Page 1

MODEL 8144-DD

Clock Selector/Distribution Amplifier

Instruction Manual

SPECTRACOM CORPORATION

95 Methodist Hill Drive, Suite 500

Rochester, NY 14623

Phone 585.321.5800

Fax 585.321.5219

www.spectracomcorp.com

REVISIONS, IF ANY, ARE LOCATED AT THE END OF THE MANUAL

REVISION A

December 2003

(Model 8144-DD/075020)

Page 2

5-Year Warranty

LIMITED WARRANTY________________________________

Spectracom warrants each new product manufactured and sold by

it to be free from defects in material, workmanship, and

construction, except for batteries, fuses, or other material normally

consumed in operation that may be contained therein, for five

years after shipment to the original purchaser (which period is

referred to as the "warranty period"). This warranty shall not

apply if the product is used contrary to the instructions in its

manual or is otherwise subjected to misuse, abnormal operations,

accident, lightning or transient surge, repairs or modifications not

performed by Spectracom.

The GPS receiver is warranted for one year from date of shipment

and subject to the exceptions listed above. The power adaptor, if

supplied, is warranted for one year from date of shipment and

subject to the exceptions listed above.

The Rubidium oscillator, if supplied, is warranted for two years

from date of shipment and subject to the exceptions listed above.

All other items and pieces of equipment not specified above,

including the antenna unit, antenna surge suppressor and antenna

pre-amplifier are warranted for 5 years, subject to the exceptions

listed above.

WARRANTY CLAIMS________________________________

Spectracom's obligation under this warranty is limited to in-factory

service and repair, at Spectracom's option, of the product or the

component thereof, which is found to be defective. If in

Spectracom's judgment the defective condition in a Spectracom

product is for a cause listed above for which Spectracom is not

responsible, Spectracom will make the repairs or replacement of

components and charge its then current price, which buyer agrees

to pay.

Spectracom shall not have any warranty obligations if the

procedure for warranty claims is not followed. Users must notify

Spectracom of the claim with full information as to the claimed

defect. Spectracom products shall not be returned unless a return

authorization number is issued by Spectracom. Spectracom

products must be returned with the description of the claimed

defect and identification of the individual to be contacted if

additional information is needed. Spectracom products must be

returned properly packed with transportation charges prepaid.

EXCEPT FOR THE LIMITED WARRANTY STATED ABOVE,

SPECTRACOM DISCLAIMS ALL WARRANTIES OF ANY KIND

WITH REGARD TO SPECTRACOM PRODUCTS OR OTHER

MATERIALS PROVIDED BY SPECTRACOM, INCLUDING

WITHOUT LIMITATION ANY IMPLIED WARRANTY OR

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Spectracom shall have no liability or responsibility to the original

customer or any other party with respect to any liability, loss, or

damage caused directly or indirectly by an Spectracom product,

material, or software sold or provided by Spectracom,

replacement parts or units, or services provided, including but not

limited to any interruption of service, excess charges resulting from

malfunctions of hardware or software, loss of business or

anticipatory profits resulting from the use or operation of the

Spectracom product or software, whatsoever or howsoever

caused. In no event shall Spectracom be liable for any direct,

indirect, special or consequential damages whether the claims are

grounded in contract, tort (including negligence), or strict liability.

EXTENDED WARRANTY COVERAGE___________________

Extended warranties can be purchased for additional periods

beyond the standard five-year warranty. Contact Spectracom no

later than the last year of the standard five-year warranty for

extended coverage.

SPECTRACOM 95 Methodist Hill Drive Suite 500 Rochester, NY 14623

+1.585.321.5800 FAX: +1.585.321.5218 www.spectracomcorp.com sales@spectracomcorp.com

Page 3

TABLE OF CONTENTS

SECTION 1 GENERAL INFORMATION

1.0 INTRODUCTION............................................................................... 1-1

1.1 FEATURES ....................................................................................... 1-1

1.2 WARRANTY INFORMATION AND PRODUCT SUPPORT .............. 1-2

1.3 MANUAL ERRATA AND SPECIAL DOCUMENTATION................... 1-2

1.4 UNPACKING..................................................................................... 1-2

1.5 CONFIGURATION OPTIONS ........................................................... 1-3

1.6 SPECIFICATIONS ............................................................................ 1-3

1.6.1 Inputs ................................................................................ 1-3

1.6.2 Outputs ............................................................................. 1-4

1.6.3 Power Requirements......................................................... 1-4

1.6.4 Mechanical and Environmental Specifications .................. 1-4

1.6.5 Status Indicators ............................................................... 1-5

1.6.6 Operator Controls.............................................................. 1-5

1.6.7 User-Configurable Options................................................ 1-6

1.6.8 Alarm Outputs ................................................................... 1-6

1.6.8.1 Alarm Classification ..................................... 1-6

1.6.8.2 Alarm Interface ............................................ 1-7

SECTION 2 INSTALLATION

2.0 INTRODUCTION............................................................................... 2-1

2.1 PREPARATION FOR USE................................................................ 2-1

2.1.1 AC Line Voltage Selection................................................. 2-1

2.1.2 Power Options................................................................... 2-2

2.2 SWITCH AND HEADER SETTINGS................................................. 2-3

8144-DD/075020

Page 4

SECTION 3 OPERATION

3.0 INTRODUCTION ...............................................................................3-1

3.1 THEORY OF OPERATION................................................................3-2

3.2 FRONT PANEL FUNCTIONS............................................................3-2

3.3 REAR PANEL CONNECTIONS.........................................................3-4

SECTION 4 OPTIONS

4.1 DC POWER OPTIONS 52 AND 54....................................................4-1

4.2 MOUNTING OPTIONS ......................................................................4-1

4.2.1 Option 11, Rack Mount with Slides ....................................4-1

4.2.2 Option 102, 23/24-inch Rack Mount ..................................4-2

4.2.3 Option 103, Setback Mount ...............................................4-3

SECTION 5 SERVICE INFORMATION

5.0 MAINTENANCE AND CALIBRATION ...............................................5-1

5.1 FUSE REQUIREMENTS ...................................................................5-1

8144-DD/075020

Page 5

LIST OF TABLES

TABLE 1-1 CONFIGURATION SUMMARY .........................................1-3

TABLE 2-1 SWITCH AND HEADER SETTINGS .................................2-3

TABLE 2-2 OUTPUT LINE LENGTH SWITCH ASSIGNMENTS .........2-8

TABLE 2-3 OUTPUT LINE LENGTH SWITCH SETTINGS..................2-8

TABLE 3-1 CLOCK OUTPUT CONNECTOR PINS .............................3-5

TABLE 4-1 OPTION 11 CHECKLIST...................................................4-1

TABLE 4-2 OPTION 102 CHECKLIST .................................................4-2

TABLE 4-3 OPTION 103 CHECKLIST .................................................4-3

LIST OF ILLUSTRATIONS

FIGURE 2-1 LINE VOLTAGE SELECTION/FUSE REPLACEMENT .....2-2

FIGURE 2-2 MODEL 8144-DD COMPONENT LAYOUT .......................2-4

FIGURE 2-3 8144-DD REAR PANEL.....................................................2-9

FIGURE 2-4 8144-DD FRONT PANEL ..................................................2-9

FIGURE 3-1 MODEL 8144-DD BLOCK DIAGRAM................................3-1

FIGURE 3-2 MODEL 8144-DD FRONT PANEL.....................................3-3

FIGURE 3-3 MODEL 8144-DD REAR PANEL .......................................3-4

8144-DD/075020

Page 6

SECTION 1 GENERAL INFORMATION

1.0 INTRODUCTION

1.1 FEATURES

1.2 WARRANTY INFORMATION AND PRODUCT SUPPORT

1.3 MANUAL ERRATA AND SPECIAL DOCUMENTATION

1.4 UNPACKING

1.5 CONFIGURATION OPTIONS

1.6 SPECIFICATIONS

Page 7

GENERAL INFORMATION

M

AJOR MINO

ALARMS

R

RESET ACO AB

READY

Clock Selector/Distribution Amplifier

INPUT SELECT

AB

AUTO

MANUAL

1.0 INTRODUCTION

Reliable timing in T1 networks is critical. The 8144 Clock Selector/Distribution Amplifier

enhances reliability by providing manual or automatic switchover to a backup system

clock when the primary system clock has failed. The 8144 also provides twelve outputs

for distribution of the selected clock.

1.1 FEATURES

The 8144 Clock Selector/Distribution Amplifier offers the following features:

• Manual or automatic switchover between two clock sources or single input

operation.

• Local and remote alarm indicators, normal or latched, reset from the front

panel.

• Redundant power sources

• Twelve independent outputs.

• DS1 input and output signals.

Instruction Manual 8144-DD/075020 Page 1-1

Page 8

Section 1: General Information

1.2 WARRANTY INFORMATION AND PRODUCT SUPPORT

Warranty information is found on the leading pages of this manual. Contact Spectracom

Corporation to obtain a replacement or service.

Spectracom continuously strives to improve its products. We greatly appreciate any and

all customer feedback given. Please direct any comments or questions regarding

application, operation, or service to Spectracom's Customer Service Department.

Customer Service is available Monday through Friday from 8:30 A.M. to 5:00 P.M.

Eastern time at 585-321-5800.

Before returning any instrument to Spectracom Corporation, please contact Customer

Service to obtain a Return Material Authorization Number (RMA#). Please provide the

serial number and failure symptoms. Transportation to the factory is to be prepaid by

the customer.

1.3 MANUAL ERRATA AND SPECIAL DOCUMENTATION

Information concerning manual corrections or changes made to the instrument

occurring after the printing of this manual are found on the errata sheet located at the

rear of this manual.

Spectracom sometimes makes instrument modifications upon special request. The

documentation associated with any special modifications is also located in the back of

the manual.

1.4 UNPACKING

Upon receipt, examine the carton and its contents carefully. If there is carton damage

which results in damage to the unit, contact the carrier immediately so its representative

may witness such damage. If you fail to report shipping damage immediately, you may

forfeit any claim against the carrier. You should also notify Spectracom Corporation of

shipping damage or shortages so that we can either help you obtain a replacement or

repair the damaged equipment.

Open the shipping carton carefully and remove the packing list from the envelope on the

outside of the carton. Check the packing list against the contents to be sure all items

have been received, including an Instruction Manual and an ancillary kit.

Retain the carton and packing materials in the event the unit is reshipped or returned to

the factory.

Page 1-2 Instruction Manual 8144-DD/075020

Page 9

Section 1: General Information

1.5 CONFIGURATION OPTIONS

The Model 8144-DD Clock Selector/Distribution Amplifier can be ordered in a variety of

power and mounting configurations. When specific configurations are referenced in this

Instruction Manual, the format 8144-DD-P-M is used, P and M are the power and

mounting option designations, respectively. The options are listed below in Table 1-1,

Configuration Summary.

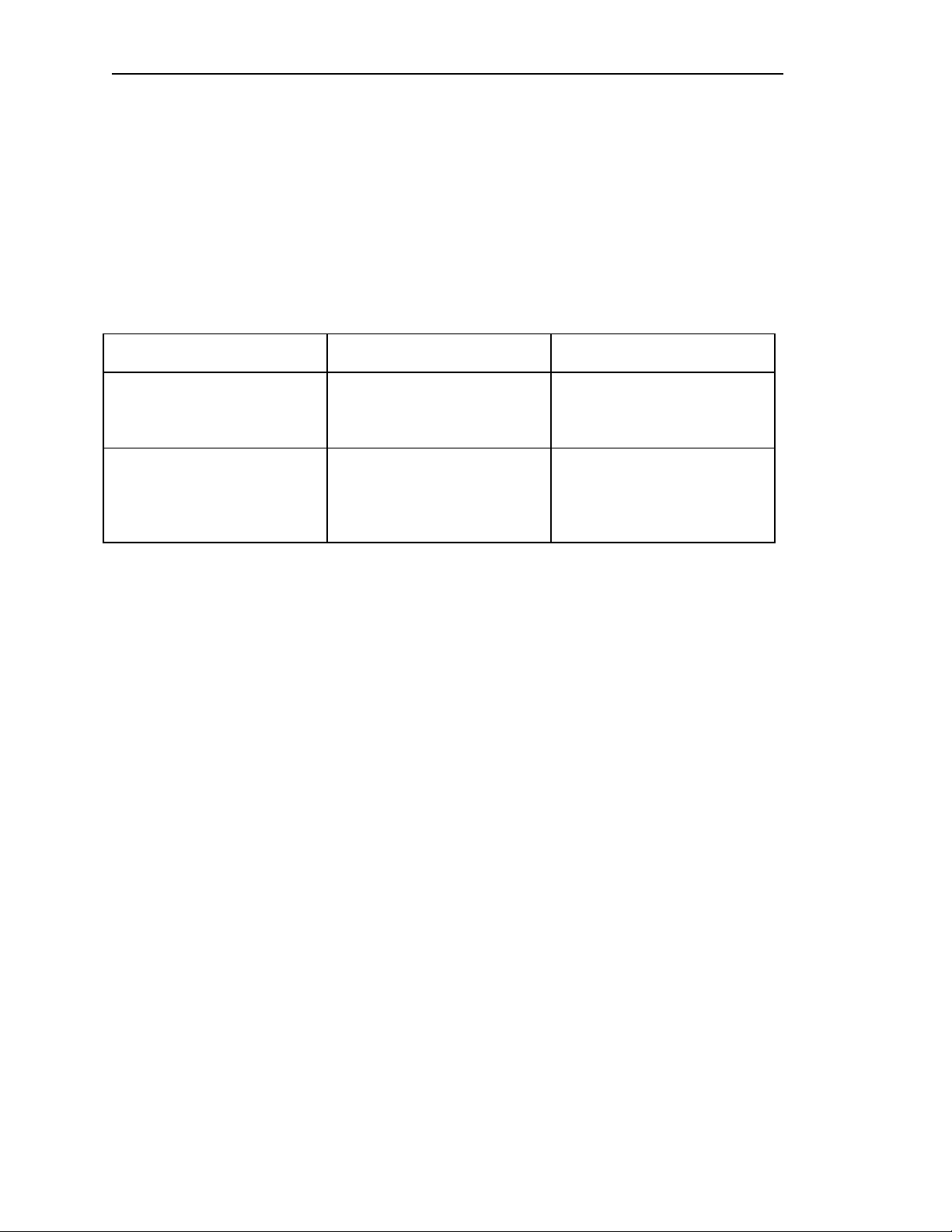

Option Type Option Designation

Power

(P)

Mounting

(M)

AC (Standard)

12 to 24 VDC Power

48 VDC Power

19" Rack (Standard)

19" Rack with Slides

23/24" Rack

19" Setback Rack

TABLE 1-1 CONFIGURATION SUMMARY

(none)

52

54

(none)

11

102

103

1.6 SPECIFICATIONS

1.6.1 Inputs

The Model 8144-DD accepts one or two clock inputs as well as one or two alarm inputs.

DS1 CLOCK INPUTS

The DS1 clock inputs comply with ANSI T1.102-1987 as follows:

Line Rate: 1.544 Mb/s

Tolerance: ±130 ppm (200.72 Hz)

Level: 1.0 to 3.6V base-to-peak

Termination: Balanced twisted pair

Impedance: Terminated: 100 ohms ±5%, bridging >1500 ohms

Pulse Shape: Per ANSI T1.102-1987

Instruction Manual 8144-DD/075020 Page 1-3

Page 10

Section 1: General Information

ALARM INPUTS

The alarm inputs are configured to operate as RS-422/485 receivers as follows:

Line Rate: DC

Level: Sensitivity ±200 mV, hysteresis 50 mV typical

Termination: Balanced twisted pair

Impedance: Terminated 120 ohms ±5%

Unterminated > 4K ohms

Alarm inputs can also be configured for contact closure input. A contact closure

between pins 1 and 3 on the alarm inputs alarms the A channel. A contact closure

between pins 4 and 6 alarms the B channel.

1.6.2 DS1 Outputs

The Model 8144-DD provides up to twelve clock outputs.

DS1 CLOCK OUTPUTS

The twelve DS1 clock outputs comply with ANSI T1.102-1987 as follows:

Line Rate: 1.544 Mb/s

Tolerance: Same frequency as input

Level: 2.4 to 3.6V base-to-peak into 100 ohms ±5%

Termination: Balanced twisted pair

Impedance: 100 ohms ±5%

Pulse Shape: Per Figure 1 of ANSI T1.102-1987

1.6.3 Power Requirements

Standard Option: 115/230 VAC ±15% 50/60 Hz, 15 watts

Option 52, 12 to 24 VDC: ±11.0 to 32.0 VDC, 12 watts

Option 54, 48 VDC: ±55.2 VDC ±20%, 12 watts

1.6.4 Mechanical and Environmental Specifications

Height: 2 rack units (3.50 inches)

Width: EIA 19" rack

Depth: 10 inches

Weight: 6 lbs. maximum

Temperature: 0 to +50°C operating range

Humidity: 95% R. H. non-condensing

Page 1-4 Instruction Manual 8144-DD/075020

Page 11

Section 1: General Information

1.6.5 Status Indicators

The red MAJOR ALARM lamp is latched on for the following conditions:

LOS Loss of DS1 reference signal on both inputs.

AIS An Alarm Indication Signal on both reference inputs if

AIS is enabled for both inputs.

EXTERNAL ALARM INPUT An External Alarm Input on both alarm inputs.

The red MINOR ALARM lamp is latched for the following conditions:

LOS Loss of DS1 reference signal on one input.

AIS An Alarm Indication Signal on one reference input if

AIS is enabled.

EXTERNAL ALARM INPUT An External Alarm Input on one alarm input.

READY A/B

The green lamps indicate that clock input at A and/or B is available and that the

corresponding alarm input is not activated.

SELECTED A/B

The green lamps indicate that the A or B clock input has been selected.

1.6.6 Operator Controls

RESET: A momentary contact switch that resets latched MAJOR and

MINOR alarms

ACO: A

AUTO/MANUAL: Enables automatic switchover or manual selection of references.

PWR Turns power ON or OFF. Switch must be pulled out to toggle.

larm Cut Off. A momentary contact switch that removes the

remote alarm condition (unlatches the alarm relays).

Instruction Manual 8144-DD/075020 Page 1-5

Page 12

Section 1: General Information

1.6.7 User-Configurable Options

Various options are configured using internal DIP Switches and headers. These options

are:

• Channel A/B RS-422/485 Alarm Input Termination – selects the termination

impedance for the alarm inputs.

• Channel A/B Clock Input Termination – selects the termination impedance for the

input reference clocks.

• Disable Channel B – for installations where only Channel A input is used.

• Major Alarm Indicator/Relay Latch – selects whether a Major Alarm is latched, or

reported only while the problem condition exists.

• Minor Alarm Indicator/Relay Latch – selects whether a Minor Alarm is latched, or

reported only while the problem condition exists.

• A/B AIS – selects whether the unit recognizes or ignores the Alarm Insertion Signal.

• DS1 Output Framing Mode – selects ESF or D4 framing outputs.

• DS1 Output Line Length Compensation – selects line buildout waveshaping for each

output.

1.6.8 Alarm Outputs

Alarm relays allow remote monitoring of operational status. Relay contacts are provided

for Major and Minor Alarms.

1.6.8.1 Alarm Classification

Major Alarm: A Major Alarm is asserted when detected faults compromise output

function. The outputs are removed during a Major Alarm condition. The latched alarm

relay is reset from the front panel ACO Switch. Faults and conditions listed below

actuate a Major Alarm.

LOS Loss of DS1 reference signal on both inputs.

AIS An Alarm Indication Signal on both reference inputs.

EXTERNAL ALARM INPUT An External Alarm Input on both alarm inputs.

POWER FAILURE External power failure, fuse or internal power supply

failure.

Page 1-6 Instruction Manual 8144-DD/075020

Page 13

Section 1: General Information

Minor Alarm: A Minor Alarm is asserted when failures detected do not affect output

function. The latched alarm relay is reset from the front panel ACO switch. Faults and

conditions listed below actuate a Minor Alarm:

LOS Loss of DS1 reference signal on one reference input

AIS Alarm Indication Signal on one reference input.

EXTERNAL ALARM INPUT An External Alarm Input on one alarm input.

1.6.8.2 Alarm Interface

Alarm Outputs: Major Alarm, Minor Alarm

Relay Contacts: NO, NC and common.

Contact Rating: 30 VDC, 2 amps

Connector: 7-position terminal block (supplied)

Instruction Manual 8144-DD/075020 Page 1-7

Page 14

SECTION 2 INSTALLATION

2.0 INTRODUCTION

2.1 PREPARATION FOR USE

2.2 SWITCH AND HEADER SETTINGS

Page 15

INSTALLATION

2.0 INTRODUCTION

This section contains installation instructions for the Model 8144-DD Clock

Selector/Distribution Amplifier. To ensure proper operation, read this chapter

before operating the unit. There are several internal jumpers and switches that

may have to be configured for your specific application.

2.1 PREPARATION FOR USE

This section outlines the set-up procedure for the Model 8144-DD. The switches

described in this section are located inside the unit. Refer to Figure 2-2, Model

8144-DD Component Location.

2.1.1 AC Line Voltage Selection

The Model 8144-DD is factory set for 115 VAC ±10%, 50/60 Hz power line

operation. The instrument may also be operated from a 230 VAC ±10%, 50/60

Hz power line. For 230 VAC operation, change the voltage selection drum and

line fuse as illustrated in Figure 2-1, and as described below:

1. Remove the line cord (if installed) from the line voltage connector.

2. Open the fuse and selector drum cover with a small flat-bladed

screwdriver. Insert the screwdriver blade into the cover notch and

pry.

3. Pull the voltage selection drum from the power connector

assembly. Insert the drum back into the assembly so that the

desired line voltage appears through the cover cut-out.

4. Pull the fuse block from the power connector assembly. Replace

the fuse with a 1/4 amp, 250V slow-blow fuse for 230 VAC

operation.

5. Reinstall the fuse block into the lower fuse compartment. Make

certain the arrow on the fuse block is pointing down.

6. Snap the cover door closed.

Instruction Manual 8144-DD/075020 Page 2-1

Page 16

Section 2: Installation

FIGURE 2-1 LINE VOLTAGE SELECTION/FUSE REPLACEMENT

2.1.2 DC Power Options

Check that the power options on the unit match the power available:

Option 52, 12 VDC to 24 VDC: ±11.0 to 32.0 VDC

Option 54, 48 VDC: ±55.2 VDC ±20%

Page 2-2 Instruction Manual 8144-DD/075020

Page 17

Section 2: Installation

2.2 SWITCH AND HEADER SETTINGS

The switches and headers determine the input alarm and clock termination,

reaction to loss of primary (A) and secondary (B) inputs, the waveshapes of the

DS1 outputs, whether a second clock input is used, and the latching of the alarm

lamps and relays.

A summary of the internal settings is below. A more detailed description follows

on subsequent pages.

HEADER FUNCTION A B

H1 B Alarm Termination High impedance1 120 ohms

H2 A Alarm Termination High impedance1 120 ohms

H3 B Clock Termination 100 ohms1 High impedance /bridging

H4 A Clock Termination 100 ohms1 High impedance /bridging

H7 B Input Alarm Enable No B Input B Input1

H8 Major Alarm Indicator Latch Select Latched1 Not Latched

H9 Minor Alarm Indicator Latch Select Latched1 Not Latched

H10 Major Alarm Relay Latch Select Latched1 Not Latched

H11 Minor Alarm Relay Latch Select Latched1 Not Latched

H14 A Channel AIS Alarm Select Alarm on AIS1 No Alarm on AIS

H15 B Channel AIS Alarm Select Alarm on AIS1 No Alarm on AIS

H16 Switching Priority Non-revertive1 Revertive with A Priority

H17 DS1 Output Framing Select ESF D41

SWITCH FUNCTION

S1 “B” Receiver Mode, factory test use only, place all switches OFF1.

S2 “A” Receiver Mode, normal operation, place all switches OFF

S3 - S14 Transmit Length Selected, 0-133 feet, Switch 3 ON, Switches 1, 2 and 4 OFF1.

S15 Data Output Select Factory Test Framed all one’s1

1

= Factory setting

TABLE 2-1 SWITCH AND HEADER SETTINGS SUMMARY

.1

Refer to Figure 2-2, Component Layout, to locate and identify functions of the

internal switches and jumpers.

Instruction Manual 8144-DD/075020 Page 2-3

Page 18

Section 2: Installation

FIGURE 2-2 MODEL 8144-DD COMPONENT LAYOUT

Page 2-4 Instruction Manual 8144-DD/075020

Page 19

Section 2: Installation

Remove the top cover of the unit to configure the internal jumpers and switches

as follows:

Header Position

H1 B Alarm Input Termination

B Terminates the B Alarm RS-422/485 input with

120 ohms between terminals 4 and 5.

A Removes the 120-ohm termination from the B Alarm input. This

position may be used as an RS-422/485 input between

terminals 4 and 5, or a relay closure between terminals 4 and 6.

Use position B-C unless RS-422/485 input line needs

termination. If relay closure input is used, the header must be in

the B-C position.

H2 A Alarm Input Termination

B Terminates the A Alarm RS-422/485 input with 120 ohms

between terminals 1 and 2.

A Removes the 120-ohm termination from the A Alarm input. This

position may be used as an RS-422/485 input between

terminals 1 and 2 or a relay closure between terminals 1 and 3.

Use position B-C unless RS-422/485 input line needs

termination. If relay closure input is used, the header must be in

the B-C position.

H3 B Clock Termination

A Terminates the B Clock input at terminals 4 and 5 with

100 ohms for DS1 input.

B Removes the terminating resistor for high-impedance input at

terminals 4 and 5 for bridging applications.

H4 A Clock Termination

A Terminates the A Clock input at terminals 1 and 2 with 100

ohms for DS1 input.

B Removes the terminating resistor for high-impedance input at

terminals 1 and 2 for bridging applications.

Instruction Manual 8144-DD/075020 Page 2-5

Page 20

Section 2: Installation

Header Position

H7 B Input Alarm Enable

A If the 8144-DD is used with only an A clock input, connecting A

to B on header H7 disables the alarm inputs for the B clock

input. Loss of the A reference or the assertion of the A Alarm

input now results in a major alarm.

B This is the normal connection using two clock input signals.

A Major Alarm exists when both references are not ready (AIS or LOS), or when

both external alarm inputs are asserted. A Minor Alarm exists when one of the

references is not ready (AIS or LOS), or when a single external alarm input is

asserted.

Header Position

H8 Major Alarm Indicator Latch Select

A The MAJOR ALARM INDICATOR on the front panel is latched

on by a Major Alarm. A Major Alarm exists when both

references are not ready (AIS or LOS), or when both external

alarm inputs are asserted. The indicator is reset by the RESET

switch if either fault is no longer present.

B The MAJOR ALARM INDICATOR on the front panel does not

latch. The indicator is ON only when a Major Alarm is present.

The light extinguishes automatically when the condition clears.

The RESET switch does not reset the indicator.

H9 Minor Alarm Indicator Latch Select

A The MINOR ALARM INDICATOR on the front panel is latched

on by a Minor Alarm. A Minor Alarm exists when one of the

references is not ready (AIS or LOS), or when a single alarm is

asserted. The indicator is reset by the RESET switch if the fault

is no longer present.

B The MINOR ALARM INDICATOR on the front panel does not

latch. The indicator is ON only when a Minor Alarm is present.

The light extinguishes automatically when the condition clears.

The RESET switch does not reset the indicator.

H10 Major Alarm Relay Latch Select

A The MAJOR ALARM RELAY is latched on by a Major Alarm. A

Major Alarm exists when both references are not ready (AIS or

LOS), or when both external alarms are asserted. The relay is

reset by the ACO switch, even though the fault may still be

present.

B The MAJOR ALARM RELAY does not latch. A remote indicator

shows only if the fault is present. The ACO switch does not

clear the MAJOR ALARM relay.

Page 2-6 Instruction Manual 8144-DD/075020

Page 21

Section 2: Installation

H11 Minor Alarm Relay Latch Select

A The MINOR ALARM RELAY is latched on by a Minor Alarm. A

Minor Alarm exists when one of the references is not ready (AIS

or LOS), or when a single alarm is asserted. The relay is reset

by the ACO switch even though the fault may still be present.

B The MINOR ALARM RELAY does not latch. A remote indicator

shows only if the fault is present. The ACO switch does not

clear the MINOR ALARM relay.

H14 A Channel AIS Alarm Select

A An AIS (Alarm Indication Signal from receiver chip) on the A

channel causes switchover to B and/or alarm.

B Unit does not look for the AIS on the A clock input.

H15 B Channel AIS Alarm Select

A An AIS on the B channel causes an alarm.

B The unit does not look for the AIS on the B clock input.

H16 Switching Priority

A Non-revertive switching - in automatic, unit stays on last input

selected until an alarm causes a change to the other input.

B Revertive switching with the A input having priority - in

automatic, unit selects A input if it is ready.

H17 Output Framing Select

A Sets DS1 output framing to ESF.

B Sets DS1 output framing to D4.

Switch

S1 Switches 1-4 OFF for normal operation

S2 Switches 1-4 OFF for normal operation

S2 Position 4 is reserved for factory use only

S15 Data Output Select

A Reserved for factory use only

B Framed all ones

Position

Instruction Manual 8144-DD/075020 Page 2-7

Page 22

Section 2: Installation

The output line length compensation switches are assigned to the output

channels as follows:

SWITCH

S8 Programs DS1 output on J1 pins 1 and 2

S14 Programs DS1 output on J1 pins 4 and 5

S7 Programs DS1 output on J1 pins 7 and 8

S13 Programs DS1 output on J1 pins 10 and 11

S6 Programs DS1 output on J2 pins 1 and 2

S12 Programs DS1 output on J2 pins 4 and 5

S5 Programs DS1 output on J2 pins 7 and 8

S11 Programs DS1 output on J2 pins 10 and 11

S4 Programs DS1 output on J3 pins 1 and 2

S10 Programs DS1 output on J3 pins 4 and 5

S3 Programs DS1 output on J3 pins 7 and 8

S9 Programs DS1 output on J3 pins 10 and 11

TABLE 2-2 OUTPUT LINE LENGTH SWITCH ASSIGNMENTS

Refer to Figure 2-2 for the locations of connectors J1 through J3 and switches S3

through S14.

Set the switch sections according to Table 2-3 for DS1 applications.

S3 thru S14 OPTION

APPLICATION

SELECTED

-1 -2 -3 -4

OFF OFF ON DON’T CARE 0 dB Buildout

0 – 133 FT

1

ANSI T1.403

DSX-1 Cross-Connect

ON ON OFF DON’T CARE 133 – 266 FT DSX-1 Cross-Connect

OFF ON OFF DON’T CARE 266 – 399 FT DSX-1 Cross-Connect

ON OFF OFF DON’T CARE 399 – 533 FT DSX-1 Cross-Connect

OFF OFF OFF DON’T CARE 533 – 655 FT DSX-1 Cross-Connect

1

= Factory setting

TABLE 2-3 OUTPUT LINE LENGTH SWITCH SETTINGS

Page 2-8 Instruction Manual 8144-DD/075020

Page 23

Section 2: Installation

FIGURE 2-3 8144-DD REAR RANEL FIGURE 2-4 8144-DD REAR PANEL

Instruction Manual 8144-DD/075020 Page 2-9

Page 24

Section 2: Installation

INSTALLATION CHECKOUT

1.0 If applicable, attach one of the optional mounting kits to the unit. Refer

to Section 4.4, Mounting Options, for assembly instructions.

2.0 Check the unit for physical damage and ensure the PWR switch is

OFF. Connect a good earth ground to the CHASSIS GROUND if

desired.

3.0 Locate the terminal block connectors in the ancillary kit and install onto

rear panel connectors as needed. Refer to Figure 2-3, 8144-DD Rear

Panel, for locations.

4.0 Connect the A clock source to terminals 1 and 2 on the CLKS IN

terminal block. All wiring to the rear panel terminal blocks can be

twisted pair. A ground connection is provided for a shield if desired.

5.0 Connect the B clock source to CLKS IN terminals 4 and 5.

6.0 External alarm sources used to force an input switchover are

connected to the ALM INPUTS terminal block. The alarm inputs can

be either RS-422/485 levels or contact closures.

Pins 1 and 2 are the RS-422/485 A channel alarm inputs. Pins 4 and 5

are the RS-422/485 B channel alarm inputs. In the AUTO mode, a

contact closure between 1 and 3 (GND) causes the unit to switch from

the A clock source to the B clock source and causes a Minor Alarm. A

contact closure between pins 4 and 6 (GND) causes an alarm on the B

clock source. The alarm termination headers H1 and H2 must be in

their high impedance (B-C) position to use contact closure for

alarm inputs. An alarm on both inputs will cause a major alarm.

7.0 ALM OUTPUTS are relay contact closures used for remote indications

of clock source failures. During a Major Alarm, Pin 1 on the alarm

terminal block is connected to Pin 2 and Pin 3 is open. During a Minor

Alarm, Pin 4 on the alarm terminal block is connected to Pin 5 and

Pin 6 is open.

8.0 Up to twelve loads may be connected to the CLOCK OUTPUTS.

9.0 Connect the unit to the appropriate power source and switch PWR ON.

Page 2-10 Instruction Manual 8144-DD/075020

Page 25

Section 2: Installation

10.0 Check the front panel controls and indicators. Refer to Figure 2-4,

8144-DD Front Panel, for locations of these controls and indicators.

10.1 ALARMS and INDICATORS

The Major indicator is red if both clock sources have failed.

The Minor indicator is red if there is a failure of one clock

source. Front panel alarm indicators may be cleared with the

RESET if the clock sources have been restored. The ACO

clears remote fault indicators even though the alarm conditions

still exist.

10.2 The READY indicators are green if the corresponding clock

input is present and not in an AIS condition.

10.3 The green SELECTED indicator switch corresponds to the input

currently selected.

10.4 AUTO/MAN switch:

If revertive A priority has been selected on H16 - in the AUTO

position, a ready A clock source has priority. Failure of the A

clock switches the unit to the B clock input. When the A input

returns, the unit will switch back to the A input.

If non-revertive switching has been selected on H16 - in the

AUTO position, selected input can be A or B. Unit stays on the

selected input until an alarm causes a switch to the other input.

In the MAN position, clock selection is operator-controlled by

the A or B Select pushbuttons.

11.0 The Model 8144-DD is now operational.

Instruction Manual 8144-DD/075020 Page 2-11

Page 26

SECTION 3 OPERATION

3.0 INTRODUCTION

3.1 THEORY OF OPERATION

3.2 FRONT PANEL FUNCTIONS

3.3 REAR PANEL CONNECTIONS

Page 27

OPERATION

3.0 INTRODUCTION

This section describes the front and rear panel functions, switch functions, and

operation information for the Model 8144-DD Clock Selector/Distribution

Amplifier.

FRONT PANEL

MANUAL

CONTROL

PRIMARY

REFERENCE

INPUT A

SECONDARY

REFERENCE

INPUT B

ALARM

INPUTS

ALARM

OUTPUTS

DS1

Clock Extractor

DS1

Clock Extractor

SELECTOR

SWITCH

DS1

FRAMER

DISTR AMP #1

DISTR AMP #2

DISTR AMP #3

DISTR AMP #4

DISTR AMP #5

DISTR AMP #6

DISTR AMP #7

DISTR AMP #8

DISTR AMP #9

DISTR AMP #10

DISTR AMP #11

DISTR AMP #12

OUTPUT #1

OUTPUT #2

OUTPUT #3

OUTPUT #4

OUTPUT #5

OUTPUT #6

OUTPUT #7

OUTPUT #8

OUTPUT #9

OUTPUT #10

OUTPUT #11

OUTPUT #12

FIGURE 3-1 8144-DD BLOCK DIAGRAM

Instruction Manual 8144-DD/075020 Page 3-1

Page 28

Section 3: Operation

3.1 THEORY OF OPERATION

The Model 8144-DD Clock Selector/Distribution Amplifier is a clock switch and

splitter. The input circuit can automatically or manually select a clock input, the

send that clock to distribution amplifiers. The distribution amplifiers split the clock

to twelve outputs and sends them to the rear panel connectors.

The Model 8144-DD can operate in two modes: Automatic or Manual. In

automatic mode, the primary (A) clock has priority and is selected if it is present.

If the A clock is not present, the secondary (B) clock is automatically selected.

Unit default is “switch and stay” (non-revertive switching), but can be configured

to “switch back “ (revertive switching) when the A channel returns. In manual

mode, the front panel select pushbuttons determine which channel is selected.

In automatic mode, the channels can be selected remotely by asserting an alarm

on the rear panel alarm inputs. Putting an alarm condition on the A channel

causes the unit to select channel B. An alarm on channel B causes channel A to

be selected.

In manual mode, if a channel is selected and an alarm input is asserted for that

channel, the outputs are removed. In either mode, if an alarm is asserted on

both rear panel outputs, the outputs are removed.

3.2 FRONT PANEL FUNCTIONS

The following paragraphs describe the front panel functions. Refer to Figure 3-2,

8144-DD Front Panel.

MAJOR ALARM Indicator:

A major alarm exists when both clock references are not ready (AIS or

LOS) or both alarm inputs have been activated.

This indicator can be either latched on after the occurrence of an alarm, or

on only during the alarm condition. This option is selected by internal

header H8.

If there is only one reference and internal header H7 is set to A-B, the loss

of the A reference or activation of the A alarm causes a major alarm.

A major alarm removes the outputs from the rear panel connectors.

Page 3-2 Instruction Manual 8144-DD/075020

Page 29

Section 3: Operation

Clock Selector/Distribution Amplifier

MAJOR MINOR RESET ACO A B

ALARMS

READY INPUT SELECT

AB

AUTO

MANUAL

FIGURE 3-2 MODEL 8144-DD FRONT PANEL

MINOR ALARM Indicator:

A minor alarm exists when one of the clock references is lost, or

upon the activation of one of the alarm inputs.

When only one clock reference is being used, the MINOR ALARM

indicator is on constantly, unless header H7 is set to the A-B

position.

RESET Pushbutton:

This pushbutton turns off the alarm lamps if the fault causing the

alarm has been corrected. If the lamps have been set to nonlatching with internal headers H8 and H9, this button has no effect.

ACO Pushbutton:

Alarm Cut Off. This pushbutton unlatches the alarm relays if the

fault causing the alarms has been corrected. If the relays have

been set to non-latching with the internal headers H10 and H11,

this button has no effect.

A READY Indicator:

This lamp is illuminated if the A reference is ready for use and the A

alarm is not activated.

B READY Indicator:

This lamp is illuminated if the B reference is ready for use and the B

alarm is not activated.

Instruction Manual 8144-DD/075020 Page 3-3

Page 30

Section 3: Operation

A SELECTED Indicator:

In manual mode, pressing this button selects the A reference. If the

A reference is ready, the light remains on to show A is selected.

In automatic mode, if revertive (A priority) has been configured

(H16), the lamp is on if the A READY indicator is on. If nonrevertive switching has been configured (H16), the lamp will be on

only if A is selected.

B SELECTED Indicator

In manual mode, pushing this button selects the B reference. If the

B reference is ready, the light remains on to show B is selected.

In automatic mode, if revertive ( A priority) has been configured

(H16), the lamp is on only if the B READY indicator is lit and the A

READY indicator is off. If non-revertive switching has been

configured (H16), the lamp will light when B is selected, and remain

on until A is selected.

AUTO/MANUAL Switch

This switch selects automatic switchover or manual control of the

clock references. In the AUTO position, the unit will automatically

switch to the backup channel if it is ready.

In the MANUAL position, the SELECTED pushbuttons control which

reference is used. With two ready inputs, if either channel is

selected and the corresponding input is removed or goes unready,

the output is disabled and the MINOR alarm indicator is lit.

3.3 REAR PANEL CONNECTIONS

Figure 3-3, 8144-DD Rear Panel, and the following paragraphs describe the rear

panel functions. Each terminal block is a pluggable connector.

FIGURE 3-3 8144-DD REAR PANEL - AC AND DC CONNECTORS

Page 3-4 Instruction Manual 8144-DD/075020

Page 31

Section 3: Operation

CLOCK OUTPUTS:

There are three connectors with four clock outputs per connector. Each clock

output consists of a Tip, Ring, and Ground triad.

Pin # Function

1 Tip Output #1, 5, 9

2 Ring Output #1, 5, 9

3 Ground

4 Tip Output #2, 6, 10

5 Ring Output #2, 6, 10

6 Ground

7 Tip Output #3, 7, 11

8 Ring Output #3, 7, 11

9 Ground

10 Tip Output #4, 8, 12

11 Ring Output #4, 8, 12

12 Ground

TABLE 3-1 CLOCK OUTPUT CONNECTOR PINS

CLKS IN:

The reference clocks are connected here. There are Tip, Ring, and Ground

triads for each input. The A reference input is connected at pins 1, 2, and 3;

the B reference is connected at pins 4, 5, and 6.

ALM INPUTS:

The alarm inputs are connected here. There are two + (plus), - (minus), ground

triads for each alarm. The A alarm is on pins 1, 2, and 3, and the B alarm is on

pins 4, 5, and 6. The alarm inputs can be either RS-422/485 levels or contact

closures. A contact closure between pins 1 and 3 activates the A alarm. A

contact closure between pins 4 and 6 activates the B alarm. Making the + (plus)

more negative than the - (minus) input activates the alarm.

The alarm termination headers must be in their high-impedance (B-C) position to

use contact closures for alarm inputs.

Instruction Manual 8144-DD/075020 Page 3-5

Page 32

Section 3: Operation

ALM OUTPUTS:

Relay contacts are provided for remote alarm indications. Terminals 1 and 2

provide a contact closure for a MAJOR ALARM (loss of both clock inputs, power

failure, etc.), and terminals 1 and 3 provide a contact open. Terminals 4 and 5

provide a contact closure and terminals 4 and 6 provide a contact open for a

MINOR ALARM (loss of one reference input). Contacts are rated for 2 amps at

30 VDC and are isolated from ground.

Power Connections:

Check the serial number tag to verify the power option(s) installed in your

8144-DD.

Standard: 115/230 VAC 50/60 Hz

Option 52,12 VDC to 24 VDC: ±11.0 to 32 VDC

Option 54,48 VDC: ±55.2 VDC ±20%

DC options provide dual fused inputs and reverse polarity protection.

The DC PWR terminals are provided for two DC power sources and polarity is

marked on the chassis. Both sources must have the same polarity

referenced to ground.

If AC power is provided, check the voltage selector in the AC power connector

and connect the power cord. If necessary, refer to Section 2.1.1, AC Line

Voltage Selection, to change to 230 VAC power.

CHASSIS GROUND:

This ground stud allows connection of the Model 8144-DD chassis to earth

ground. Connect the chassis ground to a known well-grounded frame or a

ground stake using the largest cable conductor possible.

PWR ON/OFF:

This switch turns power on to the DC to DC converter in the unit.

WARNING: The AC section is always on, if AC

power is used.

The red LED inside the unit is illuminated whenever AC power is connected to

the unit.

Fuses:

Two DC power fuses are provided if unit is configured for either of the DC power

options (Option 52 or Option 54). Fuse markings on rear panel, are listed in

Section 5.1.

Page 3-6 Instruction Manual 8144-DD/075020

Page 33

SECTION 4 OPTIONS

4.1 DC POWER OPTIONS 52 AND 54

4.2 MOUNTING OPTIONS

Page 34

OPTIONS

4.1 DC POWER OPTIONS 52 AND 54

DC Power Options allow the Model 8144-DD to operate from a DC voltage

source. The DC power connection is made at the DC PWR terminal block. The

optional input voltages are listed below:

OPTION 52 12 to 24 VDC 12 watts (±11.0 to 32 VDC)

OPTION 54 48 VDC 12 watts (±55.2 VDC ±20%)

The isolated inputs of the DC to DC converter permits either polarity of voltage to

be used. Dual sources must have the same polarity referenced to ground.

4.2 MOUNTING OPTIONS

There are three mounting options available in addition to the standard 19-inch

rack mount.

4.2.1 Option 11, Slides

Option 11 allows the Model 8144-DD to be mounted in a 19-inch rack with slideout capabilities. Table 4-1 lists the hardware supplied with Option 11. Verify that

these items have been received.

Quantity Description

1 Right-hand slide assembly

1 Left-hand slide assembly

2 Filler plates (not used)

2 Adjustable rear support bracket

1 Hardware Pack containing nut plates, small rear

support brackets, and assorted hardware.

1 Hardware pack containing #10 nuts and #10-32 x 1/2

truss head screws

1 Hardware pack containing #10 nuts and #10-32 x 3/8

pan head screws

TABLE 4-1 OPTION 11 CHECKLIST

Instruction Manual 8144-DD/075020 Page 4-1

Page 35

Section 4: Options

Install Option 11 as described below:

1. Remove the chassis section from the right-hand slide rail assembly.

The right hand assembly is designated with the letters RH after the

manufacturer's date code label.

Attach the chassis section to the Model 8144-DD using #10-32

screws. The locking tab must be toward the rear of the unit.

2. Repeat Step 1 for the left chassis section.

3. Mount the right and left stationary sections into the rack using the

appropriate rear support brackets, nut plates and required

hardware.

4. Insert the unit into the rack assembly. Secure the Model 8144-DD

to the rack using the front panel mounting holes.

4.2.2 Option 102, 23/24-inch Rack Mount

Option 102 provides the hardware to mount the Model 8144-DD in a 23- or 24inch rack. Table 4-2 lists the parts supplied with Option 102. Verify that these

items have been received.

Quantity Description

2 23/24 Mounting Plate

4 #10-32 Hex Nut

4 #10 Split Lock washer

4 #10 Flat Washer

4 #10-32 x 1/2 Philips Pan Head Screw

TABLE 4-2 OPTION 102 CHECKLIST

A Philips screwdriver and a 3/8-inch nut driver are needed to assemble the rack

mount kit. To assemble the kit, attach the mounting plates to each side of the

Model 8144-DD with the hardware provided.

Page 4-2 Instruction Manual 8144-DD/075020

Page 36

Section 4: Options

4.2.3 Option 103, Setback Mount

Option 103 provides the necessary hardware to mount the Model 8144-DD in a

setback position. Table 4-3 list the parts supplied with Option 103. Verify that

these items have been received.

Quantity Description

2 Setback Mounting Bracket

4 #10 Split Lock washer

4 #10-32 x 1/2 Philips Pan Head

Screw

TABLE 4-3 OPTION 103 CHECKLIST

A Philips screwdriver is needed to assemble the setback mounting kit. To

assemble the kit, attach the mounting brackets to each side of the

Model 8144-DD with the hardware provided.

Instruction Manual 8144-DD/075020 Page 4-3

Page 37

SECTION 5 SERVICE INFORMATION

5.0 MAINTENANCE AND CALIBRATION

5.1 FUSE REQUIREMENTS

Page 38

SERVICE INFORMATION

5.0 MAINTENANCE AND CALIBRATION

There are no components that require periodic maintenance or adjustments.

5.1 FUSE REQUIREMENTS

115 VAC, 0.5 Amp, 250V, Fast-Blo.

230 VAC, 0.25 Amp, 250V, Fast-Blo.

DC options have different fuse requirements.

Option 52,12 to 24 VDC input: 2.0 Amp, 250V, Slo-Blo (2 required).

Option 54, 48 VDC input: 0.5 Amp, 250V, Slo-Blo (2 required).

Instruction Manual 8144-DD/075020 Page 5-1

Loading...

Loading...