Page 1

Spectra T200, T380, T680,

T950, and T-Finity

Drive Installation or Replacement

SpectraLogic.com

Page 2

Copyright Copyright © 2008 – 2013 Spectra Logic Corporation. All rights reserved. This item and the

information contained herein are the property of Spectra Logic Corporation.

Notices Except as expressly stated herein, Spectra Logic Corporation makes its products and

associated documentation on an “AS IS” BASIS, WITHOUT WARRANTY OF ANY

KIND, EITHER EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO

THE IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, BOTH OF WHICH ARE EXPRESSLY DISCLAIMED. In no

event shall Spectra Logic be liable for any loss of profits, loss of business, loss of use or

data, interruption of business, or for indirect, special, incidental or consequential

damages of any kind, even if Spectra Logic has been advised of the possibility of such

damages arising from any defect or error.

Information furnished in this manual is believed to be accurate and reliable. However, no

responsibility is assumed by Spectra Logic for its use. Due to continuing research and

development, Spectra Logic may revise this publication from time to time without notice,

and reserves the right to change any product specification at any time without notice.

Trademarks BlueScale, CarbideClean, Python, RXT, Spectra, SpectraGuard, Spectra Logic, TeraPack,

T-Finity, TranScale, the CarbideClean logo and the Spectra Logic logo are registered

trademarks. Endura, EnergyAudit, and Tape without Pain are trademarks of Spectra

Logic Corporation. All rights reserved worldwide. All other trademarks and registered

trademarks are the property of their respective owners.

Part Number 91010010 Revision C

Revision

History

Revision Date Description

A November 2008 Initial release

B May 2010 Added the T-Finity library

C April 2013 Added LTO-6 and TS1140 technology drives

Contacting

Spectra Logic

To Obtain General Information

Spectra Logic Website: www.spectralogic.com

United States Headquarters European Office

Spectra Logic Corporation

Phone: 1.800.833.1132 or 1.303.449.6400

International: 1.303.449.6400

Fax: 1.303.939.8844

Spectra Logic Technical Support

Technical Support Portal: support.spectralogic.com

United States and Canada

Phone:

Toll free US and Canada: 1.800.227.4637

International: 1.303.449.0160

Email: support@spectralogic.com

Mexico, Central and South America, Asia, Australia, and New Zealand

Phone: 1.303.449.0160

Email: support@spectralogic.com

Spectra Logic Europe Ltd.

Phone: 44 (0) 870.112.2150

Fax: 44 (0) 870.112.2175

Europe, Middle East, Africa

Phone: 44 (0) 870.112.2185

Email: support@spectralogic.com

Deutsch sprechende Kunden

Phone: 49 (0) 6028.9796.507

Email: spectralogic@stortrec.de

To Obtain Documentation

Spectra Logic Website: www.spectralogic.com/documents

April 2013 Drive Installation or Replacement—Spectra T200, T380, T680, T950, and T-Finity Library

2

Page 3

DRIVE INSTALLATION OR

REPLACEMENT

This guide provides instructions for either installing an additional drive or

replacing an existing drive in a Spectra T200, T380, T680, T950, or T-Finity

library (the library).

Task

Prepare for Maintenance page 5

Continuing or Stopping Backups page 5

Ensuring ESD Protection page 5

Gathering Tools and Supplies page 6

Replace or Install a Drive page 9

Preparing the Library page 9

Accessing the Drives page 12

Removing the Malfunctioning Drive page 14

Determining Drive Sled Adaptor

Requirements

Installing the Drive page 17

page 15

Complete the Procedure page 20

Resolving Firmware Mismatches page 20

Connecting the Cables page 21

Testing the Drive page 25

Installing the Cover or Securing the

Rear Door

Adding the Drive to a Partition page 26

Restarting Backups page 26

Return the Component page 27

page 26

3

Page 4

Illustrations The replacement drive that you received may not look

exactly like the drives shown in this document.

Most of the figures in this guide show the Spectra T380 library. The relative

locations of the components and the procedures are the same for the other

libraries unless otherwise indicated. The differences are indicated by

library type; for example:

Spectra T200, T380, or T680—items indicated with this text refer to any

one of these three libraries.

Spectra T950 and T-Finity—items indicated with this text refer to

either of these two libraries.

User Interface Updates The BlueScale user interface changes as new

features are added or other modifications are made between software

revisions. Therefore, the user interface screens on your library may differ

from those shown in this document.

Drive Bay Assemblies Each drive is mounted on a drive sled which is

installed in a drive bay assembly (DBA) in the back of the library. If there

are no empty drive bays in your library, you must install a new DBA to

accommodate additional drives.

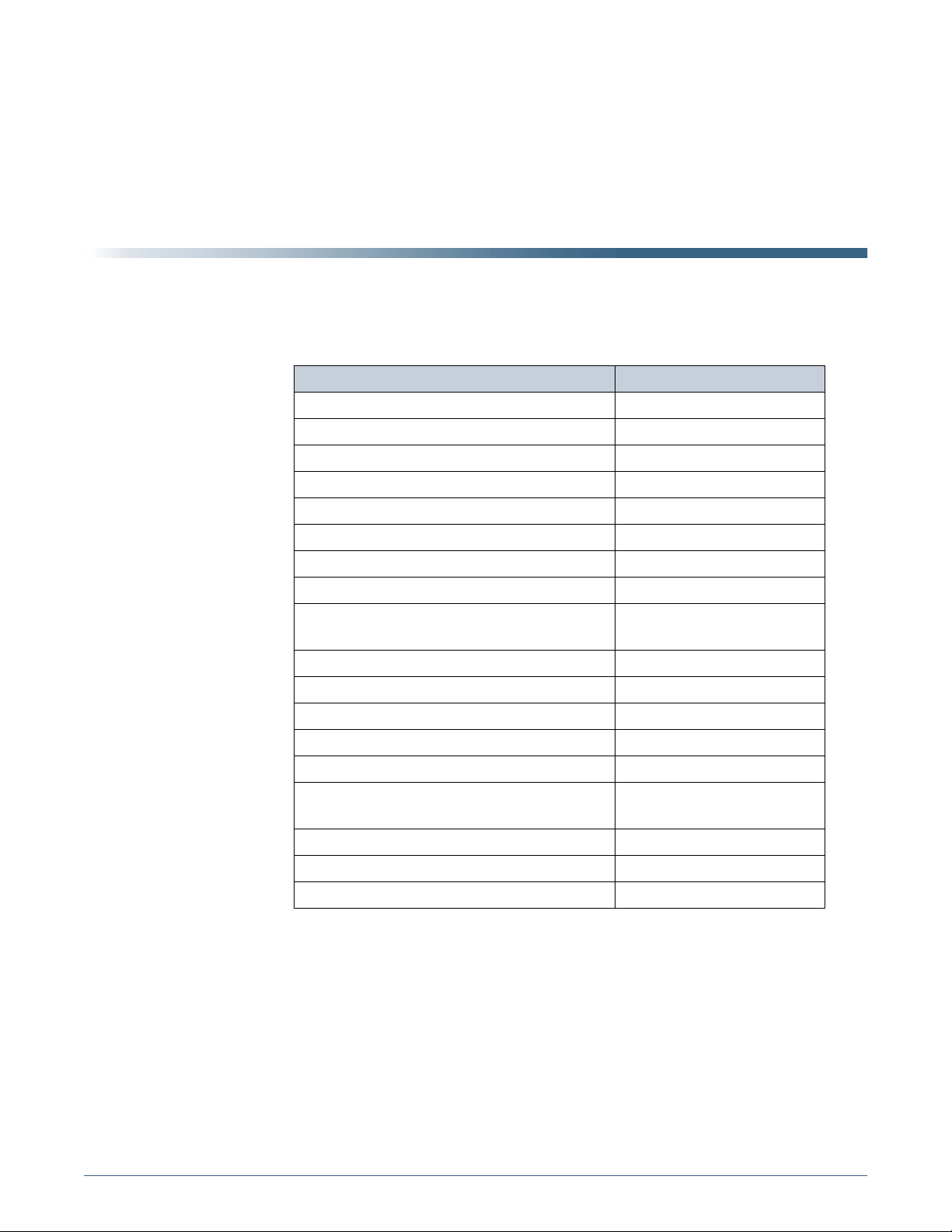

Tape Drive Support This table shows the tape drives supported by the

individual libraries.

Library LT O - 3 LT O - 4 LT O - 5 LT O - 6 TS1140

technology

T200 YYYY N

T380 YYYY N

T680 YYYY N

T950 YYYY N

T-FinityNYYY Y

April 2013 Drive Installation or Replacement—Spectra T200, T380, T680, T950, and T-Finity Library

4

Page 5

Prepare for Maintenance Continuing or Stopping Backups

PREPARE FOR MAINTENANCE

Make sure you fulfill the prerequisites described in this section and

familiarize yourself with all the sections in the document before starting.

Continuing or Stopping Backups

Use the following guidelines if you are installing or replacing a drive in a

drive bay assembly (DBA) already in the library.

Robotic Control

Path

QIP or RIM

(all libraries)

Direct-attached

Fibre Channel drive

(Spectra T200,

T380, T680)

Note: Selecting a drive to provide the robotic control path is part of configuring a partition. Refer to

the library’s User Guide for more information.

Description

Backups running to all other drives in the library (or partition) can safely

continue while you install a new drive or replace an existing one.

Backups running to other drives in the library (or partition) can safely continue

while you install a new drive or replace an existing one, unless the drive you are

replacing is the one exporting the library (that is, providing the robotic control

path for the partition). If the drive you are replacing provides the control path

for the robotics, stop backup operations to the partition.

Note: T950 and T-Finity libraries do not support using a direct-attached drive

to provide the robotic control path.

Ensuring ESD Protection

The repair environment for the library must be free of conditions that

could cause electrostatic discharge (ESD). To protect the library from ESD,

follow these procedures when repairing or testing the library:

Place a static protection mat on the work surface used while removing

and installing library components. Use a 1-megohm resistor to ground

the static protection mat.

Wear a static protection wrist band whenever you handle library

components that have been removed from their antistatic bags. Connect

this wrist band to the static protection mat or to other suitable ESD

grounding.

Keep all electronic components in antistatic bags when not in use.

April 2013 Drive Installation or Replacement—Spectra T200, T380, T680, T950, and T-Finity Library

5

Page 6

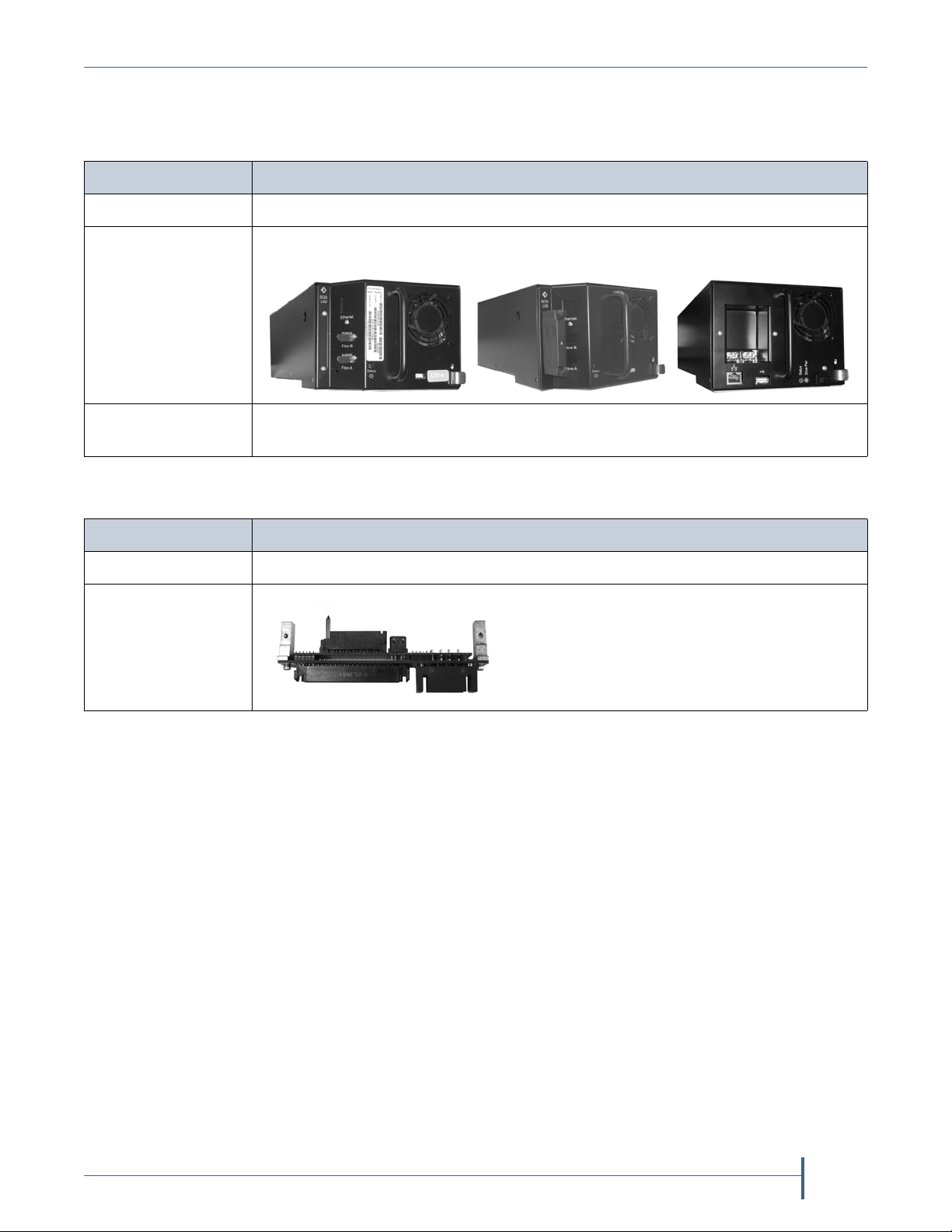

Prepare for Maintenance Gathering Tools and Supplies

Fibre Channel SCSI

tape drive example tape drive example

TS1140 technology

tape drive example

Gathering Tools and Supplies

You must have the following to complete this procedure:

Item Description

Supplies ESD protection equipment

A Replacement

Drive from Spectra

Logic

To ol s

T200 and T380 only

A #2 Phillips screwdriver

You need the following if you need to install a drive sled adaptor. See

Determining Drive Sled Adaptor Requirements on page 15.

Item Description

To ol s A #1 Phillips screwdriver

Drive Sled Adaptor

(PN 90948360)

Understanding Component Identifiers

Each drive in the library has a unique drive component identifier.

Drives are identified in the library’s BlueScale user interface using the

format shown in the following sections.

Spectra T200, T380, or T680 Library on page 7

Spectra T950 or T-Finity Library on page 8

April 2013 Drive Installation or Replacement—Spectra T200, T380, T680, T950, and T-Finity Library

6

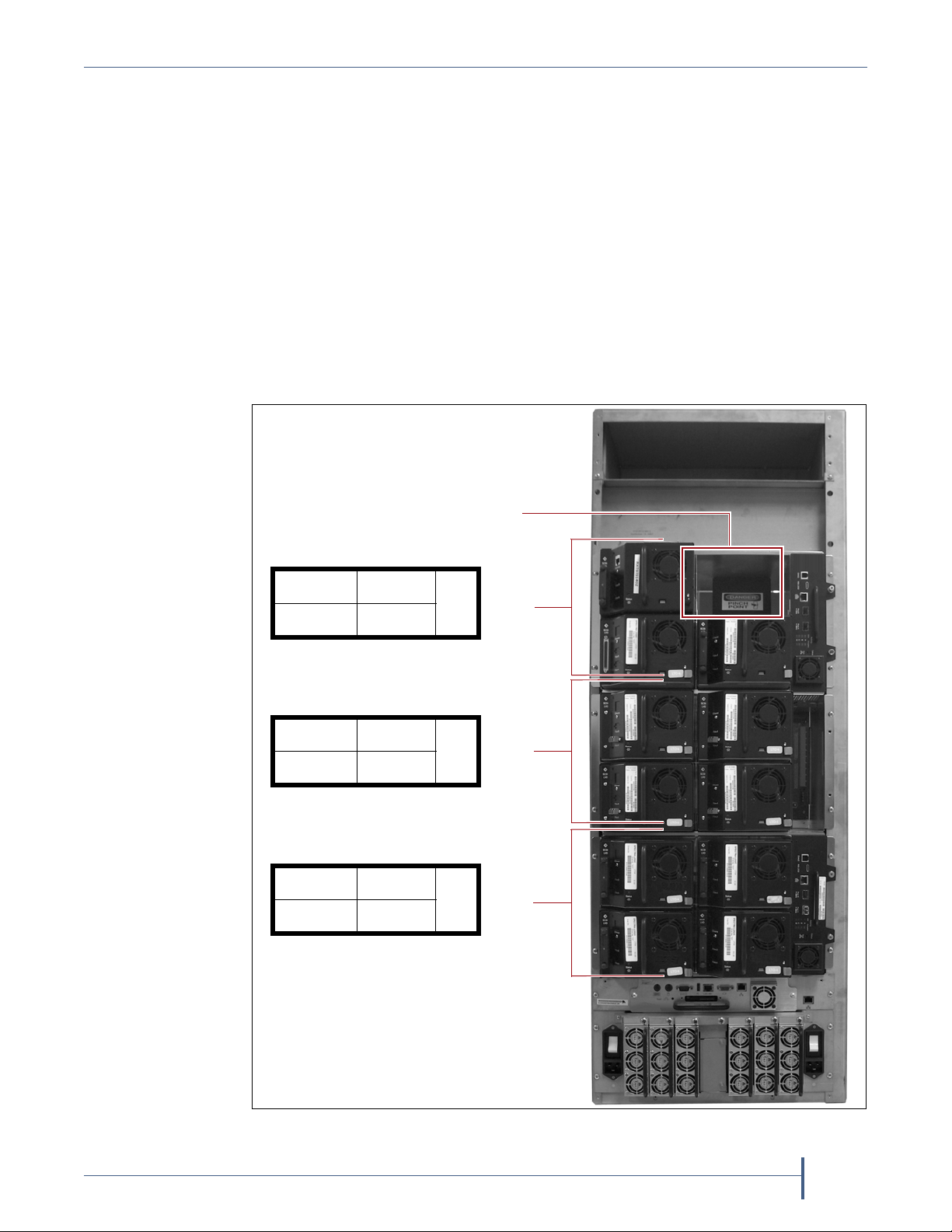

Page 7

Prepare for Maintenance Understanding Component Identifiers

QIP

QIP

QIP

Drive 4

Drive 3

Drive 1 Drive 2

Drive 4

Drive 3

Drive 1 Drive 2

Drive 4

Drive 3

Drive 1 Drive 2

DBA 3

DBA 2

DBA 1

3

2

1

This figure shows the relationship between the

DBA number and the drive locations used in

the identifier.

Back panel drive locations and

their identifiers (T380 shown)

Drive bay

opening

Spectra T200, T380, or T680 Library The BlueScale software

component identifier for drives has the form DBAx/Y-DRVx:

DBAx

is the number of the drive bay assembly (DBA) containing the

drive

; a DBA holds up to four drives and one Quad-Interface

Processor (QIP) or Robotics Interface Module (RIM

).

Y is the drive type.

fLTO refers to a Fibre Channel LTO drive.

LTO refers to a SCSI LTO drive.

DRVx is the number of the drive bay in the DBA, as viewed from the

back of the library.

Example If a Fibre Channel drive is installed in DBA2, drive position 4,

its identifier is DBA2/fLTO-DRV4.

April 2013 Drive Installation or Replacement—Spectra T200, T380, T680, T950, and T-Finity Library

7

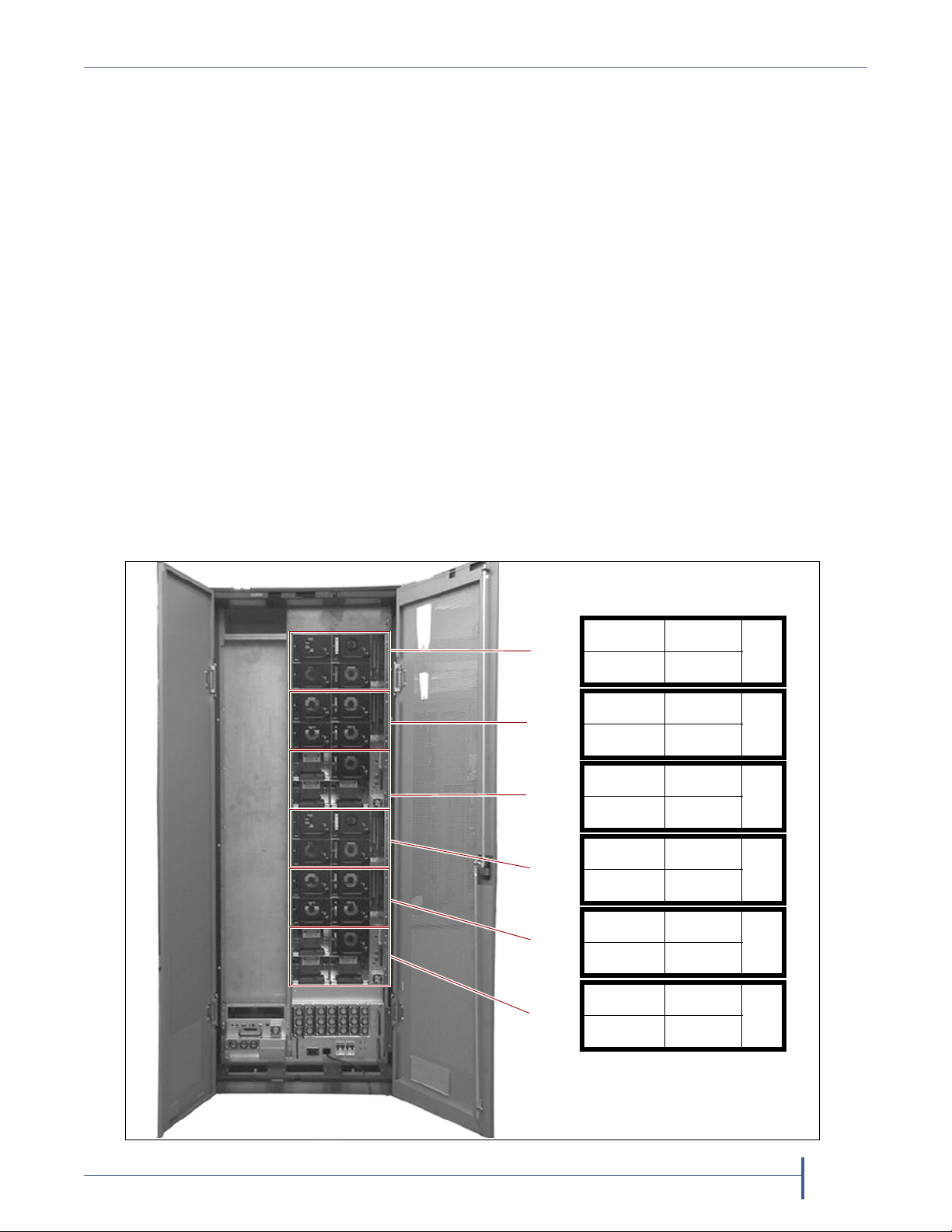

Page 8

Prepare for Maintenance Understanding Component Identifiers

QIP

QIP

QIP

Drive 4

Drive 3

Drive 1 Drive 2

Drive 4

Drive 3

Drive 1 Drive 2

Drive 4

Drive 3

Drive 1 Drive 2

DBA 3

DBA 2

DBA 1

3

2

1

QIP

Drive 4

Drive 3

Drive 1 Drive 2

4

QIP

Drive 4

Drive 3

Drive 1 Drive 2

5

QIP

Drive 4

Drive 3

Drive 1 Drive 2

6

Frame 1

DBA 4

DBA 6

DBA 5

Back panel drive locations and

their identifiers (T950 shown)

(optional)

(optional)

(optional)

Spectra T950 or T-Finity Library The BlueScale software component

identifier for drives has the form FRx/DBAx/Y-DRVx:

FRx is the number of the frame from left to right when viewed from

the front of the library.

DBAx is the number of the drive bay assembly containing the drive;

a DBA holds up to four drives. If the optional DBAs shown in the

photo are replaced by TeraPack Bay Assemblies, the top DBA

becomes DBA 3.

Y is the drive type

fLTO refers to a Fibre Channel LTO drive.

LTO refers to a SCSI LTO drive.

fTS11x0 refers to a Fibre Channel TS1140 technology drive.

DRVx is the number of the drive bay in the DBA.

This figure shows the relationship between the DBA number and the

drive locations used in the identifier. The relationship between the DBA

number and drive locations is the same for each additional drive frame.

Example If a Fibre Channel drive is installed in frame 1, DBA2, drive

position 4, its identifier is FR1/DBA2/fLTO-DRV4.

April 2013 Drive Installation or Replacement—Spectra T200, T380, T680, T950, and T-Finity Library

8

Page 9

Replace or Install a Drive Preparing the Library

Important

Failed drive

Component

Identifier

REPLACE OR INSTALL A DRIVE

The following sections describe how to replace an existing tape drive or

install an additional tape drive:

When replacing a drive, the new drive must be the same type (interface and

generation) as the one you replace.

Preparing the Library

Prepare the library to add or replace a drive using the appropriate

instructions:

Drive Replacement Preparation on page 9

—OR—

Drive Installation Preparation on page 11

Drive Replacement Preparation

Your backup software, the library, or both may indicate a drive problem.

Identify the problem drive and then check the Drives screen on the library

user interface for the drive’s component identifier.

If the malfunctioning drive contains a cartridge, attempt to use the backup

software or BlueScale user interface to move the cartridge to an empty slot

before replacing the drive. See your library’s User Guide for instructions. If

you are unable to remove the cartridge, continue with the replacement

without removing the cartridge.

After you determine which drive needs replacing, follow these steps to

shut down the drive so that you can remove it from the library.

1. Log into the library with superuser or administrator privileges.

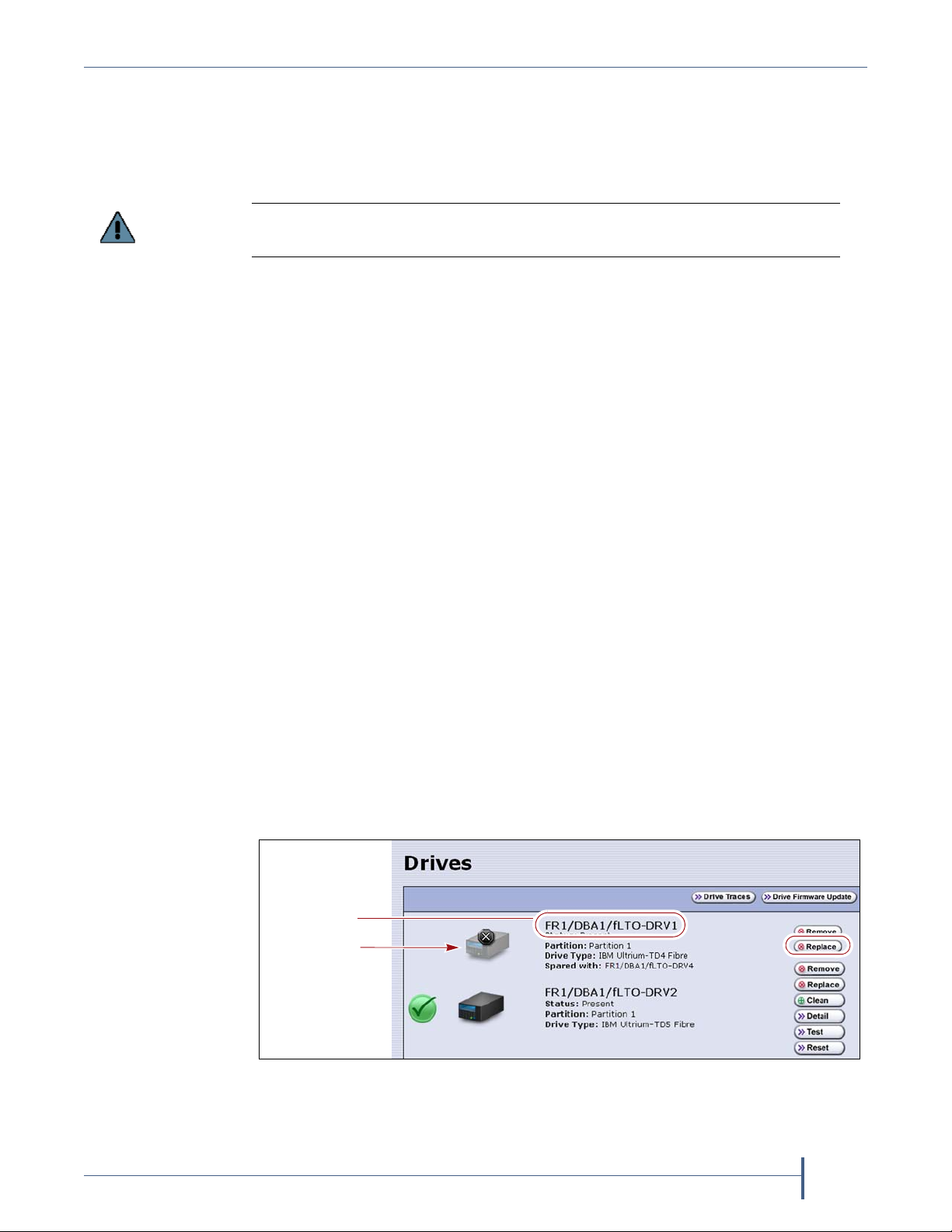

2. Select Configuration > Drives (or DLM). The Drives screen displays.

Figure 1 The Drives screen.

9

April 2013 Drive Installation or Replacement—Spectra T200, T380, T680, T950, and T-Finity Library

Page 10

Replace or Install a Drive Preparing the Library

Important

Status LED

Important

3. Click Replace for the drive that you want to replace.

Do not click Remove. This option permanently removes the drive from the

partition. When the replacement drive is installed, it will not be assigned to the

partition from which the malfunctioning drive was removed.

If you click

partition will be deleted.

Remove and the selected drive is the only drive in the partition, the

A Feedback Required screen prompts you to confirm that you want to

replace the drive.

4. Determine the physical location of the failed drive, either by looking for

the drive sled status light that blinks amber or by using the drive’s

component identifier displayed on the Drives screen.

Figure 2 The drive sled (Fibre Channel drive sled shown).

5. Click OK.

Another Feedback Required screen indicates that the requested drive

has been successfully shut down.

Do not respond to the prompt in the Feedback Required screen or perform any

other operations from the user interface (either locally or remotely) until you

complete the replacement procedure. Responding before you replace the drive will

power on and configure the drive you just powered down.

6. Proceed to Accessing the Drives on page 12.

April 2013 Drive Installation or Replacement—Spectra T200, T380, T680, T950, and T-Finity Library

10

Page 11

Replace or Install a Drive Preparing the Library

Important

Drive Installation Preparation

This section describes how to prepare to add a new drive to the library.

1. Log into the library with superuser or administrator privileges.

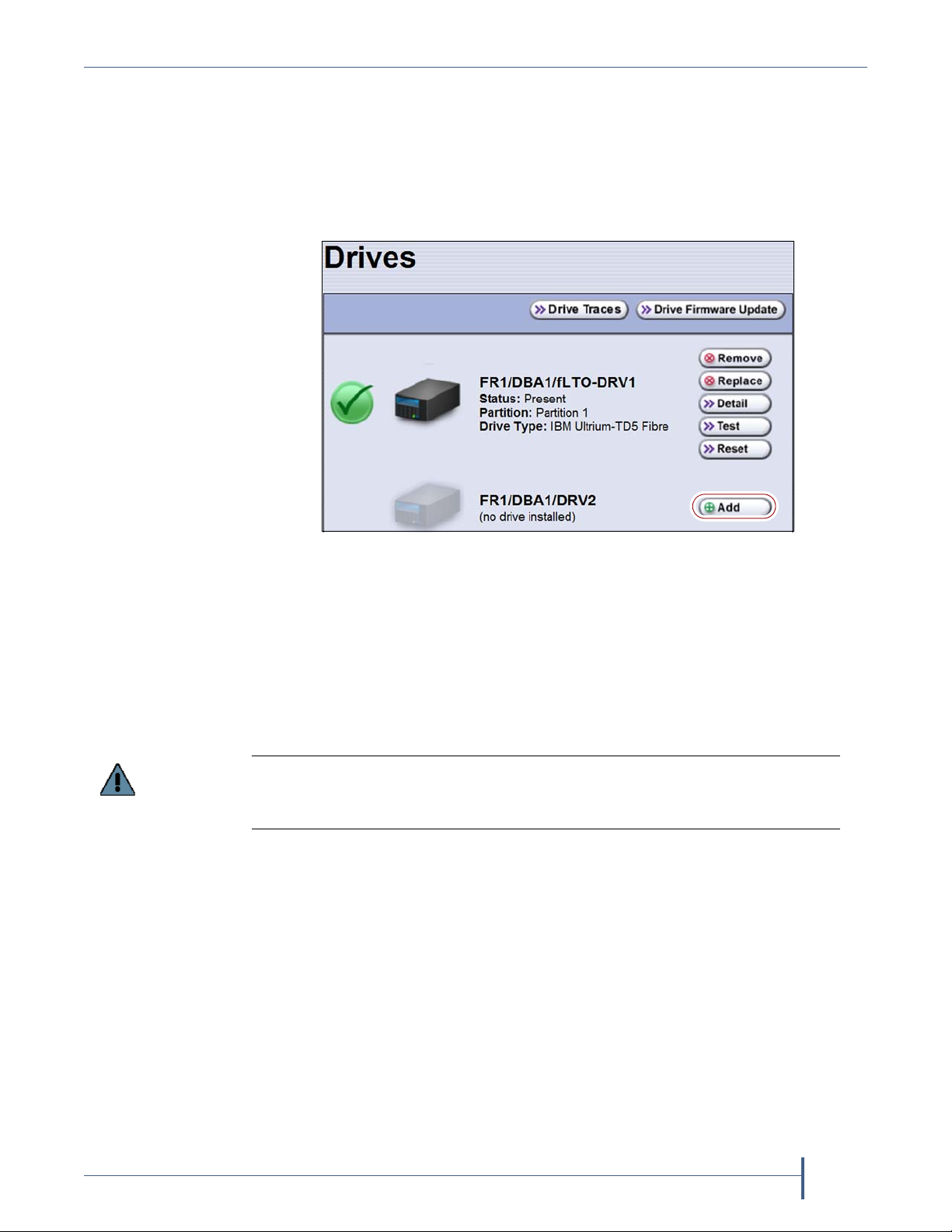

2. From the toolbar menu, select Configuration > Drives (or DLM). The

Drives screen appears.

Figure 3 The Drives screen.

3. Click Add next to the location where you want to add a drive.

A Feedback Required screen prompts you to confirm that you want to

add the drive.

4. Click OK.

Another Feedback Required screen indicates that the library is ready

for you to install the new drive.

Do not respond to the prompt in the Feedback Required screen or perform any

other operations from the user interface (either locally or remotely) until you

complete the drive installation.

April 2013 Drive Installation or Replacement—Spectra T200, T380, T680, T950, and T-Finity Library

11

Page 12

Replace or Install a Drive Accessing the Drives

Cover

Knurled

screw

Alignment nut

Accessing the Drives

This section describes how to access the tape drives.

Spectra T200 or T380 Remove the rear panel cover (if present) in order to

install or replace drives.

1. Using your fingers or a #2 Phillips screwdriver, loosen the two knurled

screws securing the bottom of the cover to either side of the chassis.

Figure 4 The rear panel cover and screws (T380 shown).

2. Lift the cover upward and away from the chassis to disengage the two

nuts extending from the back of the cover from the holes on either side

of the chassis. Set the cover aside.

Figure 5 Cover alignment nuts (one on each side).

April 2013 Drive Installation or Replacement—Spectra T200, T380, T680, T950, and T-Finity Library

12

Page 13

Replace or Install a Drive Accessing the Drives

Handle

Lock

(tilt up and out

to disengage)

Drive

1. Lift

2. Turn

Empty

drive bay

Spectra T680 The T680 is shipped and installed in a rack. Access the back

of the rack and open the door. You may need to unlock the handle first.

Figure 6 The T680 rack door handle.

Spectra T950 or T-Finity The drives are shielded by protective doors.

1. Locate the door handle on the back of the library.

2. Lift the handle and turn it either direction to disengage it and open the

library doors. You may need to unlock the handle first.

Figure 7 The back of the library (T950 shown).

April 2013 Drive Installation or Replacement—Spectra T200, T380, T680, T950, and T-Finity Library

13

Page 14

Replace or Install a Drive Removing the Malfunctioning Drive

Unlock drive

Remove drive

Removing the Malfunctioning Drive

Note: If you are installing an additional tape drive, skip to

Determining Drive Sled Adaptor Requirements on page 15.

Follow these steps to remove a drive:

1. Locate the drive, as described in Drive Replacement Preparation on

page 9.

2. Make sure that the Status LED (see Figure 2 on page 10) is blinking

amber, indicating that the drive is powered off.

3. Carefully disconnect any cables from the drive.

Note: Label the cables before you disconnect them so you can

reconnect them to the same locations on the new drive.

4. Unlock the drive by pushing the drive lock inward.

Note: Depending on the type of drive, the drive lock may look

different from the one shown in Figure 8.

Figure 8 Releasing the drive lock and removing the drive.

April 2013 Drive Installation or Replacement—Spectra T200, T380, T680, T950, and T-Finity Library

14

Page 15

Replace or Install a Drive Determining Drive Sled Adaptor Requirements

Caution

Hold the cable of

the adjacent Fibre

Channel tape drive

out of the way

while removing

or installing a

tape drive.

Note: the Fibre

channel connector

on your tape drive

may not look the

same as the one

shown here.

Caution

5. If the drive you are removing is adjacent to another drive, hold the

other drive’s cables out of the way as you remove the failed drive.

If your Fibre Channel tape drive has the connectors on the side, as shown in

Figure 9, ensure that you hold the Fibre Channel cable of the adjacent Fibre

Channel tape drive out of the way to prevent damaging the cable.

Figure 9 Hold the cables out of the way.

6. While supporting the bottom of the drive sled, pull outward on the

drive sled handle to remove the drive from the library.

The drive sled weighs approximately 15 lb. (7 kg). Be careful not to drop it.

When removing the drive, be careful not to damage or dislodge any cables

connected to adjacent drives.

7. Set the drive aside for return to Spectra Logic. See Return the

Component on page 27.

Determining Drive Sled Adaptor Requirements

There are two types of Drive Bay Assemblies (DBAs) in the field. Certain

drives require an adaptor to fit in one style of DBA, but not the other. If

your installation requires an adaptor, one will be include in the shipping

materials.

Note: This section is not applicable if you are replacing an LTO-4 or

earlier generation drive.

April 2013 Drive Installation or Replacement—Spectra T200, T380, T680, T950, and T-Finity Library

15

Page 16

Replace or Install a Drive Determining Drive Sled Adaptor Requirements

Part number

Part number

The original Drive Bay Assembly (DBA), part number 90948021, requires

an adaptor, part number 90948360, on the bottom of TS1140 and LTO-5 and

later generation tape drives for connection with the DBA.

The Ethernet DBA, part number 90948496, uses a different connector that

will not mate with the adaptor.

TS1140 and LTO-5 and later generation tape drives with adaptors

need the drive adaptors removed before they are installed into an

Ethernet DBA.

TS1140 and LTO-5 and later generation tape drives without

adaptors need adaptors installed before they are installed in the

original DBAs.

LTO-4 and earlier generation tape drives are only supported in the

original DBA.

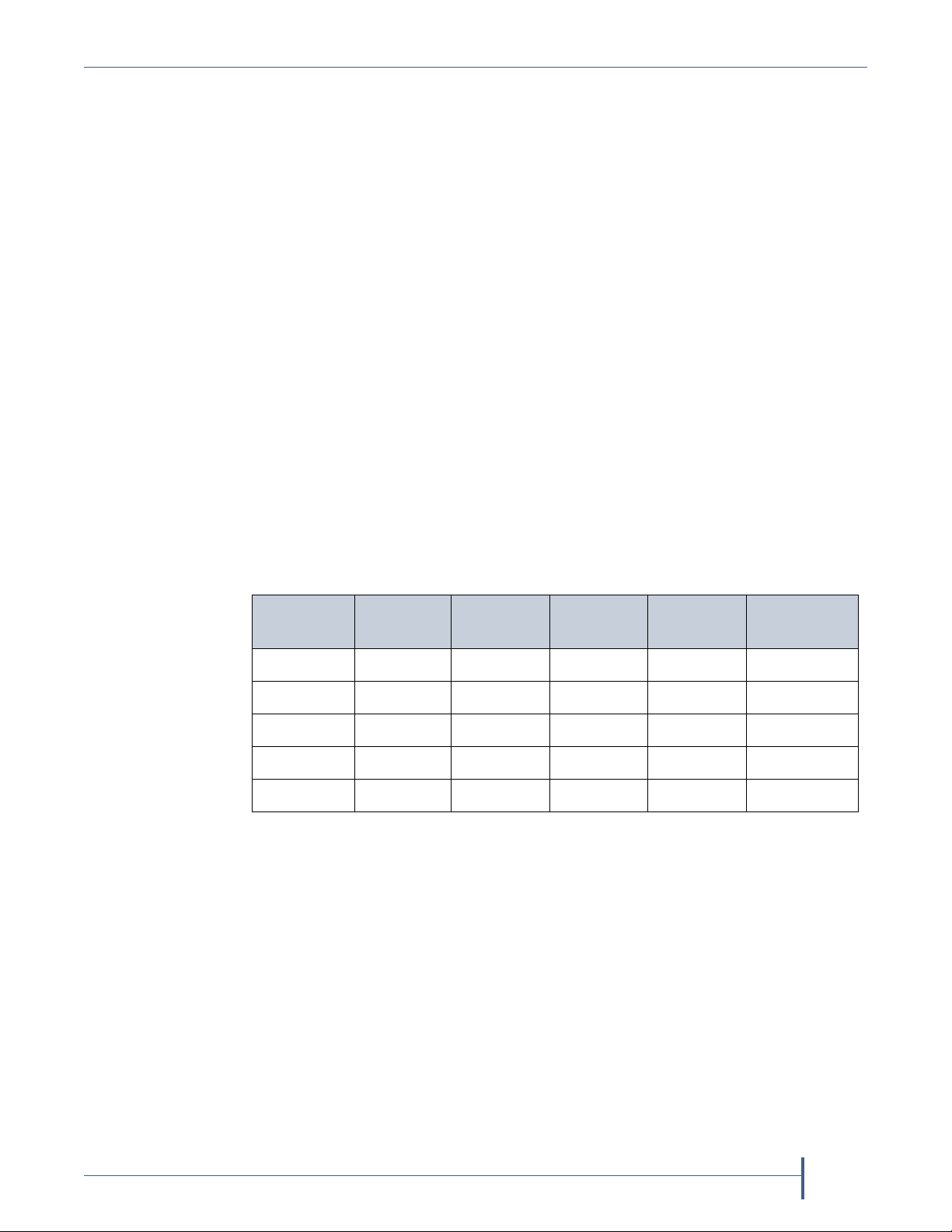

DBA LTO-4 and earlier

drive

generations

Original DBA

(has blue and black

drive connectors)

Ethernet DBA

(has black drive

connectors)

No adaptor

required

Not supported No adaptor

LTO -5 an d l ate r

drive

generations

Adaptor

required

required

TS1140

technology

Adaptor

required

No adaptor

required

Use the following steps to identify if a drive sled adaptor is needed and to

install or remove an adaptor.

1. Determine the type of DBA that is in the library by looking at the drive

connectors. The original DBA has blue and black connectors. The

Ethernet DBA has only black drive connectors.

If needed, you can also determine which style DBA is in the library by

checking the part number sticker in the controller bay.

Figure 10 The original DBA, part number

90948021, with black and blue connectors.

April 2013 Drive Installation or Replacement—Spectra T200, T380, T680, T950, and T-Finity Library

Figure 11 The Ethernet DBA, part number

90948496, with black connector only.

16

Page 17

Replace or Install a Drive Installing the Drive

2. Based on the DBA type, and the type of drive you are replacing, remove

or install the drive adaptor as needed.

Note: The drive adaptor ships in a different box than the drive.

For the original DBA (Figure 10) with black and blue connectors

(part number 90948021), install the adaptor on the bottom of LTO-5

and later generation and TS1140 technology drives, if not present.

a. Carefully plug the adaptor into the bottom of the drive. The

connector is keyed and will only fit one way (Figure 13).

b. Using a #1 Phillips screwdriver, secure the adaptor with the two

screws provided (Figure 12).

For the Ethernet DBA (Figure 11) with black connectors only (part

number 90948496), remove the adaptor on the bottom of LTO-5 and

later generation and TS1140 technology drives, if present.

a. Using a #1 Phillips screwdriver, remove the two screws securing

the adaptor in place (Figure 12).

b. Carefully remove the adaptor as shown (Figure 13).

Figure 12 Two screws secure the

adaptor.

Figure 13 The adaptor connector only

fits one way.

Installing the Drive

Follow the steps in this section to install a tape drive in your library.

1. Refer to Drive Replacement Preparation on page 9 to determine where

to install each drive.

If the library includes QIPs—a drive must be installed in the same

DBA as the QIP that will connect it to the network.

If the library uses direct-attached Fibre Channel drives for the

robotic control path—installing the drives sequentially, beginning

with the next available drive bay, simplifies the configuration. For

example, if drive 1 is in drive bay 1, install drive 2 in drive bay 2,

and so forth. The T950 and T-Finity libraries do not allow using

direct-attached drives for the robotic control path.

April 2013 Drive Installation or Replacement—Spectra T200, T380, T680, T950, and T-Finity Library

17

Page 18

Replace or Install a Drive Installing the Drive

Important

Hold the cable of

the adjacent Fibre

Channel tape drive

out of the way

while removing

or installing a

tape drive.

Note: the Fibre

channel connector

on your tape drive

may not look the

same as the one

shown here.

Caution

2. Remove the drive from its protective packaging.

3. While supporting the bottom of the drive sled, slide the new drive into

the empty drive bay (Figure 15). Push the drive in until an audible click

indicates that it has locked into place.

If your Fibre Channel tape drive has the connectors on the side, as shown in

Figure 14, ensure that you hold the Fibre Channel cable of the adjacent Fibre

Channel tape drive out of the way to prevent damaging the cable.

Figure 14 Hold the cables out of the way.

The drive sled weighs approximately 15 lb. (7 kg). Be careful not to drop it.

Be careful not to damage or dislodge any cables connected to adjacent drives.

Figure 15 Installing the drive sled into the library.

April 2013 Drive Installation or Replacement—Spectra T200, T380, T680, T950, and T-Finity Library

18

Page 19

Replace or Install a Drive Installing the Drive

4. Return to the Feedback Required screen displayed on the user interface

(see Step 5 on page 10 for a replacement drive, or Step 4 on page 11 for

a new drive) and click OK.

The next step depends on whether you are installing a new drive or

replacing a drive.

Replacement drive—The library powers on the replacement drive

and begins the process of configuring it.

New drive—If you installed a new drive, you need to add the new

drive to a partition before it can be used (see Adding the Drive to a

Partition on page 26). New drives added to the library display an

orange square icon with a “?”, indicating that the drive is not part of

any partition.

When the configuration is complete, the Drives screen refreshes to

show the status of the newly installed drive.

Figure 16 The Drives screen after adding a drive.

5. Repeat Step 2 through Step 4 for each additional drive.

April 2013 Drive Installation or Replacement—Spectra T200, T380, T680, T950, and T-Finity Library

19

Page 20

Complete the Procedure Resolving Firmware Mismatches

System Status icon

COMPLETE THE PROCEDURE

Follow the steps in this section to complete the installation or replacement

procedure.

Resolving Firmware Mismatches

When the new drive completes its power on sequence, the library may

display a firmware mismatch error. Determine the type of firmware

mismatch and update the firmware as necessary.

DCM Firmware Mismatch All components in the library should be at the

same library package level. Check the system messages to for any firmware

mismatch messages associated with the drive you just installed or

replaced.

To check the system messages, login to the BlueScale user interface and

click the System Status icon on the status bar.

Figure 17 The System Status icon.

If a DCM firmware mismatch is displayed in the System Messages after the

new drive powers on, then:

If the current BlueScale package is 11.x or greater, run Package Update

to re-apply the current library package, which will update any noncompliant components. See the BlueScale Package Update Instructions for

more information. In most cases this will upgrade the DCM firmware,

in some cases it will downgrade the DCM firmware.

For libraries running BlueScale 10.x or earlier, contact Spectra Logic

Technical Support (see Contacting Spectra Logic on page 2) before

running Package Update.

April 2013 Drive Installation or Replacement—Spectra T200, T380, T680, T950, and T-Finity Library

20

Page 21

Complete the Procedure Connecting the Cables

Important

Important

Drive Firmware Mismatch Use the instructions in your User Guide or in the

Spectra T-Series Libraries Drive Firmware Upgrade Instructions to compare the

firmware level of the new drive to the currently recommended level and

update the firmware if necessary.

Always make sure that you have the most current firmware for your drives. Check

the Drive Firmware tab on the Software, Firmware and Drivers page of the

Technical Support portal for the latest supported firmware, as well as important

notifications.

Always download drive firmware from the Spectra Logic website to ensure that the

latest firmware posted by the drive manufacturer has been qualified by Spectra Logic.

Connecting the Cables

Connect the cables according to the guidelines in this section.

Task Cable Connection

Replaced a drive Connect the cables to the same positions they were

connected to on the old drive.

Installed a new

drive

Connect the cables as described in Drive Connectivity on

page 21.

Drive Connectivity

The drives in the library can have either a Fibre Channel interface or a SCSI

bus interface.

Note: SCSI interface drives are not compatible with the T-Finity library.

Fibre Channel drives connect directly to the host using a Fibre Channel

arbitrated loop or fabric, as described in Partitions Using Direct-

Attached Fibre Channel Drives (all libraries) on page 22.

SCSI drives are connected using a QIP to provide the Fibre Channel

connectivity, as described in Partitions Using QIP-Attached SCSI Drives

(T200, T380, T680, and T950 libraries) on page 23. The QIP acts as a

bridge to connect SCSI drives in the DBA to a Fibre Channel fabric or

arbitrated loop. The terminator for each SCSI bus in the DBA is

installed on the drive’s external LVD SCSI connector.

Keep in mind that all of the drives on an arbitrated loop or SCSI bus must

share the data transfer capacity (bandwidth) of the interface. Having

multiple devices on the same loop can negatively impact the performance

of all the devices.

April 2013 Drive Installation or Replacement—Spectra T200, T380, T680, T950, and T-Finity Library

21

Page 22

Complete the Procedure Connecting the Cables

Partitions Using Direct-Attached Fibre Channel Drives (all

libraries)

When a partition includes Fibre Channel drives, the drives are connected

directly to the host using a Fibre Channel arbitrated loop or fabric.

Figure 18 is a simple representation of how the robotics and direct-

attached Fibre Channel drives are connected directly to a Fibre Channel

SAN through a switch or hub.

Figure 18 An example of a RIM or an F-QIP in a partition with direct-attached Fibre Channel drives.

April 2013 Drive Installation or Replacement—Spectra T200, T380, T680, T950, and T-Finity Library

22

Page 23

Complete the Procedure Connecting the Cables

Partitions Using QIP-Attached SCSI Drives (T200, T380, T680, and

T950 libraries)

When a partition includes SCSI drives, an QIP can be used to provide the

connectivity to the host. Each QIP has two external ports and provides

connectivity for up to four SCSI drives. If a partition contains more than

four drives, additional QIPs are required to provide the connectivity for

those drives.

Notes: Depending on the configuration, one of the QIPs used for

drive connectivity can also be used to provide the robotic

control path.

The Controller Failover feature is not supported for any QIP

that has SCSI drives connected to it. The QIP pair configured

for Controller Failover can only be used to provide the

robotic control path.

April 2013 Drive Installation or Replacement—Spectra T200, T380, T680, T950, and T-Finity Library

23

Page 24

Complete the Procedure Connecting the Cables

The F-QIP acts as a bridge to connect SCSI drives in the DBA to a Fibre

Channel fabric or arbitrated loop. Figure 19 is a simple representation of

how the drives and robotics in a library with a single F-QIP-based partition

are connected to a Fibre Channel arbitrated loop or fabric through a switch

or hub.

Figure 19 An example of a QIP-based partition with QIP-attached

drives connected to a SAN.

In the example shown in Figure 19, the SCSI drives in the partition (four

drives per DBA) are connected to the Fibre Channel arbitrated loop or

fabric through Port A of the F-QIP in each DBA. Port B of the F-QIP in

DBA 3 provides the path over which the SCSI commands to control the

motion of the robotics within the partition are sent from the host. These

commands are relayed to the LCM, which in turn controls the motion of

the robotics.

April 2013 Drive Installation or Replacement—Spectra T200, T380, T680, T950, and T-Finity Library

24

Page 25

Complete the Procedure Testing the Drive

Drive 3

Drive 1 Drive 2

Internal cabling

Fiber port (Fibre Channel or Gigabit Ethernet)

QIP

Drive Bay Assembly (DBA)

Drive 4

Important

As illustrated in Figure 20, a QIP provides any-to-any connectivity to the

SCSI drives it controls. Every drive (target) is potentially visible to servers

through both ports on the F-QIP. This permits flexibility in configuring

which servers can access which drives (target visibility).

Testing the Drive

Figure 20 QIP-attached SCSI drive connectivity.

For example, an F-QIP-based partition can be configured so that Drive 1

and Drive 2 are only accessible through Port A and Drive 3 and Drive 4 are

only accessible through Port B. In this configuration, Drive 1 and Drive 2

can only be accessed by the host connected to Port A; Drive 3 and Drive 4

can only be accessed by a host connected to Port B. In a more complex

configuration, the F-QIP can be configured so that all drives are visible

through both ports. Such a configuration is typically used in a shared

storage environment or an environment with failover capabilities.

If drives are visible to multiple servers, your backup software must support this

visibility. Otherwise server contention for a single drive can create network and

system problems.

1. Power on and restart the host computer, if you powered it off.

2. Determine whether your backup software and drive are

communicating properly.

a. Use the software to write several megabytes of data using the newly

installed drive.

b. Perform a comparison check on the backup data to confirm that it

was written correctly.

April 2013 Drive Installation or Replacement—Spectra T200, T380, T680, T950, and T-Finity Library

25

Page 26

Complete the Procedure Installing the Cover or Securing the Rear Door

Caution

Installing the Cover or Securing the Rear Door

Spectra T200 or T380 Replace the protective cover after you complete the

installation.

1. Lift the cover and align it so that the two nuts extending from the back

of the cover fit into the corresponding holes on either side of the chassis

(Figure 5). If the cables to the drives and QIPs installed in the library are

routed from the:

top of the library, make sure that they fit into the cutout in the top of

the cover.

bottom of the library, make sure that they fit into the cutout in the

bottom of the cover.

Make sure that any cables are not pinched between the cover and the chassis of the

library.

2. Using your fingers or a #2 Phillips screwdriver, tighten the two screws

to secure the bottom of the cover to the chassis (see Figure 4 on

page 12).

Spectra T680 Close and lock the protective door on the back of the library

rack (see Figure 6 on page 13).

Spectra T950 or T-Finity Close and lock the protective doors on the back of

the library (see Figure 7 on page 13).

Adding the Drive to a Partition

Replacement drive—If you replaced a drive, the replacement drive is

automatically added to the partition of the old drive.

New drive—If you installed an additional (new) drive, you need to add

it to a partition before you can begin using it for backup operations.

Refer to the individual User Guide for instructions.

Restarting Backups

Use your backup software to restart any backup processes that had been

running to the replaced drive. This restart ensures that the software

recognizes the drive as working and available.

April 2013 Drive Installation or Replacement—Spectra T200, T380, T680, T950, and T-Finity Library

26

Page 27

Return the Component Restarting Backups

Caution

RETURN THE COMPONENT

Return Guidelines

Unless Spectra Logic Technical Support informs you otherwise, return the

defective component to Spectra Logic following the guidelines in the next

section. If Spectra Logic Technical Support informs you that the component

does not need to be returned, dispose of it in a manner appropriate for

your company guidelines.

Return Procedures

After you complete the replacement procedure, return the defective

component using ALL the packaging that the replacement component

arrived in (including any anti-static bags or foam inserts).

Severe damage can occur if the component is not packaged correctly, and you may

be invoiced if it is received with damage due to improper or insufficient packaging.

Use the return label and instructions that were included with the

replacement component when preparing to ship the replacement part. If

you cannot locate these, contact Spectra Logic for another copy (see

Contacting Spectra Logic on page 2). The return label and RMA printed on

it are used to associate the returned part with your account. To avoid being

invoiced for failure to return the part, do not ship the part back without the

RMA return label.

April 2013 Drive Installation or Replacement—Spectra T200, T380, T680, T950, and T-Finity Library

27

Loading...

Loading...