Page 1

INSTALLATION, OPERATING

AND MAINTENANCE INSTRUCTIONS

DERV(DX/CHW)

C/W CHILLED WATER AND SPLIT SYSTEMDX COOLING

QA/IOM/63 ISSUE 2 – DERV

UNITS

Page 2

1 General Description

SPC DERV(DX/CHW) units are heat recovery ventilator units incorporating heat recovery heat

pipes, dehumidifier heat pipes and an active DX cooling coil or chilled water cooling coil. DX units

are supplied with a matched condensing unit for external mounting and for piping to the DERVDX

unit which acts as the indoor unit in the split system.

The units are intended to fully condition outside air by taking advantage of the cooling potential of

dirty extract air and the cooling and dehumidifying potential of a DX evaporator coil or chilled

water cooling coil.

The units are constructed in two halves; one half incorporating the extract fan(s) and extract

section of the heat recovery heat pipe, the other half contains the supply fan(s), supply section of

the heat recovery heat pipe plus chilled water/DX cooling coil c/w heat pipe wrapped around it.

The wrap around heat pipe precools the air prior to the cooling coil and reheats it after the cooling

and dehumidifying process to generate neutral ventilation air.

Units incorporate filtration on both the supply and extract side and are designed to be mounted

out of sight above false ceilings, suspended from the ceiling slab.

The supply and extract sections terminate in sheet metal flanges for the attachment of ducting.

Ducting design will be to suit the desired distribution within the premises and is largely beyond the

scope of this manual.

Units are supplied with an on/off and three speed controller to control the rotational speed of the

backward curved centrifugal fans and hence control the throughput of air on both the supply and

extract side. Further control of the air throughput must be made as part of the ducting design with

branch sizes matched to air volumes and manual volume control dampers fitted where

necessary. DX versions supplied with matched outdoor units incorporate a relay for switching of

the compressor and an additional temperature setting switch.

2 Technical Details

The table below gives details of the nominal operating characteristics of the DERV units along

with pertinent weights and dimensions. Operating limits for the units are as follows:

Maximum outside air temperature: 55°C

Minimum outside air temperature: 5°C

Maximum extract air temperature: 40°C

Minimum extract air temperature: 5°C

Units should be installed in a non-condensing environment.

Minimum outside air temperature for condensing unit operation of DX model: 20°C

QA/IOM/63 ISSUE 2 - DERV Page 2 of 19

Page 3

DERV chilled water units

Unit size 80 150 250

Nominal supply volume (litres/s) 107 155 236

Nominal extract volume (litres/s) 107 155 236

Nominal supply external static (Pa) 80 80 80

Nominal extract external static (Pa) 80 80 80

Total net cooling (W) 6375 9788 15127

Sensible cooling (W) 3313 4929 7561

Cooling coil total capacity (W) 5150 7779 11462

Supply air dry bulb (°C) 20.2 19.5 19.3

Supply air wet bulb (°C) 17.1 16.0 15.7

Heat recovery heat pipe cooling load saving (W) 1225 2009 3665

Wraparound heat pipe precool load saving (W) 622 1040 1660

Wraparound heat pipe reheat load saving (W) 622 1040 1660

Power supply (V/Ph/Hz) 230/1/50 230/1/50 230/1/50

Nominal current draw (A) 0.6 1.0 1.7

Nominal power draw (W) 138 230 391

Weight (kg) 75 100 130

Water flowrate (litres/s) 0.22 0.33 0.51

Water pressure drop (kPa) 10 9 18

Coil inlet connection size (mm) 15 22 22

Coil outlet connection size (mm) 15 22 22

The conditions upon which the above data is based are as follows:

Outside air @ 46/30°C

Extract air @ 25°C

CHW flow/return @ 7.2/12.8°C

500

473

473

80

80

30310

15155

23970

19.3

15.7

6340

3320

3320

230//1/50

3.4

782

190

1.02

19

28

28

QA/IOM/63 ISSUE 2 - DERV Page 3 of 19

Page 4

DERV DX version

Unit size 150 250

Nominal supply volume (litres/s) 155 236

Nominal extract volume (litres/s) 155 236

Nominal supply external static (Pa) 80 80

Nominal extract external static (Pa) 80 80

Total net cooling (W) 9788 15127

Sensible cooling (W) 4929 7561

Supply air dry bulb (°C) 19.5 19.3

Supply air wet bulb (°C) 16.0 15.7

Cooling coil total capacity (W) 7779 11462

Heat recovery heat pipe cooling load saving (W) 2009 3665

Wraparound heat pipe precool load saving (W) 1040 1660

Wraparound heat pipe reheat load saving (W) 1040 1660

Power supply (V/Ph/Hz) 230/1/50 230/1/50

Nominal current draw (A) 1.0 1.7

Nominal power draw (W) 230 391

Weight (kg) 100 130

Suction connection (“) 7/8 7/8

Liquid connection (“) 3/8 3/8 5/8 5/8

Outdoor unit power supply (V/Ph/Hz) 230/1/50 230/1/50 400/3/50 400/3/50

Outdoor unit nominal power draw (A) 13.1 18.0 8.4 8.4

Outdoor unit nominal power draw (W) 3013 4140 4143 4143

Compressor Reciprocating Reciprocating Scroll Scroll

Refrigerant R22 R22 R22 R22

Expansion device Capillary Capillary Valve Valve

Outdoor unit size WxHxD (mm) 1020x954x406 1020x954x406 1020x1270x406 1020x1270x406

Outdoor unit weight (kg) 80 90 110 120

375 500

358 473

358 473

80 80

80 80

22907 30310

11470 15155

19.3 19.3

15.7 15.7

18125 23970

4782 6340

2504 3320

2504 3320

230/1/50 230/1/50

2.0 3.4

460 782

170 190

1,1/8 1,1/8

The conditions upon which the above data is based are as follows:

Outside air @ 46/30°C

Extract air @ 25°C

Table1: Technical data

QA/IOM/63 ISSUE 2 - DERV Page 4 of 19

Page 5

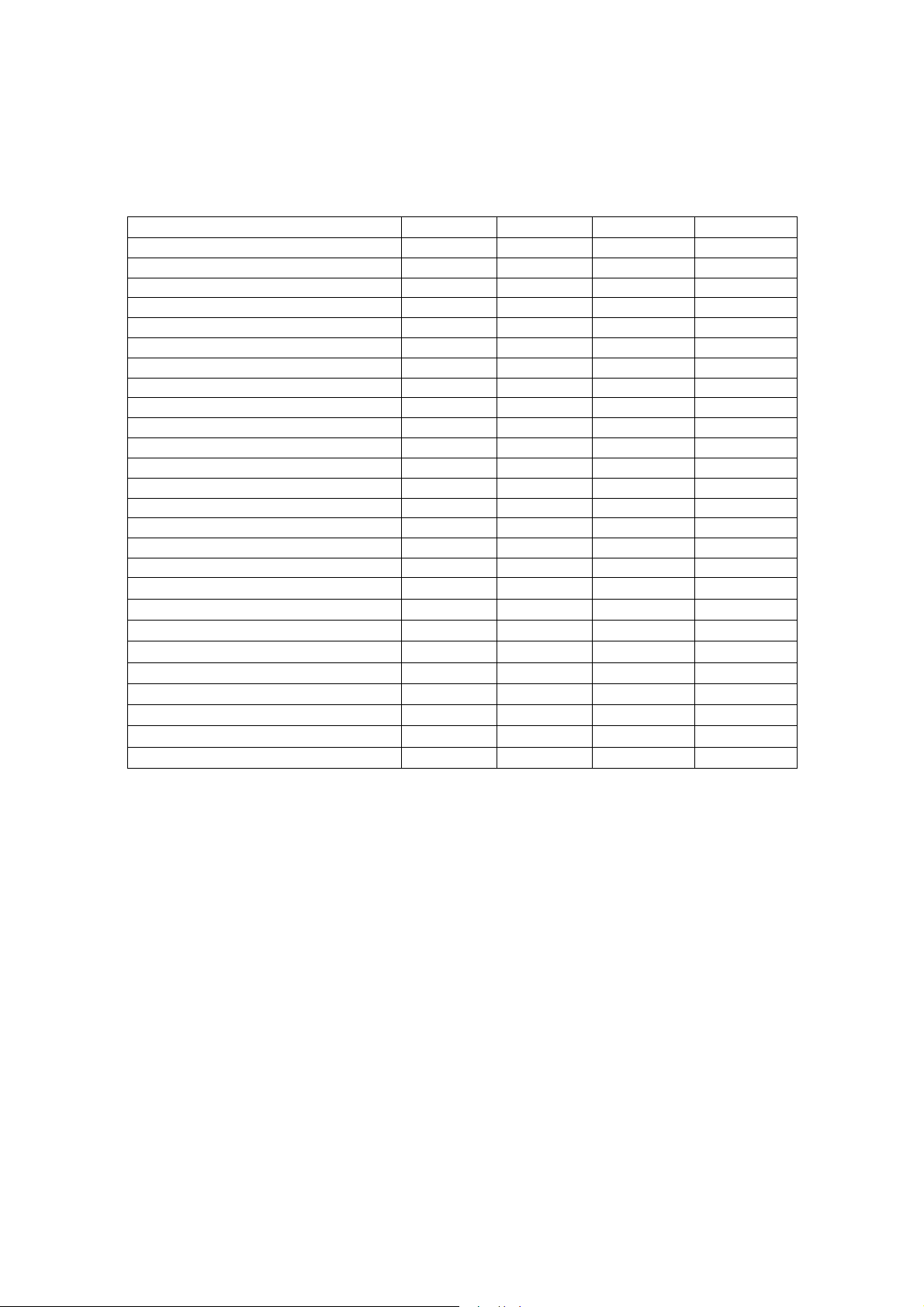

Detailed unit dimensions and construction information is highlighted on the figure below:

igure 1: Physical unit data

F

Outdoor unit sizes for DERVDX models are given in the performance table above.

QA/IOM/63 ISSUE 2 - DERV Page 5 of 19

Page 6

3 Reception & storage

DERV units are delivered in purpose made cardboard containers, if ordered as a DX version with

outdoor unit then this will be packaged separately. Upon receipt of the units the packaging should

be checked for any obvious damage and the labeling checked against the project requirement.

Any damage or delivery discrepancy should be reported to the SPC local office immediately. After

checking the packaging the units should be removed and a visual inspection carried out and any

damage reported immediately. If the units are not to be installed immediately then they should be

returned to the packaging for storage.

It is recommended that the units be stored in a safe location away from site activity and they must

not be exposed to the ambient. Units must be stored in non-condensing atmospheres where

temperatures cannot exceed 50°C.

4 Installation

4.1 Mounting of Indoor Unit

DERV and DERVDX indoor units must be installed horizontally and are intended to be fitted in a

concealed location, ideally above a false ceiling. The units must be suspended from the concrete

ceiling slab or other fixed and firm horizontal steelwork. Care must be taken to ensure that the

DERV(DX) unit is fixed to a structure that will accept the unit weight as shown in the above table

and that vibrations are not transmitted.

DERV(DX) units are supplied with 4-off robust fixing lugs at each of the corners of the unit (6-off

on the size 500). Each of these lugs incorporates a rubber bush to prevent unit vibrations being

directly transmitted to the mounting/support rods. The units should be mounted from the

ceiling/steelwork using threaded drop-rods. These drop-rods are not supplied with the units but

we recommend the use of M8 threaded rod.

The ceiling or support structure should first be marked out to match the position of the holes in

the DERV(DX) unit fixing lugs. The structure should then be drilled and fitted with suitable

anchors capable of accepting the weight of the DERV(DX) unit. Brackets can then be secured to

the ceiling anchors for securing the threaded drop rods. The rods should be cut to length and

secured to the ceiling bracket or supporting steelwork and the other end passed through the fixing

lugs on the DERV(DX) unit.

The drop-rods should be secured with suitable nuts on either side of the fixing lugs around the

anti-vibration bushes. It is important that the unit is fitted level in both directions so that correct

operation and drainage are ensured. A maximum deviation of 3mm from the horizontal should be

maintained and checked on installation using a spirit level and adjusted using the retaining nuts

on the fixing lugs.

4.2 Mounting/Location of Outdoor Unit (DERVDX only)

Outdoor units supplied with DERVDX are suitable for floor mounting and are side discharge

models. It is important that there is no obstruction on the air inlet and outlet sides of the unit and

that there is no possibility of hot discharge air being drawn back into the inlet.

QA/IOM/63 ISSUE 2 - DERV Page 6 of 19

Page 7

A minimum clearance of 600mm must be ensured on all sides of the unit except the air discharge

side where the clearance must be a minimum of 1500mm.

The unit must be located outside and must not be ducted. Ensure that the unit is not subject to

direct sunlight and cannot be subjected to any water run-off.

The unit must be mounted on a flat horizontal surface where vibrations cannot be transmitted to

the building structure and securely fixed.

A location should be found whereby the length of refrigerant pipes between the outdoor unit and

the indoor DERVDX unit is minimized.

4.3 Refrigerant Piping (DERVDX only)

The detailed instructions regarding the refrigerant piping given in the condensing unit IOM manual

should be followed. The text below gives general guidance. All refrigeration pipework should be

undertaken by a suitably qualified refrigeration engineer.

4.3.1 Liquid/Vapour lines

The table below identifies the recommended liquid and vapour line sizes based on the size of

DERVDX unit being installed. All refrigeration piping should be clean, dehydrated refrigeration

grade copper and should remain sealed until ready for use. A filter drier and liquid sight glass

may be installed in the liquid line upstream of the expansion device.

Unit size Liquid line OD Vapour line OD

DERVDX 150

DERVDX 250

DERVDX 375

DERVDX 500

Table 2: Recommended refrigerant line sizes.

Both vapour and liquid lines should be insulated to prevent sweating and performance reduction.

A minimum of ½” thick pipe insulation should be used. In order to avoid any reduction in

performance it is recommended that the maximum distance between indoor and outdoor unit

(including any vertical lift) be limited to 15m.

Whenever tubing is cut it should be carefully deburred so as to prevent any chips falling into the

tubing to be used. Any bends in the pipework should be made using proper tube bending

equipment so as to prevent any kinking.

Wherever possible tube connections should be of the sweat type and made using copper brazing

material. For copper to copper brazing up to 5% silver content brazing rods should be used, for

copper to brass or steel then 35% silver content is recommended. Tubing and fittings should be

cleaned with wire wool prior to brazing and any debris prevented from entering the pipe. When

brazing at or near to the service valves the caps and Schraeder cores should be removed to

prevent damage and the valves themselves covered in wet rags. A flow of nitrogen should be

directed through a service port and tubing while brazing.

If flare joints are to be used these must be properly made ensuring the following:

3/8” 5/8”

3/8” 7/8”

3/8” 7/8”

1/2” 1,1/8”

QA/IOM/63 ISSUE 2 - DERV Page 7 of 19

Page 8

• No thinning of the flare tube material

• No cracked or split tubes

• No longitudinal scoring or tool marks

• Correct torque setting used to match diameter of nuts

After having completed the pipework the system should be pressure tested to ensure that there

are no leaks. Dry nitrogen up to a maximum pressure of 10 bar should be used and all joints

should be tested using leak detection spray or detergent.

4.3.2 Coil connections

For DERVDX size units 150 and 250 the evaporator coil in the indoor unit is equipped with a

capillary type expansion device. This device is factory brazed onto the coil within the casing of the

indoor unit. The liquid and vapour connections terminate outside the casing of the unit and are

sealed; the coil contains a holding charge of nitrogen which should be heard escaping when the

connections are opened with a hole cutter.

For unit sizes 375 and 500 the indoor units are supplied with a loose thermostatic expansion

valve. The valves must be fitted outside the casing of the unit and should be installed in line with

the instructions supplied with the device. When brazing the TEV into the liquid line it is important

that the valve is protected using wet rags so as to avoid any damage to same. The TEV should

be fitted as close as possible to the liquid connection on the coil.

4.3.3 Evacuation

After leak testing, the pipework should be evacuated before any of the valves are opened. The

vacuum pump should be connected to both the high and low side of the system and a deep

vacuum drawn to 500 microns. Triple evacuation is recommended if the vacuum pump cannot

achieve such deep vacuum levels.

4.3.4 Refrigerant charge

The outdoor unit is shipped with sufficient refrigerant for operation of the system with up to 5m

liquid line distance between the indoor and outdoor unit. The required system charge will be

indicated on the charging chart inside the access cover of the outdoor unit.

If the length of the liquid line exceeds 5m then additional charge should be added according to

the diameter of the liquid line. For 3/8” diameter pipe refrigerant should be added at a rate of 60

grams/metre and for ½” diameter pipe at a rate of 120 grams/metre.

If the unit is supplied without refrigerant or the refrigerant recovered and the whole system

evacuated then the full charge as shown on the charging table will need to be added.

4.3.5 Oil traps

To ensure adequate oil return to the compressor it is recommended that oil traps be fitted with at

least one trap for every 3m of vertical height. When the outdoor unit is above the indoor unit the

traps should be fitted in the suction line, if the indoor unit is above the outdoor unit then the traps

need to be fitted in the liquid line.

QA/IOM/63 ISSUE 2 - DERV Page 8 of 19

Page 9

4.4 Electrical connections

4.4.1 DERV units

DERV units are designed to allow simple operation with the minimum of electrical power and

control wiring required on site. A wiring diagram for the unit is attached to the unit next to the

terminal block. A copy of the wiring diagram is shown below.

Figure 2. Wiring details DERV units

For the size 500 unit the fuse rating is 5A not 2A as shown above.

Power supply to the units is single phase 230V/50Hz. A three wire supply is required (PH/N/E)

and this should be taken from a suitably isolated power supply. Maximum running current and

power drawn are given in the technical data table but minimum wire size for the power supply

should be 1mm2.

The terminal block is accessible on the side of the indoor unit. The 3-core power cable should be

connected to this terminal block as shown on the wiring diagram attached to the unit.

The DERV units incorporate a built-in controller allowing the speed to be changed (speed 1,2 & 3)

along with an on/off switch. Provision has also been made for remote control of the DERV units

via two volt free contacts. These contacts can be used to switch the units on and off remotely via

switches or relays attached to BEMS, occupancy sensors etc. The two remote contacts are wired

into terminals R1/R2 and R3/R4 respectively. Again wire should be a minimum of 1mm2 and

remote contacts should be rated at a minimum of 2A (5A, 500 unit).

If one or both of the remote contacts are not used then links must be fitted between R1/R2 and

R3/R4.

QA/IOM/63 ISSUE 2 - DERV Page 9 of 19

Page 10

4.4.2 DERVDX units

DERVDX units are designed to allow simple operation with the minimum of electrical power and

control wiring required on site. A wiring diagram for the indoor unit and interconnection to the

outdoor unit is attached to the indoor unit next to the terminal block. A copy of the wiring diagram

is shown below.

Figure 3. Wiring details DERVDX units

While all indoor units use a single phase supply the outdoor units for the larger models, size 375

and 500 are three phase as shown above.

For the smaller single phase units (150, 250) a three wire supply is required (PH/N/E) and this

should be taken from a suitably isolated power supply. Maximum running current and power

drawn are given in the technical data table but minimum wire size for the power supply should be

1mm2. Both the indoor and outdoor units must be earthed and the power cables should be taken

from the terminal block of the outdoor unit to the indoor unit terminal block.

QA/IOM/63 ISSUE 2 - DERV Page 10 of 19

Page 11

The larger three phase units (375, 500) require cables for each of the phases and a neutral. Both

indoor and outdoor units must be earthed and a phase and neutral cable must be taken from the

3 phase terminal block in the outdoor unit to the indoor unit.

Two control wires must be run between the terminals on the controller of the indoor unit and the

relay terminals on the outdoor unit. It is recommended that these wires be a minimum of 1mm2.

The DERVDX units incorporate a built-in controller allowing the speed to be changed (Low, Med

& High) along with an on/off switch, see figure below. Provision has also been made for remote

control of the DERV units via two volt free contacts. These contacts can be used to switch the

units on and off remotely via switches or relays attached to BEMS, occupancy sensors etc. The

two remote contacts are wired into terminals R1/R2 and R3/R4 respectively. Again wire should be

a minimum of 1mm2 and remote contacts should be rated at a minimum of 2A (5A, 500 unit). If

one or both of the remote contacts are not used then links must be fitted between R1/R2 and

R3/R4.

The controller is connected to a thermistor sensor located between the heat recovery heat pipe

and the dehumidifier heat pipe inside the indoor unit and senses the temperature at this point.

The three temperature settings available equate to 22, 24 and 26°C respectively, when the

sensed temperature falls below the set temperature then the outdoor unit will switch off. It is

recommended that the lowest temperature setting is used to provide continuous operation of the

outdoor unit.

The controller incorporates a built in time delay on the compressor to prevent hunting and has a

non-volatile memory allowing the settings to be saved.

Figure 4. Controller display

When the compressor delay timer is operating the set temperature LED will blink on and off for

half a second each. The on delay timer is set at 180 seconds.

When the compressor is not running according to the temperature setting the LED blinks on for

0.1 seconds and off for 0.9 seconds.

The compressor is set to run if the sensed temperature >= to the set temperature+1 and set to off

if the sensed temperature < set temperature.

QA/IOM/63 ISSUE 2 - DERV Page 11 of 19

Page 12

The variable indoor unit fan speed is achieved using phase angle control. When the phase angle

is changed the RMS value of the voltage at the fan motor is changed and hence the fan speed.

When the input AC Voltage is 230 V, 50 Hz the following voltage is applied at the fan motor.

Fan Speed AC Voltage applied at fan motor

Low 195 V

Medium 205 V

High Input AC voltage

Table 3: Fan speed details

If there is a thermistor fault this will be indicated on the display by flashing of all the cooling LEDs

and remote on/off by flashing of the fan speed LEDs.

4.5 Drain connection piping

The DERV(DX) units incorporate two internal draintrays; one beneath the heat recovery heat pipe

and one beneath the cooling coil/heat pipe section. There is an individual drain pipe extending out

from the side of each drainpan. These drainpipes are 30mm diameter plastic and must be

properly trapped in order to ensure than condensate is not held within the unit. The drainpans are

both on the suction side of the supply fan and subject to negative pressure and if not fitted with

drain traps will draw air into the unit and prevent the release of moisture. As these two drain

points are adjacent to one another and subject to very similar levels of vacuum it is permissible to

join the two together prior to the trap.

Suction pressures at the inlet to the supply fan can be as high as 200Pa depending on the

external resistance of the systems and traps should be sized to cope with this level of pressure.

Incorporating a safety factor to account for the effect of dirty filters etc, the required minimum

dimensions are shown in the diagram below.

QA/IOM/63 ISSUE 2 - DERV Page 12 of 19

Page 13

Figure 5. Trap dimensions

The minimum value for H should be 40mm which represents an equivalent water column height

of 400Pa.

Traps should be regularly inspected, particularly after periods of inoperation, to ensure that they

are not dry.

Immediately downstream of the drain trap there should be an air break to prevent any back

pressure. From this point the drain piping should either slope to waste or a condense pump

should be included. As the drain piping contains cool condense it should be insulated to prevent

sweating.

4.6 Ductwork connections

DERV(DX) units are complete with four rectangular spigots; two for the supply air and two for the

extract air. The spigots are sized to give a resultant velocity which is sufficiently low as to allow air

distribution through ducting or direct to diffusers without transformation of the duct size.

The ducting can be transformed to a smaller size after the outlet spigot and can be transformed to

circular ducting if this is preferred. A single DERV(DX) unit can be arranged to take its extract air

from one or more sources and its supply ducting can be arranged to supply one or a number of

different areas. Extract and supply grilles and diffusers should be used in line with good air

distribution practice.

Duct sizes should be selected to maintain an air velocity of less than 5m/s in all main ducts and

branches. This will not only minimize the external static pressure that the unit is operating against

but will also eliminate any noise problems. If the ducting runs through areas subject to high

humidity then the ducting should be lagged to prevent moisture formation, this is particularly

important for the supply ducting from the DERV(DX) unit which will be carrying cool air at around

20°C. Supply diffusers should be fitted with plenum boxes to reduce the velocity of the air before

introducing it to the occupied space.

If designing against a maximum duct velocity of 5m/s than a good approximation to the pressure

drop associated with the straight ducting is 2Pa/m. Fittings, branches, bends and grilles offer

additional dynamic resistances due to momentum changes of the air flow. A reasonable

approximation is to sum the number of the above fitting losses and allow 5 Pa for each. The

above will allow duct sizes to be reasonably approximated but the final design should be

undertaken by a designer/installer qualified in duct design and space air diffusion.

It is recommended that manually operated butterfly dampers are incorporated in the final branch

of all duct connections. This will simplify the commissioning process and provide the facility for

accurately setting the airflows to and from each zone. Without the use of dampers the air volumes

from each zone will only vary with the length and diameter of the ducting runs.

5 Operation

DERV(DX) units are supplied with a speed controller, on/off switch and the possibility to

incorporate remote contacts to switch the units on and off. The above controls vary the

throughput of air by varying the power supply to the fans. The units incorporate two-off fans; one

for the supply air and one for the extract air (375 and 500 units have two pairs of fans). In

QA/IOM/63 ISSUE 2 - DERV Page 13 of 19

Page 14

addition, DERVDX units are supplied with a matching condensing unit and are interconnected via

two wire control of the compressor relay.

For DERVDX units with crankcase heaters it is not recommended that the units are turned off by

disconnecting the mains. On/off control should be via the controller and remote contacts.

The units will have been selected to provide a particular supply and extract air volume; these will

be equal for a balanced ventilation application. If the area is to be pressurized then the supply air

volume will be higher than the extract and vice versa if the space is to be kept under negative

pressure.

The respective air volumes must be set by both adjusting the fan speed on the controller located

in the unit electrical box and manual adjustment of damper blades in the ducting. The speed of

the fans can be adjusted between speeds 1, 2 and 3 and the power supplied to the fan motors is

then controlled by the phase angle controller which varies the RMS value of the voltage. This

controller provides the same voltage to both supply and extract fans so the speed selection

switch should be used to achieve just in excess of the required air volume through the least

favoured leg of ducting. Accurate balancing of the air distribution system should then be carried

out by adjustment of the dampers.

The units can be put into operation by simply switching the on/off switch in the control box but

under normal circumstances this would be inaccessible to users. More obvious control

possibilities are to break the supply to the units via a switched fuse spur box or to take advantage

of the remote contacts provided. These contacts are discussed in the installation section and

allow on/off control of the units via switched contacts (manual switching or via relay). If the units

are to be controlled from a central system or BEMS then the requirement for ventilation should be

sensed via occupancy or carbon dioxide sensors.

DERVDX units have their outdoor units controlled by a temperature sensor connected to the

indoor unit controller; when the sensed temperature drops below the set point the compressor is

switched off as no further cooling of the ventilation air is required.

DERV units require a supply of chilled water to achieve the necessary dehumidification of the

ventilation air. The correct flowrate and flow temperature will be documented with the quotation

documents for the project. If these are unavailable then the values given in the technical data

table can be used. To ensure that the chilled water arrives at the cooling coil connections ensure

that all isolating valves are open and that the coil has been properly vented through the vent plug

provided. The pump system for the DERV units should be sized against the total flowrate for the

units and the waterside resistance figures with due consideration given to additional losses

associated with pipework, fittings and other flow regulating valves. All valving and control of the

chilled water flow is by others but it is recommended that the flow of chilled water bypasses the

DERV unit when the outside temperature drops considerably below the space temperature.

Under normal operating conditions the DERV(DX) units will generate considerable amounts of

condensed moisture. This must be adequately trapped and run to waste as described in the

installation section above.

6 Maintenance

It is suggested that the DERV(DX) units should be maintained on a monthly basis so as to ensure

continued correct operation. The maintenance routine should involve the following:

Filter cleaning: The indoor units incorporate two filters; one on the extract air side and one on the

supply air side. Access is provided for filter withdrawal from the sides of the unit via the slimmer

QA/IOM/63 ISSUE 2 - DERV Page 14 of 19

Page 15

removable panels on either side of the unit, held in place by wing nuts (see diagram above). After

removing the panel the filters can be slid out of the unit and cleaned using a vacuum hose or

pressure line. During cleaning the air should be drawn/blown through the filter in the opposite

direction to the operating airflow.

Airflow check: A check should be made to ensure that both the supply and extract fans are

operating. This can usually be ascertained by placing a hand over the supply/extract grilles within

the space. If there is no airflow through either the supply or the extract system then a further

investigation should be made. The fans and their associated wiring are accessible from either

side of the unit via the larger access panels which are released by unscrewing the wing nuts. Any

electrical servicing must be undertaken by qualified personnel after electrically isolating the unit.

Drain trap check: Drain trap(s) should be regularly checked to ensure that they are not dry and

that there is a liquid seal.

Indoor unit coil cleaning: The coil fin blocks should be regularly checked and cleaned with a soft

brush, vacuum or pressure hose to clear any debris from the surfaces. This will involve removal

of access panels and in some instances removal of the ducting attached to the spigots of the

DERV unit.

Indoor unit general cleaning: The outer casing of the DERV(DX) unit is finished in corrosion

resistant epoxy paint and can be wiped down with a wet cloth or with dilute cleaning agents.

DERVDX units are supplied with matching condenser units. The outer casing of the units should

be kept clean with a proprietary cleaner, the blades of the axial fan and the condenser coil should

also be regularly inspected/cleaned to ensure continued efficient performance.

If the condenser coil in the outdoor unit becomes contaminated by dirt, dust etc. then the system

performance will be reduced as the airflow is throttled; this leads to high operating pressures.

Before cleaning the condenser coil the power to the unit must be cut-off, material blocking the coil

can then be removed, manually, using compressed air or a water spray. If a spray is used it must

be directed from the inside of the casing to the outside in the opposite direction to normal airflow.

Ensure that the condensing unit is clean and dry before reconnecting the power, the unit should

then be left for several hours before switching on via the controller or remote contacts.

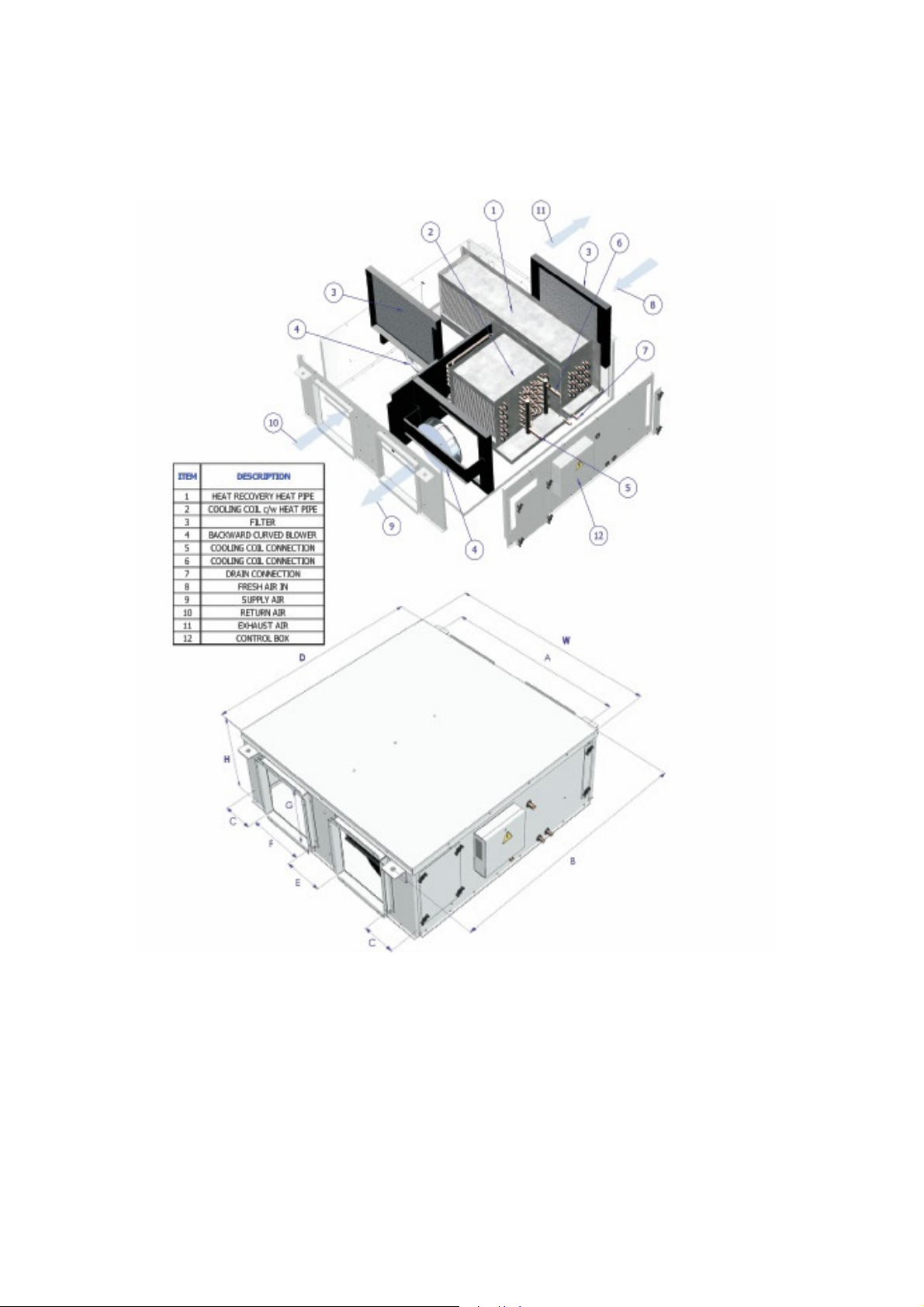

7 Fault finding

The tables below details faults that may occur, their cause and means of rectification

QA/IOM/63 ISSUE 2 - DERV Page 15 of 19

Page 16

Fault Cause Remedy

One fan does not

run

Both fans do not run Unit switched off Switch on at unit or remote

Low airflow Dirty filter Remove and clean

High airflow High speed selected Reduce speed setting

High supply air

temperature

Humid supply air No chilled water available Check chilled water supply

Moisture in supply

airstream

No moisture from

unit

Ductwork sweating Humid environment Insulate ducting

Pipework sweating Uninsulated piping Insulate all piping

Motor failure Replace faulty fan/motor

assemby

Loose wire Check integrity of wiring on

fan terminal

Capacitor burn-out Look for signs of damage

and replace capacitor

switch

Unit held off by remote

contact/switch

Power failure Check power supply to unit

Fuse blown Replace fuse

Loose wire Check and tighten

Low speed selected Increase speed setting

Ducting blocked Check dampers, grilles etc

Unbalanced ducting Check damper positions

No chilled water available Check chilled water supply

Chilled water flowrate too low Check position of valves and

Chilled water temperature too

high

Air trapped in coil Vent coil

Chilled water flowrate too low Check position of valves and

Chilled water temperature too

high

Air trapped in coil Vent coil

No drain trap fitted Fit drain trap

Drain trap dry Prime trap

Drain trap too small Increase trap height

No drain trap fitted Fit drain trap

Drain trap dry Prime trap

Drain trap too small Increase trap height

Check power at terminals

and remote contact signals

pump operation

Check chiller operation or

temperature of chilled water

supply

pump operation

Check chiller operation or

temperature of chilled water

supply

T

able 4. Fault finding DERV units

QA/IOM/63 ISSUE 2 - DERV Page 16 of 19

Page 17

Fault Cause Remedy

One indoor unit fan

does not run

Both indoor unit

fans do not run

Low indoor unit

airflow

High indoor unit

airflow

Insufficient cooling No chilled water available Check chilled water supply

Moisture in supply

airstream

No moisture from

unit

Ductwork sweating Humid environment Insulate ducting

Pipework sweating Uninsulated piping Insulate all piping

Outdoor unit does

not run

Outdoor fan runs,

compressor doesn't

Motor failure Replace faulty fan/motor

assemby

Loose wire Check integrity of wiring on

fan terminal

Capacitor burn-out Look for signs of damage

and replace capacitor

Unit switched off Switch on at unit or remote

switch

Unit held off by remote

contact/switch

Power failure Check power supply to unit

Fuse blown Replace fuse

Loose wire Check and tighten

Dirty filter Remove and clean

Low speed selected Increase speed setting

Ducting blocked Check dampers, grilles etc

High speed selected Reduce speed setting

Unbalanced ducting Check damper positions

Chilled water flowrate too low Check position of valves and

Chilled water temperature too

high

Air trapped in coil Vent coil

No drain trap fitted Fit drain trap

Drain trap dry Prime trap

Drain trap too small Increase trap height

No drain trap fitted Fit drain trap

Drain trap dry Prime trap

Drain trap too small Increase trap height

Loose connection Check terminal wiring

Thermostat not calling Check temperature setting

Defective contactor Check voltage at contactor

High pressure trip Reset

Start capacitor/relay

defective

Check power at terminals

and remote contact signals

pump operation

Check chiller operation or

temperature of chilled water

supply

coil

Replace

QA/IOM/63 ISSUE 2 - DERV Page 17 of 19

Page 18

Compressor short

cycles

High head pressure,

low vapour pressure

High head pressure,

normal vapour

pressure

Low head pressure,

high vapour

pressure

Low vapour

pressure, cold

compressor &

indoor coil

High vapour

pressure

Pulsing at

expansion device

Fluctuating

pressures

Loose connection Check compressor wiring

Compressor jammed or

motor winding open

Incorrect voltage Must be within 10% of

Defective overload protector Replace

Restriction in liquid line,

expansion device or filter

drier

Dirty outdoor coil Clean coil

Refrigerant overcharge Correct system charge

Outdoor fan not running Repair or replace

Air in system Recover, evacuate and

Defective compressor valves Replace

Low indoor unit airflow Increase speed of indoor

Excessive load Check load calculations

Defective compressor Replace

Air in system Recover, evacuate and

Air in system Recover, evacuate and

Wait for overload to reset (2

hours). Replace compressor

if necessary.

nameplate

Remove or replace

recharge

blowers or reduce restriction

recharge

recharge

Table 5. Fault finding DERVDX units

8 Spares

Spare filters, fans, coils and other components are available for DERV(DX) units. These can be

ordered with the units or subsequently. Please contact the local SPC office for details.

QA/IOM/63 ISSUE 2 - DERV Page 18 of 19

Page 19

SPC Heat Pipes FZC

PO Box 50816, Dubai, UAE

Tel: 0097143341178, Fax: 0097143341179

e-mail: spcoils@spcoils.ae Web: www.spcoils.ae

QA/IOM/63 ISSUE 2 - DERV Page 19 of 19

Loading...

Loading...