Page 1

Maintenance and Diagnostics

Link Wireless Telephone System

Link 3000 MCU

Part Number: 72-0059-04

Issue E

Page 2

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

NOTICE

SpectraLink Corporation has prepared this document for use by SpectraLink personnel and clients. The

drawings and specifications contained herein are the property of SpectraLink and shall be neither

reproduced in whole or in part without the prior written approval of SpectraLink, nor be implied to grant

any license to make, use, or sell equipment manufactured in accordance herewith.

SpectraLink reserves the right to make changes in specifications and other information contained in this

document without prior notice, and the reader should in all cases consult SpectraLink to determine whether

any such changes have been made.

The terms and conditions governing the sale of SpectraLink hardware products and the licensing of

SpectraLink software consist solely of those set forth in the written contracts between SpectraLink and its

customers. No representation or other affirmation of fact contained in this document including but not

limited to statements regarding capacity, response-time performance, suitability for use, or performance of

products described herein shall be deemed to be a warranty by SpectraLink for any purpose, or give rise to

any liability of SpectraLink whatsoever.

In no event shall SpectraLink be liable for any incidental, indirect, special, or consequential damages

whatsoever (including but not limited to lost profits) arising out of or related to this document, or the

information contained in it, even if SpectraLink has been advised, knew, or should have known of the

possibility of such damages.

Trademark Information

SpectraLink

LinkPlus

Link Wireless Telephone System

NetLink Telephony Gateway

NetLink Wireless Telephone

NetLink SVP Server

SpectraLink Voice Priority

ccLink Wireless Telephone System

are trademarks and registered trademarks of SpectraLink Corporation.

All other trademarks used herein are the property of their respective owners.

Maintenance and Diagnostics

Link WTS

Link 3000 MCU

System Documentation

© 2002 SpectraLink Corporation.

All Rights Reserved

Printed in the United States of America

SpectraLink Corporation

5755 Central Avenue

Boulder, CO 80301

Within the United States, dial

303.440.5330 or toll free

800.676.5465

Outside the U.S., dial

+1.303.440.5330

www.spectralink.com

Part Number: 72-0059-04-E.doc Page 2

Page 3

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

Note concerning the Master Control Unit:

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

Note concerning shielded cable:

SpectraLink recommends the use of shielded cable for all external signal connections in order to maintain

FCC Part 15 emissions requirements.

Note concerning the Wireless Telephone and Base Stations:

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

WARNING Changes or modifications to this equipment not approved by SpectraLink Corporation may

cause this equipment to not comply with part 15 of the FCC rules and void the user’s authority to operate

this equipment.

WARNING SpectraLink products contain no user-serviceable parts inside. Refer servicing to qualified

service personnel.

Part Number: 72-0059-04-E.doc Page 3

Page 4

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

UL Information

This symbol on the nameplate means the product is listed by Underwriter’s

Laboratories, Inc. It is designed and manufactured to meet rigid U.L. safety

The following are statements required for UL certification, related to safety procedures

that must be adhered to during installation.

Follow these general precautions while installing telephone equipment:

Never install telephone wiring during a lightning storm.

Never install telephone jacks in wet locations unless the jack is specifically designed

for wet locations.

Never touch uninsulated telephone wires or terminals unless the telephone line has

been disconnected at the network interface.

standards against X-radiation, fire, casualty, and electrical hazards.

Use caution when installing or modifying telephone lines.

When installing Base Stations outside or in buildings other than the one containing the

System Controller, take the following precaution:

If wiring for a Base Station exits a building—whether to reach an outdoor Base Station

location or to reach a Base Station in another building—the wiring must be protected at

both ends by a Quick Clip Fuse from Illinois Tool Works, Linx Division, model number

SCP-2X2. The Quick Clip Fuse replaces the bridging clips on the 66 blocks for all four

connections to the non-internal Base Station.

Part Number: 72-0059-04-E.doc Page 4

Page 5

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

FCC Information

The Master Control Unit Complies with Part 68, FCC Rules

FCC Registration Numbers:

Link 3000: IYGUSA-7385Q-PX-T

Ringer Equivalence:

Link 3000: 0.3B

SpectraLink Corporation

Link 3000

Made in the USA

This equipment complies with Part 68 of the FCC Rules. On the back of this equipment is a label that

contains, among other information, the FCC Registration Number and Ringer Equivalence Number (REN)

for this equipment. If requested, this information must be given to the telephone company.

This equipment uses RJ-21 connectors.

The REN is useful to determine the quantity of devices you may connect to your telephone line and still

have all of those devices ring when your number is called. In most, but not all, areas, the sum of the RENs

of all devices connected to one line should not exceed five (5.0). To be certain of the number of devices

you may connect to your line, as determined by the REN, you should contact your local telephone company

to determine the maximum REN for your calling area.

If your telephone equipment causes harm to the telephone network, the telephone service may discontinue

your service temporarily. If possible, they will notify you in advance. But if advance notice isn’t practical,

you will be notified as soon as possible. You will be informed of your right to file a complaint with the

FCC.

Your telephone company may make changes in its facilities, equipment, operations or procedures that

could affect the proper functioning of your equipment. If they do, you will be notified in advance to give

you an opportunity to maintain uninterrupted telephone service.

If you experience trouble with this telephone equipment, please contact SpectraLink Corporation for

information on obtaining service or repairs.

SpectraLink Corporation

5755 Central Avenue

Boulder, CO 80301

303-440-5330

The telephone company may ask that you disconnect this equipment from the network until the problem

has been corrected or until you are sure that the equipment is not malfunctioning. There are no user

serviceable parts in this equipment.

This equipment may not be used on coin service provided by the telephone company. Connection to party

lines is subject to state tariffs.

Part Number: 72-0059-04-E.doc Page 5

Page 6

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

Industry Canada (IC) Notice

Notice:

The Industry Canada (IC) label identifies certified equipment. This certification means that the

equipment meets telecommunications network protective, operational, and safety requirements as

prescribed in the appropriate Terminal Equipment Technical Requirements document(s). The

department does not guarantee the equipment will operate to the user’s satisfaction.

Before installing this equipment, users should ensure that it is permissible to be connected to the

facilities of the local telecommunications company. The equipment must also be installed using an

acceptable method of connection. The customer should be aware that compliance with the above

conditions may not prevent degradation of service in some situations.

Repairs to certified equipment should be coordinated by a representative designated by the

supplier. Any repairs or alterations made by a user to this equipment, or equipment malfunctions,

may give the telecommunications company cause to request the user to disconnect the equipment.

Users should ensure for their own protection that the electrical ground connections of the power

utility, telephone lines and internal metallic water pipe system, if present, are connected together.

This precaution may be particularly important in rural areas.

Caution: Users should not attempt to make such connections themselves, but should contact the

appropriate electric inspection authority, or electrician, as appropriate.

Notice: The Ringer Equivalence Number (REN) assigned to each terminal device provides as

indication of the maximum number of terminals allowed to be connected to a telephone interface.

The termination of an interface may consist of any combination of devices.

REN 0.3B

Approval Numbers:

Link 3000: 2128-9508 A

Warranty and Repair Service Center:

SpectraLink Corporation

5755 Central Avenue

Boulder, CO 80301

303-440-5330

DOC Spread Spectrum certification

Base Station Cert. No. 2128-K1373

Wireless Telephone Cert. No. 2128-K1374

Part Number: 72-0059-04-E.doc Page 6

Page 7

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

Table of Contents

1. ABOUT THIS DOCUMENT 9

1.1 Contacting SpectraLink 9

1.2 Icons Used in this Document 9

1.3 Troubleshooting Overview 9

2. SYSTEM MAINTENANCE 11

2.1 Replace an Interface Module (Hot Swap) 11

2.2 Add a Wireless Telephone 12

2.3 Replace a Wireless Telephone 12

2.4 Delete a Wireless Telephone 13

2.5 Add a Base Station 14

2.6 Replace a Base Station 15

2.7 Delete a Base Station 15

2.8 Add a Shelf 16

2.9 Delete a Shelf 16

3. WIRELESS TELEPHONE PROBLEMS 17

3.1 Using the Link Wireless Telephones 17

3.2 No Extension/Wrong Extension Displayed 17

3.3 “No Svc” Displayed 18

3.4 No Dialtone / No Audio 18

3.5 No Handoff 19

3.6 Calls Ring on the Wrong Wireless Telephone 19

3.7 Multiple Wireless Telephones Not Working 19

4. BASE STATION PROBLEMS 21

4.1 Multiple Base Stations Not Working 21

4.2 Base Station LED not lit 21

4.3 Base Station LED Flashing Red and Green 22

4.4 Base Station Disabled 22

4.5 Base Station Will Not Download 24

4.6 Base Station LED Flashing Red 24

4.7 Base Station LED Solid Red or Yellow 24

4.8 Base Station LED Flashing Red, Yellow, Green 25

Part Number: 72-0059-04-E.doc Page 7

Page 8

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

5. TROUBLESHOOTING DURING START-UP PHASE 26

5.1 Boot ROM LEDs 26

5.2 Boot ROM Alarms 27

5.3 Downloads 27

5.4 Configuration Changes 27

6. TROUBLESHOOTING CARD ALARMS 28

6.1 System and Shelf Controller Card Status Indicators 28

6.2 Interface Module Status LEDs 30

6.3 Reading the Status LEDs 31

7. LED AND ALARM TROUBLESHOOTING TABLES 32

7.1 System Controller Card Alarm Matrix 32

7.2 System Controller Card Troubleshooting Matrix 33

7.3 Shelf Controller Card Alarms 38

7.4 Shelf Controller Card Troubleshooting Matrix 39

7.5 Interface Module Alarm Matrix 41

7.6 Interface Module Troubleshooting Matrix 43

7.7 T1 Alarms 46

8. TERMS AND ACRONYMS 48

Part Number: 72-0059-04-E.doc Page 8

Page 9

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

1. About This Document

This document describes the procedures for troubleshooting, maintaining, and expanding

the Link Wireless Telephone System (Link WTS).

Additional information about the Link WTS can be found in the following SpectraLink

user manuals:

Installation - Part Number 72-0059-01

Operator's Console - Part Number 72-0059-02

LinkPlus Interface Guide - Part Number 72-0171-xx as appropriate for the PBX.

Facility Preparation - Part Number 72-0059-05

1.1 Contacting SpectraLink

SpectraLink wants every customer to have a successful installation. Please refer questions

to our Customer Support Hotline at (800) 775-5330. The Hotline is open Monday

through Friday, 7:00 AM to 6:00 PM Mountain Time.

1.2 Icons Used in this Document

This manual uses the following icons and conventions.

Caution! Follow these instructions carefully to avoid danger.

Note these instructions carefully.

NORM

This typeface indicates a key, label, or button.

1.3 Troubleshooting Overview

The Link WTS software constantly monitors system components for problems. If a

problem is detected, the system will flag the problem with an alarm. Alarms are displayed

in two places:

Operator's Console - the Chk3000 program allows the administrator or technician to

display details about each system component. If the component is in an alarm state,

details about the alarm will display on the appropriate screen. See the Link WTS –

Link 3000 MCU: Operator's Console manual (72-0059-02) for more information.

Part Number: 72-0059-04-E.doc Page 9

Page 10

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

LEDs - The front panels of all system cards (System Controller, Shelf Controller, and

Interface Modules) have six LEDs: one red (labeled ALARM), and five green

(labeled 1-5) to indicate status, including alarm conditions. LED sequences,

descriptions, and recommended procedures are provided in the section on

Troubleshooting Alarm Codes for each type of card.

Part Number: 72-0059-04-E.doc Page 10

Page 11

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

2. System Maintenance

This section explains some common maintenance procedures.

2.1 Replace an Interface Module (Hot Swap)

Interface Modules can be removed and replaced without shutting the system down.

Interface Modules must be replaced with the same type of card.

To perform a “hot swap” of an Interface Module:

1. From the Operator’s Console, select F2, Port Card Status. Display the port card

to be swapped, so you can monitor its status during the process.

2. On the card to be replaced, move the Normal/Disable switch to the Disable

position. This locks the card and disables the Base Stations to prevent new calls

from starting, but does not drop active calls. Existing calls are allowed to

complete before the card is locked.

3. When the alarm light stops blinking and turns solid red, the card is idle. Verify

this on the Operator’s Console, all lines and Base Stations should show no

activity. If you unplug the card before it is idle, the system may alarm.

4. At the Operator’s Console, press ESC. This stops the Operator’s Console from

trying to monitor the card you are about to remove.

5. Unplug the 25 pair cable from the card.

6. Unscrew the card from the shelf and slide it out.

7. Slide the replacement Interface Module into the slot, until the card clicks into

place. Tighten the screws at the top and bottom of the card to secure it.

8. Connect the 25 pair cable to the card.

9. When the heartbeat LED sequence displays on the Interface Module (LED 1

flashes 1/3 of the time), select

the new card. It should be

F2 on the Operator’s Console to verify the status of

Running.

Part Number: 72-0059-04-E.doc Page 11

Page 12

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

2.2 Add a Wireless Telephone

Before adding a new Wireless Telephone, you must have a port location on the

demarcation block on the switch and a port location on the Link 3000 MCU Interface

Module. If no ports are available on the Link 3000 MCU, you must install another

Interface Module in the shelf. See Link WTS – Link 3000 MCU: Installation.

1. Connect the host telephone system port to the Link 3000 MCU Interface Module

port assigned to the new Wireless Telephone.

2. On the Operator’s Console, select F4, Port Card Configuration Display and

Administration.

3. Using the arrow keys or mouse, position the cursor on the port location to be

configured, and press Enter.

4. When the menu displays, scroll down to Edit Line, and press Enter.

5. At the pop-up menu, type the information for the Wireless Telephone.

Serial Number – the factory assigned serial number for this telephone, located

inside the battery compartment under the battery. Double check this number when

it is entered. If the Serial Number is entered incorrectly the telephone will not

function and will appear to be defective.

Note - (optional) user name or any other information. Do not enter double quotes

(“) in this field, an error message will display.

Extension/SPID - extension number or SPID. Must be numeric.

6. When information is correctly entered, select SAVE to save it.

7. To program the Wireless Telephone to display the correct extension number, hold

down the FCN key until Volume Level displays. Press the # > key (NEXT) until

EXTENSION displays on the Wireless Telephone. Press 0, then enter the correct

extension number. Press END when finished.

8. When the Wireless Telephone is turned ON, the extension will be displayed. Test

the new Wireless Telephones by placing a call to each one to verify that the

correct telephone rings.

2.3 Replace a Wireless Telephone

Use this procedure to replace a Wireless Telephone with a new Wireless Telephone.

1. On the Operator’s Console, select F4,

Administration. Use the Search function to locate the Wireless Telephone to be

replaced, searching for the extension or the serial number.

2. Highlight the port location of the telephone and select

Port Card Configuration Display and

Edit Line.

3. When the pop-up screen displays, replace the serial number of the old telephone

with the serial number of the new telephone.

4. Select SAVE to save the change.

Part Number: 72-0059-04-E.doc Page 12

Page 13

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

2.4 Delete a Wireless Telephone

Use this procedure to completely remove a Wireless Telephone from the system, without

replacing the telephone with another.

1. On the Operator’s Console, select F4, Port Card Configuration Display and

Administration.

2. Using the arrow keys or mouse, position the cursor on the port location of the

telephone to be deleted, and press Enter.

3. When the menu displays, scroll down to Delete Line, and press Enter.

4. Scroll to DELETE and press Enter.

5. If you do not plan to re-use the port on the Link WTS, remove the cabling for this

telephone between the host telephone system and the Link WTS’s demarc block.

Part Number: 72-0059-04-E.doc Page 13

Page 14

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

2.5 Add a Base Station

Before adding a new Base Station you should have a port location for the new equipment.

If no ports are available on the Link 3000 MCU, you must install another Interface

Module in the shelf. See Link WTS – Link 3000 MCU: Installation.

1. Install the new Base Station. See Link WTS – Link 3000 MCU: Installation.

2. On the Operator’s Console, select F4, Port Card Configuration Display and

Administration

3. Using the arrow keys or mouse, position the cursor on the port location to be

configured, and press Enter.

.

4. When the menu displays, scroll down to

Edit RCU (Base Station), and press

Enter.

5. At the pop-up menu, type the information for each Base Station.

Offset - Offset IDs manage the division of the frequency (spectrum) among the

Base Stations. To prevent interference, neighboring Base Stations require

different offset values. Each Base Station is assigned a unique two-digit offset.

Press Right Arrow to see a menu of choices.

For half-hop systems with up to 25 Base Stations, or whole-hop systems with

up to 50 Base Stations, number the Base Stations in order 1-25 or 1-50.

If the system has more Base Stations, the offset IDs must be reused. Consult

the map that was generated during system installation. Assign unique offsets

such that adjacent or nearby Base Stations do not share the same offset. When

selecting offset assignments, keep in mind through-floor penetration and the

Base Station’s proximity to windows.

Offset usage is summarized on the Show RCU Offset Reuse function from

F2 - Port Card State. This report shows how many times each Offset has

been used.

Isolated? - If this Base Station is isolated from all other Base Stations, enter Y.

An isolated Base Station is one that is located physically apart from other Base

Stations, therefore will never be heard during a Listen/Verify diagnostic.

Designating a Base Station as Isolated will disable the Listen Verify alarm for that

Base Station and avoid generating spurious alarms.

Note - (optional) type a short description of where the Base Station was installed

(a room or floor number, for example). Up to 30 characters. Do not enter double

quotes (“) in this field, an error message will display.

6. When information is correctly entered, select SAVE to save it.

Part Number: 72-0059-04-E.doc Page 14

Page 15

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

2.6 Replace a Base Station

To replace a Base Station, unplug the existing Base Station and plug in the new Base

Station.

The LED will blink red and green as the system software downloads to the

Base Station and the Base Station is tested.

When the LED blinks amber, the system is ready for operation.

When the LED blinks green, a Wireless Telephone has established a radio link

with that Base Station.

If the LED turns solid red, blinks red, or continues to blink red and green,

refer to Base Station Problems.

2.7 Delete a Base Station

Use this procedure to completely remove a Base Station without replacing it with a new

one.

1. On the Operator’s Console, select F4, Port Card Configuration Display and

Administration.

2. Using the arrow keys or mouse, position the cursor on the port location of the

Base Station to be deleted, and press Enter.

3. When the menu displays, scroll down to Delete RCU, and press Enter.

4. Scroll to DELETE and press Enter.

5. If you do not intend to move the Base Station to a new location, disconnect the

cabling for this Base Station from the demarc block.

Part Number: 72-0059-04-E.doc Page 15

Page 16

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

2.8 Add a Shelf

If the existing shelves in the MCU are not large enough to hold the required Interface

Modules, you must add a shelf to the system. The system can support 19 Expansion

Shelves.

1. Install the shelf. See Link WTS – Link 3000 MCU: Installation.

2. If you moved Interface Modules from one shelf into the new shelf, use the Move

Port Card function to modify the existing Interface Module configuration to

reflect the change.

3. Register the new Wireless Telephones and/or Base Stations on the new shelf. See

Add A Wireless Telephone and Add A Base Station.

2.9 Delete a Shelf

If you move or reconfigure your system, you may need to completely delete a shelf.

1. On the Operator’s Console, select F4, Port Card Configuration Display and

Administration.

2. If you are completely removing the Wireless Telephones and Base Stations from

this system, delete the Base Stations and Wireless Telephone by deleting each

Interface Module on the shelf using the Delete Port Card (Interface Module)

option.

3. If you are moving the Wireless Telephones and Base Stations from this shelf to

another, use the Move Port Card (Interface Module) option to designate the new

shelf location of the Interface Module. Note that you cannot move an Interface

Module to a slot which already contains configuration information. Also, the

Interface Module must be physically moved to the new slot and connected with a

cable in order for the module to become operational.

4. When all Interface Modules have been deleted or moved from the shelf, select F1

– Supervisor State Display. Select the Delete Cabinet (shelf) option to delete

the shelf.

5. After the shelf is deleted from the system you can physically remove it and its

cabling.

Part Number: 72-0059-04-E.doc Page 16

Page 17

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

3. Wireless Telephone Problems

3.1 Using the Link Wireless Telephones

The Link WTS is an in-building wireless communication system that allows hand-held

Wireless Telephones to communicate using the existing telephone system. Calls are sent

to and received by the Wireless Telephones via small radio transceivers called Base

Stations, located throughout the building or campus. When using and troubleshooting the

Wireless Telephones, consider the following concepts.

Call hand off – as the user moves through the facility, your conversation will be

“handed off” from one Base Station to another.

In range/Out of range – service will be disrupted if a user moves outside the

transmission area of the Link WTS. Service is restored if the user moves back within

range of a Base Station. If a call drops because a user moves out of range, the

Wireless Telephone will recover the call if the user moves back into range within a

few seconds.

Capacity – in areas of heavy use, the call capacity of a particular Base Station may

be filled. If this happens, the user can wait until another user terminates a call, or

move within range of another Base Station and try the call again. If a user is on a call

and moves into an area where capacity is full, it is the same as moving out of range of

a Base Station.

Transmission Obstructions – a thorough site survey was done prior to installation

to determine the best location for Base Stations for optimum transmission coverage.

However, small pockets of obstruction may still be present, or obstructions may be

introduced into the facility after system installation. This loss of service can be

restored by moving out of the obstructed area. Base Stations can also be added to

overcome obstructions.

3.2 No Extension/Wrong Extension Displayed

1. Hold down the FCN key until Volume Level display.

2. Press the # key twice until the display reads “Extension.”

3. Press

4. Press END when finished.

0, then enter the correct extension number.

Part Number: 72-0059-04-E.doc Page 17

Page 18

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

3.3 “No Svc” Displayed

The Wireless Telephone is either not registered, out of range, or can’t pick up a signal

from a Base Station.

1. Visually check to see if the telephone is within range of a Base Station where

other telephones are working.

2. From the Operator’s Console, search for the telephone’s serial number or

extension number to be sure it is properly registered.

3. If other telephones in the area are also not working, see Multiple Wireless

Telephones Not Working below.

3.4 No Dialtone / No Audio

If the Wireless Telephone has no dialtone, or if the user is unable to hear the other party’s

voice or heard echo or dead air.

1. Be sure the Wireless Telephone is powered on.

2. Be sure the No Svc icon turns off a few seconds after the Wireless Telephone is

powered on.

3. Swap the Battery Pack with a Battery Packfrom a functional Wireless Telephone.

If this corrects the problem, charge the Battery Pack.

4. Turn the Wireless Telephone off then on again, then test again for dial tone and

voice quality.

5. Move through several Base Station areas to be sure the Wireless Telephone is

within range of an operating Base Station.

6. Check for alarms on the System Controller, Shelf Controller, or Interface Module

cards (F1, Supervisor State or F2, Port Card State). If the Wireless Telephone

is connected through a digital interface, the system will show an alarm. If the state

is anything but idle, the Wireless Telephone is in alarm. If there are alarms, see

Troubleshooting Alarms section.

7. Check that the system connects when the user goes off-hook. On the Operator’s

Console, from theF2 -

Port Card State screen, view the status of the Line when

the user goes off-hook.

8. Make sure the Wireless Telephone’s Interface Module is connected to a working

phone line. Use a telephone test set to check the line at the demarc block.

9. Check the cabling between the Interface Modules and the demarc block, and

between the demarc block and the telephone system ports. See Link WTS – Link

3000 MCU: Installation for more information.

10. Isolate the Wireless Telephone line on the PBX from the Link 3000 MCU.

Connect a wired telephone to the port to see if the wired telephone operates

properly.

11. Move the Wireless Telephone to a different port location and test again.

Part Number: 72-0059-04-E.doc Page 18

Page 19

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

3.5 No Handoff

If the user walks between Base Station coverage areas, the conversation is not handed off,

and the call is dropped.

1. Using another Wireless Telephone, confirm that both Base Stations are

operational.

2. Verify that the Wireless Telephone can hand off between other Base Stations.

3. On the Operator’s Console, from the Port Card State screen (F2) check the status

of the Base Stations. It is possible that the Base Stations have four calls (the

maximum) in progress. If the Base Station is handling three or fewer calls and

still drops the call, see Base Station Problems.

3.6 Calls Ring on the Wrong Wireless Telephone

The Wireless Telephone has probably not been registered correctly.

1. From the Operator’s Console, use the Search function to find the telephone’s

serial number and check its port location.

2. Trace the wires from the back of the Interface Module to the host telephone

system to be sure it is actually connected to that port location.

3. If the physical location is different, note the correct port location. From F4 - Port

Card Configuration Display and Administration

, use the Edit Line function to

change the serial number on the correct port. If the port location is already in use

by another Wireless Telephone, you will need to delete the other telephone (using

Delete Line), then change the serial number on that port location to the serial

number of the new telephone.

3.7 Multiple Wireless Telephones Not Working

If several of the Wireless Telephones are not working there may be a problem with the

Interface Module that controls them, or with one or more Base Stations.

1. Check to see that the Wireless Telephones are correctly registered. See Link WTS

– Link 3000 MCU: Operator’s Console for instructions.

2. At the Operator’s Console, use the

Wireless Telephones (searching for serial number, extension, or user name). If

they are all connected to the same Interface Module, there may be a problem with

that Interface Module.

3. Try replacing the Interface Module with a different Module of the same type (see

Replacing Interface Modules.)

Search function to display details about the

4. Check the cabling between the Interface Modules and the demarc block, and

between the demarc block and the telephone system ports. See Link WTS – Link

3000 MCU: Installation for more information.

5. If the problem persists, diagnose the Base Stations.

Part Number: 72-0059-04-E.doc Page 19

Page 20

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

4. Base Station Problems

The first step in diagnosing Base Station problems is to isolate the problem to the Base

Station. Be sure the problem is not limited to a single Wireless Telephone. When a

problem occurs with a Wireless Telephone, try the same procedure using another

telephone, or several telephones (see Wireless Telephone Problems.)

If all or several Wireless Telephones are affected, try the following troubleshooting

procedures.

If you try the following troubleshooting procedures and the Base Station still does not

work, return the unit to SpectraLink for service.

4.1 Multiple Base Stations Not Working

If several of the Base Stations are not working there may be a problem with the Interface

Module that controls them.

1. At the Operator’s Console, check for alarms on the Supervisor State (F1) and

Port Card State (F2) screens. Cards or components in alarm will have an

exclamation point (!). See Troubleshooting Alarms for more information.

2. Check to see that the Base Stations are correctly registered. See Link WTS – Link

3000 MCU: Operator’s Console for instructions.

3. If all of the Base Stations are connected to the same Interface Module, there may

be a problem with that Interface Module. Try replacing the Interface Module (see

Replacing Interface Modules) and re-testing the Base Stations.

4. Use a voltmeter to check for 48V DC on the Base Station wiring.

4.2 Base Station LED not lit

The Base Station is not receiving power. On the Port Card Status screen (F2) the status

may show Reset.

1. Be sure the RJ-45 connector is plugged into the Base Station.

2. Be sure the MCU is turned on.

3. With a voltmeter, check the 48V DC on the wiring between the MCU and the

Base Station.

Part Number: 72-0059-04-E.doc Page 20

Page 21

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

4.3 Base Station LED Flashing Red and Green

The LED on the Base Station is designed to flash in specific colors and patterns to reflect

its functioning. At startup the system goes through a “listen” procedure to ensure that the

Base Stations do not interfere with each other. During the “listen” process the LED will

flash red and green for approximately two minutes.

Certain flashing patterns indicate a problem that needs to be addressed:

If the System Controller disables a Base Station because it interferes with another

Base Station, the disabled Base Station’s LED will flash red and green.

If the Base Station is stuck in “download” the LED will flash red and green. In this

case, verify the status of the Base Station at the Operator’s Console. Select F2 -

Interface Module Status.

If status is Disabled, see Base Station Disabled, below.

If status is Download and the DL Time is longer than 1-2 minutes, see Base Station

Will Not Download, below. Also:

Try disconnecting and reconnecting the power from the Base Station. Unplug

the RJ-45 connector on the Base Station then plug it back in again, or remove

the bridging clips from the demarc block and replace them. If necessary, reset

several Base Stations at once by removing the cable from the Interface

Module. Remember, this will also disconnect Lines and drop calls!

Make sure there are no bridge taps (Ys) on the demarc blocks. Remove any

you find.

Use a voltmeter to check the lines for the 48 V dc to be sure there are no

power problems.

4.4 Base Station Disabled

The System Controller will disable a Base Station if it is too close to another Base Station

or if there are communication errors between the Base Station and the System Controller.

Once disabled the Base Station does not handle any calls.

1. On the Port Card Display (F2) check that the status of this Base Station is

Disabled.

2. Before moving Base Stations, check the facility’s floorplan and the latest Listen

Verify diagnostic (F1,

errors and information.

3. To enable this Base Station, disconnect it and relocate it so it is farther from other

Base Stations.

4. Disconnecting and reconnecting the Base Station will automatically activate the

“listen” procedure. Run the Listen Verify Diagnostic (F1, Run Listen Verify) and

review results to be sure the problem is corrected without creating any new

problems.

Check Listen Verify Report or Show Listen Report) for

Part Number: 72-0059-04-E.doc Page 21

Page 22

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

4.5 Base Station Will Not Download

If a Base Station is stuck in download, the LED may flash red and green or just red; the

status on the Operator’s Console will show Reset or Download; and the Base Station

will be locked up (not handling calls).

1. At the Operator’s Console, check to see that the Base Station is registered, using

F2 - Port Card Display.

2. Check the status of the Base Station. If the status shows Download or Download

Data, the Base Station has locked up during download.

3. To reset the Base Station: From F2, Port Card Display, highlight the Base

Station and press Enter, then select Reset RCU from the menu.

4. If the Base Station still does not download, try disconnecting power from the Base

Station and then reconnecting it (unplug the RJ-45 connector on the Base Station

then plug it back in again, or remove the bridging clips from the demarc block and

then replace them.)

5. On the Port Card Display (F2) screen, select the Base Station in question and

press Enter to show Base Station Detail. This shows continuous update of the

Base Station’s status. The DL Errors field shows the number of Download Errors.

Any number greater than 0 indicates a problem. RCU Link shows current

transmission errors. These errors are generally caused by hardware problems.

Contact SpectraLink Customer Support for assistance.

4.6 Base Station LED Flashing Red

This indicates that the Base Station is not communicating with the MCU.

1. Follow the instructions in Base Station LED Flashing Red and Green.

2. Be sure there are no bridge taps (“Y”s) on the demarc block. Remove any you

find.

3. If the problem persists, follow instructions in Base Station’s LED Solid Red or

Yellow, below.

4.7 Base Station LED Solid Red or Yellow

This indicates a short in the Base Station’s transmit or receive wire pairs, usually within a

pair.

Be sure none of the wires are shorted together. Remove the RJ-45 connector from the

Base Station. Remove the cable between the Interface Module and the demarc block.

Then use an ohmmeter to be sure there is an open circuit between pins on the RJ-45. If

you do not want to remove the cabling from the Interface Module (so you do not interfere

with system operation), remove the bridging clips on the demarc block for that Base

Station, then test with the ohmmeter.

Part Number: 72-0059-04-E.doc Page 22

Page 23

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

4.8 Base Station LED Flashing Red, Yellow, Green

The Base Station’s microprocessor is faulty. Replace the Base Station and contact

SpectraLink Customer Service.

Part Number: 72-0059-04-E.doc Page 23

Page 24

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

5. Troubleshooting During Start-Up Phase

This section describes the sequence of the LEDs on all system cards when the system is

first powered on (Boot ROM and Download of software).

5.1 Boot ROM LEDs

When the system is powered on, the normal sequence is for the green LEDs to 'count' up

from 1 to 12 in binary. The following table outlines the sequence.

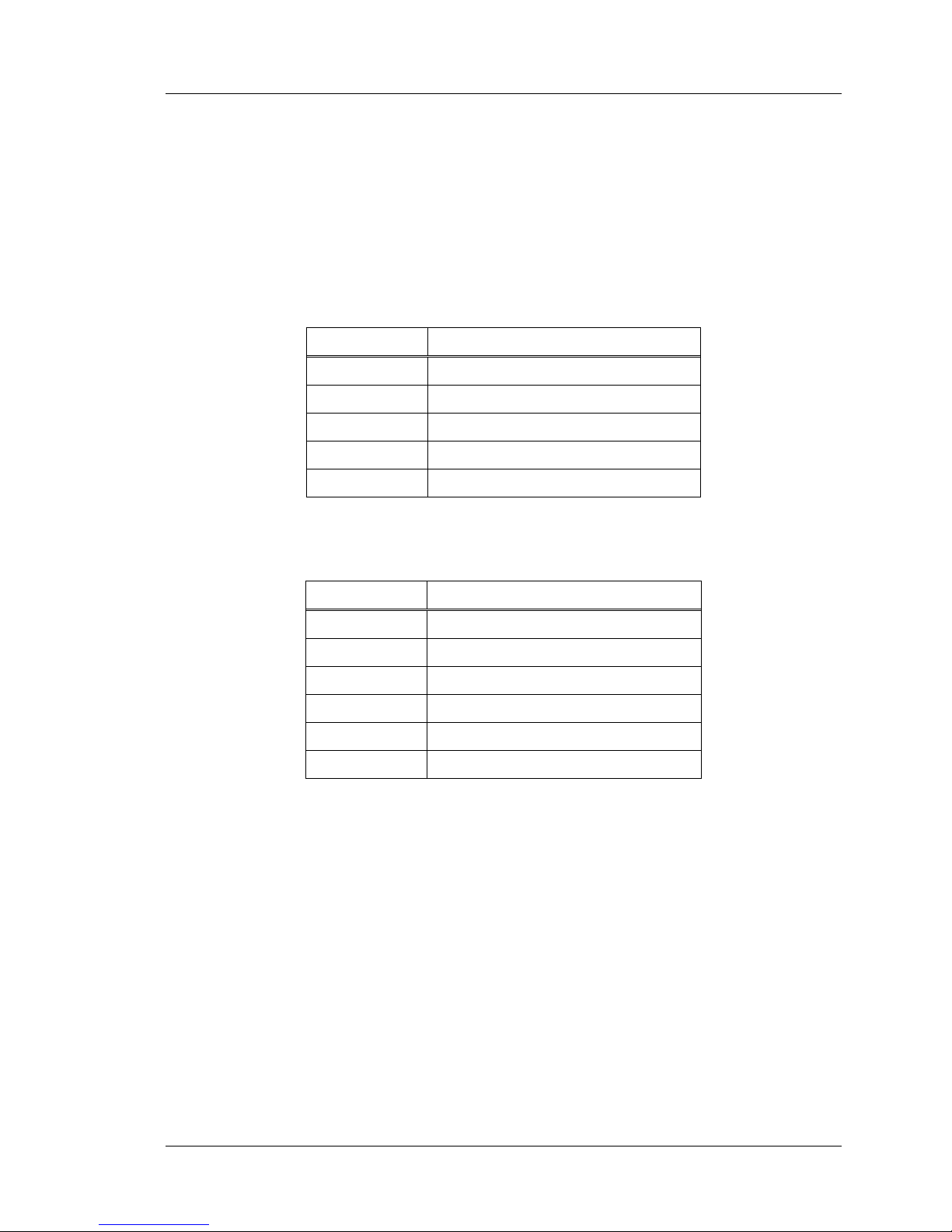

LEDs Code Description

0 0 Entered boot code

1 1 Done RAM test (check boot code CRC, flash type, factory page CRC,

downloaded CRC in that order)

2 2 Sent recognition character at 115200 (if carrier detected)

1,2 3 Sent recognition character at 57600 (if carrier detected)

3 4 Sent recognition character at 38400 (if carrier detected; send recognition

character at 9600 if carrier detected)

1,3 5 Jumping to downloader code

2,3 6 Entered downloader code

1,2,3 7 Copied to RAM, entered C code (check flash type, sense board slot,

check board type, CRC functional code, start IPC, in that order)

4 8 Checking for a KEEPALIVE message

1,4 9 Sent version to supervisor **

2,4 10 Awaiting download (sending requests if no other download) **

1,2,4 11 Jumping to functional code (functional code then blinks all the LEDs)

** Note: Codes 9 and 10 both blink at 1-second intervals while awaiting a response

Part Number: 72-0059-04-E.doc Page 24

Page 25

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

5.2 Boot ROM Alarms

During system boot, if alarms are encountered the red LED will be on. The alarm code

will display on the green status LEDs, consisting of one second of blank lights followed

by two LED sequences which each display for one second.

LED 1 LED 2 Description Recommendation

1 1 RAM test failed Replace card.

1 2 Flash Type incorrect Replace card.

1 1,2 Boot code CRC incorrect Contact SpectraLink Customer

Support.

1 3 Factory page CRC incorrect Contact SpectraLink Customer

Support.

1 1,3 Downloader CRC incorrect Contact SpectraLink Customer

Support.

1 2,3 Bad Board Type Contact SpectraLink Customer

Support.

1 1,2,3 Bad Board Slot Contact SpectraLink Customer

Support.

1 4 Bad Functional Code Contact SpectraLink Customer

Support.

2 1 Error starting IPC Replace card.

2 2 Supervisor communications refusal. Interface Module card is not

configured for PBX type.

2 1,2 No keepalives detected. Shelf Controller card is not yet

operating.

2 3 Bad Shelf Number Contact SpectraLink Customer

Support.

1,2 1 Error writing or erasing flash Replace card.

1,2 2 Error downloading FPGA (not used

by Interface Module)

Replace card.

5.3 Downloads

During downloads, either from the serial port or across the IPC, the green LEDs 'count'

up to show progress in the download. Each serial packet or IPC page increments the

count and it wraps to zero after getting to 31.

5.4 Configuration Changes

When changes are made to the configuration (Base Stations or Lines added or changed),

the information is sent from the System Controller to the Shelf Controller and Interface

Modules. Status LED

Part Number: 72-0059-04-E.doc Page 25

5 blinks on each card during the configuration download.

Page 26

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

6. Troubleshooting Card Alarms

This section contains information about how to read the alarm LEDs on the system cards.

For a complete list and description of alarms, see the Troubleshooting Matrix.

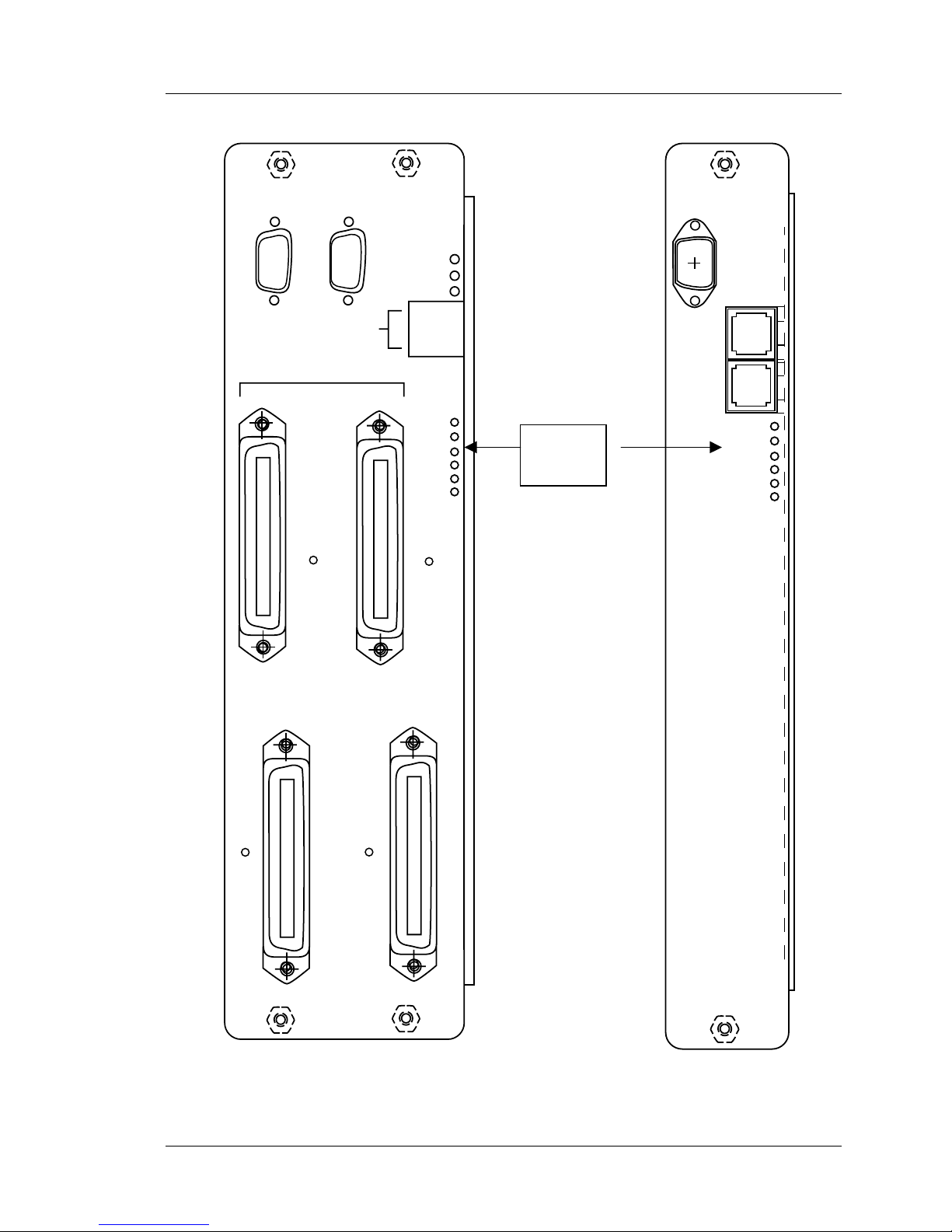

6.1 System and Shelf Controller Card Status Indicators

If the red LED is off but one or more green LEDs are on, the green LEDs indicate status,

as follows:

LED Description

Green 1 Normal Status when on

Green 2 Card Download in progress

Green 3 Reserved for future use

Green 4 Listen Verify in progress

Green 5 Configuration update in progress

When the red LED is lit, it indicates an alarm code is currently shown on the 5 green

LEDs. When indicating Alarms (from top to bottom):

LED Description

Red Alarm is present

Green 1 Low order bit (bit 1) alarm code

Green 2 Bit 2 alarm code

Green 3 Bit 3 alarm code

Green 4 Bit 4 alarm code

Green 5 High order bit (bit 5) alarm code

Part Number: 72-0059-04-E.doc Page 26

Page 27

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

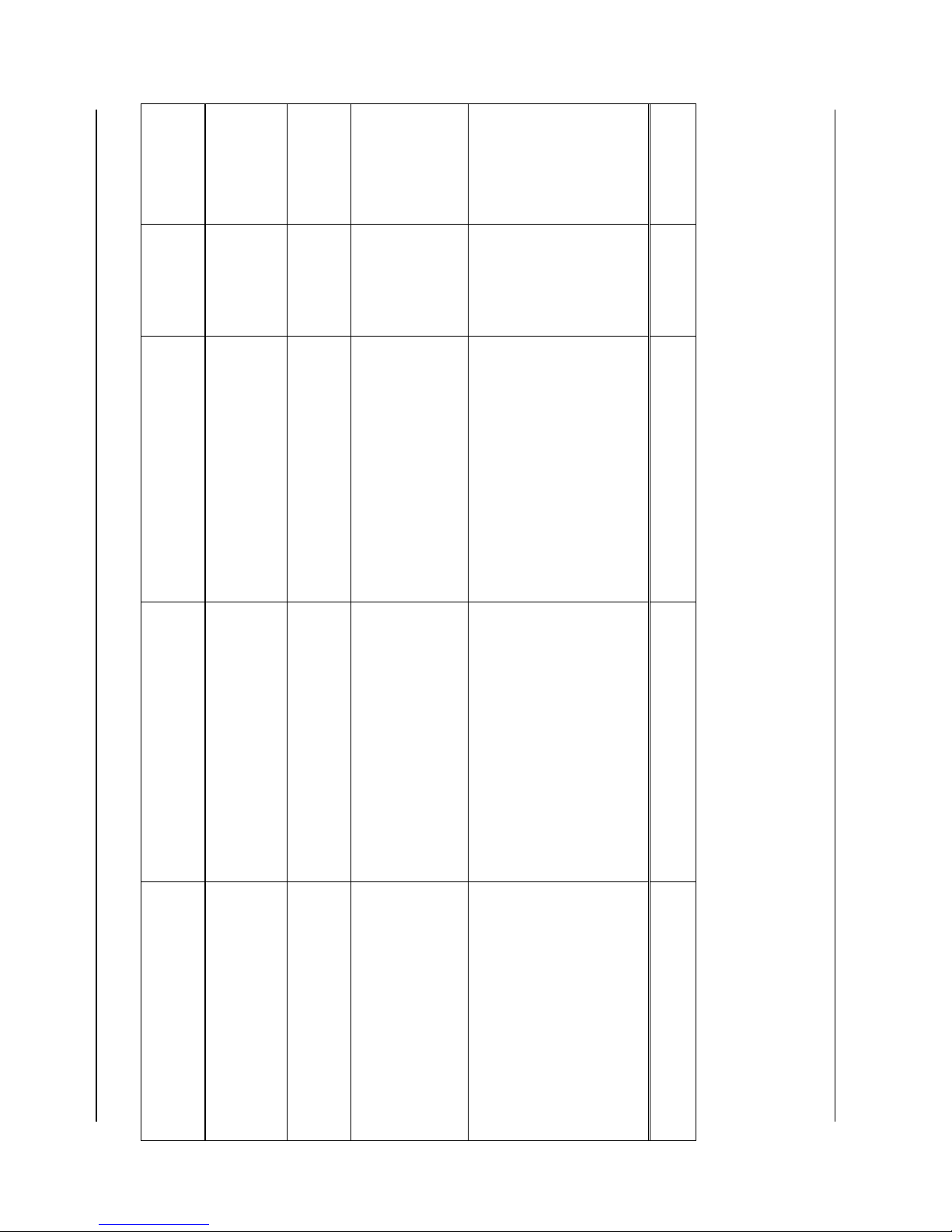

The following diagram shows the System Controller and Shelf Controller cards.

RS-232

A

B

LNKOK

ACT

COL

RS-232

NETWORK

SHELF

17-20 7-11

12-16 2-6

ALARM

(RJ45)

SC/A

(RJ45)

SC/B

1

2

3

4

5

Status

LEDs

ALARM

1

2

3

4

5

System Controller Card Shelf Controller Card

Part Number: 72-0059-04-E.doc Page 27

Page 28

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

6.2 Interface Module Status LEDs

The Status display on the Interface Module consists of:

LED Description

Red/Alarm Always Off

Green 1 Card is up and running

Green 2 One or more lines in use

Green 3 One or more Base Stations in use

DISABLE

NORMAL

CONN

B

ALARM

CONN

A

1

2

3

4

5

Part Number: 72-0059-04-E.doc Page 28

Interface Module

Page 29

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

6.3 Reading the Status LEDs

The LEDs cycle in the following sequence:

1. Status

2. Alarm Code (all LEDs off if no alarm exists)

3. Component (all LEDs off if no alarm exists)

The card will iterate through the list of active alarms showing only one of the active

alarms at a time. A System Controller with two alarms, for example, would flash the

following sequence on the LEDs:

Status - alarm code 1 - alarming component 1 - Status - alarm code 2 - alarming

component 2 - Status - alarm code 1 - alarming component 1 etc

Part Number: 72-0059-04-E.doc Page 29

Page 30

Part Number: 72-0059-04-E.doc Page 30

2,3,5

1,3,5

3,5

1,2,5

2,5

1,5

5

1,2,3,4

2,3,4

1,3,4

3,4

1,2,4

2, 4

LEDs

Router Funnel CTLSW IPC Flash

Alarm Code Alarm Components

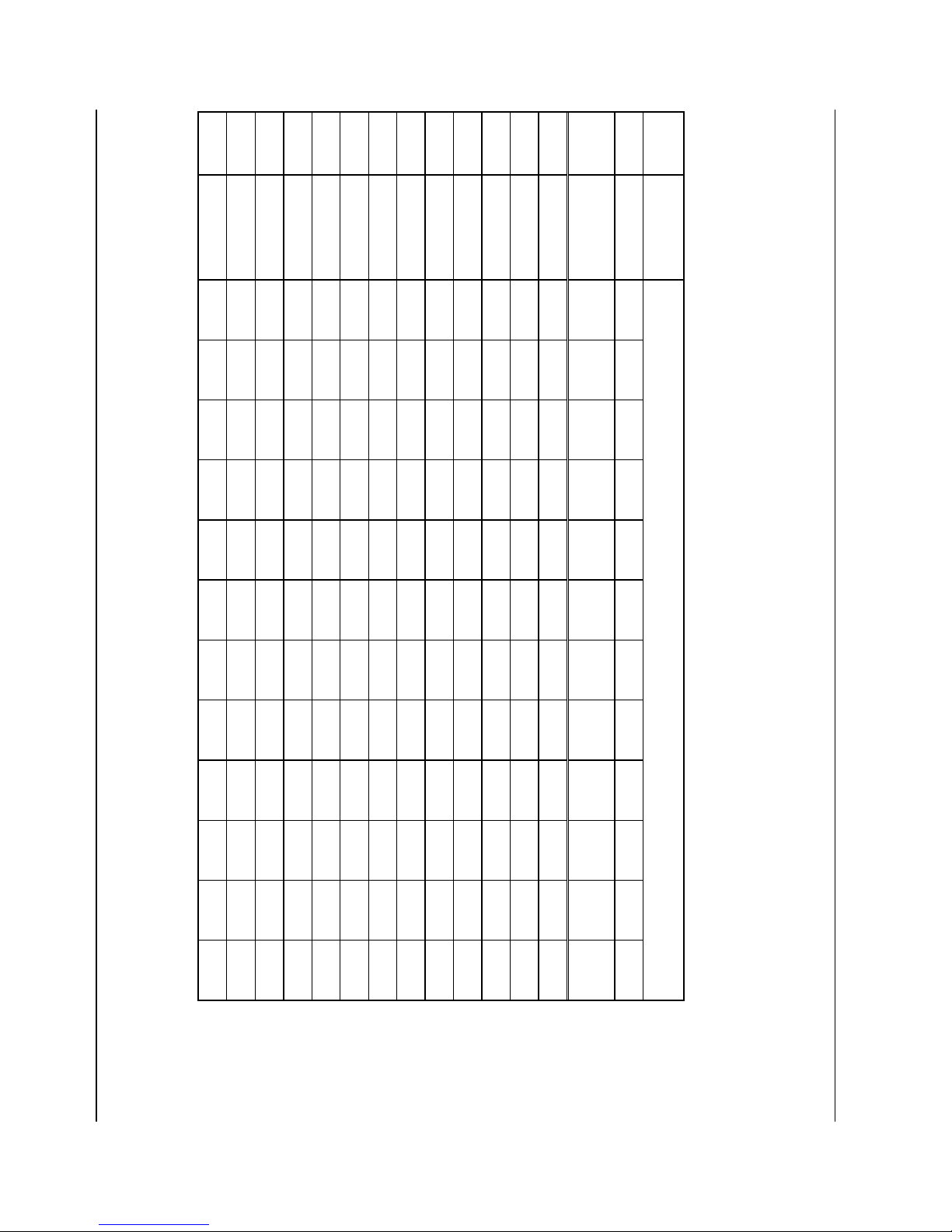

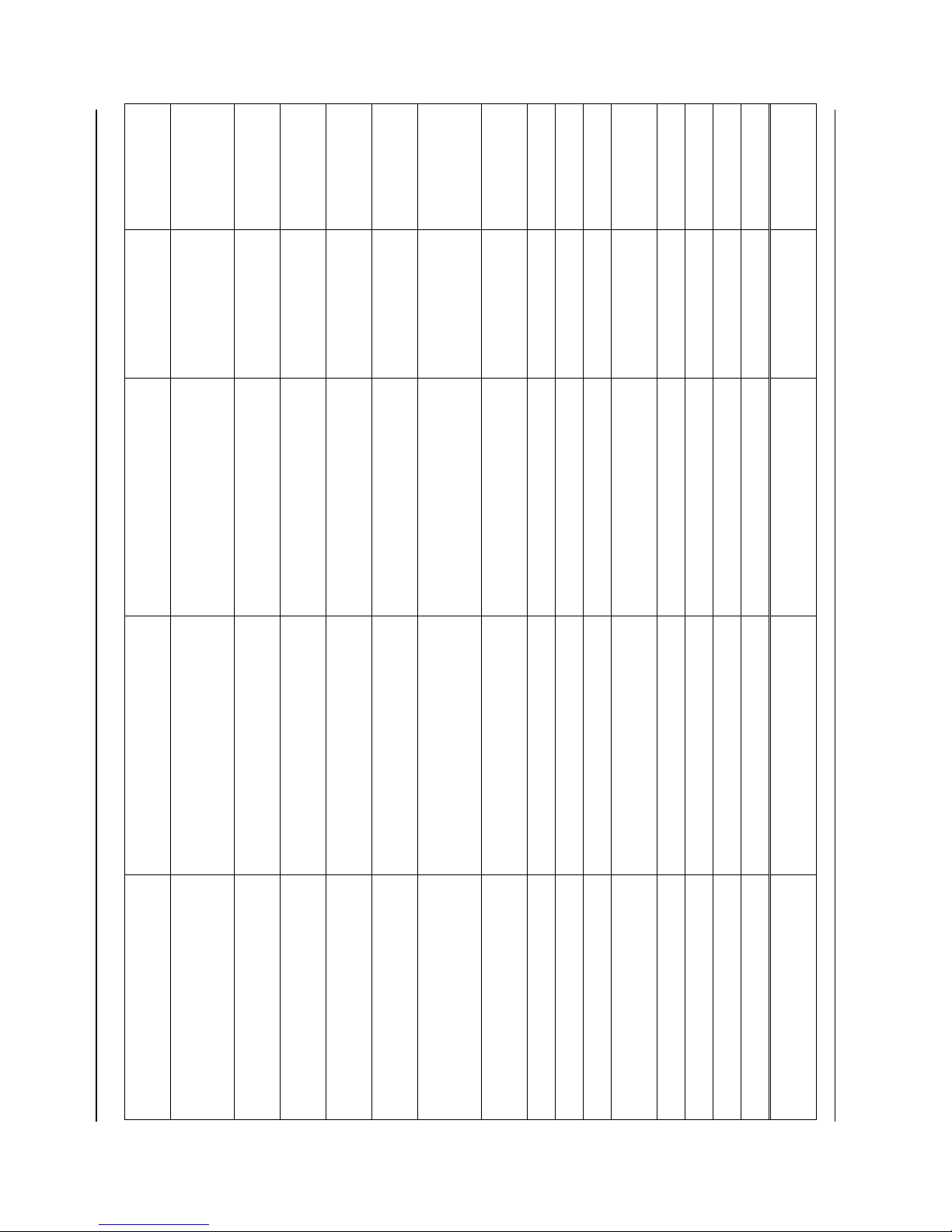

7.1 System Controller Card Alarm Matrix

This table summarizes the possible alarm codes which can occur for the System Controller card.

7. LED and Alarm Troubleshooting Tables

Link WTS – Link 3000 MCU

SpectraLink Corporation Maintenance and Diagnostics

Download

HW

X X X

Write

X

X

Erase

Read

X

X X X X

RX Full

TX Full

X X X X

X X X

Keepalive

Error

X X X X

X X

Program

Start

X X X X

X X X

No Code

Test

X X X X X

X X X X X X X

1 2 1,2 3 1,3 2,3 1,2,3 4 1,4 2,4 1,2,4 3,4

Config

PC

Config

SCC

UART

1

UART

2

Cards MCU DL

Page 31

Part Number: 72-0059-04-E.doc Page 31

Cards. 2,4 Test - 1,2,4 Often the result of inserting the

Cards -2,4 NoCode - 2,4 No valid code found in the flash

Cards - 2,4 Unknown

SpectraLink Corporation Maintenance and Diagnostics

Cards - 2,4 Start - 1,3,4 This alarm occurs because a card

Cards - 2,4 Keepalive -

7.2 System Controller Card Troubleshooting Matrix

On the Operator’s Console, System Controller alarms display on the Show Cabinet Detail screen for the Primary Shelf (Shelf 1),

accessible from Supervisor State screen (F1). The table is sorted alphabetically by component. LEDs for Component and Alarm are

also shown in the table.

Component -

Second LED

Link WTS – Link 3000 MCU

configured shelf slot.

wrong card into a previously

Insert a card that supports the desired

interface (PBX) type.

Hardware -

2,3,5

did not start running functional

code. This can happen if a card is

Often the result of inserting a newer

Download the code necessary for the

card into an older system.

current revision.

Upgrade the supervisor software to a

memory of the System Controller

card.

card that is alarming.

unplugged while it is starting.

If the card is missing, reinsert the card

or deconfigure it in the Interface

Module configuration window. If the

card is present, look at its alarm LEDs

for clarification of the cause of the

problem.

shelf going to the alarming Interface

Module.

Interface Module and the

supervisor.

Possible incorrect cabling between

the System Controller and a Shelf

Controller. Check the cabling for the

2,3,4

a removed card in the system. Also

caused by a breakdown in IPC

communications between the

the system. If no card is present,

either insert a card or deconfigure it

by deleting the PBX type.

Alarm - First

LED

Often the result of a missing card or

Probable Cause Recommendation Notes

Check to see if a card is present in

Missing card code may be seen in

conjunction with another error such

as Supervisor DL error Bad

Download Image.

in an idle, locked state as this or

other alarms may occur.

Avoid removing a card before it is

Stations by the time the keepalive

timeout occurs will be dropped.

have not handed off to other Base

Any active calls that are on the

missing card's Base Stations and

Can be caused by removing a card

before it has reached its normal

state. Removing a card before it is

an idle, locked state should be

generally avoided at this or other

alarms may occur.

Page 32

Part Number: 72-0059-04-E.doc Page 32

Funnel - 2 Start - 1,3,4 Internal error Contact SpectraLink Customer

Funnel - 2 Program - 3,4 Funnel/router FPGA on System

Funnel - 2 Error -

DownLoad -

Flash - 1,3 Erase - 2,5 Bad flash Replace System Controller card.

Flash - 1,3 Read - 1,2,5 Bad flash Replace System Controller card.

Flash - 1,3 Test - 1,2,4 Bad or wrong flash memory Replace System Controller card.

Flash - 1,3 Write - 3,5 Bad flash Replace System Controller card.

3,4

Control SW-

1,2

Control SW -

1,2

Control SW -

1,2

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

Component -

Second LED

Support.

Controller will not accept a

download.

Controller will not accept a

download.

Program - 3,4 Control SW FPGA on System

NoCode - 2,4 No valid code to program Control

Alarm - First

LED

SW-FPGA

1,2,3,4

Internal error Contact SpectraLink Customer

NoCode - 2,4 Bad code in flash If the result of a software download to

Test - 1,2,4 FPGAs on System Controller will

not accept download.

Probable Cause Recommendation Notes

Replace System Controller card. IPC Communications will not work

Support.

system, check downloaded code.

Replace System Controller card. Indicates a condition that affects all

Replace System Controller card. The MCU start alarm can be seen

board is probably bad and should be

replaced.

did a download, retry the download. If

a no download was done lately, the

Check supervisor software. If you just

Base Station and the line are on a

in system. Keepalive card alarms

can be seen because of conditions

causing this alarm.

As a result of this error, audio may

be interrupted on calls where the

Base Station and the line are on a

different half-shelf.

different half-shelf.

As a result of this error, audio may

be interrupted on calls where the

with a flash error.

as a result of this problem.

The MCU start alarm can be seen

as a result of this problem.

FPGAs on the System Controller.

(no FPGA will download). MCU

alarm also seen as a result.

Alarm may occur in conjunction

Page 33

Part Number: 72-0059-04-E.doc Page 33

MCU - 1,2,4 TX Full - 1,5 Internal error Contact SpectraLink Customer

MCU - 1,2,4 Read - 1,2,5 Internal erro. Contact SpectraLink Customer

MCU - 1,2,4 Test - 1,2,4 Code downloaded to the System

MCU - 1,2,4 Error -

IPC - 3 RX Full - 5 Supervisor encountered a

IPC - 3 HW - 2,3,5 Cabling problem between the Shelf

IPC - 3 TX Full - 1,5 Supervisor encountered a

IPC- 3 Start - 1,3,4 HW failed to start in the System

IPC - 3 Error -

Second LED

Funnel -2 NoCode - 2,4 No valid code to program Funnel

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

Component -

Alarm - First

for the hardware

Controller was not the correct code

1,2,3,4

Internal error Contact SpectraLink Customer

Controller.

Controller and the System

Controller card.

temporary period of heavy traffic.

temporary period of heavy traffic.

on.

1,2,3,4

temporarily disturbed when a card

is hot inserted or a shelf is powered

IPC communications can be

LED

FPGA

Probable Cause Recommendation Notes

Support.

If problem persists, contact

Support.

Support.

Download the correct code.

Support.

Check cabling. If problem persists,

contact SpectraLink Customer

Replace System Controller card.

If the result of a software download to

system, check downloaded code.

Alarm can occur in conjunction

with Control Switch alarms.

Support.

Contact SpectraLink Customer

Support.

Contact SpectraLink Customer

SpectraLink Customer Support.

Check supervisor software. If you just

did a download, retry the download. If

a no download was done lately, the

board is probably bad.

causing this alarm.

IPC Communications will not work

in system. Keepalive card alarms

can be seen because of conditions

Page 34

Part Number: 72-0059-04-E.doc Page 34

Router - 1 Program - 3,4 Hardware failure Replace System Controller card.

Router -1 NoCode - 2,4 Bad SW download Check supervisor software. If you just

Router- 1 Keepalive -

Router - 1 Start - 1,3,4 Possibly a bad software download

Router - 1 Error -

Router - 1 Download -

Router - 1 Test - 1,2,4 Hardware failure Replace System Controller card IPC communications will not work

PC Cfg - 2 NoCode - 2,4 Configuration not present (will occur

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

Component -

Second LED

Alarm - First

2,3,4

1,2,3,4

1,3,5

LED

a no download was done lately, the

board is probably bad.

Internal error Contact SpectraLink Customer

or Internal error

Internal error Contact SpectraLink Customer

Hardware failure or wrong software If software is suspected, check

at 1st start up) or flash memory

error

Probable Cause Recommendation Notes

did a download, retry the download. If

Support.

If software is suspected, check

supervisor software, otherwise

contact SpectraLink Customer

Support.

Support.

If flash alarm is present, replace

supervisor software, otherwise

replace System Controller card.

System Controller card.

causing this alarm.

IPC Communications will not work

in system. Keepalive card alarms

can be seen because of conditions

causing this alarm.

IPC Communications will not work

in system. Keepalive card alarms

can be seen because of conditions

causing this alarm.

in the system. Keepalive card

alarms can be seen because of

can be seen because of conditions

causing this alarm.

IPC Communications will not work

in system. Keepalive card alarms

can be seen because of conditions

IPC Communications will not work

in system. Keepalive card alarms

can be seen because of conditions

causing this alarm.

IPC Communications will not work

in system. Keepalive card alarms

conditions causing this alarm.

errors.

May occur in conjunction with flash

stored in the flash will be erased.

Config not present error will occur

at first start up but should not

occur in field. Any configuration

Page 35

Part Number: 72-0059-04-E.doc Page 35

but has been configured for OAI.

UART2 - 1,3

UART2 - 1,3 HW - 2,3,5 System Controller does not support

UART1 - 4

TX Full - 1,5 Internal error Contact SpectraLink Customer

Open Applications Interface (OAI)

UART2 - 1,3

UART1 - 4

RX Full - 5 Internal error Contact SpectraLink Customer

UART2 - 1,3

UART1 - 4

1,2,3

Read - 1,2,5 Bad serial port communications Verify serial port works properly on

Second LED

Sys Config -

NoCode - 2,4 Bad SW download Check supervisor software. If you just

LED

Component -

Alarm - First

Probable Cause Recommendation Notes

Link WTS – Link 3000 MCU

SpectraLink Corporation Maintenance and Diagnostics

Unconfigure the OAI support on the

System Controller.

Support.

Support.

the Operator’s Console PC.

a no download was done lately, the

board is probably bad.

can be seen because of conditions

causing this alarm.

did a download, retry the download. If

IPC Communications will not work

in system. Keepalive card alarms

Page 36

Part Number: 72-0059-04-E.doc Page 36

2,3,5

1,2,5

1,5

5

1,2,3,4

2,3,4

1,3,4

3,4

1,2,4

2, 4

LEDs

CTLSW MCU IPC UART1

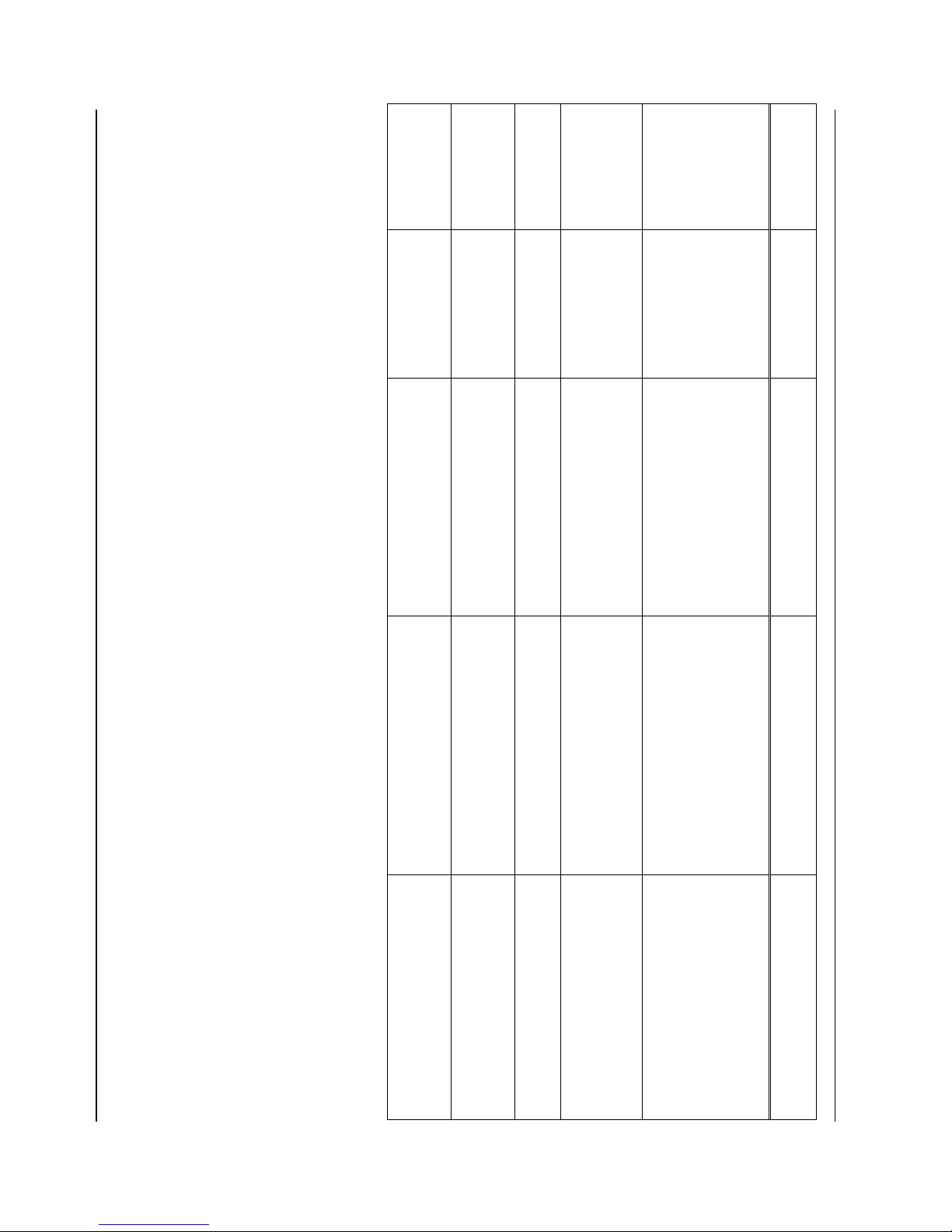

7.3 Shelf Controller Card Alarms

This table summarizes the possible alarm codes which can occur for the Shelf Controller card.

Link WTS – Link 3000 MCU

SpectraLink Corporation Maintenance and Diagnostics

TX Full

Read

HW

X

X X X

X X

RX Full

X

Keepalive

Error

X X

X X

Program

Start

X

Test

X

X X

No Code

X X

Alarm

Code

1 2 1,2 3

Alarm Components

Page 37

Part Number: 72-0059-04-E.doc Page 37

SpectraLink Corporation Maintenance and Diagnostics

Control SW - 1 Test - 1,2,4 FPGAs on Shelf Controller will not

IPC - 1,2 Error - 1,2,3,4 IPC communications can be

temporarily disturbed when a card

is hot inserted or a shelf is

accept download.

keepalive from Shelf Controller

IPC - 1,2 Keepalive - 2,3,4 Shelf controller is not receiving

powered on.

IPC - 1,2 RX Full - 5 Supervisor encountered a

MCU - 2 Error - 1,2,3,4 Internal error Contact SpectraLink Customer

IPC - 1,2 TX Full - 1,5 Supervisor encountered a

temporary period of heavy traffic.

IPC - 1,2 Start - 1,3,4 HW failed to start in the Shelf

Controller card.

temporary period of heavy traffic.

Control SW - 1 Program - 3,4 CTLSW FPGA on Shelf Controller

will not accept a download.

Second LED

LED

also shown in the table.

Component -

Alarm - First

Probable Cause Recommendation Notes

7.4 Shelf Controller Card Troubleshooting Matrix

On the Operator’s Console, Shelf Controller alarms display on the Show Cabinet Detail screen for Expansion Shelves (Shelf 2-20),

accessible from Supervisor State screen (F1). The table is sorted alphabetically by component. LEDs for Component and Alarm are

Link WTS – Link 3000 MCU

Support.

If problem persists, contact

SpectraLink Customer

Support.

Check the cabling between the

Shelf Controller and the

System Controller.

Contact SpectraLink Customer

Support.

If the result of a software

download to shelf, check

downloaded code. Replace

Shelf Controller card.

Contact SpectraLink Customer

Support.

also seen as a result.

Control Switch alarms.

Alarm can occur in conjunction with

Replace Shelf Controller card Indicates a condition that affects all

FPGAs on the Shelf Controller. (no

FPGA will download). MCU alarm

Replace Shelf Controller card. The MCU start alarm can be seen as

a result of this problem.

Page 38

Part Number: 72-0059-04-E.doc Page 38

UART1 - 3 Keepalive - 2,3,4 OAI PC is not properly connected

UART1 - 3 RX Full - 5 Internal error Contact SpectraLink Customer

UART1 - 3 TX Full - 1,5 Internal error Contact SpectraLink Customer

configured for OAI.

UART1 - 3 HW - 5,3,1 System Controller does not

support OAI but has been

to the MCU.

MCU - 2 TX Full - 1,5 Internal error Contact SpectraLink Customer

MCU - 2 Read - 1,2,5 Internal error Contact SpectraLink Customer

Controller was not the correct code

for the hardware

Second LED

MCU - 2 Test - 1,2,4 Code downloaded to the Shelf

LED

Probable Cause Recommendation Notes

Component -

Alarm - First

Link WTS – Link 3000 MCU

SpectraLink Corporation Maintenance and Diagnostics

Unconfigure the OAI support

on the System Controller.

Support.

Support.

Check the OAI PC connection

to the MCU.

Support.

Support.

Download the correct code

Page 39

Part Number: 72-0059-04-E.doc Page 39

SpectraLink Corporation Maintenance and Diagnostics

7.5 Interface Module Alarm Matrix

1,3,5

Lockout

5

Interrupt

1,2,3,4

2,3,4

Clocks

Errors

1,3,4

Disabled

3,4

Keepalive

1,2,4

Download

1,4

2,4

Code

Type

LEDs

MCU CT 1 CT 2

Code

This table summarizes the possible alarm codes which can occur for the Interface Modules.

Alarm

Link WTS – Link 3000 MCU

X

X

X X X

X X

X X X X X

X X X X X

X X X X

X X X X X

1

2

1-6

1-16

1 2 1,2 3 1,3 See table below

Alarm Components

DAA

DAA

Bs Stn

Line

Page 40

Part Number: 72-0059-04-E.doc Page 40

1,2,3 2 1,3,4 2 1,2,5 8 1,4,5 14

4 3 2,3,4 3 3,5 9 2,4,5 15

1,4 4 1,2,3,4 4 1,3,5 10 1,2,4,5 16

2,4 5 5 5 2,3,5 11

1,2,4 6

1,5 6

1,2,3,5 12

2,3 1 3,4 1 2,5 7 4,5 13

LEDs for Base Stations and Lines

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

LED

Base

Stn

LED LINE LED LINE LED LINE

Page 41

Part Number: 72-0059-04-E.doc Page 41

SpectraLink Corporation Maintenance and Diagnostics

Line 7 - 2,5 Disabled - 1,3,4 Configured line not in sync Check cabling.

Type - 1,4 PBX type not found in bin file or

Keepalive - 3,4 Too slow/fast keepalive from

Keepalive - 3,4 Too slow/fast keepalive from

Code - 2,4 DAA processor code not found

Download - 1,2,4 DAA processor download failed Contact SpectraLink Customer

Download - 1,2,4 CT processor download failed Download current software. If

Second LED

Code - 2,4 CT processor code not found in

CT 1 - 2 or

CT 2 - 3

CT 1 - 2 or

CT 2 - 3

CT 1 - 2 or

CT 2 - 3

DAA 1 - 3 or

DAA 2 - 1,3

DAA 1 - 3 or

DAA 2 - 1,3

DAA 1 - 3 or

DAA 2 - 1,3

DAA 1 - 3 or

DAA 2 - 1,3

Line 1 - 3, 4 Disabled - 1,3,4 Configured line not in sync Check cabling.

Line 2 - 1,3,4 Disabled - 1,3,4 Configured line not in sync Check cabling.

Line 3 - 2,3,4 Disabled - 1,3,4 Configured line not in sync Check cabling

Line 4 - 1,2,3,4 Disabled - 1,3,4 Configured line not in sync Check cabling.

Line 5 - 5 Disabled - 1,3,4 Configured line not in sync Check cabling.

Line 6 - 1,5 Disabled - 1,3,4 Configured line not in sync Check cabling.

component. LEDs for Component and Alarm are also shown in the table.

Component -

Alarm - First LED Probable Cause Recommendation Notes

7.6 Interface Module Troubleshooting Matrix

On the Operator’s Console, Interface Module alarms display on the Port Card State (F2) screen. The table is sorted alphabetically by

Link WTS – Link 3000 MCU

incorrect AUX DAA type

CT processor

Support.

in bin file

Contact SpectraLink Customer

Support.

Download current software.

SpectraLink Customer Support.

DAA processor

Contact SpectraLink Customer

Support.

Download current software.

bin files

problem persists contact

Download current software.

Page 42

Part Number: 72-0059-04-E.doc Page 42

RCU 1 - 6 Code - 2,4 Base Station (RCU) code not

Component -

Link WTS – Link 3000 MCU

MCU - 1 Interrupt - 5 Unknown interrupt type Contact SpectraLink Customer

MCU - 1 Errors - 2,3,4 IPC CRC errors (or underrun,

MCU - 1 Keepalive - 3,4 No IPC keepalive message for

MCU - 1 Type - 1,4 Incorrect HW Board ID (not a

MCU - 1 Disabled - 1,3,4 Card/System locked Unlock system via Operator’s

MCU - 1 Clocks - 1,2,3,4 Missing frame interrupts

Second LED

Line 8 - 1,2,5 Disabled - 1,3,4 Configured line not in sync Check cabling.

Line 9 - 3,5 Disabled - 1,3,4 Configured line not in sync Check cabling.

Line 10 -1,3,5 Disabled - 1,3,4 Configured line not in sync Check cabling.

Line 11 - 2,3,5 Disabled - 1,3,4 Configured line not in sync Check cabling.

Line 12 -

1,2,3,5

Line 13 - 4,5 Disabled - 1,3,4 Configured line not in sync Check cabling.

Line 14 - 1,4,5 Disabled - 1,3,4 Configured line not in sync Check cabling.

Line 15 - 2,4,5 Disabled - 1,3,4 Configured line not in sync Check cabling.

Line 16 -

1,2,4,5

SpectraLink Corporation Maintenance and Diagnostics

found in bin file

Disabled - 1,3,4 Configured line not in sync Check cabling.

(Interface Module should reset

Support.

itself)

Contact SpectraLink Customer

Support.

overrun, queue full)

10 seconds

3000 Interface Module)

Contact SpectraLink Customer

Support.

Contact SpectraLink Customer

Support.

Replace with a correct Interface

Console or unlock card using the

Module.

Download current software.

Disable Switch on the card.

Disabled - 1,3,4 Configured line not in sync Check cabling.

Alarm - First LED Probable Cause Recommendation Notes

Page 43

Part Number: 72-0059-04-E.doc Page 43

Component -

Link WTS – Link 3000 MCU

RCU 1 - 6 Errors - 2,3,4 Base Station (RCU)/MCU link

3.0)

RCU 1 - 6 Type - 1,4 Unsupported Base Station

(RCU) type (not Base Station

following startup listen

RCU 1 - 6 Lockout - 1,3,5 Base Station (RCU) locked out

errors too high

RCU 1 - 6 Download - 1,2,4 Base Station (RCU) download

failed

RCU 1 - 6 Disabled - 1,3,4 Base Station (RCU) not

configured but present, or Base

Station (RCU) disabled

Second LED

Alarm - First LED Probable Cause Recommendation Notes

SpectraLink Corporation Maintenance and Diagnostics

supported Base Station type.

Replace Base Station with

Customer Support.

persists, contact SpectraLink

Reset Base Station. If problem

SpectraLink Customer Support.

Check cabling, if OK replace Base

Station.

Check if Base Station is

configured. If not, configure

through the Operator’s Console.

If Base Station is disabled, see

Base Station Disabled in Section

4.

Reset Base Station. See Base

Station Will Not Download, Section

4. If problem persists, contact

Page 44

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

7.7 T1 Alarms

The remote card has two LEDs for each T1 connection labeled LOS and LNKOK. The

LOS LED is controlled by the hardware (T1 transceiver). The LOS is on (red) to indicate

Loss Of Signal. The

indicate that IPC data with good CRC is being received.

LNKOK is controlled by software and is turned on (green) to

The six LEDs labeled

Alarm, 1, 2, 3, 4, 5 to display status, alarm type, and alarm

component. Each of these three values (status, alarm type, alarm component) is

displayed for one second. The card continuously cycles through these three displays,

completing a cycle every three seconds.

The status display consists of:

ALARM LED Always off

LED 1 Card is up and running

Alarm type display:

ALARM 1 2 3 4 5 Alarm Type

OFF OFF OFF OFF OFF OFF No active alarms

ON ON OFF OFF ON OFF Type

ON OFF ON OFF ON OFF Code

ON ON ON OFF ON OFF Download

ON OFF OFF ON ON OFF Keepalive

ON ON OFF ON ON OFF Disabled

ON OFF ON ON ON OFF Errors

ON ON ON ON ON OFF Clocks

ON OFF OFF OFF OFF ON Interrupt

ON ON OFF OFF OFF ON SW Error

Alarm component display:

ALARM 1 2 3 4 5 Alarm Component

OFF OFF OFF OFF OFF OFF No active alarms

ON ON OFF OFF OFF OFF FPGA

ON OFF ON OFF OFF OFF IPC LOCAL

ON ON ON OFF OFF OFF IPC T1 A

ON OFF OFF ON OFF OFF IPC T1 B

Part Number: 72-0059-04-E.doc Page 44

Page 45

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

List of possible port card alarm conditions and the probable causes:

Component Alarm Probable Cause

MCU Disabled Card/System Locked

MCU Keepalive No IPC Keepalive message for 10 seconds

MCU Type Incorrect HW Board ID (not a 3000 remote card)

MCU Interrupt Unknown interrupt type

MCU Clocks Missing frame interrupts (remote card should reset)

MCU Clocks Near/Far GPS pulses out of sync (remote card does not reset)

MCU SW Error Queue overflow (IPC, main, or time)

FPGA Code FPGA code not found in bin file

FPGA Download FPGA download failed

FPGA Clocks External sync pulse too fast/slow or missing

IPC LOCAL Clocks Frequency Lock Loop (FLL) adjustment failed

IPC LOCAL Errors IPC errors (CRC, overrun, underrun)

IPC T1A/T1B Errors IPC Errors (CRC, overrun, underrun)

IPC T1A/T1B Disabled T1 not in sync (missing)

Part Number: 72-0059-04-E.doc Page 45

Page 46

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

8. Terms and Acronyms

These terms are used in alarms or alarm resolution on the Link WTS.

CRC - Cyclical Redundancy Check. Used to check for communication errors between

MCU and Base Stations.

CT - Internal abbreviation for communication algorithm used in SpectraLink telephone.

CTLSW - Control Switch. One of the FPGAs which provides fault tolerance within a

shelf.

DAA - hardware on the Interface Module. A DAA alarm concerns lines.

DL - Downloader. Downloads software to Interface Modules and Shelf Controllers from

the System Controller.

DSP - Digital Signal Processor.

Flash - Flash Memory.

FPGA - Field Programmable Gate Array.

Funnel - component of the System Controller card which transfers audio between half-

shelves. The funnel connects time slots on the highways between shelves.

HW - Hardware

IPC - InterProcessor Communications. Manages the control data packets that run through

the router.

Keepalive - a heartbeat signal that indicates good communication between 2

components.

Router - component of the System Controller card which transfers audio between

shelves.

RX Full - receive overflow error.

Shelf Controller - card in the expansion shelf which contains configuration and software.

System Controller - the card in the primary shelf which contains system configuration

and software. The controller has three main components: supervisor, router, and funnel.

Supervisor - component of the System Controller which contains the system

configuration.

SW Error - software error.

TX Full - transmit overflow error.

UART - Universal Asynchronous Receive/Transfer. Protocol used on the COM ports of

the system and Shelf Controllers.

Part Number: 72-0059-04-E.doc Page 46

Page 47

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

Index

Adding

Base Station, 14

Shelf, 16

Wireless Telephone, 12

Alarms

Display, 9

Interface Module, 39

Shelf Controller, 36

System Controller, 30

Audio problems, 18

Base Station

Adding, 14

Deleting, 15

Disabled, 21

Download problems, 22

LED Flashing, 21, 23

LED Not Lit, 20

Problems, 20

Red LED, 22

Replacing, 15

Reset, 22

Boot ROM LEDs, 24

Cabinet. See Shelf

Capacity, 17

Customer Support Hotline, 9

Deleting

Base Station, 15

Shelf, 16

Wireless Telephone, 12, 13

Dialtone, 18

Disabled Base Station, 21

Download, 22

Extension, 12, 17

Wireless Telephone, 12

Wrong, 19

Hand off, 17

Handoff, 19

Hot swap, 11

Hotline, 9

Icons, 9

Interface Module

Alarms, 39

LEDs, 28

Replacing, 11

Isolated Base Station, 14

LED

Base Station, 20

LEDs

Alarms, 9

Interface Module, 28

Reading, 29

System and Shelf Controller, 26

No Dialtone, 18

No Svc Message, 18

Notes

Base Station, 14

Wireless Telephone, 12

Obstructions, 17

Offset

Defining, 14

Out of range, 17

Port Card. See Interface Module

PT. See Wireless Telephone

RCU. See Base Station

Replacing

Base Station, 15

Interface Module, 11

Wireless Telephone, 12

Ringing

To wrong Wireless Telephone, 19

Serial number

Wireless Telephone, 12

Shelf

Adding, 16

Part Number: 72-0059-04-E.doc Page 47

Page 48

SpectraLink Corporation Maintenance and Diagnostics

Link WTS – Link 3000 MCU

Deleting, 16

Shelf Controller

Alarms, 36

LEDs, 26

Start-Up, 24

System Controller

Alarms, 30

LEDs, 26

User name

Wireless Telephone, 12

Wireless Telephone

Adding, 12

Audio problems, 18

Deleting, 13

Dialtone, 18

Multiple Wireless Telephones with problems, 19

No Handoff, 19

No Svc, 18

Replacing, 12

Ring to wrong extension, 19

Wrong Extension, 17

Part Number: 72-0059-04-E.doc Page 48

Loading...

Loading...