Spectra-Physics Millennia eV Series, Millennia eV 15, Millennia eV 10, Millennia eV 5 User Manual

Millennia eV

User’s Manual

Diode-Pumped, CW Visible Laser Systems

Millennia eV 15

Millennia eV 10

Millennia eV 5

This laser product complies with performance

standards of United States Code of Federal

Regulations, Title 21, Chapter 1 – Food and

Drug Administration, Department of Heal th and

Human Services, Subchapter J – Parts

1040.10 or 1040.11, as applicable.

Spectra-Physics

3635 Peterson Way

Santa Clara, CA 95054

Part Number 90062440

June 2013

Revision A

Copyright © 2013 Newport Corporation. All rights reserved.

Newport, the Newport logo, and other Newport company and product names referenced in the document are

registered trademarks, trademarks, or service m arks of Newport Corpor ation or its subsidiaries. Other comp any

and product names may be the trademarks of the respective co mpanies with which they are associated.

Spectra-Physics ma kes no express or implied re presentations or warranties with respect to the contents or use

of this manual, and specifically disclaims any implied warranties of merchantability or fitness for a particular

purpose. In no event is Spectra-Physics liab le for any direct, indirect, special, incidental, or consequential

damages resulting from any defects in this documentation.

This manual is copyrighted with all rights reserved. Under the copyrigh t laws, this manu al can not be cop ied in

whole or in part without the express written consent of Spectra-Physics. Documents that are authorized to be

copied must bear all the proprietary and copyright notices of the original.

Every effort has been made to ensure that the information in this manual is accurate. Spectra-Physics further

reserves the right to revise this manual and to make changes to its contents at any time, without obligation to

notify any person or entity of such revisions or changes.

If you encounter any difficulty with the co ntent or style of this manual or encounter problems with the laser itself,

please let us know.

“Form for Problems and Solutions” aids in bringing such issues to our attention.

Preface

About this Guide

The Spectra-Physics Millennia eV system is a diode-pumped, continuous-wave, visible

laser system. This manual contains information for the safe installation, operation, and

maintenance of the laser system.

Overview of this Guide

The Millennia eV User’s Manual includes the following sections:

Chapter 1, “Introduction,” is a brief overview of the Millennia eV system.

Chapter 2, “Laser Safety,” contains warnings and important information regarding

laser safety. Review this chapter before using the Millennia eV system.

Chapter 3, “Laser Description,” provides a description of the Millennia eV laser

system and concludes with system specifications and outline drawings. For optical

specifications, visit the Newport website at

http://www.newport.com/Millennia-eV-High-Power-CW-DPSS-Lasers/1011478/1

033/info.aspx

Chapter 4, “Controls, Indicators, and Connections,” describes the external control

features of the Millennia eV system.

Chapter 5, “Installation,” contains instructions for installing the system, including

hook-up diagrams and lists of required components.

Chapter 6, “Preparing for Operation,”provides instructions for installing the USB

driver and GUI software.

Chapter 7, “Operation,” describes in detail how to operate the laser.

Chapter 8, “Maintenance,” is intended as a guide for routine maintenance and

diagnosing and fixing common problems.

Chapter 9, “Customer Service,” describes our product warranty, return policy, and

training programs, and provides information on contacting customer service,

including a list of our service center locations.

Appendix A, “Programming Reference Guide,” contains the command reference.

“Notes” provides space to keep track of the service history for the Millennia eV

laser.

“Form for Problems and Solutions” is our feedback form, which the user can use to

report problems with our instruments or documentation, submit comments, suggest

new features, or request more information.

iii

Overview of this Guide

iv Preface

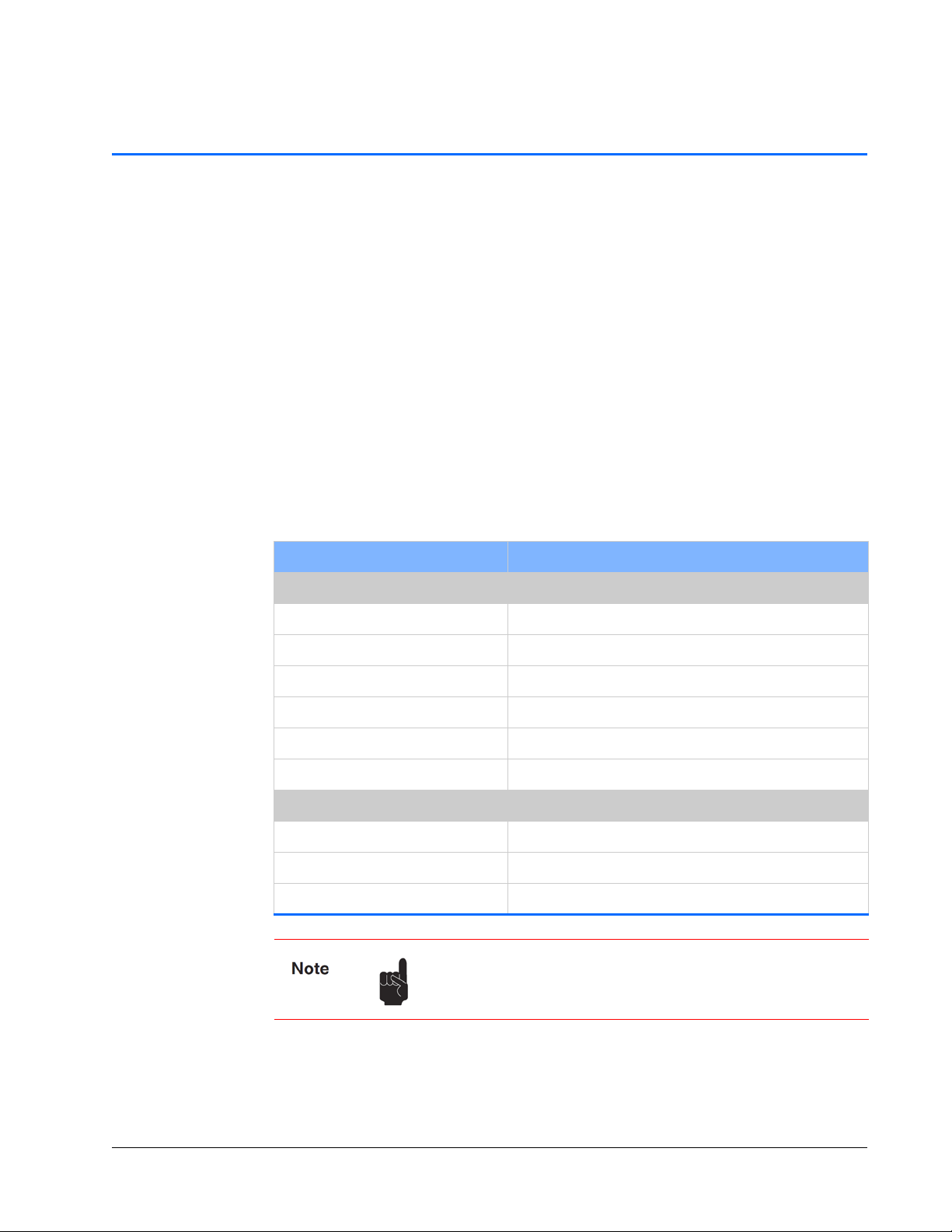

Environment al Specifications

CE Electrical Equipment Requirements

For information regarding the equipment needed to provide the required electrical

service, refer to specification EN-60309, “Plug, Outlet and Socket Couplers for

Industrial Uses,” listed in the official Journal of the European Communities.

Environmental Specifications

The environmental conditions under which the laser system function are listed at

http://www.newport.com/Millennia-eV-High-Power-CW-DPSS-Lasers/1011478/1

033/info.aspx

These specifications reflect indoor use conditions.

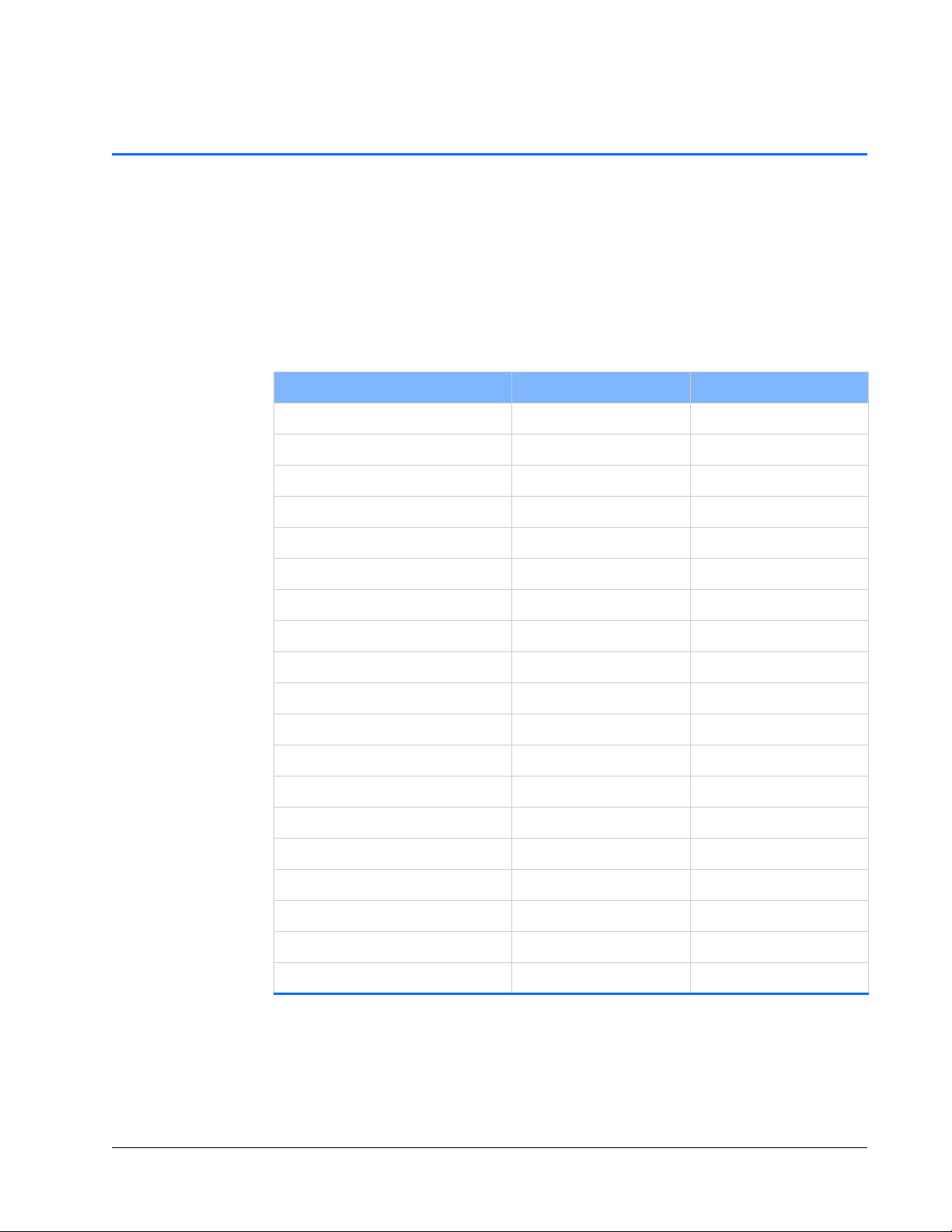

Feature Specification

Operating

Temperature ra ng e 18 °C to 35°C

Altitude 0 to 3,000 m

Relative humidity < 80%, non-condensing

Mains supply voltage Do not exceed ± 10% of the nominal voltage

Insulation category II

Pollution degree 2

Non-operating

Temperature ra ng e -20°C to 50°C

Altitude 0 to 12,000 m

Relative humidity < 90%, non-condensing

Also see “Specifications” for power, heat, and cooling

specifications.

v

FCC Regulations

FCC Regulations

This equipment has been tested and found to comply with the limits for a Class A digital

device pursuant to Part

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, can cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference, in which case the

user is required to correct the interference at his own expense.

Modifications to the laser system not expressly approved by Spectra-Physics could void

the user’s right to operate the equipment.

15 of the FCC Rules. These limits are designed to provide

CDRH Compliance

This product conforms to the requirements of 21 CFR 1040.10 CDRH.

vi Environmental Specifications

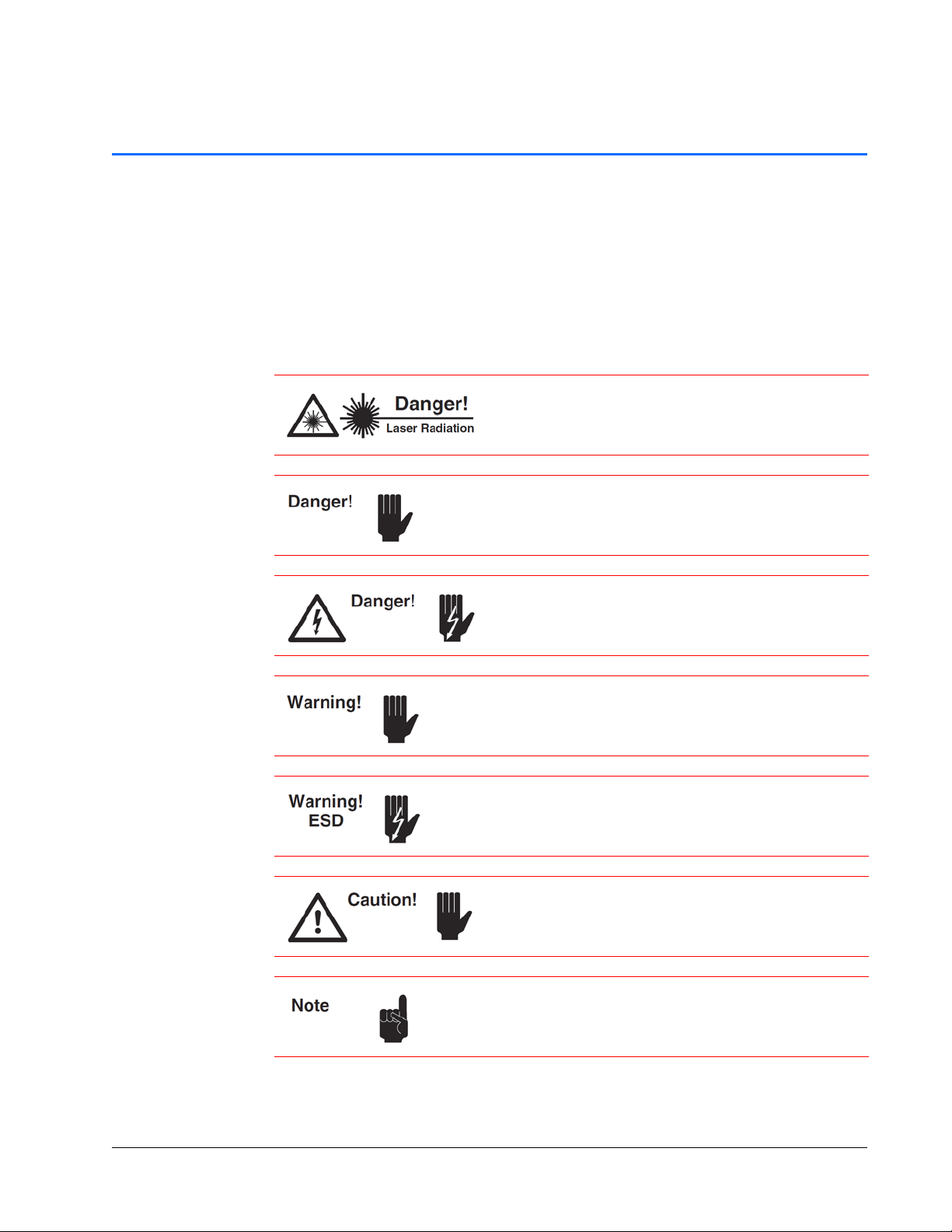

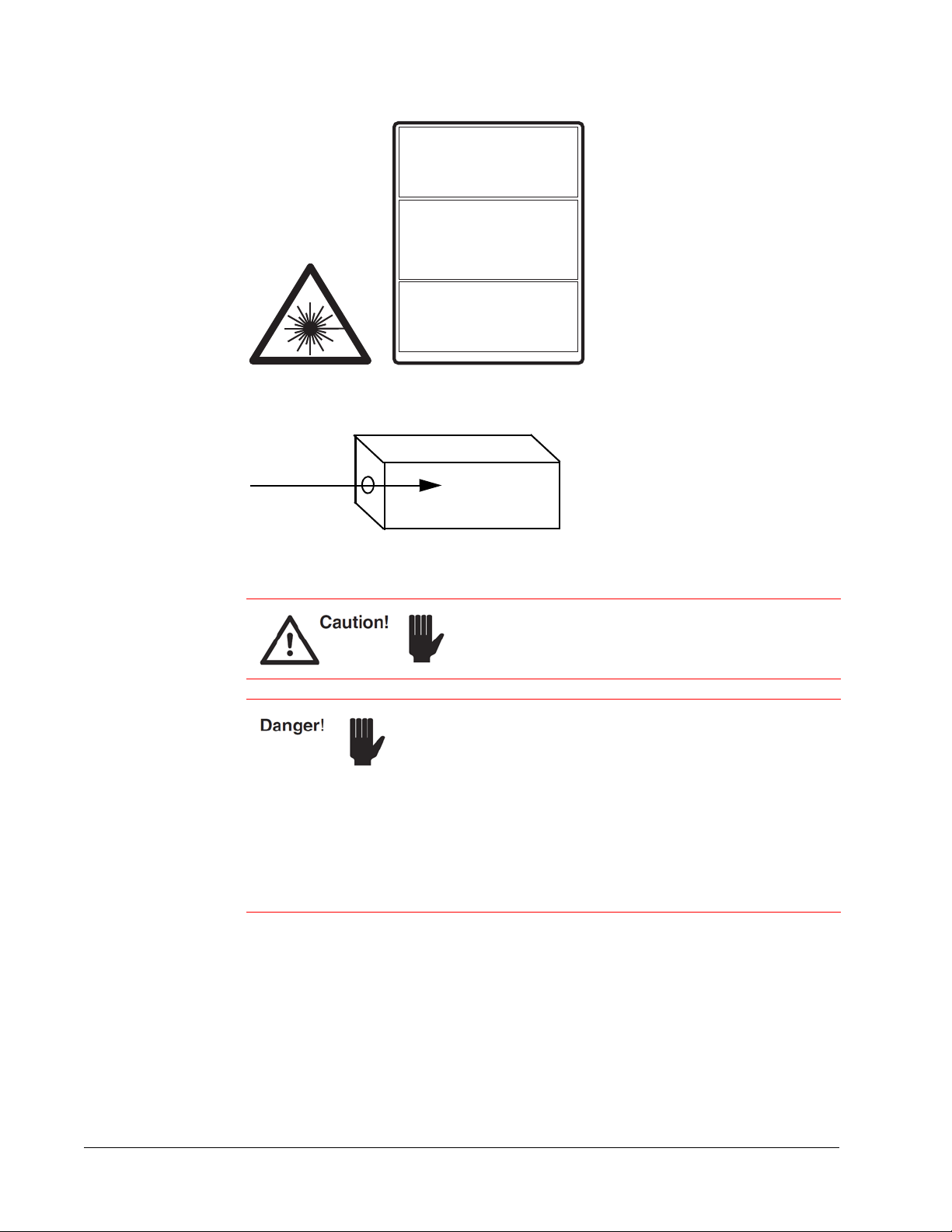

Warning Conventions

W arning Symbols

The following symbols are used throughout this manual to draw the user’s attention to

situations or procedures that require extra attention. They warn of health hazards,

damage to equipment, sensitive procedures, and exceptional circumstances. All

messages are set apart by a thin line above and below the text as shown here.

Condition or action may present a hazard to personal safety.

Laser radiation is present.

Condition or action may present an electrical hazard to

personal safety.

Condition or action may cause damage to equipment.

Action may cause electrostatic discharge and cause damage

to equipment.

Condition or action may cause poor performance or

error.

Text describes exceptional circumstances or makes a special

reference.

vii

Warning Symbols

Factory Trained

Do not touch.

Appropriate laser safety eyewear should be worn during this

operation.

Refer to the manual before operating or using this device.

Serviceable only by Spectra-Physics factory trained personnel.

viii Warning Conventions

Table of Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Warning Con v entions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

List of Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiii

List of Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Standard Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Chapter 1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Environmental Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Patents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Chapter 2: Laser Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Safety Precautions for Class IV High-Power Lasers . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Safety Device Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Emission and Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

ENABLE Keyswitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

External Safety Interlock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Power Disconnect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Maximum Emission Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Operating the Laser via a User-Created GUI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

CE Radiation Control Drawings and Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Label Placement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Label Illustrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

CE Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

WEEE Recycling Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Other Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Additional Safety Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Laser Safety Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Equipment and Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Chapter 3: Laser Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

ix

Millennia eV Series System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Millennia eV Laser Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Frequency Doubling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Light Pick-off and Power Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

System Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Chiller Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Outline Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Chapter 4: Controls, Indicato rs, and Connections . . . . . . . . . . . . . . . . 4-1

Laser System Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

ANALOG Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Monitoring Laser Status Via the ANALOG Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Using the Indicator Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Chapter 5: Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Pre-Installation Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Utility Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Mounting the Laser Head. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Connecting the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

AC Power Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Analog Control Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Installing the Chiller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Chapter 6: Preparing for Operation. . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Installing the USB Driver and User GUI Software . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Installing the Millennia eV USB Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Installing Millennia eV GUI Control Software . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

Chapter 7: Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Millennia eV GUI Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

The Main Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

The View Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

Start-up Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

Operating the Laser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

Turning the Laser On and Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

Shutter Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

Using Serial Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-9

x Table of Contents

SHG Autotune . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Alignment Mode Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Chapter 8: Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Flushing and Refilling the Chiller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Maintenance Tips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

Replacing the Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Diagnostics and Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

System Event Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

Troubleshooting Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Chapter 9: Customer Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

Contacting Customer Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

Return Policy and Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-2

Service Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-2

Service Centers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-3

Appendix A: Programming Reference G uide. . . . . . . . . . . . . . . . . . . . . A-1

Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Basic Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Important Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-5

Less Common Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-8

Form for Problems and Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Form-1

Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Notes-1

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Index-1

Table of Contents xi

xii Table of Contents xiii

List of Figures

Figure 1-1: Millennia eV laser. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Figure 2-1: Safety warning labels (EN 60825-1: 2007, ANSI Z136.1 Section 4.7). . . . . .2-2

Figure 2-2: Beam dump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Figure 2-3: Laser head emission indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Figure 2-4: Laser safety devices, rear panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Figure 2-5: Millennia eV system conformance labels, front (left) and rear (right). . . . . . .2-6

Figure 2-6: Millennia eV system conformance labels, bottom . . . . . . . . . . . . . . . . . . . . . 2-7

Figure 2-7: Millennia eV system conformance labels, top view . . . . . . . . . . . . . . . . . . . .2-7

Figure 2-8: Safety warning labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Figure 3-1: Millennia eV laser system outline drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Figure 3-2: Interlock safety block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Figure 3-3: Millennia eV system block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Figure 4-1: Millennia eV laser head, rear panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Figure 4-2: Millennia eV laser emission indicator and output beam . . . . . . . . . . . . . . . . . 4-3

Figure 4-3: ANALOG output drain schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Figure 5-1: System interconnect drawing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Figure 6-1: Setup icon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Figure 6-2: Preparing to Install window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Figure 6-3: InstallShield wizard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Figure 6-4: Setup Status window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Figure 6-5: Device Driver Installation wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Figure 6-6: Driver installation in progress. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Figure 6-7: Completing the Device Driver Installation window . . . . . . . . . . . . . . . . . . . . .6-5

Figure 6-8: Software installed successfully message. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Figure 6-9: Setup file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Figure 6-10: .NET license agreement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Figure 6-11: .NET installation progress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Figure 6-12: Welcome window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

Figure 6-13: Select installation folder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

Figure 6-14: Confirm installation window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Figure 6-15: Installing window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Figure 6-16: Installation Complete window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Figure 6-17: Spectra-Physics desktop icon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Figure 7-1: Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Figure 7-2: View menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

Figure 7-3: Communication window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

Figure 7-4: Oven window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

Figure 7-5: About menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Figure 7-6: GUI connection in progress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Figure 7-7: Laser turning on notice. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

xiv List of Figures xv

List of Tables

Table 1-1: Millennia eV system patents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Table 2-1: Maximum emission levels from the laser head . . . . . . . . . . . . . . . . . . . . . . .2-5

Table 2-2: Conformance label descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Table 3-1: Millennia eV laser system general specifications. . . . . . . . . . . . . . . . . . . . . .3-3

Table 3-2: Millennia eV laser output characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Table 4-1: Laser head rear panel controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Table 4-2: IBM-PC/AT serial port pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Table 4-3: ANALOG port pin description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Table 7-1: Main menu features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

Table 7-2: Communication window features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

Table 7-3: SHG Oven window features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

Table 8-1: System event codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

Table 8-2: Non-event faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

Table 8-3: Troubleshooting guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Table 9-1: Service centers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-3

xvi List of Tables xvii

Standard Abbreviations

The following units, abbreviations, and prefixes are used in this Spectra-Physics

manual.

Unit Abbreviations

Quantity Unit Abbreviation

mass kilogram kg

length meter m

time second s

frequency hertz Hz

force newton N

energy joule J

power watt W

electric current ampere A

electric charge coulomb C

electric potential volt V

resistance ohm Ω

inductance henry H

magnetic flux weber Wb

magnetic flux density tesla T

luminous intensity candela cd

temperature Celsius C

pressure pascal Pa

capacitance farad F

angle radian rad

Prefixes

Prefixes

Prefix Power Abbreviation Prefix Power Abbreviation

tera (1012) T milli (10-3) m

giga (109) G micro (10-6) µ

mega (106) M nano (10-9) n

kilo (103) k pico (10

deci (10-1) d femto (10

centi (10-2) c atto (10

-12

) p

-15

) f

-18

) a

Abbreviations and Acronyms

Abbreviation Description

AC alternating current

ACGIH American Conference of Governmental and Industrial

Hygienists

ALPS active laser purification system

ANSI American National Standards Institute

AOM acousto-optic modulator

AR antireflection

CDRH Center for Devices and Radiological Health

CW continuous wave

DC direct current

fs femtosecond or 10

LBO lithium triborate

ns nanosecond or 10-9 second

ps picosecond or 10

-15

-12

second

second

RF radio frequency

SCPI Standard Commands for Programmable Instruments

SHG second harmonic generator

THG third harmon ic generator

UV ultraviolet

xviii Standard Abbreviations

Abbreviations and Acronyms

Abbreviation Description

VAC volts, alternating current

VDC volts, direct current

λ wavelength

WEEE waste electrical and electronic equipment

Standard Abbreviations xix

Abbreviations and Acronyms

xx Standard Abbreviations

CHAPTER 1: Introduction

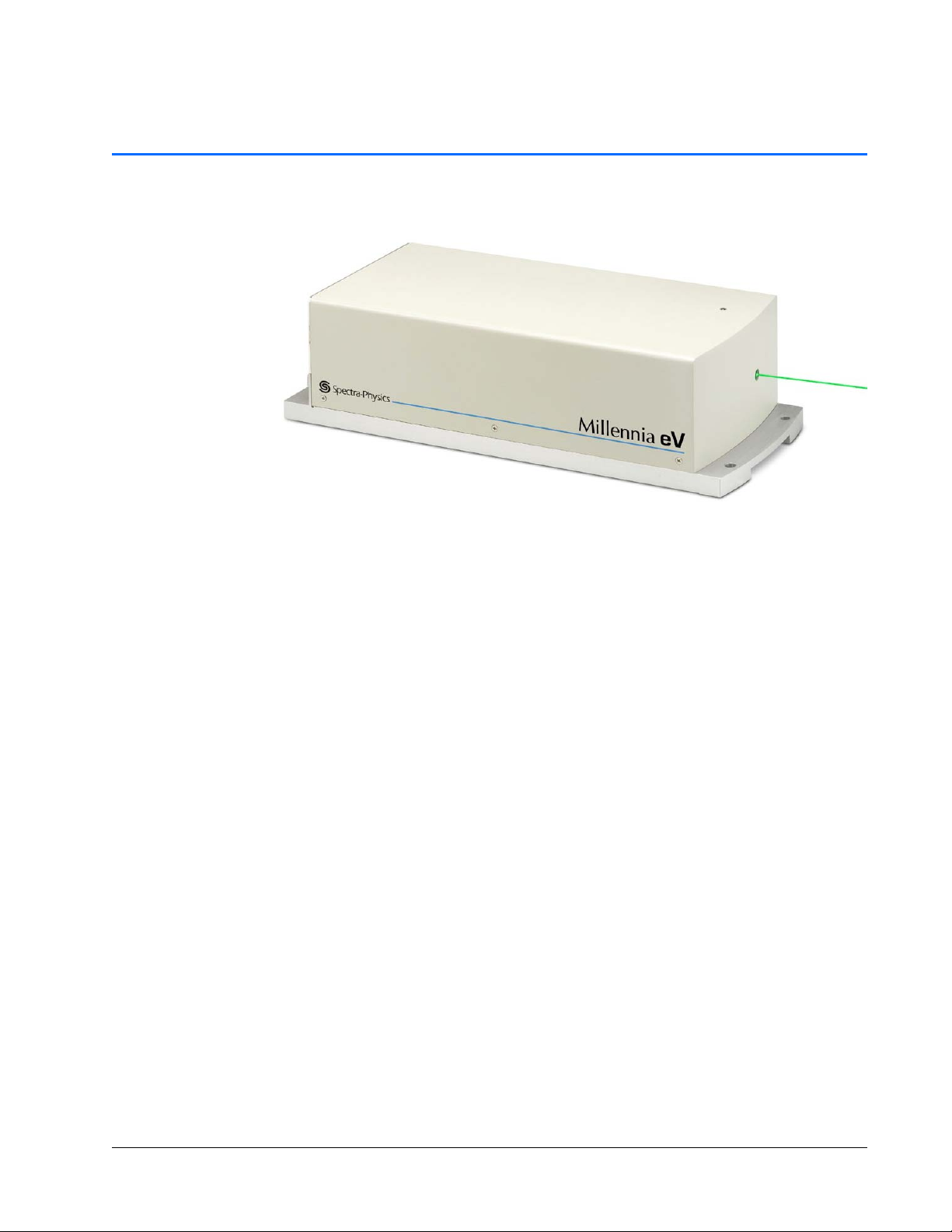

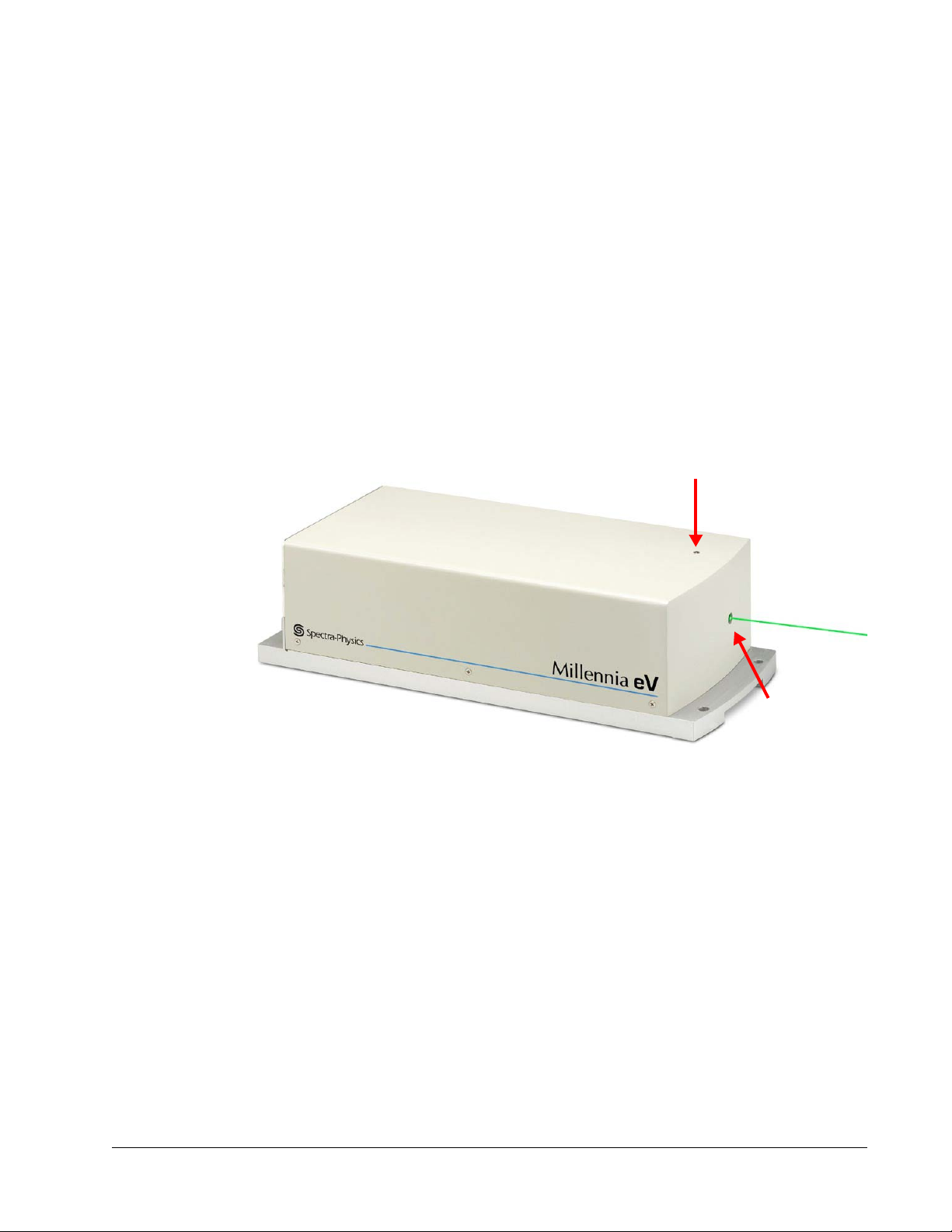

Figure 1-1 Millennia eV laser

The Spectra-Physics Millennia eV laser system is a diode-pumped, continuous-wave,

visible system. This laser system is a rugged, sealed unit designed for simple hands-free

operation.

The Millennia eV laser is smaller than competitive DPSS lasers of similar power. With

its intuitive GUI, automated command set, and superior design, the Millennia eV laser

is nearly maintenance free.

Millennia eV lasers have excellent near- and far-field beam pointing stability.

Some of the advantages of the Millennia eV laser are:

Reliable design and manufacture for high uptime

Lower cost of ownership

Excellent product value and low cost per watt

Robust manufacturing processes

The Millennia eV laser system was specifically designed for applications requiring a

high-quality beam, along with good mode quality in a cost-effective package. For a

more detailed description of the Millennia eV laser system, see

Description.”

System Control

During setup, a user-supplied computing device (typically a Windows-based personal

computer) must be connected to the Millennia eV laser head by means of either its

RS-232 or USB port to provide system control. Control software is provided on the

included USB memory stick for this purpose.

Chapter 3, “Laser

1-1

Environmental Control

Environmental Control

The Millennia eV laser system requires cooling fluid to remove heat and to stabilize the

temperature of various system components. A closed-loop chiller is used for this

purpose. The recirculating, temperature-controlled fluid flows to the laser head to

remove excess heat.

Patents

Millennia eV laser systems are manufactured under one or more of the following

patents.

Table 1-1 Millennia eV system patents

Millennia eV Laser Head

5,410,559 5,412,683 5,446,749 5,504,762

5,561,547 5,577,060 5,608,742 5,638,397

5,651,020 5,696,780 5,812,583 5,907,570

5,999,544 6,185,235 6,241,720 6,287,298

6,504,858 6,697,390 6,816,536 6,853,655

6,890,474 6,931,037 7,352,570 7,361,145

7,510,529 7,627,386 7,382,309 7,699,781

8,002,705 8,226,561

1-2 Introduction

CHAPTER 2: Laser Safety

This chapter provides important information on laser safety and Spectra-Physics

recommends that the user read it carefully.

The Millennia eV laser system is a Class IV laser that emits laser radiation that can

permanently damage eyes and skin. This section contains information about these

hazards and offers suggestions on how to safeguard against them.

The Spectra-Physics Millennia eV laser is a

Class

IV — High-Power Laser whose beam is, by

definition, a safety and fire hazard. T ake precautions to

prevent accidental exposure to both direct and

reflected beams. Diffuse as well as specular beam

reflections can cause severe eye or skin damage.

Residual light at 1064

might also be present.

Safety Precautions for Class IV High-Power Lasers

nm and 8xx nm wave-lengths

Wear protective eyewear at all times. Eyewear selection depends on the wavelength

and intensity of the radiation, the conditions of use, and the visual function required.

Protective eyewear is available from suppliers listed in the Laser Focus World,

Lasers and Optronics, and Photonics Spectra buyer’s guides. Consult the ANSI and

ACGIH standards listed in

Maintain a high ambient light level in the laser operation area so that the eye’s pupil

“Additional Safety Resources” for guidance.

remains constricted, reducing the possibility of retinal damage.

Avoid looking at the output beam; even diffuse reflections are hazardous.

Avoid blocking the output beam or its reflections with any part of the body.

Establish a controlled access area for laser operation. Limit access to personnel

trained in the principles of laser safety.

Enclose beam paths wherever possible.

Post prominent warning signs near the laser operating area (Figure 2-1).

Install the laser so that the beam is either above or below eye level.

Set up shields to prevent any unnecessary specular reflections or beams from

escaping the laser operation area.

When the target is not present, set up a beam dump to capture the laser beam and

prevent accidental exposure (

Do not block off access to any disconnect device such as the keyswitch, shutter

Figure 2-2).

control, power cord, etc.

2-1

Safety Precautions for Class IV High-Power Lasers

VISIBLE AND / OR INVISIBLE

LASER RADIATION

Avoid eye or skin exposure

to direct or scattered radiation.

Nd:YVO

, Nd:YAG, or Nd:YLF Laser. Various

4

ultraviolet, visible or infrared wavelengths

may be emitted. Consult instruction manual.

Class 4 laser product per IEC 60825-1 (2007)

SICHTBARE UND / ODER UNSICHTBARE

LASERSTRAHLUNG

Bestrahlung von Haut oder Auge durch

direkte oder Streustahlung vermeiden.

Nd:YVO

, Nd:YAG, oder Nd:YLF Laser.

4

Verschiedene ultraviolett, sichtbara oder infrarote

Laserstrahlung kann austreten. Weitere

Informationen siehe Bedienungsanleitung.

Laserschutzklasse 4 nach IEC 60825-1 (2007)

RAYONNEMENT LASER

VISIBLE ET / OU INVISIBLE

Eviter l’exposition de l’œil ou de la peau

au rayonnement direct ou diffus.

Laser Nd:YVO

, Nd:YAG ou Nd:YLF.

Emission potentielle dans l’ultraviolet, visible ou infrarouge.

Laser de classe 4 conformément à IEC 60825-1 (2007)

4

Consulter le manuel d’utilisation.

0129-4842

Figure 2-1 Safety warning labels (EN 60825-1: 2007, ANSI Z136.1 Section 4.7)

Figure 2-2 Beam dump

Operating this laser without due regard for these precautions or

in a manner that does not comply with recommended

procedures may be dangerous. At all times during installation,

maintenance or service of the laser, avoid unnecessary

exposure to laser or collateral radiation

electronic product radiation, except laser radiation, emitted by a

laser product as a result of or necessary for the operation of a

laser incorporated into that product) that exceeds the accessible

emission limits listed in “Performance Standards for Laser

Products,” United States Code of Federal Regulations,

21CFR1040.10(d).

Use of controls or adjustments, or performance of

procedures other than those specified herein can

result in hazardous radiation exposure.

(defined as any

2-2 Laser Safety

Safety Device Locations

Emission indicator

(white)

Output

beam port

Safety Device Locations

Emission and Status Indicators

The system provides the following emission and power indicators:

A white EMISSION indicator on top of the laser head (Figure 2-3) turns on about 3

seconds before actual emission occurs.

The STATUS fault indicator (Figure 2-4) flashes amber during the harmonic crystal

warm-up sequence. When the unit is warmed up and all of the safety requirements

are met, the indicator turns green and blinks. This indicator turns red and blinks

when a fault has occurred.

Pin 14 of the ANALOG connector can be used to control an external emission

indicator.

Figure 2-3 Laser head emission indicator

Laser Safety 2-3

Safety Device Locations

Figure 2-4 Laser safety devices, rear panel

ENABLE Keyswitch

The keyswitch on the rear panel (Figure 2-4) prevents unauthorized use of the laser

when it is turned to the horizontal (off) position and the key is removed. Placing this

switch in the

External Safety Interlock

Interlock pins 8 and 13 (Figure 2-4) of the ANALOG connector must be connected for

normal system operation. They can be used in an interlock circuit to terminate laser

emission when a normally closed safety switch wired to these pins is opened. Such a

switch can be attached to an access point, such as an entry panel, that might be opened

unexpectedly. See

requirements.

Power Disconnect

The utility unit is provided with a grounded appliance inlet. To help maintain the safety

of the equipment, it must be connected to a grounded connection. The ground should be

verified prior to use.

Access to the power connection cord should be maintained to allow the unit to be

disconnected from power in the event of an emergency.

ENABLE position allows the laser to be turned on when commanded.

Chapter 4, “Controls, Indicators, and Connections,” for the circuit

2-4 Laser Safety

Maximum Emission Levels

Maximum Emission Levels

Table 2-1 lists the maximum emission levels possible for the Millennia eV lasers. Use

this information for selecting appropriate laser safety eyewear and to implement

appropriate safety procedures. These values do not imply actual system power or

specifications.

The diode pump laser used in the Millennia eV laser system produces infrared light.

Laser light at longer wavelengths is generated in the production of green emission.

These wavelengths are confined to the inside of the laser head.

Table 2-1 Maximum emission levels from the laser head

Feature Specification

Emission wavelength Laser output: 532 nm

Maximum power 20 W

Operating the Laser via a User-Created GUI

The Millennia eV laser system can be controlled by a device provided by or software

written by the user. In this case, the following features must be provided for safety:

Keyswitch: Limits access to the laser and prevents it from being turned on. The

keyswitch can be a real key lock, a removable computer disk, a password that limits

access to computer control software, or a similar “key” implementation. The laser

must only operate when the key is present and in the ON position.

Emission indicator: Indicates laser energy is present or can be accessed. The

indicator can be a power-on lamp, a computer display that flashes a statement to this

effect, or an indicator on the control equipment specifically for this purpose. It need

not be marked as an emission indicator so long as its function is obvious. This

indicator is required on any control panel that affects laser output.

Laser Safety 2-5

CE Radiation Control Drawings and Labels

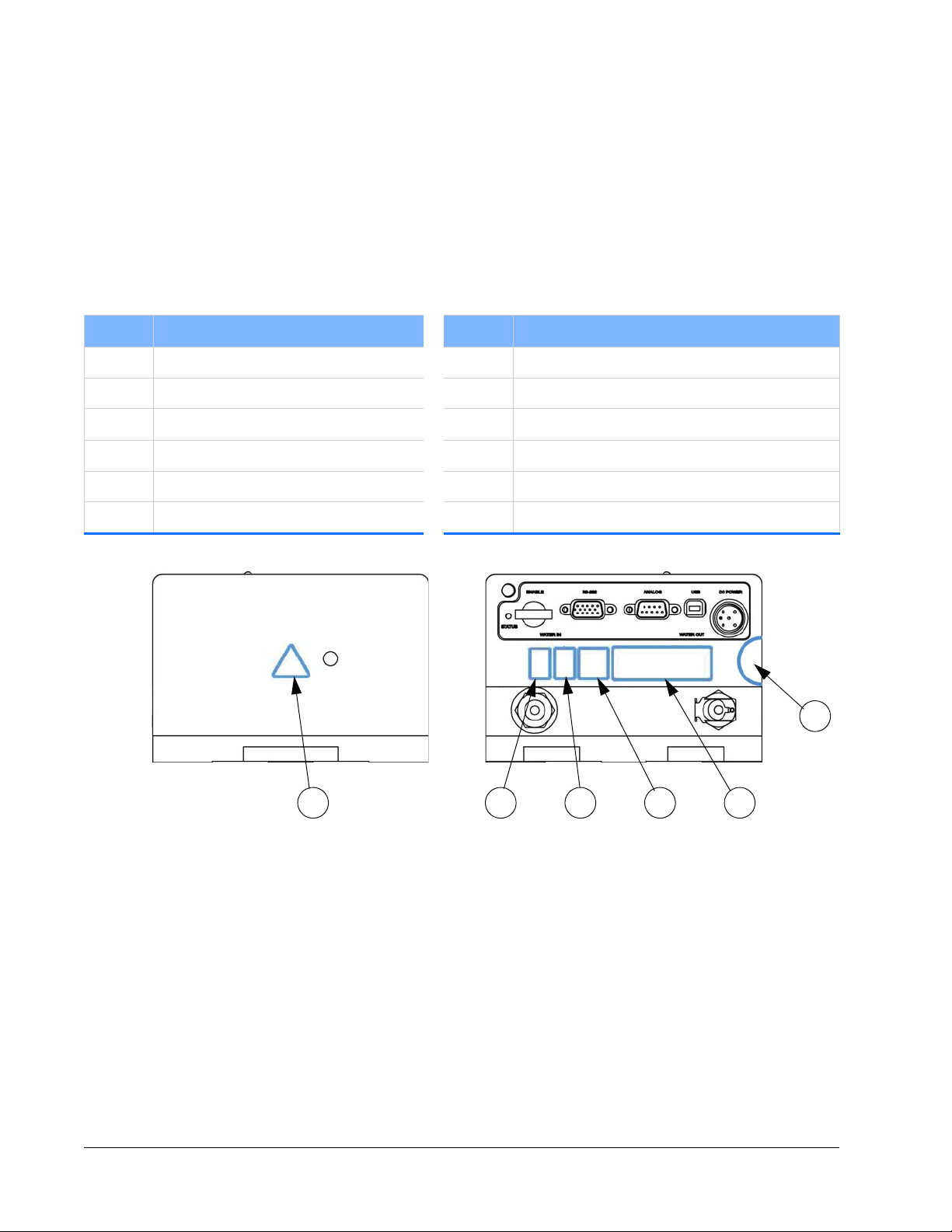

126 7 2 1

9

CE Radiation Control Drawings and Labels

Label Placement

See “Label Illustrations” for images of the numbered labels on the device. The number

key for the following figures is listed in Tabl e 2-2.

Table 2-2 Conformance label descriptions

Number Description Number Description

1 Label, S/N head, CDRH 7 Label, WEEE

2 Label, CE conformity 8 Label, Euro danger Millennia eV

3 Label, class 4, warning 9 Label, void

4 Label, non-interlocked housing 10 Aperture label, visible and invisible laser radiation

5 Patent label, Millennia eV 11 Label, FCC class A compliance

6 Label, star burst 12 Label, .75 x .50 silver RoHS

Figure 2-5 Millennia eV system conformance labels, front (left) and rear (right)

2-6 Laser Safety

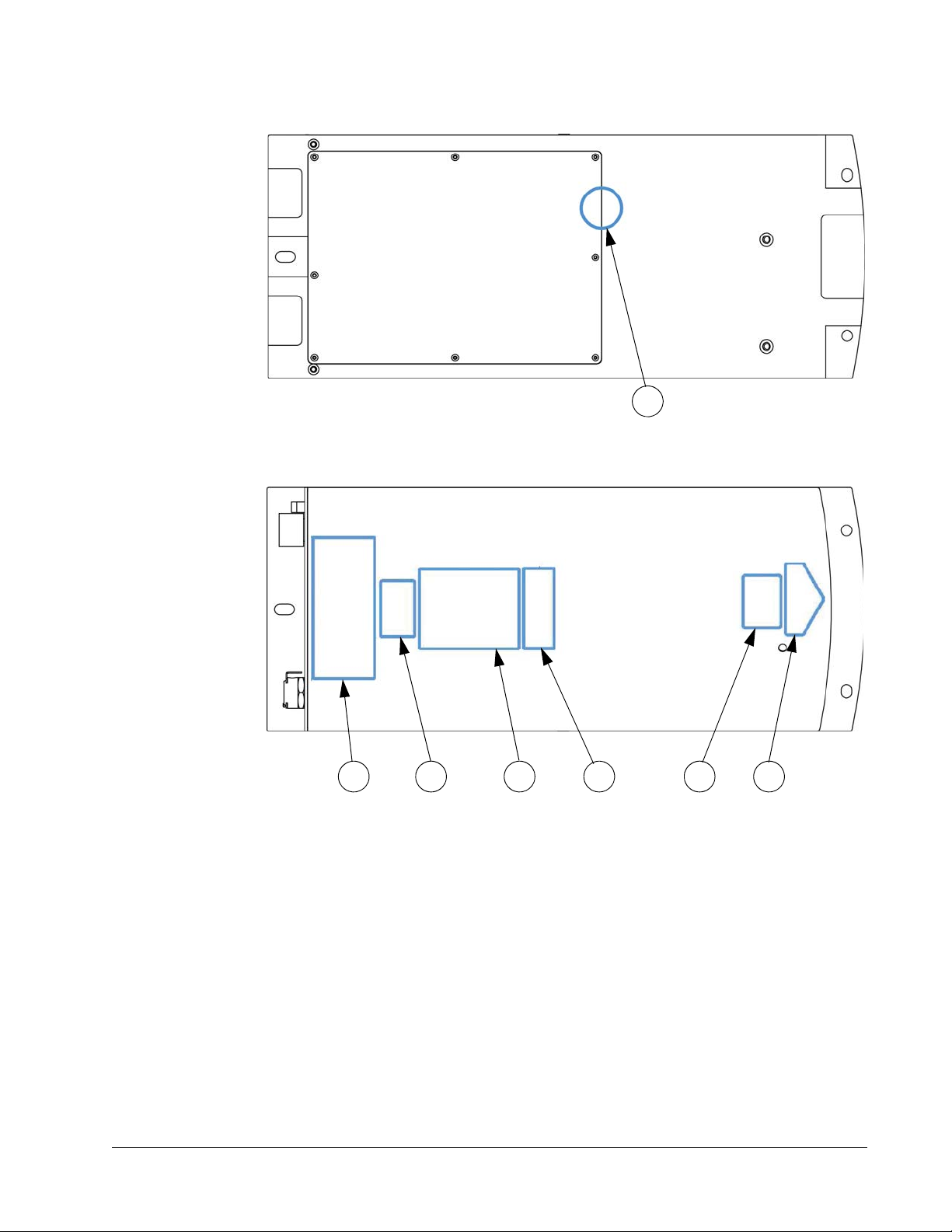

CE Radiation Control Drawings and Labels

9

8 3 11 45 10

Figure 2-6 Millennia eV system conformance labels, bottom

Figure 2-7 Millennia eV system conformance labels, top view

Laser Safety 2-7

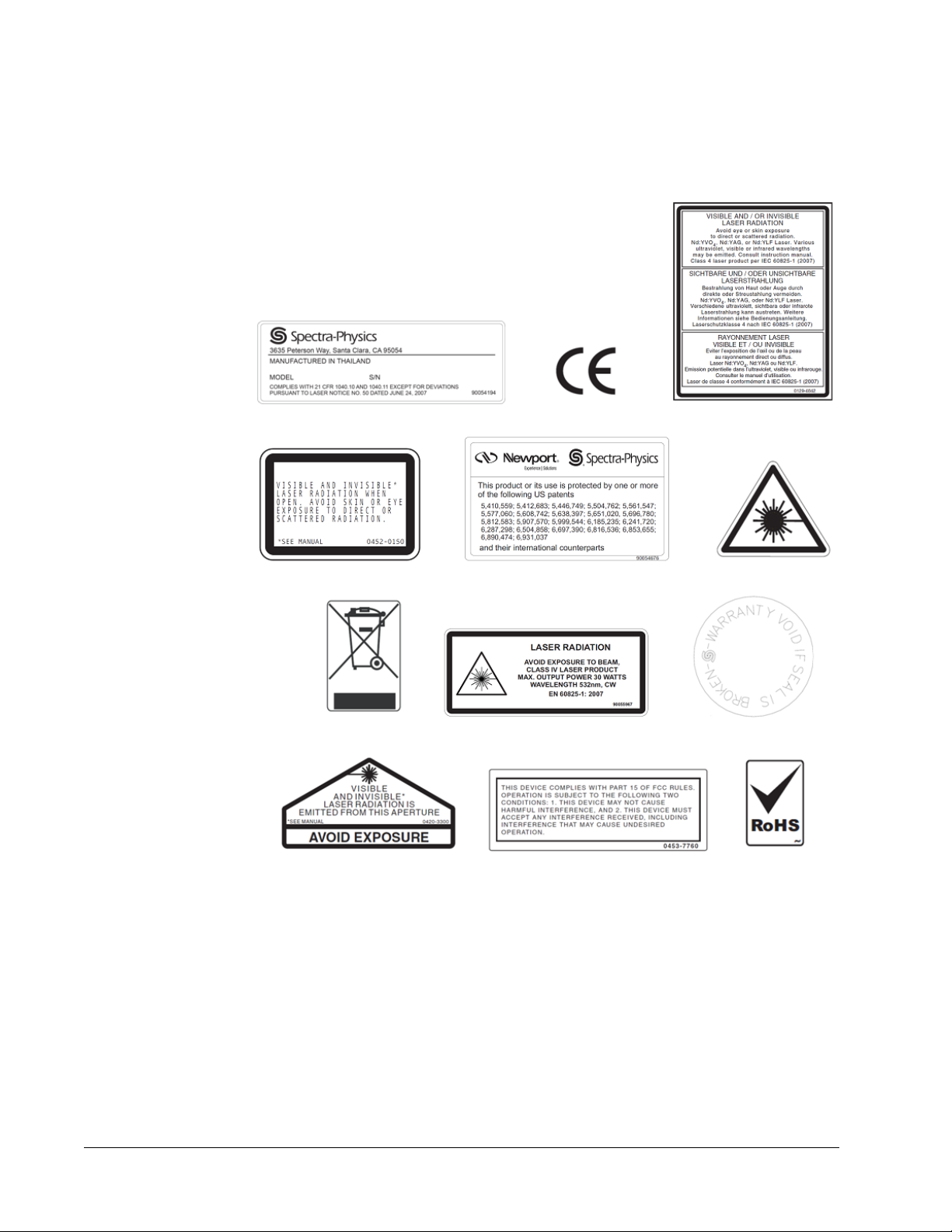

CE Radiation Control Drawings and Labels

1

23

4

8

6

7

5

9

10 11 12

Label Illustrations

See “Label Placement” for the locations of the numbered labels on the device.

Figure 2-8 Safety warning labels

2-8 Laser Safety

CE Declaration of Conformity

CE Declaration of Conformity

We,

Spectra-Physics, a Newport Corporation Brand

3635 Peterson Way

Santa Clara, CA 95054

United States of America

declare under sole responsibility that the:

Millennia eV Family of Diode Pumped Solid State Lasers

Manufactured after September 10, 2012

Meet the intent of EMC Directive 2004/108/EC for Electromagnetic Compatibility and

2006/95/EC for the Low Voltage Directive. Compliance was demonstrated to the

following specifications as listed in the official Journal of the European Communities:

EMC Dir ective 2004/108/EC

EN 61000-6-4: 2007: Emission standard for industrial environments—generic

standards

EN 61000-3-2: 2006: Limits for harmonic current emissions (equipment input

up to and including 16A per phase)

EN 61000-3-3: 2008: Section 3: Limitation of volt ag e ch anges, vo ltage fluctua-

tions, and flicker

EN 61000-6-2: 2005: Generic sta ndards—Immunity for industrial environments

EN 61000-4-2: 2009: Part 4: Section 2: Electrostatic discharge immunity test

EN 61000-4-3: 2011: Part 4: Section 3: Testing and measurement tech-

niques—radiated, radio-frequency, electromagnetic field

EN 61000-4-4: 2010: Part 4-4: Testing and measurement techniques—electri-

cal fast transient/burst immunity test

EN 61000-4-5: 2006: Testing and measurement techniques—surge immunity

test

EN 61000-4-6: 2009: Part 4 - 6: Testing and measurement

techniques

quency fields

EN 61000-4-8: 2010: Testing and measurement techniques—power frequency

magnetic field immunity test

EN 61000-4-11: 2004: Testing and measurement techniques — voltage dips,

short interruptions, and voltage variations

—immunity to conducted disturbances induced by radio-fre-

Low Voltage Directive 2006/95/EC

EN 61010-1: 2010 Safety requirements for electrical equipment for measure-

ment, control, and laboratory use — Part 1 General requirements

EN 60825-1: 2007 Part 1—Safety of Laser Products—Equipment Classification,

Requirements, and User’s Guide

I, the undersigned, hereby declare that the equipment specified above conforms to the

above Directives and Standards.

David Allen

Vice President/General Manager

Spectra-Physics, a Newport Corporation Brand

September 10, 2012

Laser Safety 2-9

WEEE Recycling Label

WEEE Recycling Label

To Our Customers in the European Union:

As the volume of electronics goods placed into commerce continues to grow, the

European Union is taking measures to regulate the disposal of waste from electrical and

electronic equipment. Toward that end, the European Parliament has issued a directive

instructing European Union member states to adopt legislation concerning the

reduction, recovery, re-use, and recycling of waste electrical and electronic equipment

(WEEE). In accordance with this directive, the accompanying product has been marked

with the WEEE symbol (label 7 in

The main purpose of the symbol is to designate that, at the end of its useful life, the

accompanying product should not be disposed of as normal municipal waste, but instead

should be transported to a collection facility that ensures the proper recovery and

recycling of the product’s components. The symbol also signifies that this product was

placed on the market after 13 August 2005. At this time, regulations for the disposal of

waste electrical and electronic equipment vary within the member states of the

European Union. Please contact a Newport

information concerning the proper disposal of this product.

Figure 2-8).

/ Spectra-Physics representative for

Other Hazards

In addition to optical hazards, the Millennia eV equipment can present fire, electrical, or

mechanical hazards. Available electrical power within the box is <

Appropriate cooling must be provided during operation. Electrical voltages contained

within the unit can exceed 24

The unit weight is <

elements have been implemented in the product to reduce these hazards. Failure to

follow the instructions within this manual can impair the protection provided by these

elements.

7 kg (< 16 lb.) and must be supported properly. Safety design

volts. Always operate the unit with the covers in place.

Additional Safety Resources

Laser Safety Standards

Safe Use of Lasers (Z136.1)

American National Standards Institute (ANSI)

25 West 43rd Street, 4th Floor

New York, NY 10036

Tel: (212) 642-4900

600 watts.

Occupational Safety and Health Administration (Osha Standard, 01-05-001-pub8-1.7

U. S. Department of Labor

200 Constitution Avenue N. W., Room N3647

2-10 Laser Safety

Additional Safety Resources

Washington, DC 20210

Tel: (202) 693-1999

Website: http://www.osha.gov

A Guide for Control of Laser Hazards, 4th Edition, Publication #0165

American Conference of Governmental and Industrial Hygienists (ACGIH)

1330 Kemper Meadow Drive

Cincinnati, OH 45240

Tel: (513) 742-2020

Website: http://www.acgih.org/home.htm

Laser Institute of America

13501 Ingenuity Drive, Suite 128

Orlando, FL 32826

Tel: (800) 345-2737

Website: http://www.laserinstitute.org

International Electrotechnical Commission

Journal of the European Communities

IEC 60825-1 Safety of Laser Products—Part 1: Equipment classification, requirements,

and user’s guide

Tel: +41 22-919-0211 Fax: +41 22-919-0300

Website: http://www.iec.ch

Cenelec

35, Rue de Stassartstraat

B-1050 Brussels, Belgium

Tel: +32 2 519 68 71

Website: http://www.cenelec.eu

Document Center, Inc.

111 Industrial Road, Suite 9

Belmont, CA 94002

Tel: (650) 591-7600

Website: http://www.document-center.com

Equipment and Training

Laser Safety Guide

Laser Institute of America

13501 Ingenuity Drive, Suite 128

Orlando, FL 32826

Tel: (800) 34LASER

Website: http://www.laserinstitute.org

Laser Focus World Buyer's Guide

Laser Focus World

Pennwell Publishing

98 Spit Rock Road

Nashua, NH 03062

Tel: (603) 891-0123

Website: http//:pennwell.365media.com/laser focus world/search.html

Laser Safety 2-11

Additional Safety Resources

Photonics Spectra Buyer's Guide

Photonics Spectra

Laurin Publications

Berkshire Common

PO Box 4949

Pittsfield, MA 01202-4949

Tel: (413) 499-0514

Website: http://www.photonics.com

2-12 Laser Safety

CHAPTER 3: Laser Description

This chapter provides information about the Millennia eV laser system.

Overview

The Spectra-Physics Millennia eV laser system is a diode-pumped, continuous-wave,

visible laser that produces a superior quality, 532

The Millennia eV laser system was specifically designed for applications requiring a

continuous-wave, high-quality beam, along with good mode quality in a cost-effective

package. This laser is a rugged, sealed unit designed for simple, hands-free operation.

The laser head contains all system electronics and optical components, along with

microprocessors and memory for storing system parameters. The Millennia eV system

is designed for maximum reliability with minimum complexity. The laser head does not

require any adjustments for normal operation.

The host system connects to the laser through the SERIAL or USB port. Analog/TTL

control signals via the

serial commands. The

“Controls, Indicators, and Connections,” and the commands are listed in Appendix A,

“Programming Reference Guide.”

ANALOG port can either be used alone or in combination with

ANALOG and SERIAL controls are fully described in Chapter 4,

nm green output beam.

The following sections briefly describe the design of the Millennia eV laser head.

Controls and connections are described in

Connections,” and the methods of operating the laser are described in Chapter 7,

“Operation.”

Millennia eV Series System

The Millennia eV system comprises these basic components:

Millennia eV water-cooled laser head

48 VDC utility unit

Computer with Millennia eV control software

A recirculating chiller is required for cooling the laser head. The customer can order a

chiller from Spectra-Physics as optional equipment.

The Millennia eV laser system has three models:

Millennia eV 15 (15 W of CW 532 nm)

Millennia eV 10 (10 W of CW 532 nm)

Millennia eV 5 (5 W of CW 532 nm)

Chapter 4, “Controls, Indicators, and

3-1

Millennia eV Laser Head

The controller for the Millennia eV laser system is a customer-supplied computer or

laptop. The customer can order a laptop from Spectra-Physics as optional equipment.

The following sections describe the laser head and utility unit hardware. Operating the

Millennia eV laser system is described in

described in the user’s manual shipped with the chiller.

Chapter 7, “Operation.” The chiller is

Millennia eV Laser Head

The optical cavity of the Millennia eV laser head uses a folded cavity resonator. In this

design, the fiber-coupled output from the diode module is used to end-pump a vanadate

crystal. The crystal is the driving engine of the laser. It absorbs the diode laser light and

emits its own laser beam light at 1064

Millennia eV cavity.

A telescope is used to focus the pump light through a dichroic fold mirror and into the

vanadate laser crystal. This dichroic mirror is highly transmissive at the diode pump

laser wavelength and highly reflective at 1064

nm, which is resonated (and confined) in the

nm.

Frequency Doubling

Frequency-doubling converts the 1064 nm light from the laser crystal to the green

nm light that becomes the output of the laser.

532

A noncritically phase-matched lithium triborate (LBO) crystal placed in the cavity

converts the intracavity light to the green 532

acceptance angle, which makes it insensitive to any slight misalignment of the Millennia

eV cavity. A compact, low power, temperature-regulating oven is used to maintain the

crystal at the appropriate phase-matching temperature to keep the 532

optimized.

The patented Quiet Multi-Axial Mode Doubling (QMAD) technique provides

exceptionally low-noise performance. It uses a very large number of axial modes and

balances gain, nonlinear conversion, and excited-state lifetime to provide high power

and extremely stable amplitude.

Virtually all the doubled light reflects off the dichroic output coupler where the beam is

then directed out of the laser. A beam splitter and photodiode sample the output and

provide feedback to the pump laser driver to provide a constant output in power mode

operation. A shutter placed outside the cavity enclosure blocks the beam until

commanded to open.

A dichroic mirror allows the 532 nm light to exit the cavity while keeping the 1064 nm

light inside the cavity. The 90° polarization rotator aligns the polarization to the vertical

axis required in many applications.

nm wavelength. LBO offers a large

nm power

3-2 Laser Description

Specifications

Light Pick-off and Power Control

A beam splitter near the output of the laser head samples a small portion of the green

beam and directs it to the photodetector for the power control feedback circuit. Power

mode is the standard operating mode for the Millennia eV laser; the control loop adjusts

the diode pump current to keep the power constant to within ±

1% of the set point.

System Control

The Millennia eV laser operates through a Spectra-Physics supplied GUI for day-to-day

operation. This GUI is described in

In the context of this manual, the diode laser module is

sometimes referred to simply as the “diode,” e.g., “the diode

current.”

Chapter 7, “Operation.”

Specifications

Table 3-1 lists the general characteristics of the Millennia eV laser. Due to our

Complete environmental specifications for operating and non-operating conditions are

listed in

Table 3-1 Millennia eV laser system general specifications

Feature Specification

Operating Conditions

continuous product improvement program, specifications can change without

notice. For the most current specifications and performance characteristics, visit the

Newport website at

http://www.newport.com/Millennia-eV-High-Power-CW-DPSS-Lasers/1011478/1

033/info.aspx

“Environmental Specifications.”

Warm-up time (from cold start) < 30 min .

Temperature ra ng e 18 °C to 35°C

Altitude 0 to 3,000 m

Relative humidity < 8 0%, non-condensing

Non-operating Conditions

Temperature ra ng e -20°C to 50°C

Altitude 0 to 12,000 m

Relative humidity < 90%, non-condensing

Laser Description 3-3

Specifications

Table 3-1 Millennia eV laser system general specifications (Continued)

Feature Specification

Physical Characteristics (Laser Head)

Dimensions (L x H x W) 37.47 x 10.38 x 15.24 cm (14.75 x 4.09 x 6 in.)

Weight < 7 kg (< 16 lb.)

Electrical/Mechanical Specifications

Operating voltage 100–240 VAC ± 10%, 50/60 Hz, single phase

Power consumption, end of life < 300 W

Other Product Features

Constant power Yes

RoHS Yes

Data logging Yes (service personnel access only)

Chiller Requirements

Water temperature range 20 ± 0.1°C

Water flow rate 0.5 gpm @ 15 psi

Thermal load 300 W

All performance specifications shown in Tab le 3-2 are guaranteed at specified output

power only. Due to our continuous quality improvement program, specifications are

subject to change without notice.

Table 3-2 Millennia eV laser output characteristics

Feature Specification

Power 5 W, 10 W, or 15 W

Wavelength 532 nm

Spatial mode

Beam diameter at 1/e2 points

Beam divergence, full angle

Polarization

Power stability

Beam pointing stability

Noise

1

2

2

3

4

5

6

TEM

00

2.3 mm ± 10%

< 0.5 mrad ± 10%

> 100:1 vertical

± 1%

< 2 μrad/°C

< 0.04% rms

3-4 Laser Description

Specifications

Table 3-2 Millennia eV laser output characteristics (Continued)

Feature Specification

Boresighted Yes

1. M2 < 1.1; beam ellipticity < 10%.

2. Measured at the exit port.

3. Vertical polarization standard; horizontal polarization available on request.

4. Measured over a 2-hour period after a 30 minute warm-up.

5. Measured as far-field x and y positions, after a 30 minute warm-up.

6. Measured over a 10 Hz to 0.1 GHz bandwidth at the specified output power.

Chiller Specifications

It is critical that the chiller meet the requirements for cooling the laser head. Failure to

do so will result in poor performance, and possibly damage the laser. Such damage is

not covered by the warranty.

The following requirements must be met by the chiller in order to properly cool the

Millennia eV laser head. Refer to the manual provided with the chiller for its

dimensions, specifications, and utility requirements. Here are some basic requirements:

The chiller should use distilled (not de-ionized) water.

The chiller should have at least 300 W thermal capacity at maximum ambient air

temperature.

The chiller output flow must use a partial flow liquid filter of 10 µm or smaller filter

size.

Laser Description 3-5

Outline Drawings

Outline Drawings

Dimensions shown are in inches over millimeters.

Figure 3-1 Millennia eV laser system outline drawing

3-6 Laser Description

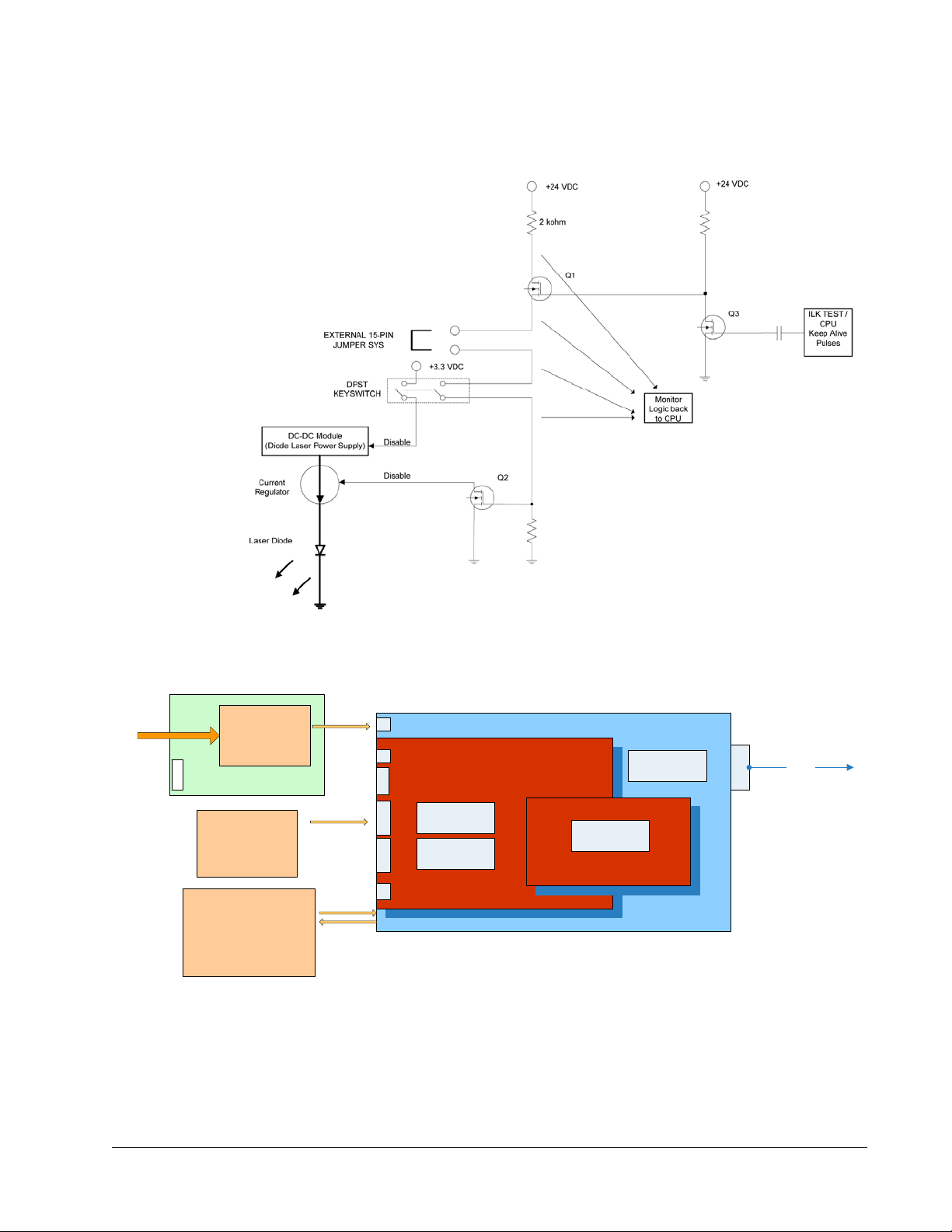

Block Diagrams

)$1

&21752//(5

3&%

$&,13879$&$

+]

,1387

3:5

9'&

86%

&RQQ

6DIHW\

,QWHUORFN

6+877(5

$&,QSXW

*5((1/$6(5

',2'('593&%

&206:

212))

0,&52&21752//(50+]

)3*$0+]

&8,9+%

NK=VZLWFKLQJIUHT

/DVHUGLRGH

&+$66,6

&+,//(5

3&

5625

86%

Block Diagrams

Figure 3-2 Interlock safety block diagram

Figure 3-3 Millennia eV system block diagram

Laser Description 3-7

Block Diagrams

3-8 Laser Description

CHAPTER 4: Controls, Indicators, and

Power

switch

Connections

This chapter describes the user controls, indicators, and connectors of the Millennia eV

laser system. Instructions for operating this system are found in

Laser System Controls

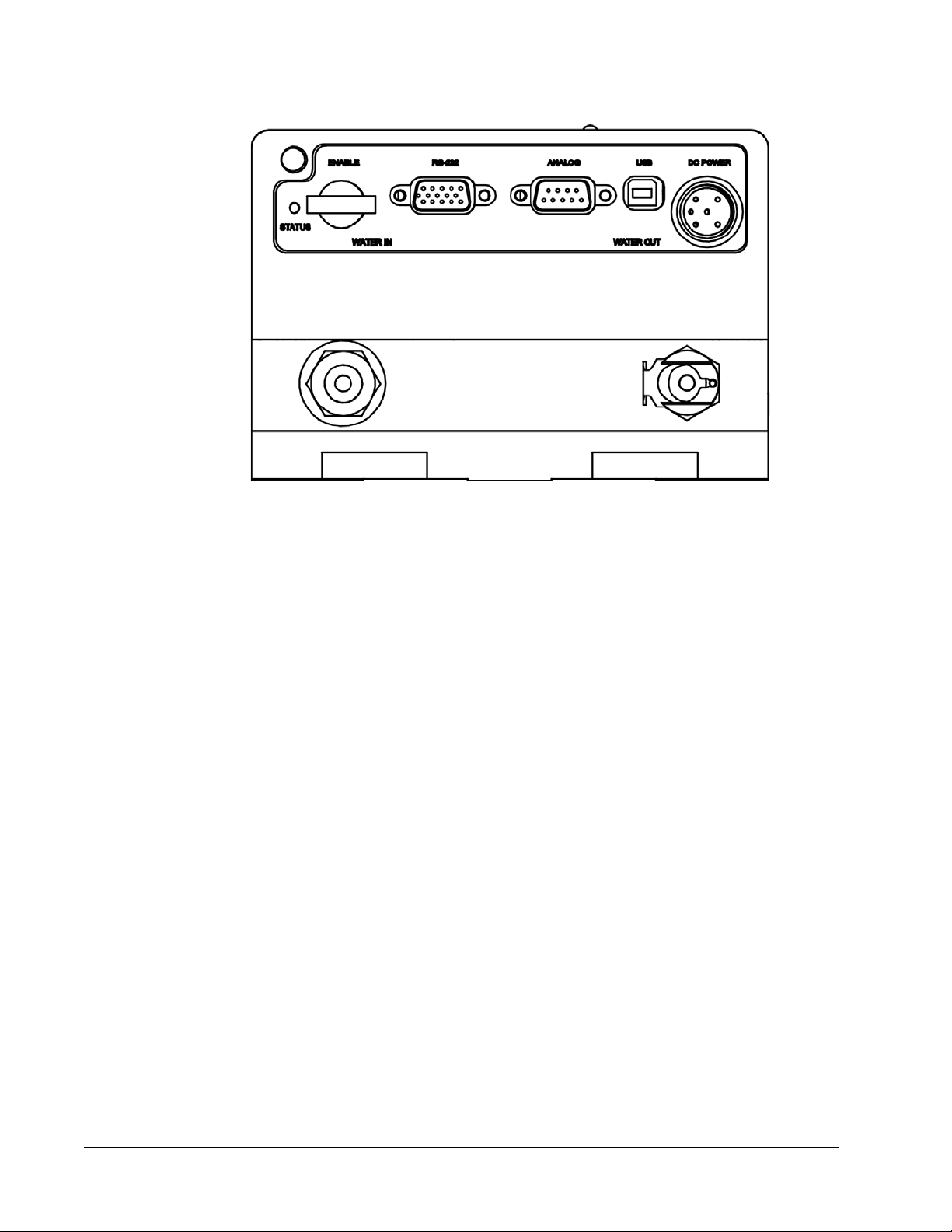

Figure 4-1 shows the rear panel of the laser, which contains all the controls, indicators,

and connectors for this system, except the main emission indicator, which is located on

top of the laser near the output end. These controls are described in

Chapter 7, “Operation.”

Table 4-1.

Figure 4-1 Millennia eV laser head, rear panel

4-1

Laser System Controls

Table 4-1 Laser head rear panel controls

Control Description

Power switch The soft-power switch on the back of the laser interrupts power to the laser CPU. When this

switch is in the OUT position, the laser is considered “off.” No laser emission is possible.

However, there is still some +48 VDC power available inside the control board.

C

AUTION

:

Under ALL conditions, when servicing the laser (such as replacing any PCBs),

it is critical to unplug the external power by removing the AC plug from the wall.

To turn the laser on, depress the power switch. The switch “clicks” into the IN position and

remains there.

When the button is in the IN position, the laser can be turned on. A green lamp on the

button lights, providing confirmation that power is active and the button is in. The CPU is

alive, laser emission is possible, the SHG crystal begins to warm up, and so on.

The power switch has no interaction with the interlock system. It is not necessary to touch

the switch when a fault occurs (such as interlock or overtemperature).

ENABLE keyswitch Closes the interlock when it is set to the ENABLE position. The keyswitch prevents

unauthorized use of the laser when it is turned to the horizontal (off) position and the key is

removed. Placing this switch in the ENABLE position allows the laser to be turned on.

For safety, when the system is not inst alled in the master OEM system, or is not in use, turn

the keyswitch to the horizontal position and remove the key to prevent unauthorized use of

the laser.

Emission indicator (white lamp

on top of the laser, Figure 4-2)

ST ATUS indicator (green/red

lamp on the rear panel)

48 V power connector Attachment for the cable from a 48 VDC utility unit. Spectra-Physics provides this utility unit

Illuminates to indicate that laser emission is present or imminent. This can only happen

after all of the safety requirements are met, the keyswitch is turned to the ENABLE position,

and an appropriate command or analog signal is provided. The indicator remains on during

laser emission and turns off immediately when commanded or the analog signal is

removed.

Flashes amber during the harmonic crystal warm-up sequence. When the unit is warmed

up and all of the safety requirements have been met, the indicator turns green and blinks.

The indicator blinks red to indicate that a fault has occurred.

(PN 90059738) with the system.

4-2 Controls, Indicators, and Connections

Laser System Controls

Emission indicator

(white)

Output

beam port

Table 4-1 Laser head rear panel controls (Continued)

Control Description

ANALOG connector (15-pin,

D-sub, HD, female)

RS-232 connector

(9-pin, D-sub, female)

Attachment for a control cable from an analog control device.

15

11 15

Among its many functions, this connector can be used to provide an interlock to turn off

laser emission in the event that a safety switch is opened unexpectedly. This connector

also provides a STATUS output that can be used to drive an emission indicator. Refer to

Table 4-3 for a complete description of these pins, and to “ANALOG Interface” for

instructions on how to use this connector to control advanced features of the Millennia eV

laser.

NOTE: In order for the laser to turn on, pins 8 and 13 of this connector must be shorted

together, either directly or through a user-supplied, normally closed interlock

switch.

The male mating connector is TYCO/AMP 1658681-1 (housing, RoHS-compliant), using

pins TYCO/AMP 1658686-1 (crimp pin, RoHS-compliant).

Attachment for a serial cable from a control device, such as a personal computer. Refer to

Table 4-2 for a description of these pins.

15

USB input connector

(USB, Type B)

96

Attachment for a type-B USB cable between the control device, such as a personal

computer, and the laser. A USB driver is provided on the GUI USB flash drive that ships

with the system. The USB driver must be installed on the control computer before this port

can be used.

Figure 4-2 Millennia eV laser emission indicator and output b eam

Controls, Indicators, and Connections 4-3

ANALOG Interface

Table 4-2 describes the pins for the RS-232 serial connector.

Table 4-2 IBM-PC/AT serial port pinout

Computer or Terminal Laser Head

RS-232-C Signal Name Signal Pin No. (9-Pin) Pin No. Signal

Transmit data TXD 3 3 RXD

Receive data RXD 2 2 TXD

Signal ground 55

Protective ground SHELL SHELL

ANALOG Interface

The 15-pin HD D-sub ANALOG port (Table 4-3) is used to monitor the laser system via

user-supplied TTL-level signals.

The ANALOG interface is used in conjunction with serial commands executed through

the RS-232 interface. It provides the following features:

Safety interlock

Indicate emission output

Ready and fault indicators

Average power monitor

The configuration and status of the pins of the ANALOG interface are set and queried

using serial commands.

Table 4-3 ANALOG port pin description

Pin Type Description Function

1 Output, analog POWER_OUT When referenced to pin 2, an uncalibrated DC analog signal

proportional to laser output power is provided to the user for

monitoring laser output power. No scale.

2 Ground, analog AGND Ground reference for pin 1.

3 Input, analog RESERVED Leave this pin unconnected.

4 Output, digital TEMP_OK Open drain. Used to indicate that an over-temperature situation

exists. Maximum sink current is 50

mA. Low = Temperat ure is OK

5 Output, digital ILK_FAULT Open drain. Used to indicate that the interlock is OPEN. Maximum

sink current is 50

turn-on).

6 Input, digital RESERVED Leave this pin unconnected.

7 Input, digital RESERVED Leave this pin unconnected.

mA. Low = interlock is OPEN (laser will NOT

4-4 Controls, Indicators, and Connections

Monitoring Laser Status Via the ANALOG Port

Table 4-3 ANALOG port pin description (Continued)

Pin Type Description Function

8 Output, analog ILK_OUT Provided for the attachment of a user interlock switch. The

open-circuit voltage is +24 VDC with 2 k output impedance. Use a

low-impedance external switch to connect this pin back to pin 13 to

complete the interlock circuit. The voltage drop across the external

switch must be <

mA current.

25

9 Output, digital SHUTTER_OPEN Open drain. Used to indicate that the shutter is OPEN. Maximum sink

current is 50 mA. Low = shutter is OPEN (emission hazard is present).

10 Output, digital RESERVED Leave this pin unconnected.

11 Input, digital RESERVED Leave this pin unconnected.

12 Input, digital RESERVED Leave this pin unconnected.

13 Input, digital ILK_RTN Must be connected to pin 8 through a normally closed switch in order

for the laser to turn on.

14 Output, digital EMISSION Open drain. Used to indicate that the laser EMISSION is ON.

Maximum sink current is 50 mA. Low = EMISSION ON.

1 volt, and the switch must be capable of handling

15 Ground, digital DGND Ground reference pin for 4,5,6,7,9,10, and 11.

Monitoring Laser Status Via the ANALOG Port

Using the Indicator Outputs

The following pins can be used to sync LED indicators or TTL logic circuits:

Pin 4 high, over temperature condition

Pin 5 low, interlock fault condition

Pin 9 low, shutter is open

Pin 14 low, laser emission is present

The pin is pulled low through the field effect transistor (FET) shown in Figure 4-3,

which is a schematic of a simple drain circuit used by the ANALOG connector.

Figure 4-3 ANALOG output drain schematic

When the condition corresponding to one of these pins is active, the logic output pulls

low.

Controls, Indicators, and Connections 4-5

Monitoring Laser Status Via the ANALOG Port

Note that pin 15 is the reference digital ground pin on the ANALOG connector and should

be used with pins

4, 5, 9, 10, and 14.

4-6 Controls, Indicators, and Connections

CHAPTER 5: Installation

This section provides detailed instructions and notes for planning for and installing the

Millennia eV laser system. If the user has not set up the laser before, or if is moving the

laser system to a new location, review this section in its entirety before use.

Pre-Installation Check

Required Tools

The following items are required in order to install the system:

Cleanroom-grade gloves

3/32 in. and 3/16 in. Allen wrenches

6 mm Allen wrench

Power meter or beam dump

Safety goggles for 532 and 1064 nm wavelengths

Personal computer running Windows XP or later

DB-9 male to DB-9 female serial cable or

type A/B USB cable

Be sure to follow all safety precautions for laser use while handling or storing the laser

system. Be sure to install all laser safety devices before using the laser. Refer to

Chapter 2, “Laser Safety,” for more information.

Utility Requirements

Millennia eV laser systems require 100-240 VAC electrical service. The chiller has its

own electrical requirements. Consult the chiller manual for this information.

The Millennia eV system introduces up to 100 W (341 BTUH) of heat into the room

(excluding chiller power). Provide enough room cooling capacity to remove this waste

heat to prevent the system from overheating.

Newport P/N 818P-050-17W, Newport power m eter P/N 1918-R

or 1917-R, and detector P/N 818P-050-50W are recommended.

5-1

Mounting the Laser Head

Utility unit

connection

Chilled water

connection: In

Host serial control

Host analog/TTL

system control

Chilled water

connection: Out

Mounting the Laser Head

Following standard practice, mount the laser head on a suitable flat surface.

Carefully remove the laser head from the Mylar bag

and set it on the table. DO NOT DROP the laser head

onto the table.

1. Select either three 1/4-20 (SAE) or three M6 metric Allen screws.

2. Insert the center Allen screw with flat washer into the laser head, and align the laser

to the table or plate.

3. Secure the center bolt but do not tighten until all bolts have been installed.

4. Install the front two bolts with flat washers.

5. Tighten the three mounting bolts and torque them to 0.25 N*m (2.25 in-lb).

Refer to “Outline Drawings” for dimensions and hole locations.

Connecting the System

Figure 5-1 shows how the Millennia eV laser system is connected to the host controller,

utility unit, and chiller.

Figure 5-1 System interconnect drawing

5-2 Installation

Installing the Chiller

1. Attach two hoses between the chiller and the WATER IN and WATER OUT connectors.

Hoses are provided with Spectra-Physics chillers; hose fittings are supplied when a

user-supplied chiller is used.

2. If analog control is to be used, attach a user-supplied analog cable between the host

system and the

3. Attach either type A/B USB cable from the host system to the USB port

(Spectra-Physics highly recommends using the

from the host system to the RS-232 port.

4. Attach the DC power cable from the utility unit to the 48V connector, but do not

connect the utility unit AC input at this time.

5. Install the ENABLE key.

ANALOG connector (see “Analog Control Considerations”).

USB port) OR a standard serial cable

AC Power Considerations

The unit is provided with a grounded appliance inlet. To help maintain the safety of the

equipment, it must be connected to a grounded connection. The ground should be

verified prior to use.

Access to the power connection cord should be maintained to allow the unit to be

disconnected from power in the event of an emergency.

Analog Control Considerations

If analog signals are to be used to control the laser, the user must make a cable that

attaches between the analog port of the host controller and the

laser head.

Installing the Chiller

General Information

The Millennia eV system requires a chiller that meets the requirements shown in

Table 3-1.

ANALOG connector on the

If analog control is not to be used, pins 8 and 13 of the ANALOG

connector must be shorted together (preferably through a safety

switch) in order for the laser to operate. For installation and test

purposes, a shorting jumper plug is provided.

Spectra-Physics offers a chiller that is suitable for use with the Millennia eV laser

system. If the user ordered the chiller from the factory with the laser, it meets these

requirements. For specific information about the chiller shipped with the system,

consult the chiller manual included with the system.

Installation 5-3

Installing the Chiller

If the user did not order the chiller from Spectra-Physics, make sure that it meets the

requirements in

Table 3-1. Spectra-Physics highly recommends speaking with one of

our representatives about the chiller’s design and capabilities.

Use distilled water only! The use of improper coolant in the

laser can cause irreparable damage to the laser which would

not be covered by the warranty. Be certain of the coolant and

chiller specifications prior to using any non-factory chiller with

this laser.

Installation

1. Consult the chiller’s user manual and follow the manufacturer’s suggested

operation requirements.

2. Verify that the local voltage and line frequency are within the acceptable input range

for the specific chiller.

3. Set the chiller on the floor or mount it close enough to the Millennia eV system so

that the cooling hoses reach the laser head without strain.

Position the chiller so that the warm air exhausted from

it is not drawn back into itself. Allowing it to do so could

affect the stability of the chiller and, therefore, the

laser.

Do not place the chiller directly above the laser or utility

unit. If a leak or condensation ever developed in the

chiller, dripping water could damage the unit below it

and constitute a safety risk.

4. Connect the coolant hoses between the laser head and chiller.

The direction of coolant flow is important for proper operation of the laser system. The

coolant connectors on the laser head are polarized (

Figure 5-1) to prevent incorrect

connection at the laser head. If the chiller was ordered from Spectra-Physics, the hoses

and the connections on the chiller are already set for proper water flow direction.

However, if the chiller was ordered elsewhere, make sure the hoses are assembled with

the correct fittings to allow water to flow in the proper direction.

If it is necessary to release the hose connections, shut off the laser and chiller first, then

disconnect the hoses. On chillers provided by Spectra-Physics, when the hoses are

released, the hoses separate slightly from the connections and self-seals under spring

pressure.

NEVER remove a hose while the chiller is operating, and never

operate the chiller with the hoses disconnected.

5. Fill the chiller reservoir with distilled water and turn on the chiller. As the fluid in

the reservoir drops, continue to fill it with distilled water until it no longer drops.

5-4 Installation

Installing the Chiller

6. Verify that there are no water leaks from the chiller, the hoses or the laser.

Make

sure the reservoir does not empty!

7. Fill the reservoir with new distilled water and run the chiller until no more bubbles

appear. Top off the reservoir when necessary.

8. Verify that the chiller is set to 20°C.

If the chiller was ordered from Spectra-Physics, it was pre-set at the factory to

operate at 20°C.

If the chiller was not purchased from Spectra-Physics, refer to the chiller’s user

manual for instructions on how to set the temperature.

9. Turn off the chiller.

The system is now ready for use. Remove any protective covering from the laser’s

output window, and place a suitable power detector or beam dump in front of the laser

output exit port.

Installation 5-5

Installing the Chiller

5-6 Installation

CHAPTER 6: Preparing for Operation

Installing the USB Driver and User GUI Software

The Millennia eV system can be controlled using the Millennia eV graphical user

interface (GUI) control software that is included with the system, or it can be controlled

by sending commands one at a time using the Communication window in the GUI

control program. Installation instructions for the Millennia eV control software are

given in the next section.

The GUI control software is provided on a USB memory stick along with the USB

driver. The following two sections provide directions for installing this software.

To run the GUI control software, the control computer must meet these minimum

requirements

Intel or AMD 32- or 64-bit, single or multi-core processor with > 1 GHz clock speed

1 GB RAM

100 MB available disk space for installation

Mouse or other Windows-compatible pointing device

Video display with 1366 x 768 (SVGA) or higher resolution

Available USB or RS-232 serial port

Microsoft Windows XP, Vista, or 7 operating system

A type A/B USB cable (preferred) or a standard 9-pin serial cable can be used for

communication between the host computer and the laser system.

Installing the Millennia eV USB Driver

NOTE: If the USB connection is to be used, the Millennia eV USB driver must be

installed before connecting the USB cable or turning on the laser. No driver

software is necessary when the

connection is to be used, skip to

Software.”

This section describes how to install the USB driver software. This driver is located on

the USB flash drive packed in the accessory kit.

To install the USB driver software:

1. Place the USB memory stick containing the Millennia eV software in an available

USB port.

2. Browse to the Millennia eV USB Driver folder on the memory stick and open it.

3. Double-click the VCP_V1.3.1_Setup icon.

SERIAL COM port is used. If an RS-232 serial

“Installing Millennia eV GUI Control

6-1

Installing the USB Driver and User GUI Software

Figure 6-1 Setup icon

4. Wait for the installation process to initialize.

Figure 6-2 Preparing to Install window

5. When the InstallShield wizard opens, click Next.

6-2 Preparing for Operation

Installing the USB Driver and User GUI Software

Figure 6-3 InstallShield wizard

6. Wait for the Setup process to finish.

Figure 6-4 Setup Status window

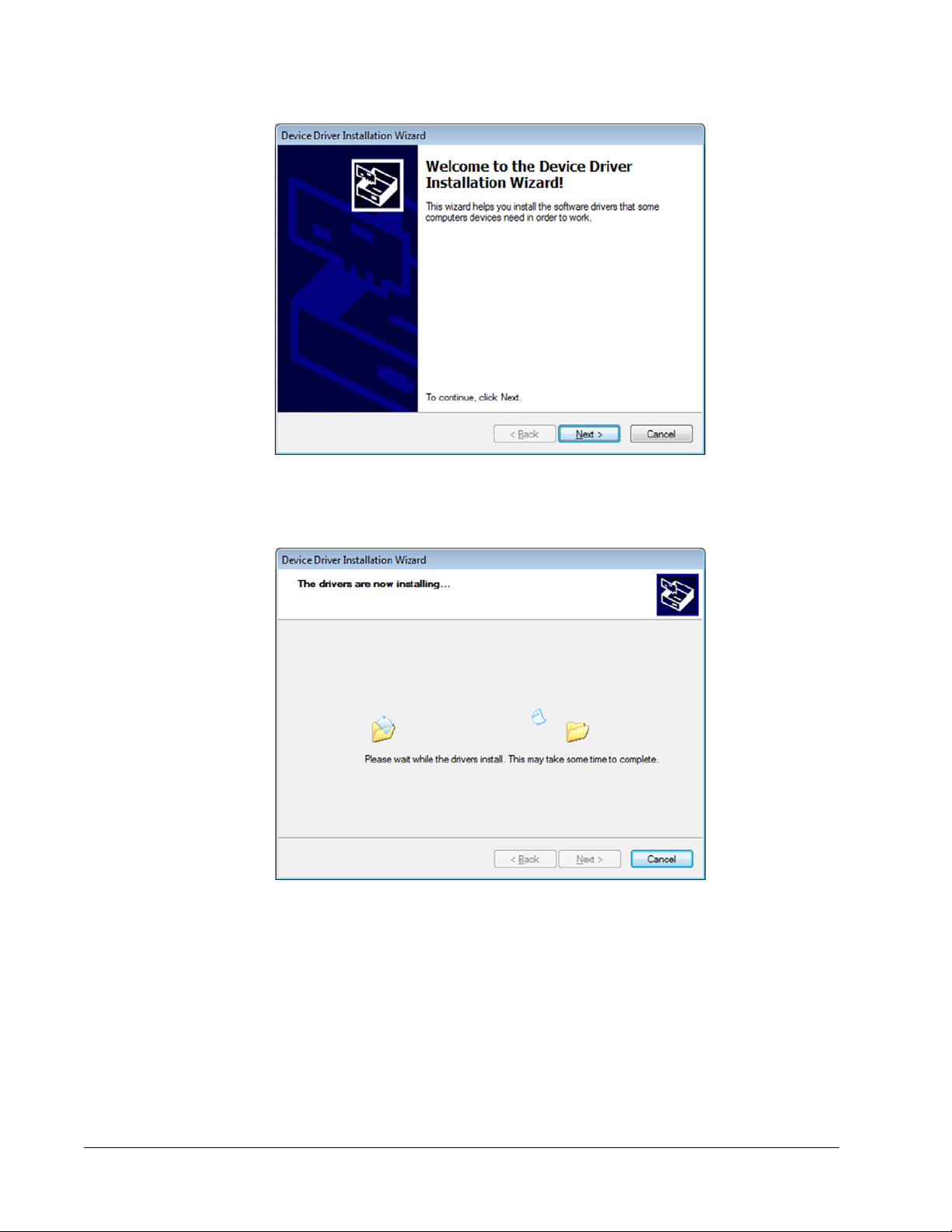

7. In the Device Driver Installation wizard, click Next.

Preparing for Operation 6-3

Installing the USB Driver and User GUI Software

Figure 6-5 Device Driver Installation wizard

8. Wait for the drivers to install, and then click Next.

Figure 6-6 Driver installation in progress

9. When the Completing the Device Driver Installation window opens, click Finish.

6-4 Preparing for Operation

Installing the USB Driver and User GUI Software

Figure 6-7 Completing the Device Driver Installation window

10. Attach the provided USB cable from the Millennia eV laser head to the control

computer, and power on the Millennia eV laser head by depressing the Power switch

in the rear panel to the IN position.

An Installing device driver software message appears.

11. When the driver is successfully installed, a message appears in the taskbar similar

to the one shown below.

Figure 6-8 Software installed successfully message

The Millennia eV USB driver installation is now complete.

12. Turn off the Millennia eV laser head.

Installing Millennia eV GUI Control Software

The Millennia eV GUI control software provides an easy way to monitor and control the

laser system. System operation and a complete explanation of the GUI control software

is described in

Chapter 7, “Operation.” To install the GUI control software:

1. Place the Millennia eV USB memory stick in an available USB port.

2. Browse to the Millennia eV USB Driver folder on the memory stick and open it.

3. Double-click the Setup icon (or setup.exe) and follow any prompts that appear

during installation.

Preparing for Operation 6-5

Installing the USB Driver and User GUI Software