ProTone

MIDI Analog Synthesizer

Service Manual

Copyright © 1996-2001 by Spectral Audio, Switzerland

CAUTION!

All instructions in this manual must be carried out by a professional who observes the valid safety

regulations. In operation, they have got dangerous voltages in the instrument. Spectral Audio

GmbH accepts no liability for personal injur y or m aterial damage.

Service Manual ProTone Page 1 of 20 © 1996-2001 Spectral Audio

1 Description of the Operating Elements 3

1.1 Sockets on the Rear of the Housing 3

1.2 Front Panel Controls 4

2 Functional Description 5

3 History of Series 7

4 Improvements and explanations 7

4.1 Sense of R174 and R175 7

4.2 Sense of C63 – C65 7

4.3 Sense of R174 and R175 8

4.4 Hum Problems 8

4.5 Increasing the Gate voltage to +12V 8

5 Adjustment of the ProTone 9

5.1 Digital PCB (MIDI to CV converter) 9

5.2 Analog PCB (VCO1 and VCO 2) 9

5.2.1 VCO1 9

5.2.2 VCO2 9

6 Digital PCB 11

6.1 Assembly plan 11

6.2 Part list 11

7 Analog PCB 13

7.1 Assembly plan 13

7.2 Part list 15

8 Mechanical part list 20

Service Manual ProTone Page 2 of 20 © 1996-2001 Spectral Audio

1 Description of the Operating Elements

Warning : Shock Hazard - do not open!

Vorsicht : Lebensgefahr - nicht öffnen!

Avis : Risque de choc Electrique - ne pas ouvrir!

230 V~

max. 500mAT

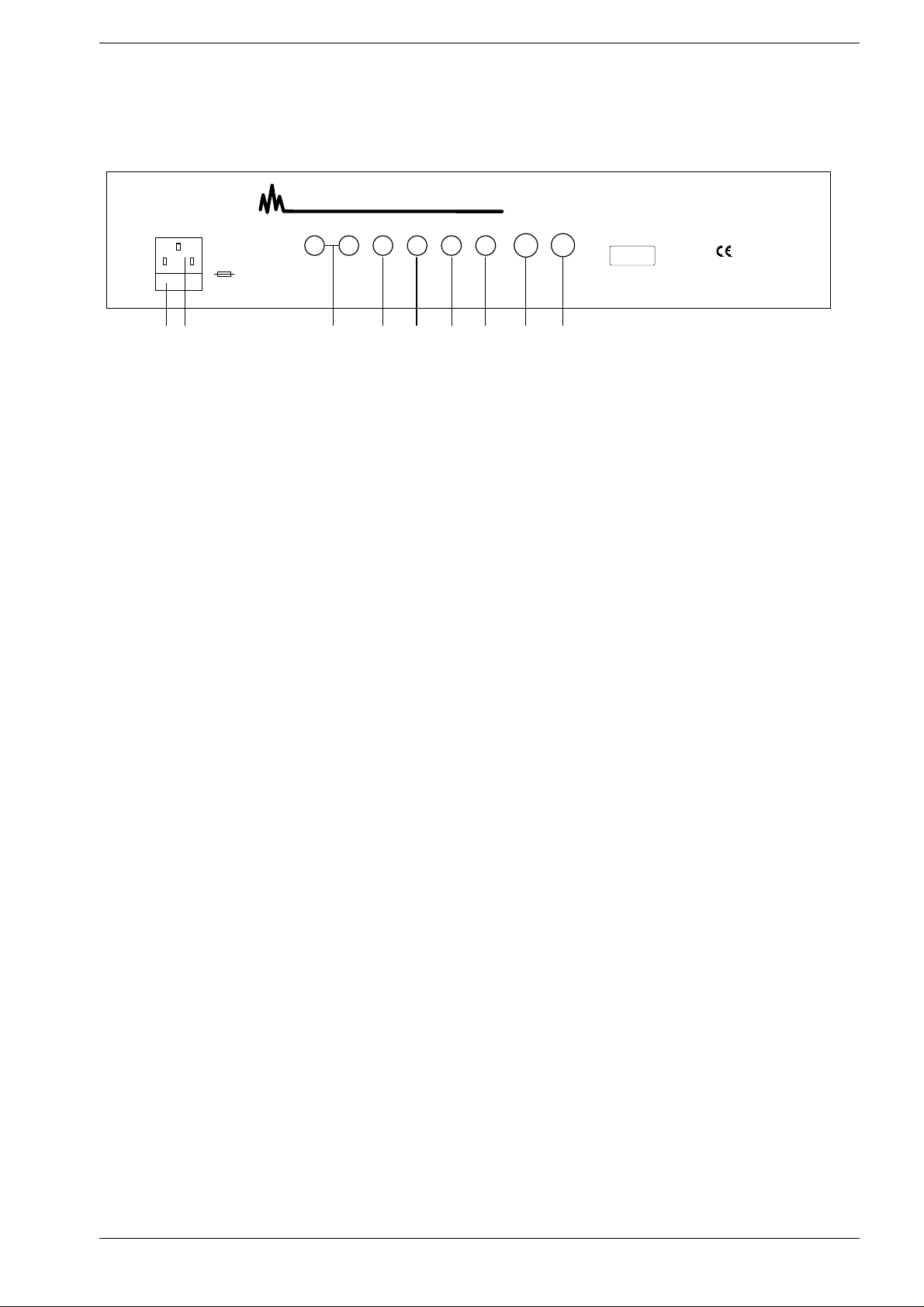

37 36 38 39 40 41 42 43 44

SPECTRAL AUDIO GmbH

Out

Out

Right

Left

Extern

Extern

VCO

LFO

Input

Input

0.7 Veff 0.7 Veff

Gate CV

5V:On

1V/Oct

0V:Off

MIDI

Thru

ProTone

MIDI

IN

Serial No.

Made in Switzerland

1.1 Sockets on the Rear of the Housing

36. Power socket

37. Fuse compartment, fuse max. 500 mA, 250V type

38. Audio outputs right / left

39. External VCO input, switched on with switch (7)

40. External modulation input, selected with selector switch (22)

41. Gate input/output (dependent on the jumper setting inside the unit, standard setting: output)

42. CV input / output (dependent on the jumper setting inside the unit, standard setting: output)

43. MIDI Thru socket

44. MIDI IN socket

Service Manual ProTone Page 3 of 20 © 1996-2001 Spectral Audio

12 3

VCO 1

0

6

1

1

2

3

4

5

6

-

TUNE PW

6

5

4

3

2

1

0

SLIDE

4567

7

5

2

8

4

9

3

3

NOISE

4

2

10

5

1

11

0

12

6

+

VCO 2

0

1

1

7

8

2

2

9

3

3

10

4

4

11

5

5

12

SYNC

6

6

-

+

TUNE

3

2

1

3

2

1

EXT

3

2

1

89 11

6

5

7

8

4

9

10

11

0

VOL VCO 1

4

0

RINGMOD

4

0

VOL VCO 2

3

12

2

1

6

7

5

8

9

10

11

12

6

3

5

7

8

2

9

1

10

11

12

12 13 18 19

FILTER

6

6

7

5

4

0

CUTOFF RESONANZ

6

5

4

0

ACCENT

1410

7

5

8

9

10

11

12

7

8

9

10

11

12

ON

15 16 17 25 26 27

HIGHPASS

8

4

9

3

2

10

1

11

LOWPASS

0

12

KEY-

12 dB

FOLLOW

24 dB

20

SPECTRAL AUDIO

LFO

6

7

5

MIDDLE

LOW

RANGE

4

3

2

1

0

8

4

9

3

HIGH

2

10

1

11

0

12

FREQUENCY

6

5

7

8

4

9

3

10

2

11

1

0

12

DECAYATTACK SUSTAIN RELEASE

21 22 23 24

ProTone

RANDOM

NOISE

6

7

5

8

4

EXT.

3

2

1

0

WAVE

6

5

7

5

8

4

9

3

10

2

11

1

0

12

12

MODULATION

6

6

7

5

8

4

9

3

10

2

11

1

0

12

28 29 313032

MIDI ANALOG SYNTHESIZER

VCO 1

CUT

OFF

VCO 2

9

10

11

7

8

12

9

10

11

PW 1

LFO ON ...

5

4

3

2

1

0

ENV MOD

PAN

6

7

8

9

10

11

12

6

5

4

3

2

1

0

GROUND-

LEVEL

C

1

2

3

4

5

L

PAN

33

34 35

1

7

8

0

9

10

POWER

11

12

GATE /

LEARN

1

2

LEARN

3

4

5

R

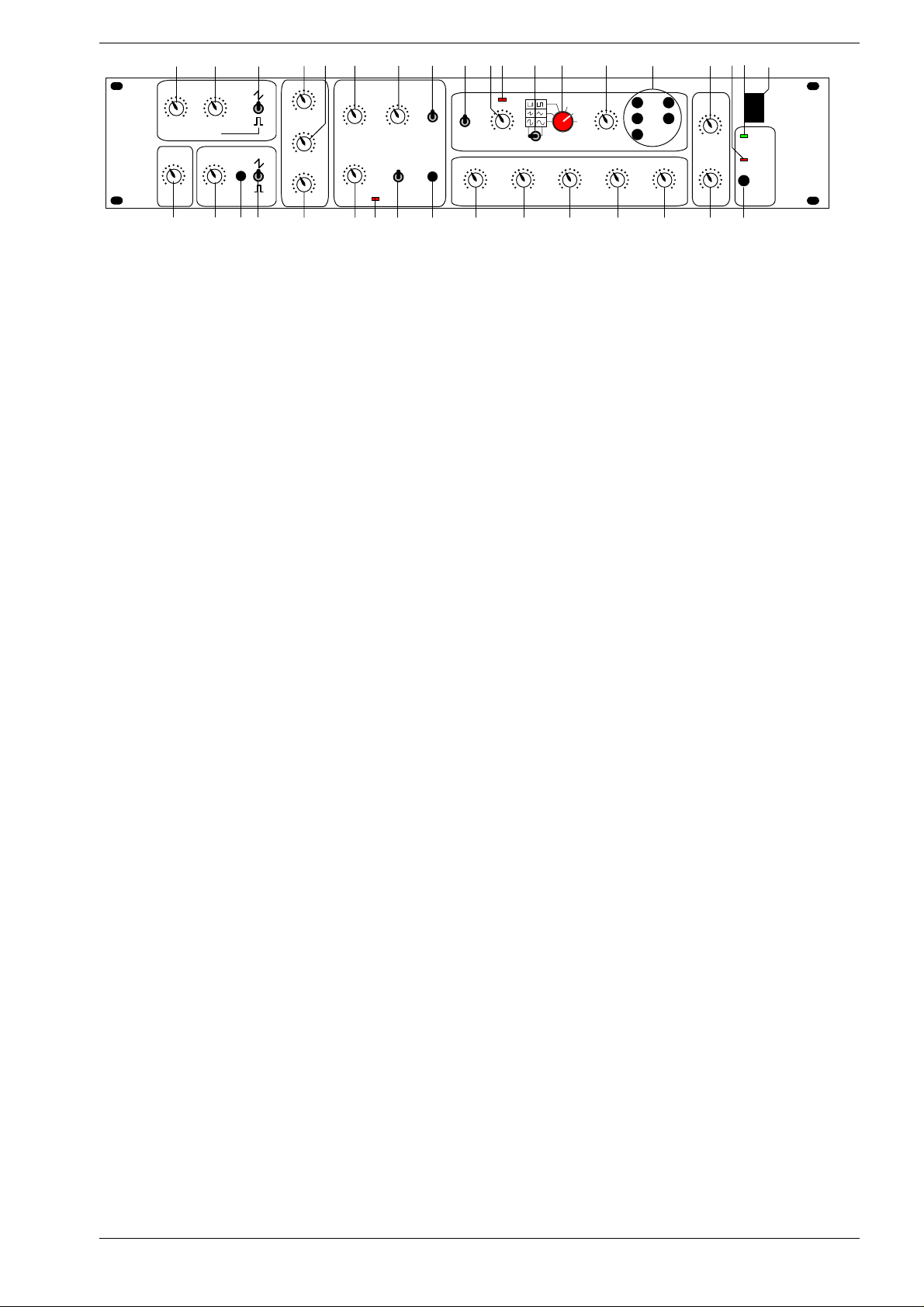

1.2 Front Panel Controls

VCO 1:

1. TUNE: Regulates the pitch of the VCO 1

2. PW: Pulse width of the rectangular pulse

3. Changeover between the signal types saw tooth, noise and rectangle

4. SLIDE: regulates the time balance of VCO 1 and VCO 2

VCO 2:

5. TUNE: Regulates the pitch of the VCO 2

6. SYNC: Synchronises VCO 2 with VCO 1

7. Changeover between the signal types saw tooth, external (input on rear of housing) and rectangle

Mixer:

8. VOL VCO 1: Volume of VCO 1

9. RINGMOD: Volume of the ring modulation of VCO1 and VCO2

10. VOL VCO 2: Volume of VCO 2

VCF:

11. CUTOFF: Cut-off frequency of the filter

12. RESONANCE: increases the harmonics at the cut-off point

13. Changeover between lowpass and highpass

14. ACCENT: Pulsed increase of the cut-off frequency and the volume

15. ACCENT ON Indicator: Lights when the accent function is switched on (MIDI Controller 65)

16. Determines the edge steepness of the filter: 12 or 24dB / octave

17. KEYFOLLOW: The cut-off frequency is influenced by the actual note

LFO:

18. RANGE: Changeover between three LFO frequency ranges

19. FREQUENCY: Setting the LFO frequency

20. LFO Indicator: Indicates each positive half wave of the LFO.

Note:

The eye recognises frequencies larger than 60 Hz as being static.

21. Changeover between symmetrical and asymmetrical LFO waveforms

22. Selector s witch for different LF O waveforms. By means of the m atrix presentation, there are a total of 9

signal forms available: sinus , asymm etric al sinus, triangle, s aw tooth, rectangle, pulse, r andom , noise and

external (input on the rear of the housing)

23. MODULATION: Determines the strength of the LFO influence

24. LFO ON..: LFO assignment possibilities: VCO 1, VCO 2, PW 1, cut-off, pan (any combination possible)

Envelope:

25. ATTACK: Rise time

26. DECAY: Decay time

27. SUSTAIN: Hold level

28. RELEASE: Release time

29. ENV MOD: Influences the cut-off frequency with the envelope

Stereo VCA:

30. GROUNDLEVEL: Ground level of the unit. This also includes the volume increase influenced by the

accent.

31. PAN: Regulates the relationship of the volume from the left and right-hand channel

Various:

32. LEARN Key; Switches the ProTone to the learn mode

33. GATE / LEARN indicator

34. Switch-on indicator

35. Main switch

Service Manual ProTone Page 4 of 20 © 1996-2001 Spectral Audio

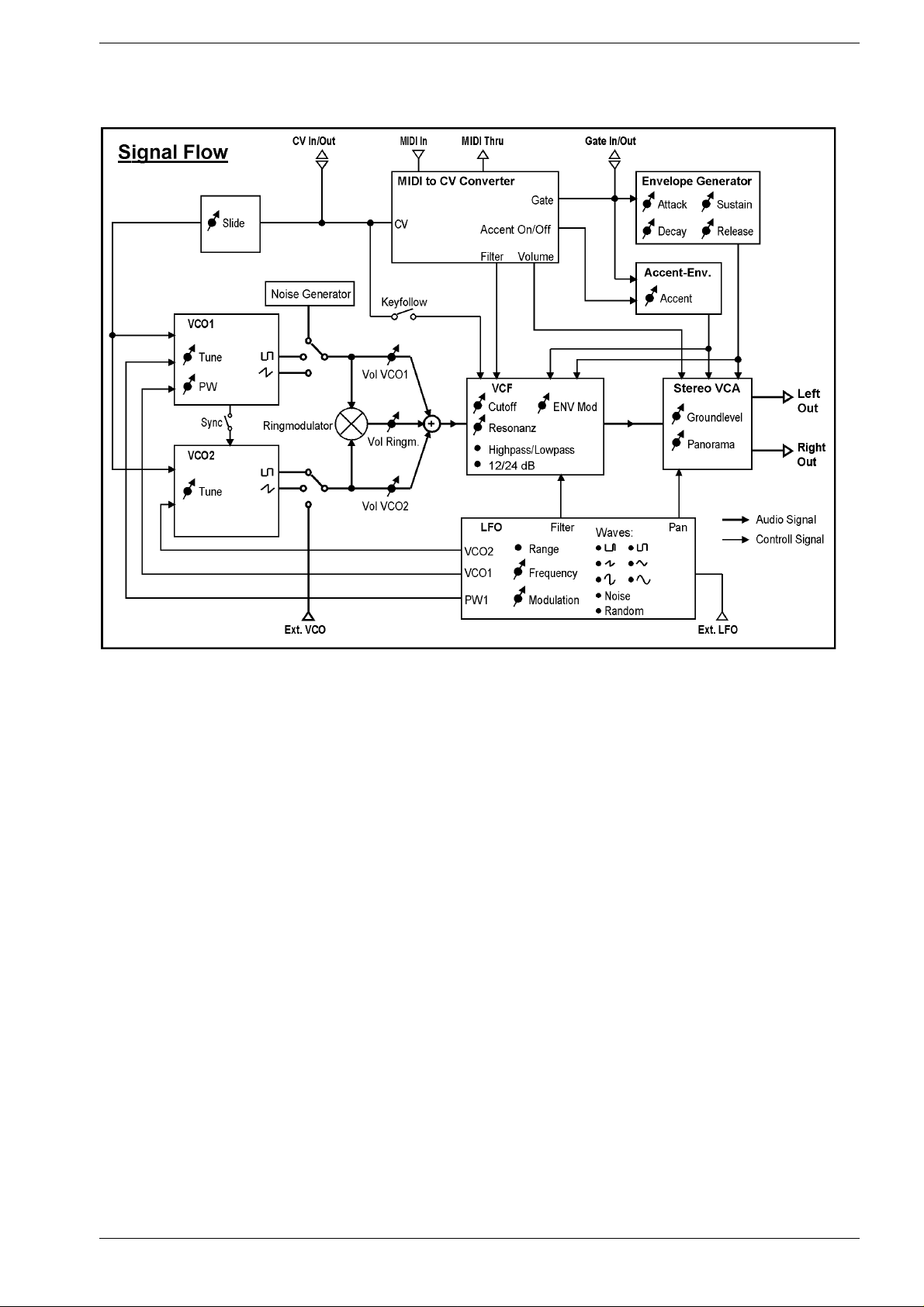

2

Functional Description

The basic principle of the ProT one c orres ponds to the tried and test ed analog synthesizer principle with VCO,

VCF, VCA, envelope generator and LFO. This principle is called subtractive synthesis.

In order that the Pr oTone is suitable for MIDI, an additional MIDI to CV conver ter is necess ary which converts

the MIDI signals into analog signals with which the VCOs, the filter, as well as the envelope generator are

controlled.

The raw material for the s ound is of f er ed by the VCOs (V

or rectangular signal as well as the noise generator (f or effects such as wind and thunder sounds) . The width

of the rectangular signal from VCO1 can be changed with the PW regulator (2). The narrower the rectangular

signal (regulator turned to the right), the 's harper ' the sound. VCO 2 is synchronised f rom VCO1 with the SYNC

switch (6). The tone will be interesting in this case when the TUNE regulator (5) of VCO2 is turned (or by

modulating with the LFO VCO 2), which results in a typical "Sync-Sound".

By means of the external VCO input, other sounds can also serve as raw material. The ring modulator

multiplies the signals of the two VCOs which markedly amplifies the beat (frequency difference).

Note:

When the SYNC switch (6) is switched on, no beats are developed and the ring modulator has

therefore no effect.

The SLIDE regulator (4) determines the time balance from one note to another and is valid for both VCOs.

Afterwards, the signal flows through the voltage controlled f ilter (VCF=V

certain frequency ranges are suppress ed. The lowpass filter allows low frequencies to pass and suppr esses

the high ones, the highpass filter lets high fr equencies through and suppresses the low ones. The frequency

from which the signals are s uppr ess ed is c alled the limit or cut-off f r equenc y. With the ProTone, this is formed

from various sources:

oltage Controlled Oscillator) in the for m of a sawtooth

oltage Controlled Filter), within which

1. CUTOFF frequency regulator (11)

2. ENV MOD regulator (29) (influence of the envelope on the cut-off frequency)

3. LFO

4. ACCENT regulator (14)

5. KEYFOLLOW switch (17).

With the KEYFOLLOW s witch (17), the cut- off fr equency increases on higher notes so that audible f requency

bands always remain the same. The res onance forms a feedback of the output to the input of the filter and

causes an amplification of the frequencies around the cut-off frequency.

The ACCENT regulator (14) s ets the s har e of the s econd envelope and affects the cut-off frequency as well as

the volume. It is only active when the ACCENT indicator ( 15) lights, i.e., when the accent function is switched

on via the MIDI controller 65. The accent f unction is always active when the unit is switched on. By means of

the MIDI controller 65, it is now possible, as with the TB 303, to give individual notes an accent (value 127) or

to take an accent away (value 0). For this purpose, the corresponding control value must be sent in the

sequencer, timed either before or with the note.

Before the signal leaves the ProTone, it arr ives at the VCA (V

the ProTone in stereo form. Here the input signal is multiplied with a contr ol signal. In this way, the volume can

be influenced by a control signal which comes from the envelope generator and the MIDI converter. The

volume of the ProT one is c ontrolled with the GRO UND LEVEL regulator ( 30) as well as via the MIDI c ontroller

EXT (7). Additional to this level is the s hort-ter m increas e through the acc ent func tion. The panor am a (volum e

relationship of the left-hand to the right-hand signal) can be set with the PAN regulator (31).

The LFO is particularly developed with the ProTone. Using its signal, the pitch from VCO1 and VCO2, the

pulse width of the rectangular signal from VCO1, the cut-off frequency of the filter as well as the panorama can

be modulated with the LFO ON ... switches (24).

oltage Controlled Amplifier) which is available in

With switches (21) and (22) select ion can be m ade between 9 diff erent signal f orm s. By means of the external

LFO input on the rear of the housing, it is also pos sible to use any other signal for modulation. To do this,

switch (22) m ust be turned completely to the right. A microphone, etc , must be connected via a pre-am plifier

as this is a high level input. When the external inputs of the ProTone are used, the ProTone must

simultaneously receive a note command (the same MIDI channel) in order that something is audible.

The envelope generator determines the chronological sequence of the volume after receiving a note

command. The MIDI to CV converter then gives out a gate signal (+5V) with which the sequence of the

envelope generator begins. The gate signal rem ains at +5V until the 'note off ' com m and com es, i.e., the key is

Service Manual ProTone Page 5 of 20 © 1996-2001 Spectral Audio

released. The parameter s of the envelope can be set with regulators (25) to (28) . How the envelope should be

imagined is described later on in the glossary.

Service Manual ProTone Page 6 of 20 © 1996-2001 Spectral Audio

3 History of Series

There where 3 different ser ies made:

Serie # 1 : 960000 .. 960020 with golden front panel

Serie # 2 : 960021 .. 960161 with red front panel, C66 and C67 added

Serie # 3 : 960162 .. 960470 with red front panel, now with switch and trafo for 115V / 230V; R173,

R174, C63-C65 inbuilt; R174 and R175 (NTCs) added (by hand); G ND Connection to case

This manual describe the last serie.

This manual contains no the hole schematics. Spectr al Audio m ay send it to you for important

reasons, please write to info@spectralaudio.ch

.

4 Improvements and explanations

4.1 Sense of R174 and R175

These two resistors helps to increase the lower limit of the cutoff f r equency. Otherwise a ploopnoise may occur when reaching 0 Hz cutoff fr equency with a high resonance. You may reach the

0Hz using the LFO.

They are in serie connected from U20 pin 16 to G ND.

4.2 Sense of C63 – C65

With tim e, the pots may become noisy. You may hear this effect especially at t he Cut off pot. Using

the C63 – C65 solve this problem.

They are connected from the middle pin ( + ) of the pot to GND (-). Resonance has negative voltage,

so middle pin is (-) and GND is (+):

Service Manual ProTone Page 7 of 20 © 1996-2001 Spectral Audio

4.3 Sense of R174 and R175

These NTC resistors improves the te m per ature stability of the two VCOs a lot. I t is important that, if

you add these NTCs, also change the resistors R81 and R86 to 5k1. Use hot glue to glue them

onto U16. Sold them parallel to R81 and R86:

After this change, a readjustment must be done.

4.4 Hum Problems

In some circumstances, the internal connect ion from GND to the metal case cr eat es a hum noise

because of closed earth loops.

In this case it may help to cut this internal G ND connection.

You will find it (on later Proton's series only) on the digital pcb, a pretty wide track to one screw. Cut

it with a sharp cutter.

4.5 Increasing the Gate voltage to +12V

To increase the Gate voltage f rom +5V to +12V, two additional resistors and one NPN transistor are

necessary.

Apart from this, port 1.3 (pin 4) of the microprocessor must be connected to GND that the gate

signal output from the microprocessor is inverted.

The circuit change appears as follows:

Service Manual ProTone Page 8 of 20 © 1996-2001 Spectral Audio

5 Adjustment of the ProTone

5.1 Digital PCB (MIDI to CV converter)

The slope of the control voltag e CV is set with tr immer R10. Octave jumps which are initiated via

MIDI-IN, must result in a 1.00 V change.

For this purpose, an accurate voltmeter must be connect ed to the CV socket J3 and the refer ence

note (default: 36=C1) initiated and the voltage value noted (some mV). Now initiate t he MIDI not e

four octaves higher (C4) and adjust R10 so t hat the voltage is 4.00 V higher. Check the reference

note again and repeat the adjustment if necessary.

5.2 Analog PCB (VCO1 and VCO 2)

In order to tune the VCOs, t he analog PCB must first be separated from the front panel ( 6 scr ews

with spacers). The analog PCB must then be reconnect ed to the digital PCB and started.

After disassembly, the Tune VCO1 and Tune VCO2 knobs must be replaced and positioned exactly

in the centre (Tune setting = 0).

Before adjustment, the unit should be in operation for approximately one hour. The adjustment

should be made at room temperature.

Before adjusting the VCO , check the CV slope (chapter above). The setting of R10 in the MIDI to

CV converter is valid for both VCO of cour se.

5.2.1 VCO1

The frequency of t he oscillat or can be taken from pin 8 of U11 or at the unit output, whereby the

filter must be open and set to Lowpass. Only VCO1 must be audible (set the mixer correctly). Make

sure that no LFO modulation take place.

The offset for VCO1 is set with R21 and the slope with R157. Nonlinearity in the upper frequency

range is adjusted with R29.

Proceed as follows to make the adjustment:

1. Set trimmers R21, R157 and R29 to the base set t ings shown below.

2. Set the ProTone

3. Press key A3 and set the VCO1 frequency with R21 to 220.00 Hz, measur ed with an exactly

frequency meter.

4. Press key A1 and set the frequency to 55.00 Hz with R157.

5. Repeat steps 3 and 4 until frequency values are stable.

MIDI reference note

to C1 by pressing the learn-key.

6. Press the key A5 and set the freq uency to 880. 0 Hz with R29.

7. Repeat steps 3 to 6 and re-adjust if necessar y.

5.2.2 VCO2

The offset for VCO2 is set with R131 and the slope with R156. Nonlinearity in the upper frequency

range is adjusted with R132.

Proceed as follows to make the adjustment:

8. Set trimmers R131, R156 and R132 to the base set t ings shown below.

9. Set the ProTone

Service Manual ProTone Page 9 of 20 © 1996-2001 Spectral Audio

MIDI reference note

to C1 by pressing the learn-key if not done yet.

10. Press key A3 and set the VCO2 frequency with R131 to 220.00 Hz, measured with an

exactly frequency meter.

11. Press key A1 and set the frequency to 55.00 Hz with R156.

12. Repeat steps 3 and 4 until frequency values are stable.

13. Press the key A5 and set the frequency to 880.0 Hz with R132. Check here if no beat s are

audible with VCO1 open, too. If so, adjust R132 in that way that no beats are audible.

14. Repeat steps 3 to 6 and re-adjust if necessary.

15. done!

Service Manual ProTone Page 10 of 20 © 1996-2001 Spectral Audio

6 Digital PCB

6.1 Assembly plan

6.2 Part list

Resistors

R1 220

R2 220 100R

R3 220 4k7

R4 1k 24k

R5 10k 30k

R6 10k 62k

R7 1k 91k

R8 47k 100k

R9 47k 300k

R10 2k Trimmer 1M

R11 10k

R12 10k

R13 220

R14 10k

R15 1K

Metal Film Resistor, 1%:

Service Manual ProTone Page 11 of 20 © 1996-2001 Spectral Audio

Capacitors

Kind Gird [mm] Dimensions [mm]

C1 100p Foil 5 2.5 x 7.2

C2 10u Elko 2 d=5

C3 100n Ker 2.54 3.2 x 5.1

C4 100n Ker 2.54 3.2 x 5.1

C5 100n Ker 2.54 3.2 x 5.1

C6 100n Ker 2.54 3.2 x 5.1

C7 100n Ker 2.54 3.2 x 5.1

C8 10u Elko 2 d=5

C9 1000u/25V Elko 5 d=12.5

C10 100n Ker 2.54 3.2 x 5.1

C11 1000u/25V Elko 5 d=12.5

C13 10u Elko 2 d=5

C14 10u Elko 2 d=5

C15 100n Ker 2.54 3.2 x 5.1

C16 22p Ker 2.54 2 x 5

C17 22p Ker 2.54 2 x 5

C56 10u Elko 2 d=5

C66 2.2u Elko 2 d=5

C67 2.2u Elko 2 d=5

Semiconductors

Q1 TL 431 CLP

D1 1N4148

D2 1N4148

D3 1N4148

D4 DF 02 M

D13 1N4148

U1 CNY17-3 / SFH 601-3

U2 TL 074 CN

U3 24C01/02 CB

U4 P80C32 / SAB-C501-LP

U5 MAX 512 CPD

U6 27C64 Q200

U7 LM 2940CT-12

U8 74HC573 N

U9 LM 7805

U10 LM 7912

Various

Socket for U6 28 pin assemble with EPROM "ProTone V1.04"

QZ1 12 MHz (HC 49)

T1 BV 030-7010.0 L Transformer

S16 V20212MS02Q C&K

J1 DIN 5pol Socket

J2 DIN 5pol Socket

J3 Jack Socket 6,3mm

J4 Jack Socket 6,3mm

J5 Jack Socket 6,3mm

J6 Jack Socket 6,3mm

J7 Jack Socket 6,3mm

J8 Jack Socket 6,3mm

J9 PCB-Plug 4.8 x 0.8 mm

J10 PCB-Plug 4.8 x 0.8 mm

J11 Plug Connector 18 pole angular

Service Manual ProTone Page 12 of 20 © 1996-2001 Spectral Audio

W1 Plug Ledge 3 pole

W2 Plug Ledge 3 pole

Jump1 Jumper 2.54 mm assemble on W1 "Out"

Jump2 Jumper 2.54 mm assemble on W2 "Out"

7 Analog PCB

7.1 Assembly plan

Service Manual ProTone Page 13 of 20 © 1996-2001 Spectral Audio

Service Manual ProTone Page 14 of 20 © 1996-2001 Spectral Audio

7.2 Part list

Resistors

R16 1M

R17 100K *

R18 270K *

R19 220K

R20 47K

R21 100K Trimmer

R22 100K

R23 100K

R24 100K

R25 100K

R26 10K

R27 15K

R28 1K

R29 10K Trimmer

R30 4K7

R31 10K

R32 1M

R33 1M

R34 300K

R35 2K2

R36 390

R37 2K2

R38 470

R39 220

R40 10K

R41 1K

R42 91K

R43 15K

R44 10K

R45 91K

R46 10K

R47 15K

R48 10K

R49 10K

R50 15K

R51 24K

R52 47K

R53 100K *

R54 10K

R55 100

R56 100

R57 4K7

R58 10K

R59 30K

R60 100

R61 24K

R62 2K2

R63 1K

R64 4K7

R65 10K

Service Manual ProTone Page 15 of 20 © 1996-2001 Spectral Audio

R66 22

R67 470K

R68 100K

R69 47K

R70 470K

R71 1M

R72 470K

R73 10K

R74 10K

R75 10K

R76 1K

R77 100K *

R78 100K *

R79 100K *

R80 220K

R81 5k1 *

R82 100 *

R83 1M *

R84 1M *

R85 100 *

R86 5k1 *

R87 10K

R88 10K

R89 100K *

R90 180K

R91 470K

R92 2M2

R93 470

R94 2M2

R95 220K

R96 220K

R97 24K

R98 300K

R99 62K

R100 24K

R101 300K

R102 470K

R103 100

R104 100

R105 4K7

R106 24K

R107 10K

R108 100

R109 2K2

R110 1K

R111 4K7

R112 10K

R113 220K

R114 47K

R115 100K

R116 4K7

R117 390

R118 390

R119 270K *

R120 1M

R121 1K

Service Manual ProTone Page 16 of 20 © 1996-2001 Spectral Audio

R122 4K7

R123 15K

R124 10K

R125 100K

R126 100K

R128 47K

R129 1K

R130 24K

R131 100K Trimmer

R132 10K Trimmer

R133 300K

R134 120K

R135 100K

R136 100K

R137 100K

R138 30K

R139 100K

R140 220

R141 180K

R142 10K

R143 470

R144 470

R146 15K

R147 1K

R148 1K

R149 4K7

R150 10K

R151 24K

R152 300K

R153 10K

R154 47K

R155 100

R156 1K Trimmer

R157 1K Trimmer

R158 30K

R159 1K

R160 470K

R162 470

R163 15K

R164 1K

R165 1K

R166 24K

R167 1K

R168 47K

R169 100K

R170 100K

R171 15K

R172 15K

R173 10M

R174 4M7

R175 NTC 68k mounted with hot glue on U16 parallel to R81

R176 NTC 68k mounted with hot glue on U16 parallel to R86

* must be a Metal Film Resistor, 1%

P1 47K LIN TUNE VCO1 Solder Temp. 235 Grad Celsius max,

Service Manual ProTone Page 17 of 20 © 1996-2001 Spectral Audio

P2 47K LIN PW VCO1 solder time max. 5 sec

P3 47K LIN VOL VCO1

P4 47K LIN CUTOFF

P5 47K LIN RESONANZ

P6 10K LOG F LFO

P7 47K LIN MOD LFO

P8 10K LOG LEVEL

P9 47K LIN VOL RING

P10 1M LOG SILDE

P11 47K LIN TUNE VCO2

P12 47K LIN VOL VCO2

P13 47K LIN ACCENT

P15 1M LOG ATTACK

P16 1M LOG DECAY

P17 47K LIN SUSTAIN

P18 1M LOG RELAISE

P19 47K LIN ENV MOD

P20 47K LIN PAN

Capacitors

Kind Gird [mm] Dimensions [mm] Producer

C18 3.3n Foil 5 2.5 x 7.2 WIMA

C19 100p Foil 5 2.5 x 7.2 WIMA

C20 100p Foil 5 2.5 x 7.2 WIMA

C21 22p Ker 2.54 1.8 x 3.5 Phillips

C22 470p Foil 5 2.5 x 7.2 WIMA

C23 470p Foil 5 2.5 x 7.2 WIMA

C24 4p7 Ker 2.54 1.8 x 3.5 Philips

C25 1u Foil 5 6 x 10.5 EVOX

C26 47n Foil 5 2.5 x 7.2 EVOX

C27 470p Foil 5 2.5 x 7.2 WIMA

C28 470p Foil 5 2.5 x 7.2 WIMA

C29 47n Foil 5 2.5 x 7.2 EVOX

C30 100n Ker 2.54 3.2 x 5.1

C31 100n Ker 2.54 3.2 x 5.1

C32 100p Foil 5 2.5 x 7.2 WIMA

C33 100n Ker 2.54 3.2 x 5.1

C34 100n Ker 2.54 3.2 x 5.1

C35 22p Ker 2.54 1.8 x 3.5 Philips

C36 100n Ker 2.54 3.2 x 5.1

C37 470p Foil 5 2.5 x 7.2 WIMA

C38 470p Foil 5 2.5 x 7.2 WIMA

C39 4p7 Ker 2.54 1.8 x 3.5 Philips

C40 470n Foil 5 6 x 10.5 EVOX

C41 47u Elko 2 d=10

C42 1n Ker 2.54 1.8 x 3.5 Philips

C43 1u Elko 2 d=5

C44 47n Foil 5 2.5 x 7.2

C45 100n Ker 2.54 3.2 x 5.1

C46 470p Foil 5 2.5 x 7.2 WIMA

C47 3.3n Foil 5 2.5 x 7.2 WIMA

C48 2.2u Elko 2 d=5

C54 10u Elko 2 d=5

C55 100p Foil 5 2.5 x 7.2 WIMA

C57 100n Ker 2.54 3.2 x 5.1

C58 100n Ker 2.54 3.2 x 5.1

C59 100n Ker 2.54 3.2 x 5.1

Service Manual ProTone Page 18 of 20 © 1996-2001 Spectral Audio

C60 1u Elko 2 d=5

C61 1u Elko 2 d=5

C62 1u Elko 2 d=5

C63 1u Elko 2 d=5

C64 1u Elko 2 d=5

C65 1u Elko 2 d=5

Semiconductors

Q2 BC 556 B

Q3 BC 546 B

Q9 BC 546 B

Q10 BF 245 B

Q11 BC 546 B

Q17 BC 556 B

Q18 BC 556 B

Q19 BC 546 B

Q20 BC 556 B

Q21 BC 546 B

Q22 BC 546 B

Q23 BC 546 B

Q24 BC 556 B

Q25 BC 556 B

Q26 BC 556 B

D7 1N4148

D8 1N4148

D9 1N4148

D10 1N4148

D11 1N4148

D12 1N4148

D14 1N4148

D15 1N4148

D16 1N4148

DL1 2.5 x 5mm Green Assemble with 8 mm spacer (Total 17mm)

DL2 2.5 x 5mm Red Assemble with 8 mm spacer (Total 17mm)

DL3 2.5 x 5mm Red Assemble with 8 mm spacer (Total 17mm)

DL4 2.5 x 5mm Red Assemble with 8 mm spacer (Total 17mm)

U11 TL 074 CN

U13 TL 074 CN

U14 TL 072 CN

U15 TL 074 CN

U16 CA 3046

U17 TL 074 CN

U18 XR 2208 CP

U20 LM 13700 N

U21 LM13700 N

U22 TL 074 CN

U23 TL 074 CN

U24 LM13700 N

U25 LM13700 N

U26 CD 4001 BCN

Various

Service Manual ProTone Page 19 of 20 © 1996-2001 Spectral Audio

S1 E103-SD1CBE 1pole on-off-on Toggle Switch C&K

S2 E201-SD1CBE 2pole on-on Toggle Switch C&K

S3 E103-SD1CBE 1pole on-off-on Toggle Switch C&K

S4 PVA1-EE 1 pole on-off Push-Push Switch ITT

S5 PVA1-EE 1 pole on-off Push-Push Switch ITT

S6 PVA1-EE 1 pole on-off Push-Push Switch ITT

S8 E101-SD1CBE 1pole on-on Toggle Switch C&K

S9 E101-SD1CBE 1pole on-on Toggle Switch C&K

S10 PVA1-EE 1 pole on-off Push-Push Switch ITT

S11 PVA1-EE 1 pole on-off Push-Push Switch ITT

S12 PVA1-EE 1 pole on-off Push-Push Switch ITT

S13 E103-SD1CBE 1pole on-off-on Toggle Switch C&K

S14 PVA1-EE 1 pole on-off Push-Push Switch ITT

S15 PVA1-OA 1 pole on-off Momentary Switch ITT

SW1 56P36-01-1-06N 6 pole Rotary Switch Grayhill

J12 Connector 18 pole (Socket) mounted on Solder Side

8 Mechanical part list

Pcs. Part

1 Front Panel

1 Chassis

1 Backside

4 Screw M3 x 5mm with counter bore head black

5 Cylinder head screw M3 x 5mm black

1 Nut M3 for grounding

1 Washer for grounding

8 Sheet metal screw 2.9 x 6.5mm black

6 Sheet metal screw with counter bore head 2.9 x 22mm black

6 Spacer 14 mm

2 Spacer 25 mm metal with thread M3

1 Analog PCB assembled

1 Digital PCB assembled

6 Nuts for Phone Jack

19 Knobs 18 splines

1 Knob "D" Shape 1/8"

1 Inlet IEC Socket with Fuse Box

1 Fuse 250mA

1 Cable blue with thimbles 4.8mm

2 Cable brown with thimbles 4.8mm

1 Cable yellow-green with thimbles

1 Power switch 1 pole with 4.8mm terminals

Service Manual ProTone Page 20 of 20 © 1996-2001 Spectral Audio

Loading...

Loading...