Series 800 Camera System User's Manual

2002

Spectral Instruments, Inc.

TUCSON, ARIZONA

P/N 2500

Spectral Instruments

Pt # 2500- 2

Spectral Instruments

TABLE OF CONTENTS

1 INTRODUCTION 7

1.1 S800 Series Camera System Overview 7

1.1.1 SICCD - The Important Distinction 8

1.1.2 CCDs And How They Work 8

1.1.3 Cooling The CCD - Why 10

1.1.4 Sensitivity Of The Camera 10

1.2 The S800 Camera 10

1.2.1 The Camera Head And Electronics 12

1.2.2 The Camera Power Supply 14

1.2.3 Camera Interface Module 14

1.2.4 Hooking Up Your Camera To Your Equipment 14

1.2.5 TDI Operation 15

1.2.6 Shutters And Timing Considerations 15

1.2.7 Lenses, Light Paths and Vignetting 16

1.3 The S800 Power Supply 16

1.3.1 Power Requirements 16

1.3.2 Power-On Startup Sequence 16

1.3.3 Externally Supplied Power 17

1.4 The S800 Camera Cable Set 17

1.4.1 Camera To Computer 17

1.4.2 Shutter Connector 17

1.4.3 The Auxiliary Port 18

1.5 The Cooling System 18

1.5.1 System Description 18

1.5.2 Hooking Up A Cooler 18

1.5.3 Cooling Cycle 19

2. RECEIVING YOUR S800 CAMERA SYSTEM 21

2.1 Shipping Configuration 21

2.1.1 Incoming Inspection Of Cartons 21

2.1.2 Opening The Cartons 21

2.2 Environment Requirements For S800 Cameras 21

2.2.1 Temperature - Humidity - Pressure 21

2.2.2 Electrical Requirements 21

2.2.3 Other Requirements 21

2.3 Assembly Of The Camera System 22

2.3.1 Assembly Of The Camera 22

2.3.2 Assembly Of The Camera Power Supply 22

2.3.3 Digital Camera Interface 23

2.3.4 Software Installation 24

2.3.5 Software Operation 24

2.4 Startup 24

2.4.1 Power-On Condition And Indicators 24

Pt # 2500- 3

Spectral Instruments

2.5 Commanding The Camera 25

2.6 Initial Tests 25

2.6.1 Types Of Images 26

2.6.2 Default Camera Readout Format 26

2.6.3 Dark Image 28

3. RUNNING THE COOLED CAMERA 31

3.1 Image Quality 31

3.2 Performance Metrics 31

3.2.1 Noise 31

3.2.2 Dark Signal Generation Rate 32

3.3 Other Metrics 32

4. USING THE CAMERA 33

4.1 Kinds Of Images 33

4.1.1 Bias Images 33

4.1.2 Dark Images 33

4.1.3 Light Images 34

4.2 Fixing Problems With Images - The Master Image Solution 35

4.2.1 Master Bias Images 35

4.2.2 Master Dark Images 35

4.2.3 Master Flat Images 36

4.3 Correcting Images 37

4.3.1 Why Correct At All? 37

4.3.2 How 38

4.3.3 Limitations On The Flat Field Process 38

4.3.4 Understanding The Scaling Effects 39

5. CAMERA SYSTEM WARRANTY AND SERVICE 41

5.1 The Warranty Conditions 41

5.2 Returning A Camera For Service 41

5.3 Diagnosing A Camera Problem 41

5.3.1 No Response 41

5.3.2 Fuses 41

5.4 Determining When To Refresh The Vacuum 42

5.4.1 Measuring The Camera Head Pressure 42

5.4.2 Why Pump 42

5.5 Refreshing The Camera Vacuum 42

5.5.1 Equipment Required 43

5.5.2 The Refresh Process 45

5.6 Cleaning The Window 46

Pt # 2500- 4

Spectral Instruments

5.6.1 Equipment Required 46

5.6.2 The Process 47

6. FIELD REPLACEABLE COMPONENTS 49

6.1 Cables 49

6.1.1 Camera Cables 49

6.1.2 Camera To PDCI Cable 49

6.2 The PDCI Card 49

6.3 The Camera 49

7. SYSTEM OPERATION AND SAFETY 51

7.1 Electrical Requirements 51

7.1.1 Incoming Power 51

7.1.2 Power Cords 51

7.1.3 Power Required 51

7.2 Physical Operating Conditions 51

7.2.1 Temperature 51

7.2.2 Humidity 51

7.2.3 Altitude 51

7.2.4 Vibration 51

7.2.5 Aggressive Vapors 52

7.3 Warnings 52

7.3.1 Electrical System 52

7.3.2 Camera Head 52

7.3.3 Opening The System 52

7.3.4 Refreshing The Vacuum 52

7.3.5 The Camera Window 52

8. TROUBLESHOOTING 53

8.0 Power Problems 53

8.0.1 Main Power Failure 53

8.0.2 DC Voltage Failure 53

8.1 Image Quality Issues 53

8.1.1 No Image 53

8.1.2 Streaks In The Image 54

8.1.3 Noisy Image 55

8.2 The Camera Seems Not To Be Stable 56

8.3 Camera Reports The Proper Temperature But Dark Is High 56

8.4 Camera Does Not Cool 57

8.5 Condensation On The Camera Window 57

Pt # 2500- 5

Spectral Instruments

APPENDIX A 58

CCD Readout Format 58

APPENDIX B 61

Multi-Port CCD Readout Parameters 61

Multi-Port CCD Image Pixel Data Format 61

Single-Port CCD Image Orientation 61

Over-Scan in Multi-Port CCD Readout 62

APPENDIX C 65

Sensitivity And Attenuation 65

Dual Slope Integrator Sensitivity 65

APPENDIX D 67

APPENDIX E 68

External Trigger 68

APPENDIX F 70

S800 DC Power Specification 70

Pt # 2500- 6

1 Introduction

This manual documents the standard Series 800 (S800) camera. Features that pertain

to a specific version of a camera are described in detail in Appendix G. It is

recommended that you read that section before operating your camera.

The S800 is a multi-port (from one to four ports) 14- or 16-bit camera where the

CCD can be cooled to temperatures in the range of –40oC using a thermoelectric

cooler. This camera system can read out at up to 1,000,000 pixels per second from

each port for multi-port CCDs. It reads out at up to 4,000,000 pixels per second as a

single port camera. It offers high precision, high stability and relatively short

readout times.

1.1 S800 Series Camera System Overview

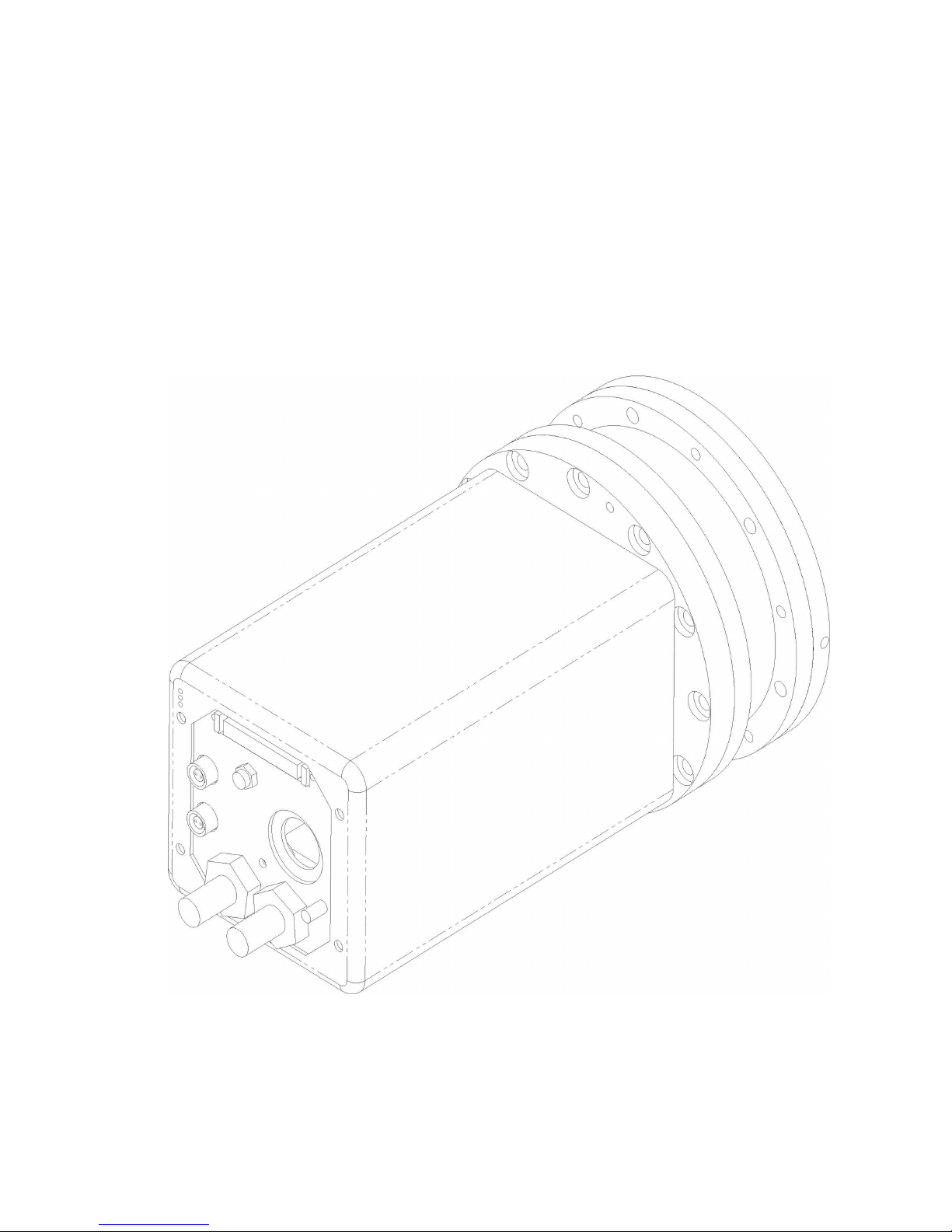

A typical form of the S800 camera is shown in Figure 1. It consists of an evacuated

and sealed camera head chamber with the CCD inside and an attached module that

contains all of the electronics required to operate the camera. An external camera

Figure 1.

Spectral Instruments

power supply and a re-circulating water-cooler are also provided. The preamplifier

and analog processing circuits as well as the clock drivers, temperature and pressure

measurement hardware and digital image output driver circuits are all located inside

the electronics module.

The camera system is “self-aware” – that is, the camera knows, and reports to the

application software, all the information required to properly operate the camera

regardless of the type of CCD or the number of ports.

1.1.1 SICCD - The Important Distinction

Spectral Instruments manufactures precision digital imaging systems utilizing

scientific-grade CCDs. Innovative and detailed mechanical and electronic design

coupled with careful component specification and system manufacture provides

the ultimate in stable, high dynamic range digital imaging. Spectral Instruments

has invented the term Scientific Imaging CCD with SICCD as the symbol that

captures this high precision and high quality character of your camera. This

symbol occurs throughout our documentation as a shorthand reminder of those

high precision and high quality aspects of your camera system.

1.1.2 CCDs And How They Work

CCDs are used in a variety of consumer electronic products. A large assortment

of CCD sizes and types are available because of the popularity of this type of

sensor for low-cost digital imaging cameras. Most of these CCDs are not

scientific grade. Moreover, they are operated so as to give you a “TV” image.

CCD cameras that produce high quality digital images are designed to produce a

precision digital image and not a TV image. They are cooled well below ambient

temperature to reduce dark signal and they are operated in “slow readout mode”

to minimize readout noise.

Digital images are organized in a row/column format. Image elements (pixels)

emerge from a corner of the sensor. A sensor with more than one active corner

produces more than one stream of pixels during readout. Figure 2., below,

illustrates a single-port and a four-port CCD.

Referencing the left-hand portion of Figure 2., the checkered center region is the

imaging area. It is called the parallel register. To read out the CCD, the grid of

pixels is moved, one row at a time to the left, along columns, into the serial

register, labeled SR. Once a row is moved into the serial register, it is then

moved, one pixel at a time to the output node, shown as a triangle and labeled A.

A column is a line of pixels consisting of one pixel from each row. The CCD

does not read out columns, it reads out rows. But many characteristics of the

image that results are shared by all of the pixels at the same location in each row

(the same column) so they are analyzed as columns of information. Defects

involving multiple pixels are almost always column defects.

Pt # 2500- 8

Spectral Instruments

The address of the first pixel out of a CCD camera is row 0 column 0. Readout

occurs along rows, so the second pixel address is row 0 column 1. For a sensor

with 512 imaging pixels in a row and 512 rows, pixel 513 has the address row 1,

column 0. The last pixel out is row 511, column 511

.

One Port CCD Four Port CCD

Figure 2.

It is possible to move more than one row into the serial register before the serial

register is moved into the output node. It is also possible to move more than one

pixel at a time from the serial register into the output node before it is digitized.

This process is called binning. The total number of pixels is reduced in each

direction by the amount of binning in that direction. The effective size, on the

parallel register, of each binned “super” pixel is enlarged. This decreases the

resolution of the image by the binning factors (which may be different for rows

and columns).

Referencing now the right-hand side of Figure 2., the CCD illustrated supports

four-port readout so there are two serial registers labeled SR1 and SR2. Each

serial register is divided into two halves, which is shown figuratively as a black

line in the parallel register. The parallel register is also divided and that is shown

as a vertical black line. Neither black line exist in the CCD nor in the image that

is read out four ports, the divisions are presented as black lines for clarity in

showing how the single sensor is effectively divided into quadrants for four-port

readout. The first pixel comes out A, B, C and D at the same time. They are

combined into a single data stream with pixel data from A then pixel data from B

then C and finally D. This pixel data stream has pixels from all of the quadrants

interleaved. Software must sort them out so they are presented properly.

Spectral Instruments’ SI-Image software performs this task automatically. The

columns are still horizontal and rows are vertical in the final image just as if they

came out of a single port. SI-Image software displays the first pixel, the 0,0

pixel, at the lower left-hand side of your display. The pixels in each row are

displayed vertically. Row numbers increment from left to right in the display.

Pt # 2500- 9

Spectral Instruments

1.1.3 Cooling The CCD - Why

SICCD cameras are cooled to reduce the image contaminant called dark signal.

Images accrue this unwanted signal at a rate that decreases as the temperature of

the CCD is lowered. It is not the dark signal that is the problem (it could be

subtracted from the image), it is the noise associated with the dark signal. That

noise cannot be subtracted; it must be prevented.

The S800 camera system employs a thermoelectric cooler that is capable of

lowering the temperature of a typical CCD to -40

of the TEC is removed by a liquid heat exchanger that is connected to the camera

head. As long as the temperature of the camera is not reduced below the local

dew point, it is possible to lower the operating temperature of the CCD by using

chilled water in the heat exchanger rather than water at room-air temperature.

1.1.4 Sensitivity Of The Camera

SICCD cameras are designed to “see in the dark”. They do so quite well. You

can’t permanently hurt your camera by exposing it to too much light although, if

you have done so, it will affect your ability to make precise measurements of low

light level scenes until after you have warmed up the camera and then cooled it

back down again.

Dark images are a good way to find out how much light is leaking into your

equipment. An image obtained with no external light coming through the normal

path provides a view of how much light is coming from extra-normal paths. This

camera can see light leaks very well! To realize the full potential of your SICCD

camera, it, and the equipment to which it is attached, must be light tight.

o

C. The heat from the hot side

1.2 The S800 Camera

The camera is shown in profile in Figure 3. In this view, the position of the CCD

relative to the front flange, or plate, of the camera is shown. Also shown are the

overall dimensions of the camera. The camera back-view is shown in Figure 4.

Several different connections are required to integrate the camera into your

application. The dimensions are all millimeters.

Power is provided through a 14-pin twist-lock connector. The DC voltages to

operate the camera are supplied at this connector. The source of power may be a

Spectral Instruments S800 rack mount power supply or a DC source in your

application (typically through a DC - to - DC converter package supplied by

Spectral). In either case, a power sub-system is an integral part of a S800

camera. Connection to the computer is either through a 50-pin sub-miniature D

(looks like a SCSI) connector (as shown in Figure 4.) or by a MT-RJ type of fiber

optic data and communication connector.

The computer interface module will have a matching connector. Adapters are

available that split the twin MT-RJ fiber pair into two ST type of fibers. The

dual ST to MT-RJ combining equivalent is also available for use at the data

interface card. The data rate is limited to a maximum of 4,000,000 pixels per

Pt # 2500- 10

Spectral Instruments

second. If a multi-output CCD is used, the rate per output port is appropriately

lower.

Figure 3

Pt # 2500- 11

Figure 4

Spectral Instruments

Coolant is supplied to a pair of ¼" Swagelock VCO couplings. The appropriate

part numbers for the mating connector is: SS-4-VCO-3-4TA “Tube Gland

Adapter” and SS-4-VCO-4 “Female Nut”. Other gland forms are available if

flexible tube is not your choice for the cooling hose connection. Coolant can be

supplied by your application or by a refrigeration unit provided by Spectral

Instruments. It is necessary to maintain the back plate of the camera just above

the dew point to avoid condensation. It is important to monitor the supply line

temperature where chilled liquid is supplied to the camera so that no moisture

forms inside the camera electronics chamber.

The camera operates a shutter. Two types of signals for driving a shutter are

provided. The two-pin Lemo connector labeled shutter is designed to drive a 6-v

shutter from Vincent Associates or from Melles Griot. A suitable shutter can be

supplied by Spectral as an option. The 4-pin Lemo connector, labeled AUX,

provides a TTL or Opto isolated signal that indicates the shutter status across

pins 1 and 2. When the shutter is open the voltage across these pins is +5v.

When the shutter is closed the signal is 0 volts. The mating Lemo connector

specification is given in Section 1.4.2.

The camera can activate an exposure cycle in conjunction with an external event

through the trigger input signal across pins 3 and 4 of the 4-pin Lemo connector

labeled AUX. The signal can either be a TTL switch closure or an Opto isolated

version of the same switch closure. Details are shown in Appendix E.

Three small LEDs indicate: that the camera is receiving DC power, “PWR”;

whether the camera head internal vacuum needs to be refreshed, “VAC”; and

whether the camera temperature regulation is active, “COOL”, by, respectively,

green yellow and green lights. The light comes on when the condition is true.

1.2.1 The Camera Head And Electronics

The camera consists of a camera head chamber and an electronics module that is

physically attached to the camera head. All of the electronics required to operate

the camera are located in the electronics module.

As mentioned in Section 1.1.3, the CCD is cooled to reduce dark signal. Just as

your eyeglasses fog when you come out of the cold into a warm room, cold

objects condense moisture from the surrounding air. The CCD is maintained

inside a sealed evacuated camera head chamber to insure that moisture does not

condense on the cold CCD.

In a lens-based camera, the camera head chamber aperture seal is a fused-silica

window large enough that the CCD sensor is not shaded from the incoming

beam. The CCD sensor is typically located 14.85 mm behind the front surface of

the window. The window thickness is typically 3 mm. Other back-distances and

window thickness options are available for custom applications.

Pt # 2500- 12

Spectral Instruments

Fiber-optic based cameras seal the camera head chamber at the fiber optic. The

fiber optic protrudes a few millimeters in front of the chamber so the camera can

be coupled to other optics.

The S800 camera is cooled by a thermoelectric cooler. That cooler is capable of

o

cooling the CCD below –40

C for small size CCDs that are not connected to a

fiber optic. The cold end of the TEC is inside the camera head vacuum chamber.

The amount of current flowing to the CCD is regulated to maintain the CCD at

the operating temperature, which is typically between –20

o

C and –40oC.

As shown in Figure 5., a 6X M5 115 mm clearance bolt circle pattern is provided

for mounting the camera to your application. As shown in Figure 4., a 4X M5

tapped bolt circle is also available on the back plate if mounting the camera by

the back plate is appropriate.

Pt # 2500- 13

Figure 5.

Front Plate

Spectral Instruments

1.2.2 The Camera Power Supply

The DC voltages necessary to operate the camera are provided through a separate

power supply module. This module is connected to the camera head by a 14-pin

Twist-lock connector. The power supply pin-out is shown in Appendix F.

WARNING: Turn off the power to the camera power supply before connecting

or disconnecting the camera power connector either at the camera head or at the

power supply!

The SICCD camera is buffered against electrical transient events - radiated or

conducted - through the power connection. This buffering suffices for

coexistence of the camera with typical laboratory equipment.

WARNING: The camera system incoming power mains must be filtered against

exceedingly strong transients such as that produced by lightning.

1.2.3 Camera Interface Module

The camera communicates to the host computer either through a proprietary

AIA-style communications and data transfer protocol or by a MT-RJ fiber optic

link. The two different communication protocols utilize different host interface

cards. Both types of connection permit the camera to receive instructions from

application software and to read the status of the camera through a serial

protocol. The data transfer is different between the two options.

The copper-wire AIA connection transfers image data down the AIA cable as 16bit parallel pixel values over differentially driven lines. The communication

signal is RS422 bi-directional with control characters and parameters transmitted

to the camera and status and configuration parameters transmitted back to the

host computer.

The optional fiber optic communication and data protocol replaces the AIA

drivers and receivers on both ends of the communication with a two-fiber bundle.

The communication is still serial but the pixel data is also transferred serially and

reconstructed at the fiber optic interface module.

1.2.4 Hooking Up Your Camera To Your Equipment

A detailed description of the system setup and interconnect process is provided

in Section 2.3. An important system aspect of connecting the camera to your

application is minimizing ground loops. Ground loops result from small voltage

differences among grounds of different power sources. They can have a serious

effect on images obtained from your SICCD camera. If ground loops are present,

various lines, bars, chevrons or wood-grain patterns can occur in the background

of low light images (they show up especially well in a bias image). The patterns

are of no significance when imaging high light level scenes but can disturb low

light images and are exceedingly annoying as the eye is very good at picking out

such patterns even if the amplitude is not statistically measurable.

Pt # 2500- 14

Spectral Instruments

Spectral Instruments has designed a camera that is essentially bias-pattern-free

when it is operated from a suitable power source as directed in Section 2.3. If

that camera is mechanically connected to some apparatus that is at a different

ground potential than the power source, small currents flow through the camera

body. These small currents are always visible in the image; they are always

undesirable!

If the camera and the equipment cannot be grounded to the same point, it may be

necessary to introduce an electrical insulator (including screws) where the

camera physically is attached to your equipment.

1.2.5 TDI Operation

Spectral Instruments cameras can image in conjunction with a moving field. In

this mode the camera operates either through a timed delay or by synchronizing

the shifting of the image on the sensor to an external event. In the latter case, the

trigger input provides the synchronization. In TDI mode, a frame is discarded at

each end, which is overhead for this imaging mode.

1.2.6 Shutters And Timing Considerations

The camera provides millisecond resolution in timing your SICCD camera. That

resolution is useful when the camera is shuttered by equipment that responds in

tens of milliseconds.

The camera is also designed to obtain “images upon external signal”. This is

known as “triggered mode”. In this mode the camera is programmed to clear

charge continuously with the CCD staring into the application waiting for a

trigger event. The trigger event is provided by the application. The camera

ceases clearing immediately (within 5 milliseconds depending upon the CCD)

upon receipt of the trigger and stares into the application accumulating an image.

The camera stares for the currently set integration time and then it reads out.

When a SICCD camera is shuttered by any conventional multi- or twin-blade

shutter mechanism, the shutter requires some time to open and to close. These

shutter open and close delays must be considered when obtaining short

exposures. A user changeable shutter-close delay is programmed into the

exposure readout so readout does not start until the shutter is fully closed.

However, a good twin-blade shutter requires at least ten milliseconds to open as

well as close. A 10-millisecond exposure with such a shutter means that the

integration time is effectively 20 milliseconds for the center of the image and is

much less for the edge of the image. The resulting variation in effective

exposure is noticeable. The exact pattern observed depends upon the type of

shutter. In every instance, you must not expect uniformly exposed images when

the exposure times are within a factor of 10 of the shutter delay times. Large

shutters can take more than 50 milliseconds to open and close.

Pt # 2500- 15

Spectral Instruments

While it is possible, in principle, to correct for shutter-caused patterns in a flat

field image, shutters are electro-mechanical devices that are not very stable so

one flat field may not suffice for effective shutter shading correction.

1.2.7 Lenses, Light Paths and Vignetting

Spectral Instruments usually does not provide a lens. This is because most

applications that can utilize the precision of a SICCD camera already provide an

image plane at which the SICCD camera is positioned. Typically, a lens is only

useful for imaging with the camera “straight out of the box” and is usually

discarded soon thereafter.

There is always some variation across the image of a “uniformly illuminated”

application. It is exceedingly difficult to obtain a uniform illumination field and

most equipment vignettes to some extent. There are methods to compensate for

this vignetting and they are discussed in Section 4.

One type of application that is frequently troubled by imaging artifacts is the

“long focal ratio”. When the camera is exposed to light that is nearly collimated,

that beam acts to reveal very small dust specks on the window. The camera is

assembled with great care to eliminate any dust on the inside of the window. The

outside of the window is also cleaned and the camera is shipped with a protective

cover to keep the window clean. Life conspires to change that. Dust particles

collect on the outside of the window. Only those customers with applications

involving highly collimated incoming beams will notice. What they will notice

are “little donuts”. These are shadows of the dust particles on the outside of the

window. They can be corrected using a process discussed in Section 4., but if

your application does not include image correction you will see the dust in a

collimated beam illumination of the camera.

Although cleaning the outside of the window is not recommended; Section 5.6

describes how to clean the window of your camera if such activity is really

necessary.

1.3 The S800 Power Supply

The round 14-pin power connector (POWER) connects to a cable leading to the

camera head. This connection provides critical voltages to operate the CCD and

must supply completely noise-free DC voltages to the camera.

1.3.1 Power Requirements

The power supply operates on incoming AC power in the 48 to 62 Hz frequency

range and can run on 100, 120, 230 or 240 volts. A power entry module allows

the power selection to be changed. The fuses required for the incoming mains

are located in the power entry module.

1.3.2 Power-On Startup Sequence

When power is applied to the camera head the DSP turns on, reads stored

parameters from a local flash RAM and is ready to operate the CCD. The DSP

Pt # 2500- 16

Spectral Instruments

flashes the power LED three times to indicate that it is ready. Static voltages are

applied to the CCD. Continuous clearing of the CCD is started. The camera is

not caused to expose and readout without an application command to do so.

1.3.3 Externally Supplied Power

The camera may be operated from an application-supplied DC power source. In

principle, it is possible for the application to provide all of the DC voltages

required by the camera. These voltages are detailed in Appendix F.

More likely, your application has a 28-volt or 24-volt DC power source that is

preferred for operating the camera instead of sourcing 110- or 230-volt AC

power to a Spectral Instruments power supply. Spectral Instruments provides

DC - DC converter modules (two modules, one for the camera and the other for

the TE cooler) that have two-pin input connectors to receive the incoming DC

power. Each module produces all of the camera-specific DC voltages which

“wye” into a standard 14-pin output power cable. The length of the cable to the

camera head should be short when the DC - DC converter is used in order to

minimize line drop. Such converter modules should be located somewhere near

the camera head and mounted according to the requirements of the application.

1.4 The S800 Camera Cable Set

1.4.1 Camera To Computer

The camera communicates with the computer either by a copper-wire 50-pin

parallel digital connection or by a two-fiber fiber-optic serial connection. In

either case, a communication link is included within the cable along with the data

lines. The copper-wire cable to the computer connects to the Spectral

Instruments proprietary PDCI AIA digital imaging module by a 50- to 68-pin

AIA cable.

The fiber optic connection connects to a Spectral Instruments proprietary PDCI

FO fiber optic input module. This module presents the identical interface

register set and I/O addresses as the PDCI AIA module. The host computer

drivers are identical for the two interface modules.

The fiber optic communication configuration provides “fiber active” indicators at

each end of the fiber that are turned on if the fiber is not properly connected.

Indicators are located at the camera head next to the link and at the computer

interface module.

1.4.2 Shutter Connector

If a shutter is supplied, that cable is also included with the camera system. At the

back of the camera head, a 2-pin shutter connector port, labeled SHUTTER, is

provided for cameras that use a standard 6-volt shutter. The camera head end

varies to meet the application requirements and/or physical shutter selected.

Pt # 2500- 17

Spectral Instruments

The camera shutter connects to a Lemo connector that is available as LemoUSA

part number FGG.0B.302.CLAD52Z. The wire must not be bigger than 22gauge and the cable must be between 4.1 and 5.0 mm in diameter.

1.4.3 The Auxiliary Port

A 4-pin Lemo connector at the camera head provides for external control out of

and in to the camera. The current status of the camera shutter is provided as a

signal between pins 1 and 2 of the auxiliary port. When the shutter is open the

signal is + 5 volts. Otherwise it is 0 volts. A switch closure between pins 3 and

4 on the auxiliary port sends a signal to initiate an exposure when the camera is

in the "triggered exposure" mode.

The auxiliary connects to a Lemo connector that is available as LemoUSA part

number FGG.0B.304.CLAD56Z. The wire must not be bigger than 22-gauge

and the cable must be between 5.1 and 5.5 mm in diameter.

1.5 The Cooling System

1.5.1 System Description

The thermoelectric cooler that lowers the temperature of the CCD is sized

according to the load provided by the camera head configuration. The design

load is determined by the size of the CCD, the presence of a fiber optic

attachment or the distance between the CCD and the window. The operating

load is very much affected by the pressure inside of the camera head chamber.

The watts to be removed from the camera head by an external cooling liquid

supply vary according to the size of the TEC. TE coolers run between 30 and

150 watts. Cooling liquid at +20oC flowing at rates between 3 and 10 liters per

minute are sufficient for TE coolers at 30 and 150 watts respectively.

It is possible to supply cooling liquid at a controlled temperature by use of a

closed cycle refrigeration system. This is necessary in the event that the ambient

temperature is high. It is important to avoid bringing the inlet tube to the camera

head below the dew point because condensation would result and condensation is

always bad.

1.5.2 Hooking Up A Cooler

The camera is fitted with two ¼” Swagelock VCO fittings. Spectral Instruments

supplies a closed cycle refrigeration system as a cooling option. The liquid is a

50% ethylene glycol and 50% de-ionized water mixture. It is important that the

fluid used be non-corrosive to the metal camera head chamber. As a minimum, a

buffered solution must be used. Glycol is not required unless the system is

exposed to temperatures that could freeze.

Pt # 2500- 18

Spectral Instruments

1.5.3 Cooling Cycle

The camera will start to cool immediately when the TE cooler is turned on. It

requires a few minutes (for a small CCD camera) to stabilize and it will only

stabilize if the temperature requested is at least five degrees warmer than the

open-loop temperature.

If the camera is started running with the stabilization temperature requested to be

colder than the TEC can provide, the temperature of the CCD will lower to an

initial minimum and then rise again to the "open loop" temperature. This small

rise in temperature reflects the attainment of a thermal equilibrium throughout

the mechanical parts of the camera head.

To disable cooling the camera, set the stabilization temperature above the current

ambient temperature. Alternatively, the cooling On/Off configuration parameter

can be used to enable or disable power to the TEC.

Pt # 2500- 19

2. Receiving Your S800 Camera System

The camera system is shipped in double-walled heavy weight cardboard boxes that are

industry standard for fragile electronic equipment. Do not discard these cartons if the

equipment is to be transported.

2.1 Shipping Configuration

The camera and the computer interface module, with its cable, are shipped in one box.

The DC power supply, with its cable, is shipped in a second carton. A cooler, if

provided by Spectral, is in another carton. The test report and the SI-Image software

are shipped in the box with the camera.

2.1.1 Incoming Inspection Of Cartons

Inspect the cartons to make certain that there is no visible damage. Check for

puncture-type damage. If there is any evidence of damage, have the packages

inspected by your local freight carrier so that responsibility for damage to the camera

components is borne by the carrier.

2.1.2 Opening The Cartons

Open the cartons in such a manner that they can be reused. It is important to use these

or equivalent packing materials if the camera system is to be transported.

2.2 Environment Requirements For S800 Cameras

2.2.1 Temperature - Humidity - Pressure

The camera system operates at temperatures from 60oF (15oC) to 95oF (35oC). The

camera system operates at relative humidity from 10% to 60%. The camera is rated to

operate from sea level to 10,000 feet.

2.2.2 Electrical Requirements

The camera system runs on regular AC power as long as the frequency is between 48

Hz and 62 Hz and the voltage is 100, 120, 230 or 240 volts. The requirements for the

fuses are described in Section 2.3.2. The system must be protected against line surges

by using a surge-suppresser in the incoming AC power line.

2.2.3 Other Requirements

The camera components must be protected from aggressive atmospheric conditions

such as are the result of operating in salt laden air or in air that contains corrosive

chemical vapors.

Spectral Instruments

2.3 Assembly Of The Camera System

Camera assembly consists of verifying proper AC line voltage setting, connecting AC

line power to the power supply, connecting the power cable between the power supply

and camera, and connecting the computer interface cable between the camera and the

computer interface card.

Figure 6.

S800 Interconnect Diagram

Figure 6. shows how the components connect and how the main power must be

connected.

2.3.1 Assembly Of The Camera

Assembly of the camera involves mounting the head onto a test fixture or onto your

equipment. Normal precautions should be taken against handling damage.

2.3.2 Assembly Of The Camera Power Supply

The AC power setting must be verified or set to the proper configuration before power

is applied to the camera. The power-entry module has a recessed IEC male connector

for the power cord. To the right of this recessed male plug is a fuse module that has an

indicator for the current power configuration. The indicator is a white dot that appears

to the right of one of the four power settings marked in the black plastic on the fuse

holder. The indicator MUST agree with the mains power that will be used. If the

indicator does not show that the camera power supply is set to the proper AC power, it

must be changed. All of the output fuses must also be changed whenever the incoming

power setting is changed from 100/120 to 230/240 volt configurations. The fuse

Pt # 2500- 22

Spectral Instruments

requirements are given below and are labeled on the back of the power supply. Power

and fuse changes are accomplished as follows:

1) Make certain that the power cord is not plugged into the power supply!

2) Using a small flat-head screw driver, insert it into the small recess on the left hand

side of the fuse holder module. Gently pry the fuse holder out of the module. Inside,

fuses are visible. Inspect the fuse values. For 230-240 mains, the fuses must be T1.0

fuses or T1.5 depending upon the TEC power supply installed. For 100-120 mains the

fuses must be T2.0 or T3.0 fuses, again depending upon the TEC supply installed. All

of the fuses are 5-20 (metric) fuses and they must be TUV approved.

3) Using a small pair of pliers or strong tweezers, carefully remove the very small

circuit board assembly that resides on the right hand side of the cavity exposed when

the fuse holder was removed. This is a 2-part power selector. The circuit board,

inserted with the correct power indicated at the leading edge of the circuit board,

actually makes the proper power connection to the power entry module. The small

plastic indicator can be “wiggled around” so as to point its dot in the opposite

direction. The effect of repositioning the dot is to move it up or down to indicate the

proper power selection when the unit is reassembled. Once the dot is opposite the

power label you selected, replace the circuit board assembly.

4) Insert the fuse holder module and inspect the power setting now indicated by the

white dot. If it is not correct then redo steps 2 and 3 until it is correct.

5) The six fuses (labeled F1, F2, F3, F4, F5 and F6) for the DC power must be correct

for the incoming line voltage. The first three fuses are identical and are T0.5A for

100/120 volts incoming power. The second set of fuses are also identical and are

T1.5A for 100/120 voltage. For 230/240 the two sets are 1.4A and 0.75A

respectively.

Once the AC power setting on the electronics unit has been set up for the local AC

power, assembly of the camera consists of connecting the power supply cable to the

camera.

2.3.3 Digital Camera Interface

Spectral provides two versions of the computer interface module. One is the PDCIAIA parallel data card that is a PCI bus interface card for the Spectral Instruments 500,

600 and 800 Series cameras. It accepts camera image data at rates up to 10 MHz and

directs it to computer memory by bus-master direct memory access. It also transmits

and receives RS422 levels for camera communications. The interface card connects to

the camera by a 68-pin to 50-pin high-density cable.

The other data interface option is the PDCI-FO, a fiber optic module with the same

characteristics insofar as the host computer device driver is concerned. It has a MT-RJ

fiber optic connector instead of the 68-pin AIA connector.

Pt # 2500- 23

Spectral Instruments

To install either module in your computer, first turn off your computer and plug the

interface card in any available PCI slot. Insert the Spectral Instruments CDROM into

the CDROM reader on the computer.

2.3.4 Software Installation

Camera control and imaging software is provided by Spectral Instruments. This

imaging software, called SI-Image, is supplied on a CDROM. The installation disk

contains a setup.exe installation program that automatically detects the operating system

(Win9x, WinNT, Win2K or WinXP) and installs the appropriate driver and camera

interface .dll into a directory path that you may redefine as part of the installation.

When the computer is switched back on, a Windows 98 operating system will find that

the card has been installed and finish the installation. For Windows NT and Windows

2000, become system administrator and run the setup.exe on the CDROM. Note that

installing the software as administrator requires a re-boot cycle to again be able to run

the software as a normal user.

2.3.5 Software Operation

The software is typically installed into a sub-directory under the directory containing

other Program Files. Two icons are provided, one to run the program and the other to

uninstall the application. The SI Image SGL program uses an internal representation of

image data as floating point pixel values which means that image data are 32-bits (4bytes per pixel). The data can be stored under any of several file-storage formats. It is

important to select a file storage format that is appropriate to the range of values in the

image data! If the image has negative values (as a result of image arithmetic perhaps)

those pixels are not represented correctly except as signed 16-bit integers or as 32-bit

floating-point values.

Once the program screen appears, the pull-down labeled Operate provides a control to

initialize the camera. When this has finished properly, the camera is then ready to

operate. A software manual, Part # 2523, is provided as a .pdf file on the CDROM that

also contains the software.

2.4 Startup

After the software is installed, the camera has been connected to the power supply and the

data cable connected to the PDCI interface, the system is ready to image.

2.4.1 Power-On Condition And Indicators

When the unit is switched on, the ”PWR“ indicator on the camera head flashes three

times and then remains illuminated. The amber high-pressure ”VAC“ light will turn on

if the camera pressure is above 4 torr. This indicates that vacuum service is required.

The green “COOL” LED indicator light on the back of the camera housing turns on

when DC power is applied to the thermoelectric cooler. The brightness of the light

shows the amount of power being applied to the cooler. When the TE cooler is first

turned on, maximum cooling power is applied and the light is bright. When the

Pt # 2500- 24

Spectral Instruments

camera has reached the selected operating temperature the “COOL” LED glows but not

as brightly.

2.5 Commanding The Camera

The camera accepts a number of commands and parameters from the host computer. The

commands are all single ASCII letters, which can be upper case or lower case. No

termination characters, such as carriage return and or line feed, are necessary to initiate

the command. Only those characters that are part of the command set are valid. The

command set is available from Spectral Instruments upon request as part number 1870.

Termination characters are treated as invalid commands and thus should never be

transmitted. For any valid command, the command is echoed back to the host, the

command is executed and then a reply of an ASCII Y is sent, to indicate successful

completion of the command, or a reply of an ASCII N is sent to indicate that the

command is invalid. Some variations occur in exactly when the various Y responses are

transmitted to the host computer depending upon the activity commanded.

If a command requires a parameter or parameters, it (they) must be sent as 32-bit binary

word(s) with the most significant byte sent first, immediately after the command letter

echo is received. The camera knows from the command what sort of parameter(s) is/are

expected and waits for transmission of requisite number of bytes. The parameter(s) is/are

not echoed. The camera waits for the number of bytes that are expected for the command

so it is important that every command that requires a parameter be followed by the proper

number of bytes. After the parameter(s) is/are received the terminal Y or N response is

returned. If a parameter is out of range for that command a N reply is issued and the

command is not executed.

Commands from the host computer, that ask the camera for status or configuration, send

the information after the command is echoed. These numbers are also 32-bit and are sent

with the most significant byte first. After the parameters are sent the Y or N is sent. The

camera communications protocol is documented also under SI Part Number 1870.

2.6 Initial Tests

To assure the camera is functional even before it is cooled, it is reasonable to run through

initial imaging tests while the camera is cooling down. Final performance metrics cannot

be undertaken until the camera has stabilized at its regulating operating temperature.

There are several configurations the camera can assume. For some of them it is not

possible to “take an image” without fully integrating the camera into the application

apparatus. This manual uses tests for which a dark environment is sufficient.

The following also assumes that the SI-Image program is used to run the camera. Any

other operational software will work as long as the equivalent camera operations can be

commanded from within that software.

Pt # 2500- 25

Spectral Instruments

2.6.1 Types Of Images

SICCD cameras provide access to all of the components of an image. These are:

1) the electrical offset introduced to keep all of the pixel values as positive integers the bias,

2) the dark image which includes the bias and shows the sensitivity of the camera to

thermal signal and

3) the light image at which the camera was directed. The light image includes the

dark and the bias components.

If the exposures are short and of constant duration, then the bias and dark images need

not be measured separately - particularly if a dark image is obtained essentially for

every light image. Bias images may exhibit a low-level spatial structure that is stable

over time. The bias image is different according to the way the camera is set up to

image. It changes with readout speed, attenuation and binning. The bias image is a

uniform array of very low-level “gray values” superimposed upon on a background

DC offset. The value of the offset can be set by software command.

Binning, attenuation (gain) and readout speed all affect the bias image. Some

structure may be visible along one edge of the bias image. This stable structure

reflects the analog readout electronics responding to the startup transients involved in

beginning each row read out. Bias images also incur some thermal signal (dark

image) if the readout is slow and the camera is warm. This thermal signal introduces

a ramp effect from one side of the bias image to the other. Referring to Figure 7., the

thermal signal is uniform along rows and increases along columns. The plot

overlaying the image in Figure 7 shows a horizontal cross section at the red cursor in

the image. Colors only show up in the .pdf form of this document.

Dark images are bias images along with the additional thermal signal accrued during

the exposure time. Dark accrues more or less uniformly over the entire sensor

although some areas of the CCD may contribute thermal image at a higher rate than

other areas. This non-uniformity is stable for a given exposure.

Very bright “speckles” will appear in dark images – in fact, they sometimes appear in

bias images as well. These are the record in the CCD sensor made by the passage of

highly energetic particles. Classical CCD imaging literature calls these particles

“cosmic rays”, in this manual they are referred to as spurious events. They are

random in occurrence and must be located as described in Section 4.

2.6.2 Default Camera Readout Format

The default image readout format, as delivered by Spectral Instruments, reads out more

pixels than just the illuminated pixels. This readout mode is called “overscan”, reading

imaginary pixels as well as illuminated pixels. Appendix A contains an illustration of

overscan readout mode.

When overscan readout is employed, the images that result depend upon the design of

the CCD sensor itself. Table A1., in Appendix A, includes the pixel count appropriate

Pt # 2500- 26

Spectral Instruments

to overscan some representative CCDs. The illustration shows you how to relate each

of the tabulated parameters to the image read from the camera.

Figure 7, below, shows an image from a warm camera displayed with SI Image and the

plot for a column near the center of the image overlaying the image.

Camera Image Showing Overscan

The serial register is on the left hand side of the image. The first pixel read is displayed

at the lower left hand corner and the readout progresses up rows starting with the first

row at the left and progressing to the last row that is displayed on the right hand side of

the image. The image is darker on the left and brighter on the right. The column plot

shows the “ramp” of increasing dark signal with time. Because of the slow-scan

Pt # 2500- 27

Figure 7.

Spectral Instruments

readout, rows on the right hand side of the image were exposed to dark signal longer

than those on the left hand side – hence the ramp.

The image shows dark bands at the bottom and top. These bands are from pixels that

were digitized but that did not come from the active area of the sensor. The band at the

bottom is the 8-pixel prescan extension of the serial register. The wider band at the top

is the post scan extension of the serial register. The pre scan and post scan are

combined into the general term overscan.

The image shown in Figure 7 includes overscan in the parallel direction as well as in

the serial direction. It is not too easy to tell but the last 100 rows in the image have all

about the same signal level since all of those rows experienced the same exposure to

dark signal during readout. This is because they do not exist on the sensor and are sort

of “created” at the far (from the readout) edge and transit the sensor just like the last

real row did.

The best image for showing all of the components of overscan readout is a lightexposure from a cold camera. This circumstance results in the light-sensitive pixels

being differentiated from the masked pixels and those from the “imaginary” bias pixels

that do not exist on the CCD sensor.

Dark signal only arises in pixels that exist within the parallel register of the CCD.

Note that the parallel overscan, while representing a region that is not on the imaging

area of the CCD does show dark signal. This signal is flat because all of the parallel

overscan rows are exposed to dark charge for some time (exactly the same time) while

passing over the active area during readout (which is when dark signal is experienced.)

Reference Figure A1 in Appendix A for an illustration of overscan readout

components.

2.6.3 Dark Image

In a dark image, the signal from those pixels that are exposed to the same dark signal

integration time all have the same brightness. With overscan, darker pixels show up

along one edge of the image. These are readout pixels that did not integrate dark signal

for the exposure-time duration - they are the “imaginary” bias pixels that do not exist

on the CCD sensor. Adjust the windowing of the software to show low pixel values as

gray levels and you will see several distinctly different levels along the sides of the

image. The brighter level corresponds to physical pixels on the sensor, some of which

may be masked to incoming light but can still detect dark signal. The other pixels are

not physically on the sensor but are generated by reading past the physical extent of the

edges of the CCD sensor. Depending upon the camera temperature and the amount of

the exposure, it may be possible to "see" the difference between masked pixels and

illuminated pixels on the parallel register. Finally, the dark signal that accrues during

readout is a ramp that starts near the bias level on the side of the serial register and

increases to a constant level in the parallel overscan.

Insure that all external illumination is extinguished and obtain a ½ second dark image.

The result is a dark image from a moderately cooled camera - a gradient in brightness

Pt # 2500- 28

Spectral Instruments

shows up with the brighter pixels on the side of the image away from the serial

register.

Some number of very bright spots may be visible. Most of these are pixels that

generate an excess of dark signal compared to the average; they are hot pixels. Any

hot column defects are also visible. The test report lists the hot and dark columns on

your sensor when it is operating at normal temperature.

Pt # 2500- 29

3. Running The Cooled Camera

Once the camera head has become thermally controlled it is possible to verify some

camera performance metrics, as described in subsequent sections.

3.1 Image Quality

Now that the camera head is cold, a bias image is a more uniform array of gray

values with a lower-level ramp along columns. The image is otherwise pretty

uniform, or else there is a light leak where the camera head joins the application

or within the application itself (assuming there is no shutter between the camera

and the application). Two bias images taken in succession and subtracted are

flat, although you may be able to notice the increase in noise (because of higher

dark signal) at the side away from the serial register.

Dark images from moderately cooled cameras exhibit a wide variety of patterns

that are typical for different CCDs but may vary in visibility from one CCD of a

type to another of the same type. In deeply cooled CCD cameras, you can expect

fairly uniform dark images. In moderately cooled CCD cameras, dark nonuniformity is the rule. Many CCDs show wafer-dependent patterns in the dark

signal.

With that said, a 100-second dark image shows a structure similar to the bias

although the background will be higher (depending upon the CCD and the

temperature of the camera). The cold-CCD dark image integrates both internal

dark sources and extraneous light (again assuming no shutter) and it shows up

light leaks in a way that short exposures typically do not. Light leaks are usually

not uniform so they are revealed in dark images. Very low-level light leaks can

emulate dark signal – so be wary.

3.2 Performance Metrics

Continue to avoid exposing the CCD to light. It is time to measure some

performance parameters. The SICCD camera meets a number of primary

performance metrics two of which can be verified without other instrumentation.

These are:

3.2.1 Noise

The camera readout noise is determined by the rms of a region from a bias-only

section of the CCD. Obtain a overscan bias image and note the rms of the

ensemble of pixels in a region of the image that is off of the parallel register.

The camera test report shows the conversion factor from counts to electrons for

each readout speed and attenuation state. Multiply the rms value by the

conversion factor for the settings you are using to determine the noise in

electrons. The result will be the noise reported in the test report ±10%.

Spectral Instruments

This test is sensitive to structure in the bias and, at the factory, the noise is

determined by subtracting two bias images to eliminate the structure. The result

has twice the noise contribution so the rms of the difference image must be

divided by √2.

3.2.2 Dark Signal Generation Rate

Having insured that all light leaks have been extinguished, it is possible to look

at another important camera performance metric - the dark signal generation rate.

It is necessary that the camera not have been exposed to any light signal since it

was most recently cooled or else this measurement is subject to errors due to

residual image retained in the CCD if the CCD is cold.

Obtain a 100 second dark image from a freshly cooled camera and determine the

mean signal from a region on the parallel register of the sensor that does not

include any hot columns. Obtain a bias image at the same readout rate and

attenuation settings and determine the mean value from the same region adjusted

in location to avoid spurious events. From the mean count value of the dark,

subtract the mean count value of the bias. Multiply the difference by the

conversion factor for the attenuation used and divide by 100 to yield the dark

signal generation rate in electrons per pixel per second. The result will agree

with the test report within 10%.

3.3 Other Metrics

A number of other performance parameters are specified for SICCD cameras.

All of these require a more elaborate setup to evaluate and are beyond the scope

of this document.

If another metric is vital to your application, that performance metric - and its

method of evaluation - have been established between Spectral Instruments and

yourself and a process set up to validate that metric on each of your cameras.

Pt # 2500- 32

4. Using The Camera

4.1 Kinds Of Images

An image obtained from a SICCD camera is made up of:

a) a dc offset, or bias, introduced to assure all pixel values are positive

integers,

b) the thermal signature of your camera - the dark signal image, and

c) the target image at which you pointed your camera.

For bright targets, the bias and the dark may be negligible. For faint targets,

especially those requiring a long exposure to get enough signal, the bias and dark

must be subtracted.

4.1.1 Bias Images

The dc offset, or bias, is stable over a matter of days provided the environment is

regulated. SICCD cameras on telescopes, where 40oF differences day-to-night

are routine, require more frequent bias calibration images.

The dc offset, which provides the average value of the bias image, is introduced

to be able to use the full range of the Analog-to-Digital Converter (ADC) by

guaranteeing that the smallest signal will ever be greater than 0. Otherwise, one

bit of the ADC is needed to tell whether a number is positive or negative. This

halves the useful range of the ADC.

Structure in a bias image is typically due to transients that occur in SICCD-type

cameras when a new row or column starts to be read out. These transients are

small but the precision with which the camera electronics measures things is so

high as to be able to “see” them.

The most important thing to understand about the bias image is that it is linked to

the readout mode. This is because the transients visible in the bias image are

totally different when a subarray is read, when the binning is different, when the

attenuation is different. In short, when anything changes in a readout mode, the

bias image changes - ever so slightly.

These small variations in offset over the image are important when you are fully

utilizing the SICCD character of your camera. For many imaging activities the

bias can be included with the dark as described in the next section.

4.1.2 Dark Images

A CCD sensor records incoming photons and converts them to electrons stored

in the array of active picture elements. Unfortunately, the structure upon which

the CCD is formed contributes thermal photons that result in indistinguishable

electrons. These electrons obey identical Poisson statistics, which means that

they also contribute noise. The noise from dark signal is the square root of that

Spectral Instruments

signal. An image with 16 electrons of dark signal contributes 4 electrons to the

total system noise for that image. If you look only at readout noise and dark

noise without considering image noise (reasonable for measuring the dark areas

between bright areas) it doesn’t take a lot of dark noise to make it difficult to

measure background-level image signals.

To reduce the impact of dark signal, S800 cameras utilize a thermo-electric

cooling system that allows the CCD to be operated at as low a temperature as is

consistent with that CCD and the camera configuration.

Dark signal noise combines with readout noise as the square root of the sum of

the squares (this is called quadrature). For a camera with a readout noise of 4

electrons and a dark signal of 4 electrons, the combined noise is 5.6 electrons.

For a 4-electron camera that is running at one thermal electron per 10 minutes,

this means that it is possible to integrate for some tens of minutes before the

noise from a dark image significantly degrades the total noise figure for the

system.

Dark signal is not uniform in its distribution over an image. Variations in dark

signal generation rate are all (but one - preamp glow) related to inhomogeneities

in the sensor or in the substrate upon which it is built. The variation to be

expected - the dark signal non-uniformity (DSNU) - can be as high as 25% for

some CCDs. It is rarely less than 10%. Because the stable dark image patterns

are visible and because the dc level is significant to low-light-level imaging it is

important to correct for dark before quantitative analysis is performed.

4.1.3 Light Images

Light images are what you are after. They all offer their own individual “quirks”

when it comes to making quantitative measurements. The most important of

these “quirks” relates to non-uniform illumination. The second relates to nonuniform quantum efficiency in the sensor.

If you want to know how much signal is contributed by an event in one area

compared to a similar event in another area you need to be assured that there is

no instrumental effect affecting the measurements. There usually is!

The basic process for correcting light images is called “shading correction” in

some literature, it is called “flat fielding” in other literature. If you can get a

measure of the shading effect then you can compensate for it - although you can

never recover from the reduced signal in the shaded areas. This reduced signal

means that the signal-to-noise ratio (SNR) is ever poorer in a shaded region than

it is in a non-shaded region. The only fix for this problem is preventative - it is

not recuperative.

Pt # 2500- 34

Spectral Instruments

4.2 Fixing Problems With Images - The Master Image Solution

The SI Image software includes tools to correct images for offset and patterns

that are introduced by dark signal and for sensitivity variations that arise in the

incoming light signal caused by the entire application optical light path and

possibly by camera effects (especially if the CCD is bonded to a fiber optic). The

details of operating that software are presented in the software manual. This

section of the hardware manual discusses the basic requirements of image

calibration.

4.2.1 Master Bias Images

If the read noise on your SICCD camera system is 4 electrons; that read noise

applies to every image read from that camera. If you readout a bias image and

then readout a second bias image they each have four electrons of noise. If you

subtract the two of them to eliminate the dc offset and any structure, the result is

very flat but has a noise of 5.65 electrons. The same thing happens when you

subtract a single bias image from any other image - the noise increases by 1.4.

Since the bias image is stable with time, for a stable operating environment, it is

possible to create a master bias image that is the average of many individual bias

images. Because it is the average of many images, this master bias has virtually

no noise and can provide a better bias offset and bias structure corrector than a

“fresh-off-the-camera” bias with standard readout noise.

It is possible to use this master bias with small incremental dc offsets to correct

for changes in the dc bias with time. The easiest way to implement this is to

obtain an occasional “fresh” bias and determine the difference in the mean

between the “fresh” bias and the master bias. To within ± ½ count the master

bias can be adjusted to the current bias level of the camera without needing to

obtain a new master bias. In this manner, the master bias provides a very

accurate image of the bias structure. You adjust the dc level of this structure

image to correct for the current camera offset level. SI Image actually manages

images as floating point arrays so numerical processes are not limited to ± ½

count. It is possible to use the bias overscan to measure the short-term DC

changes in the bias level.

4.2.2 Master Dark Images

For a S800 camera, the dark image is not equivalent to the bias image unless a

very short (typically less than one second) exposure is obtained. However, if all

of the exposures to be obtained from your camera are going to be the same

duration with the camera in the same readout mode, there is no need to obtain

separate bias and dark images as master images. Average a large number of

identical exposure dark images and you have a master dark+bias image.

Unfortunately it isn’t quite that easy. Spurious bright or hot events show up in

dark images. These are occasionally visible in bias images but the frequency is

low enough that they disappear in the average that makes the master bias. Dark

Pt # 2500- 35

Spectral Instruments

images, because they “sit” on the CCD for some number of minutes, show

numerous bright pixels. Some of these are single-pixel (probably hot pixels) and

some of these are multi-pixel “blobs” or “streaks”. These are images of the path

taken by some exceedingly energetic particle as it passed through the sensor.

These are called “cosmic rays” in classical CCD imaging literature. We call

them spurious events because their source is likely much nearer than the general

cosmos. Glass products are notorious for thorium decay emissions that are very

energetic. Brick buildings can have particularly high natural background

radioactivity that generates high spurious event count rates.

The best method of building up a master dark image is to select an exposure time

that is the longest exposure you expect to use where this master dark image will

be the reference. Obtain some number of dark images at this exposure and

perform a temporal median or coincidence filter among them. Such a filter

detects and rejects random bright pixels. The effective exposure time is that for

each image, not the sum! The result is a noise-free master dark + bias image

with hot pixels.

From this master dark image, subtract the master bias image formed above and

record the resulting bias-corrected master dark image as the master dark image

(with the effective exposure time also recorded somewhere).

Hot pixels must be discarded at some point. A decision must be made as to what

constitutes a pixel so hot that it must be discarded. That determination is

strongly a function of the application. It is preferable to generate a master dark

image that is hot-pixel-free since the end use of the master dark is for it to be

scaled by the ratio of the exposure times for the target image and the master dark.

Hot pixels don’t scale as typical background dark signal pixels so they should be

removed from the master dark image. Furthermore, having them absent from the

master dark image makes it much easier to scale the display of the master dark

image so as to see any dark image structure.

4.2.3 Master Flat Images

The major instrumental characteristic of a light image is the variation in

attenuation experienced by photons traveling to each pixel. If they are all

attenuated - but equally - the problem becomes one of scaling. Usually there is a

strong spatial component to the attenuation so it is not possible to measure the

counts of an event “here” and compare it to the counts of a similar event in the

same image “over there” without having previously applied a correction for the

spatial attenuation.

How to determine the spatial attenuation? The “pat” answer is to use a uniform

illumination at the input of your application and record the image that results.

Again, some averages are important because this master image is going to be

used to divide into each target image and in this instance the photon noise in the

flat image is inserted into each target image.

Pt # 2500- 36

Spectral Instruments

Uniform illumination is hard to obtain. The degree of difficulty is determined

entirely by the application. In many instances the application was not designed

so that a uniform illumination source could easily be introduced. Selfluminescent targets are difficult. Microscopes are the most difficult instrument.

Nevertheless, it is essential to invent some means of introducing a known

illumination pattern (even if it is not flat - so long as it can be modeled) and

averaging some number of images that result.

Pinholes in front of wide-angle scattering fixtures, integrating spheres, LEDs and

electro-luminescent panels are all options. For some applications it may be

necessary to invent quite a complicated fixture to obtain the flat image.

Using the most uniform illumination possible, average a number of images that

are exposed so that the bright regions are somewhat over ½ full scale. Exclude

pixels that were determined to be "hot" in the master dark image. Bilinear

interpolation from the row-column quadrant neighbors is the easiest method.

Subtract the master bias image from the master flat image. Scale the master dark

image by the ratio of the exposure time of the master flat image to the exposure

time of the master dark image. Subtract the result from the master flat image.

The result is a fully corrected master flat image that can be used on any target

image obtained with the same equipment setup and readout mode.

4.3 Correcting Images

The preceding section discussed obtaining master calibration images.

Presumably you now have a master bias, a master dark and a master flat image

for the current configuration of your application and for the readout mode you

are going to use.

Note that one-each of these master images is required for each configuration of

the image readout, attenuation, binning etc.

4.3.1 Why Correct At All?

If you are just looking for something - you don’t need to do a lot of image

correction unless that something is at the noise limit of the image and may be

affected by patterns in the bias + dark. In this case you need a master dark of the

same duration - one that includes the bias. Subtract it and view away.

Similarly if you are looking for something among a sequence of images taken

under the same conditions you usually don’t need to correct individual images in

the sequence unless patterns affect visibility.

To inter-compare one region of an image with another you do need to correct for

the variation in attenuation over the imaged field of view.

Pt # 2500- 37

Spectral Instruments

4.3.2 How

The three calibration constituents must each be manipulated differently. The

master bias is used as is. The master dark image must be multiplied by the ratio

of the exposure time of the target image to the exposure time of the master dark

image. For most imaging systems this scaling is by integer values, as floating

point images are not usually used. SI Image uses floating point so fractions are

not a problem and neither are negative numbers.

When you actually apply a flat field image correction, the target image must first

be multiplied by some constant before it is divided by the flat image in order to

preserve the significance in integer format images. A good choice is the average

value of a typical "bright" region in the master flat image. Select such an area in

the master flat, set a region of interest and determine the average value in this

region of interest. Record the value of this average from the ROI in master flat

image “bright area”. This average is the multiplier or “scaling parameter” you

will use to scale all target images that will be corrected using this master flat

image.

You have a master bias, a master dark of some exposure time that has been

corrected for hot pixels and a master flat from which you got a scaling parameter.

You are ready to proceed to correct a target image.

Bring up the target image and subtract the master bias. Multiply the master dark

by the ratio of the exposure times and subtract it from the target image. Multiply

the target image that has now been bias and dark corrected by the scaling

parameter obtained above. This step requires that the result be an extended

precision image. Either floating point or signed long will suffice.

Now divide the scaled target image by the master flat image. This step requires

promoting the master flat image to the same type as you selected for the scaled

target scene image before the division. It may also require a demotion of the

result to a shorter word-length afterwards. Again, in SI Image, these tasks are

automated for you.

The result is a new version of the target image where the shading pattern is

removed. This is a flat-fielded target image.

4.3.3 Limitations On The Flat Field Process

Effective flat field correction depends upon stability of the illumination and the

attenuation. CCDs are strongly wavelength sensitive. The quantum efficiency

variation across the sensor is different for different wavelengths of incoming

light. There for, flat field images vary with the color of the incoming light –

especially if that light is in a very limited wavelength band. The target images

and the master flat images must be exposed to nearly the same color of light.

Pt # 2500- 38

Spectral Instruments

The flat field is also sensitive to illumination angle of the incoming light. Since

collimated light shows up many optical defects, such as dust, in a way that wide

angle illumination does not, it is important that master flats and target images are

both obtained with very similar (if not identical) illumination beams.

4.3.4 Understanding The Scaling Effects

The example above derived the scaling number from the brightest area in the

master flat image. After correction, the values of pixels in the target image are

essentially unchanged in the area of the ROI from which the mean was

determined. Any number you might have used would work for scaling the target

image to preserve significance in the pixel values provided it is large enough. It

does not say that the magnitude of the pixel values is now “correct”.

Provided that the master flat image is exposed so that it is about half of the full

range of the ADC, a scalor of half the maximum ADC value retains the

theoretical maximum pixel dynamic range.

Clearly, the value of the scalor affects the pixel values of the resulting images.

For inter-comparison among a number of different sets of images or sequences of

images a constant scalor for the entire set is essential - as is a constant setup so

the same master flat field image reflects the spatial attenuation and the constant

scalor assumption is valid.

To determine the scale factor to correct images to an absolute scale requires

introduction of known objects into the application “field”. Most measurements

are relative. You look for changes in intensity within an image or from image to

image. Few measurements require absolute measurement scales.

Pt # 2500- 39

5. Camera System Warranty And Service