Page 1

The Producer™ System

Reverse Osmosis Water Purification System

INSTALLATION AND OPERATING

REV : 10-31-2012

MANUAL

Page 2

SpectraPure

TABLE OF CONTENTS:

®

Thank You for your purchase of a

installation and maintenance, this system will provide you with high quality

water for years to come. All SpectraPure® products are rigorously tested

by us for safety and reliability. If you have any questions or concerns, please

contact our customer service department at 1.800.685.2783 or refer to our

online troubleshooting at www.spectrapure.com.

System Specifications

System Description..............................................................................................................3

System Specifications..........................................................................................................4

System Initialization

Tap Water Hook-Up............................................................................................................5

Carbon Rinse.........................................................................................................................5

RO Membrane Rinse...........................................................................................................5

Waste Flow Adjustment................................................................................................5-6

Installation for optional SVC floats.............................................................................7-8

Maintenance..................................................................................................................................9

Troubleshooting and Replacement Parts.................................................................10-12

SpectraPure® System. With proper

COPYRIGHT 2009© BY SPECTRAPURE INC

No part of this publication may be reproduced, stored in a retrieval system, or transmitted

in any form or by any means, electronic, mechanical, photocopying, recording or otherwise

without the prior written permission of SpectraPure Inc.

SpectraPure®Inc.

2

2167 East Fifth St, Tempe, Arizona 85281

ALL RIGHTS RESERVED

480.894.5437 Call us toll-free 1.800.685.2783

Page 3

®

SpectraPure

- SYSTEM DESCRIPTION -

The Producer™ RO System is a three stage reverse osmosis system.

1. First, the incoming feed water is passed through a Carbon Tank pre-filter.

This filter removes organics and chlorine from the feed water that can

damage the membrane.

2. The second stage of filtration is a 0.5 micron Sediment pre-filter. This filter is

required to remove excess turbidity (particulate matter) that may

cause the membrane to plug.

NOTE: At this point you can add an (optional) Water Softener to increase

the membrane life

3. The third filtration stage of the system is a high rejection thin film composite

(TFC) reverse osmosis membrane. It removes over 98% of most inorganic

salts, all micro-organisms and almost all high molecular weight organics in

the water.

Fig. A: Filter Diagram

Tap

Water

IN

Optional

Back

Flush

Valve

Carbon

Tank

.5 micron

MicroTec™

Sediment

Pre-Filter

OPTIONAL SVC

(Solenoid Valve Controller)

Pressure

Gauge

OUT To

Membrane

OPTIONAL

Big Blue 2-Stage DI

Add-On w/ TDS meter

Membrane

Mounting Clips

SpectraPure®Inc

E-mail: spectra@spectrapure.com Visit us on the web www.spectrapure.com

. Fax 480.894.6109 Fax us toll-free 1.877.527.7873

3

Page 4

®

SpectraPure

- SYSTEM SPECIFICATIONS -

Sediment Pre-Filter 0.5 micron MicroTec™ sediment pre-filter

Carbon Media Granulated Activated Carbon

RO Membrane Type Thin-Film Composite (TFC)

Rejection Rate Greater than 98% average

Input Water Pressure 60 psi (4.15 bar) line pressure*

Input Water Temp 77°F (25°C)

Recovery Rate 20% (i.e. 20% of the water will be

collected as pure water)

Nominal Membrane Flow Rates @ 60 psi & 77° F :

GPD Product Water Flow Rate Concentrate Flow Rate

600 25 gal/hr 264 ml/min

1400 105 gal/hr 420 ml/min

Reverse Osmosis Feed Water Requirements

For the 1 year TFC membrane pro-rated warranty to be honored, the following conditions

must be met:

Operating Pressure* 40 – 80 psi (2.75 – 5.5 bar)

pH Range 3 – 11

Maximum Temperature 100° F (38° C)

Maximum Turbidity 1.0 NTU

Maximum Silt Density Index 5.0 (based on 15 min. test time)

Maximum Chlorine less than 0.1 ppm

Maximum TDS 2000 ppm

Maximum Hardness 10 grains (170 ppm as CaCO3)

Maximum Iron less than 0.1 ppm

Maximum Manganese less than 0.1 ppm

Maximum Hydrogen Sulfide 0 ppm

Langlier Saturation Index LSI must be negative

*Operating pressure less than 40 psi will require a booster pump.

*Operating pressure greater than 80 psi will require a pressure reducing valve.

SpectraPure®Inc. assumes no responsibility for water damages

due to leaks. It is the user’s responsibility to determine that the

system is leak-free by monitoring installation for 72 hrs.

SpectraPure®Inc.

4

2167 East Fifth St, Tempe, Arizona 85281

480.894.5437 Call us toll-free 1.800.685.2783

Page 5

®

SpectraPure

- SYSTEM INITIALIZATION -

If you are setting up your system for the first time or replacing a membrane,

p

lease adjust the ratio of waste vs. product shown in steps 6-8.

Tap Water Hook-Up:

1. Attach the garden hose adapter to your

water (greater than 100° F (38° C)) through the system.

Carbon Rinse:

2. Remove Sediment Filter from the 10” housing and screw the empty

housing back on. (Do not tighten housing with provided filter wrench.

The wrench is used to unscrew housings only).

the membrane at this time.

3. Run water through the Carbon tank until the water runs clear. Discard this

water down the drain.

4. Once the water runs clear, re-install Sediment Filter and connect to RO

membrane.

cold

water source. Never run hot

Do not connect water to

Reverse Osmosis (RO) Membrane Rinse:

5. You must rinse out the membrane preservative by running 2 gallons of

purified water. If you have DI resin cartridges after the membrane, rinse

the membrane with the down-stream DI’s removed. Discard this water

down the drain.

* When replacing the membrane, bypass the RO water to a drain for 2

gallons.

Waste to Product Flow Adjustment:

6. Place the yellow concentrate tubing and the blue purified water tubing into

a drain. Do not restrict flow from these lines.

7. Open the cold water supply valve. You may use pressure up to 80 psi (5.5

bar).

8. Adjust the flow restrictor needle valve, page 6, (#13) until you receive a 3/1

ratio of waste/product water by measuring product & waste water

production for 1 minute each.

Check the system to ensure that all fittings are tight and leak-free before

leaving the system unattended.

If the unit is not used for several days, run the system for at least 15 minutes

before collecting any water.

SpectraPure®Inc

E-mail: spectra@spectrapure.com Visit us on the web www.spectrapure.com

. Fax 480.894.6109 Fax us toll-free 1.877.527.7873

5

Page 6

SpectraPure

that the system is leak-free.

®

SpectraPure®Inc. assumes no responsibility for water

damage due to leaks. It is the user’s responsibility to determine

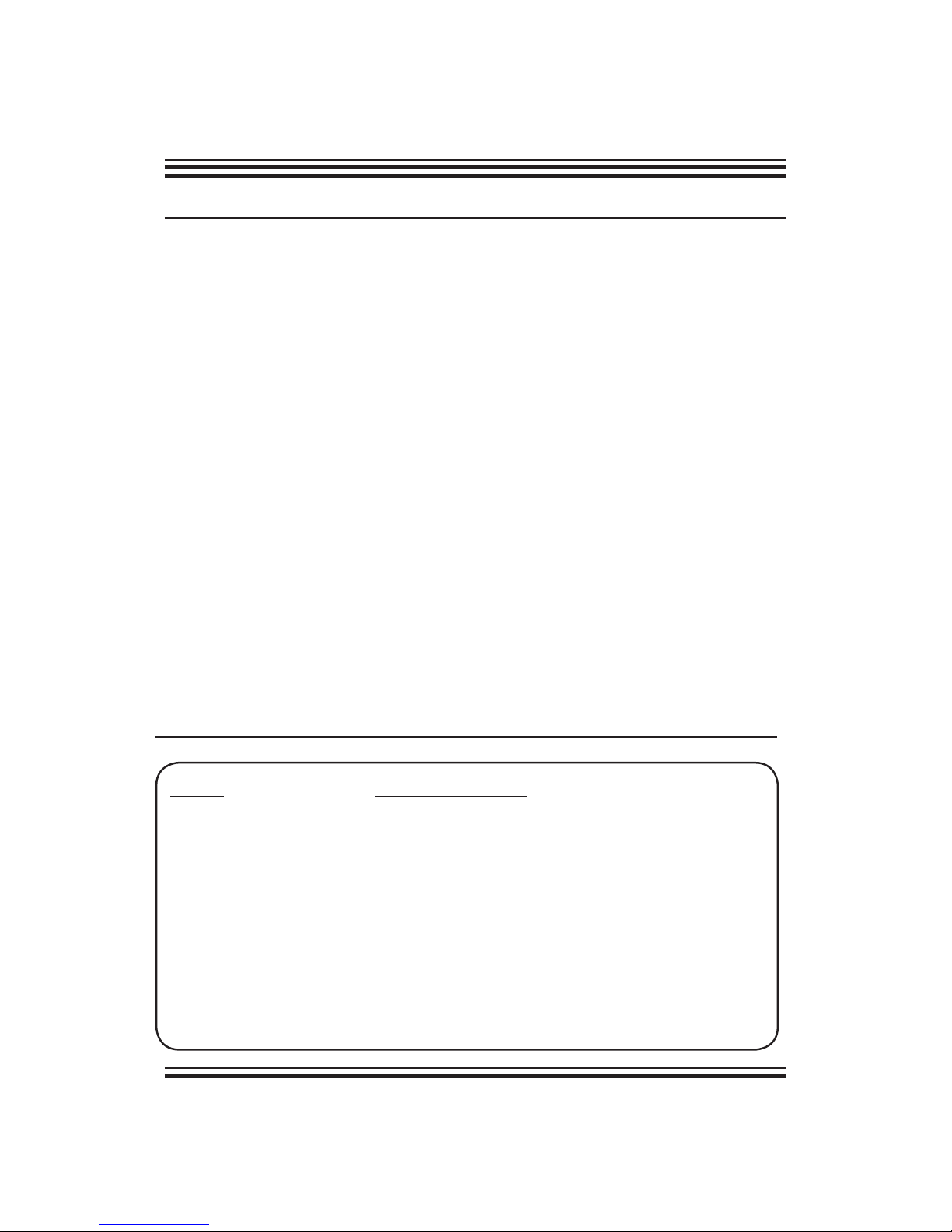

9 - Push Fitting Connections, 1/2T x 1/2MPT (DM-10-8-8)

10 -Nylon Hex Bushing, 3/4MPT x 1/2FPT (NY-HB-12-8)

11 - Push Fitting Connection, 3/8T x 1/2MPT (DM-10-6-8)

12 - Brass Swivel Garden Hose Adapter, FGH x 1/2FPT (GHA-8FPT-BR)

13 - Flow Restrictor 1/4” Needle Valve

14 - Tap Water “IN” Black Tubing, 1/2” (TUB-8BK)

15 - Waste Water “OUT” Yellow Tubing, 1/4” (TUB-4YW)

16 - Product Water “OUT” Blue Tubing, 3/8” (TUB-6BL)

1 - Stainless Steel Housing (HSG-M-SS-4x40)

2 - Carbon Tank w/ Cap (CF2050-0.5CF)

3 - Clear SlimLine 10” Sediment Housing (HSG-F-12-#10-SL-CLR)

4 - Wet Pressure Gauge (GA-W-2.0-B-1/4-160)

5 - Brass 4” Nipple (BR-NP-12-4.00)

6 - Membrane Housing Clamps (CLIP-CLIC-4.0)

7 - Nylon Plug (NY-PL-8)

8 - Nylon Hex Bushing, 3/4MPT x 1/8FPT (NY-HB-12-2)

SpectraPure®Inc.

6

2167 East Fifth St, Tempe, Arizona 85281

480.894.5437 Call us toll-free 1.800.685.2783

Page 7

®

SpectraPure

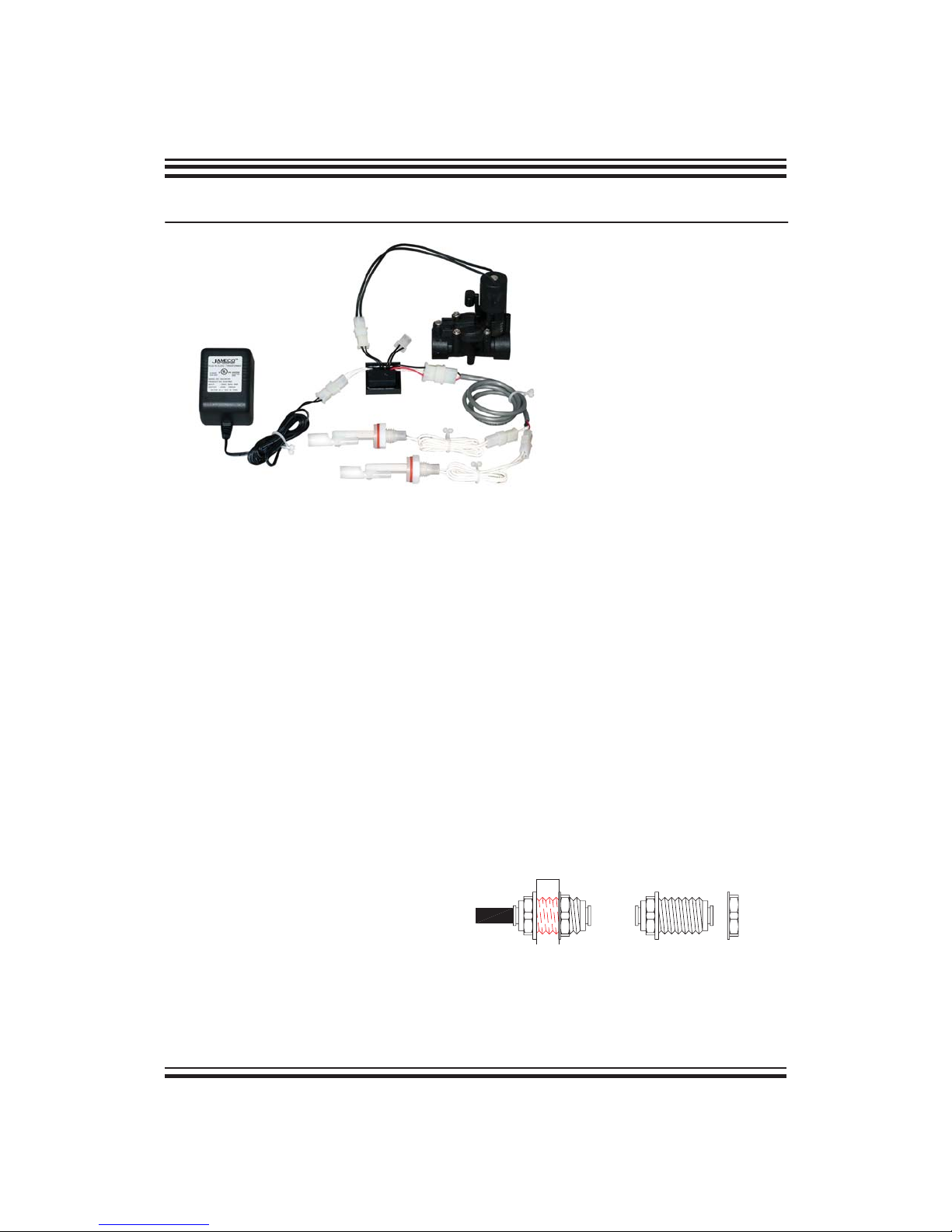

- INSTALLATION PROCEDURE FOR OPTIONAL FLOATS -

NOTE: Floats are to be

SOLENOID

TRANSFORMER

SVC

mounted horizontal when

dry and float up when

wet. In most instances we

recommend locating the

low float approx. half way

down your reservoir. DO

NOT OVERTIGHTEN when

installing the floats.

Float Installation:

1. Instal both the High and Low Floats onto a open container like a

Rubber Maid

5/8” hole. (The High Float shuts down the system, while the Low

Float turns the system on).

2. Connect the floats to the grey electrical extension cable and then to

the 3-socket connector on the S.V.C.

Solenoid Installation:

3. Un-screw current push-fitting from the carbon tank. (This fitting is

the input connection for the tap water).

4. Thread on the Brass Nipple to the Carbon Tank and then the

Solenoid. (Arrow on Solenoid points in the direction where the water

flows). PAGE 8.

5. Connect electrical cable to S.V.C. and thread last two fittings onto the

solenoid as shown on page 8.

6. 3/8” BULK HEAD FITTING: Use

a paddle bit and carefully drill a.

13/16” hole for installation at the top of the reservoir (above the high

level float)

TM

FLOATS

trash can. The floats can be mounted by drilling a

7. Provide over-flow plumbing suitable for your storage tank and installation.

SpectraPure®Inc

E-mail: spectra@spectrapure.com Visit us on the web www.spectrapure.com

. Fax 480.894.6109 Fax us toll-free 1.877.527.7873

7

Page 8

SpectraPure

®

SpectraPure®Inc.

8

2167 East Fifth St, Tempe, Arizona 85281

480.894.5437 Call us toll-free 1.800.685.2783

Page 9

®

SpectraPure

-MAINTENANCE -

Using the Pressure Gauge

The pressure gauge is used to monitor the condition of the pre-filters.

When the pre-filters are new, the gauge will indicate the actual available

water pressure. As the filter collects particulates, the pressure will begin

to drop.

Sediment Pre-Filter and Carbon Tank:

1. A 10-15% (or more) drop in pressure would indicate that the

Sediment Pre-Filter or Carbon needs replacement. To determine

which needs to be changed, follow this procedure:

- Note the pressure reading on the gauge.

- Remove the Sediment Pre-Filter out of the 10” housing and

screw the empty housing back on.

- Run water through the system to see if you get an increase in

pressure on the gauge.

* If you do get an increase in pressure when running this test, then

the sediment filter needs to be replaced.

* If the pressure stays the same, then you need to back wash the

carbon tank. (An optional manual back wash valve is available for

the carbon tank).

* If the carbon tank plugs prematurely and you do not have a

manual backwash valve, please contact us for further instructions.

2. Monitor the Carbon tank for chlorine removal by using a chlorine

test kit (TK-CL-5-KIT). If there is any presence of chlorine after the

carbon tank, change the carbon.

SpectraPure®Inc

E-mail: spectra@spectrapure.com Visit us on the web www.spectrapure.com

. Fax 480.894.6109 Fax us toll-free 1.877.527.7873

9

Page 10

®

SpectraPure

TROUBLESHOOTING GUIDE:

Product Water - Low Production Rate

Cause Corrective Action

Plugged pre-filters Replace pre-filters

Low water temperature Heat feed water or use higher GPD membrane

Low water pressure Use booster pump or use higher GPD membrane

Fouled membrane Replace membrane

MEMBRANE TROUBLESHOOTING GUIDE

The following chart illustrates the procedure for determination of RO membrane

performance. However, the chart represents only rough guidelines for determining performance of RO membrane. Depending on your tap water chemistry, the

rejection characteristics of the membrane may vary significantly.

Method of Calculate % Test Results Conclusion

Testing Rejection

TDS/ Measure feed water (X) Is Rejection No - Replace Membrane

Conductivity

Tester for TDS/Conductivity 95% ?

Alkalinity Measure feed water (X) Is Rejection

Test Kit RO product water (Y) greater than Yes - Membrane OK

for Alkalinity 90% ?

Hardness Measure feed water (X) Is Rejection

Test Kit** RO product water (Y) greater than Yes - Membrane OK

for Hardness 90%?

**Caution: This test is will not work on softened water sources.

RO product water (Y) greater than Yes - Membrane OK

No - Replace Membrane

No - Replace Membrane

SpectraPure®Inc.

10

2167 East Fifth St, Tempe, Arizona 85281

480.894.5437 Call us toll-free 1.800.685.2783

Page 11

®

SpectraPure

TIPS FOR LONG MEMBRANE LIFE:

1. Replacement of 1 micron sediment filter once every 6 months. This will

prevent mem brane fouling due to silt or sediment depositing on the

membrane.

3. Membrane should not be operated at lower than the recommended

concentrate to purified water ratios, as described on page 5.

4. Operating reverse osmosis systems on softened feed water greatly reduces

the chances of membrane fouling.

STORAGE

1. Your RO System must be protected from freezing or temperatures above

100° F (38°C). If the unit is used outside, avoid putting the system in direct

sunlight or connecting it to a garden hose that may be exposed to sunlight.

Light Sources

A. Most of the components of this system are plastic and are

subject to damage by ultraviolet light from the sun and other

sources such as metal halide lighting.

B. Algae is more likely to thrive inside the clear filter housings

when exposed to bright light.

C. Avoid installing this unit in bright light or direct sunlight.

REPLACEMENT PARTS

Model Replacement Part

SF-MT-1-10 1 micron MicroTec™ Sediment Filter

AC-20X50-COCO Carbon bag refill (refills tank twice)

MEM-1000 Replacement membrane for 600gpd system

MEM-2600 Replacement membrane for 1400gpd system

GHA-8FPT-BR Garden Hose Adapter with 1/2in Tubing

Push Fitting

WR-UNIV Universal Filter Wrench

SpectraPure®Inc

E-mail: spectra@spectrapure.com Visit us on the web www.spectrapure.com

. Fax 480.894.6109 Fax us toll-free 1.877.527.7873

11

Page 12

®

SpectraPure

ONE YEAR LIMITED WARRANTY:

Effective on products purchased after March 10, 2005.

All standard water purification products manufactured by SpectraPure have a 3 year limited warranty,

except the Eliminator™ MarinePro™, Industrial, Laboratory, Custom Systems, Commercial and electrical

products which have a 1 year limited warranty. LiterMeters™ & UPLC™ have a 5 year limited warranty. OEM

equipment resold by SpectraPure (pumps and monitors) carry the original manufacturer’s warranty.

SpectraPure, Inc.® warrants the product to the original owner only to be free of defects in material and

workmanship for a period of three years from the date of receipt. SpectraPure’s liability under this warranty

shall be limited to repairing or replacing at SpectraPure’s option, without charge, F.O.B. SpectraPure’s factory,

any product of SpectraPure’s manufacture. SpectraPure will not be liable for any cost of removal, installation,

transportation or any other charges which may arise in connection with a warranty claim. Products which

are sold but not manufactured by SpectraPure are subject to the warranty provided by the manufacturer

of said products and not by SpectraPure’s warranty. SpectraPure will not be liable for damage or wear to

products caused by abnormal operating conditions, accident, abuse, misuse, unauthorized alteration or

repair or, if the product was not installed in accordance with SpectraPure’s or other manufacture’s printed

installation and operating conditions, or damage caused by hot water, freezing, flood, fire or acts of God.

SpectraPure will not be responsible for any consequential damages arising from installation or use of the

product, including any water or mold damage due to flooding which may occur due to malfunction or faulty

installation, including, but not limited to failure by installer to over- or under-tighten fittings, housings, and/

or push-style fittings, or improper installation of push-style fittings. Consumable items such as pre filters and

membranes are not covered under the 3 year warranty.

SpectraPure warrants (pro-rated) the performance of tested SpectraSelect™ RO membrane elements only,

for one year from date of receipt by the buyer, providing that the loss of performance was not caused by

fouling, neglect or water conditions exceeding the feed water parameters listed in the applicable product

manual (refer to detailed membrane warranty information). SpectraPure will, on confirmation of loss of

performance during the warranty period, credit the pro-rated amount of the current catalog price of the

element. The disposable filters and cartridges are not covered under the warranty.

To obtain service under this warranty, the defective system or components must be returned to SpectraPure

with proof of purchase, installation date, failure date and supporting installation data. Any defective product

to be returned to the factory must be sent freight prepaid; documentation supporting the warranty claim

and a Return Goods Authorization (RMA) number must be included. SpectraPure will not be liable for

shipping damages due to the improper packaging of the returned equipment and all returned goods must

also have adequate insurance coverage and a tracking number.

SpectraPure will not pay for loss or damage caused directly or indirectly by the presence, growth,

proliferation, spread or any activity of “fungus”, wet or dry rot or bacteria. Such loss or damage is excluded

regardless of any other cause or event that contributes concurrently or in any sequence to the loss. We

will not pay for loss or damage caused by or resulting from continuous or repeated seepage or leakage

of water, or the presence or condensation of humidity, moisture or vapor, that occurs over a period of 14

days or more. “Fungus” and “fungi” mean any type or form of fungus or Mycota or any by-product or type

of infestation produced by such fungus or Mycota, including but not limited to, mold, mildew, mycotoxins,

spores, scents or any biogenic aerosols.

SpectraPure will not be liable for any incidental or consequential damages, losses or expenses arising from

installation, use, or any other causes. There are no expressed or implied warranties, including merchantability

or fitness for a particular purpose, which extend beyond those warranties described or referred to above.

* The thee year limited warranty does not apply to consumable items, including but not

limited to, filters and cartridges unless specifically stated above

SpectraPure®Inc.

12

2167 East Fifth St, Tempe, Arizona 85281

480.894.5437 Call us toll-free 1.800.685.2783

Loading...

Loading...