have been made!

Accuracy: good

Precision: poor

Calculation of the mean values from at least three – or better even more –

parallel determina tions yields an approximation of the true value.

Accuracy: poor

Precision: good

The high degree of precision mis takenly indicates a correct value!

22

Accuracy: good

Precision: good

The ideal objective!

Release 06/2014

Page 23

Spectroquant

®

UV/VIS Spectrophotometer

Pharo 300

Description of Function

Spectroquant

®

Pharo 300

Page 24

Spectroquant® Pharo 300

Accuracy when going to

press

The use of advanced technology and the high quality standard of our

instruments are the result of continuous development. This may result

in differences between this operating manual and your instrument.

Also,

we cannot guarantee that there are absolutely no errors in this manual.

Therefore, we are sure you will understand that we cannot accept

any legal claims resulting from the data, figures or descriptions.

Copyright © Merck KGaA

Frankfurter Str. 250

D-64271 Darmstadt

Germany

Internet: www.analytical-test-kits.com

Reprinting - even as excerpts - allowed only with the explicit written

authorization of Merck KGaA, Darmstadt.

ba75703e07 04/2014

Page 25

Spectroquant® Pharo 300 Contents

Spectroquant® Pharo 300 - Contents

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1.1 Overview of the instrument . . . . . . . . . . . . . . . . . . . . . . 29

1.2 Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1.3 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.1 Target group and user qualification . . . . . . . . . . . . . . . . 33

2.2 Authorized use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.3 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . 34

2.4 Handling of hazardous substances . . . . . . . . . . . . . . . . 35

3 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.1 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.2 General notes on handling . . . . . . . . . . . . . . . . . . . . . . . 38

3.3 Initial commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.3.1 Inserting the buffer batteries . . . . . . . . . . . . . . . 39

3.3.2 Connecting the power supply . . . . . . . . . . . . . . 40

3.3.3 Switching on the photometer for the first time . . 41

3.3.4 Setting the language . . . . . . . . . . . . . . . . . . . . . 41

3.3.5 Setting the date and time . . . . . . . . . . . . . . . . . 42

3.4 Connecting optional accessories . . . . . . . . . . . . . . . . . . 43

3.4.1 Communication interfaces . . . . . . . . . . . . . . . . . 43

3.4.2 PC/printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.4.3 USB memory device . . . . . . . . . . . . . . . . . . . . . 45

3.4.4 PC keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3.4.5 Barcode reader . . . . . . . . . . . . . . . . . . . . . . . . . 46

3.4.6 12 V-Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.1 Switching on or off the photometer . . . . . . . . . . . . . . . . 49

4.2 General operating principles . . . . . . . . . . . . . . . . . . . . . 52

4.2.1 Navigating with function keys and menus . . . . . 52

4.2.2 Display of navigation paths in short form . . . . . 54

4.2.3 Entry of numerals, letters and characters . . . . . 55

4.2.4 Detailed operating example: Changing the

language . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.3 Photometer settings and system administration . . . . . . 58

4.3.1 Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.3.2 Date/Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.3.3 Display settings . . . . . . . . . . . . . . . . . . . . . . . . . 60

ba75703e07 04/2014

25

Page 26

Contents Spectroquant® Pharo 300

4.4 Zero adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.5 Measuring in Concentration mode . . . . . . . . . . . . . . . . . 66

4.5.1 Measuring cell tests with barcode . . . . . . . . . . . 66

4.5.2 Measuring reagent tests with AutoSelector . . . . 67

4.5.3 Measuring reagent-free tests and user-defined

methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4.5.4 Exceeding the upper or lower limits of the

measuring range . . . . . . . . . . . . . . . . . . . . . . . . 71

4.5.5 Selecting a method manually . . . . . . . . . . . . . . . 72

4.5.6 Settings for Concentration mode . . . . . . . . . . . . 73

4.5.7 Measuring diluted samples . . . . . . . . . . . . . . . . 75

4.5.8 Sample blank value . . . . . . . . . . . . . . . . . . . . . . 77

4.5.9 Reagent blank value . . . . . . . . . . . . . . . . . . . . . 79

4.5.10 User calibration (standard adjustment) . . . . . . . 83

4.5.11 Automatic Turbidity correction . . . . . . . . . . . . . . 90

4.5.12 Programming / modifying user-defined methods 90

4.6 Measuring the Absorbance / % Transmission . . . . . . . 101

4.6.1 General information . . . . . . . . . . . . . . . . . . . . . 101

4.6.2 Measuring the absorbance or transmission . . . 101

4.6.3 Measuring against the Reference absorbance 103

4.7 Special / Multi wavelengths methods . . . . . . . . . . . . . . 105

4.7.1 Basic information on Special / Multi wavelengths

measurements . . . . . . . . . . . . . . . . . . . . . . . . . .105

4.7.2 Programming / modifying the Special / Multi

wavelengths methods . . . . . . . . . . . . . . . . . . . 106

4.7.3 Selecting a Special / Multi wavelengths method113

4.7.4 Carrying out Special / Multi wavelengths

measurements . . . . . . . . . . . . . . . . . . . . . . . . . 114

4.8 Spectrum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

4.8.1 General information . . . . . . . . . . . . . . . . . . . . . 117

4.8.2 Recording the Spectrum . . . . . . . . . . . . . . . . . 118

4.8.3 Loading/editing a spectrum . . . . . . . . . . . . . . . 121

4.8.4 Saving / exporting a spectrum . . . . . . . . . . . . . 124

4.9 Kinetics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

4.9.1 Creating/editing profiles for Kinetics recordings 125

4.9.2 Loading a profile for Kinetics recording . . . . . . 128

4.9.3 Recording the Kinetics . . . . . . . . . . . . . . . . . . . 129

4.9.4 Saving / exporting a Kinetics record . . . . . . . . 132

4.9.5 Loading a Kinetics record . . . . . . . . . . . . . . . . 134

4.9.6 Editing a Kinetics record . . . . . . . . . . . . . . . . . 134

4.10 Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

4.10.1 User defined timer . . . . . . . . . . . . . . . . . . . . . . 138

4.10.2 Analysis timer . . . . . . . . . . . . . . . . . . . . . . . . . 138

4.11 Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

4.11.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

4.11.2 Instructions on using USB memory devices 144

4.11.3 Measurement datasets . . . . . . . . . . . . . . . . . . 145

4.11.4 Saving measurement datasets manually . . . . 145

26

ba75703e07 04/2014

Page 27

Spectroquant® Pharo 300 Contents

4.11.5 Saving measurement datasets automatically . 145

4.11.6 Displaying measurement data memory . . . . . . 146

4.11.7 Filtering measurement datasets . . . . . . . . . . . 148

4.11.8 Inverting filters . . . . . . . . . . . . . . . . . . . . . . . . . 149

4.11.9 Erasing stored measurement datasets . . . . . . 150

4.11.10 Saving kinetic recordings, spectra and AQA

files . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

4.11.11 Saving data as a pdf file . . . . . . . . . . . . . . . . . 151

4.12 Saving / exporting files . . . . . . . . . . . . . . . . . . . . . . . . . 152

4.12.1 Copying all measurement data files to a USB

memory device . . . . . . . . . . . . . . . . . . . . . . . . 152

4.12.2 Copying user-defined methods / profiles to a

USB memory device . . . . . . . . . . . . . . . . . . . . 153

4.12.3 Copying files to a PC . . . . . . . . . . . . . . . . . . . . 154

4.13 Importing files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

4.13.1 Importing spectra or kinetic recordings from a

USB memory device . . . . . . . . . . . . . . . . . . . . 155

4.13.2 Importing methods / profiles from a

USB memory device . . . . . . . . . . . . . . . . . . . . 155

4.13.3 Importing files from a PC . . . . . . . . . . . . . . . . . 156

4.14 Printing data (RS232, USB) . . . . . . . . . . . . . . . . . . . . . 157

4.14.1 Printer and terminal programs . . . . . . . . . . . . . 157

4.14.2 Settings for data transmission . . . . . . . . . . . . . 158

4.14.3 Printing measurement datasets . . . . . . . . . . . 159

4.14.4 Printing Kinetics records . . . . . . . . . . . . . . . . . 160

4.14.5 Printing spectra . . . . . . . . . . . . . . . . . . . . . . . . 161

4.15 Analytical quality assurance (AQA) . . . . . . . . . . . . . . . 162

4.15.1 General information . . . . . . . . . . . . . . . . . . . . . 162

4.15.2 Photometer monitoring (AQA1) . . . . . . . . . . . . 163

4.15.3 Total system monitoring (AQA2) . . . . . . . . . . . 168

4.15.4 AQA3/MatrixCheck . . . . . . . . . . . . . . . . . . . . . 172

4.16 User management . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

4.16.1 User levels and user rights . . . . . . . . . . . . . . . 178

4.16.2 Activating or deactivating the User

management function . . . . . . . . . . . . . . . . . . . 179

4.16.3 Creating, changing or deleting a user account 180

4.16.4 Login with active user management . . . . . . . . 182

4.16.5 Changing the password . . . . . . . . . . . . . . . . . 184

4.17 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

4.18 Photometer information ([Info]) . . . . . . . . . . . . . . . . . . 186

4.19 Lamp counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

4.20 Software and methods update . . . . . . . . . . . . . . . . . . . 187

4.20.1 Update using a USB memory device . . . . . . . 187

4.20.2 Update using a PC . . . . . . . . . . . . . . . . . . . . . 189

4.20.3 Language update . . . . . . . . . . . . . . . . . . . . . . 189

ba75703e07 04/2014

27

Page 28

Contents Spectroquant® Pharo 300

5 Maintenance and cleaning . . . . . . . . . . . . . . . . . . . . . 191

5.1 Exchanging the buffer batteries . . . . . . . . . . . . . . . . . . 191

5.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

5.2.1 Cleaning the enclosure . . . . . . . . . . . . . . . . . . 192

5.2.2 Cleaning the cell shaft . . . . . . . . . . . . . . . . . . . 192

5.2.3 Cleaning the detector lens . . . . . . . . . . . . . . . . 193

6 What to do if ... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

6.1 Actions in the case of a broken cell . . . . . . . . . . . . . . . 195

6.2 Error causes and remedies . . . . . . . . . . . . . . . . . . . . . . 196

7 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

7.1 Measurement characteristics . . . . . . . . . . . . . . . . . . . . 199

7.2 Measured value documentation and quality assurance 202

7.3 General meter data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

8 Accessories and options . . . . . . . . . . . . . . . . . . . . . . . 207

8.1 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

8.2 Test equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

8.3 Optional equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

8.4 Connection cable: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

A.1 Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

A.1.1 Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

A.1.2 General settings and functions . . . . . . . . . . . . 215

A.2 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

A.3 List of trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

A.4 Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

28

ba75703e07 04/2014

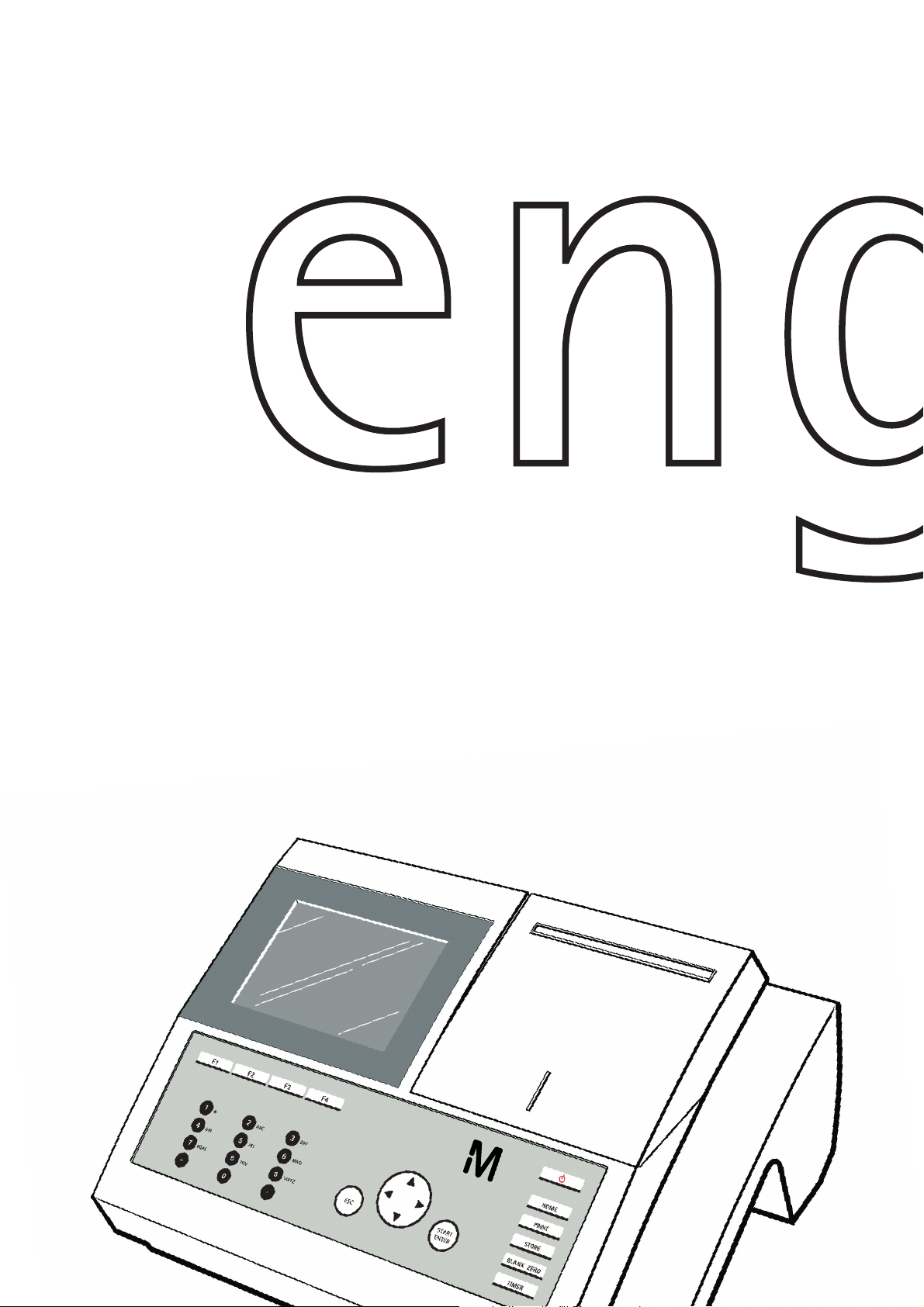

Page 29

Spectroquant® Pharo 300 Overview

1 Overview

1.1 Overview of the instrument

Front of the

instrument

Socket field on the

rear panel

35

1

4

6

2

Fig. 1-1 Front of the instrument with operating elements

7

8

9

10

1 Display

2 Keypad

3 Shaft for rectangular cells

4 Turn-up lid

5 Shaft for round cells

6 Cell shaft cover

ba75703e07 04/2014

7 Connection for power pack

8 RS232 connection

9 USB-A connection

10 USB-B connection

Fig. 1-2 Rear panel with socket field

Note

All connections comply with SELV.

29

Page 30

Overview Spectroquant® Pharo 300

1

2

3

1.2 Keypad

Overview

1 Function keys F1 to F4 (function menu-depending)

2 Alphanumeric keypad

3 Keys with dedicated function

Fig. 1-3 Keypad

Key functions The keys on the right side of the keypad have the following functions:

Key Designation Functions

<ON/OFF> – Switches on and off the photome-

ter

<HOME> – Switches to the main menu from

any operating situation. Actions

that are not completed are canceled.

<PRINT> – Outputs the displayed measured

value to an interface if the

Printer symbol is displayed in the

status line.

<STORE> – Saves a displayed measured

value or spectrum if the Save

symbol is displayed in the status

line.

<BLANK ZERO> – Starts one of the following mea-

surements, depending on the

operating situation:

- Zero adjustment

- Blank value measurement

- Baseline measurement

30

ba75703e07 04/2014

Page 31

Spectroquant® Pharo 300 Overview

Key Designation Functions

<TIMER> – Opens the menu, Timer.

<ESC> – Cancels the running action.

Entries that have not yet been

accepted are discarded.

– Switches to the next higher menu

level.

<START ENTER> – Starts an action (e.g. measure-

ment)

– Opens a selected menu

– Confirms a selection or entry

<▲>or

<▼>

– Moves the selection in menus and

lists one position up or down

<> – Deletes the character left of the

cursor during character entries

– Moves the cursor to the left in a

spectrum or kinetic diagram

(Arrow keys)

<> – Moves the cursor to the right in a

spectrum or kinetic diagram

Function keys The function keys F1 to F4 have different functions depending on the operat-

ing situation. The current functions are displayed in the function key menu at

the bottom edge of the display (see section 4.2.1).

ba75703e07 04/2014

31

Page 32

Overview Spectroquant® Pharo 300

1

2

3

Concentration

16.04.07 9:52

1.92

mg/l

18: 14752

NH4-N

10 mm

0.05 - 3.00 mg/l

Setup

Method list

Citation form Unit

1.3 Display

Display elements

1 Status line (current state, date and time)

2 Display range for menus and measurement results

3 Function keys menu

Fig. 1-4 Display

Symbols in the

status line

Symbol Designation Function

Save The <STORE> key is active.

You can store the displayed data with

<STORE> (see section 4.11).

Printer The <PRINT> key is active.

You can output to an interface the displayed

data with <PRINT> (see section 4.14).

Progress bar During the warm-up time (15 minutes) a

progress bar appears on the display.

The reproducibility of measured values is

limited during the warm-up time (see section

4.14).

32

ba75703e07 04/2014

Page 33

Spectroquant® Pharo 300 Safety instructions

2 Safety instructions

This operating manual contains basic instructions that you must follow during

the commissioning, operation and maintenance of the photometer. Consequently, all responsible personnel must read this operating manual carefully

before working with the meter. Keep this operating manual in the vicinity of

the meter.

General safety

instructions

Other labels

Safety instructions in this operating manual are indicated by the warning symbol (triangle) in the left column. The signal word (such as "CAUTION") indicates the danger level:

WARNING

indicates instructions that must be followed precisely in order to prevent serious dangers to personnel.

CAUTION

indicates instructions that must be followed precisely in order to avoid

slight injuries to personnel or damage to the instrument or the environment.

Note

indicates notes that draw your attention to special features.

Note

indicates cross-references to other documents.

2.1 Target group and user qualification

ba75703e07 04/2014

Carrying out photometric determinations with the aid of test sets frequently

requires the handling of hazardous substances.

We assume that the operating personnel know how to handle hazardous substances due to their professional training and experience. The operating personnel must particularly be able to understand and correctly implement the

safety labels and safety instructions on the packages and inserts of the test

sets.

33

Page 34

Safety instructions Spectroquant® Pharo 300

2.2 Authorized use

The Photometer was developed for use in the laboratory for water analysis.

Follow the technical specifications of the cells in chapter 7 T

ECHNICAL DATA.

Any other use is considered to be unauthorized.

2.3 General safety instructions

The photometer is built and inspected according to the relevant guidelines

and norms for electronic instruments (see chapter 7 T

the factory in a safe and secure technical condition.

Note

The opening of the photometer or adjustment and repair work must only be

performed by specialist personnel authorized by the manufacturer. Noncompliance invalidates any claim with regard to the warranty.

ECHNICAL DATA). It left

Function and

operational safety

The smooth functioning and operational safety of the photometer can only be

guaranteed if the generally applicable safety measures and the specific

safety instructions in this operating manual are followed during operation.

The smooth functioning and operational safety of the photometer can only be

guaranteed under the environmental conditions that are specified in chapter

ECHNICAL DATA.

7 T

If the photometer was transported from a cold environment to a warm environment, the formation of condensate can lead to the faulty functioning of the

meter. In this event, wait until the temperature of the meter reaches room

temperature before putting the meter back into operation.

Safe operation If safe operation is no longer possible, the photometer must be taken out of

operation and secured against inadvertent operation.

Safe operation is no longer possible if the photometer:

has been damaged in transport

has been stored under adverse conditions for a lengthy period of time

is visibly damaged

no longer operates as described in this manual.

34

If you are in any doubt, contact the supplier of your photometer.

ba75703e07 04/2014

Page 35

Spectroquant® Pharo 300 Safety instructions

2.4 Handling of hazardous substances

When developing test sets, Merck carefully sees that the tests can be carried

out as safely as possible. Some hazards by dangerous substances, however,

cannot always be avoided.

WARNING

Improper handling of certain reagents can cause damage to your

health.

In any case follow the safety labels on the packing and the safety instructions of the package insert. Protective measures specified there

have to be followed exactly.

Safety datasheets The safety datasheets of the chemicals comprise all instructions on safe han-

dling, occurring hazards, preventive actions and actions to take in hazardous

situations. Follow these instructions in order to work safely.

ba75703e07 04/2014

35

Page 36

Safety instructions Spectroquant® Pharo 300

36

ba75703e07 04/2014

Page 37

Spectroquant® Pharo 300 Commissioning

3 Commissioning

3.1 Scope of delivery

Spectrophotometer Spectroquant® Pharo 300

Power pack connection cable

Buffer batteries 4 x AA alkaline manganese (Mignon)

Zero cell (16 mm, round)

Short instructions

CD-ROM with

– Detailed operating manual

– Analysis instructions

– SpectralTransfer software

– Language updates to install additional character sets (see section

4.20.3)

Packing This photometer is sent out in a protective transport packing.

CAUTION

Keep the original packing including the inner packing to protect the instrument against hard shocks if it has to be transported.

Note that damage caused by improper transport voids all warranty

claims.

ba75703e07 04/2014

37

Page 38

Commissioning Spectroquant® Pharo 300

3.2 General notes on handling

The Spectroquant® Pharo 300 photometer is an optical precision meter.

Therefore, it should always be handled with care, especially in mobile use.

Always protect the meter from conditions that could damage the mechanical,

optical and electronic components. Heed the following points especially:

The temperature and humidity during operation and storage must be

within the limits specified in chapter 7 T

The following influences always have to be avoided with the meter:

– Extreme dust, moisture and wetness

– Exposure to intensive light and heat

– Fumes that are corrosive or contain high concentrations of solvents.

For measuring, the meter must be placed on a flat surface.

Spilled liquid or other material should be removed immediately (see sec-

tion 5.2 C

LEANING).

ECHNICAL DATA.

If a cell has broken in the cell shaft, the cell shaft should be cleaned imme-

diately (see section 6.1 A

CTIONS IN THE CASE OF A BROKEN CELL).

The cell shaft should always be closed when the photometer is not used.

During transport of the photometer, the cell shaft has to be empty.

For mobile use we recommend the suitable transport case (see section

8.1 A

CCESSORIES).

38

ba75703e07 04/2014

Page 39

Spectroquant® Pharo 300 Commissioning

3.3 Initial commissioning

Perform the following activities:

Insert the buffer batteries (see section 3.3.1)

Connect the power supply (see section 3.3.2)

Switch on the photometer (see section 3.3.3)

Set the language (see section 3.3.4)

Set the date and time (see section 3.3.5)

Carry out a zero adjustment (see section 4.4)

Note

When you set the language, date and time according to the mentioned sections of this operating manual you will quickly become familiar with the simple

operation of the Spectroquant

operation are given in section 4.2 G

®

Pharo 300. More detailed instructions on

ENERAL OPERATING PRINCIPLES.

3.3.1 Inserting the buffer batteries

The buffer batteries supply the integrated clock while the photometer is

switched off. Four alkaline manganese batteries (type AA or Mignon) separately included in the scope of delivery are used as the buffer batteries.

Insert the batteries as follows:

1 Turn the photometer upside down

1

and place it on a soft surface.

2 Open the lid of the battery com-

partment (1).

3 Insert the four batteries in the bat-

tery compartment. Make sure that

the poles of the batteries are in the

correct position.

The ± signs on the batteries must

correspond to the ± signs in the

battery compartment.

4 Close the lid of the battery com-

partment.

Battery service life The power consumption of the clock is very low. The lifetime of high quality

batteries is at least 5 years.

ba75703e07 04/2014

39

Page 40

Commissioning Spectroquant® Pharo 300

1

3.3.2 Connecting the power supply

The power is supplied via the enclosed plug-in power pack. The power pack

supplies the photometer with low voltage (12 VDC).

CAUTION

The line voltage of the usage location must fulfill the specifications stated on the power pack (the specifications are also given in chapter 7

T

ECHNICAL DATA). Always use the supplied 12 V original power pack on-

ly. The power pack is not suitable for operation with older photometers

(ser.no. prior to 1319xxxx).

Connecting the

plug-in power pack

Operation with a

mobile 12 V power

source

1 Connect the miniplug of the power

pack to the socket (1) of the photometer.

2 Connect the power pack to an

easily accessible power socket.

The display illumination switches

itself on and then off again.

You can also operate the Spectroquant

®

Pharo 300 on the move and inde-

pendent of the local power supply.

To do so, a 12 V power supply such as a commercial 12 V portable power

source or a 12 V car battery and the 12 V-Adapter available as an accessory

is required (see section 8.1).

More detailed information on operation is available:

in section 3.4.6 and

in the operating manual of the 12 V-Adapter .

40

ba75703e07 04/2014

Page 41

Spectroquant® Pharo 300 Commissioning

3.3.3 Switching on the photometer for the first time

During the initial commissioning, the photometer automatically guides you

through the setting of the meter language, date and time after switching on

(see following sections).

Language

Englisch ✓

English

Fran?ais

Espa?ol

Italiano

Bulgarian/Български

?esko

Simplified Chinese/ 中文

Traditional Chinese/ 繁體中文

Greek/Ελληνικ?

Indonesian/Indonesia

16.04.07 9:52

1 Press <ON/OFF>.

The photometer is switched on.

The display switches to the setting

of the language (see section

3.3.4).

After the setting of the language

the photometer carries out the

self-test.

When the initial commissioning is completed, the photometer displays the

Home menu each time after it is switched on and after the self-test (see section 4.1).

3.3.4 Setting the language

During the initial commissioning the photometer automatically guides you to

the setting of the meter language after switching on.

Language

Englisch ✓

English

Fran?ais

Espa?ol

Italiano

Bulgarian/Български

?esko

Simplified Chinese/ 中文

Traditional Chinese/ 繁體中文

Greek/Ελληνικ?

Indonesian/Indonesia

16.04.07 9:52

1 Select a language with <▲><▼>.

2 Confirm the selected language

with <START ENTER>.

The language has been set.

The currently selected language is

marked by a check.

The display switches to the setting

of the Date and Time (see section

3.3.5).

ba75703e07 04/2014

After the initial commissioning, you can change the language in the General

setup / Language menu at any time (see section 4.2.4).

41

Page 42

Commissioning Spectroquant® Pharo 300

Date/Time

16.04.07 9:52

Date 16.04.2007

Time 9:52:09

OK

Date/Time

16.04.07 9:52

Date 16.04.2007

Time 9:52:09

OK

Date

23 .10.2006

Date/Time

16.04.07 9:52

Date 16.04.2007

Time 9:52:09

OK

Time

10

:22 :09

3.3.5 Setting the date and time

During the initial commissioning, the instrument automatically guides you to

the setting of the time and date after the setting of the language.

The Date/Time menu is open.

Using <▲><▼>, select a menu

item and

confirm or open it with

<START ENTER>

.

1 Select and confirm Date.

The input field for the current date

pops up.

2 Enter the current date with <0...9>

and confirm.

The input field closes.

The date is accepted.

3 Select and confirm Time.

The input field for the current time

pops up.

4 Enter the current time with <0...9>

and confirm.

The input field closes.

The time is accepted.

After the initial commissioning, you can change the date and time in the Gen-

eral setup / Date/Time menu at any time (see section 4.2.4).

42

ba75703e07 04/2014

Page 43

Spectroquant® Pharo 300 Commissioning

3.4 Connecting optional accessories

3.4.1 Communication interfaces

Connections

RS232

USB-A

figure 3-1 Communication interfaces on the rear panel

USB-B

You can connect the following accessories to the photometer:

PC (see section 3.4.2)

Printer (see section 3.4.2)

USB storage media (see section 3.4.3)

USB-PC keyboard (see section 3.4.4)

Barcode reader (see section 3.4.5)

12 V-Adapter (see section 3.4.6)

Note

If you want to connect several USB devices such as a USB-PC keyboard and

a USB memory device to the meter, you can increase the number of USB-A

sockets by a commercially available USB-2 hub with separate power supply.

ba75703e07 04/2014

43

Page 44

Commissioning Spectroquant® Pharo 300