SpearheadSpearhead

SpearheadSpearhead

Spearhead

1

Q15S, Q18S & Q21S

Q15S, Q18S & Q21S

and 15/18/21 Park

St andard Flail Mower

Operator’s manual

& part s list

Fourth edition

June 2004

© Spearhead Machinery Limited 2004

IMPORTANT - The information contained in this manual is correct

at the time of publication. However, in the course of constant

development, changes in specification are inevitable. Should you

find the information given in this book different to the machine it

relates to please contact the “After Sales Department” for advice.

Please ensure that this manual is handed to the operator before

using the machine for the first time. The operator must fully

understand the contents of this manual before using the machine.

(If the machine is resold the Manual must be given to the new owner.)

SpearheadSpearhead

SpearheadSpearhead

Spearhead

Q15S, Q18S & Q21S

2

Important

The purchaser should ensure that this manual is handed to the operator

before using the machine for the first time and should be satisfied that the

operator fully understands the contents of this manual before being allowed to proceed. If the machine is resold the Operators Manual must be

given to the new owner.

Fill in the details below, you will find it useful to refer to when ordering

spare parts.

Spearhead Machinery Ltd

Green View ,

Salford Priors,

Evesham, Worcestershire

WR1 1 8SW

T el: 01789 491860Fax: 01789 778683

e-mail: enquiries@spearhead.uk.com

Vist our web site: www.spearhead.uk.com

Serial No.

Date of Delivery

Dealer’s address

T elephone No.

SpearheadSpearhead

SpearheadSpearhead

Spearhead

3

Q15S, Q18S & Q21S

Contents

Safety ..............................................................................................4

EC declaration.....................................................................................5

Introduction..........................................................................................6

Safety first ...........................................................................................6

Tractor requirements ...........................................................................6

Attaching to the tractor ........................................................................7

Setting up and adjustment...................................................................8

Front linkage mounting ........................................................................9

Operation ..........................................................................................10

Rotor care ......................................................................................... 11

Servicing and maintenance

Gearbox .....................................................................................12

Flail Rotor (daily)........................................................................ 12

Greasing ....................................................................................13

Regular ...................................................................................... 14

Skids..........................................................................................14

Storage ...................................................................................... 15

Servicing checklist .....................................................................15

T orque Settings..........................................................................16

Troubleshooting .........................................................................16

Servicing log ..............................................................................17

Warranty Conditions .................................................................. 18

Extended warranty .....................................................................19

Parts List

Main body Assembly ..................................................................22

Rotor and Roller Assembly ........................................................24

Headstock - Pre May 2000......................................................... 26

Headstock - Post May 2000 .......................................................28

P.T.O. Shaft Assembly ..............................................................30

Cross shaft Assembly ...............................................................32

Gearbox Assembly ....................................................................34

Stickers...................................................................................... 36

SpearheadSpearhead

SpearheadSpearhead

Spearhead

Q15S, Q18S & Q21S

4

! Never operate the machine with other people present, as it is possible for debris,

including stones, to be discharged from the front and rear of the flail hood.

! Always ensure all cab safety guards are in place and all tractor windows closed.

! Never allow an inexperienced person to operate the machine without supervision.

! Never allow children to play on or around the machine at any time.

! Never attempt any maintenance or adjustment without first disengaging the PTO,

lowering to the ground, stopping the tractor engine and applying the tractor parking

brake.

! Before leaving the tractor cab always ensure that the machine is firmly on the ground,

and the rotor has stopped spinning.

! Never stop the engine with the PTO engaged.

! Always check that all guards are properly fitted, check there are no damaged or loose

parts. Particular attention should be given to the flails to ensure they are not

damaged, cracked or missing.

! Never operate with flails missing.

! Always operate PTO at recommended speed, 540 r.p.m.

! Always inspect work area for wire, steel posts, large stones and other dangerous

materials and remove before starting work.

! Never operate with wire around the rotor. Stop immediately .

! Never attempt to use the machine for any purpose other than that it was designed for .

! Ensure that all warning labels are always visible and that they are not damaged,

defaced or missing.

! Never transport with the PTO engaged.

! When parking up always lower to the ground.

Safety

SpearheadSpearhead

SpearheadSpearhead

Spearhead

5

Q15S, Q18S & Q21S

EC declaration of conformity, conforming to EEC

directive 89/392/EEC

We, S pearhead Machinery Lt d, Greem V iew, Salford Priors, Evesham,

Worcestershire WR11 8SW declare under our sole responsibility that the

product

product code

serial no. & date

type

.........................................................................

.........................................................................

.........................................................................

.........................................................................

Manufactured by the above company complies with the required

provisions of the directive 89/392/EEC, and AMD 91/368/EEC, AMD 93/44/

EEC, AMD 93/68/EEC and conforms with European norm. BSEN 292;

Part 1: 1991 safety of machinery - Terminology, methodology; Part 2; 1991

Safety of machinery - Technical specifications and other national

standards associated with its design and constructions as listed in the

T echnical File.

Signed

Status

Date

.........................................................................

on behalf of Spearhead Machinery Ltd

.........................................................................

.........................................................................

SpearheadSpearhead

SpearheadSpearhead

Spearhead

Q15S, Q18S & Q21S

6

Introduction

The Spearhead Q15S, Q18S and Q21S are robust high capacity flail mowers that are

easy to operate and maintain, but to ensure trouble-free operation this manual should be

carefully studied.

Safety First

Do not start the machine until you fully understand operation and safety precaution

requirements.

Tractor requirements

! Spearhead strongly recommend using a 25 - 50hp tractor with CATEGORY 1 rear

linkage.

! Minimum tractor weight including ballast must be 2500kg.

! PTO must be independent live drive to enable continuous PTO drive even when

tractor clutch is pressed down.

! Before hitching, ensure position control is selected. Do not attempt to hitch in draft

control.

! Check chains and stabilisers must be in good working order to hold the machine

firmly . Do not operate with out checking that chains and st abilisers are tight.

! Spearhead particularly recommend ‘turn buckle’ type check chains.

! Set linkage lift rods to an equal length.

SpearheadSpearhead

SpearheadSpearhead

Spearhead

7

Q15S, Q18S & Q21S

Attaching to the tractor

Fit the machine to the tractor linkage in the standard way , ensuring the correct match of linkage

(CAT 1 pins). Check that the top link is in good order and threads are well lubricated, (as fine

adjustment to height of cut is regulated by the top link). Use stabilisers to take any free movement

out of lower link arms. Before fitting the machine to the tractor linkage you should ensure there is

sufficient front weight to ensure the front wheels are always in contact with the ground. This is

most important for safe transport and stability when turning on slopes.

Before fitting the PTO for the first time, it may be necessary to adjust the length. There should be

maximum engagement of the sliding tubes without bottoming at the shortest operation position. To

check, first connect the mower to the tractor. Pull the PTO shaft apart and connect to the tractor

PTO output shaft and the gearbox input shaft. Hold the half shafts next to each other in the shortest

working position.

If necessary, shorten the inner and outer guard tubes equally (Fig. 2). Shorten the inner and outer

sliding profiles by the same length as the guard tubes. File all sharp edges and remove burrs.

Grease sliding profiles.

To fit the PTO, first clean and grease. Press

pins on the yoke and simultaneously push

the PTO drive shaft on to PTO shaft of the

tractor until pins engage.

The PTO shaft is fitted with a non-rotating

safety guard. It should be secured to the

machine and tractor with the two retaining

chains provided.

Fig. 2

Warning

Fully tighten check chains and linkage stabilisers to hold the machine rigid. There

must be no side ways movement, it is dangerous

SpearheadSpearhead

SpearheadSpearhead

Spearhead

Q15S, Q18S & Q21S

8

Setting up and Adjustment

Height adjustment

To achieve major adjustment to height of cut; reposition the two side plates attached to the

rear roller. A finer adjustment to cut can be achieved by lengthening or shortening the top

link of the tractor (Fig. 3).

Mechanical Offset - The linkage ‘A’ frame (Fig. 4) can be slid along the tube to

obtain numerous settings from central to fully offset by simply slackening the clamping

bolts, position the ‘A’ frame and re-tighten the bolts. Remember to regularly check that

these bolts are tight.

Adjusting height of roller

Fig. 3

Fig. 4

SpearheadSpearhead

SpearheadSpearhead

Spearhead

9

Q15S, Q18S & Q21S

Front linkage mounting

Simply remove the clamping bolts and revolve the ‘A’ frame through 180 degrees so the

linkage mounting pins are facing the rear of the mower. It is recommended the slotted

hole in the top link bracket is used when mounting onto the front linkage, this allows the

front of the mower to float over obstacles more easily.

The tractor front PTO has no standard rotation so it may be necessary to rotate the

gearbox through 180 degrees, to compensate for this irregularity. For most conditions it

is important the rotor rotates as indicated in Fig. 5a.

540 or 1000 rpm

If the tractor has only 1000 rpm. PTO output speed, it is possible to compensate by

swapping the top drive pulley on to the rotor and rotor pulley to the top drive shaft i.e.

smaller pulley driving the larger pulley will act as a reducer (Fig. 5b). Never operate the

PTO at 1000 rpm with the larger pulley driving the smaller rotor pulley. This will

drive the rotor at higher speed and will result in severe damage to the machine.

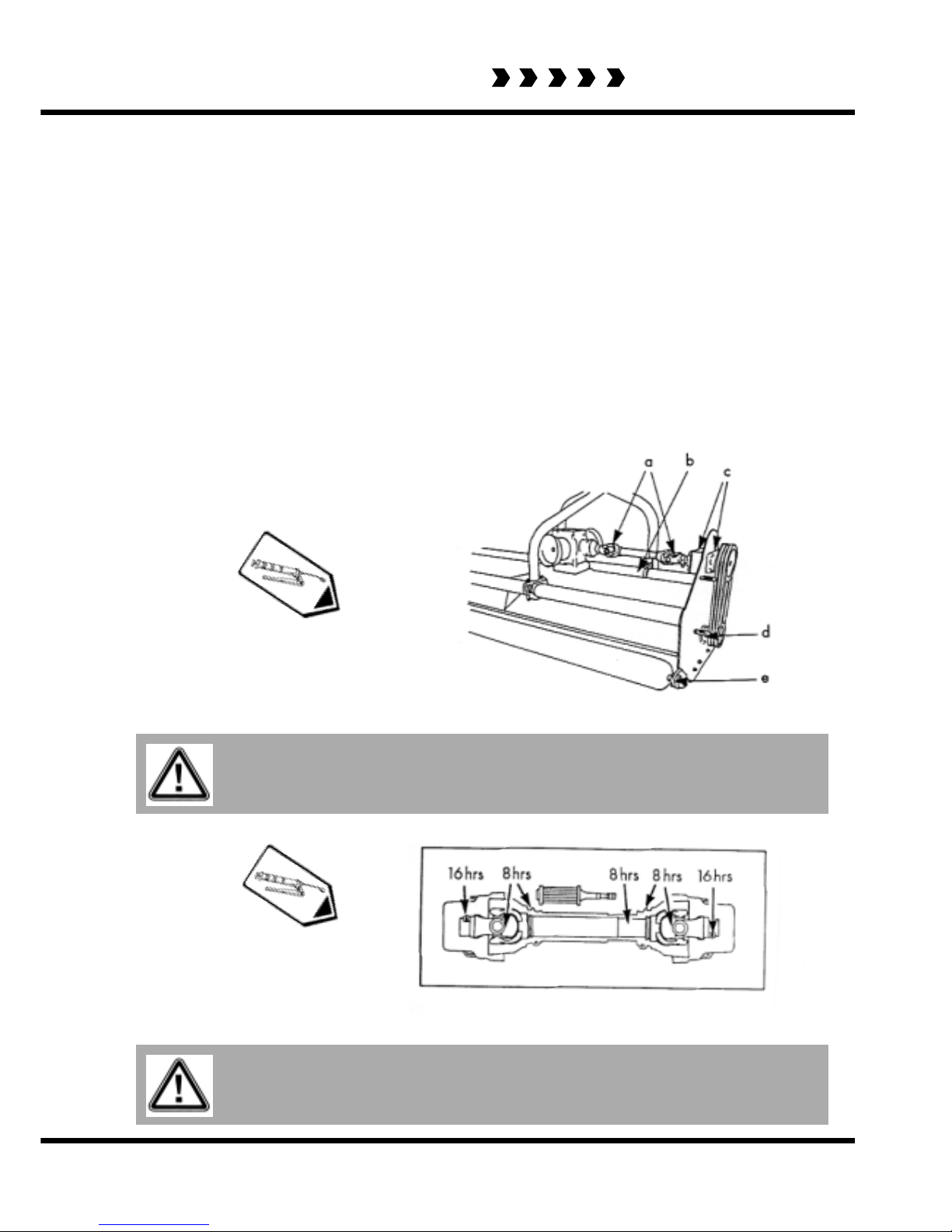

Fig. 5a - position of pulleys for 540r.p.m.

Fig. 5b - position of pulleys for 1000r.p.m.

a Rotation anti-clockwise

b Shaft pulley 150mm

c Shaft pulley 200mm

540r.p.m. 1000r.p.m.

SpearheadSpearhead

SpearheadSpearhead

Spearhead

Q15S, Q18S & Q21S

10

Operation

Engage the PTO only when the tractor engine is at low revs to prevent shock damage

to machine. Slowly increase the engine revs to achieve the standard 540 rpm PTO

speed. If at any time serious vibration occurs, stop the engine immediately and

check that no flails are missing, (following all safety precautions). The cause must

be found and rectified immediately or other components may be affected.

When in work, lower the machine to the ground carrying all its weight on the rear roller ,

allowing the machine to follow the contours of the ground. Select a sensible forward

speed bearing in mind the density of growth, the terrain, and the available horsepower,

taking extra care when turning, particularly on slopes. When turning it is not necessary

to lift the

machine

off the ground but instead allow sufficient room to turn in a large

radius. The machine only needs to be raised when turning a tight corner, or reversing

over dense undergrowth.

Quality of finish is determined by the forward speed i.e. a slow speed will produce a

high quality of cut, whereas faster forward speeds are used when high output is first

priority.

When cutting in extreme conditions or when small stumps, stones and other such solid

objects are likely to be found it is recommended the operator reduces the engine revs

to allow the flails to pivot more easily when striking solid objects, and procede with

caution.

SpearheadSpearhead

SpearheadSpearhead

Spearhead

11

Q15S, Q18S & Q21S

Remember, the rotor is highly complex andexpensive to manufacture, please treat with

care and enjoy the benefits of the Spearhead Rotor.

Rotor Care

Always inspect the condition of flails and bolts on a very regular basis.

Always replace bolts and nuts when replacing flails.

Always use genuine flails, bolts and nuts. The flails and bolts are made to a very high

standard from a high tensile steel, being fully heat treated and subjected to

rigorous testing in very stringent conditions to comply with our rigid quality

control requirements.

Never operate with bolts loose or flails missing.

Never change to a different spec or type of flail, this will immediately put the rotor out of

balance.

Never engage rotor at high PTO speeds.

Warning

Rotor is balanced to be run at PTO speed, do not operate above or below

this speed.

Warning

Never carry out any servicing or maintenance work without first

disengaging the PTO and stopping the tractor.

SpearheadSpearhead

SpearheadSpearhead

Spearhead

Q15S, Q18S & Q21S

12

Servicing and maintenance

Gearbox

! Before first use check gearbox oil level, thereafter check every 8hours.

! After the first 50 hours drain and replace the gearbox oil, thereafter

annually . Replace with EP90.

! Regularly inspect gearbox seals. If oil is leaking replace immediately .

This is your responsibility to maintain a long and reliable working life.

! Check that gearbox bolts are fully tightened.

Warning

Check that all gearbox bolts are tight. When the machine is new there will

be a ‘bedding in’ period when very frequent checking is important.

Warning

It is imperative the grubscrews are checked on the taper locks (once bedded in, loctite glue may prove useful).

Warning

Never carry out any servicing or maintenance work without first disengaging the PTO and stopping the tractor..

Flail Rotor (daily)

! Grease all bearings daily .

! Check there is no wrapping of string, plastic, grass or other debris on rotor shaft and rear

roller bearing.

! Check the condition of flails and ensure all retaining bolts are tight. When flails are re

placed, care must be taken to maintain balance of the rotor shaft, do not change to a

different type.

! Check flail retaining bolt and nut for tightness

! Never operate with any flails missing. This will cause severe vibration and lead to rapid

bearing wear and quickly cause the hood to crack. Cont’d

"

SpearheadSpearhead

SpearheadSpearhead

Spearhead

13

Q15S, Q18S & Q21S

! Blunt flails leave an untidy finish and absorb excessive power, when re-sharpening

always wear protective clothing and goggles.

! When flails are showing severe wear, damage or cracking, they must be replaced

immediately . Never attempt to weld the flails as this will make them very brittle, thus

extremely dangerous. Do not take risks with the cutting flails, if in doubt replace.

! When replacing flails always replace bolts and nuts for new.

! Regularly check that all rotor bearing bolts are tight.

! It is imperative the grubscrews are checked on the taper locks (once bedded in loctite

glue may prove useful).

Greasing

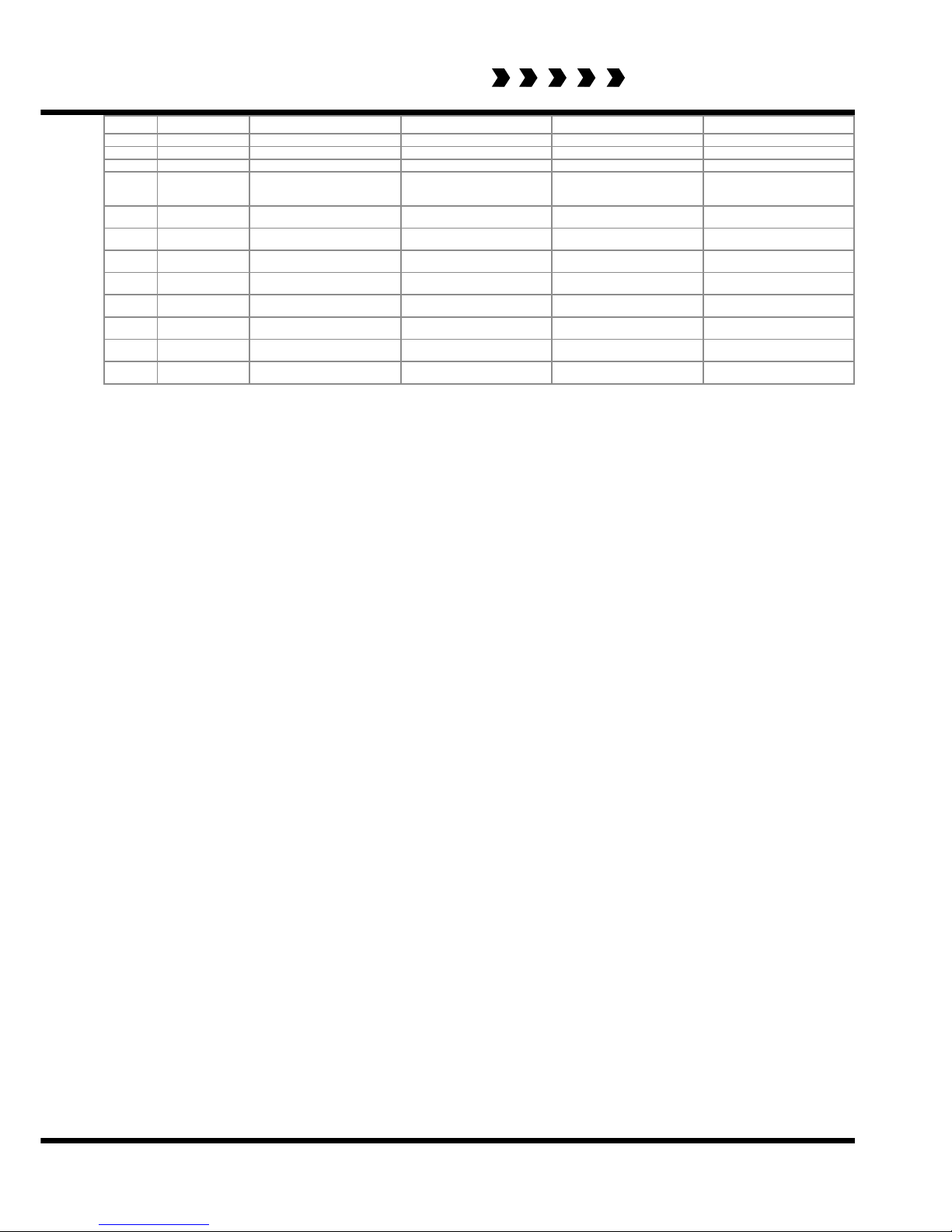

Daily grease all points shown below.

Fig 7

PTO greasing points.

Warning

Grease rotor bearing and rear roller at least every 8 hours and especially

after washing.

Warning

Dismantle and clean PTO sliding surfaces and re-grease universal joints.

Fig. 6

Grease points for rotor , cross shaft and rear roller bearings.

SpearheadSpearhead

SpearheadSpearhead

Spearhead

Q15S, Q18S & Q21S

14

Regular

! Check the condition of drive belts, ensuring they are aligned and properly tensioned to

avoid any unnecessary belt wear.

! Remove both guards for access when tensioning belts, ensure belts are running in

line after adjustment.

! Check there is no wrapping of string, plastic, grass or other debris on rear roller.

N.B.

The pulleys are fitted with taper locks which have 7 screws to tighten, and 3 holes to aid

removal in the pulley centres.

Fig. 8

Tensioning drive belts

Skids

When operating on abrasive soils, particularly in stubbles and similar conditions with thin

ground cover, excessive skid wear may be expected. To provide extra protection and to

prolong life of the skids, special hard facing rods can be used.

SpearheadSpearhead

SpearheadSpearhead

Spearhead

15

Q15S, Q18S & Q21S

Storage

At the end of the season before storing, thoroughly wash the machine off, removing all traces of

grass and dirt. Great care must be taken when washing with high pressure hoses, do not hold the

water jet close to the paintwork. Use steam cleaners with caution and be sure to remove all

detergents to avoid any discolouring or damage to paint. Grease all grease points until fresh

grease shows. Store PTO shaft and drive belts in a dry place.

Servicing checklist (see relevant sections for full details)

Regularly Gearbox: Inspect seals, check bolts for tightness.

Flail rotor: check bolts for tightness, check condition of flails,

check retaining bolts for tightness, check rotor bearing bolts for

tightness.

Daily Maintain correct belt tension.

Check gearbox oil level.

Grease PTO shaft.

Grease all points as shown in diagram.

Every year Drain and replace gearbox oil with EP90.

SpearheadSpearhead

SpearheadSpearhead

Spearhead

Q15S, Q18S & Q21S

16

Problem Caus e Solution

Oil leve l incor rect Check oil level

Oil grade incorrect Check oil grade

Implement overloaded Reduce forward speed

Wrong p. t.o. speed

En sur e tr acto r p.t.o. spee d

matches implement

Belt an d Pulley condit ion Repla ce if ne cessary

Pulley Alignment Check Alignm ent

Incorrect Belt tension Tension belts to sp e c.

Overloading of Implem ent

Reduce forward speed or

increas e height of cut

Wo rking angle too great Red uce offset of implement

Shaft inco rrect length i.e.

bottoming out

R e size p .t.o. shaft as

recommended

Lack of maintenance

Grease p.t.o. shaft as

recommended

Flails worn Replace worn flails

Rotor speed/Direction Check tractor p.t.o. speed

Crop condition Look for suitable conditions

Rotor out of balance See rotor vibration

Wire/st ring in bearing Repla ce bearings

Lack of maintenance Re-balance/replace rotor

Water in bearing Remove debris

Rotor be ar ing failure

Gearbox Overheating

Exce ssive Belt W ear

P.t.o . wear UJ failure

Cut quality

Note:

When operating in arduous conditions with a tractor of more than 80hp, you can reduce the strain

on the drive line by:

a) Running with 1000 speed setup

b) Keeping the PTO shaft straight.

Troubleshooting

Size: Tensile strength: Description: Torque setting:

Nm.

M8 12.9 Pulley clamps 45

M10 8.8 General fasteners 65

M12 8.8 General fasteners 114

M16 8.8 Roller plate bolts 280

M14 10.9 Flail bolts 200

M24 8.8 Head stock bolts 950

Wheel nuts 270

Torque Settings

The torque figures given are recommended maximum settings only

SpearheadSpearhead

SpearheadSpearhead

Spearhead

17

Q15S, Q18S & Q21S

Servicing Log

Date..................................... Details ..................................................................................

...........................................................................................................................................

...........................................................................................................................................

...........................................................................................................................................

Date..................................... Details ..................................................................................

...........................................................................................................................................

...........................................................................................................................................

...........................................................................................................................................

Date..................................... Details ..................................................................................

...........................................................................................................................................

...........................................................................................................................................

...........................................................................................................................................

Date..................................... Details ..................................................................................

...........................................................................................................................................

...........................................................................................................................................

...........................................................................................................................................

Date..................................... Details ..................................................................................

...........................................................................................................................................

...........................................................................................................................................

...........................................................................................................................................

Date..................................... Details ..................................................................................

...........................................................................................................................................

...........................................................................................................................................

...........................................................................................................................................

Date..................................... Details ..................................................................................

...........................................................................................................................................

...........................................................................................................................................

...........................................................................................................................................

Date..................................... Details ..................................................................................

...........................................................................................................................................

...........................................................................................................................................

...........................................................................................................................................

Date..................................... Details ..................................................................................

.............................................................................................................................................

.............................................................................................................................................

SpearheadSpearhead

SpearheadSpearhead

Spearhead

Q15S, Q18S & Q21S

18

The Spearhead Warranty

Spearhead warrant s that the Spearhead machine referred to in the W arranty Registration Form will

be free from defects in materials and workmanship for a period of 12 months from the date of sale.

This warranty does not affect your statutory rights, but merely adds to them. Should you have a

problem within 12 months from the date of sale please contact your original Spearhead dealer , or

Spearhead’ s Service Department. Any part found to be defective during this period will be replaced

or repaired, at Spearhead’ s discretion, by the dealer or a Spearhead Service Engineer .

Spearhead Warranty Conditions

1 The Warranty Registration Form must be completed and returned to S pearhead within 30

days of the date of sale.

2 This warranty does not cover defects arising from fair wear and tear , wilful damage,

negligence, misuse, abnormal working conditions, use in competition, failure to follow

Spearhead’s instructions (oral or written, including all instructions and recommendation

made in the Operator’s Manual) or alteration or repair of the machinery without Spearhead’s

approval.

3 The machinery must have been serviced in accordance with the Operator’s Manual and the

Service Log must have been kept up to date and made available to the dealer should

service, repair or warranty work be undertaken.

4 This warranty does not cover claims in respect of wearing parts such as blades, flails,

paintwork, tyres, belts, hydraulic hoses, bearings, bushes, linkage pins, top links, ball ends

unless there is a manufacturing or material defect or the cost of normal servicing items such

as oils and lubricants.

5 This warranty does not cover any expenses or losses incurred whilst the machinery is out of

use for warranty repairs or parts replacement.

6 This warranty does not extend to parts, materials or equipment not manufactured by

Spearhead, for which the Buyer shall only be entitled to the benefit of any such warranty or

guarantee given by the manufacturer to Spearhead. Only genuine S pearhead replacement

parts will be allowable for warranty claims.

7 All parts replaced by S pearhead under warranty become the property of Spearhead and

must be returned to Spearhead if S pearhead so request. Such parts may only be disposed

of after a warranty claim has been accepted and processed by Spearhead.

8 Spearhead is not liable under this warranty for any rep airs carried out without Spearhead’s

written consent or without Spearhead being af forded a reasonable opportunity to inspect the

machinery the subject of the warranty claim. Spearhead’ s written consent must, therefore,

be obtained before any repairs are carried out or parts replaced. Use of non-S pearhead

parts automatically invalidates the S pearhead Warranty . Failed components must not be

dismantled except as specifically authorised by Spearhead and dismantling of any

components without authorisation from Spearhead will invalidate this warranty .

9 All warranty claims must be submitted to Spearhead on S pearhead W arranty Claim Forms

within 30 days of completion of warranty work.

Using the machine implies the knowledge and acceptance of these instructions and

the limitations contained in this Manual.

SpearheadSpearhead

SpearheadSpearhead

Spearhead

19

Q15S, Q18S & Q21S

Extended Warranty

As an extension to the 12 month warranty set out above, Spearhead will provide an additional 12

month warranty cover subject to the Spearhead W arranty Conditions above and the Extended

Warranty Conditions below .

Extended Warranty Conditions

1 The extended warranty applies to hydraulic pumps, motors, valves and gearboxes only . It

does not apply to other parts, to consumables such as lubricants, seals or filters or to

labour charges.

2 The machinery must have had an annual service carried out by an Authorised S pearhead

Dealer or a Spearhead Service Engineer within 1 month of the first anniversary of the date

of sale and the Service Report form must have been completed and stamped by the

servicing dealer or Spearhead Service Engineer and sent to S pearhead within 14 days after

the first annual service.

3 The extended warranty does not cover costs of transportation of the machinery to or from

the dealer or Spearhead or the call out costs or travelling expenses of on-site visit s.

Transfer of W arranty

The Spearhead warranty may be transferred to a subsequent owner of the machinery (for use within

the UK) for the balance of the warranty period subject to all of the warranty conditions and provided

that the Change of Owner form is completed and sent to Spearhead within 14 days of change of

ownership.

Spearhead reserves the right to make alterations and improvements to any machinery

without notification and without obligation to do so.

SpearheadSpearhead

SpearheadSpearhead

Spearhead

Q15S, Q18S & Q21S

20

SpearheadSpearhead

SpearheadSpearhead

Spearhead

21

Q15S, Q18S & Q21S

Q15, Q18S & Q21S

Standard Flail Mower

Parts list

SpearheadSpearhead

SpearheadSpearhead

Spearhead

Q15S, Q18S & Q21S

22

Main Body Assembly

SpearheadSpearhead

SpearheadSpearhead

Spearhead

23

Q15S, Q18S & Q21S

Main Body Assembly

Ref. No Part No. English Description French Description German Description Danish Description

Réfé Numéro de Dési

g

nation en Anglais Désignation en Français Désignation en Allemand Désignation en Danois

Ref. No Teilenummer En

g

lische beschreibun

g

Französische beschreibungDeutsche beschreibun

g

Dänische beschreibun

g

Ref. No Reservedelsnu Engelsk beskrivelse Fransk beskrivelse Tysk beskrivelse Dansk beskrivelse

1771532 1.5m Main body Caisse Körper Krop

1771538 1.8m Main body Caisse Körper Krop

1771584B 2.1m Main body Caisse Körper Krop

1771584C

2.1m body (Post ser. No.

10312444526)

Caisse Körper Krop

2 5770010 Gearbox Multiplicateur Getriebekasten Gearkasse

3 4770860EC Bearing EC collar Douille Klemmring Klemring

4 1771513 Bracket Support - Étrier Konsole Konsol

5 1771520 Bearing bracket Support - Étrier Konsole Konsol

6 4770926 Pulley Poulie Riemenscheibe Remskive

7 4770927 Pulley Poulie Riemenscheibe Remskive

8 4770922 Clamping element Palier - Roulement Lager Leje

9 4770923 Clamping element Palier - Roulement Lager Leje

10 4770870 Drive belt Caoutchouc Gummi Gummi

11 1772211 Layshaft Arbre Welle Aksel

12 4772229 Key Clavette Nut Not

5770066 Cross shaft Arbre Welle Aksel

5770115

Cross shaft - post serial

no. 1031421392

Arbre Welle Aksel

14 2770436 Flat washer Rondelle Spannscheibe Spændeskive

15 2770419 Bolt Boulon Bolzen Bolt

16 2770417 Nut Écrou Mutter Møtrik

17 2770443 Bolt Boulon Bolzen Bolt

18 2770442 Spring washer Rondelle Spannscheibe Spændeskive

1771511A Shaft guard Protecteur Schutz / Deckel Beskyttelse / Dæksel

1771511L

Shaft guard - post serial

no. 1031421392

Protecteur Schutz / Deckel Beskyttelse / Dæksel

21 2770469 Spring washer Rondelle Spannscheibe Spændeskive

22 2770396 Bolt Boulon Bolzen Bolt

23 2770535 Bolt Boulon Bolzen Bolt

24 2770536 Full nut Écrou Mutter Møtrik

25 2770393 Bolt Boulon Bolzen Bolt

8550130 Rubber flap 1.5m Caoutchouc Gummi Gummi

8400205 Rubber flap 1.8m Caoutchouc Gummi Gummi

8400209 Rubber flap 2.1m Caoutchouc Gummi Gummi

27 5770107 Cone Protecteur Schutz / Deckel Beskyttelse / Dæksel

1771514A Belt guard Protecteur Schutz / Deckel Beskyttelse / Dæksel

1771514B

Belt guard - Post serial

No. 1031221394

Protecteur Schutz / Deckel Beskyttelse / Dæksel

1771534 Retaining strip 1.5m Caoutchouc Gummi Gummi

1771531 Retaining strip 1.8m Caoutchouc Gummi Gummi

1771572 Retaining strip 2.1m Caoutchouc Gummi Gummi

31 2770418 Bolt Boulon Bolzen Bolt

32 1771530 Skid Construction Fabrikationsteil Fabrikatiensdel

33 2770458 Bolt Boulon Bolzen Bolt

34 2770381 Bolt Boulon Bolzen Bolt

41 8777516 End cap Protecteur Schutz / Deckel Beskyttelse / Dæksel

28

1

26

30

19

13

SpearheadSpearhead

SpearheadSpearhead

Spearhead

Q15S, Q18S & Q21S

24

Rotor and Roller Assembly

Rotor

Roller

SpearheadSpearhead

SpearheadSpearhead

Spearhead

25

Q15S, Q18S & Q21S

Rotor and Roller Assembly

Ref. No Part No. English Description French Description G erman Description Danish Description

Réfé Numéro de Désignation en Anglais Désignation en F r ançais Désignation en Al lemand Dés ignation en Danoi s

Ref. No Teil enummer En

g

li sche beschreibungFranzösische Deutsche beschreibungDäni sche bes chreibun

g

Ref. No Reservedelsn Engelsk beskrivelse Fransk beskrivelse Tysk beskrivelse Dansk beskrivelse

SA00092 1.5m rotor assembly Rotor Rotor Rotor

SA00102 1.8m rotor assembly Rotor Rotor Rotor

SA00103 2.1m rotor assembly Rotor Rotor Rotor

2 7770715 Twist e d flail Fléau Schlegel Slagle

3 1777310 Beari n g housing Carter Gehäuse Hus

4 1771529 Housing Carter Gehäuse Hus

5 4770891 Rotor bearing Palier - Roulement Lager Leje

6 2771610 Circlip C irclip Sicherungsring Lasering

7 1777209 Retai n i n g washer Rondelle Spannscheibe Spændeskive

8 2770506 Bolt Boulon Bolzen Bolt

9 4771123 Seal Rondelle Spannscheibe Spændeskive

10 1777312 Rotor shaft cover Prot ecteur Schutz / Deckel Beskyttelse / Dæksel

11 2770467 Grease nipple Graisseur Schmiernippel Smørenippel

11a 2770497 G rease nipple Graisseur Schmierni ppel Smørenippel

12 2770436 Flat washer Rondelle Spannscheibe Spændeskive

13 2770443 Bolt Boulon Bolzen Bolt

14 2770397 Bolt Boulon Bolzen Bolt

15 2770417 Nut Écrou Mutter Møtrik

1

Rotor

Roller

Re f. No Part No. English Des cription French Description Ger m an Des cription Danish Description

Réfé Numéro de Désignation en Anglais Désignation en Français Désignation en Allemand Désignation en Danoi s

Ref. No Tei lenummer Englis c he Franz ösis che Deutsc he bes chrei bung D äni sche bes chreibung

Ref. No Reservedelsn Engelsk beskrivelse Fransk beskrivelse Tysk beskrivelse Dansk beskrivelse

1771533 Roller - 1.5m Rouleau Hinterlaufwalze Bagvalse

1771527 Roller - 1.8m Rouleau Hinterlaufwalze Bagvalse

1771582 Roller - 2.1m Rouleau Hinterlaufwalze Bagvalse

2 1777314 Stub shaft Arbre Well e Aksel

3 4771604 Rear roller bearing Palier - Roulement Lager Leje

4 2777519 Circlip Rondelle Spanns cheibe Spændeskive

5 2771108 Circ lip Bague - Anneau Ring Ring

6 1777231A Hub cover Protecteur Schut z / Deckel Beskyttelse / Dæksel

7 2770468 Grease nipple Graisseur Schmiernippel Smørenippel

1771526A Roller plate - LH Plaque Platte Plade

1771526AR Roller plate - RH Plaque Platte Plade

9 2770436 Fl at washer Rondelle Spannscheibe Spændeskive

10 2770397 Bolt Boulon Bolzen Bolt

2770397 Bolt Boulon Bolzen Bolt

2770259

Coach Bolt - Post

seria l No's

1040815199 (Q15S)

1041918308 (Q18S)

1042121442 (Q21S)

Boulon Bolzen Bolt

12 2770417 Nut Écrou Mutter Møtrik

Not illustrated

Sans gravure Nicht abgebildet Ikke illustreret

6770933 1.5m scraper wire ropeChaîne - chaînette Kette Kæde

6770932 1.8m scraper wire rop

e

Chaîne - chaînette Kette Kæde

1

8

11

SpearheadSpearhead

SpearheadSpearhead

Spearhead

Q15S, Q18S & Q21S

26

Headstock Assembly

Pre May 2000

SpearheadSpearhead

SpearheadSpearhead

Spearhead

27

Q15S, Q18S & Q21S

Ref. No Part No. English Description Fre nch Description German Description Danish Description

Réfé Numéro de Dési

g

nation en Anglais Désignation en Français Désignation en Al lemand Désignation en Danois

Ref. N o Teile nu mmer En

g

lisc he beschreibungFranzösische Deutsche beschreibungDäni sche beschreibun

g

Ref. No Reservedelsn Engelsk beskrivelse Fransk beskrivelse Tysk beskrivelse Dansk beskrivelse

1 1771524

Headstock - Pre May

2000

Poupée A-rahmen A-ramm e

2 1771503 Headstock clamp Bride de retenue Halter Holder

3 2770454 Flat washer Rondelle Spannscheibe Spændeskive

4 2770425 Bolt Boulon Bolzen Bolt

5 2770447 Nut Écrou Mutter Møtrik

6 1771525 L/H Lower link brkt Plaque Platte Pl ade

7 1771525R R/ H Lower link brkt Plaque Platte Plade

8 6310206 Lynch Pin Goupille B olzen Bolt

11 6310202 Cat 1Top link pin Goupille Bolzen Bolt

Headstock Assembly

Pre May 2000

SpearheadSpearhead

SpearheadSpearhead

Spearhead

Q15S, Q18S & Q21S

28

Headstock Assembly

Post May 2000

SpearheadSpearhead

SpearheadSpearhead

Spearhead

29

Q15S, Q18S & Q21S

Re f. No Part No. English Description French Description German Description Danish Description

Réfé Numéro de Dési

g

nation en Anglais Désignation en Français Désignation en Allemand Dés ignation en Danois

Ref. No Teilenummer En

g

lische beschreibungFranzösische Deutsche beschreibungDänische beschreibun

g

Ref. No Reservedelsn Engelsk beskrivelse Fransk beskrivelse Tysk beskrivelse Dansk beskrivelse

1 1 771524 A

He adst ock - Post M ay

2000

Poupée A-rahmen A-ram me

2 1771573 Headstock rear li nk Construction Fabrikat ionsteil Fabrikat iensdel

3 1771503A Headstock clamp Bride de retenue Halter Holder

4 2770517 F lat washer Rondelle Spannscheibe S pændeskiv e

5 2 770409 Nut Écrou Mutter Møtrik

6 8777516 End cap Bouchon Sc hr aube Prop

7 2770454 F lat washer Rondelle Spannscheibe S pændeskiv e

8 2770456 Spr ing washer Rondelle Spannscheibe Spændeskive

9 2 770425 Bolt Boulon Bolzen Bolt

10 6310229 Lower link pin Goupille Bolz en Bolt

11 6310202 Top link pin Goupille Bolz en Bolt

12 63 102 06 Pin Goupille Bolze n Bolt

13 2770549 Bolt Boulon Bolzen Bolt

Headstock Assembly

Post May 2000

SpearheadSpearhead

SpearheadSpearhead

Spearhead

Q15S, Q18S & Q21S

30

4

3

PTO Shaft Assembly

1

11

2

12

SpearheadSpearhead

SpearheadSpearhead

Spearhead

31

Q15S, Q18S & Q21S

PTO Shaft Assembly

R ef. No Part N o. E nglish Description French Description G erman D escription Da nish Description

Réfé Numéro de

p

ièce Désignation en Anglais Désignation en Français Désignation en Allemand Désignation en Danois

Ref. No Teilenummer En

g

lische beschreibungFranzösische beschreibungDeutsche beschreibungDänisch e be sch re ibun

g

Ref. No Reservedelsnum Engelsk beskriv e lse Fra n sk be skriv else Tysk beskrivelse Dansk be skriv e lse

5770069 P.t.o. shaft assembly Prise de froce Gelenkwelle Pto-aksel

1 5772259 Complete guard Protecteur Schutz / Deckel Beskyttelse / Dæksel

2 5771020 R etaining chain Chaîne - chaînette Kette Kæde

3 5770112 Y oke Joint (d'assemblage) Gelenkteil Gaf fel

4 5771023 Release button Levier Bedienungshebel Betjeningshåndtag

5 5770113 Cross journal

Portée d'arbre

transversale

Kreuzgarnitur Kardan k ryds

6 5772273 Inner tube y oke Joint (d'assemblage) Gelenkteil G affel

7 5772274 O uter tube y oke Joint (d'assemblage) Gelenkteil Gaffel

8 277 05 1 5 Ro ll p in G o u pille Bo lzen Bolt

9 5772270 O uter profile tube Tube Schlauch Slange

10 5772269 Inner profile tube Tube Schlauch Slange

11 5771336 Outer bearing Palier-Roulement Lager Leje

12 5771337 Inner bearing Palier-Roulement Lager Leje

SpearheadSpearhead

SpearheadSpearhead

Spearhead

Q15S, Q18S & Q21S

32

Cross Shaft Assembly

SpearheadSpearhead

SpearheadSpearhead

Spearhead

33

Q15S, Q18S & Q21S

Cross Shaft Assembly

Ref. Part No. English Description French Description German Description Danish Description

Réfé Numéro de pièce Désignation en Anglais Désignation en Français Désignation en Désignation en Danois

Ref. Teilenummer Englische beschreibung Französische Deutsche beschreibung Dänische beschreibung

Ref. Reservedelsnum Engelsk beskrivelse Fransk beskrivelse Tysk beskrivelse Dansk beskrivelse

1 5772279 6 Spline yoke Cannelure Nut Not

2 2770467 Gr ea se nipple Graisseur Sc hmiernippel Smørenippe l

3 5770113 Cross journal

Portée d'arbr e

transvers ale

Kreuzgarnitur Kardankryds

4 5772274 Tube y oke Tube Sc hlauch Slange

5 2770527 Pin Goupill e Bolzen Bolt

6 5772275

Outer profile tube 150mm

Tube Schlauch Slange

7 5772271 Clamp y oke - 35mm Bride de retenue Halter Holder

2770424 Bolt Boulon Bolzen Bolt

2770417 Ny loc nut Écrou M u t t e r Mø trik

2770436 Flat wa sher Rondelle Span nscheibe Spændeskiv e

8

SpearheadSpearhead

SpearheadSpearhead

Spearhead

Q15S, Q18S & Q21S

34

Gearbox Assembly

15

15

16

17

18

19

15

SpearheadSpearhead

SpearheadSpearhead

Spearhead

35

Q15S, Q18S & Q21S

Gearbox Assembly

Ref. No Part No. English Description French Description German Description Danish Description

Réfé Numéro de Désignation en Anglais Désignation en F rançais Désignation en Allemand Désignation en Danois

Ref. No Teilenumme

r

Englische beschreibungFranzösische Deutsche beschreibungDänische beschreibun

g

Ref. No Reser vedelsn Engelsk beskrivelse Fransk beskrivelse Tysk beskrivelse Dansk beskrivelse

1 N/A Casing Chässis Rahmen Ramme

2 5777201 Cover Protecteur Schutz / Deckel Beskyttelse / Dæksel

3 5 777203 Gasket Garnitu re Dichtung Pakning

4 2770402 Cover bolt Boulon Bolz en Bolt

5 N/A S haft Arbre Welle Aksel

6 4777205 Bearing Palier - Roulement Lager Leje

7 4771620 Bearing Palier - Roulement Lager Leje

8 4771506 Oi l seal Joint Öldichtung Pakning

9 4777201 Bearing Palier - Roulement Lager Leje

10 4771600 B ear ing Palier - Roulement Lager Leje

11 4771124 Oil seal Joint Öldic htung Pakning

12 N/A Gearwheel & pinon Vitesse Getriebe Gear

13 1777602 Rear shaft guard Protecteur Schutz / Deckel Beskyttelse / Dæksel

14 5777208 Plug Bouchon Schraube Prop

15 27711 29 Circlip Circlip Sicherungsring Las e ring

16 27711 08 Circlip Circlip Sicherungsring Las e ring

17 27711 07 Circlip Circlip Sicherungsring Las e ring

18 2770407 Bolt Boulon Bolzen Bolt

19 2770434 Washer

Rondelle Spanns cheibe Spændeskive

SpearheadSpearhead

SpearheadSpearhead

Spearhead

Q15S, Q18S & Q21S

36

123

45

6

7

Stickers Assembly

SpearheadSpearhead

SpearheadSpearhead

Spearhead

37

Q15S, Q18S & Q21S

Stickers Assembly

Ref. No Part No. English Description French Description German Description Danish Description

Réfé Numéro de Désignation en Anglais Désignation en Français D és ignation en Al lemand Désignation en Danois

Ref. N o Teile n u m m e r En

g

lisc he besc hreibungFranzösische Deutsche beschreibungDäni sche beschreibun

g

Ref. No Reservedelsn Engelsk beskrivelse Fransk beskrivelse Tysk beskrivelse Dansk beskrivelse

1 8770357

Keep safe distance

when machine is

running' Sticker

---

2 8770356

'Do not remove/open

guard' Sticker

---

3 8770358

'Shut off engine,

remove key' Sticker

---

4 8770360

' S tay clear of mower

flails' Stic k er

---

5 8770363 'Read manual' St i cker - - 6 8770306 'Keep bol t tight' Sticker - - 7 8770322 'Grease point' St icker - - -

SpearheadSpearhead

SpearheadSpearhead

Spearhead

Q15S, Q18S & Q21S

38

5

1

Stickers Assembly

4

3

2

SpearheadSpearhead

SpearheadSpearhead

Spearhead

39

Q15S, Q18S & Q21S

Stickers Assembly

R ef . No Part No. En glish Descriptio n French Descript ion German Description Danish Descript ion

Réfé Numéro de Désignation en Anglais Désignation en Français Désignation en Allemand Désignation en Danois

Ref. No Teilenummer En

g

lische beschreibungFranzösische Deutsche beschreibungDänische beschreibun

g

Ref. No Reserv edelsn Engelsk beskrivelse Fransk beskrivelse Tysk beskr ivelse Dansk beskrivelse

1 8770346

'Check - chains''

Sticker

---

2 8770307

'Manufactured in Gr eat

Britain' Sticker

---

3 8770340 'Read Manual' S ticker - - -

4 8770305

'Recommended PTO

speed 540 rpm' S t ic k er

---

5 8770341 'Belt t ension' S ticker - - -

Loading...

Loading...