Page 1

The Link

Wireless

Telephone System

Installation and Operation

Link 150 Model 2

Part Number: 72-0060-01

Issue B

May, 1999

Page 2

SpectraLink Corporation Link 150 M2 Installation and Operation

Trademark Information

Comdial is a Registered Trademark of Comdial Corporation

DEFINITY is a Registered Trademark of Lucent Technologies Inc.

MERLIN LEGEND is a Registered Trademark of Lucent Technologies Inc.

Meridian is a Registered Trademark of Northern Telecom Ltd.

Mitel SX is a Registered Trademark of Mitel Corporation

Norstar is a Registered Trademark of Northern Telecom Ltd.

ROLMphone is a registered trademark of Siemens Business Communication Systems Inc.

Strata is a Registered Trademark of Toshiba America Information Systems, Inc.

Page 2 08/11/99

Page 3

SpectraLink Corporation Link 150 M2 Installation and Operation

Note concerning the Master Control Unit:

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

Note concerning shielded cable:

SpectraLink recommends the use of shielded cable for all external signal connections in order to maintain

FCC Part 15 emissions requirements.

Note concerning the Wireless Telephone and Base Stations:

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

WARNING Changes or modifications to this equipment not approved by SpectraLink Corporation may

cause this equipment to not comply with part 15 of the FCC rules and void the user’s authority to operate

this equipment.

WARNING The SpectraLink Link 150 Wireless Telephone System contains no user-serviceable parts

inside. Refer servicing to qualified service personnel.

NOTICE

SpectraLink Corporation has prepared this document for use by SpectraLink personnel and clients. The

drawings and specifications contained herein are the property of SpectraLink and shall be neither

reproduced in whole or in part without the prior written approval of SpectraLink, nor be implied to grant

any license to make, use, or sell equipment manufactured in accordance herewith.

SpectraLink reserves the right to make changes in specifications and other information contained in this

document without prior notice, and the reader should in all cases consult SpectraLink to determine whether

any such changes have been made.

The terms and conditions governing the sale of SpectraLink hardware products and the licensing of

SpectraLink software consist solely of those set forth in the written contracts between SpectraLink and its

customers. No representation or other affirmation of fact contained in this document including but not

limited to statements regarding capacity, response-time performance, suitability for use, or performance of

products described herein shall be deemed to be a warranty by SpectraLink for any purpose, or give rise to

any liability of SpectraLink whatsoever.

In no event shall SpectraLink be liable for any incidental, indirect, special, or consequential damages

whatsoever (including but not limited to lost profits) arising out of or related to this document, or the

information contained in it, even i f SpectraLink has be en advised, knew, or should have known of the

possibility of such damages.

SpectraLink is a trademark of SpectraLink Corporation.

SpectraLink Corporation

Link Wireless Telephone System Installation

© SpectraLink, 1999. All Rights Reserved

Printed in the United States of America

May 1999

Part Number 72-0060-01, Issue B

5755 Central Avenue

Boulder, CO 80301

(303) 440-5330 or

800.676.5465

www.spectralink.com

08/11/99 Page i

Page 4

SpectraLink Corporation Link 150 M2 Installation and Operation

UL Information

This symbol on the nameplate means the product is listed by Underwriter’s Laboratories, Inc. It

is designed and manufactured to meet rigid U.L. safety standards against X-radiation, fire,

casualty, and electrical hazards.

The following are statements required for UL certification, related to safety procedures that must be

adhered to during installation.

Follow these general precautions while installing telephone equipment:

• Never install te lephone wiring during a l ightning storm.

• Never install telephone jacks in wet locations unless the jack is specifically designed for wet

locations.

• Never touch uninsulated telephone wires or terminals unless the telephone line has been

disconnected at the network interface.

• Use caution when installing or modifying telephone lines.

When installing Base Stations outside or in buildings other than the one containing the System Controller,

take the following precaution:

If wiring for a Base Station exits a building—whether to reach an outdoor Base Station location or to reach

a Base Station in another building—the wiring must be protected at both ends by a Quick Clip Fuse from

Illinois Tool Works, Linx Division, model number SCP-2X2. The Quick Clip Fuse replaces the bridging

clips on the 66 blocks for all four connections to the non-internal Base Station.

Page ii 08/11/99

Page 5

SpectraLink Corporation Link 150 M2 Installation and Operation

FCC Information

The Master Control Unit Complies with Part 68, FCC Rules

FCC Registration Number IYGUSA-33816-PX-E

Ringer Equivale nce 0.3B

SpectraLink Corporation

Link 150 Model 2

Made in the USA

This equipment complies with Part 68 of the FCC Rules. On the back of this equipment is a label that

contains, among other information, the FCC Registration Number and Ringer Equival ence Number (REN)

for this equipment. If requested, this information must be given to the telephone company.

This equipment uses RJ-21 connectors.

The REN is useful to determine the quantity of devices you may connect to your telephone line and still

have all of those devices ring when your number is called. In most, but not all, areas, the sum of the RENs

of all devices connected to one line should not exceed five (5.0). To be certain of the number of devices

you may connect to your line, as determined by the REN, you should contact your local telephone company

to determine the maximum REN for your calling area.

If your telephone equipment causes harm to the telephone network, the telephone service may discontinue

your service temporarily. If possible, they will notify you in advance. But if advance notice isn’t practical,

you will be notified as soon as possible. You will be informed of your right to file a complaint with the

FCC.

Your telephone company may make changes in its facilities, equipment, operations or procedures that could

affect the proper functioning of your equipment. If they do, you will be notified in advance to give you an

opportunity to maintain uninterrupted telephone service.

If you experience trouble with this telephone equipment, please contact:

SpectraLink Corp.

5755 Central Avenue

Boulder, Colorado 80301

303-440-5330

for information on obtaining service or repairs. The telephone company may ask that you disconnect this

equipment from the network until the problem has been corrected or until you are sure that the equipment is

not malfunctioning. There are no user serviceable parts in this equipment.

This equipment may not be used on coin service provided by the telephone company. Connection to party

lines is subject to state tariffs.

08/11/99 Page iii

Page 6

SpectraLink Corporation Link 150 M2 Installation and Operation

INDUSTRY CANADA (IC) NOTICE

Notice:

The Industry Canada (IC) label identifies certified equipment. This certification means that the

equipment meets telecommunications network protective, operational, and safety requirements as

prescribed in the appropriate Terminal Equipment Technical Requirements document(s). The

department does not guarantee the equipment will operate to the user’s satisfaction.

Before installing this equipment, users should ensure that it is permissible to be connected to the

facilities of the local telecommunications company. The equipment must also be installed using an

acceptable method of connection. The customer should be aware that compliance with the above

conditions may not prevent degradation of service in some situations.

Repairs to certified equipment should be coordinated by a representative designated by the

supplier. Any repairs or alterations made by a user to this equipment, or equipment malfunctions,

may give the telecommunications company cause to request the user to disconnect the equipment.

Users should ensure for their own protection that the electrical ground connections of the power

utility, telephone lines and internal metallic water pipe system, if present, are connected together.

This precaution may be particularly important in rural areas.

Caution: Users should not attempt to make such connections themselves, but should contact the

appropriate electric inspection authority, or electrician, as appropriate.

Notice: The Ringer Equivalence Number (REN) assigned to each terminal device provides as

indication of the maximum number of terminals allowed to be connected to a telephone interface.

The termination of an interface may consist of any combination of devices

REN 0.3B

Approval Number 2128-9760 A

Warranty and Repair Service Center:

SpectraLink Corp.

5755 Central Avenue

Boulder, Colorado 80301

303-440-5330

DOC Spread Spectrum certification

Base Station Cert. No. 2128-K1373

Wireless Telephone Cert. No. 2128-K1374

Page iv 08/11/99

Page 7

SpectraLink Corporation Link 150 M2 Installation and Operation

Table of Contents

1. ABOUT THIS DOCUMENT 1

1.1. Questions? 1

1.2. Icons and Conventions 1

1.3. Installation Overview 1

2. LINK 150 MODEL 2 OVERVIEW 3

2.1 System Operation 3

2.2 The Front Panel of the MCU 5

3. SITE PREPARATION 6

3.1 Required Materials 6

3.2 Determine Location of MCU 6

4. RUN CABLE FOR SYSTEM 7

4.1 Run Cables to Base Station Locations 7

4.1.1 Wire Specifications 7

4.2 Pull Cable 8

4.3 Terminate Cable at Base Station Locations 8

4.4 Prepare Demarc Blocks 9

4.4.1 Multiple Power Pairs 10

4.4.2 Dedicated Line for Diagnostic Modem 10

4.4.3 Two Wire Analog or Digital Interface 11

4.4.4 Four Wire Digital Interface 12

4.5 Install Demarc Blocks 13

4.6 Assign and Program Ports 13

4.7 Connect Cables from Base Stations and Phone Lines to Demarc Blocks 14

4.7.1 Two Wire Analog or Digital Demarc Block 15

4.7.2 Four Wire Digital Demarc Block 16

5. INSTALL SPECTRALINK SYSTEM 18

5.1 Survey Site 18

5.2 Check Components 18

5.3 Insta ll MCUs 19

5.3.1 Mount MCUs to Wall 19

5.3.2 Connect MCU to Demarc Blocks 19

5.3.3 Connect Multi-Unit Systems 20

08/11/99 Page v

Page 8

SpectraLink Corporation Link 150 M2 Installation and Operation

5.3.4 Connect Power 21

5.4 Install Base Stations 22

5.4.1 Mount Base Stations on Dropped Tile Ceilings 22

5.4.2 Mount Base Stations On Finished Ceilings 23

5.5 Install Outdoor Base Stations 24

5.5.1 Wire and Connect Outdoor Base Stations 24

6. CONNECT AND REGISTER WIRELESS TELEPHONES 25

6.1 Set Up Diagnostic Modem 25

6.2 Register Wireless Telephones 25

6.3 Unregister Wireless Telephones 27

6.4 Program Wireless Telephone Features 27

6.5 Test Wireless Telephones 27

7. SITE CERTIFICATION 28

8. SYSTEM ADMINISTRATION 29

8.1 Troubleshoot Error Codes 29

8.2 Troubleshoot Phone Features 29

8.3 Status LED Codes 30

8.3.1 Wireless Telephone Status Indicator Messages 32

8.4 Replace a Wireless Telephone 33

8.4.1 Delete Old Wireless Telephone 33

8.4.2 Register New Wireless Telephone 33

8.5 Replace an MCU 34

8.5.1 Clear Configuration on Replacement MCU 34

8.5.2 Connect the Replacement MCU 34

8.6 Replace a Base Station 35

A. TECHNICAL PARAMETERS 37

B. PROGRAM ANALOG FEATURES 39

Open Application Interface 39

2. Plan Programming 39

3. Program Macro Codes 40

C. INSTALLING THE OPEN APPLICATIONS INTERFACE (OAI) GATEWAY42

Before Installing the OAI Gateway 42

The OAI Gateway’s Front Panel 43

Page vi 08/11/99

Page 9

SpectraLink Corporation Link 150 M2 Installation and Operation

1. Mount Gateway to Wall 43

2. Initial Test 44

3. Connect the OAI Gateway to the MCU 45

4. Connect the OAI Gateway to the Application Server 46

5. Assign A Function Key to OAI 46

6. Certification Test 47

C. WIRELESS TELEPHONE PLANNING WORKSHEET 48

D. BASE STATION LOCATION WORKSHEET 50

08/11/99 Page vii

Page 10

Page 11

SpectraLink Corporation Link 150 M2 Installation and Operation

1. About This Document

This document explains installation and operation of SpectraLink’s Link Wireless

Telephone System (WTS), Link 150, Model 2. The Link 150 Model 2 adds wireless

service to your existing telephone system. The installation process connects the Link 150

to your telephone system, and activates the Link Wireless Telephones.

1.1. Questions?

SpectraLink wants you to have a successful installation. If you have questions please

contact our Customer Support Hotline at (800) 775-5330. The Hotline is open

Monday through Friday, 7:00 AM to 6:00 PM Mountain Time.

1.2. Icons and Conventions

This manual uses the following icons and conventions.

Caution! Follow these instructions carefully to avoid danger.

Note these instructions carefully.

NORM

This typeface indicates a key, label, or button on the MCU or Wireless

Telephone.

1.3. Installation Overview

Installation has three phases. In most cases, a separate person is responsible for each

phase.

•••• Site preparation and wire installation – this is usually done by a wire technician or

contractor.

•••• Installing the SpectraLink system – this is done by SpectraLink or one of our

certified distributors.

•••• Programming the customer's telephone system to work with the SpectraLink

system – this is usually done by the customer’s system administrator or technician.

Because these major steps require some parallel activities, it is important to coordinate

the activities among the persons involved.

08/11/99 Page 1

Page 12

SpectraLink Corporation Link 150 M2 Installation and Operation

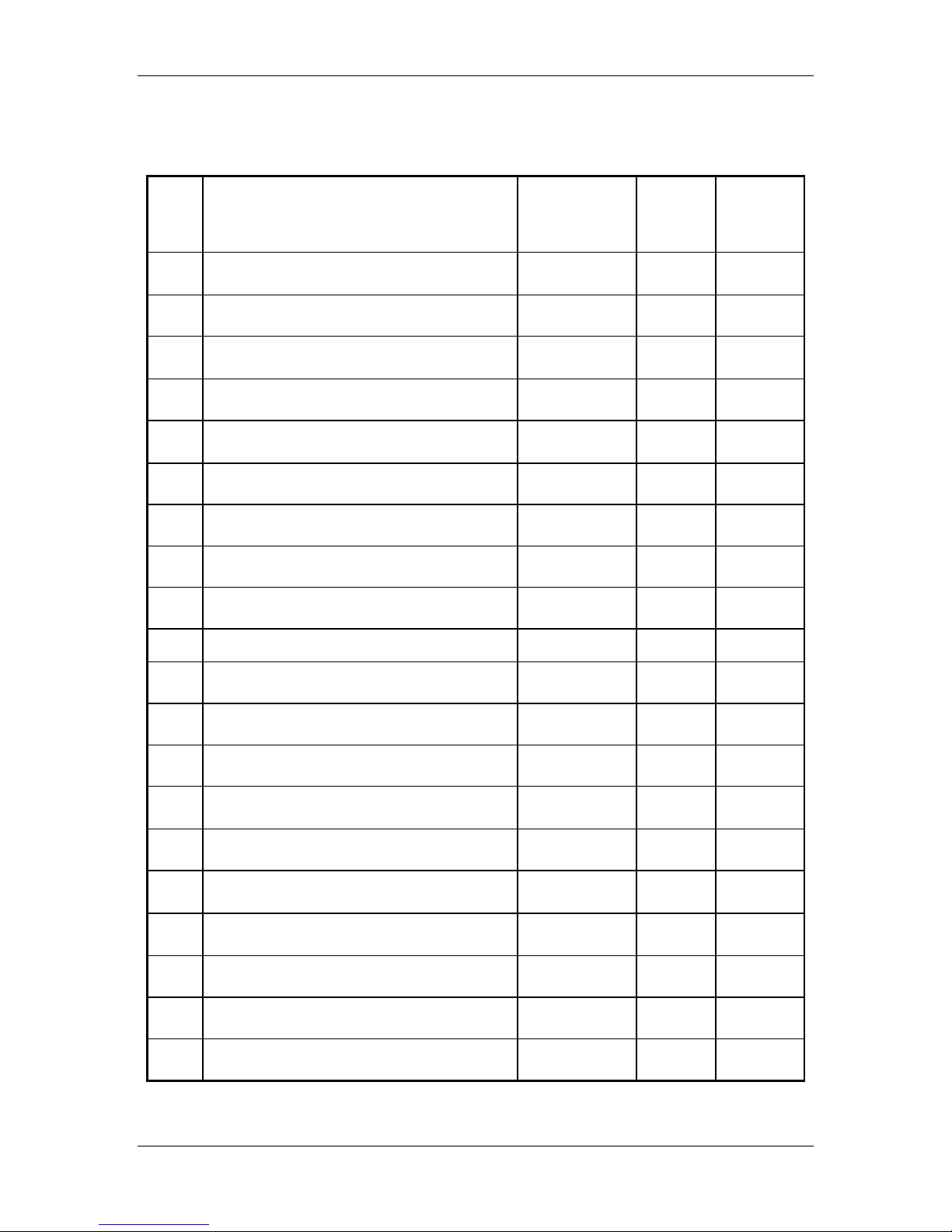

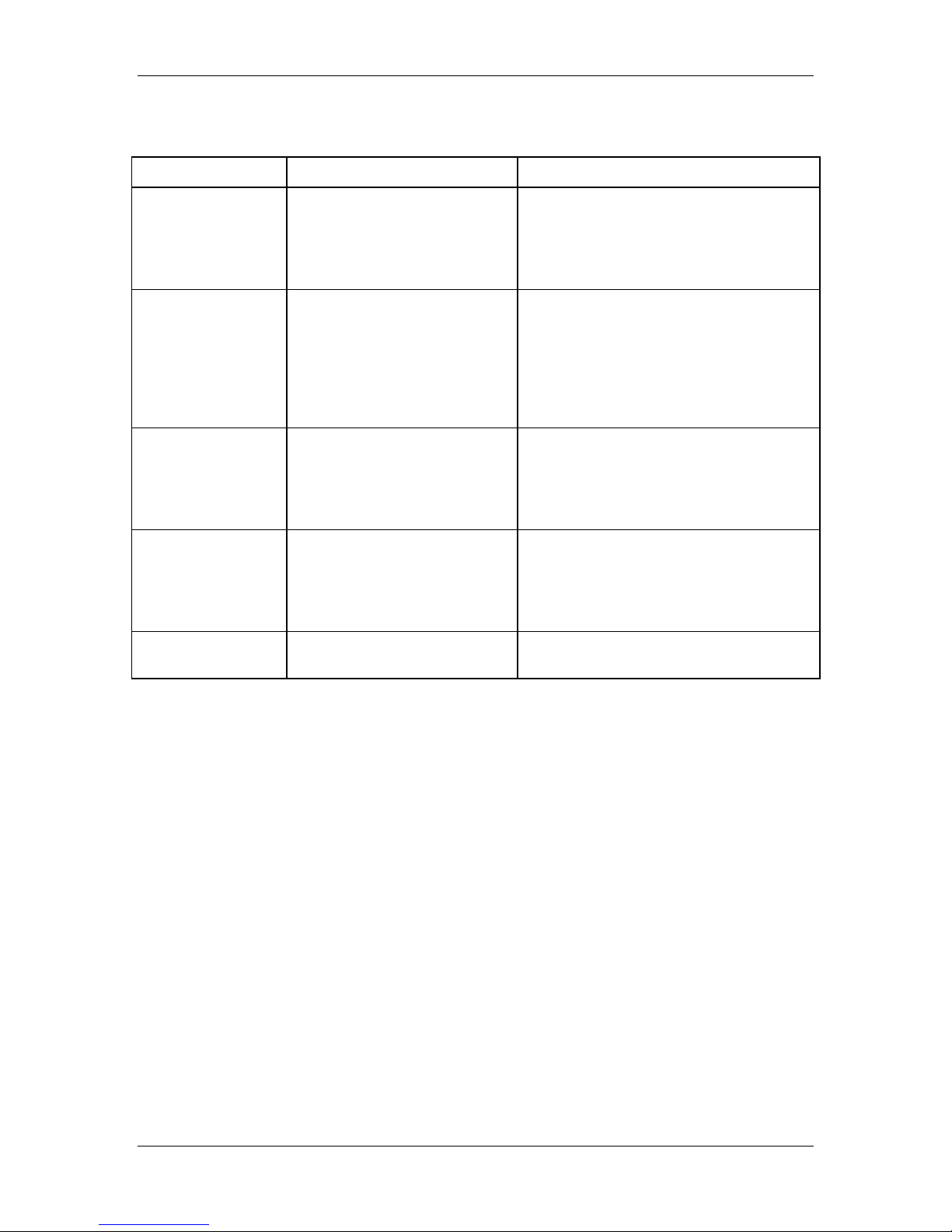

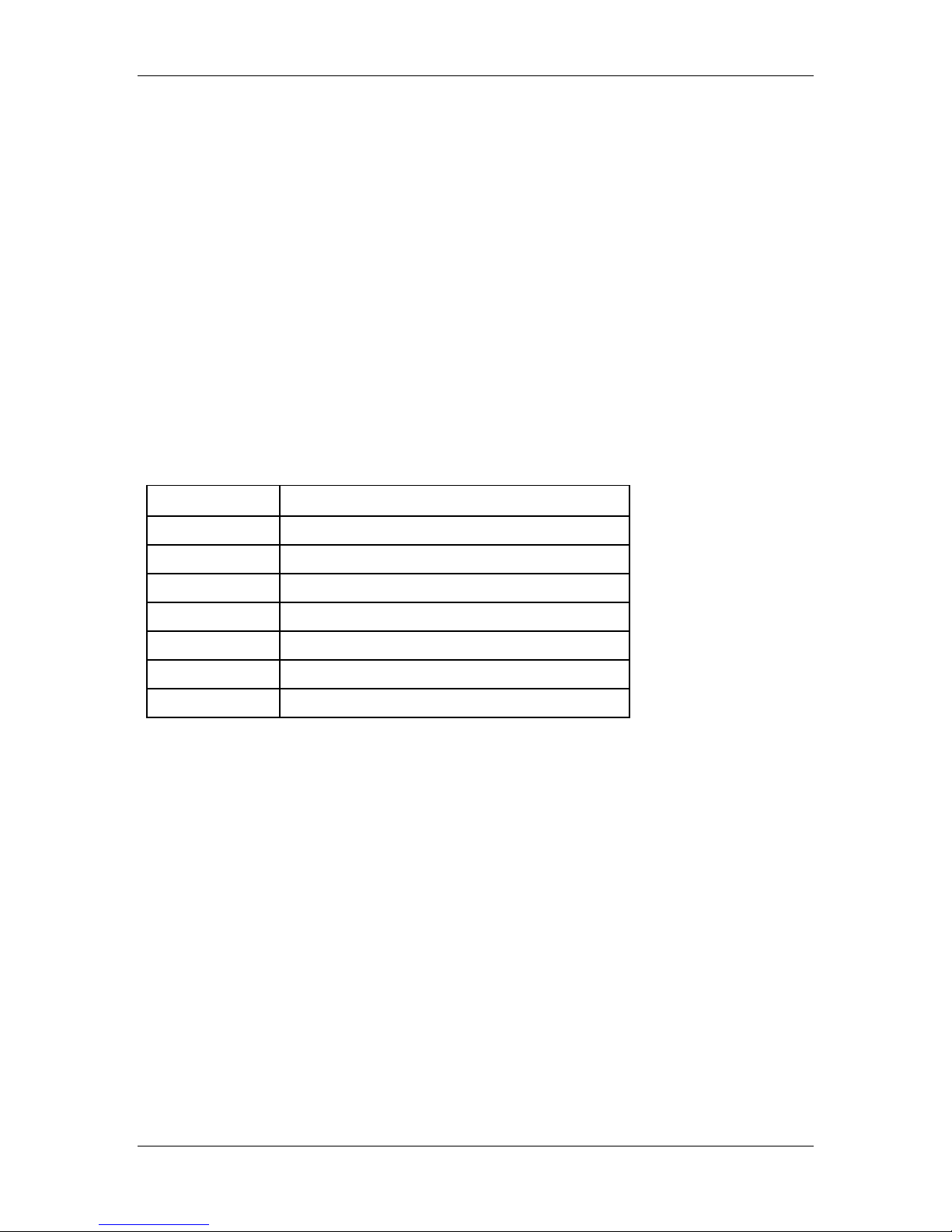

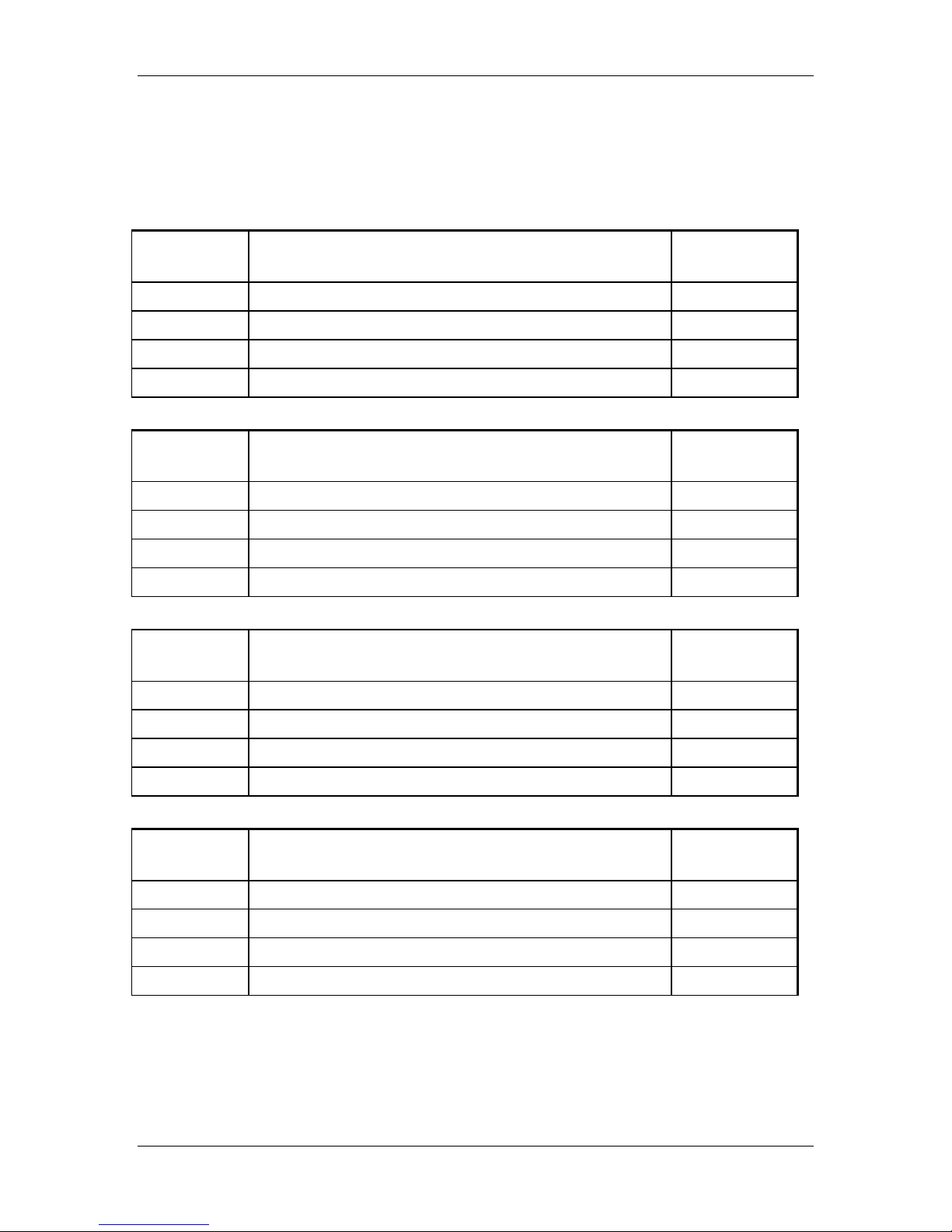

This table lists the installation steps and the person usually responsible for each step.

Site Preparation

Determine Location of MCU

Run Cable for System

Run Cable to Base Station Locations

Pull Cable

Terminate Cable at Base Station Locations

Prepare and Install Demarc Blocks

Assign and Program Ports

Connect Cables to Demarc Blocks

Install SpectraLink System

Task

Description

Wire

Contractor

Installer

System

Admin

Survey Site and Check Components

Install MCUs

Install Base Stations

Install Outdoor Base Stations

Connect and Register Wireless Telephones

Set Up Diagnostic Modem

Register Wireless Te le phones

Program Wireless Telephone Features

Test Wireless Te le phones

Site Certification

Page 2 08/11/99

Page 13

SpectraLink Corporation Link 150 M2 Installation and Operation

2. Link 150 Model 2 Overview

Review this section if you are unfamiliar with the features and operation of the Link 150

Model 2.

2.1 System Operation

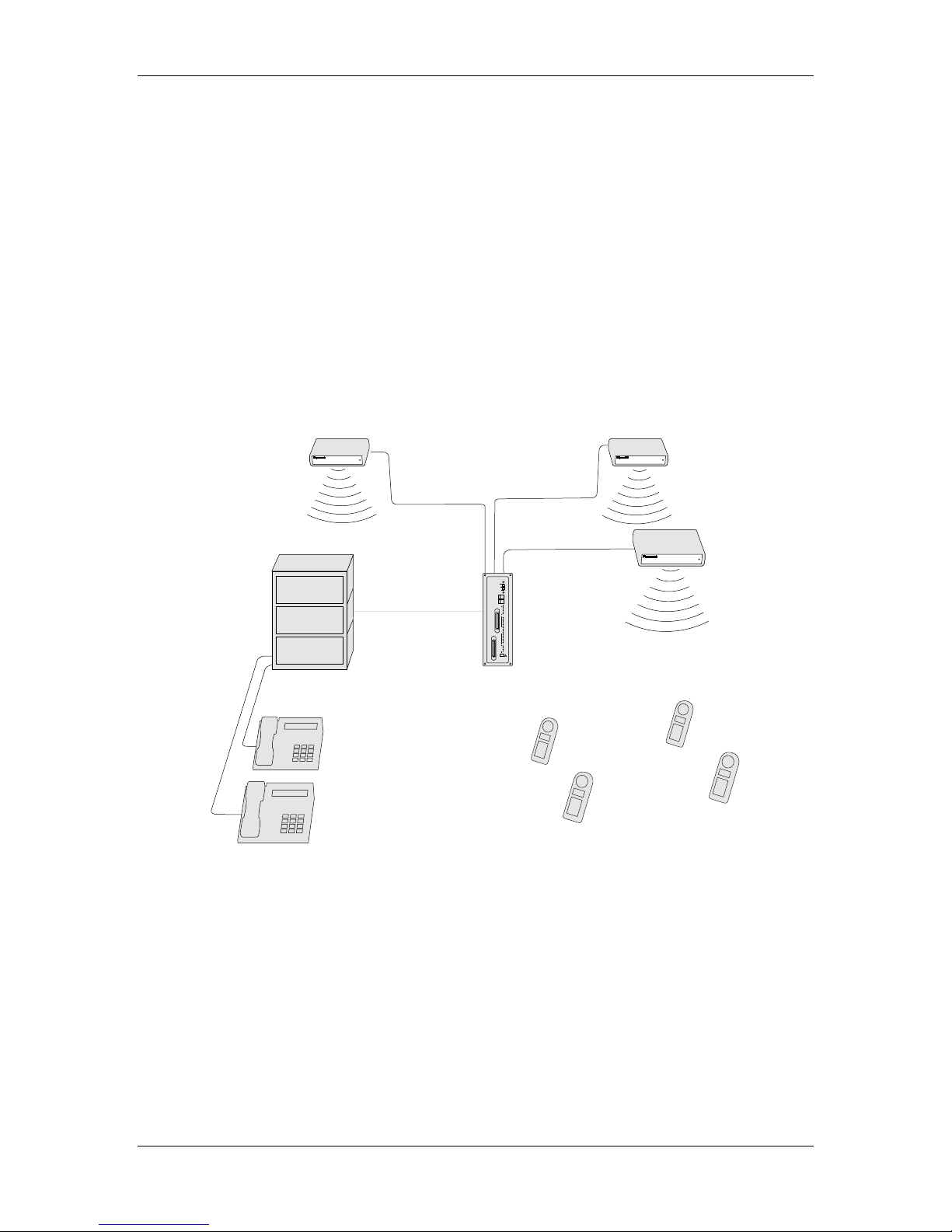

The Link 150 Wireless Telephone System (WTS) is a wireless communication system

that offers direct telephone access for incoming and outgoing calls anywhere within a

facility.

The Link WTS consists of three basic components: the Master Control Unit (MCU), the

Base Station and the Link Wireless Telephone. This diagram shows an overview of

system. Components are described below.

Base Station Base Station

Existing

Telephone

Base Station

System

STEP

ADMIN

NORMAL

Link150

REGISTER

DEL / ENTER

IPC IN

MCU

IPC OUT

CONN

B

STATUS

LINES

CONN

A

STNS

BASE

PWR

!

Telephone Room

Wireless

Telephones

Desksets

The Link 150 Wireless Telephone System

•••• Master Control Unit (MCU) – serves as the connecting point, or gateway, between

the Base Stations and the existing telephone system. One or more of these boxes

(approximately 12 x 3 x 7 inches) are typically installed in the telephone equipment

room and provide connectivity from the telephone system to the wireless system.

Each MCU is hard-wired to one or more Base Stations, which in turn provides the

wireless link to each of the Wireless Telephones. The MCU establishes the

connection from the telephone line to the appropriate Base Station in order to reach a

Wireless Telephone.

08/11/99 Page 3

Page 14

SpectraLink Corporation Link 150 M2 Installation and Operation

The MCU supports four Base Stations and up to 16 Wireless Telephones. Up to four

Link 150 MCUs can be linked together for extended coverage area. Chained MCUs

support up to 64 Wireless Telephones maximum.

SpectraLink offers an analog MCU that works with telephone systems (CO, PBX or

Key Systems) with analog (loop start) ports. We also offer digital MCUs that work

with the most common brands of telephone systems' (PBX or key systems) digital

ports.

•••• Base Stations – act as a radio transceiver to provide the communications signal

between the Wireless Telephone and the MCU. Base Stations are slightly larger than

a smoke detector and are typically mounted on the ceiling, in strategic locations

throughout the facility. A single Base Station can provide radio coverage for an area

of 5,000 to 50,000 square feet depending on building obstructions. Base Stations may

be located up to 2,200 cable feet from the MCU.

When a Wireless Telephone user makes or receives a call, the Wireless Telephone

and Base Station establish a digital radio communication link. As the user moves

around the coverage area, calls are “handed off” to the Base Station that is able to

provide the best radio signal (typically the closest Base Station). These handoffs

involve the Wireless Telephone establishing a communication link with another Base

Station and dropping the previous link.

•••• Link Wireless Telephones – communicate with the Base Station using digital spread

spectrum transmission at 902-928 MHz. Employees can carry Wireless Telephones

to keep in contact as they move throughout the building. The Wireless Telephones

use on-premise wireless technology; they are not cellular or satellite phones. They are

connected to the facility's existing telephone system and, just like wired telephones,

can receive calls directly, receive transferred calls, transfer calls to other extensions,

and make outside and long distance calls (subject to the restrictions applied in your

facility.)

Page 4 08/11/99

Page 15

SpectraLink Corporation Link 150 M2 Installation and Operation

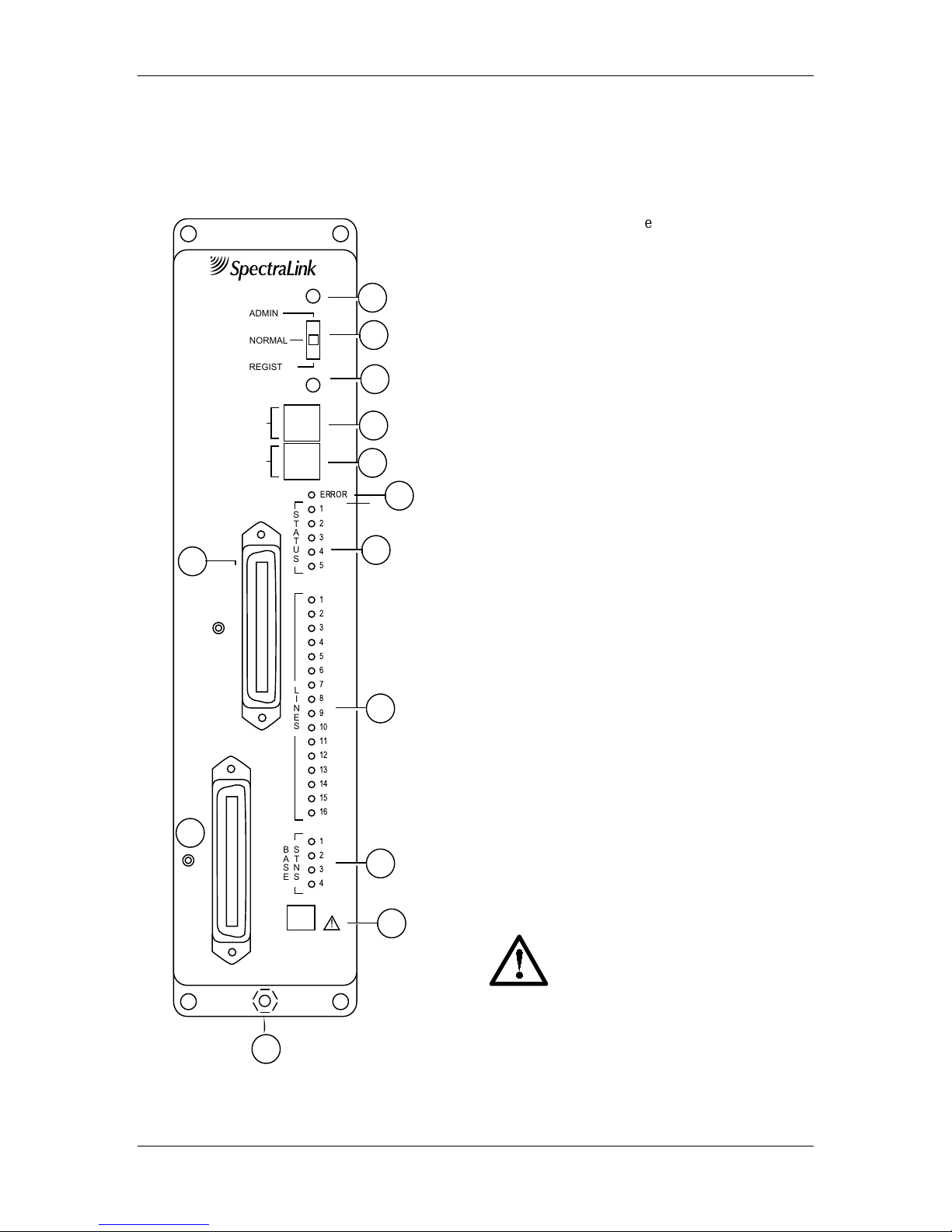

2.2 The Front Panel of the MCU

The MCU's front panel contains the connections to the telephone system, switches to

control system administration, and status LEDs.

1. STEP Button – Selects a specific line or Base

Station during re gi st ration proce ss.

S

ADMIN

NORMAL

REGISTER

DEL / ENTER

IPC IN

IPC OUT

CONN

B

10

CONN

A

10

STEP

1

2

3

4

5

ERROR

1

S

2

T

A

3

T

U

4

S

5

1

2

3

4

5

6

7

L

8

I

N

9

E

S

10

11

12

13

14

15

16

1

S

B

2

T

A

N

S

3

S

E

4

PWR

!

6

7

8

9

11

2. Mode Switch – Selects the mode of operation

for the Link 150 system.

ADMIN: Administration mode, used to set

up system features to match features on the

telephone system.

NORMAL: Normal mode, used during dayto-day operations.

REGISTER: Registration mode, used to

add or delete Wireless Telephones and Base

Stations.

3. DEL/ENTER Button – Removes a registered

Wireless Telep hone from the system.

4. IPC IN Port – Used to connect preceding

MCUs in a multi-MCU configuration.

5. IPC OUT Port – Used to connect sequential

MCUs in a multi-MCU configuration or to

connect to an Open Applications Interface (OAI)

Gateway.

6. Error LED – Flashes when the system has

detected an error. When flashing, check the

Status LEDs for an error code.

7. Status LEDs – Indicate system error messages

and status. Refer to LED Status Codes for more

information.

8. Line LEDs – Indicate the line status of each

Wireless T elephone: ringing, in use, or not

active.

9. Base Stn LEDs – Indicate the status of each

Base Station.

10. Conn A or B – RJ-21 connector to the crossconnect demarc block. Connector B is supplied

and used only with 4 wire interface.

11. Power Jack – Connects to the AC adapter

to supply power to the system.

Use only the provided Class II AC

Adapter with output 24VDC, 1A.

12

08/11/99 Page 5

12. Grounding Lug- For use on the SCA

408/416.

Page 16

SpectraLink Corporation Link 150 M2 Installation and Operation

3. Site Preparation

3.1 Required Materials

The following equipment must be provided by the customer.

1. Outlet Strip – Recommended for installations with more than one MCU. This

will allow the MCUs to be turned on and off together.

2. Cross-Connect Block – required to connect the PBX ports and the Base Stations

to the MCU.

3. 25 Pair Cables – RJ-21 male at MCU end, required to connect the MCU to the

cross-connect blocks.

4. Backboard space – the MCU is designed to be wall mounted to ¾” plywood

securely screwed to the wall.

5. Quick Clip Fuse – Required with an RCO410 Outdoor Base Station or when a

Base Station is located in a separate building from the Link 150. Recommended

Quick Clip Fuse is available from Illinois Tool Works, Linx Division, Model #

SCP-2X2.

6. Base Station Mounting Hardware – If the Base Stations will be mounted on

finished walls or ceilings, a 4-5" long ¼" bolt, nuts, and washers will be required

for each Base Station mounted.

3.2 Determine Location of MCU

Each MCU is approximately 2.75 inches wide, 12.5 inches high, and 7 inches deep, and

weighs about 5 pounds. The unit is designed to be wall mounted over ¾”plywood.

Select a location for the MCU with sufficient backboard space and an available outlet.

Since the front panel is used for cabling and as an operator's console, mount the units so

the front panel is accessible.

The MCU must be within 2,200 feet of the Base Stations.

If your system has more than one MCU, the units should be

mounted vertically, side by side, physically touching the adjacent

unit. Do not stack units on top of one another. Stacked MCUs can

cause overheating and failure.

Page 6 08/11/99

Page 17

SpectraLink Corporation Link 150 M2 Installation and Operation

4. Run Cable for System

4.1 Run Cables to Base Station Locations

The Base Station locations should be designated on the building floorplans provided to

the installer. Base Stations can be mounted easily on raised or acoustical ceiling tiles, or

on the wall. Avoid locating Base Stations in high or hard-to-reach places, as this will

hinder maintenance, testing, or repositioning.

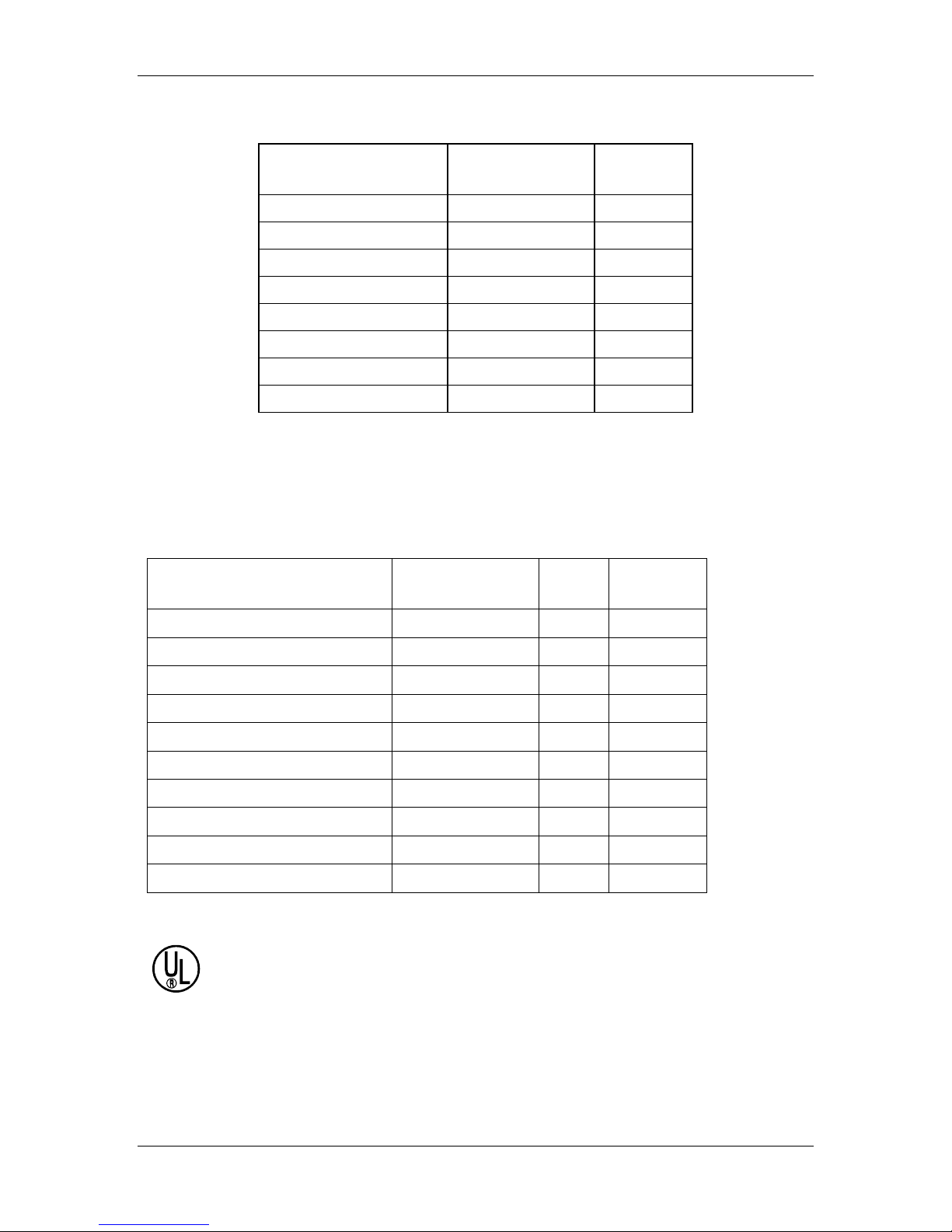

4.1.1 Wire Specifications

The customer's wire contractor is responsible for adhering to all local codes

SpectraLink recommends UL-Listed Wire that conforms to the following specifications

for AWG, distance, and number of power pairs required for this installation.

for wiring.

Power

Pairs

1 1,100 750 470

2 2,200 1,500 940

3 2,200 2,200 1,400

One additional pair is required for Data.

Attenuation must not exceed 6.8 dB/1,000 feet @ 772KHz.

Wire that is already installed (spare house cable) can be used when it is available. House

cable will usually run from the MDF in the telephone equipment room to Intermediate

Distribution Frames (IDFs) spread throughout the facility. Install new wire from the

closest IDF to the Base Station. Be sure no bridge taps, multiples, or “Y” connections are

created or present.

Determine the amount of wire needed to connect the Base Station to the MCU by scaling

from a floorplan or a sketch, pacing, measuring, or estimating. Remember to include

enough wire to reach the ceiling.

Max Cable

Feet

22 AWG

Max Cable

Feet

24 AWG

Max Cable

Feet

26 AWG

The wire length between the MCU and each Base Station may not exceed

08/11/99 Page 7

2,200 cable feet.

Install an extra 25 feet of wire at the Base Station to allow for possible

relocation.

Page 18

SpectraLink Corporation Link 150 M2 Installation and Operation

4.2 Pull Cable

Pull the cable from the MCU location (usually in the telephone equipment room) to the

Base Station locations designated on the floorplans.

If the cabling exits the building, consult the telephone system manual, the

NEC, and local codes for instructions on providing lightning and other overcurrent protection.

When cabling an external Base Station or a Base Station with wiring that

exits the building, protect all Base Station wiring with the Quick Clip Fuse

(Illinois Tool Works, Linx Division, SCP-2X2) before bridging with other

Base Station power leads.

Run all cable before attaching the RJ-45 connectors to the Base Stations. Label both the

demarcation block end and the Base Station end of each wire with the Base Station

number using a wire tie marker or other form of marker.

Remove bridge taps, multiples, or "Y" connections to the Base Station wires;

these will cause data transmission errors.

The area above some suspended ceilings is used as an environmental air

plenum. The National Electric Code requires that wire installed in plenums

be rated for plenum installation.

4.3 Terminate Cable at Base Station Locations

After running the wire to the Base Station location, terminate the wire using an RJ-45

modular crimp-on plug. Connect the data pair to pins 1 and 2 and the power pair to pins

7 and 8.

If the connection uses more than two pair, refer to the table on the following page.

To avoid damage to the connectors or crimps, be sure to run the wire to the

Base Station before connecting the RJ-45 connectors.

1

8

Page 8 08/11/99

RJ-45 Modular Cable

Page 19

SpectraLink Corporation Link 150 M2 Installation and Operation

When wiring the 8-pin connector, use the following table as a guide.

8-pin modular

connector

1 Data 1 Any

2 Data 2 Any

3Power 3 +

4Power 2 5Power 2 +

6Power 3 7Power 1 8Power 1 +

MCU Pin

Function

Polarity

4.4 Prepare Demarc Blocks

The MCU is connected to the existing telephone system using RJ-21 connections. An

MCU is designed to operate with a specific interface to the telephone system: two wire

digital or analog, or four wire digital. The number of demarcation blocks required for the

system depends on the number and type of Interface Modules to be installed.

Interface Type MCU

Part Number

Wire

Pairs

# Blocks

Analog POTS SCA-416/SCA-408 1 1

Comdial SCC-416/SCC-408 1 1

DEFINITY SCD-416/SCD-408 1 1

Merlin Legend SCL-416/SCL-408 2 2

Mitel (DNIC) SCX-416 1 1

NEC SCE-41611

Nortel Meridian SCM-416/SCM-408 1 1

Nortel Norstar SCN-416/SCN-408 1 1

Siemens Rolm SCS-416/SCS-408 1 1

Toshiba SCK-416/SCK-408 1 1

If the wiring between the Link 150 and the telephone system leaves the

building, consult your telephone system manual for instructions on providing

adequate lightning and other over-current protection. All MCUs (except the

SCA-416 and SCA-408) are intended only for connection to the isolated side

of an on-premise PBX. The interfaces are intended to connect to digital PBX

ports that provide signals of 5Vp-p (max) AC component and some PBXs

provide a 48 V DC offset.

Based on the number and type of interfaces in the system, determine the number of 25pair cables required to connect line ports and Base Stations to the demarcation blocks.

08/11/99 Page 9

Page 20

SpectraLink Corporation Link 150 M2 Installation and Operation

The diagrams which follow provide an overview of the connections.

4.4.1 Multiple Power Pairs

Some sites may prefer to wire Base Stations to a separate demarc block in order to split

out power pairs.

4.4.2 Dedicated Line for Diagnostic Modem

The Link 150 can be accessed remotely using an internal modem. To use the modem for

remote access, a dedicated dial-in line must be provided. On digital interface systems this

line must be terminated as a digital extension to the MCU.

Page 10 08/11/99

Page 21

SpectraLink Corporation Link 150 M2 Installation and Operation

4.4.3 Two Wir e Analog or Digital Interface

The wiring diagram below shows the connections required for a two-wire analog or

digital interface. The MCU can be a SCA-416 or 408, SCC-416 or 408, SCD-416 or 408,

SCX-416, SCE-416, SCM-416 or 408, SCN-416 or 408, SCS-416 or 408, or SCK-416 or

408.

A

Telephone Ports

To

PBX

Pair 1-16

Pair 17 Unused

Pair

18-19

To

Base Stations

Data Pair

20-23

Pair 24 & 25

Unused

Power Pairs

Base Stn. 1-4

Data Pairs

Base Stn. 1-4

Two Wire Analog or Digital Connection

08/11/99 Page 11

Page 22

SpectraLink Corporation Link 150 M2 Installation and Operation

4.4.4 Four Wire Digital I nter f ace

The wiring diagram below shows the connections required for a four-wire interface .

Each MCU of this type requires two demarcation blocks which will be wired as indicated.

B

A

Receive (RX)

To PBX

Telephone Ports

Pair 1-16

Pair 17-25 Unused

To

PBX

To

Base Stations

Transmit (TX)

From PBX

Telephone Ports

Pair 1-16

Pair 17 - Unused

Power Pairs 18-19

Base Stn. 1-4

Data Pairs 20-23

Base Stn.1-4

Pair 24 & 25 Unused

Four Wire Digital Connection

Page 12 08/11/99

Page 23

SpectraLink Corporation Link 150 M2 Installation and Operation

4.5 Install Demarc Blocks

The demarcation blocks used to connect the telephone system and Base Stations to the

MCU should be installed on a typical telephone facility backboard. A ½" or ¾" thick

board mounted on the wall near the MCU is typical. Although this manual uses 66blocks as examples, any standard cross-connect blocks are acceptable.

When cabling an external Base Station or a Base Station with wiring that

exits the building, protect all Base Station wiring with the Quick Clip Fuse

(Illinois Tool Works, Linx Division, SCP-2X2) before bridging with other

Base Station power leads.

If the cabling between the MCU and the telephone system leaves the

building, consult the telephone system manual, the NEC, and local codes for

instructions on providing lightning and other over-current protection.

4.6 Assign and Program Ports

The wire contractor should inform the system administrator which port numbers have

been designated for the Wireless Telephones and the remote diagnostics modem line.

The system administrator must assign extension numbers to the Wireless Telephones and

plan the functions (trunk access, toll restrictions, system features, ringing options etc.) to

be programmed for the Wireless Telephones. This programming will be done after the

Wireless Telephones are registered, but will be faster if it is planned in advance by

verifying the parameters and features on the current telephone system and wired phones.

For details, refer to the section of Switch Programming (PN 72-0060-02) for the type of

telephone system for the MCU in use at your location.

08/11/99 Page 13

Page 24

SpectraLink Corporation Link 150 M2 Installation and Operation

4.7 Connect Cables from Base Stations and Phone

Lines to Demarc Blocks

Two-pair twisted cable from Base Stations installed throughout the facility converge at

the demarc block or backboard. Each MCU can support four Base Stations and up to 16

Wireless Telephones. The Base Station and Wireless Telephone cables are punched

down onto the demarc/cross-connect blocks as shown in the demarc block diagrams

below. Refer also to the diagrams in Section 4.4.

Photocopy the Base Station Location Form and Extension Assignments Worksheets

(Appendix D and E) as needed. Use the forms to track the Base Stations and Wireless

Telephone port assignments connected to each MCU. As the installer makes each Base

Station or Wireless Telephone connection, fill in the information on the form to identify

the position of the Base Station or Wireless Telephone (the building and floor number,

for example) and a detailed description of the location (perhaps a room number). A copy

of this form should be posted near the cross-connect block.

Up to four Base Stations can be connected on a single MCU. Each Base

Station uses 2 pair, one for data and one for power.

When cabling an external Base Station or a Base Station with wiring that

exits the building, protect all Base Station wiring with fuse protection. One

method is to use a Quick Clip Fuse (Illinois Tool Works, Linx Division,

SCP-2X2) to provide protection from external wiring.

If the wiring between the MCU and the telephone system leaves the building,

consult the telephone system manual, the NEC, and local codes for

instructions on providing lightning and other over-current protection.

Page 14 08/11/99

Page 25

SpectraLink Corporation Link 150 M2 Installation and Operation

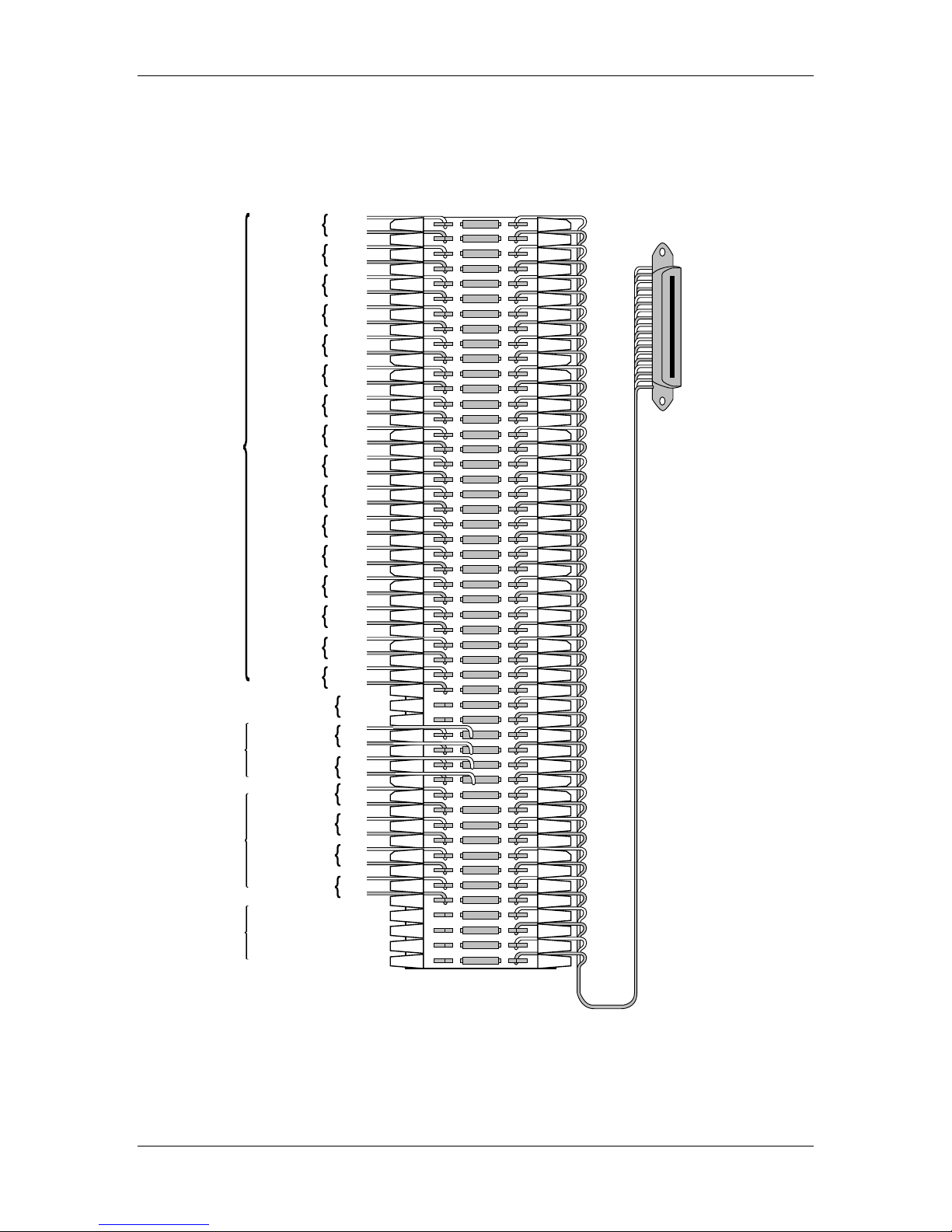

4.7.1 Two Wire Analog or Digital Demarc Block

The demarc block for the two-wire analog or digital interface should be wired as follows.

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

1

2

3

4

25 PAIR MALE

CONNECTOR

CABLE TO

MCU

CONNECTOR A

Telephone

Ports

Base

Station

Power

Pairs

Base

Station

Data

Pairs

LINE1

LINE 2

LINE 3

LINE 4

LINE 5

LINE 6

LINE 7

LINE 8

LINE 9

LINE 10

LINE 11

LINE 12

LINE 13

LINE 14

LINE 15

LINE 16

UNUSED

1 & 2

3 & 4

UNUSED

08/11/99 Page 15

Page 26

SpectraLink Corporation Link 150 M2 Installation and Operation

4.7.2 Four Wire Digital Demarc Block

The four wire digital interface (future release) requires two demarc blocks, one to

Connector A and one to Connector B on the MCU. They should be wired as follows.

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

1

2

3

4

25 PAIR MALE

CONNECTOR

CABLE TO

MCU

CONNECTOR A

Telephone

Ports

Note:

TX denotes

data transmitted

from the telephone

system to the

Link150

Base

Station

Power

Pairs

Base

Station

Data

Pairs

Line 1 TX

Line 2 TX

Line 3 TX

Line 4 TX

Line 5 TX

Line 6 TX

Line7 TX

Line 8 TX

Line 9 TX

Line 10 TX

Line 11 TX

Line 12 TX

Line 13 TX

Line 14 TX

Line 15 TX

Line 16 TX

UNUSED

1, & 2

3 & 4

Unused

Page 16 08/11/99

4-Wire Connector A

Page 27

SpectraLink Corporation Link 150 M2 Installation and Operation

Telephone

Ports

Note:

RX denotes

data received by

the telephone

system from Link 150

Line 1 RX

Line 2 RX

Line 3 RX

Line 4 RX

Line 5 RX

Line 6 RX

Line 7 RX

Line 8 RX

Line 9 RX

Line 10 RX

Line 11 RX

Line 12 RX

Line 13 RX

Line 14 RX

Line 15 RX

Line 16 RX

ring

ring

ring

ring

ring

ring

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

ring

tip

tip

tip

tip

tip

tip

tip

25 PAIR MALE

CONNECTOR

CABLE TO

MCU

CONNECTOR B

Unused

Pairs

DO NOT

USE

4-Wire Connector B

08/11/99 Page 17

Page 28

SpectraLink Corporation Link 150 M2 Installation and Operation

5. Install SpectraLink System

5.1 Survey Site

Check the site to be sure pre-installation work has been completed correctly. This

includes:

1. Location chosen for the MCU is adequate, and power is available.

2. Wiring to Base Station locations has been pulled and correctly terminated.

3. Phone lines for the Wireless Telephones are installed and properly terminated.

4. Dedicated line is available for remote access to diagnostic modem.

5. Telephone system administrator is on-site to program the existing telephone

system.

If the work has not been completed, the SpectraLink installer can leave the site and

reschedule the installation when the items have been completed or corrected, or assist in

preparing the site.

5.2 Check Components

The following items should be at the installation site.

• Link 150 Model 2 Master Control Unit – Depending on the size of your

system, there may be up to four MCUs, which will be chained together to

extend the coverage area.

• AC Adapter – Supplies power to the Link 150 Model 2.

Use only the provided Class II AC Adapter

with output 24VDC, 1A.

• IPC Cable – Each MCU is shipped with one Inter-Processor Communication

(IPC) cable to carry signals between Link 150 units. It is used only when

multiple MCUs are chained together.

• Base Stations – SpectraLink Part Number RCC 400/410 or RCO 400/410 (for

outdoor use). Your system may have up to four Base Stations for each MCU

shipped.

• Base Station Mounting Hardware – A ceiling clip and plastic bolt used to

attach each Base Station to the T-bar ceiling tile grid.

• MCU Mounting Hardware – four #8-3/4” panhead wood screws and star

washers, used to mount the MCU to the wall.

• ESD Bonding Straps - to provide static protection for the MCU.

• Link Wireless Telephones – The correct number of Wireless Telephones

Page 18 08/11/99

Page 29

SpectraLink Corporation Link 150 M2 Installation and Operation

(PTB400 or PTB410) for this installation.

• Battery Chargers – The Wireless Telephone has two different battery

charging options, the trickle charger (PTC300) or the quick charger (PTQ360).

Either or both may be present, depending on which option your site will use.

• Batteries – The system may have one or more batteries per Wireless

Telephone, depending on the needs at your location (PTS330 NiCAD or

PTS360 NiMH).

• Documentation and Training Information – This includes a Link Wireless

Telephone User Guide for each telephone.

5.3 Install MCUs

5.3.1 Mount MCUs to Wall

The MCUs are designed to be mounted on a backboard of ¾ inch plywood, securely

fastened to the wall. Mount the MCUs vertically, side by side, using 2.75 inch spacing

center-to-center for each unit. Do not stack MCUs on top of one another.

To mount the MCUs:

1. Using a 1/8” drill bit, drill four pilot holes, on 2 inch by 12.1 inch centers.

2. In each pilot hole, sandwich a star washer between the ESD bonding strap and the

backboard, then insert the screw (#8 panhead wood screw, 3/4 inch long) and

tighten it, leaving approximately 1/8 to ¼ inch gap from the wall.

3. Slide the MCU over the screws until it drops in place.

4. Tighten screws fully.

5. When installing an SCA-408 or SCA-416, the grounding terminal in the rear

panel of each unit must be electrically connected to earth ground. Consult the

NEC and local codes for instructions on making the connection to the ground.

5.3.2 Connect MCU to Demarc Blocks

Connect the male RJ-21 connector from the appropriate demarcation block to the

designated RJ-21 connector (A or B) on each MCU. Secure the cables using the keeper.

08/11/99 Page 19

Page 30

SpectraLink Corporation Link 150 M2 Installation and Operation

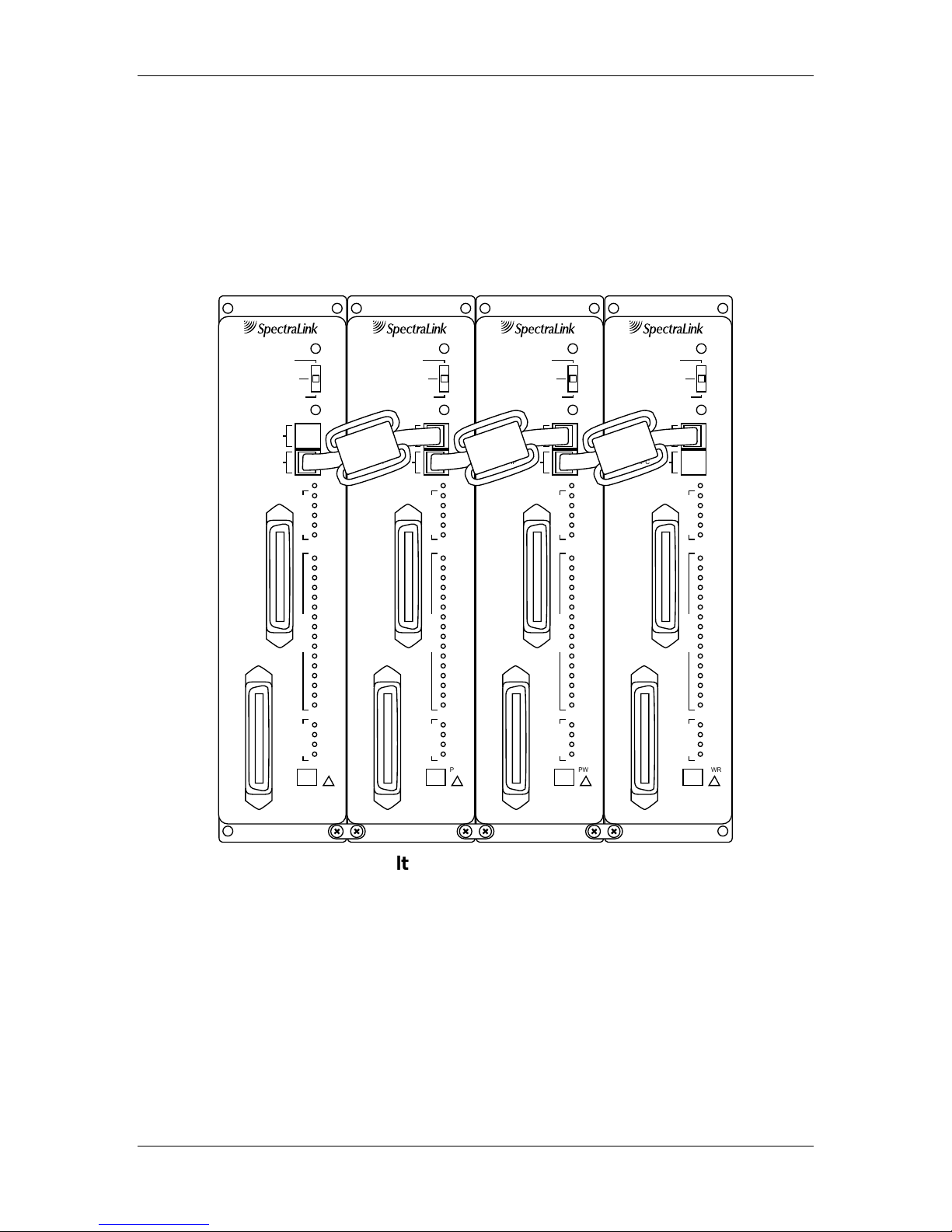

5.3.3 Connect Multi-Unit Systems

Use the following procedure to connect multiple MCUs.

1. Mount the MCUs side by side.

2. Connect the IPC cable from the OUT Port of the first unit to the IN Port of the

adjacent unit. Repeat until all units are connected, as shown in the following

illustration.

S

DEL / ENTER

IPC IN

IPC OUT

CONN

B

CONN

A

STEP

ADMIN

NORMAL

REGISTER

S

STEP

ADMIN

NORMAL

REGISTER

DEL / ENTER

IPC IN

IPC OUT

PWR

CONN

B

CONN

A

!

S

T

A

T

U

S

L

I

N

E

S

S

B

T

A

N

S

S

E

PWR

S

T

A

T

U

S

L

I

N

E

S

S

B

T

A

N

S

S

E

!

S

DEL / ENTER

IPC IN

IPC OUT

CONN

B

CONN

A

STEP

ADMIN

NORMAL

REGISTER

S

STEP

ADMIN

NORMAL

REGISTER

DEL / ENTER

IPC IN

IPC OUT

PWR

CONN

B

CONN

A

!

S

T

A

T

U

S

L

I

N

E

S

S

B

T

A

N

S

S

E

PWR

!

S

T

A

T

U

S

L

I

N

E

S

S

B

T

A

N

S

S

E

No IPC cable is connected to the IN Port of the first unit. An Open

Applications Interface (OAI) Gateway may be connected to the out port of

the last unit.

Page 20 08/11/99

Multi-Unit Link 150 WTS

Page 31

SpectraLink Corporation Link 150 M2 Installation and Operation

5.3.4 Connect Power

1. Connect the power plug from the AC adapter to the jack labeled PWR on the

MCU.

Use only the provided Class II AC Adapter

with output 24VDC, 1A.

For installations with more than one MCU, use an outlet strip with a built in

2. Plug the AC adapter into a 110VAC outlet or switch on the outlet strip to apply

3. The Status LEDs will cycle through diagnostic testing. When the system is ready

power switch. This allows the MCUs to be turned on and off together.

power to the MCU.

for use, the error LED should be off, and the LED for the MCU Number (1-4) will

be lit. If the LED for the box ID does not light, or if a box ID is duplicated, there

is most likely a problem with the IPC cabling.

4. If the system displays an error refer to Troubleshoot Error Codes.

08/11/99 Page 21

Page 32

SpectraLink Corporation Link 150 M2 Installation and Operation

5.4 Install Base Stations

Be sure the Base Station is positioned clear of anything that might damage it. The Base

Station should be well above head height, away from doors and other objects that might

strike it, and away from areas open to the elements or possible water leaks.

Check your location for other radio antenna devices and place the Base Stations to avoid

interference. Leave enough slack wire (approximately 25 feet) to account for possible

future Base Station moves.

5.4.1 Mount Base Stations on Dropped Tile Ceilings

A ceiling clip and plastic bolt are supplied to install Base Stations on the drop ceiling

rails (T-bars) used to support acoustical tile. The plastic bolt screws into the top of the

Base Station, then snaps into the ceiling clip which has been attached to the rails that hold

the acoustical tile. The fastener is designed for use on 15/16" wide rails.

1. Attach the metal fastener to the rail (T-bar) supporting the dropped ceiling by

rotating it into position until it snaps into the locked position.

2. Screw the plastic bolt to the 1/4 x 20 captive nut into the top of the Base Station.

3. Slide the bolt into the exposed prongs of the metal clip until it snaps into position.

When properly attached the Base Station should sit almost flush against the

ceiling and be tightly attached to the clip and T-bar grid work.

4. Once the Base Station is anchored to the fastener, lift the acoustical tile and plug

the RJ-45 8-pin modular plug into the connector on the top of the Base Station.

− The LED will blink red and green as the system software downloads to the

Base Station and the Base Station is tested.

− When the LED blinks amber, the system is ready for operation.

− When the LED blinks green, a telephone has established a radio link with that

Base Station.

− If the LED turns solid red, there should be an error message on the MCU's

status LEDs. Refer to Troubleshoot Error Codes.

Page 22 08/11/99

Page 33

SpectraLink Corporation Link 150 M2 Installation and Operation

5.4.2 Mount Base Stations On Finished Ceilings

If your site does not have a dropped tile ceiling, the Base Station can be mounted to a

finished ceiling or wall with a 4-5" long 1/4" –20 TPI plastic or nylon screw or bolt (such

as a lag screw).

The customer's wire contractor is responsible for this installation.

1. Drill two holes approximately one inch apart. Make the holes large enough to

accommodate the RJ-45 connector and a bolt to secure the Base Station.

2. Insert a wide washer above the ceiling, then screw the bolt into the beam or

ceiling.

3. Insert three nuts on the bolt, then screw the Base Station into the bolt, being

careful not to insert the bolt more than 1/3 inch, five full turns, into the Base

Station.

If the ceiling is open with I-beams or pipe construction, mount the Base Station with Ibeam clamps or pipe clamps.

08/11/99 Page 23

Page 34

SpectraLink Corporation Link 150 M2 Installation and Operation

5.5 Install Outdoor Base Stations

Outdoor Base Stations are equipped with a protective enclosure, designed to be mounted to

a wall or pole. After the enclosure is mounted, the Base Station is inserted in the enclosure

and connected.

Only RCO Base Stations can be used outdoors.

The customer's wire contractor is responsible for wiring and mounting the outdoor Base

Station enclosure. The contractor is responsible for supplying screws, brackets, and other

appropriate hardware.

5.5.1 Wire and Connect Outdoor Base Stations

If the wiring for a Base Station exits a building—whether to reach an

outdoor Base Station location or to reach a Base Station in another

building—it should be equipped with primary protection according to

the National Electric Code (NEC) and/or local codes.

Wiring that exits the building must also be fuse protected at both ends.

For example, use a Quick Clip Fuse from Illinois Tool Works, Linx

Division, model number SCP-2X2. Insert the Quick Clip fuses in

place of bridging clips on a 66 Block for the non-internal Base Station

circuits.

1. Mount the outdoor Base Station enclosure to a wall or pole. The enclosure should

be attached at the highest point available that will provide central coverage for the

outdoor area.

2. Insert the Base Station cable through the compression fitting and tighten the

fitting.

3. Wire the Base Station connector just as you wired the RJ-45 connectors for the

indoor Base Stations.

4. Place the Base Station inside the enclosure with the part number label facing the

back of the enclosure.

5. Screw the protective cover onto the Base Station enclosure.

Page 24 08/11/99

Page 35

SpectraLink Corporation Link 150 M2 Installation and Operation

6. Connect and Register Wireless Telephones

6.1 Set Up Diagnostic Modem

Each MCU has an internal modem feature that allows SpectraLink technicians to dial into

the system for troubleshooting and maintenance. The modem is enabled on Line 1 when

no Wireless Telephone is registered to Line 1. When enabled, the modem will

autoanswer an incoming call to that line.

This internal modem uses proprietary communication software. You cannot

To set up the diagnostic modem:

1. Connect an analog Direct Inward Dial (DID) line to Analog Interface MCUs

use commercial software packages to access this software. If you have a

multiple MCU system, you only need to enable one modem line, on Line 1 of

MCU 1. Line 1 positions on the other MCUs can be used for Wireless

Telephones.

(SCA-416 or 408) or a digital DID line to Digital Interface MCUs.

2. Move the mode switch to the REGISTER position. The LED for Line 1 should be

off, indicating that no Wireless Telephone is registered to Line 1. If the LED is on

then a Wireless Telephone is registered to the line. Refer to Unregister Wireless

Telephones.

3. Dial the number associated with the DID line. After one or two rings, you should

hear high-pitched modem answer tone.

6.2 Register Wireless Telephones

Before a Wireless Telephone can be used it must be registered to a line on one of the

MCUs. While Wireless Telephones are being registered, the system will continue normal

operation.

Use the Wireless Telephone Planning Worksheet filled out by the system administrator to

be sure you are correctly assigning each Wireless Telephone to its port and extension

number.

All lines are unregistered when shipped from the factory. However, if you are replacing a

failed MCU you may not need to register the Wireless Telephones. Refer to the System

Administration document for details.

Line 1 MCU 1 should be skipped to allow for remote access through the

diagnostic modem.

Each MCU supports eight simultaneous conversations. To optimize

performance and reduce the possibility of call blocking, distribute the

Wireless Telephones evenly across all MCUs.

08/11/99 Page 25

Page 36

SpectraLink Corporation Link 150 M2 Installation and Operation

To register a Wireless Telephone to your system do the following:

1. Be sure all unregistered Wireless Telephones are powered off and that there is a

Base Station plugged in and within range of the Wireless Telephones to be

registered.

2. Move the mode switch to the REGISTER position. (If your system has more than

one MCU, be sure to move the switch only on the correct MCU.) The LED which

indicates the Box ID (1-4) may change. This is normal and is not an error.

The Line Indicator LEDs now show the registration status of each line.

− If the LED is on, a Wireless Telephone is registered to the line.

− If the LED is off, no Wireless Telephone is registered to the line.

3. Press the STEP button until the LED for the line to be registered flashes.

− If the LED is flashing, that line is selected. A flash with the LED mainly off

indicates no Wireless Telephone registered; a flash with the LED mainly on

indicates a Wireless Telephone is registered to the selected line.

− Initially Line 2 will flash. This is because Line 1 is usually set up as the

remote access diagnostic modem. To register a Wireless Telephone to Line 1,

press the STEP button until Line 1 flashes.

− If the desired line already has a Wireless Telephone registered to it, follow the

procedure outlined below to unregister the Wireless Telephone, then return to

this step.

4. Turn on the Wireless Telephone to be registered by holding down the PWR key

until the Wireless Telephone beeps twice. After a few seconds, the line indicator

LED on the MCU will shine solid red. Once the Wireless Telephone is registered,

the LED for the next line begins to flash.

5. To assign the extension number, hold down the FCN key until Volume Level

displays. Press the # >

key (NEXT) until EXTENSION displays on the Wireless

Telephone. Press 0, then enter the correct extension number. Press END when

done.

6. Repeat steps 3-5 for all Wireless Telephones to be registered.

7. When all Wireless Telephones are registered, return the mode switch to the

NORM position.

Page 26 08/11/99

Page 37

SpectraLink Corporation Link 150 M2 Installation and Operation

6.3 Unregister Wireless Telephones

If the desired line already has a Wireless Telephone registered to it, follow this procedure

to unregister the Wireless Telephone.

1. Move the mode switch on the MCU to the

REGISTER position. If your system

has more than one MCU, be sure to move the switch on the correct MCU. The

line indicator LEDs now show which lines have Wireless Telephones registered.

2. Use the

STEP button to select the line to be unregistered. The line indicator LED

for a line that has a Wireless Telephone registered to it will flash with the LED

mainly on.

3. Press the DEL/ENTER button. The line indicator LED for the selected line will be

off with a short on flash.

4. Register the new Wireless Telephone or return the mode switch to the NORM

position.

6.4 Program Wireless Telephone Features

PBX and Key Systems provide users with special features such as hold, transfer,

conference, camp on, and speed dial. These features can be accessed via the Wireless

Telephone, but the telephone system or Link 150 must be programmed to allow access to

these features from the Wireless Telephone. For information on programming the switch

to operate with the Wireless Telephones, refer to Switch Programming – Link 150

Model 2 (PN 72-0060-02).

• If the Link 150 is connected to your telephone system via analog lines, refer to

Programming Analog System Functions (in the Switch Programming document or

Appendix B of this document).

• If your Link 150 is connected to a digital key telephone system or PBX, refer to the

section of the Switch Programming document that deals specifically with your brand

of telephone system.

6.5 Test Wireless Telephones

Verify proper registration and operation of each Wireless Telephone by performing the

following tests.

• Press the START key on each Wireless Telephone. The extension number should

clear and you should hear dial tone. On some digital systems, depending on how the

telephone system is programmed, you may have to select a line to get dial tone.

• Place a call to each Wireless Telephone to verify ring, answer, clear transmit, and

clear receive audio.

• Verify all programmed features on each Wireless Telephone.

• Press the END key. The line indictor should turn off.

08/11/99 Page 27

Page 38

SpectraLink Corporation Link 150 M2 Installation and Operation

7. Site Certification

The installer should not leave the site before contacting SpectraLink to perform

remote install verification.

Contact a SpectraLink engineer on the technical support line 800-775-5330. The hours of

operation are 7:00 a.m. to 6:00 p.m. Mountain Time, Monday through Friday, excluding

holidays.

The engineer will connect with the diagnostic modem, verify calling functions, and listen

while you perform a walk test. The walk test will require you to walk the inside

perimeter of the coverage area. If all Base Stations are running, note any areas with

heavy static or clarity problems and report it to a SpectraLink engineer.

The installation is not complete until these certification steps have been performed.

Do not hand out Wireless Telephones at a site that has not been certified.

Page 28 08/11/99

Page 39

SpectraLink Corporation Link 150 M2 Installation and Operation

8. System Administration

8.1 Troubleshoot Error Codes

When an alarm is detected, the Error LED will light and the MCU’s status LEDs will

display an alarm code.

If the error code refers to a Base Station problem, the Base Station LED will indicate

which Base Station has the problem. If more than one Base Station LED is on, the error

code refers to the lowest numbered Base Station with an error. Use the STEP button to

select another Base Station to display its error code.

Contact SpectraLink Customer Support at (800) 775-5330 (Monday through Friday,

7:00 a.m. to 6:00 p.m. Mountain Time) for additional assistance in troubleshooting your

system.

8.2 Troubleshoot Phone Features

If Wireless Telephone features are not working properly, disconnect the Wireless

Telephone from the MCU and plug a wired telephone into the port. The telephone should

be the same type as the emulated telephone. Refer to the appropriate section of Switch

Programming (72-0060-02) for more details.

Test the features on the wired telephone.

• For analog MCUs, verify that feature access codes and switchhook flash work

correctly.

• For digital MCUs, verify that features are assigned to the correct keys and are

working properly. Refer to the appropriate section of Switch Programming (72-0060-

02) for button mapping information for the brand of telephone system at your

location.

Certain four-wire telephones (such as MERLIN LEGEND) use a different

connector on the phone than on the back of the MCU. Therefore you may

need phone cord or an adapter to perform these tests.

08/11/99 Page 29

Page 40

SpectraLink Corporation Link 150 M2 Installation and Operation

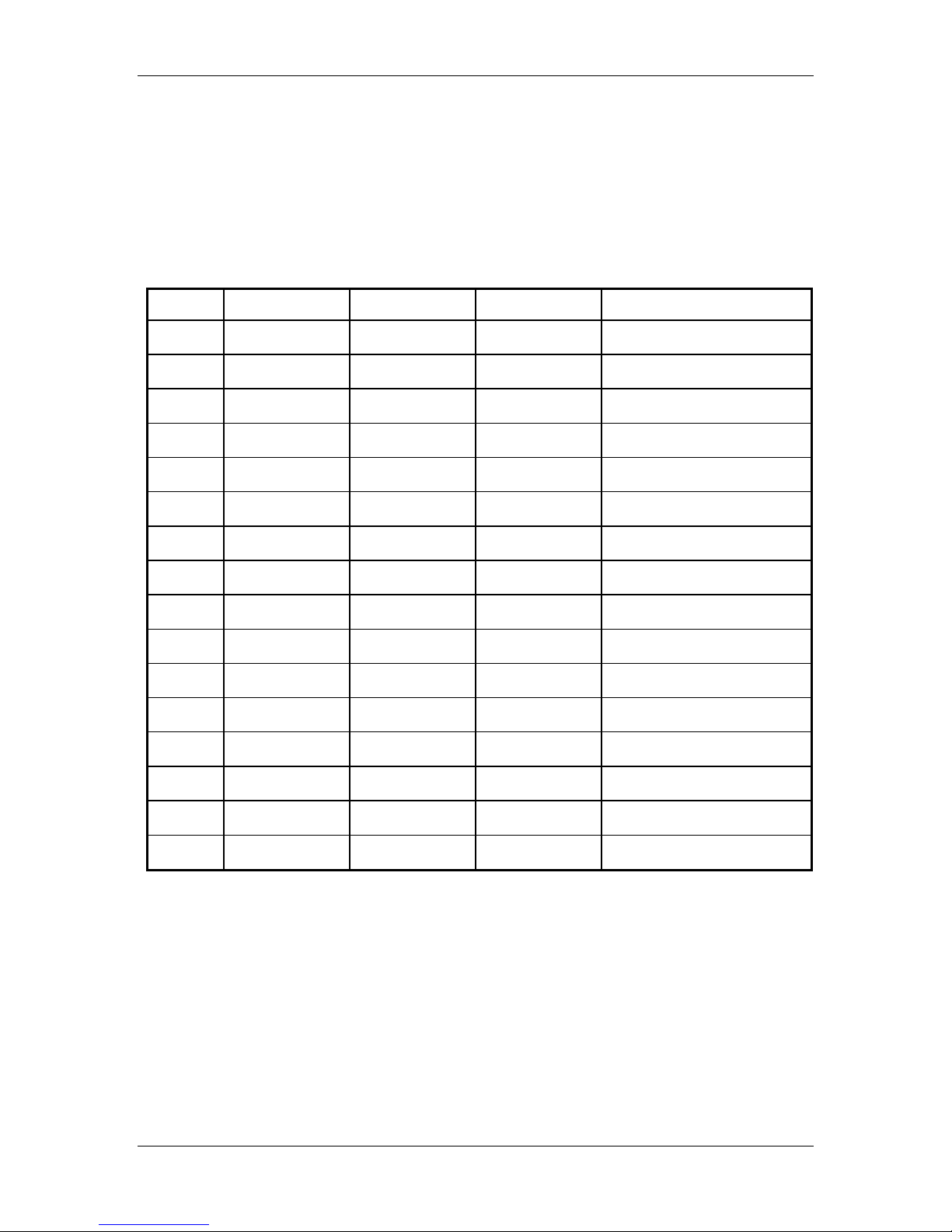

8.3 Status LED Codes

Status

Description Action

LEDs

12345

Random

Cycling

5 Link 150 is initalizing. Code number will change when finished.

1,2,3

or 4

The Link 150 is powering up. Initialization

to follow.

MCU identification number. Indicates normal operation when it is on steady.

If the same LED is lit on more than one

MCU:

If the LED is flashing and the error light is

on:

This is not an error and should change to another

code after a minute.

Check the IPC connections.

There is a problem with the MCU indicated by the

flashing box ID.

The following STATUS LEDs are displayed in combination with the ERROR LED.

Status

LEDs

1,3 A Base Station has reported an internal

problem.

Description Action

Replace the Base Station. In rare cases a problem

with the MCU can cause this error.

2,3 No communication with one or more Base

Stations on this MCU.

1,2,3 Internal communication problem with the

MCU.

4 IPC problem. Check IPC cabling by disconnecting and

Check cabling to verify that the Base Station's

cable is plugge d into and fully seated in the Base

Station port at the back of the MCU and plugged

into the Base Station at the other end.

If the LED on the Base Station is not lit, check for

proper wiring of the 8-pin modular plugs. See

section 4.3.

If the cable is over 600 feet long, verify that the

extra wire pairs have been connected correctly.

If the Base Station LED is flashing red, check for

open or shorts on pins 1 and 2 of the cable.

Verify proper Base Station operation by following

the procedures outlined in Install Base Stations.

Replace the MCU.

reconnecting the MCUs. Connect the Male RJ-21

connector from the appropriate demarcation block

to the designated RJ-21 connector (A or B) on

each MCU. Secure cables using the keeper.

If the error still occurs try using a different IPC

cable. Replace MCU if the problem still occurs.

Page 30 08/11/99

Page 41

SpectraLink Corporation Link 150 M2 Installation and Operation

Status

Description Action

LEDs

1,4 The operator is trying to register a Wireless

Telephone or place an admin call on an

MCU with no phone lines.

2,4 The MCU was powered on with the mode

switch in the wrong position.

3,4 Configurations on a multi-MCU installation

do not match in each of the units.

Most likely to occur when an MCU was just

added to the system.

1,3,4 REGISTER or ADMIN mode selected on

more than one MCU at the same time.

2,3,4 The MCU was powered on with the mode

switch in the wrong position.

Return mode switch to the NORM position.

Turn off the MCU, place the mode switch to the

NORM position and turn back on.

Erase the configuration in the MCU with incorrect

configuration definitions (probably the MCU that

was just added.) To erase the configuration, refer

to Replace an MCU.

Note: Do not erase the configurations in all the

MCUs. In multiple MCU installations the

Wireless Telephone registration information is

shared among the MCUs. This allows you to

replace an MCU without re-registering all the

Wireless Telephones.

Only one mode switch can be in ADMIN or

REGISTER at a time. Check the MCUs and take

one of them out of

REGISTER or ADMIN mode.

Turn off the unit, place the mode switch to the

NORM position and turn back on.

1,2,3,4 Internal problem with the MCU. Contact SpectraLink Customer Service for

technical support.

1,5 The MCU was powered on with the mode

switch in the wrong position.

A possible Base Station failure has been

detected. A Base Station that had

previously been heard by another Base

Turn off the MCU, place the mode switch in the

NORM position and turn back on..

Check to see if the system was powered on with

the switch in the wrong position. If not, contact

SpectraLink Customer Service.

Station can no longer be heard .

5 The MCU was powered on with the mode

switch in the wrong position.

One or more of the Base Stations on this

unit is disabled because it is located too

close to other Base Stations. The error

Turn off the MCU, place the mode switch in the

NORM position and turn back on..

Identify which Base Station has been disabled and

move it away from its nearest neighbor Base

Station

display refers to the LED that is red. If

more than one LED is red, it refers to the

lowest numbered Base Station.

If Mode switch is in ADMIN mode: Adjust the companding mode from Mu law to A

law. Refer to 2. Change Companding.

3,5 The MCUs have inc ompatible versi ons of

software.

Contact SpectraLink Customer Service for

technical support.

08/11/99 Page 31

Page 42

SpectraLink Corporation Link 150 M2 Installation and Operation

8.3.1 Wireless Telephone Status Indi cator Messages

Indicator Description Action

BATT Displays when user is on the

Wireless Telephone and the

battery charge is low. The user

has two minutes to complete the

call.

BATTERY LOW Displays when user is not on the

Wireless Telephone and battery

charge is low. The Wireless

Telephone will ring to alert user

to this condition. The Wireless

Telephone will not work until the

battery is replaced.

INTERNAL ERROR Communications error between

the Wireless Telephone and the

MCU.

NO PBX There is no telephone system port

connected to the port associated

with this Wireless Telephone, or

the telephone system has not yet

synchronized the port.

PT

UNREGISTERED

The Wireless Telephone is not yet

registered to an MCU.

Replace the battery with a charged battery.

Replace the battery with a charged battery.

Have the user turn the Wireless Telephone

off, then on again. If the error persists try

registering another Wireless Telephone to

this port. If the problem persists, contact

technical support.

This message should disappear when the

telephone system ports are wired and

programmed correctly.

Register the Wireless Telephone.

Page 32 08/11/99

Page 43

SpectraLink Corporation Link 150 M2 Installation and Operation

8.4 Replace a Wireless Telephone

If a Wireless Telephone breaks or needs to be replaced, the old Wireless Telephone must

be deleted and the new Wireless Telephone added.

8.4.1 Delete Old Wireless Tel ephone

1. Make sure all unregistered Wireless Telephones are OFF. If this is not done an

unregistered Wireless Telephone may unintentionally register to an available line.

2. Move the mode switch to the REGISTER position on the MCU.

3. Press the STEP button until the LED for the line to be deleted is flashing red.

4. Press the

DEL/ENTER button.

You can now register a new Wireless Telephone or return the mode switch to the

position.

8.4.2 Register New Wireless Telephone

1. Make sure all unregistered Wireless Telephones are OFF.

2. Move the mode switch to the REGISTER position.

3. Press the STEP button until the desired line to be registered is flashing red. Only

unregistered lines can be registered.

4. Press PWR on the Wireless Telephone that needs to be registered. The LED

should change to mostly on once the phone is registered.

5. Wait at least 3 seconds and then press END.

6. Return the mode switch to the NORM position.

7. To assign the extension number, hold down the FCN key until Volume Level

displays. Press the

Telephone. Press 0, then enter the correct extension number.

8. When the Wireless Telephone is turned ON, the extension will be displayed. Test

the Wireless Telephone by placing a call to each Wireless Telephone to verify that

the correct Wireless Telephone rings.

# > key (NEXT) until EXTENSION displays on the Wireless

NORM

08/11/99 Page 33

Page 44

SpectraLink Corporation Link 150 M2 Installation and Operation

8.5 Replace an MCU

When the system has more than one MCU, each MCU contains a complete set of

configuration information for the entire system. This includes Wireless Telephone

registration information, function definitions, and frequency sequence selection.

This Configuration Sharing feature allows a failed MCU in a multi-unit installation to be

replaced without having to register the Wireless Telephones again.

To replace a failed MCU, first clear the configuration information on the replacement

MCU, then replace the failed MCU.

8.5.1 Clear Configuration on Replacement MCU

1. Remove power from the replacement MCU. There should be no IPC cables

connected to the IPC ports.

2. Slide the mode switch on the Replacement MCU to the ADMIN position.

3. Apply power.

4. Press the STEP button until the status LEDs light 2,3, and 4 of the Replacement

MCU.

5. Press the DEL/ENTER button.

6. Remove power from the unit.

7. Slide the mode switch to the NORM position.

8.5.2 Connect the Replacement MCU

1. Remove the failed MCU from the IPC chain

2. Connect the replacement MCU in the position vacated by the failed MCU.

3. Reconnect the IPC cables for the chain. Double-check that the IN and OUT ports

are correctly connected.

4. Apply power to the MCU.

− After a few moments each MCU in the chain should have a unique box ID

number (1-4), shown on the status LEDs. If this is not the case, recheck the

IPC wiring.

− If the replacement MCU has status LED 3 and 4 lit, the configuration data has

not been successfully shared. Most likely, the replacement MCU was

powered up before it was correctly attached to the IPC chain. Repeat the

entire replacement procedure.

Page 34 08/11/99

Page 45

SpectraLink Corporation Link 150 M2 Installation and Operation

8.6 Replace a Base Station

To replace a Base Station, unplug the existing Base Station and plug in the new Base

Station.

• The LED will blink red and green as the system software downloads to the Base

Station and the Base Station is tested.

• When the LED blinks amber, the system is ready for operation.

• When the LED blinks green, a Wireless Telephone has established a radio link with

that Base Station.

• If the LED turns solid red, there should be an error message on the MCU's status

LEDs and the MCU Error LED should be lit.

08/11/99 Page 35

Page 46

SpectraLink Corporation Link 150 M2 Installation and Operation

Appendices

Page 36 08/11/99

Page 47

SpectraLink Corporation Link 150 M2 Installation and Operation

A. Technical Parameters

1. Select Alternate Spread Spectrum Sequence

The SpectraLink system uses spread spectrum radio transmission. Spread spectrum takes

a discrete signal, such as a digitized voice conversation, and spreads it over a wide range

of frequencies rather than transmitting at a single carrier frequency. The frequency range

may need to be adjusted if other wireless devices in your facility, such as data terminals

or bar code readers, share the same frequency band.

Units shipped from the factory are preset to operate on sequence 1, which spans the entire

spectrum from 902MHz to 928MHz. If interference between the SpectraLink system and

other 900MHz radio devices is anticipated or observed, any one of six alternate sequences

can be selected.

Determine the frequency band of the interfering device, then use the frequency ranges

below (given in MHz) to select the best interference avoidance pattern for the situation.

Sequence Frequencies Used by SpectraLink

1 902-928

2 902-915

3 902-909 & 921-928

4 914-928

5 902-904 & 909-921

6 904-910 & 920-928

7 908-922

To change a system to an alternate sequence, perform the following steps for EACH

MCU.

1. Wait for any calls in progress to end. Remove power from the MCU, then slide

the mode switch to the

REGISTER position.

2. Apply power. Status LEDs 5 and 2 should be lit, indicating frequency selection

mode. One of the line LEDs from 1 to 7 will be indicating the current frequency

selected for the MCU.

3. Use the STEP button to select the desired new sequence.

4. Press the

DEL/ENTER button. The LED indicates the new frequency that has

been selected.

5. Return the mode switch to the NORM position.

6. Repeat Steps 1-5 for each MCU of a multi-unit installation.

08/11/99 Page 37

Page 48

SpectraLink Corporation Link 150 M2 Installation and Operation

2. Change Companding

The factory setting on the Link 150 Model 2 is compatible with Mu-law companding

(signal compression), which is the standard used by most PBXs in North America.

Systems outside North America generally use A-law companding. If the PBX

companding is incompatible with the MCU's, the Wireless Telephones will have distorted

or hissing dial tone and voice will be unintelligible.

• Before you begin, if the system has more than one MCU, erase the

configurations from all MCUs except MCU 1. Refer to Replace an MCU for

instructions.

To change the default from Mu- to A-law on the Link 150 follow these steps.

1. Power the system OFF.

2. Slide the mode switch on the first MCU to the

ADMIN position.

3. Power the system ON.

4. Press the

STEP button until status LEDs 1, 2, and 5 are lit.

5. If the LED for LINE 1 is lit, the system is set for Mu-law.

If the LED for LINE 2 is lit, the system is set for A-law.

6. Press the DEL/ENTER button to toggle between Mu-law and A-law.

7. When the correct LINE LED is lit, return the mode switch to the NORM position.

Page 38 08/11/99

Page 49

SpectraLink Corporation Link 150 M2 Installation and Operation

B. Program Analog Features

1. Defining Macros

On an analog telephone system, telephone system features such as transfer, hold, or speed

dial are usually accessed via key presses or hook flashes. The Link Wireless System

allows these features to be customized using system macros. These features can then be

accessed from all Wireless Telephones by pressing FCN followed by a digit. The macro

definitions are the same for all Wireless Telephones in the system.

For example, suppose your telephone system uses

Link Wireless System, you can assign the transfer function to

Telephone user presses FCN followed by 2, the telephone system will enter the transfer

function. Using macros instead of complicated key presses makes it easier for users to

remember and access features.

Do not program analog features on a digital system.

Macro definitions are made up of combinations of the following characters:

0 to 9 The phone keys numbered 0 to 9

# The phone # key

* The phone * key

FFlash

S Pause 65 milliseconds

The Link Wireless System will accept programming for eleven functions. The maximum

number of key entries for each function is 20.

FLASH * 7 to transfer a call. On the

FCN 2. When the Wireless

Open Application Interface

For digital and analog systems with Open Application Interface (OAI) software, the user

may press FCN key sequences to access certain applications. Macro assignments are also

used to assign a function key to initiate an OAI application.

2. Plan Programming

Before programming the features, review the manual for your telephone system to

determine what keystrokes are used to access the desired functions. Then determine