Page 1

Operating Instructions

S-Thermatik NEO

Page 2

PREFACE / QUALITY PHILOSOPHY

You have decided in favour of a SPARTHERM fireplace insert accessory - thank you very much for your confidence in our company.

In a world of excess and mass production, our company stands for the values expressed by our owner, Gerhard Manfred Rokossa:

"High technical quality combined with contemporary design and service to the satisfaction of our customers, so they will recommend us to others".

Together with our specialist retail partners, we offer you first-class products that will touch your customers emotionally, and will inspire feelings such as a feeling of

security, safety and comfort. To achieve this, we recommend that you read the operating instructions carefully in order to get a quick and comprehensive overview

of your decorative fireplace.

In addition to the information on operation, this manual also contains important care and operating instructions for your safety as well as preserving the value of your

accessory and provides valuable tips and tricks.

For further enquiries, please contact your specialist dealer.

We hope you enjoy your new stove.

Your Spartherm team

G.M. Rokossa

Page 3

GB

GB 3

1. General information 4

1.1 Information on installation 4

1.2 Accessories 4

1.3 Functional description of S-Thermatik NEO 5

2. Safety notes 6

3. Menu structure and display 6

3.1 Menu structure 6

3.2 Main menu 7

3.3 General operation of the display 7

4. Statistics 8

5. User menu 8

6. Self-test: 10

7. Power failure 11

8. Service menu 11

9. Closed-loop control characteristics 12

10. App 13

11. Notes for stoves: 14

12. Guide 15

13. General warranty conditions 16

13.1 Area of application 16

13.2 General information 16

13.3 Warranty period 16

13.4 Warranty requirements 16

13.5 Exclusions from the warrant y 16

13.6 Elimination of defects / repair 17

13.7 Extension to the warranty period 17

13.8 Spare parts 17

13.9 Liability 17

13.10 Closing remarks 17

14. EU Declaration of Conformity 18

CONTENTS

Page 4

GB 4

1.1 INFORMATION ON INSTALLATION

Please consult your district master chimney sweep before assembling and

installing your fireplace. He will advise you on building regulations, will

check the suitability of your chimney, will commission your fireplace insert

and will issue the operating licence for your fire area.

When installing and operating the fireplace insert and connecting it to the

chimney, make sure that you comply with the national and European standards, the country-specific and local directives and regulations as well as the

fire regulations for your federal state (in Germany only) and the Technical

Rules of the Tiled Stove and Hot Air Heating System Trade (TROL).

All work on the electrical installation may only be performed by an authorised specialist company. All equipment must be switched off at the main

switch before performing work on it.

1.2 ACCESSORIES

If needed, all conduits can be extended using normal copper cable, but this

does apply to the cable on the flue gas temperature sensor. Here, a

special compensating line MUST be used.

• 5m flue gas sensor extension cable (Item No. 1013221)

• 10m extension cable for flue gas sensor (type no. 1013222)

With appliances that circulate water, if the recirculating pump is to be

controlled by the S-Thermatik NEO, at least two PT 1000 sensors should

be ordered at the same time. This is the only way of ensuring that the

"Differential temperature" function can be implemented together with the

S-Thermatik NEO.

• Temperature sensor PT1000 (part no. 1013765)

Length 3 metres, incl. immersion sleeve with a G1/2" external thread

1. GENERAL INFORMATION

You have decided in favour of a Spartherm fireplace insert accessory - thank

you for your confidence in our company.

This manual provides you with information about operation and troubleshooting for your combustion control. Details on installation and for service

purposes can be found in the "S-Thermatik NEO installation and service

instructions".

Information for setting the parameters of the control system can be found in

the accompanying supplementary sheet "Details of the S-Thermatik NEO".

Please keep this supplementary information and the operating manual in a

safe place.

Important information and safety instructions are printed in bold always comply with these points.

Before using the appliance, please read the entire operating manual.

The combustion control system is pre-set to the nominal thermal output

of the delivered fireplace insert. Information concerning the nominal heat

output and the wood feed quantity can be found in the operating manual of

the fireplace insert.

To maintain your control system, keep the door contact clean and ensure

that the combustion air channel remains clean and unobstructed. From time

to time, check here whether the permanent magnet is attached to the bottom of the door frame and that it is still undamaged.

Page 5

GB

GB 5

Door contact

switch

Temperature sensor

Display

Control

230V AC

Mains connection

Air adjustment

lever

Actuator

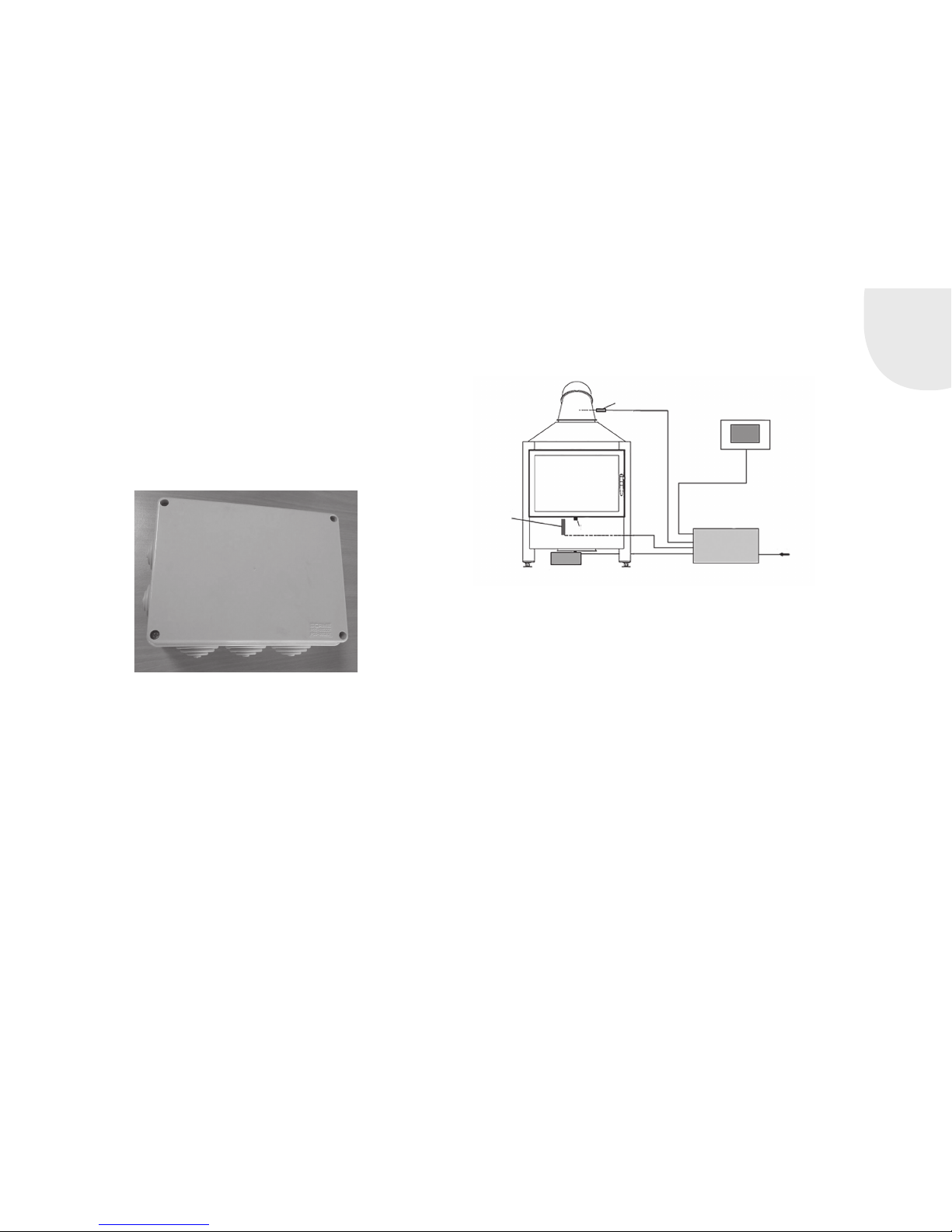

1.3 FUNCTIONAL DESCRIPTION OF S-THERMATIK NEO

The basic configuration of the S-Thermatik NEO combustion control system

consists of the control unit, the display, a flue gas temperature sensor, an

actuator motor and a door contact switch. It is only suitable for fire areas

that burn split logs.

The combustion control system is activated when the firebox door is opened

and is awakened from Standby mode. Depending on the prevailing flue gas

temperature, the control system adjusts the motor using the air slider until

the correct quantity of combustion air is directed into the appliance. The

time for adding fuel is displayed with a visual as well as an audible signal.

The control system remains active until the flue gas temperature has

dropped to about 50°C and then it returns to Standby mode.

In the event of a power failure, the air slider automatically moves into a

position in which the fire area can continue to be operated. Until power is

restored, or until the fire is extinguished, no further interventions or measures are required.

If the control system housing of the NEO is to be protected in a special manner, a dust protection box measuring 210 x 160 x 80 mm can be obtained

in which the control system can be installed.

ATTENTION: The cable housings (see 3.3) must be removed, otherwise the

control system will not fit inside.

• Dust protection box for S-Thermatik NEO (part no. 1013792)

Page 6

GB 6

2. SAFETY NOTES

• The S-Thermatik NEO combustion control may only be used in combination with a wood-fired fireplace insert.

• Only fire areas which are ordered with this combustion control system

and that are appropriately prepared from the factory can be combined

with the S-Thermatik NEO.

• The combustion control system cannot be retrofitted!

• The maximum ambient temperature for the electrical components is

50°C. Measures must be taken by the customer to ensure that this

temperature is not exceeded.

• The total electrical installation of the individual components may only be

conducted by an authorised specialist company.

• All electrical installations are to be carried out as per the VDE regulations (e.g. VDE 0105, VDE 0116, VDE 0100, etc.) and the technical

connection conditions of the local power company.

• All equipment must be switched off at the main switch before performing

work on it.

• The cables must be laid so as to allow maintenance work to be performed and the individual components of the S-Thermatik NEO to be

replaced without any problems.

• Building moisture and condensation are to be avoided as these can

result in corrosion and failure of the electrical components.

• The connecting cable of the flue gas temperature sensor can only be

extended with a special compensation cable!

• The function of the combustion control system may be checked at any

time with the air control lever. Every time the firebox door is opened,

the air control lever must move to the right to the "combustion

air fully open" position!

• The specified factory settings which are required for the safe operation

of the combustion control may not be changed.

• The installed wires on the fireplace insert must not be pulled. Outside

the fireplace insert, these must be installed so that no tensile forces and

no compression, chafing or shearing points are created.

3. MENU STRUCTURE AND DISPLAY

3.1 MENU STRUCTURE

To keep things simple, the menu is divided into just three sections:

• Statistics of the last 99 burnups

• User menu

• Service menu (password-protected)

Regardless of where you happen to be in the menu, using the Menu button

at the bottom right, you can always return straight to the menu selection.

In the same way, pressing the Home key at the bottom left returns you

immediately to the main menu.

Layout of the menu:

Home (main menu)

Statistics User menu Service menu

Overview of the last 99 burnups SESAM *

System set-up

S-USI II **

Display

Sound

Auto / Manual

Language

Deactivating the door

System information

Selecting the fireplace insert

Parameters

Relay Menu

Doorswitch Menu

Motor Menu

Overview

Test

Factory setting

Saving user data

Loading user data

System settings

* only appears if the corresponding function was selected in the Relay

menu

** Connection option for an S-USI II differential pressure monitor, available

from 2018

Page 7

GB

GB 7

3.2 MAIN MENU

1 Current status and error messages

2 Progress bar

3 Room temperature, air slider setting and flue gas temperature

4 Heating capacity levels (small / normal / big burnup)

The main menu provides information at a glance of the prevailing operating

mode of the control system. At this level, you can only click the heating

capacity levels via the flame icon and the Menu button.

The progress bar indicates the prevailing point in the combustion process.

Here is a key to the 6 points:

Standby / ignition / rising temperature / falling temperature / time to add

fuel (that is the small point) / glow phase

The flame symbol can be used to select a small / normal / big burnup. The

fire area then receives less or more combustion air respectively.

3.3 GENERAL OPERATION OF THE DISPLAY

There is a BACK button at the top left of each menu window to enable you

to go back one step in the operating process. If something is changed in a

window, the Save button appears at the top right.

Adding fresh fuel

POWER STAGES

Home

Menu

CURRENT TEMP

AIR SLIDER

EXHAUST TEMP.

4

1

2

3

CANCEL

Brightness

SAVE CHANGES

USER MENU

Auto brightness

Home

Menu

Page 8

GB 8

4. STATISTICS

This is where you will find the statistics for the last 99 combustion processes. These are always counted from one opening of the door to the next,

i.e. every single burnup is counted. In each case, the maximum temperature and the duration of the burnup are recorded. The statistics cannot be

deleted. If there are more than 99 burnups, the older data are overtyped.

5. USER MENU

The menu layout is broadly self-explanatory. Here is a sample image for

general operation:

1 BACK button

2 Name of the menu

3 Scroll keys

4 Function

5 Setting controller

6 Operating knobs

Sliders can be adjusted by fingertip control, or by holding and sliding the

round knob. The control knobs can be moved by touch, or by sliding them

gently to the left or right. If the knob is backlit in red, the selected function

is enabled.

Note: The active surface of the scroll keys is larger than shown on

the display. Scrolling is then also activated by touching beside the

grey surface.

CANCEL

Statistics

LAST COMBUSTION

Highest temperature

Highest temperature

Highest temperature

Duration

Duration

Duration

CANCEL

Sound

USER MENU

Signal transmitter active

Sound 2

Sound 1

Home Menu

1

2

3

4

5

6

Page 9

GB

GB 9

If settings have been changed, SAVE appears in red letters at the top right.

This pushbutton must be pressed otherwise the changes will not be made.

SESAM: Whenever this function is assigned to a relay in the Service menu,

this field appears at the top of the User menu. By touching this box, the

relay is activated for 3 seconds. This enables the Spartherm SESAM control

system to be activated, an electrical opening mechanism for fire doors. For

more details see Chapter 5.4.

Diagram: Here, the hydraulic schematic and the switch status of the accumulator charge pump on water-circulating fireplace inserts can be illustrated. Whenever the pump relay on the NEO has engaged, the pump vane

wheel rotates on the display panel

If the PT1000 sensors are not connected, e.g. on air-circulating fireplace

inserts, no temperature values appear. Instead, dashes (- - -) appear on

the screen.

By touching the temperature boxes, you can select which sensor should be

displayed here.

S-USI II: When using a Spartherm S-USI II differential pressure monitor,

it can be connected to the S-Thermatik NEO using a special cable. The

displays on the housing of the S-USI II can be shown on the display unit of

the NEO.

The S-USI II will probably become available in the early part of 2018.

Display: Here, among other things, is the Screen Saver sub-menu. Here you

can choose the brightness level you wish to have for the screen saver. If you

choose several temperatures, these will be displayed at 7-second intervals.

If you pull the brightness controller all the way to the left, the display will

go dark. The screen saver switches on automatically about 2 minutes after

the most recent keystroke. The screen image reappears whenever you touch

the display unit.

Note: With water applications, it is advisable to display the temperature at the top in the buffer. This means that you can see immediately the level of progress of the loading of the buffer.

In addition, there is a "Cleaning the display" sub-menu. This switches off

the display for 2 minutes. During this time, it accepts no commands. This

means you can clean without altering any of the settings. For checking

purposes, a timer runs backwards and shows the remaining time.

Sound: Here the button acknowledgement sounds and the alarm sounds

can be selected. Also, the volume level can be adjusted. All sound events

can also be switched off here.

Operation auto/manual: Here you can switch form Automatic to Manual

mode. To do this, move the "auto/man" control knob to the right. Now a

position can be selected for the air slider and it can be sent off using the

SAVE button at the top right.

CANCEL

Schematic

Home

Menu

Page 10

GB 10

To return to Automatic mode, slide the control knob to the left again and

save it.

CAUTION: Operation of the fire area in Manual mode is at the user's

own risk! During a burnup, the air control lever must never be closed

to the point where an explosion might occur.

We urgently advise that you ONLY operate the control system IN

AUTOMATIC MODE.

Language: Here, you can select the menu language of your choice.

Available at the present time: GB - DE - NL - FR - IT - ES - PL - CZ - SE

Deactivating the door: Exactly as in the display (see above), the door

switch can be deactivated for 2 minutes. This can scale down the glow without the control system initiating a new burnup when the door is next opened.

System information: Here you will find details about the details of the

respective versions of software used.

6. SELF-TEST:

To check the control system and its function, it can help to run a self-test.

This provides an indication as to whether all components in the control

system are OK.

We advise running the self-test once a year at the start of the heating

season.

The self-test is carried out every time that the control system becomes

disconnected from mains power, once mains power has been restored. To

conduct this self-test, the fire area must be cold (flue gas temperature

below 50°C) and all fire doors must be closed.

1. Switch the combustion control off (pull out the power plug)

2. Switch the combustion control on again (insert the power plug)

3. The air control lever moves to the right, up to its 100% open limit stop.

With stoves, the function monitoring LED remains lit all the time.

4. Then the air control lever moves to the left towards 0%. The function

LED on stoves goes out at this point in time. The air control lever remains

fully left, against its limit stop.

5. "Standby" must appear on the display and realistic values must be displayed for room and flue gas temperature.

6. If the firebox door is now opened, the air control lever must move automatically to the right, up to its limit stop. The function LED remains lit

continuously. While the door is open, the function LED on stoves flashes

rapidly, about 2x per second. The display shows that the door is open.

7. If no fire is ignited 10 minutes after the door has been closed, the display shows "No ignition". The air slider is closed and the control system

reverts to Standby mode.

8. Any errors on the flue gas sensor or motor are displayed in clear text. On

stoves, the function LEDs then flash rapidly.

Page 11

GB

GB 11

8. SERVICE MENU

The Service menu is password-protected and the password is known only to

the stove fitter and/or the after-sales service.

A warning is issued about adjusting these settings if you do not have

the relevant professional knowledge.

Incorrect settings can cause very serious damage to equipment as

well as personal injury.

If the test has been successful up to this point, without failures or error

messages, then the control system and its external components are OK.

Note: The self-test only functions at flue gas temperatures of less

than 50°C. At higher temperatures, the lever only moves to the right.

After that, the control system resumes normal operation.

7. POWER FAILURE

The S-Thermatik NEO is equipped with a special function. Whenever there is

a power failure, the air slider automatically moves into a safe position (about

50-60%). In this position, the fire area cannot overheat, but it can continue

being operated manually. You can also allow the fire to be extinguished.

Until mains power is restored, no intervention by the operator is required. Do

not attempt to move the air control lever mechanically. This is not necessary.

This safety function on the NEO operates entirely without the need for maintenance, and it does not require any batteries or accumulators.

CANCEL

ADVANCE SETTINGS

Password request

Type the password key for service menu

Page 12

GB 12

• Following a cold start, if a temperature of at least 50°C is not reached

within 10 minutes of the door being opened, the air slider is closed and

the control system reports "No ignition".

• Whenever the fireplace insert threatens to overheat, this is

displayed and the air slider is restricted in order to reduce the

temperature. Once the temperature has dropped far enough, the

burnup is then continued with the declining closed-loop control

curve. During the next burnup, add less wood.

9. CLOSED-LOOP CONTROL

CHARACTERISTICS

This section explains a few of the closed-loop algorithms that govern operation of the control system.

• In the event of a power failure or failure of the flue gas sensor, the air

slider moves automatically into a safe position (approx. 50 - 60%). The

fire area can continue to be operated manually.

• On cold starts (exhaust temperature below 50°C), the first burnup always

takes place during the "powerful burnup" stage. During this time, the big

flame symbol is NOT displayed. With the ensuing burnup, the system

then switches to the preselected stage.

• The acoustic signal to add more fuel only sounds once, when the time

to add more fuel is reached for the first time. After that, this signal is

not repeated.

• In Manual mode, there is no progress bar, and no selectable heating

capacity. Whenever the door is opened, the air control lever moves to

100%, stays there for one minute, then returns to its manually set position. We urgently recommend that you only operate the fire area

in Automatic mode.

• If wood is not added at the time for adding more fuel, the glowing phase

commences a short while later. Here, by alternating the air slider positions, it is possible to change the declining combustion curve several

times. The air slider is not fully closed until the flue gas temperature

has dropped below 50°C and the control system has dropped back into

Standby mode. Up until that point, the air slider is never fully closed.

• Regardless of the flue gas temperature, whenever the door is opened,

the air slider first moves to its 100% position. After a stabilisation time,

it then moves to a position that suits the prevailing flue gas temperature,

as defined in the parameter settings.

Page 13

GB

GB 13

The data link only functions using Bluetooth. The module is integrated in

the control system. At any one time, it is only possible to connect one

mobile device to NEO. You cannot select a different device until Bluetooth is

switched off to the connected device or until the device leaves the Bluetooth

reception range.

A code for your S-Thermatik NEO can be defined in the Service menu /

System / Bluetooth. This can prevent unauthorised accesses or overlaps.

The factory setting is 0000.

10. A PP

For the S-Thermatik NEO there is an app for devices with an Android or an

IOS operating system. This app goes by the name of S-Thermatik NEO and

it can be downloaded from the Play Store or from iTunes.

To install this app you need to enable Bluetooth on your device, and you may

also need to permit "Installation from unknown sources".

NEO is operated by this app on your mobile device in the same way as via

the NEO display: the menus are identical.

Page 14

GB 14

11. NOTES FOR STOVES:

Stoves are usually supplied without a display The user obtains information

about the current status of the control system from a function monitoring

LED that is usually installed in the bottom flap of the stove.

The LED works in the following manner:

OFF: control system is in standby mode, fire area is off

ON: control system working in feedback control mode OR

is currently open, performing a self-test in the direc-

tion of 100%

SLOW FLASHING: The time for adding fuel has been reached

FAST FLASHING: The door is open, the appliance has overheated or an

external component is malfunctioning

During the slow flashing mode, the LEDs light up about 1 x per second, and

about 2 x per second in the fast flashing mode.

Even on control systems without a display it is possible to connect to the

appliance using the app and Bluetooth. The standard password for the Bluetooth connection is 0000.

On stoves, a mechanical Auto / Manual control knob is usually installed in

the lower section of the appliance. This should always be set to Auto.

Only then can the S-Thermatik NEO work properly.

When switched to Manual, the NEO is switched off and the display turns

dark. At the same time, a clutch in the actuator motor is activated that separates the air actuation mechanism of the gear unit on the electric motor.

This means that the air slider can only be moved very slightly as though no

motor and no control system is installed. The control system cannot operate

in its Manual position.

Page 15

GB

GB 15

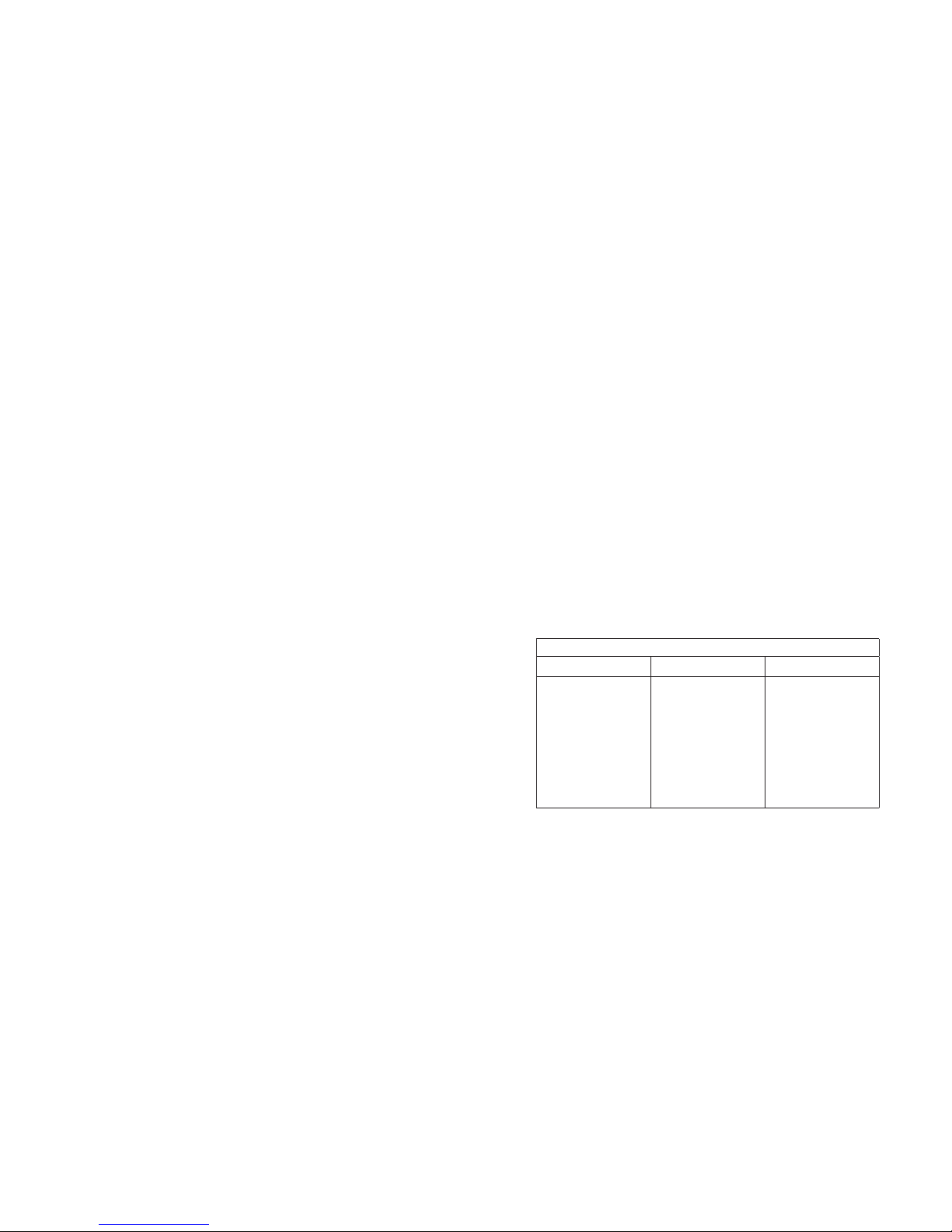

Problem description Possible cause / solution

Self-test

The air control lever only moves to the right and

stays there.

• No power between actuator motor and actuating lever, driver pin (star) has wandered out of

position.

• Link lever clamps on the primary air flap are

dragging on the ground and getting jammed.

• Check door contact and its setting.

Self-test

Air control lever first moves to the left, then to the

right, where it then stops moving.

• On the motor connector on the control system, swap over the red and white core leads

(stoves) or the brown and grey core leads (fire

place inserts).

In operation

The air lever moves too quickly back to the left in

the closed position.

• Does the current parameter set match the

appliance?

• Check the flue gas temperature display: are the

values displayed plausible?

• Check wiring of flue gas sensor for impermissible extension with copper cable or similar.

• Clean the water heat exchanger if fitted.

• Check draught conditions

• Check leak tightness of the appliance (viewing

panes, door, ash pan etc.).

In operation

Air control lever does not move to the right in the

100% closed position after the firebox door has

been opened.

• Check that the "Door open" message appears.

• Air control lever: Mechanism movement is

impaired. Loosen it up.

• Clean and degrease the rotary slide disks

• Door contact switch: Check function of door

contact switch.

• Check the wiring of the door contact switch to

the terminal box

• Check to ensure that the permanent magnet

approaches < 10 mm at the switch.

In operation

The air control lever does not close all the way.

• Make the mechanics tight but functional

• Clean and degrease the rotary vane discs

• Check the parameter setting: does the current

parameter set match the device?

• Check the air control lever mechanics for

looseness

12. GUIDE

The S-Thermatik NEO burnup controller detects the most significant errors

automatically and displays these in the form of clear text messages.

Motor errors are detected whenever the motor fails to move in response

to a movement command. Errors on the flue gas sector are detected by an

algorithm in the software. In both cases, the fire area must not be put

into operation until the error has been remedied.

First check if an error message appears on the display. Consult this advice

guide to assist you with this. If the problem cannot be resolved in this way,

please contact your dealer or stove fitter.

Problem description Possible cause / solution

Error message

Motor circuit open or motor error

Check that the motor cable is plugged into the

correct bushing.

• Check the motor cable.

NOTE: To reset the error, isolate the control unit

from its mains power supply briefly OR, in the User

menu, first select and save Manual mode then

select and save Automatic mode.

Error message

TC open or short to ground

• Check that the motor cable is plugged into the

correct bushing.

• Check the motor cable.

NOTE: The error reset is automatic whenever an

intact sensor is connected up

Door open - message:

The "Door open" message does not disappear after

the fire door has been closed

• Check door contact

• Check that the permanent magnet is still positioned above the door switch.

• Check the magnet for breakages

• Check settings in the door switch menu (NO

/ NC).

Overheated message

During the burnup, the message "Overheated"

appears

• Reduce the wood feed quantity.

• Check that the appliance setting has the correct set of parameters. The reset process is

automatic as the combustion chamber cools

down.

Page 16

GB 16

Spartherm Feuerungstechnik GmbH offers a 24-month guarantee in respect

of the sliding door mechanism, operating components such as handles, setting levers, shock absorbers, electrical and electronic components such as

fans, rotational speed controllers, the manufacturer's original spare parts,

all items purchased as additional extras and all safety appliances.

Spartherm Feuerungstechnik GmbH offers a 6-month warranty on wear parts

in the fire area, e.g. chamotte, vermiculite, fire grates and glass ceramic.

13.4 WARRANTY REQUIREMENTS

The warranty period shall begin on the date, on which the product is delivered to the dealer / distributor. Invoices or delivery notes may be used as

confirmation of the warranty commencement date. The warranty certificate

for the product must be presented by the claimant upon making a warranty

claim.

Spartherm Feuerungstechnik GmbH is not obliged to satisfy any claim if

such documentation is not presented.

13.5 EXCLUSIONS FROM THE WARRANT Y

This warranty does not cover:

• Wear to the product

• Fireclay / vermiculite: These are natural products which expand and contract on exposure to cyclical heating and cooling. This can cause cracks

to appear. The firebox linings will remain fully functional, provided they

are still in position and are not broken.

• The surfaces: Discolouration of the coating or galvanic surfaces, due to

excessive thermal loading or over-heating.

• The vertical sliding mechanism: Failure to comply with installation guidelines, resulting in over-heating of the guide rollers and bearings.

13. GENERAL WARRANTY CONDITIONS

13.1 AREA OF APPLICATION

These standard warranty terms apply for the contractual relationship

between the manufacturer, Spartherm Feuerungstechnik GmbH, and the

dealer/distributor. These warranty conditions are not identical to those warranty terms governing relations between the dealer or distributor and his

customers.

13.2 GENERAL INFORMATION

This product has been manufactured in compliance with current standards of

quality control. The materials used have been carefully selected and - like our

entire production process - are subject to on-going quality control. Specialist

knowledge is required when assembling and installing the product. The product

must, therefore, only be installed and commissioned into service by specialist

technical staff, in compliance with current statutory provisions.

13.3 WARRANT Y PERIOD

The standard warranty terms only apply within Germany and the European

Union. The warranty period and scope of the warranty are ensured within the

framework of these conditions outside the statutory warranty which remains

unaffected. Spartherm Feuerungstechnik GmbH offers a 5-year guarantee

in respect of:

• Main carcass of fireplace inserts

• Main carcass of fireplace stoves

• Main carcass of fireplace cassettes

• Main carcass of fireplace doors

Page 17

GB

GB 17

• The gaskets and seals: Reductions in sealing strength due to seal hardening as a result of thermal loading.

• The glass ceramics: Soiling, due to soot or other burnt-on combustion

materials and visual deterioration due to thermal loading.

• Careless transportation and/or incorrect storage:

• Inappropriate or careless handling of fragile components, such as glass

or ceramics

• Improper handling and/or use

• Lack of maintenance

• Incorrect installation or appliance connection

• Failure to comply with installation instructions and operating instructions

• Technical modifications made to the appliance by staff from other

companies

13.6 ELIMINATION OF DEFECTS / REPAIR

Independent of any statutory provisions acknowledged as taking precedence

over the terms of this warranty, all necessary repair works resulting from

material or manufacturing defect shall be carried out free-of-charge and shall

not invalidate the remaining provisions of the warranty. Within the scope of

this warranty promise Spartherm Feuerungstechnik GmbH reserves the right

to either remedy the fault or replace the device free of charge. The elimination

of defects shall take precedence.

The terms of this warranty shall not extend to any damage or compensation

not covered by statutory provisions.

13.7 EXTENSION TO THE WARRANTY PERIOD

The warranty period shall automatically be extended, where claims made in

respect of these warranty provisions result in the repair or replacement of

defective equipment.

13.8 SPARE PARTS

Only the manufacturer's own components, or replacement parts recommended and approved by the manufacturer, shall be used for appliance

servicing and repair.

13.9 LIABILITY

Damages and claims for compensation which are not the result of delivery of a defective appliance from Spartherm Feuerungstechnik GmbH are

excluded and are not part of this warranty promise.

The above shall not include claims made in respect of statutory legal

requirements.

13.10 CLOSING REMARKS

In addition to these warranty conditions and our commitment to them, our

dealers and contractual partners are pledged to assist you in both word and

deed. We expressly recommend that our fireplaces and stoves are regularly

inspected by a qualified technician.

We reserve the right to make alterations to the technical data contained herein and accept no liability in

respect of any errors made.

Page 18

GB 18

14. EU DECLARATION OF CONFORMITY

EC Declaration of Conformity as defined by EC directives

Low Voltage Directive 2014/35/EU - (LVD)

Electromagnetic Compatibility 2014/30/EU - (EMC)

Wireless systems directive 2014/53/EU - (RED)

We,

Spartherm Feuerungstechnik GmbH

Maschweg 38 / 49324 Melle, Germany

hereby declare that the products listed below comply with the above EU

Directives:

Product type: Combustion control

Model: S-Thermatik NEO

Melle, 11.01.2017

Gerhard Manfred Rokossa, CEO

Page 19

GB

GB 19

NOTES

Page 20

GB 20

SPARTHERM

A1-SP-GB/0.000/04/2017

DIE WELTMARKE FÜR IHR WOHNZIMMER

The Global brand for your living room | La référence mondiale pour votre salon | Il marchio mondiale per il vostro soggiorno

La marca mundial para su salón | Het merk van wereldformaat voor uw woonkamer | Światowa marka do Państwa salonu

Торговая марка № 1 для Вашего дома

D Ihr Fachhändler | UK Your specialist dealer | F Votre revendeur spécialisé

IT Il vostro rivenditore specializzato | E Sus comercios especializados

NL Uw vakhandelaar | PL Państwa sprzedawca | РУС Ваш дилер

Spartherm Feuerungstechnik GmbH | Maschweg 38 | 49324 Melle | Germany |

Tel.: +49 5422 9441-0 | www.spartherm.com

Loading...

Loading...