Page 1

ORIGINAL

INSTRUCTION

MANUAL

41 cm

3

Petrol Chainsaw

CS4100-3

Important - Please read these instructions

fully before starting assembly

These instructions contain important information that will help

you get the best from your chainsaw, ensuring it is assembled correctly

and safely. If you need help or have damaged or missing parts,

call the Customer Helpline on 0345 605 2067

AFTER SALES SUPPORT

0345 605 2067

Page 2

SPEAR & JACKSON SINCE 1760

For more than 250 years gardeners have enjoyed high quality performance and

great results using Spear & Jackson tools.

Our garden power tools combine continuous innovation and the latest in

manufacturing technologies with a proud heritage.

Each product is carefully designed with performance, comfort and durability

rmly in mind, which has earned Spear & Jackson an enviable reputation as a

maker of tools to trust.

3 YEARS GUARANTEE

As a testament to the quality of our products, we offer a 3 year manufacturers warranty and a comprehensive after sales service.

The warranty covers manufacturing faults, however in the event that the item has

been deliberately damaged, used in a commercial environment or disassembled then

the warranty will be null and void.

Please retain proof of purchase.

7 DAYS A WEEK TECHNICAL SUPPORT

We want you to get the best out of your products. Our easy-to-read instruction manual guides you with best practice use and maintenance tips. Please call 0345 605 2067

for technical support, we can solve around 80% of questions directly over the phone.

We hope you enjoy your product and we look forward to any feedback, as this allows

us to develop even better products for the future.

2 AFTER SALES SUPPORT 0345 605 2067

Page 3

CONTENTS

Safety Information 04

Description of symbols 04

General safety

Preparation safety

Operation safety

Kickback safety

Maintenance and storage safety

Intended use

in the Box 12

Assemble 13

Prepare 14

Safety features 14

Chain brake mechanical test

Adjust the chain tension

Filling with engine fuel and lubrication oil

Filling the lubrication oil

Operate 19

Start the engine 19

Checking the oil supply

Check chain brake

Stop the engine

Sawing

Felling a tree

Bucking and limbing

Maintenance 27

Technical Data 34

Troubleshooting 36

Warranty 37

05

06

07

09

10

11

15

16

17

18

21

22

23

24

24

25

3AFTER SALES SUPPORT 0345 605 2067

Page 4

SAFETY INFORMATION

Please read these instructions fully before operating or maintaining your machine

DESCRIPTION OF SYMBOLS

The following warning symbols appear throughout

safety measures you should take when operating and maintaining the electric chainsaw.

Read instruction handbook before

operating this machine.

this manual and indicate the appropriate

Do not touch to prevent burns.

WARNING!

This is a warning symbol. This

symbol is used throughout the user

guide whenever there is a risk of

personal injury. Ensure that these

warnings are read and understood

at all times..

114

Wear hearing protection and eye

protection when using the device.

Wear protective gloves

Wear robust footwear when using

the device.

Conforms to European standards.

The exhaust gas is poisonous

and asphyxiating. If inhaled it may

even be lethal. Do not operate the

engine in closed or poorly ventilated

places.

Petrol and petrol vapours are

extremely inflammable.

Beware of kickback (recoil).

Guaranteed sound power level

value in 114 dB

Avoid contact with the tip of the

guide bar (chain return point).

This will result in kickback of the

chainsaw.

Do not hold the saw

with one hand.

Hold the saw firmly with both

hands. Place your right hand on

the rear handle and your left hand

on the front handle.

Do not start or use the equipment

close to people (especially

children) or animals. During

operation, it is recommended that

a minimum distance of 10 metres

from other people be maintained.

AFTER SALES SUPPORT 0345 605 2067

4

Page 5

SAFETY INFORMATION

Please read these instructions fully before operating or maintaining your machine

PULL

STOP

MIN MAX

The port to refuel mixed gasoline.

The port to top up chain oil.

Setting the switch to the

“O”position, the engine stops

immediately.

When you start a cold engine, pull

this choke out.

Shows the directions that the chain

brake is released(white arrow)and

activated (black arrow).

Correct direction of cutting-teeth.

Indication of chain oil adjuster

screw.

GENERAL SAFETY

The chain is designed

exclusively for sawing

wood. You may only fell

trees if you have received

the appropriate training.

The manufacturer cannot

be held liable for damage

caused by improper or

incorrect usage.

Please note that our

equipment has not

been designed for use

in commercial, trade or

industrial applications. Our

warranty will be voided

if the machine is used

in commercial, trade or

industrial businesses or for

the equivalent purposes.

WARNING!

■

Keep this operating and

maintenance manual in a

safe place for reference at

a later date.

■

Read the instructions

carefully. Be familiar

with the controls and

5 AFTER SALES SUPPORT 0345 605 2067

Page 6

SAFETY INFORMATION

Please read these instructions fully before operating or maintaining your machine

the proper use of the

equipment.

■

Never allow children or

people unfamiliar with

these instructions to

use the chainsaw. Local

regulations can restrict the

age of the operator.

■

Never saw while people,

especially children or pets

are nearby. Keep in mind

that the user is responsible

for accidents or hazards

occurring to other people

or their property.

■

This appliance is not

intended for use by

persons (including

children) with reduced

physical, sensory or mental

capabilities or lack of

experience and knowledge,

unless they have been

given supervision or

instruction concerning

use of the appliance by a

person responsible for their

safety.

■

Do not touch chain.

PREPARATION

WARNING!

■

DO NOT operate a

chainsaw with one

hand! Serious injury to

the operator, helpers,

bystanders or any

combination of these

persons may result from

one-handed operation. A

chainsaw is intended for

two-handed use only.

■

Do NOT use the saw if you

are tired, ill or under the

influence of alcohol and/or

drugs.

■

Use safety footwear,

snug-fitting clothing,

protective gloves as well

as eye, hearing and head

protection devices.

■

Use caution when handling

fuel. Move the chainsaw

at least 10 feet (3m) away

from the fueling point

before starting the engine.

■

DO NOT allow other

persons to be near when

starting or cutting with the

6 AFTER SALES SUPPORT 0345 605 2067

Page 7

SAFETY INFORMATION

Please read these instructions fully before operating or maintaining your machine

chainsaw. Keep bystanders

and animals out of the

work area.

■

DO NOT start cutting until

you have a clear work

area, secure footing, and a

planned retreat path from

falling trees or branches.

OPERATION

■

Keep all parts of your body

away from the saw’s chain

when the engine is running.

■

Before you start the

engine, make sure that the

chain is not in contact with

anything.

■

Carry the chainsaw with

the engine stopped, the

chain bar and saw chain

facing rearwards, and with

the exhaust away from

your body.

■

NEVER use a chainsaw

which is damaged,

incorrectly set, incomplete

or loosely assembled.

Make sure that the chain

rotation stops when the

chain brake is applied.

■

Shut off the engine before

setting the chainsaw down.

■

Use extreme caution when

cutting a small size bush

and saplings because

slender material may catch

in the saw chain and be

whipped towards you or

pull you off balance.

■

When cutting a limb that

is under tension, be alert

for spring back so that you

will not be struck when the

tension in the wood fibers

is released.

■

Keep the handles dry,

clean, and free of oil or fuel

mixture.

■

Operate the chainsaw only

in well-ventilated areas.

■

DO NOT operate a

chainsaw from in a tree

unless you have been

specifically trained to do

so.

■

All chainsaw servicing,

7 AFTER SALES SUPPORT 0345 605 2067

Page 8

SAFETY INFORMATION

Please read these instructions fully before operating or maintaining your machine

other than the items

listed in the user manual

safety and maintenance

instructions should be

performed by competent

chainsaw service

personnel.

■

When transporting

your chainsaw, use the

appropriate chain bar

cover.

■

DO NOT operate your

chainsaw near or around

flammable liquids or gases

whether in or out of doors.

An explosion and/or fire

may result.

■

Do not fill the fuel tank, oil

reservoir or lubricate whilst

the engine of the chainsaw

is running.

■

USE THE CORRECT

TOOL: Cut wood ONLY.

Do not use the chainsaw

for purposes for which

it was not intended. For

example, do not use

the chainsaw for cutting

plastic, masonry or

building materials.

■

The engine will create toxic

exhaust fumes as soon

as the engine is started.

Never work in enclosed

areas or in areas with poor

ventilation.

■

NOTE! The chainsaw

is designed for noncommercial, occasional

use for general work such

as stump grubbing, cutting

firewood, etc. It is not

designed for lengthy use.

If it is used for a lengthy

period, the vibrations it

causes in the hands of

the user may result in

circulation problems (white

finger syndrome).

■

The chain is designed

exclusively for sawing

wood. You may only fell

trees if you have received

the appropriate training.

The manufacturer cannot

be held liable for damage

caused by improper or

incorrect usage.

■

Please note that our

equipment has not

been designed for use

in commercial, trade or

industrial applications. Our

8 AFTER SALES SUPPORT 0345 605 2067

8

Page 9

SAFETY INFORMATION

Please read these instructions fully before operating or maintaining your machine

warranty will be voided

if the machine is used

in commercial, trade or

industrial businesses or for

the equivalent purposes.

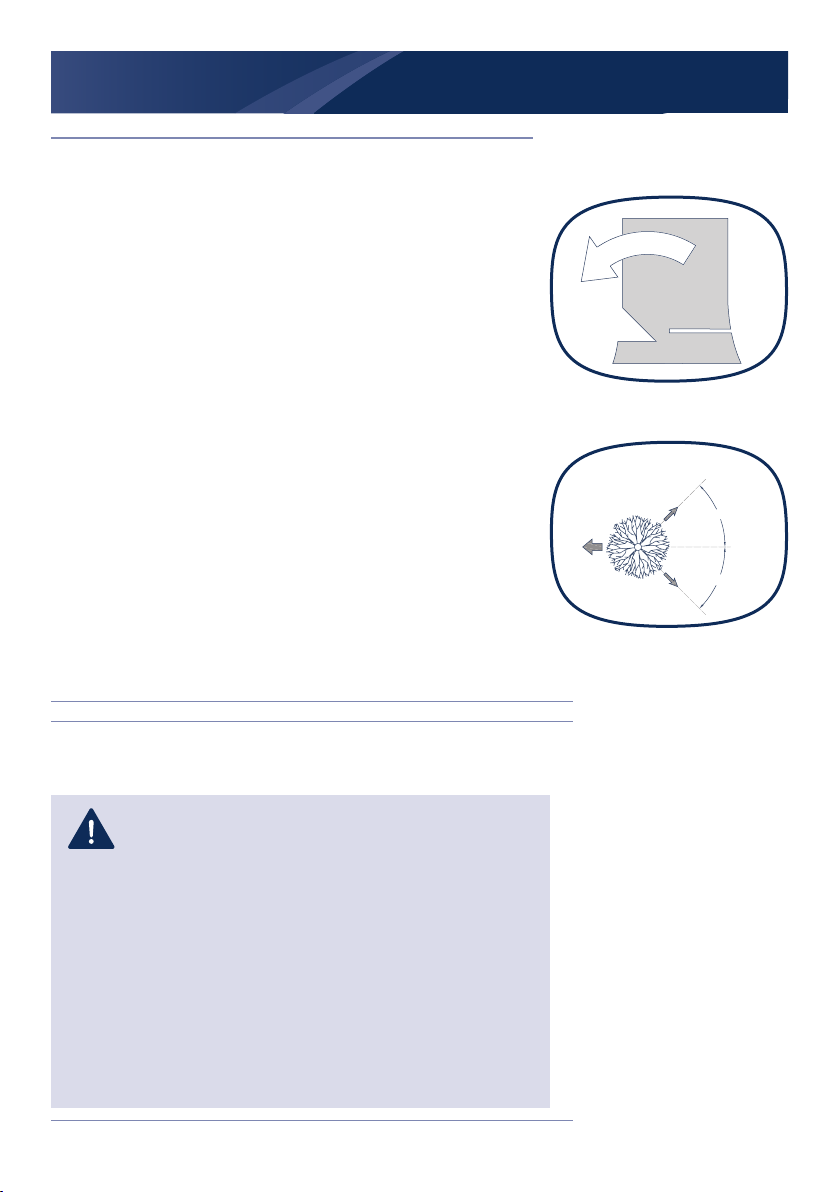

KICKBACK

Kickback may occur when

the nose or tip of the chain

bar touches an object, or

when the wood closes

in and pinches the saw

chain in the cut. If the bar

tip contacts, it may cause

an extremely fast reverse

reaction, kicking the chain

bar up and back towards

the operator. Pinching the

saw chain along the top

of the chain bar may push

the chain bar rapidly back

towards the operator. Either

of these reactions may

cause you to lose control of

the saw, which could result

in serious personal injury.

Do not rely exclusively upon

the safety devices built into

your saw. As a chainsaw

user, you should take several

steps to keep your cutting

jobs free from accident or

injury.

■

NOTE! With a basic

understanding of kickback,

you can reduce or

eliminate the element of

surprise. Sudden surprise

contributes to accidents.

■

Keep a good firm grip on

the saw with both hands,

the right hand on the rear

handle, and the left hand

on the front handle, when

the engine is running. Use

a firm grip with thumbs

and fingers encircling the

chainsaw handles. A firm

grip will help you reduce

kickback and maintain

control of the saw. Never

let go of the Chainsaw.

■

Make sure that the area

in which you are cutting

is free from obstructions.

Do not let the nose of

the chain bar contact a

log, branch, or any other

obstruction which could be

hit while you are operating

the saw.

9 AFTER SALES SUPPORT 0345 605 2067 9

Page 10

SAFETY INFORMATION

Please read these instructions fully before operating or maintaining your machine

■

Cut at high engine speeds.

■

Do not overreach or cut

above shoulder height.

■

Follow the manufacturer’s

sharpening and

maintenance instructions

for the saw chain.

■

Only use replacement bars

and chains specified by

the manufacturer or the

exact equivalent.

■

PINCHING the saw chain

along the BOTTOM of the

cutting (chain) bar may

PULL the saw forward

away from the operator.

■

PINCHING the saw chain

along the TOP of the

cutting (chain) bar may

PUSH the chain bar rapidly

back towards the operator.

■

Any of these reactions may

cause you to lose control

of the saw, which could

result in serious personal

injury.

Beware of the following:

Rotary recoil.

When cutting from under

an object using the top of

the chain the object may

pinch the chain and cause

either a forward force on

the chainsaw or a rearward

force on the object.

When cutting from the top

surface of an object using

the bottom of the chain the

object may pinch the chain

and cause either a rearward

force on the chainsaw or a

forward force on the object.

MAINTENANCE AND STORAGE

SAFETY

■

Keep all nuts, bolts and

screws tight to be sure

the equipment is in safe

working condition;

■

Never store the equipment

with petrol in the tank

inside a building where

fumes can reach an open

flame or spark;

■

Allow the engine to cool

before storing in any

10 AFTER SALES SUPPORT 0345 605 2067 10

Page 11

SAFETY INFORMATION

Please read these instructions fully before operating or maintaining your machine

enclosure;

■

To reduce the fire hazard,

keep the engine, silencer

and petrol storage area

free of hedge, leaves, or

excessive grease;

■

Replace worn or damaged

parts for safety;

■

If the fuel tank has to be

drained, this should be

done outdoors.

■

NOTE! Dispose of soiled

maintenance material and

operating materials at

the appropriate collection

point. Recycle packaging

material, metal and

plastics.

Any use of the machine that

deviates from its intended

use and is not included

in these instructions is

considered unauthorized

use and relieves the

manufacturer from his or her

legal liability.

INTENDED USE

This machine may only be

used outdoors for cutting

wood and in combination

with the original cutting

chains.

This machine is not

designed for heavy duty or

commercial use.

11 AFTER SALES SUPPORT 0345 605 2067

Page 12

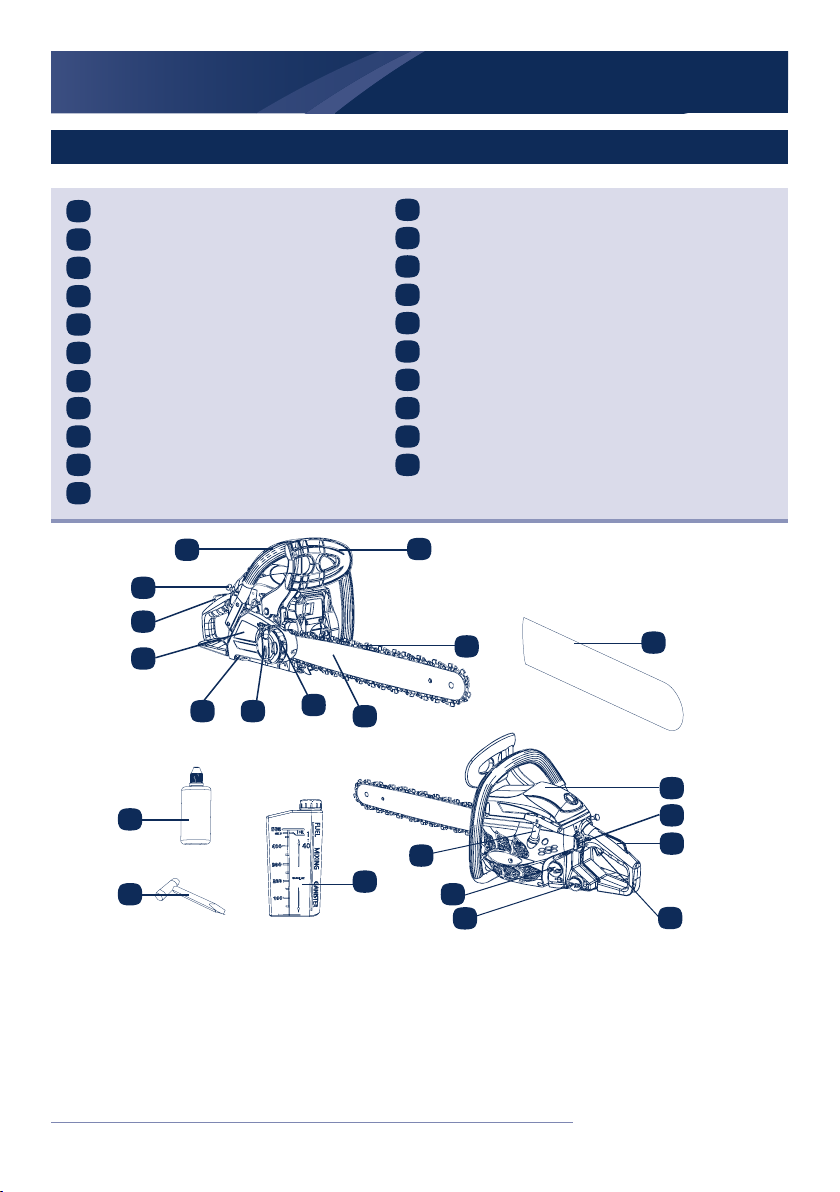

IN THE BOX

PARTS

1

Front handle

2

Brake lever/hand guard

3

Saw chain

4

Chain bar

5

Chain cover

6

Choke control lever

7

Chain tension adjustment wheel

8

Chain cover tighten wheel

9

Primer bulb

10

Fuel cap

11

Lubrication oil cap

1

6

9

5

817

19

20

12

Start handle

13

Throttle trigger

14

Safety trigger lock

15

Air lter cover

16

Stop switch

17

Chain catcher

18

Bar sheath

19

Chain oil 100ml

20

Plug wrench

21

Mixing bottle

2

3

7

4

12

21

10

11

18

15

16

14

13

You will also need:

- 2-Stroke engine oil according JASO FC classic,

- unleaded petrol

- special chainsaw oil (100ml supplied).

Any parts missing? Call the customer helpline on 0345 605 2067, most parts

can be send out on next day delivery.

12 AFTER SALES SUPPORT 0345 605 2067

Page 13

ASSEMBLE

Unpacking

1

i. Unpack all parts and lay them on a flat, stable surface.

ii. Remove all packing materials and shipping devices if

applicable.

iii. Make sure the delivery contents are complete and free

of any damage. If you find that parts are missing or

show damage do not use the product but contact the

aftersales service within 28 days of purchase. Using an

incomplete or damaged product represents a hazard to

people and property.

iv. Ensure that you have all the accessories and tools

needed for assembly and operation. This also includes

suitable personal protective equipment.

This product is free to assemble.

13 AFTER SALES SUPPORT 0345 605 2067

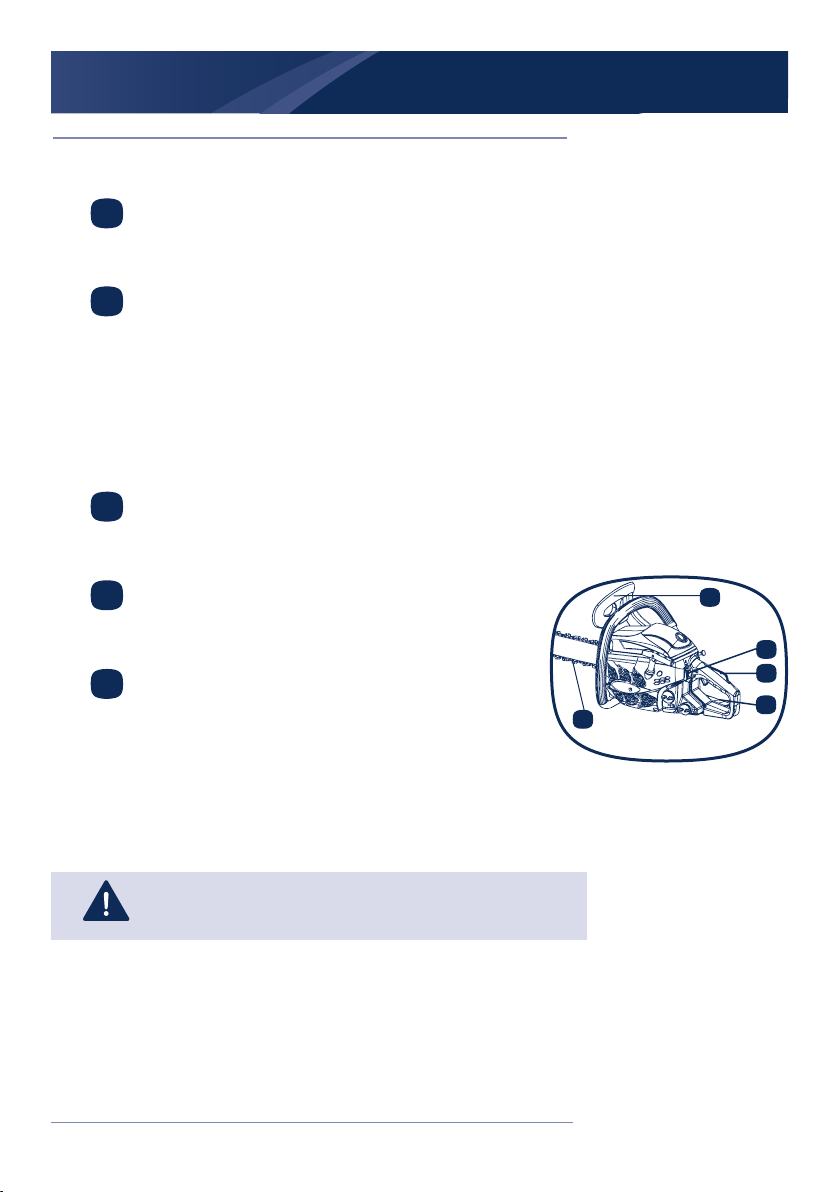

Page 14

PREPARE

16

14

17

2

3

SAFETY FEATURES

LOW KICKBACK SAW CHAIN: helps significantly reduce

3

kickback, or the intensity of kickback, due to specially

designed depth gauges and guard links.

2

CHAIN BRAKE LEVER / HAND GUARD: protects the

operator’s left hand in the event it slips off the front

handle while saw is running.

CHAIN BRAKE: it is a safety feature designed to reduce

the possibility of injury due to kickback by stopping

a moving saw chain in milliseconds. It is activated by

the CHAIN BRAKE lever.

16

STOP SWITCH: immediately stops the engine when

tripped. Stop switch must be pushed to the “START”

position to start or restart engine.

14

SAFETY TRIGGER LOCK: prevents accidental

acceleration of the engine. Throttle trigger cannot be

squeezed unless the safety latch is depressed.

17

CHAIN CATCHER: reduces the danger of injury in the

event saw chain breaks or derails during operation.

The chain catcher is designed to intercept a whipping

chain.

NOTE! Study your saw and be familiar with its parts.

14 AFTER SALES SUPPORT 0345 605 2067

Page 15

PREPARE

a

b

CHAIN BRAKE MECHANICAL TEST

WARNING!

The purpose of the chain brake is to reduce the

possibility of injury due to kickback; however, it

cannot provide the intended measure of protection if

the saw is operated carelessly.

Always test the chain brake before using your saw

and periodically while on the job.

Your chainsaw is equipped with a chain brake that reduces

possibility of injury due to kickback. The brake is activated

if pressure is applied against the brake lever when, as in

the event of kickback, the operator’s hand strikes the lever.

When the brake is actuated, chain movement stops abruptly.

To test the chain brake

a. The Chain brake is DISENGAGED (chain can move) when

the BRAKE LEVER IS PULLED BACK AND LOCKED.

b. The chain brake is ENGAGED (the chain is locked)

when the brake lever is pushed forward. It should not be

possible to move the chain.

NOTE! The brake lever should snap into both

positions. If this is not the case do not use your saw.

Contact the helpline immediately on 0345 605 2067.

15 AFTER SALES SUPPORT 0345 605 2067

Page 16

PREPARE

Tighten

Loosen

1

2

ADJUST THE CHAIN TENSION

1. Place the chainsaw on a flat ground. Slide the chain

cover lever (A) out, and slightly loosen the chain

cover(anti-clockwise rotating).

2. While holding the bar, adjust the chain tension by

turning the chain tension adjust wheel (B) until the

chain engages in the bar channel.

Clockwise= Tighten

Anti-clockwise= Loosen

3. Tighten bar knob securely (clockwise). Hand tighten

only!

NOTE! When tensioned correctly it should be

possible to pull one full chain link free of the bar

channel with ease.

- A new chain will expand its length during the first

period of use. Check and re-adjust the tension

frequently as a loose chain can easily derail or

cause rapid wear of itself and the chain bar.

16 AFTER SALES SUPPORT 0345 605 2067

Page 17

PREPARE

A

B

Tighten

Loosen

CAUTION! If the saw chain is TOO LOOSE or

TOO TIGHT the clutch, chain bar, chain and crank

shaft bearing will suffer premature wear. Above

fig. shows the correct tension A (when cold) and

tension B (when warm). FIG C shows a chain that is

too loose.

4. Tighten the chain cover.

FILLING WITH ENGINE FUEL AND LUBRICATION OIL

This product is powered by a 2-Stroke engine and

requires pre-mixing of petrol and 2-stroke oil.

Use a high quality 2-Stroke engine oil according JASO FC

classic. Do not use automotive oil or 2-stroke outboard

oil. DO NOT mix quantities larger than usable in a 30 day

period.

FUEL MIXTURE: petrol: 2 Stroke engine oil = 40:1 ratio.

Note: there are two faces of this bottle one is 40:1,

and the other is 25:1, please always use 40:1 for

reference.

Using a funnel and keeping the bottle level, pour the

petrol firstly in the left hand side (B) up to the required

level and pour oil to (A) marking level. Shake vigorously to

mix the petrol and oil prior to pouring into the tank(C).

C

D

17 AFTER SALES SUPPORT 0345 605 2067

Page 18

PREPARE

Clean surface around fuel cap to prevent contamination.

Loosen fuel cap slowly. Rest the cap on a clean surface.

Carefully pour fuel into the tank. Avoid spillage. Prior to

fastening the fuel cap, clean and inspect the seal located

inside the fuel cap. Immediately replace fuel cap and

hand tighten. Wipe up any fuel spillage.

NOTE! It is normal for smoke to be emitted from a

new engine after first use.

FILLING THE LUBRICATION OIL

Whenever you refill the fuel tank with petrol you must

also top up the level of chain oil in the chain oil reservoir.

Use special chainsaw oil to lubricate the saw chain.

NOTE! Most stores will sell acceptable oil under

the name “Chainsaw chain oil”.

Important! The fuel mix is added into fuel tank(C),

chain lubrication oil is filled into oil reservoir(D).

Seal one cap prior to removing the second cap.

If you put the fluid into the wrong tank seek

assistance from an expert immediately.

Warning! Lack of chain oil will seriously damage

the chain.

18 AFTER SALES SUPPORT 0345 605 2067

C

D

Page 19

OPERATE

switch

b

START THE ENGINE

WARNING! Do not start the engine whilst holding the

chainsaw in one hand. The saw chain may touch

your body. This is very dangerous.

1. Set the switch to the “1” position.

1

START

2. Engage the chain-brake (push it forward until an audible

click is heard.

2

1

2 3

START

4 6

5

4X

8 9

7

30s

start

10X

3. Press and release the primer bulb (B) 10 times.

3

10X

4. Pull the choke control (A) out to engage.

4

A

B

19 AFTER SALES SUPPORT 0345 605 2067

Page 20

OPERATE

1

2

3

a

5. While holding the saw unit securely on the ground (one foot

fix the rear handle, left hand hold the front handle), pull the

start handle four times to warm the engine. At this step, the

engine will usually not start.

5

4X

6. Push the choke control (A) in to disengage. (Failure to do

this may cause the engine to flood).

6

7. Pull the start handle with smooth to start the engine, usually

it wil start in 5 times.

If the engine does not start, remove the spark plug, dry it

with paper towel and replace. Repeat the start procedure.

More information, check page 28.

7

start

8. After engine starts, allow the saw to run and warm up in

this position for 30 seconds.

8

30s

9. Disengage the chain-brake, by pulling it back.

9

A

B

C

10 Push the safety trigger lock (C) firstly and engage the

throttle trigger (D).

20 AFTER SALES SUPPORT 0345 605 2067

D

Page 21

OPERATE

A

NOTE! If you fail to start your machine or require further

assistance, please contact our after sales support

team at 0345 605 2067.

- When restarting immediately after stopping the

engine or when the engine is warm, it will not be

necessary to use the choke function.

Make sure the cutting blade is pointing away from

your body at all times, the chain may rotate upon

ignition.

CHECKING THE OIL SUPPLY

NOTE! With the chainsaw fully assembled and

adjusted it is important to check the chain oil supply

is dispensing adequate lubrication.

After starting the engine, run the chain at medium speed

and see if chain oil is being dispensed as fig. shown.

NOTE! The oil reservoir should become nearly empty

by the time fuel is used up. Be sure to refill the oil

reservoir every time when refueling the saw.

With the chainsaw switched off, the chain oil flow can be

changed by inserting a screwdriver in the hole (A) on the

bottom of the side of the clutch. Increase or decrease

the oil flow according to your work conditions. Restart

the chainsaw and check the rate of flow meets your

requirements.

Chain oil

21 AFTER SALES SUPPORT 0345 605 2067

Page 22

OPERATE

a

b

CHECK CHAIN BRAKE

This machine is equipped with a chain-brake that will

immediately disable the chain upon the occurrence of

kickback during cutting. The brake is automatically operated

by inertia forces, which act on the weight fitted inside the

front guard. This brake can also be operated manually

with the front guard pushed forward to the guide bar. To

disengage the chain-brake, pull it back until it touches the

front handle.

a= brake disengage

b= brake engage

IMPORTANT! Be sure to confirm brake operation

every time you use the machine and periodically

during the period of use.

HOW TO CONFIRM IF THE CHAIN BRAKE IS FUNCTIONING

CORRECTLY

1. Turn off the engine and leave until cold.

2. With the chainsaw on a flat surface and the chain tensioned

correctly, engage the chain-brake by pushing it forward until an

audible click is heard. Then, wearing protective gloves, attempt

to move the chain by hand in the direction of normal rotation

if this is not possible the chain brake has been engaged. If the

brake is engaged when the chain is rotating at high speed for

extended periods of time this can cause damage to the clutch

or for it to fail completely. When the brake is activated whilst

cutting, immediately release it having first released the throttle

lever and set the chainsaw swtich to “O”.Call service center to

for more help.

22 AFTER SALES SUPPORT 0345 605 2067

Page 23

OPERATE

switch

STOP THE ENGINE

1. Release the throttle lever to allow the engine to idle for a

few seconds.

2. Set the switch to the “O” position.

IMPORTANT: Do not put the chainsaw on the ground

when it is still running. For additional safety, Switch

the chainsaw off when not in use or between cuts.

In the event that the ignition switch will not stop the

saw, pull the choke control out and engage the chain

brake to stop the engine. Call service center.

NOTE! When you have finished using the saw,

always relieve the tank pressure by loosening, then

retightening, both tank caps. Allow the engine to cool

before storing.

23 AFTER SALES SUPPORT 0345 605 2067

Page 24

OPERATE

SAWING

WARNING! Before proceeding to your job, read the

“Safety instructions” section. It is recommended

to first practice sawing easy logs. This also helps

you get accustomed to your unit. Always follow the

safety regulations. The chainsaw must only be used

for cutting wood. It is forbidden to cut other types

of material. Vibrations and kickback will vary with

materials other than wood and the requirements of

the safety regulations would not be met. Do not use

the chainsaw as a lever for lifting, moving or splitting

objects. Do not lock it over fixed stands. It is strictly

forbidden to attach any accessories to this product

other than those supplied by the manufacturer.

It is not necessary to force the saw into the cut. Apply only

light pressure while running the engine at full throttle.

If the saw chain gets caught in the cut, do not attempt to

force it out, but use a wedge or a lever to enlarge the cut,

freeing the saw.

FELLING A TREE

WARNING! You should have received training from a

suitable person before attempting to fell a tree.

When you fell a tree, be sure to warn anyone in close

proximity of the danger

1. Decide the felling direction considering the wind, lean of

the tree, location of heavy branches, ease of job after felling

and other factors.

2. While cleaning the area around the tree, arrange a good

foothold and retreat path.

24 AFTER SALES SUPPORT 0345 605 2067

Page 25

OPERATE

3. Make a notch cut one-third of the way into the tree on the

felling side.

4. Make a felling cut from the opposite side of the notch and

at a level slightly higher than the bottom of the notch.

1

1st cut

felling direction

2nd cut

2

5. Escape path: First clear the tree base and work area of

interfering limbs and brush and clean its lower portion with an

axe. Then, establish two paths of escape (B) and remove all

obstacles. These paths should be generally opposite to the

planned direction of the fall of the tree (A) and about at a 45°

angle. Place all tools and equipment a safe distance away

from the tree, but not on the escape paths.

BUCKING AND LIMBING

WARNING!

- Always ensure a stable foothold. Do not stand on

the log.

- Be alert to the rolling over of a cut log. Especially

when working on a slope, stand on the uphill side

of the log.

- Follow the instructions in “Safety Instructions” to

avoid kickback of the saw.

- Before starting work, check the direction of the

bending force inside the log to be cut. Always

finish cutting from the opposite side of the bending

B

45°

A

45°

B

25 AFTER SALES SUPPORT 0345 605 2067

Page 26

OPERATE

direction to prevent the chain bar from being

trapped in the cut.

- Do not use an unstable foothold or ladder.

- Do not overreach.

- Do not cut above shoulder height.

- Always use both hands to grip the saw.

A log lying on the ground.

Saw down halfway, then roll the log over and cut from the

opposite side.

A log supported off the ground.

In area A, saw up from the bottom one-third and finish by

sawing down from the top. In area B, saw down from the top

one-third and finish by sawing up from the bottom.

Cutting limb of a fallen tree .

First check to which side the limb is bent. Then make an initial

cut from the bend side and finish by sawing from the opposite

side.

WARNING! Be alert to the spring back of a cut limb.

Pruning of a standing tree.

Cut up from the bottom, finish down from the top.

26 AFTER SALES SUPPORT 0345 605 2067

Page 27

MAINTENANCE

LIST OF VULNERABLE PARTS

Description Models or specications

Spark Plug LD L8RTF/902700

Chain bar 160SDEA041

Saw chain PJ057X

MAINTENANCE AFTER EACH USE

WARNING! Before cleaning, inspecting or repairing

your unit, make sure that the engine has stopped

and is cool. Disconnect the spark plug to prevent

accidental starting.

1. Air filter

Dust on the air filter surface can be removed by detaching

the air filter cover (A), removing the filter and tapping a

corner of the filter cover (B) against a hard surface. To clean

dirt in the meshes, brush in petrol. When using compressed

air, blow from the inside.

A

B

27 AFTER SALES SUPPORT 0345 605 2067

Page 28

MAINTENANCE

B

2. Oiling port

Detach the chain bar and check the oiling port (A) for

clogging.

3. Chain bar

When the chain bar is dismounted, remove sawdust from

the bar groove and the oiling port.

Grease the nose sprocket through the grease port on the tip

of the bar.

4. To ensure that the saw’s engine retains its power,the spark

plug must be clean and have the correct electrode gap (0.6

mm).The spark plug(B) must be cleaned or replaced after

every 20 hours of service.

a. Set the 0n/0ff switch to Stop (0).

b. Remove the top air filter cover.

c. Disconnect the ignition cable from the spark plug by

pulling and twisting it simultaneously.

d. Remove the spark plug using the supplied spark plug

wrench .DO NOT USE ANY OTHER TOOLS.

e. Clean the spark plug with a copper wire brush and refit

it,or fit a new spark plug. Then replace the top cover.

A

5. Others

Check for fuel leakage and loose fastenings and damage to

major parts, especially handle joints and chain bar mounting

and Silencer. If any defects are found, make sure to have

them repaired before operating the unit again.

28 AFTER SALES SUPPORT 0345 605 2067

Page 29

MAINTENANCE

a

1

2

HOW TO REPLACE THE CHAIN

1.Pull the chain-brake back and ensure that it has been

released. (the chain cover can only be removed with the

chain-brake disengaged)

2. Then loosen the chain cover tighten wheel and the chain

cover

3. Fit the chain around the bar ensuring that the direction

of the chain is as depicted in the picture on the bar. Fit

the chain on the sprocket. Adjust the position of chain

tensioner so the tensioner pin locates in the hole (A) on

the bar.

4. Adjust the tension to ensure that there is not too much

slack in the chain. Make sure the tensioner pin (B) is

located in the assembly hole (A) on the bar. Pay attention

to the correct direction of the saw chain. Compare with

the picture near the chain sprocket and the picture on

the bar.

Direction of chain

A

B

29 AFTER SALES SUPPORT 0345 605 2067

Page 30

MAINTENANCE

5. Fit the chain cover to the power unit and fasten the

nuts to chainsaw and fasten the nuts until finger tight.

6. While holding up the tip of the bar, adjust the chain

tension by turning the adjustment wheel until the chain

engages in the bar channel. When tensioned correctly it

should be possible to pull one full chain link free of the

bar channel with ease.

7. Tighten the wheel securely finger tight. Then check

the chain for smooth rotation and proper tension while

moving it by hand. If necessary, loosen the chain cover.

8. Tighten the tensioner wheel.

NOTE! A new chain will expand its length during the

first period of use. Check and re-adjust the tension

frequently as a loose chain can easily derail or

cause rapid wear of itself and the chain bar.

CAUTION! If the saw chain is TOO LOOSE or TOO

TAUT, the clutch, chain bar, chain and crank

shaft bearing will suffer premature wear, above

FIG shows the correct tension A (when cold) and

tension B (when warm). FIG C shows a chain that

is too loose.

30 AFTER SALES SUPPORT 0345 605 2067

Page 31

MAINTENANCE

PERIODICAL SERVICE POINTS

1. Start assembly

2. Fan cover

3. Fan

4. Cylinder fins

5. Engine cover

Air cooling system

Dust clogging around the cooling system and the cylinder

fins will cause overheating of the engine. Periodically check

and clean the cooling system and the cylinder fins with a

brush after removing the cylinder cover, the air cleaner and

the recoil case. When installing the cylinder cover and the

cooling system, make sure that switch wires and grommets

are positioned correctly in place.

4

3

1

NOTE! Be sure to unblock the air intake hole.

5

2

31 AFTER SALES SUPPORT 0345 605 2067

Page 32

MAINTENANCE

MAINTENANCE OF THE SAW CHAIN AND CHAIN BAR

NOTE! It is very important for smooth and safe

operation to always keep the cutters always sharp.

The cutters need to be sharpened when:

1. Sawdust becomes powder-like.

2. Cutting requires extra force.

3. The chainsaw does not cut straight and clean.

4. Vibration increases.

5. Fuel consumption increases.

Cutter setting guidance

WARNING! Be sure to wear safety gloves.

Before filing:

1. Make sure the saw chain is held securely.

2. Make sure the engine is stopped.

3. Use a round file with the proper size for your chain

Note: Chain type: 91PJ File size: 5/32 in (4.0 mm)

Place your file on the cutter and push straight forward.

Position the file position as illustrated.

After every cutter has been set, check the depth gauge

and file it to the proper level as illustrated.

Make sure every cutter has the same length and angle as

illustrated.

32 AFTER SALES SUPPORT 0345 605 2067

Page 33

MAINTENANCE

Chain Bar

1. Reverse the bar occasionally to prevent partial wear.

2. The bar rail should always have parallel internal faces

(see diagram). Check for wear of the bar rail. Apply a ruler

to the bar and the outside of a cutter. If a gap is observed

between them, the rail is normal. Otherwise, the bar rail is

worn. Such a bar needs to be corrected or replaced.

33 AFTER SALES SUPPORT 0345 605 2067

Page 34

TECHNICAL DATA

Model CS4100-3

Engine displacement 41cm

Engine 1.5kW

Bar length 40 cm

Chain gauge (0.050˝), 1.27 mm

Idling speed 3300±300 /min

Maximum speed with cutting equipment 11000 /min

Max chain speed 21 m/s

Fuel tank capacity 260 ml

Oil tank capacity 210 ml

Anti-vibration function Yes

Chain wheel teeth 6 Teeth x 9.255 mm

Chain brake Yes

Clutch Yes

Automatic chain lubrication Yes

3

Low-kickback chain Yes

Net weight without chain and chain bar 4.5 kg

Net weight (dry) 6 kg

Fuel consumption (specic) 702g / kWh

LpA sound pressure level 99 dB(A) K=3 dB(A)

34 AFTER SALES SUPPORT 0345 605 2067

Page 35

TECHNICAL DATA

LWA sound power level 114 dB(A)

2

Vibration ahv (front handle) max. 6.5 m/s

K=1.5 m/s

Vibration ahv (rear handle) max. 6 m/s2 K=1.5 m/s

The sound intensity level for the operator may exceed 80 dB(A) and ear protection

measures are necessary.

The declared vibration value has been measured in accordance with a standard test

method and may be used for comparing one product

with another. The declared vibration value may also be used in a preliminary assessment

of exposure.

WARNING! Depending on the actual use of the product the vibration values can

differ from the declared total! Adopt proper measures to protect yourself against

vibration exposures! Take the whole work process including times the product

is running under no load or switched off into consideration! Proper measures

include among others regular maintenance and care of the product and cutting

attachments, keeping hands warm, periodical breaks and proper planning of work

processes!

2

2

35 AFTER SALES SUPPORT 0345 605 2067

Page 36

TROUBLESHOOTING

CAUTION!

- Always switch off the engine and pull the ignition cable before starting any inspection or

adjustment work.

- If, after making an adjustment or repair to the engine, you let it run for a few minutes,

remember that the exhaust and other parts will get hot. Thus, do not touch parts that

emanate heat, as these may burn you.

The following table provides solutions to common problems encountered with the chainsaw.

Fault Possible Cause Solution

1. Incorrect starting procedures

Unit won’t start

or starts but will

not run

Unit starts, but

engine has low

power

Engine hesitates 1. Incorrect carburetor mixture

No power under

load

Runs erratically 1. Incorrect carburetor mixture

2. Incorrect carburetor mixture

adjustment setting

3. Fouled spark plug

4. Fuel lter blocked

5. Chain brake is engaged

1. Incorrect lever position on

choke

2. Dirty air lter

3. Incorrect carburetor mixture

adjustment setting

adjustment setting

1. Incorrectly gapped spark

plug

adjustment setting

1. Follow instructions in the User Guide

or refer to the starting procedure check

list on page 14

2. Have carburetor adjusted by an

Authorised Service Centre

3. Clean/gap or replace plug

4. Replace fuel lter

5. Pull Chain brake in disengage position

1. Move to RUN position

2. Remove, clean and reinstall lter

3. Have carburetor adjusted by an Authorised Service Centre

1. Have carburetor adjusted by an Authorised Service Centre

1. Clean/gap or replace plug

1. Have carburetor adjusted by an Authorised Service Centre

36 AFTER SALES SUPPORT 0345 605 2067

Page 37

TROUBLESHOOTING

Smokes excessively

Poor performance when

operated

Engine dies 1. Empty petrol tank

Insufcient chain

lubrication (the

cutter rail and

chain get hot)

1. Incorrect fuel mixture 1. Use properly mixed fuel (40:1 mix)

1. Blunt chain

2. Loose chain

2. Fuel lter in the wrong position in the tank

1. Empty oil tank for the chain

2. Oil lubrication opening

blocked

1. Sharpen or replace the chain

2. Tension the chain

1. Fill up the petrol tank

2. Completely ll the petrol tank or reposition the fuel lter in the petrol tank

1. Top up the oil tank for the chain

2. Clean the oil lubrication hole in the

cutter bar

Clean the groove in the cutter bar

37 AFTER SALES SUPPORT 0345 605 2067

Page 38

WARRANTY

If your device develops a fault, please don’t hesitate to contact our customer service

department on 0345 605 2067, we can solve 80% of problems via the phone.

1. These warranty terms cover additional warranty rights and do not affect your statutory

warranty rights. All our products are covered by a 3 year manufacturer warranty.

2. Claims must be accompanied by proof of purchase. This must be in the form of a sales

receipt or bank statement and must show that the product has been purchased within the

warranty period as described under point 1, from the retailer that it was originally bought

from. Please keep your receipt safe or staple it to the back of this manual for future

reference.

3. Our warranty covers problems caused by material or manufacturing defects, and will

result in the repair of these defects or replacement of the device with a like for like or

similar article.

4. Our devices have not been designed for commercial, trade or industrial applications, any

signs of use of the equipment in these application or equivalent activities, invalidates the

warranty.

5. The following are also excluded from our warranty:

A. Faults due to accidents, customer misuse or unauthorized repairs

B. Consumable Parts such as cutting line, plant protectors, handles, knobs, extension

cable and other accessories that are compatible with the product.

C. Failure due to lack of routine maintenance.

D. Failure as a result of not using the equipment in accordance with the manual and

safety instructions

E. The adjustment of carburator, spark plug or switches.

Warranty claims should be submitted before the end of the warranty period, see point 1,

but a paid service exists for repairs commissioned after this period. The original warranty

period remains applicable to the device even if repairs are carried out or parts are replaced.

In such cases, the work performed or parts tted will not result in an extension of the

warranty period, and no new warranty will become active for the work performed or

parts tted.

If you have any problems or questions concerning your garden power tool, please contact

our after sales service at 0345 605 2067.

This device may be re-conditioned, like for like or upgraded replacement.

38 AFTER SALES SUPPORT 0345 605 2067

Loading...

Loading...