Page 1

Installation and Operating Manual

SEO S and SEO L stoves

Page 2

GB 2

PREFACE / QUALITY PHILOSOPHY

You have decided in favour of a Spartherm stove; thank you for your confidence

in our company.

In a world of excess and mass production, our company stands for the values

expressed by our owner, Gerhard Manfred Rokossa:

„High technical quality combined with contemporary design and service to the

satisfaction of our customers so they will recommend us to others“.

Together with our specialist trade partners, we offer a range of first-class products,

which not only evoke passion, but also engender feelings of comfort and security. To ensure that this occurs, we encourage you to read the operating manual

carefully so that you can become familiar with your fireplace and its accessories

quickly and thoroughly.

In addition to information on use, these instructions also include important details

on care and operation to guarantee your safety and to protect the value of your

stove as well as useful tips and guidance. Moreover, we show you how you can

operate your stove in an environmentally responsible manner.

For further enquiries, please contact your specialist dealer.

We hope you enjoy your new stove.

Your Spartherm team

G.M. Rokossa

Page 3

GB

GB 3

CONTENTS

1. General notes 4

1.1 Quality control 5

1.2 Scope of Deliver y 5

1.3 Transport damage 5

2. Installation instructions 5

2.1 Fundamental requirements for installation 6

2.1.1 Installation site 6

2.1.2 Multiple connection 6

2.2 Technical data 7

2.3 Installation / assembly 9

2.3.1 Changing the flue gas connection direction 9

2.4 Combustion air supply 10

2.4.1 Open flue operating method 10

2.4.2 Separate combustion air supply 11

2.4.3 Closed flue operation 12

2.5 Fire protection 12

2.6 Shut-off devices 15

2.7 Connecting pieces 15

2.8 Integrated throttle valve 15

2.9 Closing force for the fire door 16

3. Operating Manual 17

3.1 General information on operation 17

3.2 S-Thermatik NEO 18

3.3 Function of the rotary-base for SEO S 18

3.4 Rating plate 19

4. Combustion 19

4.1 Initial commissioning 19

4.2 SEO operating concept 20

4.2.1 The ‘SEO app’ 20

4.2.2 The indicator 20

4.2.3 Star t and menu structure of the app 21

4.2.4 Starting level 22

4.2.5 Fire area 22

4.2.6 Mode 23

4.2.7 Settings 23

4.2.8 Assistance 24

4.2.9 Fire 24

4.2.10 Monitor 25

4.2.11 Example of menu guidance 25

4.3 Heating-up / firing 26

4.3.1 Refuelling 27

4.3.2 Hourly wood consumption rate 27

4.4 Controlling heat output 27

4.5 Room heating options / indoor climate 27

4.6 Heating in the shoulder seasons/during unfavourable weather conditions 28

4.7 Chimney fire 28

5. Fuel 28

5.1 C O

2

Neutralit y 29

5.1.1 Wood storage 29

5.2 Your contribution to environmental protection 30

Page 4

GB 4

6. Cleaning and care 30

6.1 Cleaning the firebox/cladding parts 30

6.2 Firebox lining 31

6.2.1 Firebox lining SEO S 31

6.2.2 Firebox lining SEO L 32

6.3 Maintenance 32

6.3.1 Lubrication manual for door latches with Smart-Close 32

7. Troubleshooting 33

7.1 Glass becomes sooted heavily, rapidly and unevenly 33

7.2 Fire is difficult to ignite 33

7.3 Smoke escapes when adding wood 34

7.4 E xcessively rapid burn-up /

rate of wood consumption is too high 34

8. General warranty conditions 34

8.1 Application area 34

8.2 General information 34

8.3 Warranty period 34

8.4 Requirements for this warranty to be effective 35

8.5 Exclusion of warranty 35

8.6 Rectification of defects / repair 35

8.7 Extension of the warranty period 36

8.8 Replacement parts 36

8.9 Liability 36

8.10 Final comments 36

9. SEO S / L commissioning protocol 37

1. GENERAL NOTES

Please consult your district master chimney sweep before assembling and

installing your SEO stove. He will advise you of building law regulations, the

suitability of your chimney, and will conduct the ac-ceptance procedure for

your stove. The chimney calculation is executed in accordance with DIN EN

13384 with the value triplet specified in this manual (see technical data).

Important for small children, elderly or infirm persons: As is the case

with all heating devices, it is expedient that you attach a protective fixture

for these groups of persons, as the view pane and the cladding parts of the

stove can become extremely hot! Danger of burn injuries!

Never leave these groups of persons unattended near the stove when a

fire is burning or has just been extinguished! The stove should never be

operated for an extended period of time unattended.

ATTENTION: The heat-resistant glove provided serves only as thermal protection when using the operating handle and the cold hand. The glove is

not fire-proof!

National and European standards, the respective state-specific and local

directives and regulations, in particular the respective firing installation

ordinance of the German Federal State, must be complied with for setup

and operation of your stove and for the connection to the chimney.

The stove must always be operated with the door closed. Modification of the

closing device is prohibited!

Page 5

GB

GB 5

1.1 QUALITY CONTROL

OUR STOVE HAS BEEN TESTED IN ACCORDANCE WITH DIN EN 13240

AND SATISFIES THE REQUIREMENTS STIPULATED IN THE CONSTRUCTION PRODUCTS DIRECTIVE. (DECLARATION OF PERFORMANCE IS

AVAILABLE AND CAN BE VIEWED AT WWW.SPARTHERM.COM)

These stoves have a self-closing fire door which means the door is only

opened when the fireplace has to be serviced (e.g. to clean the combustion chamber or add more fuel). For safety reasons, the closing mechanism

must not be tampered with; furthermore, any such action would render the

warranty and operating licence null and void. The warranty and operating

licence are also rendered invalid if the customer modified the technology of

any other area of the stove.

1.2 SCOPE OF DELIVERY

The SEO S and SEO L stoves have the following characteristics:

• Fireplace made of refractory concrete / chamotte

• Primary and secondary air supply

• Extractable ash drawer

• Self-closing fire door with high-temperature-resistant ceramic glass.

• Insulated glove*

• Flue pipe Ø 150mm / 500mm - EN 1856-2**

• Rating plate (cf. Chapter 3.4 “Rating plate” on page 33 for fitting details).

• Supplied pre-assembled in transport-friendly disposable cardboard

packaging

** Attention: The glove provided serves only as thermal protection and is

not fireproof.

** only part of SEO L

1.3 TRANSPORT DAMAGE

Immediately on arrival, please check the goods delivered (visual inspection).

Make a note of any damage on your delivery document. Inform your stove or

fireplace fitter of the damage before the installation work begins. Protect the

visible elements of the stove from soiling and damage during installation.

Only permitted and sufficiently strong transport aids may be used to transport the stove.

The following points must be noted to ensure safe and problem-free

transport.

• It should always be shipped in an upright position, or slightly tilted on

its back!

• If wheelbarrows are used for transport, always lay the backs of stoves

in them.

2. INSTALLATION INSTRUCTIONS

The assembly and installation of your SEO S and SEO L stove must be

carried out by a specialist. Before your stove is assembled and installed you

should meet with the master chimney sweep responsible for such matters

in your area to discuss the suitability of your chimney and the installation

location and to clarify other matters.

Page 6

GB 6

2.1 FUNDAMENTAL REQUIREMENTS FOR

INSTALLATION

For installation, connection and operation of the SEO S and SEO L stoves,

all necessary national and European standards, TROL as well as local regulations (DIN, DIN EN, state construction ordinances, firing ordinances, etc.)

must be complied with and applied! The list of regulations given below is

not exhaustive.

FeuVo /

LBO / VKF

Firing Installation Ordinance of the respective German Federal State /

State building or fire protection regulations VKF (Switzerland)

1. BlmschV Erste Verordnung zur Durchführung des Bundes-Immissionsschutzgesetz (First

Ordinance on the Implementation of the Federal Immission Control Act)

TROL Regulations of the German Tiled Stove and Air Heating Constructors Association

(ZVSHK)

DIN 1298 / EN 1856: Connecting flue pipes for heat generating systems

DIN EN 13240 Stoves / solid fuel room heaters

DIN 18896 Solid-fuel fireplaces Technical specifications for installation and operation

DIN EN 13384 Chimneys - Thermal and fluid dynamic calculation methods

DIN 18160-1/2 Chimneys / house chimneys

Artikel 15a B-VG (Austria)

Fireplaces may only be installed in rooms and places where the location,

construction situation and type of utilisation do not lead to hazards. The

floor area of the installation must be of a design and size such that the

fireplace can be operated properly and as intended.

2.1.1 INSTALLATION SITE

Your SEO S / SEO L stove must not be installed:

1. In stairways, unless they are in residential buildings with two or fewer

flats.

2. In hallways with general access.

3. in garages.

4. Fireplace systems in rooms or flats that are ventilated through ventilation systems or warm air heating through the use of fans, unless the safe

operation of the stove is ensured.

5. In rooms in which highly combustible or potentially explosive substances

or mixtures are processed, stored or manufactured in quantities that

would be hazardous in the event of ignition or explosion

Closed flue stones can be installed in rooms, apartments or utilization units

of comparable size from which air can be extracted using fans, e.g. in ventilation or hot air heating systems. The condition is that the vacuum-capable

equipment cannot create a vacuum > 8 PA.

2.1.2 MULTIPLE CONNECTION

Multiple use of the chimney in accordance with DIN 18160 is possible

because the SEO S / L stove has a self-closing fire door (type A1). Without

exception, this should always be discussed and agreed in advance with the

local chimney sweep. All fireplaces connected to a chimney must also be

approved for multiple connection!

Page 7

GB

GB 7

2.2 TECHNIC AL DATA

The following details refer to the conditions for type testing as defined in

EN13240. Depending on local conditions and individual operating methods,

deviations may arise on location for specific forms of operation.

Wood burning stove SEO S SEO L

Technical data:

Fuel type: Wood logs

Wood feed quantity: 1,5 1,6 kg/h

Nominal heat output 5,1 5,5 kW*

Thermal output range: 4,5-6,5 4,5-7,2 kW

corresponding wood consumption: 1,0-1,9 1,0-2,1 kg/h

Efficiency: 80 80 %*

CO content at 13% O

2:

< 1250 <1250 mg/Nm

Dust content: <40 <40 mg/Nm

Flue gas temperature at the connector

1

: 309 283 °C*

Supply pressure**. 12 12 mbar

Mass flow of flue gas: 5,2 6 g/s*

Combustion air requirement: 16,3 15,7 m³/h*

Weight according to model 240 225 kg

Minimum distances from combustible components:

1

back1: 160 160 mm

side

1

: 310 560 mm

top

1

: 500 mm

Area of direct radiant heat

1

:* 800 mm

Requirements

BlmschV Stage 1 Ye s

EN 13240 Yes

DIN Plus Yes

Regensburg municipal ordinance Ye s

Munich municipal ordinance Yes

Aachen requirement Yes

15a (for Austria) Yes

Air cleanliness directive from 01.2011 (for Switzerland) Yes

** The specified values represent the mean value over a burn-up cycle.

These values arise under type testing conditions.

** Depending on the stove, negative pressures greater than 20-25 Pa can

influence correct operation. The viewing pane can become increasingly

contaminated or noise can be intensified!

1

refer to 2.5 for details. Fire protection, illustrating installation variants.

Page 8

GB 8

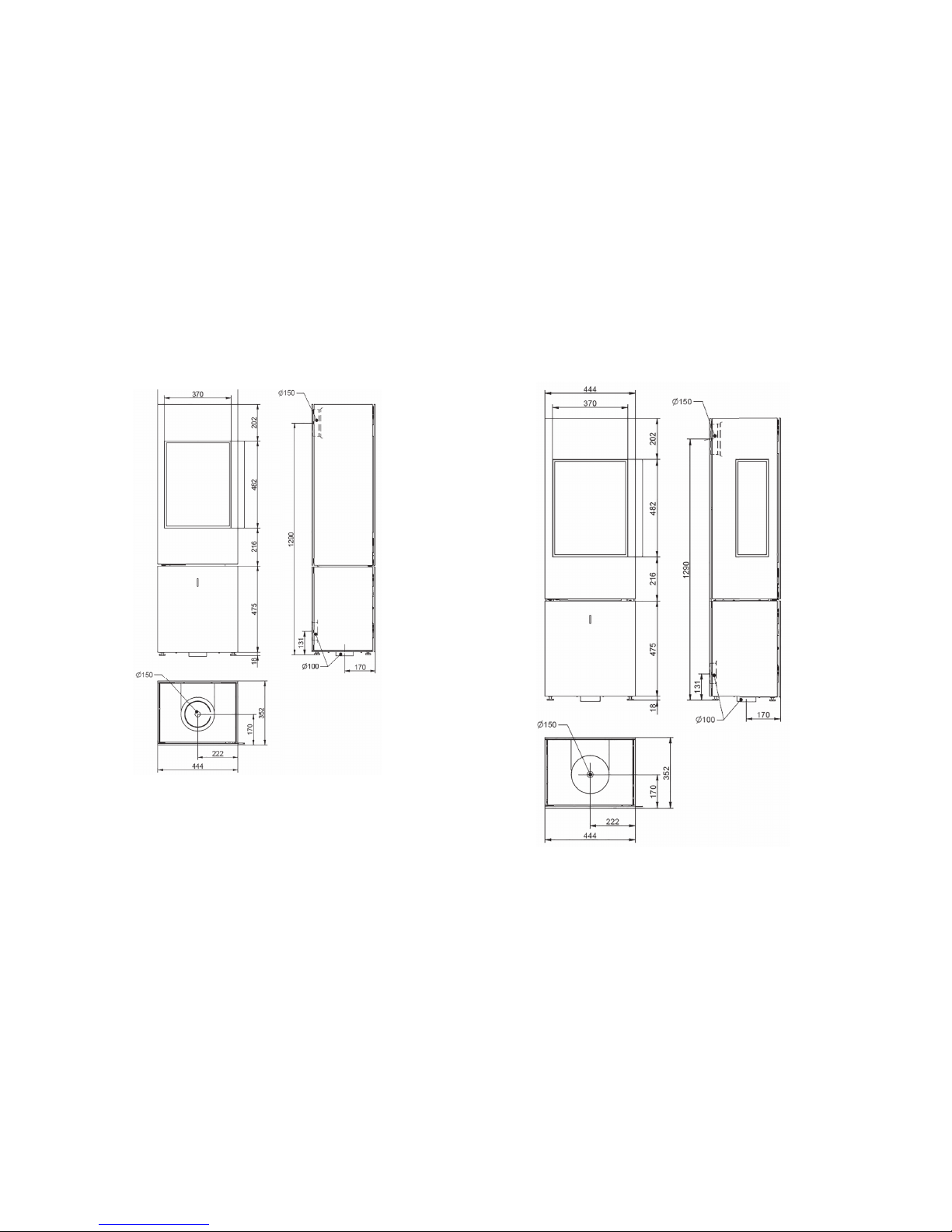

Dimensional drawing of SEO S

Dimensional drawing of SEO L

Page 9

GB

GB 9

2.3 INSTALLATION / ASSEMBLY

Your SEO S / SEO L stove must be installed on floors made of non-flammable

materials with a sufficient load-bearing capacity. Please observe the overall

weight (cf. Chapter 2.2 Technical data on page 7)! The load-bearing capacity may have to be ensured by a sufficiently thick board (weight distribution).

When selecting the installation site, also note the necessary measures for

fire protection in the floor area (cf. Chapter 2.5 Fire protection on page 12).

The stove is placed on the floor in compliance with the safety distances (cf.

Chapter 2.5 Fire protection on page 12) and aligned horizontally. The feet

are adjustable in height.

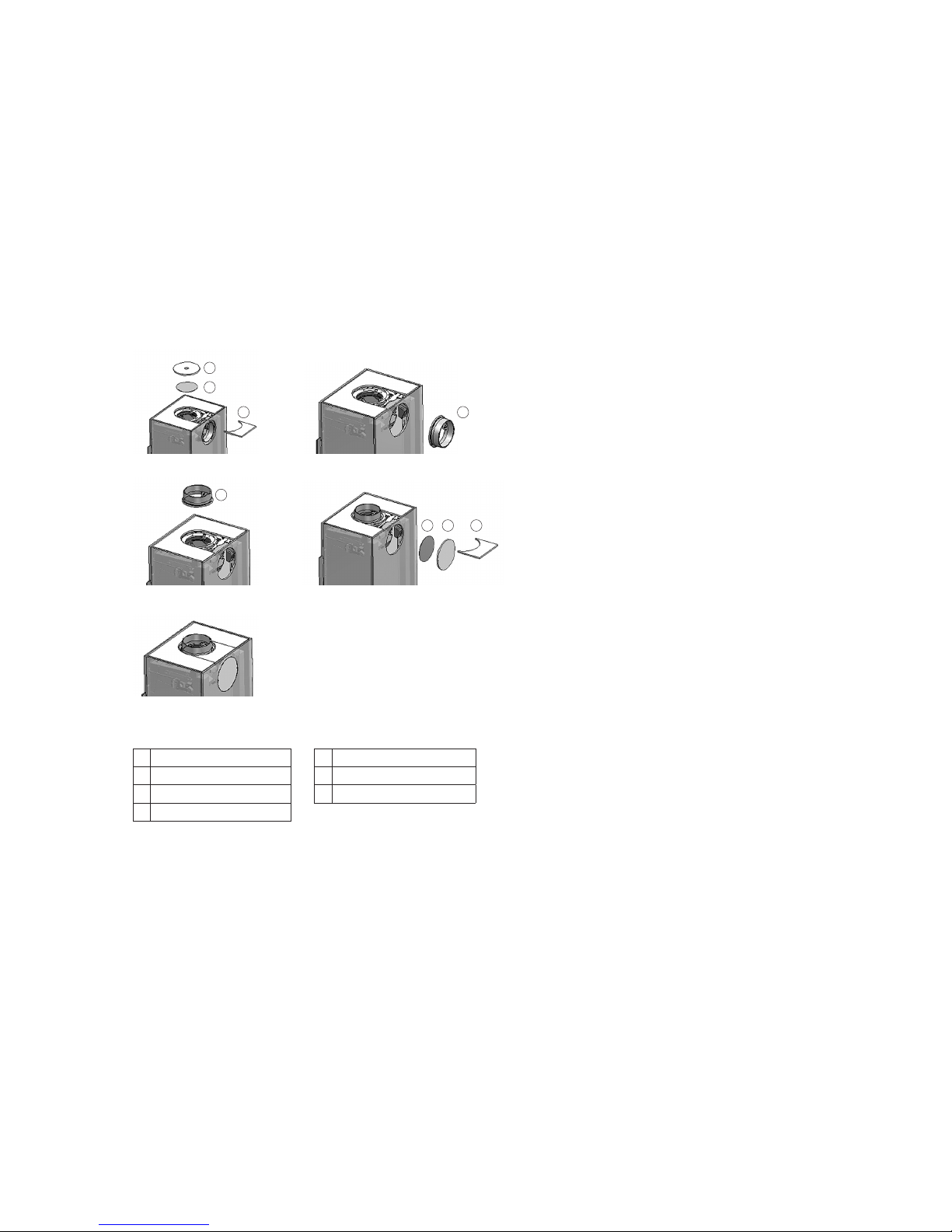

2.3.1 CHANGING THE FLUE GAS CONNECTION

DIRECTION

The stove is prepared for the flue gas connection at the top when delivered.

The flue gas connection position can be changed to the back. If the position

of the flue gas connection is changed, the following assembly steps must

be performed:

Installation from back to top

As a first step, remove the top sealing cover by pulling it forwards. Lift off

the blanking plate with the help of the recessed aperture. Dismantle the

inner cover plate by unfastening the two screws (Fig. 2a).

In the next step, remove the flue gas connector on the back of the stove by

unfastening the hexagon screws (waf 13 mm) (Fig. 2b).

Fit the unfastened connection journal at the top of the stove connection

flange (Fig. 2c) with the help of the two hex screws. Now fit the cover plate

removed in step 1 back to the inside rear wall panel using the two screws.

Seal the outer rear cladding panel with the help of a second cover plate

supplied in the stove combustion chamber.

Finally, slide the cladding cover removed in step 1 back onto the top plate

(Figs. 2d+2e).

Make sure that the sealing elements are correctly positioned under the

dummy cover and the flue gas outlet and ensure a tight seal.

Note for SEO S: If the SEO S model is connected to the rear flue point, this

blocks the turning function!

1. Remove the 3 cladding parts at the top in the following sequence (Fig.

2a):

- Cap (forwards)

- Blanking plate (upwards)

- Inside cover plate (upwards)

2. Remove the back connecting socket by unfastening the two screws (Fig.

2b)

3. Fit the connecting socket on the top appliance flange using 2 screws

(Fig. 2c).

4. Fit the 3 back cladding parts (Figs. 2d+2e)

Page 10

GB 10

Fig. 2a Fig. 2b

Fig. 2c Fig. 2d

Fig. 2e

1

2

3 4

4

5 6 7

1 Blanking 5 Cover plate, inside

2 Cover plate, inside 6 Cover plate, outside

3 Cap 7 Cladding cover

4 Pipe nozzle

Installation from top to rear occurs in reverse order:

2.4 COMBUSTION AIR SUPPLY

The combustion air can be supplied in accordance with Chapter 2.4.1 Open

flue and Chapter 2.4.3 Closed flue in different ways.

2.4.1 OPEN FLUE OPERATING METHOD

Your ambiente SEO S / SEO L stove draws the combustion air from the

installation area (open flue operation). Ensure that there is a sufficient supply of fresh air to the installation area (for more details, refer to the applicable regional Fire Installation Ordinance (German ‘FeuVO’), DIN 18896,

applicable rules of technology etc.).

The fresh air supply must be checked by the installer and the operator.

When operating several fireplaces in a single room or linked space, ensure

that sufficient air is available for combustion! It is possible that there is not

a sufficient supply of fresh air if the windows and doors are sealed (e.g., in

combination with energy saving measures).

As a result, the ventilation of the stove can be affected. This can also

adversely affect your well-being and, potentially, your safety. If necessary,

an air valve must be installed near the pellet stove for the additional supply

of fresh air, or a combustion air line must be routed outwards (see 2.4.2) or

in a well-ventilated room (except for the heating room). In particular, ensure

that the necessary combustion air pipes are open during the operation of

the fireplace insert.

This means that simultaneous operation with a ventilation system (e.g.

extractor hood, bathroom fan, etc.) in the same room or connected space

can adversely affect the function of the stove (to the point of smoke or flue

gas accumulating in the living room, despite the firebox door being closed).

It is therefore prohibited to operate appliances of this kind simultaneously

with a fireplace without first taking appropriate precautionary measures.

Page 11

GB

GB 11

2.4.2 SEPARATE COMBUSTION AIR SUPPLY

The stove can be supplied with combustion air separately. The separate

combustion air connection is located on the underside of the appliance

(Ø = 100 mm). The combustion air line to be attached can be connected

underneath or at the back. A connection is integrated in the plinth for a

bottom connection.

To connect up combustion air, the following steps must be taken.

Assembly of the combustion air channel on the underside of the

appliance:

1. Place the appliance above the combustion air port in the floor and

remove the cladding plate (Fig. 3a).

2. Next, remove the sealing cover (Fig. 3b).

3. Connect the combustion air neck to a flexible and removable combustion

air line. If the combustion air connection is rigid at floor level, the separate combustion air nozzle supplied must be pushed into the connection

to form an airtight seal.

4. Finally, press together the combustion air line and install the combustion

air neck (Fig. 3c).

Fitting the combustion air channel to the back of the appliance:

1. First of all, unscrew the outer and inner cover plates (Fig. 3d).

2. Now fit the combustion air nozzle (Figs. 3e+f).

3. Lastly, connect the combustion air nozzle with the combustion air line.

When connecting a pipe connection to the combustion air neck, the combustion air can be supplied to the stove from the outside or from other

rooms such as the cellar. When connecting the stove to a combustion

air line, the TROL instructions (technical rules), DIN 18896, etc. must be

observed and applied.

1 Cladding plate

2 Cap

3 Combustion air neck

In particular, ensure that the dimensions of the pipes are adequate!

2

3

Fig. 3a Fig. 3b

Fig. 3c Fig. 3d

Fig. 3e

1

Fig. 3f

2

3

3

Page 12

GB 12

The combustion air openings and lines must not be closed or blocked unless

it has been ensured that the fireplace can only be operated with an open

lock by means of special safety equipment. The cross-section must not be

narrowed by a fastening or a grille. A shut-off valve must be installed, if

this combustion air feed pipe runs outside the building. In doing so, it must

be possible to easily determine the shut-off device setting from outside of

the connecting line. This arrangement allows the feed pipe to be insulated

to guard against the formation of condensation. The pipe should be positioned so that no water or other foreign substances from outside cannot get

into the stove, and that any condensation formed can run out of the pipe.

Even with a separate combustion air line for the stove, its operation can be

impaired by a ventilation system. Therefore, simultaneous operation is not

possible.

In accordance with regulations, combustion air lines crossing a fire wall in

buildings with more than two floors must be established in such a manner

that smoke or fire cannot be transmitted to other floors or fire compartments. Country-specific and local fire safety regulations must be observed!

2.4.3 CLOSED FLUE OPERATION

The SEO S / SEO L closed flue stoves have been developed for use with

residential ventilation systems for a vacuum range of up to 8 Pa in the

installation area and can be operated without additional safety equipment.

The combustion air must be supplied in airtight lines from the outside or

via an LAS system to the device for room-air-independent operation without

fail. To do this, the combustion air duct must be permanently sealed to the

combustion air neck (connection type back or bottom) of the stove.

When connecting the close flue stove to a combustion air line, the TROL

instructions (technical rules) and DIN 18896, etc. must be observed and

applied. In particular, ensure that the dimensions are adequate! Comply

with all country-specific and local fire safety regulations! Make sure that

the pipes are always airtight.

2.5 FIRE PROTECTION

The handover inspection of your stove before commissioning is performed

by the chimney sweep responsible. You can also advise the chimney sweep

prior to installation about installation conditions on site, and can provide

advice on how to install your stove properly.

General information on fire prevention

Stoves are heat generators and are subject to regulations and necessary

measures for fire protection. Right from selection of the installation site

stage, fire regulations and recommended minimum individual clearances for

the appliance must be observed.

Basically, a minimum wall clearance of 5 cm to the back wall must be

adhered to. For reasons of safety and fire protection, make sure that large

distances to walls to be protected or combustible components are maintained. See the following installation examples.

The following table documents the permissible safety distances. Using the

diagrams (Figs. 4a-4f), match the mounting situation, taking into account

the specified distances that need to be complied with.

During installation, please pay attention to the fire protection instructions

and contact your local chimney sweep with any questions you may have.

• Mounting walls that are non-combustible or which do not require protection are able to withstand permanent exposure to tempera-tures > 85°C

thanks to their structure and material type.

• Combustible mounting walls in need of protection (e.g. stud partition

construction) must be protected from temperatures above 85°C.

Page 13

GB

GB 13

Before installing the stove, it is necessary to evaluate the mounting walls. If

it is not possible to identify the precise type of installation wall, a specialist

(chimney sweep) needs to be brought in.

• Wallpaper as wall coverings in accordance with DIN 4102-1 are

non-combustible components and do not require special precautions

for fire protection. Ensure here that the underlying structure of the wallpaper (e.g. timber frame construction) is very easily ignited or must be

protected and appropriate precautions must be taken!

• Ensure that the minimum clearances from chimney connecting piece to

combustible components are adhered to (see Chapter 2.7 Connecting

flue pipes on page 15).

• Combustible objects must not be located at a distance of 50 cm above

the fireplace!

Floor coverings near the fireplace:

Floors made of combustible materials in front of the firebox opening must

be protected by a board made of non-combustible materials. The board

must extend over at least 50 cm to the front and at least 30 cm to the side

(measured from the combustion chamber opening or viewing window)!

No combustible components, furniture, curtains or decorations may be

placed in the area of direct radiant heat of the fire door or inspection glass.

This distance may be reduced to 400 mm if radiation protection plates are

installed between the fireplace and combustible structures on both sides.

Installation example for the SEO S:

1. When installing against a straight wall, maintain the following distances

between that wall and your SEO S stove: a minimum distance of 160

mm must be maintained behind any combustible components (Fig. 4a)

2. For installation in the corner of a room, maintain the following wall distances: If the stove is installed as shown as in Figure 4b, a minimum

distance from the SEO S of 160 mm must be maintained to the sides of

combustible components.

Fig. 4a

Fig. 4b

Page 14

GB 14

If the stove is installed as shown in figure 4c, a minimum distance of

160 mm at the back and of 600 mm at the side must be main-tained. If

the wall is in the radiant heat area, fit a thermal protector to this area.

3. For floor coverings in close range:

Floors made of combustible materials in front of the combustion chamber opening must be protected by a board made of non-combustible

materials. The board must extend at least 670 mm to the front and at

least 570 mm to the side! Due to the fact that the SEO S fireplace can

rotate, the floor covering needs to be protected across a larger area

(Fig. 4d).

Abb. 4c

Abb. 4d

Installation example for the SEO L:

1. For installation against a straight wall, the following wall spacings must

be maintained to your SEO L stove: a minimum distance of 160 mm must

be maintained behind combustible components (Fig. 4e).

2. Floors made of combustible materials in front of the firebox opening

must be protected by a board made of non-combustible materials. The

board must extend at least 500 mm to the front and side! (Fig. 4f).

Abb. 4e

Abb. 4f

Page 15

GB

GB 15

Stove

Distance to the

rear wall

Distance to side

wall

Distance in the area

of direct radiant

heat of the view

pane.

Dimensions of the

fire protection floor

covering

A (mm) B (mm) C (mm) D (mm)

combustible

No

protection

required

combustible

No

protection

required

combustible

No

protection

required

Length x

Width

Radius (with

round floor

covering)

SEO S 160 50 310 200 800 800 500 x 300 500

SEO L

160 50 560 250 800 800 500 x 300 500

2.6 SHUT-OFF DEVICES

Flue gas systems must be created as per the technical rules of the German

Association of Tiled Stove and Hot-Air Heating Systems.

Stoves must feature a shut-off valve on the exhaust path . These devices

must not be self-closing and must not be positioned such as to prevent or

hinder the inspection and cleaning of connecting pipework. The position of

the shut-off device must be visible from the outside, e.g., from the position of the operating handle. Shut-off devices may only be installed in the

exhaust manifold or collecting pipe, the flue gas pipe stub or the pipeline

connecting piece.

2.7 CONNECTING PIECES

Connecting pieces: your SEO S / SEO L stove is connected to the chimney

by ø 150 mm connecting pieces made from steel sheet at least 2 mm thick.

These must comply with DIN 1298 or DIN EN 1856-2 and they must be

connected to the chimney in accordance with DIN 18160 or the regulations

that apply in the country concerned.

Ensure that the flue gas pipe is installed in the shortest possible route

upwards towards the chimney. The number of bends in the flue gas pipe

should be kept to a minimum. In addition, the flue gas pipe must be

connected to the chimney with a bricked-in wall lining and sealed. If necessary, the flue pipe may need to be secured with brackets to assure sufficient

stability. If the flue gas pipe is routed through components with flammable

building materials, the flue gas pipe must be insulated as specified in the

regulations.

The connecting line must always be mounted in such a manner that it is

possible to clean the connecting line at any time. This must be ensured

through a sufficient number of cleaning openings.

Depending on the information provided by the flue gas pipe manufacturer,

the minimum distance from the chimney connecting piece to combustible

components may increase the distance between the stove and combustible

building components. The specified minimum distances to combustible

components as stated in these instructions refer to the fireplace and must

be adjusted if necessary (see Chapter 2.5 Fire protection).

Ensure that a cleaning opening is located above the flue pipe connection

with gas evacuation to the top.

2.8 INTEGRATED THROTTLE VALVE

A throttle valve is integrated in the exhaust flue above the deflector plate in

the SEO stove. When the fire door is closed, this throttle valve is in its starting position. The exhaust gases can escape upwards through an opening

cross section in the sheet metal panel, optimally adjusted for combustion.

Whenever this fire is opened, e.g. for adding fuel, the throttle valve swivels

upwards, greatly increasing the opening aperture for the exhaust gases.

This ensures that the exhaust gases do not escape into the room as a result

of the change in pressure in chimney and combustion chamber while the

fire door is open.

Page 16

GB 16

The initial position of this flap is set ex-factory for optimum air cross-sections. Depending on chimney conditions, this can cause impaired or insufficient combustion, and/or to smoke escaping into the room. In such cases,

it is possible to adjust the position of the throttle valve and therefore also of

the exhaust cross sections.

1. To do this, remove the top cladding parts from the top plate. (Fig. 5a).

2. Now you have access from above to the rod mechanism on the right side

of the stove that controls the throttle valve. The driving rod, mounted

with the help of a lock nut, can be used to adjust the position of the flap

(Figs. 5b and 5c).

3. To enlarge the opening cross section in the exhaust gas flue, unfasten

the lock nut and turn the driving rod further towards the back.

4. Then tighten down the lock nut again firmly.

5. Finally, place the cladding parts back onto the top plate.

Fig. 5a

Fig. 5b - Bottom view

Fig. 5c

1 2

1 Driving rod.

2 Lock nut

2.9 CLOSING FORCE FOR THE FIRE DOOR

The closing force of the self-closing Type A1 fire door is factory-set to its

optimum level. To change the closing force, the setting can be adjusted

using a spring.

1. To do this, remove the top cladding parts from the top plate. (Fig. 6a).

2. You now have access to the spring mechanism. (Fig. 6b).

3. Unfasten the two hex screws with flange and slide the holder in the two

elongated holes. You increase the closing force of the door by continuing to tighten the spring (“tighten clockwise”), and you decrease the

closing force of the door by relieving tension on the spring (by turning it

anti-clockwise) (Fig. 6c).

Page 17

GB

GB 17

Fig. 6a

Fig. 6b

1

2

3

1 Reduce force

2 Increase force

3 Hex screws with flange

Fig. 6b

3. OPERATING MANUAL

Read these installation and operating instructions carefully before installing

and starting up your stove. All objects must be removed from the combustion chamber (except for combustion chamber liner).

Ask your specialist dealer to explain to you how to operate the SEO S / SEO

L stove and how it functions.

National and European standards and local regulations for operating the

fireplace must be observed!

3.1 GENERAL INFORMATION ON OPERATION

• Small children, elderly or infirm persons: As is the case with all heating

devices, it is expedient that you attach a protective fixture for these

groups of persons, as the view pane and the lining parts of the stove can

become extremely hot! Danger of burn injuries!

• Never leave these groups of persons unattended near the stove when

a fire is burning or has just been extinguished! Make these individuals

aware of these risks.

• No combustible objects may be placed or laid on the free surfaces and

the panels of the SEO S / SEO L stove. Do not place items of clothing on

the stove to dry. Racks for drying clothing may only be placed outside

the radiation area!

• Burning fuel releases thermal energy which heats up the various parts

of the stove, such as the surfaces, the door, the door handle and control handle, the viewing pane, the flue ducts, etc. Do not attempt to

touch these components without adequate protection (i.e. heat-resistant

gloves).

Page 18

GB 18

• The SEO S / SEO L stove may only be operated with the fire door closed.

The door should always be kept closed, even when cold. The door is only

opened for lighting up and for refuelling.

• The fireplace must never be modified! Do not insert any foreign component (any component not expressly approved by Arcadia) into the

combustion chamber, combustion passages or exhaust gas flue. Any

such modification of the fireplace without express approval will void the

warranty and operating permit.

• This applies in particular when operating several fireplaces in a single

room or linked space. It must be ensured that sufficient air is available

for complete combustion!

• Your appliance is designed to operate as a temporary or short-term combustion device. Continuous burning cannot be achieved even through

withdrawal of the combustion air and is not permitted! A longer heating

period is achieved by repeatedly by adding suitable amounts of fuel to

the fire.

3.2 S-THERMATIK NEO

Your SEO stove is equipped with S-Thermatik NEO burn-up equipment.

Supply voltage 230V AC

Power consumption during operation: approx. 10VA

Power consumption in "Stand-by" mode: approx. 6VA

Safety class I

Degree of protection IP 20

For further information about the burn-up control, please request the assembly and service instructions from the manufacturer of the S-Thermatik NEO.

3.3 FUNCTION OF THE ROTARY-BASE FOR SEO S

Attention: The swivel function is not available when the exhaust flue gas

connection is at the back!

The SEO-S model is divided into two areas: the upper combustion area and

the lower maintenance and storage area. The upper section of the stove can

be turned by 30° in either direction using the rotary base at this interface

(Fig. 7a).

Fig. 7a

2

1

1 Oberer Feuerungsbereich – lässt sich um 30° in jede Richtung drehen

2 Lower maintenance and storage area

3 Remove stop.

Page 19

GB

GB 19

To activate the swivel function, you must first operate the stop on the rotary

base. This detent pin is located centrally in the lower storage area (Figs.

7b and 7c).

After pulling out the spring-actuated stop,

the top cube can be swivelled 30° in either

direction. After swivelling, lock the stove in

its final position by engaging the stop (Fig.

7d).

Fig. 7c

Fig. 7b

3

Fig. 7d

3.4 RATING PL ATE

The rating plate is located on your warranty certificate and also on the

back of your stove. It contains technical data and notes. Never remove the

rating plate because it confirms that the appliance has been tested, and it

is also required for the acceptance procedure and annual inspections by the

chimney sweep.

4. COMBUSTION

4.1 INITIAL COMMISSIONING

The SEO S / SEO L stove must only be installed and set up by a specialised company. Initial commissioning must only be executed by an expert

employee of the installation company. A certificate confirming proper

installation and proper adjustment / function of all control components and

safety components must be given to the owner / operator of the system (see

sample, chapter 10).

When first putting your appliance into service, only start a moderate fire.

This enables you to avoid cracks in the firebox covering (which may still

contain residual humidity before the first firing). Slowly increase the heating

power to about 30% above nominal heat output by setting the fire 3 to 5

times to give the corrosion coating applied to the surfaces time to ‘burn

in’ properly. During this process, the paint can become slightly soft, do not

place any objects on the stove and do not touch the appliance. During this

burning-in process, an unpleasant yet harmless odour (sometimes accompanied by the build-up of smoke) may be given off. It is therefore important

to ensure that the room is well ventilated during the burning-in process.

Open all doors and windows to the outside of the building.

Page 20

GB 20

During heating and cooling, metallic grinding noises may be heard as the

components of your stove expand or contract. These are completely normal

and arise as a result of material expansion caused by the high temperatures.

Note: It can be helpful for the lighting up to weigh the recommended

quantity of wood (1 - 1.5 kg) to estimate what (visual) quantity of wood

corresponds to this weight. This enables you to ensure that the stove is not

overheated as a result of you adding too much wood.

4.2 SEO OPERATING CONCEPT

4.2.1 THE ‘SEO APP’

Your SEO stove is controlled fully automatically by the integrated S-Thermatik NEO burn-up controller. To operate this appliance, the “SEO APP”

provides you with an information platform. With this, you can choose various

settings, e.g. the desired power/performance level, as well as request further information about the prevailing operating condition, historical data or

information about suspected faults.

This app is available for devices running Android and the IOS operating

system. It is called “SEO App” and it can be downloaded from the Play Store

or from iTunes.

To install the app, you must activated Bluetooth on your device, and you may

need to permit “Installation from unknown sources”.

The data link only functions using Bluetooth. The module is integrated in

the control system. Only ever one mobile device can be connected to the

controller at any one time. Another device can log in once Bluetooth is

switched off on the connected device, or until that device moves outside

reception range.

Note: Depending on the configuration of the tablet or smartphone being

used, a Bluetooth coupling code can be requested during first-time installation. To enable the connection between the stove and the tablet or smartphone, please enter this numerical string:

0 0 0 0

in the input screen.

4.2.2 THE INDICATOR

An illuminated indicator acts as a direct information communicator between

the SEO stove and the operator. It is recessed into the lower door of the

storage compartment. This provides basic information about the prevailing

operating status. For further information, please consult the “SEO App”

This indicator provides basic information about the prevailing operating

status and of any faults/operating errors with a range of light signals: Off,

continuously lit, pulsating flashes and rapid flashes.

Interaction levels

Simple feedback during operation

More complex settings

Monitor

Page 21

GB

GB 21

Here are the interactions in detail:

Indicator

LED - Off

Function

Appliance

OFF

Appliance is

in standby

mode

LED - On

Function

Appliance

ON

Appliance

is in normal

operation

LED -

pulsating flashes

Function

Add fuel

signal

Burn-up

ended - add

more fuel

LED -

flashes rapidly

Function

Fault

message -

door open

Overheating

Sensor

defect

4.2.3 START AND MENU STRUCTURE OF THE APP

After starting the app, the user can retrieve further items of information.

To do this, it is possible to navigate within the following menu structure.

For details of the individual levels and menu items, please consult the following sections:

Monitor

Fire area

Combustion

chamber

temperature

Room

temperature

Enjoy

Mode Settings

Languages

Sound on/off

Assistance Fire Monitor

Lighting Standard

burn-up

Adding

fuel

Eco Performance Statistics

Page 22

GB 22

4.2.4 STARTING LEVEL

The first level offers a choice between the following modes:

Fire area / Mode / Settings

Fire area

Mode

Settings

Fire area

Mode

Settings

4.2.5 FIRE AREA

All stoves detected in the scan range are displayed at the “Fireplace” menu

item. After selecting an appliance, a connection is established between the

app and the chosen stove.

Touch here to search for available appliances Search for available appliances

Touch here to search for available appliances

Touch here to search for available appliances

Touch here to create a connection

Touch here to create a connection

S-Thermatik Neo

Page 23

GB

GB 23

4.2.6 MODE

The following levels are arranged behind the Mode menu.

Assistance / Fire / Monitor

Assistance

Fire

Mode

Assistance

Fire

Mode

4.2.7 SETTINGS

Under the Settings menu item,

• the menu language can be selected (9 standard languages available)

• German • English • French • Italian • Spanish

• Dutch • Polish • Czech • Russian

• and the acoustic signal for adding fuel can be activated/deactivated.

Language

Sound on

Sound on

Sound off

Page 24

GB 24

4.2.8 ASSISTANCE

The assistance (Help) level provides the user with additional information

about the message on the illuminated indicator.

The indicator is lit continuously. The appliance is operating in normal mode.

Depending on operating condition, the symbols for “Lighting up” or “Full

burn-up” are displayed.

The indicator flashes with a pulsating light. The user is called upon to add

wood. This signal can also be amplified acoustically.

The indicator flashes in a fast rhythm. At the same time, a fault message is

displayed. The type of fault is described and is displayed on the welcome

screen (homepage).

LED - Off

LED -

pulsating flashes

LED -

flashes rapidly

Lighting Normal burn-up

Adding fuel

Warning

The following types of fault can be displayed:

• Open door! After filling, close door correctly.

• Overheating! Next time, add less fuel.

• Sensor defective! Contact your specialist dealer.

• Motor malfunction! Contact your specialist dealer.

4.2.9 FIRE

At the “Fire” level, the user has the option of choosing between 3 performance/power levels. The power levels

Eco (lowest power)

Enjoy (moderate performance)

Performance (maximum performance)

are illustrated by different sizes of flame symbol and these can be adapted

during the burn-up phase.

Eco Enjoy Performance

Page 25

GB

GB 25

4.2.10 MONITOR

At the Monitor menu, the prevailing combustion chamber temperature and

the room temperature can be queried online.

Also, using the Statistics button, a time plot (over a period of 3 hrs.) can

be displayed showing combustion chamber temperature, room temperature

and air intake (%).

Room temperature Combustion chamber

temperature

Statistics

Temperature

356°C

256°C

200°C

Air supply

100%

50%

0%

4.2.11 EXAMPLE OF MENU GUIDANCE

The following example shows how to set the desired power level:

Activate your tablet. This app appears on the user interface

Activate the app. The main

interface appears.

Select the Mode menu.

In the sub-menu, select Fire.

Fire area

Mode

Settings

Assistance

Fire

Monitor

Page 26

GB 26

The last 3 power stages saved are then displayed.

Select the desired power level (in this example, the middle stage

of Enjoy).

The selected power level is shown in red.

By clicking the arrow in the top

left corner of the screen (back),

you can return to the main

menu.

Eco

Enjoy

Performance

Eco

Enjoy

Performance

Fire area

Mode

Settings

4.3 HEATING-UP / FIRING

Lighting this stove is very easy if you follow the instructions below.

1. The SEO S / SEO L stove must only be fuelled with correctly inserted

combustion chamber line

2. The split timber is layered crosswise in the

centre of the combustion chamber, tapering

upwards (soft wood).

3. 3. Never place more than 1 kg - 1.5 kg per

burn-up in the fireplace

4. Place commercial firelighter cubes under the

stack of firewood to assist with lighting the fire.

(Paper is not recommended because it burns too

quickly and causes ash flight).

5. Never use methylated spirits, petrol, oil or any other

highly flammable liquids.

6. Light the fire at the firelighter cubes and leave the

fire door open about 3 - 5 cm. The fire should now

ignite brightly and burn intensely.

7. If the initial stack of wood burns well, add

smaller hardwood split logs logs or larger

softwood split logs logs in a haphazard stack.

8. You can learn more about the correct amount

of timber to add in the chapter on wood feed

quantities per hour (see Point 4.3.2).

9. Once the wood has burned down completely,

or once only hot embers are left, you can add

more firewood as required (the ideal fuel is

now hardwood).

Page 27

GB

GB 27

10. Do not open the door forcefully or gases may enter your living room

through a suddenly produced negative pressure. At first, open the door

slowly and slightly.

11. By putting fresh firewood onto hot embers

you prevent the possible release of smoke

when the door is opened.

12. Never repeatedly put more than the recommended amount onto the fire.

4.3.1 REFUELLING

Do not refuel until the indicator flashes in a pulsating manner and/or until

the acoustic signal sounds (if activated) (cf. chapter 4.2 SEO operating

concept).

Caution: Never add more than the recommended amount of wood (1-1.5

kg)! Otherwise there is a risk of overheating the stove.

1. Open the combustion chamber door very slowly (use the heat protective

glove), so that no turbulence can might cause smoke to escape into the

room.

2. Place the wood logs on the embers (bark facing upwards, cut ends to

either side). Make sure that the air supply is open! Embers must not be

smothered).

3. Close the combustion chamber door (use the heat-resistant glove!)

4.3.2 HOURLY WOOD CONSUMPTION RATE

In order to avoid damage due to over-heating (discolouration of the steel,

deformation, etc.) and to guarantee optimum performance over the lifetime

of the appliance, ensure that the stove is fuelled in the proper manner.

To prevent any risk of overheating, make sure that the maximum heating

capacity is never exceeded.

The recommended amount of wood feed per hour is 1-1.5 kg. The individual

wood logs should be no more than approx. 25 cm in circumference!

Please note: Larger feed quantities lead to overheating and damage to

the chimney insert. Wood pellets (briquettes) have a much higher heating

capacity than hardwood. The hourly feed rates are therefore to be keep 20%

less than with wood logs.

In the event of damage caused by overheating (an excessively high hourly

fee rate), we shall decline all warranty claims.

4.4 CONTROLLING HEAT OUTPUT

Heat output is controlled by regulating the amount of fuel being added, and

this should never exceed the recommended quantity of wood. Ensure that

the combustion chamber door is always firmly closed to prevent combustion

being accelerated by the uncontrolled inflow of air.

The performance of your stove is also dependent on the draught in your

chimney. This draught can be adversely affected by the cross-section of the

chimney, or by environmental factors such as strong winds etc.

4.5 ROOM HEATING OPTIONS / INDOOR CLIMATE

The room heating capability used to be quoted in accordance with the DIN

18893 standard (most recent edition being August 1987) so is no longer

a meaningful indicator for modern houses constructed after 1990. As a

comparison value, or for use in relation to older housing stock that fails to

comply with the thermal insulation standard of 1977, the old indication of

room heating capability may still be of interest.

Page 28

GB 28

Precise descriptions of the terms ‘favourable’, ‘less favourable’ and ‘unfavourable’ can be found in DIN 18893. The simplified description ‘favourable’

applies to the case, where the room under consideration only has one external wall and the remaining walls are adjacent to heated internal areas of the

building, ‘unfavourably’ on the other hand is based on two exterior walls and

adjacent unheated rooms.

The values given above refer to building fabrics that do not yet meet the

requirements of the Heat Insulation Ordinance of 1977 and that therefore

also constitute a simplification valid for room sizes of up to 200 m³. DIN

18893 standard recommended a calculation according to DIN 4701 for

rooms larger than 200 m³. Nowadays, room heating capacity estimates are

made in accordance with TROL guidelines and more detailed calculations in

accordance with DIN 12831.

4.6 HEATING IN THE SHOULDER SEASONS/DURING

UNFAVOURABLE WEATHER CONDITIONS

In the ‘shoulder seasons’ (transitional periods), that is, when outdoor temperatures are above about 15°C or under unfavourable conditions (catabatic/adiabatic winds, etc.) can lead to disturbances in the chimney draught

during a sudden temperature rise, so that the hot gases are not completely

removed. To combat this, less fuel should be used and the air supply setting

(see 4.2) should be increased. This burns the fuel more quickly (with larger

flames). and stabilises the draught. In order to prevent the build-up of ash,

the fire should be carefully stoked more frequently.

4.7 CHIMNEY FIRE

When burning wood (especially softwood), sparks can often be transferred

from the fireplace to the chimney. This can ignite the coating of soot inside

the chimney (if cleaned on a regular basis by a chimney sweep, this problem is unlikely to occur). The chimney catches fire. This can be recognized

by flames that blaze from the chimney opening, excessively flying sparks,

smoke and odours, as well as the chimney walls becoming progressively

hotter. It is important to act properly in such cases. You can alert the fire

brigade by dialling 999 (or 112 in Germany). The chimney sweep must also

be informed. Combustible objects should be located away from the chimney.

Attention: Do not attempt to extinguish the fire with water before the fire

brigade arrives on the scene. Temperatures in a chimney fire can reach up

to 1300°C. Extinguishing water would immediately turn to steam. A 10-litre

bucket of water yields 17 cubic meters of steam. The enormous pressure

created as a result could cause the chimney to disintegrate. After the chimney has burned out, this is to be examined by an expert for cracks or leaks

and to be repaired if necessary.

5. FUEL

The German ‘Wald in Not’ (Forest in Peril) Foundation formulates this aptly

in an informative brochure as follows: “Wood does not run up debts for

Nature. Wood is stored solar energy. Sunlight, water and carbon dioxide are

the building blocks that make wood. During the lifetime of the tree, sunlight

is chemically captured. Solar energy is stored in lignin and cellulose. When

burned, this is released again”.

For more information, please visit the website www.wald-in-not.de. Only

those fuels listed in the 1st BlmSchV (German Federal Emissions Protection

Ordnance) may be burned in stoves.

Page 29

GB

GB 29

The only fuels author-ized for fireplaces are firewood (recommended residual humidity of 20% or less) or wooden briquettes, as defined in DIN 51731.

Incidentally: A measuring instrument for determining the moisture of wood

logs does not cost much and can pay for itself quickly.

Do not use any other fuels

It follows from this that it is not permitted to burn:

• painted or plastic-coated wood

• Fibreboard or wood that has been treated with timber preservative

• Wood from Europool pallets

• Rubbish, household waste, old clothes

• Paper, paper briquettes, cardboard

• Damp wood (residual humidity > 20%)

• Plastic or foam of any kind

• Any solid or liquid materials that contain no wood

It is prohibited to burn these or other inappropriate materials in your stove.

When burning other materials than the permitted fuels, wood logs or wood

briquettes defined in DIN 51713, toxic gases can be formed that have

an adverse effect on the combustion process, and that may even cause

explosions.

Operating SEO S / SEO L stoves with other than the approved fuels renders

the warranty invalid!

Use small bits of wood for beginning to heat. Only use split wood as firewood

that is not thicker than about 8 cm at its thickest point. The optimum length

of firewood is approximately 25 cm. Please do not add too much wood at

one time. Instead, it is better to add smaller quantities of wood at regular

intervals. When adding fuel, the embers must not be completely covered.

5.1 CO2 NEUTRALITY

Wood only emits as much carbon dioxide as it had previously gained from

the air and incorporated when it was a living tree. It is immaterial whether

the wood burns or rots in the forest – the carbon dioxide output always

remains constant. New trees absorb the carbon dioxide that the wood emits

when burned, and a closed natural carbon cycle is the result.

Conclusion: When wood burning, nature remains in balance. German Law

legislates for the sustainable management of forests. This obligation leads

to an increase in timber volumes, since the average increase in timber is

40% greater than the amount of firewood and timber that is consumed.

5.1.1 WO O D STO R AG E

In general, it is recommended to store firewood for approx. 2-3 years, the

wood should be protected from dampness and well ventilated (e.g. under a

roof overhang on a side of the building protected from the weather). When

properly stored, a wood moisture level < 20% is achieved much more

quickly. Therefore, the firewood should be split when stored, because the

bark prevents the moisture from escaping. To ensure good ventilation, you

should leave a hand gap distance between the logs, so that air can circulate

freely and so escaping moisture can be well absorbed by the air. A gap of

about 20 - 30 cm to the ground should be maintained below the log pile.

The re-absorption of moisture due to precipitation (e.g. rain or snow) should

be avoided. The storing of wood in garages, under plastic sheets or in poorly

ventilated basements is not recommended as this makes it difficult for any

moisture in the wood to escape. Use a readily available wood humidity

measuring appliance to check your fuel.

Page 30

GB 30

5.2 YOUR CONTRIBUTION TO ENVIRONMENTAL

PROTECTION

Whether or not your SEO S / SEO L stove burns in an environmentally-friendly

way very much depends on the choice of fuel and the manner in which the

fire is operated. The following tips should help you operate your stove with

minimum harm to the environment.

• Use as little wood containing resin as possible (fir, pine, spruce). These

types of wood cause soot to form on the window of your stove more

rapidly, and also cause more sparks. Therefore, for safety reasons, only

use deciduous woods (birch, beech, oak, fruit tree timber).

• Adapt the amounts of wood you add to the fire to suit your heating

requirements.

• It is advisable to purchase a wood humidity measuring appliance (inex-

pensive and easy to operate).

You can check that combustion in your stove is clean and relatively free of

pollutants in the following way:

• The ash should be white. If the ash is dark, this indicates the presence of

residual carbon, which in turn indicates incomplete combustion.

• The flue gases in the chimney after the lighting up phase should be almost

invisible (the less visible the flue gases, the better the combustion).

• The firebox lining in your stove should be bright after combustion, not

sooty.

Note: The fireplace must not be used as a waste incinerator! Furthermore,

remember that the device is designed for temporary burning only. Continuous burning cannot be achieved even through withdrawal of the combustion

air and is not permitted!

6. CLEANING AND CARE

The stove may only be cleaned when cold. Bear in mind that when cleaning

the room in which the fireplace is installed and any clothing may become

dirty. We recommend that you protect the area around the combustion

chamber opening with foil or a cloth against dirt and to wear work clothes.

After cleaning, all removed parts should be refitted.

6.1 CLEANING THE FIREBOX/CLADDING PARTS

• The stove, the combustion chamber, the smoke collecting chamber with

the heating gas diverter, the combustion air supply and the connecting

pieces to the chimney must inspected at regular intervals for deposits and cleaned if necessary annually, possibly also during and after

each heating season and after cleaning the chimney (consult your stove

dealer or responsible chimney sweep). Use a hand brush and/or an ash

vacuum (specialist dealer) to remove the debris. The chimney should be

cleaned at regular intervals by the chimney sweep! Furthermore, the

stove should be checked annually by a specialist.

• Flue gas deflector: A flue gas deflector is also located above the combustion chamber and in the exhaust manifold. This component must be

cleaned at regular intervals. The flue gas deflector can be removed for

this purpose. This must be raised, then tilted and removed through the

firebox. The deposits on the deflector can be cleaned off simply with a

handheld brush.

• Ash removal: your SEO S / SEO L stove is suitable for burning dry wood

that burns best in its own ashes. However, if you want to remove the ash

from the combustion chamber, open the fireplace door. Brush out the

ash, e.g. onto a dustpan or shovel, or use an ash vacuum to remove ash

from the combustion chamber.

• Please note that the embers can remain hot up to 24 hours or more!

Page 31

GB

GB 31

• Cleaning of ceramic glass pane: The glass view pane can be easily

cleaned using a commercial fireplace cleaner, that you can purchase at

your specialist dealer. Then, wipe (do not rub on the glass!) with a dry

cloth. The fibreglass seals should not be soaked with detergent!

• Painted surfaces and the cladding parts can be cleaned with a moist

cloth (do not use a microfibre cloth!).

• Glass surfaces can be cleaned with a standard glass cleaner and a soft

cloth (do not use a microfibre cloth!).

• Stainless steel surfaces can be cleaned with standard stainless steel

cleaning agents! Only use in the direction of the finish!

• Natural stone surfaces can be cleaned with a wet cloth or with appropriate standard cleaning agents!

• Ceramic surfaces can be cleaned with a damp cloth or with appropriate

commercial cleaners!

During the hot season, remove any dust on and below the stove furniture

regularly as dust particles can burn or char. This can cause dirt in the room

and on the furnishings where the fire is installed.

6.2 FIREBOX LINING

In the heating-up phase it is normal for the lining to have a dark coating.

Once the operating temperature is reached, the combustion chamber lining

will be burned off. Cracks are not grounds for a justified complaint. The

lining is exposed to very high loads. A tension or expansion crack is not a

matter for concern and is not a functional deficiency. However, any broken

and shifted combustion chamber fireclay must be replaced.

If replacement chamotte is required, you can order this from your stove fitter

stating the relevant order number.

6.2.1 FIREBOX LINING SEO S

Item Designation Item no. Quantity

Single stone, fireclay

1 Flagstone, front 1054254 1

2 Flagstone, back 1024256 1

3 Back wall stone, right/left 1054257 2

4 Back wall stone, bottom 1054258 1

5 Back wall stone, top 1054259 1

6 Sidewall stone, right 1054821 1

7 Sidewall stone, left 1054822 1

8 Deflector plate 1053975 1

Complete set, fire clay

Fireclay set, complete, without baffle plate 1054824 -

Accessory

Grills (small) 180/110 mm 1019059 1

Page 32

GB 32

6.2.2 FIREBOX LINING SEO L

Item Designation Item no. Quantity

Single stone, fireclay

1 Flagstone, front 1054254 1

2 Flagstone, back 1024256 1

3 Back wall stone, right/left 1055603 2

4 Back wall stone, bottom 1055605 1

5 Back wall stone, top 1055604 1

6 Edge stone, right 1054260 1

7 Edge stone, left 1054261 1

8 Deflector plate 1053975 1

Complete set, fire clay

Fireclay set, complete, without baffle plate 1054778 -

Accessory

Grills (small) 180/110 mm 1019059 1

6.3 MAINTENANCE

The door seal must be checked at regular intervals! This seal must be

replaced if necessary (in case of wear, breakage, etc.). The firebox lining is made of natural products and must therefore be checked at regular

intervals.

As long as the firebox lining maintains its position in the firebox and does

not break, it is fully functional. A crack in the chamotte is therefore no cause

for a complaint. To ensure proper functioning, it is essential that an annual

(if possible before the heating season) maintenance of the stove be carried

out by a specialist!

Furthermore, the following applies to closed flue stoves: Proper door seal is

an essential item for room-air-independent operation of the stove. Perform

a visual inspection of the seal (pressure, wear, bulges) at least once per

heating season and replace it immediately if damaged.

The fireplace must never be modified! Only original spare parts that have

been approved by the manufacturer may be used! If you have any questions,

please contact your specialist dealer.

6.3.1 LUBRICATION MANUAL FOR DOOR LATCHES

WITH SMART-CLOSE

Stoves with Smart-Close door locking mechanisms must be lubricated at

regular intervals to assure problem-free operation (once per heating season). For this purpose, the scope of delivery of each fire area includes a tube

of special stove lubrication compound.

This lubrication compound is applied to facilitate ease of movement of heavy

combustion chamber doors, and to prevent noise caused when opening

and closing the doors. The lubricating compound must be applied at least

once a year to the Smart-Close door locking mechanism and its associated

Page 33

GB

GB 33

roller. In the case of fireplaces which are

used frequently or very frequently, it may be

necessary to shorten this lubrication interval.

With the SEO S / SEO L stoves, the door lock

springs may be located below and/or above,

as well as to the side of, the fire door. In order

to lubricate the lock, you may use a standard

cotton swab/Q-tip as an aid.

Open and secure the fire door. Apply a little lubricant compound to the

cotton swab and use it to coat the spring support on the door lock; Turn the

locating roller on the body of the stove during this application process. Open

and close the combustion chamber door a few times and, if necessary, apply

the copper paste once again

Attention! Ensure that no copper paste comes into contact with trim components or similar. Remove dirt and grime directly with a cotton cloth. Never

operate the equipment during intervening periods

7. TROUBLESHOOTING

You can remedy the following problems on your SEO S / SEO L product

yourself, but for other problems, please contact your specialist dealer or

your tiled stove installer.

7.1 GLASS BECOMES SOOTED HEAVILY, RAPIDLY AND

UNEVENLY

If this did not occur from the very start, please check the following points:

• Have the correct burning materials and equipment been used?

• Combustion air control fully open (actuating lever turned fully to the

left)?

• External combustion air line free?

• This means that soot accumulates quickly, within just half an hour. (it

is normal for the fireplace unit to become progressively dirtier from

operation of the system. a car windscreen gradually gets dirty during a

drive). To remedy this, ensure that no split logs are in direct contact with

the window, or are lying very close to it.

• Is the seating of the seal perfect?

• Is the wood dry enough?

• Has enough wood been added? (insufficient amounts of wood can result

in temperatures in the stove not being high enough).

7.2 FIRE IS DIFFICULT TO IGNITE

If this did not occur from the very start, please check the following points:

• Have the correct burning materials and equipment been used?

• Is the wood dry enough?

• Is the wood thin enough?

• Is a sufficient air supply assured.

Page 34

GB 34

• Not a shoulder season?

• No thermal inversion?

• Is the combustion air controller fully opened?

• External combustion air line free?

7.3 SMOKE ESCAPES WHEN ADDING WOOD

If this did not occur from the very start, please check the following points:

• See all questions under Point 7.1

• Is the complete burn-up phase reached?

• Is the bypass flap open?

• Has the required level of negative pressure been reached?

• Is the chimney unobstructed?

• Has your stove already reached operating temperature?

• Did you open the door slowly at the beginning?

7.4 EXCESSIVELY RAPID BURN-UP /

RATE OF WOOD CONSUMPTION IS TOO HIGH

If this did not occur from the very start, please check the following points:

• Is the wood split in large enough log sections?

• Is the chimney draught too strong?

• Have you reduced the combustion air control (by turning the actuating

lever slightly to the left)?

• Are you using hardwood with 15-18% residual humidity?

• Is the door completely closed?

• Have you complied with the recommended amount of wood?

8. GENERAL WARRANTY CONDITIONS

8.1 APPLICATION AREA

These standard warranty terms apply for the contractual relationship

between the manufacturer, Spartherm Feuerungstechnik GmbH, and the

dealer/distributor. They are not congruent with the contractual and warranty

terms which the dealer/distributor offers his customers in individual cases.

8.2 GENERAL INFORMATION

This product has been manufactured in compliance with current standards

of quality control. The materials used have been carefully selected and - like

the production process - are subject to on-going quality control. Specialist

knowledge is required when assembling and installing the product. The

product must, therefore, only be installed and started up by specialist technical staff, in compliance with current statutory provisions.

8.3 WARRANTY PERIOD

The standard warranty terms only apply within Germany and the European

Union. The warranty period and scope of the warranty are ensured within the

framework of these conditions outside the statutory warranty which remains

unaffected.

The company Spartherm Feuerungstechnik GmbH offers a 5-year warranty

for:

• Main carcass combustion cells

• Main carcass fireplace stoves

• Main carcass fireplace cassettes

• Main carcass fireplace doors

Page 35

GB

GB 35

Spartherm Feuerungstechnik GmbH offers a 24-month warranty in respect

of the sliding door mechanism, operating components such as handles, setting levers, shock absorbers, electrical and electronic components such as

fans, rotational speed controllers, the manufacturer’s original spare parts,

all items purchased as additional extras and all safety appliances.

Spartherm Feuerungstechnik GmbH offers a 6-month warranty in respect of

consumables mounted in the combustion / firebox area, such as fire clay,

vermiculite, fire grates, seals and glass ceramic.

8.4 REQUIREMENTS FOR THIS WARRANTY TO BE

EFFECTIVE

The warranty period shall begin on the date, on which the product is delivered to the dealer / distributor. Invoices or delivery notes may be used as

confirmation of the warranty commencement date. The warranty certificate

for the product must be presented by the claimant upon making a warranty

claim. Spartherm Feuerungstechnik GmbH is not obliged to satisfy any claim

if such documentation is not presented.

8.5 EXCLUSION OF WARRANTY

This warranty does not cover:

Product wear:

• Chamotte/vermiculite: This is a natural product that expands and con-

tracts with every heating process. This can cause cracks to appear. As

long as the lining elements stay in position in the combustion chamber

and do not break, they are fully functional.

• The surfaces: Discolouration in the paint finish or on the galvanic sur-

faces that is due to thermal stress or overload.

• The elevating door mechanism: failure to comply with installation guidelines, resulting in overheating of the deflection rollers and bearings.

• The seals: Decrease in the leak tightness due to thermal load and

hardening.

• The glass panes: contamination, due to soot or other burnt-on combustion materials and visual deterioration due to thermal loading.

• Careless transportation and/or incorrect storage:

• Inappropriate or careless handling of fragile components

• Such as glass or ceramics.

• Improper handling and/or use

• Lack of maintenance

• Incorrect installation or appliance connection

• Failure to comply with installation instructions and operating instructions

• Technical modifications to the appliance by persons that are not

employed by the manufacturer

8.6 RECTIFICATION OF DEFECTS / REPAIR

Independent of any statutory provisions acknowledged as taking precedence

over the terms of this warranty, all necessary repair works resulting from

material or manufacturing defect shall be carried out free-of-charge and

shall not invalidate the remaining provisions of the warranty.

Within the scope of this warranty promise Spartherm Feuerungstechnik

GmbH reserves the right to either remedy the fault or replace the device free

of charge. The elimination of defects shall take precedence. The terms of

this warranty shall not extend to any damage or compensation not covered

by statutory provisions.

Page 36

GB 36

8.7 EXTENSION OF THE WARRANTY PERIOD

The warranty period shall automatically be extended, where claims made in

respect of these warranty provisions result in the repair or replacement of

defective equipment.

8.8 REPLACEMENT PARTS

Only the manufacturer’s own components, or replacement parts recommended and approved by the manufacturer, shall be used for appliance

servicing and repair.

8.9 LIABILITY

Damages and claims for compensation which are not the result of delivery of a defective appliance from Spartherm Feuerungstechnik GmbH are

excluded and are not part of this warranty promise.

The above shall not include claims made in respect of statutory legal

requirements.

8.10 FINAL COMMENTS

In addition to these warranty conditions and our commitment to them, our

dealers and contractual partners are pledged to assist you in both word and

deed. We expressly recommend that our fireplaces and stoves are regularly

inspected by a qualified technician.

Subject to technical changes and errors.

Page 37

GB

GB 37

9. SEO S / L COMMISSIONING PROTOCOL

Date Device no.:

(see rating plate)

Installation company:

Has the actual delivery pressure been checked?

yes no

Negative pressures greater than 20-25 Pa can influence correct

operation. The pane can become increasingly contaminated or noise

can be intensified!

The fireplace operator has been instructed regarding operation and

the instructions for assembly and use have been provided:

yes no

Sample - Burn-off completed:

yes no

Signatures:

Signatures

Installer / Stove fitter / Operator

Annual maintenance carried out:

Type of work

Name:

Date:

Signature:

IMPORTANT: Keep in a safe place! Store these instructions with valid and clearly dated proof of purchase and have the documents ready for our technicians in the

event of service work.

Page 38

GB 38

Page 39

GBGB

GB 39

NOTES

Page 40

GB 40

SPARTHERM

A1-SP-GB/0.000/02-2018

DIE WELTMARKE FÜR IHR WOHNZIMMER

The Global brand for your living room | La référence mondiale pour votre salon | Il marchio mondiale per il vostro soggiorno

La marca mundial para su salón | Het merk van wereldformaat voor uw woonkamer | Światowa marka do Państwa salonu

Торговая марка № 1 для Вашего дома

D Ihr Fachhändler | UK Your specialist dealer | F Votre revendeur spécialisé

IT Il vostro rivenditore specializzato | E Sus comercios especializados

NL Uw vakhandelaar | PL Państwa sprzedawca | РУС Ваш дилер

Spartherm Feuerungstechnik GmbH · Maschweg 38 · D-49324 Melle

Phone +49 (0) 5422 94 41-0 · Fax +49 (0) 5422 9441-14 · www.spartherm.com

Loading...

Loading...