Spartherm Varia M80h, Varia M100h, Varia Bh, Varia 2R-100h, Varia 2L-100h Installation And Operating Instructions Manual

...

Installation and Operating Instructions

Wood Fireplace

Varia M60h / M80h / M100h · Varia Bh / B-FDh · Varia 2L-80h / 2R-80h ·

Varia 2L-100h / 2R-100h · Arte Bh · Arte 3RL60h / 3RL80h / 3RL100h ·

Arte U-50h-2016 / U-70h-2016 / U-90h-2016

Keep this instruction for future use.

Spartherm Feuerungstechnik GmbH

Maschweg 38 · D-49324 Melle

Phone +49 (0) 5422 94 41-0

Fax +49 (0) 5422 9441-14

www.spartherm.com

V3 11/2016

2

SAFETY INFORMATION

WARNING

IF THE INFORMATION IN THESE INSTRUCTIONS IS NOT FOLLOWED

EXACTLY, A FIRE OR EXPLOSION MAY RESULT CAUSING PROPERTY

DAMAGE, PERSONAL INJURY OR DEATH. IMPROPER INSTALLATION,

ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

INJURY OR PROPERTY DAMAGE, BODILY INJURY OR EVEN DEATH.

PLEASE READ ENTIRE MANUAL BEFORE YOU INSTALL AND USE

YOUR APPLIANCE. THIS APPLIANCE HAS NOT BEEN TESTED WITH

AN UNVENTED GAS LOG SET. TO REDUCE RISK OF FIRE OR INJURY,

DO NOT INSTALL AN UNVENTED GAS LOG SET INTO THE APPLIANCE.

• This appliance can be very hot when burning.

• Combustible materials such as firewood, wet clothing, etc. placed too

close can catch fire.

• Children and pets must be kept from touching the appliance when it is

hot.

• The chimney must be sound and free of cracks. Before installing this unit,

contact the local building or fire authority and follow their guidelines.

• Operate only with the door tightly closed.

• Do not use an elevated grate or otherwise raise the fire.

• At least 14 square inches (90,3 square centimeters) of outside air must

be admitted to the room or directly to the unit through a 4´´ (101,6mm)

diameter pipe. Failure to provide this may starve other fuel burning

appliances from an adequate air supply.

• Make sure not to create negative pressure in the installation room, e.g.

by means of an exhaust fan or similar mechanical blower, as this could

affect the combustion oft the fireplace or increase the possibility of

smoke leakage.

• This appliance is designed to burn natural wood only. Higher efficiencies

and lower emissions generally result when burning air dried

NOTICE

DO NOT DISCARD THIS MANUAL

• IMPORTANT OPERATING AND MAINTENANCE

INSTRUCTIONS INCLUDED.

• READ, UNDERSTAND AND FOLLOW THESE

INSTRUCTIONS FOR SAFE INSTALLATION AND

OPERATION.

• LEAVE THIS MANUAL WITH PARTY RESPONSIBLE

FOR USE AND OPERATION.

WARNING

HOT GLASS WILL CAUSE BURNS.

DO NOT TOUCH GLASS UNTIL COOLED.

NEVER ALLOW CHILDREN TO TOUCH GLASS.

• seasoned hardwoods, as compared to softwoods or to green or freshly

cut hardwoods.

• Do not burn green or freshly cut wood.

• Do not start a fire with chemicals or fluids such as gasoline, engine

oil, etc.

• Do not burn treated wood, coal, charcoal, colored paper, cardboard,

solvents or garbage.

• Do not let the appliance become hot enough for any part to glow red.

• KEEP THE STOVE TOP TEMPERATURE BELOW 700°F (371°C). Attempts

to achieve heat output rates that exceed design specifications can result

in steel distortion and damage.

TABLE OF CONTENTS

1. Installation overview 5

2. Introduction 5

2.1 Example of

identification plate 7

2.2 Dimensions 8

2.2.1 Dimensions single faced 8

2.2.2. Dimensions single faced 9

2.2.3. Dimensions two sided 10

2.2.4. Dimensions double sided 11

2.2.5 Dimensions three sided 12

2.2.6. Dimensions three sided 13

2.3. Specifications 14

2.4. General instructions 14

2.6. Air system 15

2.7. Door opening 17

2.7.1. Flat and angled door 17

2.7.2. Double angled door 17

3. Installation planning 18

3.1. Minimum clearances to

combustibles 18

3.2. Placement 20

3.3. Flanges and anchor plate 20

3.4. Front chase 21

4. Installation 22

4.1. Hearth extension 22

4.1.2. Two sided 22

4.1.3. Double sided 23

4.1.4. Three sided 23

4.2.1. Varia M-60h 24

4.2.2. Varia M-80h 25

4.2.3. Varia M-100h 26

4.2.4. Varia Bh 27

4.2.5. Arte Bh 28

4.2.6. Varia 2L-80h 29

4.2.7. Varia 2R-80h 30

4.2.8. Varia 2L-100h 31

4.2.9. Varia 2R-100h 32

4.2.10. Varia B-FDh front 33

4.2.11. Varia B-FDh back 34

4.2.12. Arte 3RL-60h 35

4.2.13. Arte 3RL-80h 36

4.2.14. Arte 3RL-100h 37

4.2.15. Arte U-50h-2016 38

4.2.16. Arte U-70h-2016 39

4.2.17. Arte U-90h-2016 40

4.3. Chimney installation 41

4.3.1. Listed chimneys 41

4.3.2. Chimney installation notes 41

4.3.3.

Chimney installation instructions

42

4.3.5. List of mandatory components 46

4.4. Masonry 46

4.4.1. Typical existing masonr y 46

4.4.2. Factory built fireplace 47

4.5. Convection 48

4.5.1. Minimum clearances to combustibles

for convection air grills 48

4.6. Heat distribution systems 49

5. Finishing 49

5.1. Bricks and baffels installation 49

5.1.1. Varia M-60h 50

5.1.2. Varia M-80h 50

5.1.3. Varia M-100h 51

5.1.4. Varia Bh 51

5.1.5. Arte Bh 52

5.1.6. Varia 2L-80h 52

5.1.7. Varia 2R-80h 53

5.1.8. Varia 2L-100h 53

5.1.9. Varia 2R-100h 54

5.1.10. Varia B-FDh 54

5.1.11. Arte 3RL-60h 55

5.1.12. Arte 3RL-80h 55

5.1.13. Arte 3RL-100h 56

5.1.14. Arte U-50h-2016 56

5.1.15. Arte U-70h-2016 57

5.1.16. Arte U-90h-2016 58

5.2. Door removal / installation 59

6. Operation 64

6.1. Fire extinguishers /

smoke detectors 66

6.2. Fuel 66

6.3. Lighting a fire 67

6.3.1. Flash fire 67

6.3.2. Extended fire 67

6.3.3. Smoking 68

7. Maintenance 68

7.1. Ash removal procedures 69

7.2. Creosote formation and removal 69

7.3. Runaway or chimney fire 69

7.4. Chimney cleaning 70

7.5. Glass replacement 70

7.5.1 Single faced 71

7.5.2. Two sided 72

7.5.3. Double sided front 73

7.5.4. Double sided back 74

7.5.5 Three sided 75

7.6. Care of glass 76

7.7. Cleaning the glass ceramic sheet 77

7.7.1. Flat door 77

7.7.2. Angled door 77

7.8. Care of plated parts 78

8. Replacements 78

8.1. Varia M-60h 79

8.2. Varia M-80h 80

8.3. Varia M-100h 81

8.4. Varia Bh 82

8.5. Arte Bh 83

8.6. Varia 2L-80h 84

8.7. Varia 2R-80h 85

8.8. Varia 2L-100h 86

8.9. Varia 2R-100h 87

8.10. Varia B-FDh 88

8.11. Arte 3RL-60h 89

8.12. Arte 3RL-80h 90

8.13. Arte 3RL-100h 91

8.14. Arte U-50h-2016 92

8.15. Arte U-70h-2016 93

8.16. Arte U-90h-2016 94

9. Troubleshooting 95

10. General warranty terms

and conditions 95

10.1. General information 95

10.2. Warranty period 95

4

TABLE OF CONTENTS

10.3. Requirement of effectiveness

for the warranty 96

10.4. Warranty exclusions 96

10.5. Note 96

10.6. For your information 97

10.6. For your information 98

11. Service history 99

5

2. INTRODUCTION

The Spartherm fireplaces have been tested and certified by CSA based on

the following standards: UL 127 / ULC S-610-M87. EPA : exempt from current legislation. Before installing your Spartherm fireplace, please contact

the local building authorities to obtain the necessary permits and information about applicable regulations. Please read this manual carefully before

installing or using your fireplace. Incorrect installation may result in fire.

To reduce the risk of fire, follow the installation instructions. Failiure to do

so may result in property damage, bodily injury or even death. Keep this

manual handy so you can refer to it whenever necessary.

WARNING

• THIS APPLIANCE IS HOT WHEN OPERATED AND CAN CAUSE SEVERE

BURNS IF CONTACTED.

• ANY CHANGES OR ALTERATIONS TO THIS APPLIANCE OR ITS CONTROLS

CAN BE DANGEROUS AND IS PROHIBITED:

• Do not operate appliance before reading and understanding operating

instructions. Failure to operate appliance according to operating instructions could cause fire or injury.

• Before installing this appliance, contact the local building or fire authority and follow their guidelines.

• This appliance must be installed by a qualified installer.

• Do not use a fireplace insert or other product no specified for use with

this fireplace.

• Risk of burns. The appliance should be turned off and cooled before

servicing.

• Do not operate without fully assembling all components.

• Risk of cuts and abrasions. Wear protective gloves and safety glasses

during installation. Sheet metal edges may be sharp.

• Children and adults should be alerted to the hazards of high surface

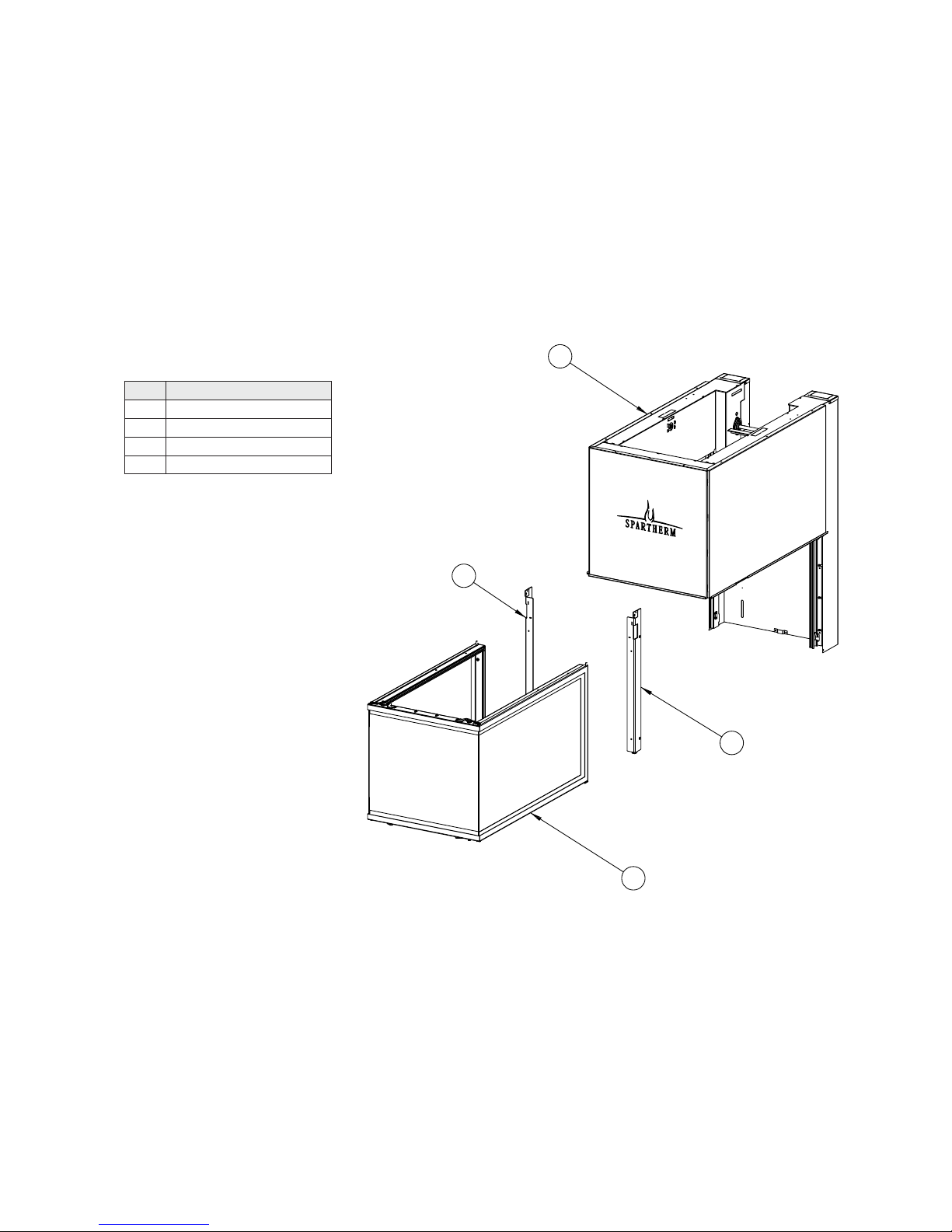

chimney connection

convection air outlet

zero clearance mantel

hood

elevating door

bricks and baffles

convection air inlet

Example shown: Varia M80h

1. INSTALLATION OVERVIEW

6

• temperature and should stay away to avoid burns or clothing ignition.

• Young children should be carefully supervised when they are in the same

room as the appliance. Toddlers, young children and others may be susceptible to accidental contact burns. A physical barrier is recommended

if there are at risk individuals in the house. To restrict access to an

appliance or stove, install an adjustable safety gate to keep toddlers,

young children and other at risk individuals out of the room and away

from hot surfaces.

• Clothing or other flammable material must not be placed on or near

the appliance. Objects placed in front of the appliance must be kept a

minimum of 48” (1220 mm) away from the front face of the appliance.

• Due to high temperatures, the appliance should be located out of traffic

and away from furniture and draperies.

• Ensure you have incorporated adequate safety measure to protect

infants/toddlers from touching hot surfaces.

• Even after the appliance is out, the glass and/or screen will remain hot

for an extended period of time.

• Check with your local hearth specialty dealer for safety screens and

hearth guards to protect children from hot surfaces. These screens and

guards must be fastened to the floor.

• Any safety screen or guard removed for servicing must be replaced prior

to operating the appliance.

• Under no circumstances should this appliance be modified.

• This appliance must not be connected to a chimney flue pipe servicing a

separate solid fuel burning appliance.

• Do not operate the appliance with glass door removed, cracked or broken. Replacement of the glass should be done by a licensed or qualified

service person.

• Do not strike or slam shut the appliance glass door.

• Only doors / optional fronts certified with the unit are to be installed on

the appliance.

• Keep the packaging material out of reach of children and dispose of the

• material in a safe manner. As with all plastic bags, these are not toys and

should be kept away from children and infants.

• If the appliance is not properly installed, a house fire may result. Do

not expose the appliance to the elements (ex. rain, etc.) and keep the

appliance dry at all times. Wet insulation will produce an odour when the

appliance is used.

• The chimney must be sound and free of cracks. Clean your chimney a

minimum of twice a year and as required.

• Do not start a fire with chemicals or fluids such as gasoline, engine

oil, etc.

• Your appliance requires periodic maintenance and cleaning. Failure to

maintain your appliance may lead to smoke spillage in your home.

• Lower emissions generally result when burning air dried seasoned hardwoods, as compared to softwoods or too green or freshly cut hardwoods.

Burning wet unseasoned wood can cause excessive creosote accumulation. When this is ignited it can cause a chimney fire that may result in

a serious house fire.

• This appliance is designed to burn natural wood only. Do not burn treated

wood, coal, charcoal, coloured paper, cardboard, solvents or garbage.

• Burn wood directly on the firebricks. Do not elevate grate or otherwise

raise the fire.

• Do not store wood within appliance installation clearances or within the

space required for re-fueling and ash removal.

• Ashes must be disposed in a metal container with a tight lid and placed

on a non-combustible surface well away from the home or structure until

completely cool.

• Ensure clearances to combustibles are maintained when building a mantel or shelves above the appliance. Elevated temperatures on the wall

or in the air above the appliance can cause melting, discolouration or

damage to decorations, a T.V. or other electronic components.

• Do not install this fireplace insert in a factory- built fireplace unless

certified with the fireplace.

Safety Information

/ Informations Sur La Sécurité

Listed by / Listée par:

Spartherm Feuerungstechnik GmbH

Maschweg 38

D – 49324 Melle, Germany

info@spartherm.com

Manufactured by / Fabriqué par:

Spartherm Feuerungstechnik GmbH

Maschweg 38

D – 49324 Melle, Germany

info@spartherm.com

Solid Fuel Room Heater – For Use with Solid Wood Fuel only /

Appareil de Chauffage a combustion solides

Tested to Standards/ Tested aux Normes:

UL-127-11, ULC-S610 M87

Model: Varia M80h–P4

Date of Manufacture / Date de Fabrication:

Month/Year / Mois/Année: 08/2016

Serial Number / No de Serie: 16 – 001

TO PREVENT HOUSE FIRES:

Contact local building or fire official s about restrictions and installation

inspection in your area. Install a nd use only in accordance with

manufacturer’s installation and op erating instructions and local codes.

In the absence of any local c odes, installation must meet minimum

requirements of NFPA 211 in the USA, and B365 in Canada. Refer to

manufacturer´s instructions and l ocal codes for precautions required

for passing a chimney through a combustibl e wall or ceiling. Inspect

and clean chimney system frequentl y in accordance with

manufacturer´s instruction. Do not connect this stove to a chimney flue

serving another appliance. Do not use grate or elevate fire. Build wood

fire directly on hearth. Installation only with listed UL-103 H T, ULCS604, ULC-S610 or ULC-S629 chimne y diameter 8”.

TO PREVENT CREOSOTE FIR ES:

Inspect and clean chimney fr equently - under certain condi tions of use,

creosote buildup may occur rapidly. Do not use fuels other than

firewood.

CAUTION: Only operate the wood heater with the doors fully closed.

Replace glass only with original 4 m m Robax ceramic glass. Areas of

the fireplace incorporating warm or cold air ducts shall be enclosed in

accordance with the manufacturer’ s installation instructions. If

provided with a hearth extension, the heart h extension must be

installed according to the ins tallation instructions! Air is needed f or

fireplace operation! At least 14 s quare inches (90.3 square

centimeters) of outside air must be adm itted to the room or directly to

the unit through a 4” (101.6mm ) diameter pipe. Failure to provide this

may starve other fuel burning appliances from an adequate air suppl y.

Do not obstruct air inlet and o utlet in any case. Components used with

fireplace must be listed. See manual .

Do not use a fireplace insert or other products not specified for use with

this product. This fireplace has n ot been tested with an unvented gas

log set. To reduce risk of fire or injury, do not install an unvented gas

log set into fireplace.

This wood heater needs periodi c inspection and repair for proper

operation. Consult the owner’s man ual for further information. It is

against federal regulations to operat e this wood heater in a manner

inconsistent with the operating in structions in the owner’s manual.

POUR EVITER LES INCENDIES DOMESTIQUES:

Contactez les Autorités des bâtimen ts et les pompiers pour obtenir des instruc tions concernant

les restrictions et inspections d´installation dans votre région. Installez et utillisez cet appareil

uniquement en respectant les instructio ns d´installation et d´utilisation du fabriquant. R espectez

également les réglementations lo cales. En l´absence de réglementations local es, l´installation

doit respecter les normes minimal es de NFPA 211 aux Etats-Unis e t B365 au Canada. Référezvous aux instructions du fabriqua nt aux réglementations locales pour obtenir des instruct ions

concernant les précautions nécessaire s pour le passage de la cheminée á travers une paroi ou

un plafond combustible. Inspecte z et nettoyez le système de cheminée fréquement selon les

instructions du fabriquant. Ne connec tez pas ce poêle à un conduit de cheminée utilisé par un

autre appareil. N´utilisez pas d e grille et ne faites pas monter le feu. Etabliss ez le feu de bois

directement dans l´âtre. L'iastallti on doit être faite exclusivement avec le cheminée l isté selon la

norue UL-103 HT, ULC-S604, ULC-S6 10 ou ULC-S629 de diaméte 8”.

POUR EVITER LES FEUX DE CREOSOTE :

Inspectez et nettoyez la cheminée r égulièrement - Sous certaines condition d´empl oi, la

creosote peut s´accumuler rapidem ent. Ne pas utiliser d´autres combustibles que l e bois.

ATTENTION: N'utilisez le poêle q ue lorsque les portes sont com plétement fermées. Remplacer

la vitre uniquement avec du verre Rob ax céramique de 4 mm.Il faut que les zones du f oyer vitré

qui portent les canaux d'alimentation d' air chaud et froid soient conformes à l'instruction de

montage du fabricant. L'approvisionnement en revêt ement fait de matériaux ininflammables

devant l'ouverture du foyer vitré doit être installé conforme a l'inst ruction de montage du

fabricant. L'aération suffisante pour l'utilisation du foyer est néces saire! Dans l'emplacement du

foyer vitré il faut assurer au moins 14 pouces carée (90,3 centimètres carée) de l'air de dehors

ou il faut assurer l'alimentation en air d e combustion directe au foyer vitré par une tube d'un

diamètre de 4 pouces carée ( 101,6mm). Un m anque d’air d’appoint pourrait priver les autres

apparells de combustion d’une alimenta tion d’air adéquate. Ne pas obstruer les entrés e t sorties

d’air en aucun cas. Les composantes utilis ées dans l’appareil doivent étre répertoriées. Voir

manuel. N'utilisez pas d'insert de cheminée ou autres produits qui ne so nt pas autorisés pour

l'usage de ce produit.

Ce foyer n'est pas encore testé pour l 'usage du chauffage au gaz non aéré. Pour diminuer le

risque de brûlure ou de blessure n'i nstallez pas de chauffage au gaz non aé rée.

Ce foyer vitré à bois doit être ent retenu et réparé à intervalles réguliers po ur assurer un

fonctionnement correct.

Veuillez consulter s.v.p. pour de pl us amples informations les instructions du fabri cant.

Il est contraire aux dispositons de l'autorité d'exploiter ce fo yer vitré à bois incompatible au m anuel

du fabricant.

MINIMUM CLEARANCES TO COMBUSTIBLE MATERIALS

A. 44 2/7" (1125 mm)

B. 16 1/2" (419 mm)

C. 24 1/7" (613 mm)

D. 84" (2134 mm)

E. 20" (500 mm)

F. 12" (300 mm)

IN FRONT OF UNIT 48" (1220 mm)*

ECARTEMENT MINIMUM AUX MATERIAUX COMBUSTIBLES

A. 44 2/7" (1125 mm)

B. 16 1/2" (419 mm)

C. 24 1/7" (613 mm)

D. 84" (2134 mm)

E. 20" (500 mm)

F. 12" (300 mm)

PLAFOND – CONDUIT 48" (1220 mm)*

* Not Tested - NFPA Guideli nes in the USA, CAN/CSA B365-M91 in

Canada. Floor protection must be minimum 3/8-inch non-combustible

material extending beneath the stov e, and to the front and sides from door

opening and to the rear as indicate d.

* Non testé - Exigences NFPA a ux Etats-Unis, CAN/CSA B365-M91 au

Canada. La protection de sol doit avoir une épaisseur de 3/8 pouces (1 cm),

être d'un matériau non combustible et êtr e placée devant et à côté de la porte

ainsi qu'à l'arrière, comme indiqu é.

C A U T I O N:

HOT WHILE IN OPERATION. DO NOT TOUCH.

KEEP CHILDREN AND CLOTHING AWAY.

CONTACT MAY CAUSE SKIN BURNS. SEE NAME PLATE

AND INSTRUCTIONS. KEEP FURNISHINGS AND OTHER

COMBUSTIBLE MATERIALS A CONSIDERABLE

DISTANCE AWAY FROM THE APPLIANCE.

NOT SUITABLE FOR MOBILE HOME INTALLATION.

DO NOT OVERFIRE – IF HEATER OR CHIMNEY CONNECTOR

GLOWS, YOU ARE OVERFIRING.

A T T E N T I O N:

CHAUD PENDANT LE FONCTIONNEMENT – NE PAS TOUCHER.

TENIR ÉLOIGNÉS LES ENFANTS ET LES VÊTEMENTS –

LE CONTACT PEU CAUSER DES BRULURES. CONSULTEZ

LA PLAQUE D'IMMATRICULATION ET LES INSTRUCTIONS.

TENIR LES FOURNITURES ET AUTRES MATIERES

COMBUSTIBLES À DISTANCE DE L´APPAREIL.

NE PAS INSTALLER DANS UNE MAISON MOBILE.

EVITER DE SURCHAUFFER – SI LE FEU OU LA CHEMINÉE

DEVIENT ROUGE, VOUS SURCHAUFFEZ.

Spartherm – v3, 01. Aug. 2016

DO NOT REMOVE THIS LABEL / NE PAS ENLEVER CETTE ETIQUETTE

Protection de sol pour Canada: 20" (5 00 mm) de l´avant de l´appareil au bord de la p rotection.

Floor protection for Canada: 20" (5 00mm) from unit to front

of floor protector.

2.1 EXAMPLE OF

IDENTIFICATION PLATE

8

BA

CD

J K L

M

G

H

I

P

V

W X

Q

Y

UT

E F

SR

N

O

H

G

H

AB

I

Z

AA

I

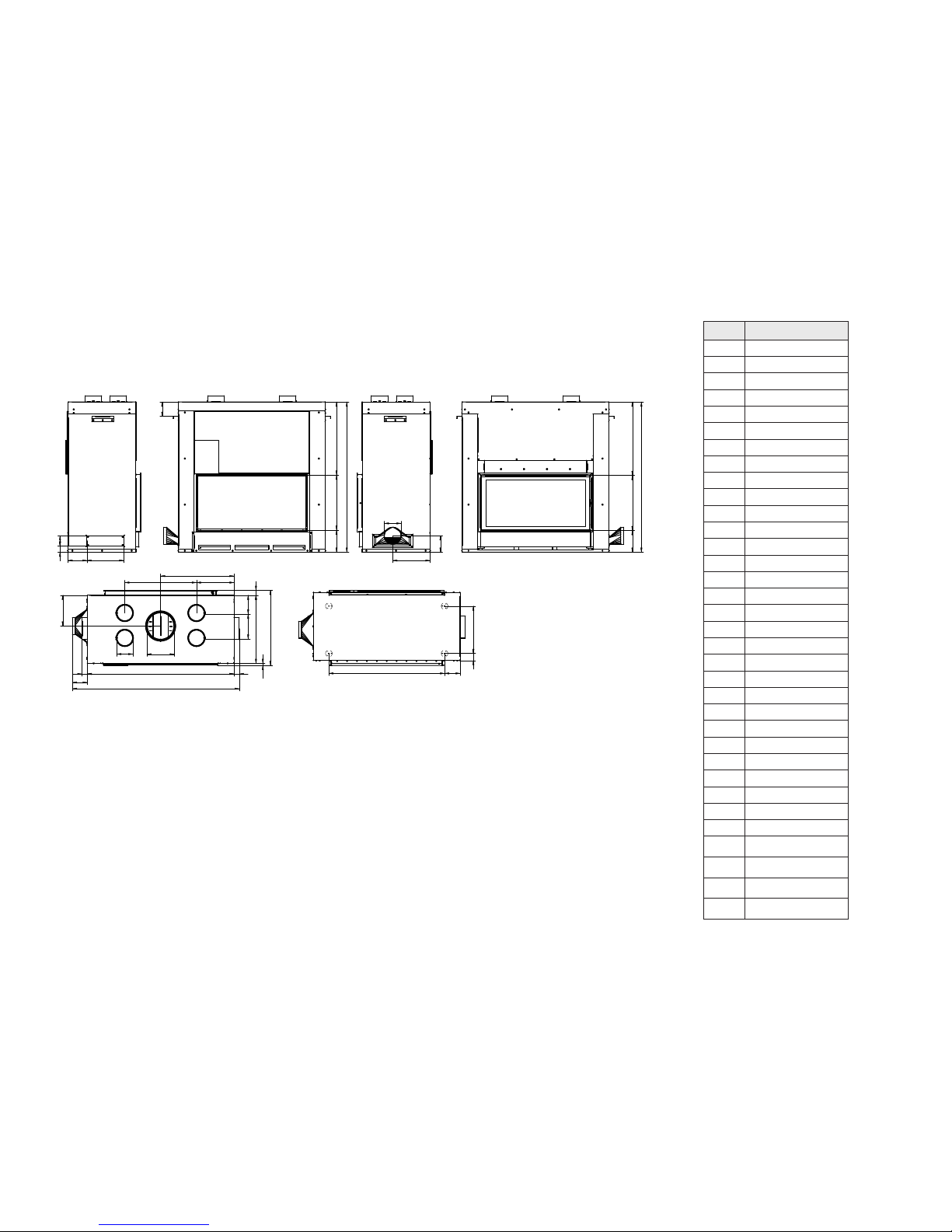

AC

Varia M60h-P4 Varia M80h-P4 Varia M100h-P4

A

25 2/5" 33 1/4" 41 1/7"

B

4" 3 1/2" 3 1/2"

C

5 1/4" 4 5/6" 4 5/6"

D

22 4/5" 30 2/3" 38 1/2"

E

5 5/9" 5 5/6" 5 5/6"

F

12 1/2" 12 1/2" 12 1/2"

G

8 3/4" 8 3/4" 8 3/4"

H

4 5/6" 4 5/6" 4 5/6"

I

7" 7" 7"

J

15 1/3" 15 1/3" 15 1/3"

K

19 2/3" 19 2/3" 19 2/3"

L

25 3/4" 25 3/4" 25 3/4"

M

60 3/4§ 60 3/4" 60 3/4"

N

5 1/8" 5 1/8" 5 1/8"

O

10 6/7" 10 7/8" 10 7/8"

P

16 3/5" 20 1/6" 24"

Q

- 8 1/3" 12"

R

- 8" 8 1/9"

S

7" 7 1/2" 7"

T

22 1/4" 22 1/4" 22 1/4"

U

1 8/9" 1 8/9" 1 8/9"

V

- 23 2/3" 24 1/6"

W

5 3/5" 28 1/3" 34 5/7"

X

8 1/3" 6" 6 7/9"

Y

33 1/4" 40 1/3" 48 2/9"

Z

6" 6" 6"

AA

7 7/8" 7 7/8" 7 7/8"

AB

16 4/7" 20 1/8" 24"

AC

6" 6" 6"

2.2 DIMENSIONS

Example shown: Varia M80h

2.2.1 DIMENSIONS SINGLE FACED

9

Example shown: Varia Bh

Pleace note: The separate combustion air connector

for model Arte Bh is oriented to the back at delivery.

The separate combustion air connector for model

Varia Bh is oriented to the side at delivery as shown.

2.2.2. DIMENSIONS SINGLE FACED

BA

CD

E F

H

JI

G

K L M

N

RQ

S

W X

P

U

T

V

O

ABHJ

G

Z

AA

AFAG

IJ

G H

AC

AE

AB

Y

ABHJ

G

IJ

G H

Varia Bh-P4 Arte Bh-P4

A

38" 28"

B

5 7/8" 4 1/2"

C

5 5/8" 8 1/2"

D

39" 19 4/5"

E

5 1/5" 4"

F

15 1/6" 16 1/6"

G

2 1/5" 1 1/4"

H

3 5/8" 4 7/8"

I

6 3/4" 4"

J

13 2/5" 14 4/7"

K

7 7/8" 10 1/6"

L

19 2/3" 30 5/7"

M

26 1/7" 23 6/7"

N

53 5/8" 64 5/7"

O

5 1/8" 5 1/8"

P

25 1/8" 13 3/8"

Q

9 1/2" 8 1/9"

R

7" 8 3/7"

S

24 3/8" 24 1/7"

T

12 1/3" 7 2/5"

U

25 1/2" 22"

V

50 1/4" 36 8/9"

W

11 2/3" 7 5/9"

X

1 8/9" 1 8/9"

Y

5 1/3" 3 2/5"

Z

6" 6"

AA

9 5/6" 7 7/8"

AB

6 3/5" -

AC

10 4/5" 18 1/2"

AD

6" 6"

AE

5 5 1/2" 5 5/6"

AF

12 1/3" 6 3/7"

AG

25 1/2" 24"

10

2.2.3. DIMENSIONS TWO SIDED

UV

T

S

HIJ

F G

CBA

D E

L

K

M

N O P

Q

R

AN

AK

AL

AM

ADAEAF

AG

AJ

Y

X

W

AIAH

Z

AC

AA

AB

Varia 2L-80h-P4

Varia 2R-80h-P4

Varia 2L-100h-P4

Varia 2R-100h-P4

A

4 1/2" 4 1/2"

B

28 2/9" 37 2/3"

C

8 1/5" 6 3/5"

D

6 1/2" 4 7/8"

E

12 2/3" 14 1/4"

F

5 4/6" 5 4/6"

G

13 1/2" 13 1/2"

H

8 1/4" 8 1/4"

I

28 2/9" 36 1/9"

J

3 1/2" 3 1/2"

K

10 1/3" 10 1/3"

L

7" 7"

M

6" 6"

N

15" 15"

O

19 3/8" 19 3/4"

P

28 1/2" 28 1/2"

Q

63 1/4" 63 2/3"

R

5 1/8" 5 1/8"

S

3 1/3" 3 1/3"

T

1 3/8" 1 3/8"

U

4 3/8" 4 3/8"

V

11 4/5" 11 4/5"

W

22 1/3" 26 2/7"

X

23 7/9" 25 3/5"

Y

10 1/2" 13 1/2"

Z

1 8/9" 1 8/9"

AA

7 1/8" 6"

AB

8 1/9" 9 4/9"

AC

23 2/3" 23 2/3"

AD

1 8/9" 1 8/9"

AE

11 2/3" 13 1/2"

AF

21 1/3" 25 3/5"

AG

40 6/7" 48 3/4"

AH

6" 6"

AI

10 2/3" 10 2/3"

AJ

9 5/6" 9 5/6"

AK

7" 7"

AL

6" 6"

AM

6" 6"

AN

23 3/4" 27 2/3"

Example shown: Varia 2L-80h

11

Example shown: Varia B-FDh

2.2.4. DIMENSIONS DOUBLE SIDED

BA

C D

E F

G H

I J K

M

L

N

O

P

S

R

Q

TW

X

Y

UV

AD

ZAAZ

AB

AC

AF AG AH

L

P

AE

Varia B-FDh-P4

A

41 1/3"

B

5 5/9"

C

2 1/2"

D

17"

E

6 7/9"

F

13 1/7"

G

2 1/5"

H

3 5/8"

I

7 7/8"

J

19 2/3"

K

26 1/7"

L

53 2/3"

M

5 1/8"

N

13 1/3"

O

5 5/6"

P

6"

Q

26 2/9"

R

25 3/4"

S

13 3/7"

T

1 7/9"

U

6 3/4"

V

8 8/9"

W

24 1/3"

X

5/7"

Y

26 7/9"

Z

1 8/9"

AA

52 4/9"

AB

5 2/7"

AC

59 4/7"

AD

11"

AE

9 5/6"

AF

7 5/7"

AG

19 2/3"

AH

26 1/4"

12

C

D

E

F

A B

K L M

N

GH

I

G H

I

AA

Z

Q

P

Y

W

RST

U

O

AC

AB

AD

AE

J

J

X

V

Arte 3RL60h-P4 Arte 3RLh80h-P4 Arte 3RL100h-P4

A

18 1/4" 26 1/7" 34"

B

3 1/2" 3 1/2" 3 5/8"

C

3 5/8" 3 2/3" 3 7/9"

D

18" 26" 33 7/9"

E

5 3/7" 5 3/7" 5 3/7"

F

13 1/3" 14 1/2" 16 1/2"

G

2" 2 3/5" 3 7/9"

H

11 4/5" 11 4/5" 11 4/5"

I

1 1/7" 1 1/7" 1 1/7"

J

3 1/3" 3 1/3" 3 1/3"

K

15 1/3" 15 1/3" 15 1/3"

L

21 4/7" 21 4/7" 21 4/7"

M

33 1/2" 30 1/3" 30 1/3"

N

70 2/5" 67 1/5" 67 1/5"

O

5" 5" 5"

P

12 2/3" 16 3/5" 20 5/8"

Q

4 5/7" 8 1/7" 9"

R

1 8/9" 1 8/9" 1 8/9"

S

4 2/4" 4 2/5" 8 1/7"

T

- 14 1/4" 9 5/6"

U

24" 24" 25 2/3"

V

4 3/5" 7 3/4" 9 2/7"

W

16 3/4" 18 1/3" 23 1/7"

X

26" 33 5/6" 41 2/3"

Y

11 1/2" 11 1/2" 13 1/9"

Z

6" 6" 6"

AA

9 5/6" 9 5/6" 9 5/6"

AB

7" 7" 7"

AC

6" 6" 6"

AD

12 1/8" 16" 20"

AE

4 3/5" 4 3/5" 4 3/5"

AC

AB

AD

AE

Example shown: Arte 3RL100h

2.2.5 DIMENSIONS THREE SIDED

13

Example shown: Arte U-90h

2.2.6. DIMENSIONS THREE SIDED

E F

DC

BA

G H

I J

K L M

O

GH

I J

RS

Q

P

VU

W

Z

T

X

AB

AC

Y

Y

N

AA

Arte U-50h-

2016-P4

Arte U-70h-

2016-P4

Arte U-90h-

2016-P4

A

14 2/3" 14 2/3" 16 6/7"

B

3 2/5" 3 3/7" 3 3/7"

C

14 1/5" 14 1/5" 16 3/8"

D

3 1/7" 3 1/7" 3 1/7"

E

7 3/5" 8 8/9" 7 2/7"

F

20 2/5" 27 1/2" 37"

G

2 3/5" 2 3/5" 2 3/5"

H

11 4/5" 11 4/5" 11 4/5"

I

1 2/7" 1 2/7" 1 2/7"

J

3 1/3" 3 1/3" 3 1/3"

K

11" 11" 11"

L

21" 20 5/9" 20 5/9"

M

29 1/7" 26 3/8" 26 3/8"

N

61" 57 7/8" 57 7/8"

O

5 4/5" 5 5/6" 5 4/5"

P

8 5/6" 8 5/6" 8 5/6"

Q

6 1/3" 6 3/8" 7 1/2"

R

1 8/9" 1 8/9" 1 8/9"

S

31 4/7" 40" 48"

T

22" 22 1/8" 24 2/7"

U

- 24 1/2" 24 1/2"

V

8" 6 1/7" 12 2/7"

W

20 1/3" 18 2/5" 24 1/2"

X

9 5/6" 9 5/6" 9 5/6"

Y

6" 6" 6"

Z

10 5/7" 10 4/5" 11 6/7"

AA

- - 8 2/3"

AB

10 1/5" 10 1/5" 7"

AC

4 5/6" 4 5/6" 4 5/6"

14

2.3. SPECIFICATIONS

Conversion Factors

Inches to millimeters (mm): 1’’ = 25.4 mm

British Thermal Unit BTU/h to Watt: 1BTU/h = 0.293 Watt

Kilogramm to Pound: 1kg = 2.205 lb

Cubicmeter to cubicfeet:

1m

3

= 35.314 ft3

2.4. GENERAL INSTRUCTIONS

WARNING

THIS APPLIANCE HAS NOT BEEN TESTED WITH ANY VENTED OR UNVENTED

GAS LOG SET: TO REDUCE RISK OF FIRE OR PREVENT INJURY, DO NOT

Fire chamber volume Minimum Power Maximum power Efficiency* Chimney type Unit weight ideal fuel size

Varia M60h

2.53 ft

3

16500 BTU 31000 BTU >78% 8" 452 lbs 18"

Varia M80h

3.5 ft

3

21500 BTU 40000 BTU >78% 8" 662 lbs 18"

Varia M100h

4.11 ft

3

26000 BTU 49000 BTU >78% 8" 772 lbs 18"

Varia Bh

4.28 ft

3

25000 BTU 46000 BTU >78% 10" 772 lbs 18"

Arte Bh

4.2 ft

3

26000 BTU 49000 BTU >78% 8" 573 lbs 20"

Varia 2L/2R-80h

4.14 ft

3

25000 BTU 46000 BTU >80% 10" 606 lbs 18"

Varia 2L/2R-100h

4.16 ft

3

26500 BTU 49000 BTU >78% 10" 617 lbs 18"

Varia B-FDh

6.83 ft

3

26500 BTU 49000 BTU >78% 10" 772 lbs 18"

Arte 3RL60h

2.71 ft

3

19000 BTU 33500 BTU >80% 10" 551 lbs 20"

Arte 3RL80h

4.38 ft

3

21500 BTU 40000 BTU >80% 10" 617 lbs 20"

Arte 3RL100h

5.88 ft

3

26000 BTU 49000 BTU >78% 10" 662 lbs 20"

Arte U-50h-2016

2.67 ft

3

21500 BTU 40000 BTU 80% 10" 529 lbs 18"

Arte U-70h-2016

3.94 ft

3

26000 BTU 49000 BTU >78% 10" 827 lbs 18"

Arte U-90h-2016

6.1 ft

3

31000 BTU 57500 BTU >78% 10" 1023 lbs 18"

*efficiency results: as per formal european testing EN 13229

INSTALL A VENTED OR UNVENTED GAS LOG SET INTO THE APPLIANCE.

DO NOT CONNECT THIS APPLIANCE TO A CHIMNEY FLUE SERVING ANOTHER

APPLIANCE.

THIS APPLIANCE AND THE COMPONENTS ARE DESIGNED TO BE INSTALLED

AND OPERATED AS A SYSTEM. ANY ALTERATION TO OR SUBSTITUTION

FOR ITEMS IN THIS SYSTEM, UNLESS ALLOWED BY THESE INSTALLATION

INSTRUCTIONS, WILL VOID THE LISTING AND MAY VOID THE PRODUCT WARRANTY. IT MAY ALSO CREATE A HAZARDOUS INSTALLATION. READ THROUGH

THESE INSTRUCTIONS THROUGHLY BEFORE STARTING YOUR INSTALLATION

AND FOLLOW THEM CAREFULLY THROUGHOUT YOUR PROJECT.

• Before beginning your installation, consult with your local building code

agency or fire officials and insurance representative to ensure compliance.

15

We suggest that our woodburning hearth products

be installed and serviced by professionals who are

certified in the U.S. by the National Fireplace

Institute® (NFI) as NFI Woodburning Specialists or

who are certified in Canada by

Wood Energy Technical

Training (WETT).

• Non-toxic smoke will be emitted during the paint curing process, to help

dissipate the smoke open a window near the appliance.

• Remove any dust or debris off the top of the appliance before firing the

appliance as the paint will become soft as the appliance heats up and

will harden as the appliance cures. To cure the paint on your appliance

burn your appliance moderately hot during the first few fires.

• To keep the gasket from sticking to the appliance as the paint is curing,

periodically open the door every 5-10 minutes.

• For the first two weeks use generous amounts of fuel and burn the

appliance for an hour as the appliance goes through a process of eliminating moisture in the steel and firebricks. The initial heat output will be

reduced while the moisture is bring drawn from the appliance and it will

be necessary to build several hot fires to remove this moisture. DURING

THIS PROCESS DO NOT OVERFIRE THE APPLIANCE.

2.5. GENERAL INFORMATION

The chimney vent system used on your wood burning appliance should be

designed with the least amount of restriction possible to enable the exhaust

products to easily flow through it. Chimney vent systems that are too short or

too long (refer to point 4.3 ”chimney installation”) can also have an adverse

affect on the flow of exhaust through it. The wood burning appliance and

chimney vent system also require a sufficient supply of combustion air not

only to support the combustion in the combustion chamber but to replace the

exhaust leaving it so it can flow freely up through the vent system and out into

the atmosphere. It is the correct balance of combustion air and the chimney

vent system that will ensure the appliance provides you with its optimum

performance.

Be sure to provide sufficient combustion air. There are many other appliances

in your home competing for air such as a kitchen range hood, forced air

heating devices or a bathroom exhaust fan.

Expansion / contraction noises during heating up and cooling down cycles

are normal and to be expected.

After extended periods of non-operation such as following a vacation or

a warm weather season, the appliance may emit a slight odour for a few

hours. This is caused by dust particles on the firebox burning off. Open a

window to sufficiently ventilate the room.

CALIFORNIA PROP 65 WARNING:

Use of this product may produce smoke which contains chemicals known to

the State of California to cause cancer, birth defects, or other reproductive

harm.

If you experience smoking problems, you may need to open a door, a window or otherwise provide some method of supplying combustion air to the

appliance.

2.6. AIR SYSTEM

When mounting the air system ensure that the air control system provides

fresh air from the outside. In order for the air system to function, you have to

ensure in the structure that no vacuum occurs in the housing. If convection

grates are installed, be sure not to block them. Air system (accessory) is

connected to the bottom of the stove.

16

wire mesh

separate combustion

air connector Ø150mm

wire mesh

separate combustion

air connector Ø150mm

Example shown: Varia M80h

is mandatory for: Varia M60h, M80h, M100h,

2L-80h, 2R-80h, 2L-100h, 2R-100h and

Arte 3RL60h, 3RL80h, 3RL100h

Models Arte 3RL-60h, Arte 3RL-80h and Arte 3RL-100h may only

be installed with a separate combustion air pipe oriented to the back.

Example shown: Varia Bh

is mandatory for: Varia Bh, B-FDh

and Arte Bh

Example shown: Arte U-90h

is mandatory for: Arte U-50h (-2016), U-70h (-2016),

U-90h (-2016)

Please note: Arte U-50h (-2016) and U-70h (-2016)

are executed with one separate combustion air

connector

wire mesh

separate combustion

air connector Ø150mm

17

operational tool

2.7. DOOR OPENING

2.7.1. FLAT AND ANGLED DOOR

Use the “operational tool” to open and close the door.

operational tool

lever

2.7.2. DOUBLE ANGLED DOOR

Use the “operational tool” to open and close the door.

Move the door up and down.

Position the “operational tool”

on the lever at the bottom

handle side of the door.

Move the door up and down. Position the “operational tool”

in the holding fixture at the

right side of the unit.

holding fixture

18

Please contact your dealer who offers suitable parts for air inlet ducts (pipes

and damper).

Make sure that the wire mesh is mounted at the combustion air inlet.

3. INSTALLATION PLANNING

Clean all ashes out of the inside of the existing fireplace opening. Make sure

that the chimney and fireplace are free of cracks, loose mortar, creosote

deposits, blockage or other signs of deterioration. If necessary, have any

repair work done by a qualified professional before installing the insert.

Do NOT remove bricks or mortar from the fireplace. In case of an outside

air inlet or ash dump, fill with fiberglass insulation. Adhere to minimum

clearances as illustrated.

WARNING

WEAR GLOVES AND SAFETY GLASSES FOR PROTECTION. CAREFULLY

FOLLOW THE INSTRUCTIONS FOR ASSEMBLY OF THE PIPE AND OTHER

PARTS NEEDED TO INSTALL THE APPLIANCE. FAILURE TO DO SO MAY

RESULT IN A FIRE, ESPECIALLY IF COMBUSTIBLES ARE TOO CLOSE

TO THE APPLIANCE OR CHIMNEY AND AIR SPACES ARE BLOCKED,

PREVENTING THE FREE MOVEMENT OF COOLING AIR. DO NOT DRAW

OUTSIDE AIR FROM GARAGE SPACES. EXHAUST PRODUCTS OF GASOLINE ENGINES ARE HAZARDOUS. DO NOT INSTALL OUTSIDE AIR DUCTS

SUCH THAT THE AIR MAY BE DRAWN FROM ATTIC SPACES, BASEMENTS OR ABOVE THE ROOFING WHERE OTHER HEATING APPLIANCES

OR FANS AND CHIMNEYS EXHAUST OR UTILIZE AIR. THESE PRECAUTIONS WILL REDUCE THE POSSIBILITY OF APPLIANCE SMOKING OR

AIR FLOW REVERSAL. THE OUTSIDE AIR INLET MUST REMAIN CLEAR

OF LEAVES, DEBRIS ICE AND/OR SNOW OR ANY OTHER OBSTACLES. IT

MUST BE UNRESTRICTED WHILE APPLIANCE IS IN USE TO PREVENT

ROOM AIR STARVATION WHICH CAN CAUSE SMOKE SPILLAGE AND

AN INABILITY TO MAINTAIN A FIRE. SMOKE SPILLAGE CAN ALSO SET

OFF SMOKE ALARMS. NEGATIVE PRESSURE WITHIN YOUR HOME MAY

INADVERTENTLY AFFECT YOUR APPLIANCE. TO PREVENT CONTACT

WITH SAGGING OR LOOSE INSULATION, THE APPLIANCE MUST NOT BE

INSTALLED AGAINST VAPOUR BARRIERS OR EXPOSED INSULATION.

LOCALIZED OVERHEATING COULD OCCUR AND A FIRE COULD RESULT.

DO NOT USE MAKESHIFT COMPROMISES DURING INSTALLATION. DO

NOT BLOCK OR RESTRICT AIR, GRILLE OR LOUVRE OPENINGS. DO NOT

ADD A HOOD. KEEP HAND TOOLS IN GOOD CONDITION; SHARPEN CUTTING EDGES AND MAKE SURE TOOL HANDLES ARE SECURE. ALWAYS

MAINTAIN THE MINIMUM AIR SPACE REQUIRED TO THE ENCLOSURE TO

PREVENT FIRES. DO NOT PACK REQUIRED AIR SPACES WITH INSULATION OR OTHER MATERIALS.

3.1. MINIMUM CLEARANCES TO COMBUSTIBLES

DO NOT PLACE ANY

COMBUSTIBLE MATERIALS (FURNITURE, FIREWOOD, ETC.) WITHIN

48”(1220mm) IN FRONT

AND ON THE SIDES OF THE

INSERT.

COMBUSTIBLE MATERIALS

CAN’T PROTRUDE ONTO

THE METAL PARTS OF THE

UNIT, THEY MUST BE COVERED WITH NON COMBUSTIBLE MATERIALS.

A

B

D

C

19

A B C D

Varia M60h

37 1/5" 16 1/2" 24 1/7" 84"

Varia M80h

44 2/7" 16 1/2" 24 1/7" 84"

Varia M100h

52 1/6" 16 1/2" 24 1/7" 84"

Varia Bh

57 1/2" 16 1/2" 26 1/4" 84"

Arte Bh

40 5/6" 16 1/2" 29 2/5" 84"

Varia

2L/2R-80h

42 3/4" 16 1/2" 25 5/9" 84"

Varia

2L/2R-100h

50 5/8 16 1/2" 25 5/9" 84"

Varia B-FDh

56 2/9" 16 1/2" 26 7/9" 84"

Arte 3RL60h

26" 48" 0" 84"

Arte 3RL80h

33 5/6" 48" 0" 84"

Arte 3RL100h

41 2/3" 48" 0" 84"

Arte

U-50h-2016

22" 48" 0" 84"

Arte

U-70h-2016

22 1/8" 48" 0" 84"

Arte

U-90h-2016

24 2/7" 48" 0" 84"

A combustible shelf can be installed above the fireplace at a minimum of

12“ from the top of the glass door. The shelf must be 6“ deep maximum.

D

C

B

A

D

B

C

A

20

3.2. PLACEMENT

NOTE! All grey colored parts have to be non combustible!

3.3. FLANGES AND ANCHOR PLATE

NOTE!! the anchor plate is not included with the unit. Use only an chimney certified as UL 103HT or ULC S-629. Be sure to place the convection

and exhaust connectors before placing the top elements of the insulation

shell. The dimensions and positioning of the different air inlet and outlet are

available in the table in chapter „dimensions“.

NOTE! All grey colored parts have to be non combustible!

21

3.4. FRONT CHASE

You must finish the front side of the fireplace using a cement board.

CAUTION!

Spartherm recommends the use of one piece cement board in

place of multiple in order to avoid cracks.

> Screw the cement board on the frame of the prefabricated shell.

> Finish the wall.

> Place L or J finishing trim to obtain sharp angles.

> Plaster

NOTE! All grey colored parts have to be non combustible!

NOTE! Do only use non combustible materials 6 inch surrounding the con-

vection air grills.

22

A

B B

A

A

B

B

2" (min)

2" (min.)

fireplace

non combustible material

meterial sheet not included

4. INSTALLATION

4.1. HEARTH EXTENSION

WARNING

INSTALL THE HEARTH EXTENSION ONLY AS ILLUSTRATED!

A 20” x 12” (500mm x 300mm) minimum hearth extension made of non

combustible material is required. To prevent any burning embers falling

between the fireplace and the hearth extension from coming into contact

with the floor, insert a metal sheet under the front of the fireplace. This

sheet must extend 4” (100mm) on both sides of the fireplace and 2” (50mm)

in front. You can also prevent embers from falling in the joint between the

fireplace and the hearth extension by filling it with mortar grout.

4.1.1. SINGLE FACED

Varia M60h Varia M80h Varia M100h Varia Bh Arte Bh

A

20” 20” 20” 20” 20”

B

12” 12” 12” 12” 12”

4.1.2. TWO SIDED

Varia 2L-80h Varia 2R-80h Varia 2L-100h Varia 2R-100h

A

20” 20” 20” 20”

B

12” 12” 12”” 12”

23

4.1.3. DOUBLE SIDED

Varia B-FDh

A

20”

B

12”

4.1.4 . THREE SIDED

Arte

3RL60h

Arte

3RL80h

Arte

3RL100h

Arte

U-50h-2016

Arte

U-70h-2016

Arte

U-90h-2016

A

20" 20" 20" 20" 20" 20"

B

20" 20" 20" 20" 20" 20"

B B

A

A

B

B

B B

A

24

4.2.1. VARIA M-60h

pos. name

1

cheese head cap screw M5x8

2

frame

3

slide

4

door

5

weight shaft sheet

25

4.2.2. VARIA M-80h

pos. name

1

door lock

2

cheese head cap screw M5x8

3

frame

4

slide

5

door

26

4.2.3. VARIA M-100h

pos. name

1

door lock

2

cheese head cap screw M5x8

3

frame

4

slide

5

door

27

4.2.4. VARIA Bh

pos. name

1

door lock

2

cheese head cap screw M5x8

3

frame

4

slide

5

door

6

weight shaft sheet, left

7

weight shaft sheet, right

28

4.2.5. ARTE Bh

pos. name

1

frame

2

slide

3

door

4

weight shaft sheet

5

door lock

6

cheese head cap screw M5x8

29

4.2.6. VARIA 2L-80h

pos. name

1

frame

2

slide

3

door

4

weight shaft sheet

5

clamp

30

4.2.7. VARIA 2R-80h

pos. name

1

weight shaft sheet

2

frame

3

slide

4

door

5

clamp

31

4.2.8. VARIA 2L-100h

pos. name

1

weight shaft sheet

2

weight shaft sheet, inside

3

frame

4

slide

5

door

32

4.2.9. VARIA 2R-100h

pos. name

1

weight shaft sheet

2

weight shaft sheet, inside

3

frame

4

slide

5

door

33

4.2.10. VARIA B-FDh FRONT

pos. name

1

lever

2

cheese head cap screw M5x8

3

hood sheet

4

slide

5

door

6

weight shaft sheet, left

7

weight shaft sheet, right

8

cadre

34

pos. name

1

frame

2

door

4.2.11. VARIA B-FDh BACK

35

4.2.12. ARTE 3RL-60h

pos. name

1

frame

2

slide, right

3

slide, left

4

door

36

4.2.13. ARTE 3RL-80h

pos. name

1

frame

2

slide, left

3

slide, right

4

door

37

4.2.14. ARTE 3RL-100h

pos. name

1

frame

2

slide, left

3

slide, right

4

door

38

4.2.15. ARTE U-50h-2016

pos. name

1

frame

2

slide, left

3

slide, right

4

door

I

2

4

3

39

4.2.16. ARTE U-70h-2016

pos. name

1

frame

2

slide, left

3

slide, right

4

door

I

2

4

3

40

4.2.17. ARTE U-90h-2016

pos. name

1

frame

2

slide, left

3

slide, right

4

door

I

2

4

3

41

marginal location

marginal location

location NOT recommended

recommended location

4.3. CHIMNEY INSTALLATION

This fireplace is designed and approved for installation with the following

brands of chimneys measuring 8 and 10“ (200 and 250mm) in diameter as

well as a minimum of 15’ (4,6m) and maximum of 45’ (13,5m) in height.

4.3.1. LISTED CHIMNEYS

chimney

manufacturer

brand type tested and listed to inner

diameter

Security chimney Secure Temp S2100+ 2" Solid Pack ULC-S629M 8"

Oliver Macleod Nova-Temp HT 6103+ 2" Solid Pack ULC-S604, ULC-S610 8"

Selkirk Super Vent 2100 (JM) 2" Solid Pack ULC-S629 8"

Selkirk CF Sentinel (CF) 2" Solid Pack ULC-S629 8"

M&G DuraVent DuraPlus HTC AC Triple Wall ULC-S629, UL-103HT 8"

Security chimney Secure Temp ASHT+ 1" Solid Pack ULC-S604, ULC-S610 10"

ICC chimney RIS 1" Solid Pack UL-103 HT 10"

The anchor plate is not included with the unit. Use only a chimney certified as UL 103HT or ULC S-629

4.3.2. CHIMNEY INSTALLATION NOTES

No other device must be added to the chimney connected to the fireplace.

• All chimney installations must include at least one support. Reducing

the amount of chimney weight on the fireplace will help avoid the noise

created when the fireplace expands. This can be achieved by having the

chimney supported by the supports. The maximum chimney length that

should be supported by the fireplace is 9 ft. (2.75 m) for 2“ Solid Pack

Chimney and 12 ft. (3.7 m) for 1“ Solid Pack Chimney.

• The chimney must extend at least 3 ft. (92 cm) above its point of contact

with the roof and at least 2 ft. (61 cm) higher than any wall, roof or

building within 10 ft. (3.1 m) of it.

• Deviations should be avoided whenever possible, especially the most

pronounced. Each deviation adds some restriction to the chimney system and may lead to draft problems.

• If the chimney extends higher than 5 ft. (1.5 m) above its point of contact

with the roof, it must be secured using a roof brace.

• A rain cap must be installed on top of the chimney. Failure to install a

rain cap may cause corrosion problems.

• Cut and frame square holes in all floors, ceilings and roof that the chimney will go through to provide a 2“ (51mm) minimum clearance between

the chimney and any combustible materials. Do not fill this space with

insulation or any other combustible material.

• Portions of the chimney which may extend through accessible spaces

must be enclosed to avoid contact with combustible materials or damage

the chimney.

• To limit creosote buildup, it is strongly recommended that an empty

enclosure space be left between the chimney stack and the outer framing of the chimney. Make sure that at all points a minimum clearance

of 2” (51 mm) separates the chimney and any combustible materials.

42

roof

chimney

ceiling

roof radiation

shield

2" min

The table below shows the minimum height requirements, fireplace included,

according to the number of elbows:

chimney number of elbows minimum height

straight installation - 15’ (4.6 m)

1 - 15° offset 2 - 15° elbows 15’ (4.6 m)

2 - 15° offset 4 - 15° elbows 18’ (5.5 m)

1 - 30° offset 2 - 30° elbows 15’ (4.6 m)

2 - 30° offset 4 - 30° elbows 20’ (6.1 m)

* 1 - 45° offset * 2 - 45° elbows 16’ (4.9 m)

* 2 - 45° offset * 4 - 45° elbows 23’ (7.0 m)

* permitted only in Canada

Refer to building code to make sure the installation seals the penetration

of the building enbelope or refer tot he listed chimney installation manual.

4.3.3. CHIMNEY INSTALLATION INSTRUCTIONS

1. Cut and frame the holes in the ceiling, floor and roof where the chimney

will pass and install radiation shields (see figure X). Use a plumb bob to line

up the center of the holes. Make sure that the size of the floor and ceiling

holes are in accordance with the chimney manufacturer’s instructions.

2. From below, install a firestop supplied by the chimney manufacturer in

each ceiling/floor separation through which the chimney will pass. At the

attic level, install an attic radiation shield from above.

3. Follow the chimney’s manufacturers’ instructions and place the first

chimney length on he fireplace. For all chimneys, you must use an anchor

plate supplied by the chimney manufacturer before installing the first chimney length (see figure 24). Continue installing chimney lengths making sure

to lock each length in place.

4. Every time the chimney passes through a ceiling or a wall, install the

appropriate firestop. When you reach the desired height, install the roof

support. (Refer to instructions included with the support.

5. Then, put the roof flashing in place and seal the joint between the roof

and the flashing with roofing pitch (see figures 24). For sloping roofs, place

the flashing under the upper shingles and on top of the lower shingles. Nail

the flashing to the roof, using roofing nails.

6. Place the storm collar over the flashing, and tighten it with the bolt

supplied. Finally, seal the joint between the storm collar and the chimney,

using silicone caulking.

7. Install the chimney cap.

8. When a ventilated roof flashing is installed, precautions are to be taken

not to caulk or seal the ventilating openings.

43

fireplace

chimney section

radiant shield

attic radiation shield

flashing

storm collar

rain cap

chimney section

basement

1st floor

attic

elbow

elbow

wall radiation shield

radiation shield

attic radiation shield

flashing

storm collar

rain cap

fireplace

basement

1st floor

attic

solin

straight chimney installation chimney with elbows installation

4.3.4. EXAMPLES OF TYPICAL INSTALLATIONS

44

elbow

fireplace

chimney section

insulated wall

radiation shield

elbow

offset support

wall band

rain cap

flashing

storm collar

basement

1st floor

attic

attic

1st floor

basement

chimney

wall band

offset support

fireplace

insulated

insulated

insulated

radiation shield

chimney section

flashing

rain cap

storm collar

exterior chimney installation isolated chase chimney installation

45

10"

24" (min.)

36" (min.)

roof

flashing

strom collar

chimney

rain cap

minimum chimney height

multi level roots

2 ft. / 3 ft. (min.)

10 ft. to nearest roofline

less than 10 ft.

2 ft. / 3 ft. (min.)

pitched roof

3 ft. (min.)

3 ft. (min.)

2ft. (min.)

less than 10 ft.10 ft. or more

wall or parapet

flat roof

windward

leeward

location NOT recommended

recommended location

recommended location

marginal location

location NOT recommended

46

4.4. MASONRY

4.4.1. TYPICAL EXISTING MASONRY

WARNING

DO NOT CONNECT THIS APPLIANCE TO A CHIMNEY FLUE SERVING

ANOTHER APPLIANCE. DO NOT CONNECT TO ANY AIR DISTRIBUTION

DUCT OR SYSTEM.

You can install your appliance using your existing masonry chimney. To do

so, follow the guidelines below. If you are using a masonry chimney, it

is important that it be built in compliance with the specifications of the

Building Code in your region. It must normally be lined with fire clay bricks,

metal or clay tiles sealed together with fire cement. (Round flues are the

most efficient).

Remove the fireplace damper or fasten it permanently open.

We recommend the following method of sealing off the damper area

around the liner:

Measure the throat of the fireplace and mark this shape on a piece of 24

gauge sheet metal (flue cover); cut a six-inch (6 3/4” / 171mm) hole to

lie directly below the fireplace flue opening. Allow two inches of material

for a flange on all sides and cut to these measurements. Bend down the

flanges. If you have never done this before, it might be a good idea to make

a cardboard pattern and test it first. Fasten this flue cover in position as

high as possible with two masonry screws per side through the flanges into

the fireplace.

In Canada: Install flexible stainless steel liner from the top of the chimney

to the insert flue collar. Attach a stainless steel liner connector or elbow to

4.3.5. LIST OF MANDATORY COMPONENTS

Chimney

Manufacturer

Components Type / Brand Part Number /

Product Code

Selkirk

Must have rafter

protectors at the roof

level if the chimney

is enclosed at the

attic level

Super Vent 2100

JSC8RRS (8“)

CF Sentinel

Security chimney

Rafter protector at the

roof level if chimney

is enclosed at the

attic level

Secure Temp S2100+ Ref. 8RS (8”)

Secure Temp ASHT+

Ref. 8XRS (8”)

Ref. 10XRS (10”)

Requires insulated

attic radiation shield

unless chimney is

enclosed at the attic

level

Secure Temp S2100+ Ref. 8RSA2 (8”)

Secure Temp ASHT+

Ref. 8XRSA2 (8”)

Ref. 8XRSA2 (10”)

M&G DuraVent

Roof radiation shield

DuraPlus HTC

Order No. (8”): 8DT-RRS

Stock No. (8”):

810000264

Attic insulation shield

Order No. (8”): 8DT-IS

Stock No. (8”):

810000263

47

floor protector

flue cover (seal) with

non-combustible

material

damper plate

removed or

fastened in open

position

listed chimney liner

masonry chimney

must have

structural

integrity

follow manufactures´s

instructions for maximum

liner extension above

chimney

connector

rain cap

the liner and insert onto the flue collar. Fasten with three screws. Secure the

top of the liner to the chimney cap using a liner support and chimney flashing. Cap the top of the chimney liner assembly using an approved rain cap.

In the United States: While it is not required, it is recommended that a

chimney liner be installed that is continuous from the insert to the top of

the chimney, particularly when the insert is installed in a basement. For

this type of connection, use the “In Canada” installation instructions above.

If a continuous liner is not installed, a “direct flue connection” must be

made. The direct flue connection requires a non-combustible connector that

extends from the insert into the chimney flue liner and also that the installed

flue cover be sealed below the entry point of the connector to prevent dilution of combustion products in the chimney flue with air from inside the

house. Cap the top of the chimney using an approved rain cap.

4.4.2. FACTORY BUILT FIREPLACE

The following installation requirements must be observed when installing

solid fuel burning inserts into factory built fireplaces.

A. The factory built fireplace must be listed per UL 127 or ULC S610.

B. Clearances to any combustible material surrounding this insert as

identified must be followed. These clearance requirements supersede

any pre-existing facing material clearances listed for the factory built

fireplace.

C. Installation must include a full height listed chimney liner meeting HT

requirements (2100°F/1149°C) as required in UL 1777 (U.S.) or ULC

S635 (Canada). The liner must be securely attached to the insert flue

collar and the chimney top.

D. Means must be provided to prevent room air passage to the chimney

48

cavity of the fireplace. This may be accomplished by sealing the damper

area around the chimney liner, or sealing the appliance front.

E. The air flow within and around the appliance shall not be altered by

the installation of the insert (i.e. no louvres or cooling air inlet or

outlet ports are blocked), unless specifically tested as such for each

factory built fireplace manufacturer and model line. NOTE: Using a

louvered face plate (surround) complies with this requirement.

F. Alteration of the appliance in any manner is not permitted with the

following exceptions;

1. External trim pieces which do not affect the operation of the appliance may be removed providing they can be stored on or within

the fireplace for reassembly if the insert is removed.

2. The chimney damper may be removed to install the chimney liner.

G. Circulating air chambers (i.e. in a steel fireplace liner or metal heat

circulator) shall not be blocked.

H. Means must be provided for removal of the insert to clean the chim-

ney flue.

I. Inserts that project in front of the fireplace must be supplied with

appropriate support means.

J. A permanent metal warning label must be attached to the back of

the fireplace stating that the fireplace must be restored to its original

condition for safe use without the insert.

4.5. CONVECTION

Spartherm stoves are convection stoves. Convection means that there is

a circulation of air, which ensures that the heat is distributed more evenly

throughout the entire room (see drawing).The cold air (blue arrows) is

drawn in at the base of the stove, then moved up through the convection

channel, which runs along the stove’s combustion chamber.

The heated air (red arrows) pours out at the top of the stove, which

ensures a circulation of warm air throughout the room. Note, however, that

all exterior surfaces become hot during use – so take extreme care. Use the

insert optimally.

By installing hot air nozzles and flexible hoses (or similar) on top of the

stove, it is possible to “distribute” the heat to other rooms.

Consider the placement of convection air inlet and outlet holes. Ensure that

the holes are not blocked from the outside. There may be discoloration of the

wall above the stove doors, and above

the convection air outlet holes. This is

due to the ascending hot air Spartherm

accepts no liability for installation or

consequential damages.

Models should be installed only with

Spartherm provided convection air kits.

4.5.1. MINIMUM CLEARANCES TO COMBUSTIBLES

FOR CONVECTION AIR

GRILLS

Connect at least 4 gravity outlets 6 inch diameter to the convection air

outlet ports.

Exceptions: Arte 3RL60h and Arte U-50h: only connect 2 gravity outlets 6

inch diameter.

The minimum distance between the convection air grills the ceiling and

combustibles is 6.5 inch.

Do only use non combustible materials 6 inch surrounding the convection

air grills.

49

Gravity Distribution Kit

The Gravity Distribution Kit may be used to heat rooms located above, behind

and either side oft he room where the fireplace is located. Note that, if the

hot air outlets are located at various levels, the heat will tend to seek the

one at the highest level. It is not permitted to connect two ducts together.

5. FINISHING

5.1. BRICKS AND BAFFELS INSTALLATION

WARNING

OPERATION OF THE APPLIANCE WITHOUT THE BAFFLES CAN RESULT

IN EXCESSIVE TEMPERATURES THAT COULD DAMAGE THE APPLIANCE,

CHIMNEY AND THE SURROUNDING ENCLOSURE.

NOTE: DO NOT OPERATE IF BAFFLE AND MANIFOLD SHIELD ARE NOT

IN POSITION.

chimney

2" (min.)

8"

chimney

chimney

4.6. HEAT DISTRIBUTION SYSTEMS

For installation use flexible aluminium liner with 1 inch insultation.

chimney

120" (max.)

120" (max.)

50

1

2

7

6

5

4

9

3

8

1

2

4

3

9

8

6

7

11

5

10

pos. name

1

base brick, left

2

base brick, right

3

rear wall brick, left

4

rear wall brick, middle bottom

5

rear wall brick, middle top

6

rear wall brick, right

7

side wall brick, right

8

side wall brick, left

9

baffle plate

pos. name

1

base brick, left

2

base brick, middle left

3

base brick, right

4

base brick, middle right

5

rear wall brick, left

6

rear wall brick, middle bottom

7

rear wall brick, middle top

8

rear wall brick, right

9

side wall brick, right

10

side wall brick, left

11

baffle plate

5.1.1. VARIA M-60h

Chamotte must be assembled strictly in numerical order!

5.1.2. VARIA M-80h

Chamotte must be assembled strictly

in numerical order!

51

1

2

4

3

11

10

9

7

8

6

13

5

12

1

2

4

3

14

11

9

10

7

8

15

5

6

12

13

pos. name

1

base brick, left

2

base brick, middle left

3

base brick, right

4

base brick, middle right

5

rear wall brick, left

6

rear wall brick, middle left

7

rear wall brick, middle bottom

8

rear wall brick, middle top

9

rear wall brick, middle right

10

rear wall brick, right

11

side wall brick, right

12

side wall brick, left

13

baffle plate

pos. name

1

base brick, left

2

base brick, middle left

3

base brick, right

4

base brick, middle right

5

rear wall brick, middle left

bottom

6

rear wall brick, middle left top

7

rear wall brick, middle bottom

8

rear wall brick, middle top

9

rear wall brick, middle right

bottom

10

rear wall brick, middle right top

11

rear wall brick, right

12

rear wall brick, left

13

side wall brick, left

14

side wall brick, right

15

baffle plate

5.1.3. VARIA M-100h

Chamotte must be assembled strictly in numerical order!

5.1.4. VARIA Bh

Chamotte must be assembled strictly in

numerical order!

52

1

2

3

4

5

6

7

8

9

10

14

11

12

13

1

2

3

4

5

6

7

8

9

10

11

pos. name

1

base brick, rear left

2

base brick, rear right

3

base brick, front left

4

base brick, front right

5

rear wall brick, left

6

rear wall brick, right

7

side wall brick, rear right

8

side wall brick, front right

9

side wall brick, rear left

10

side wall brick, front left

11

edge brick, left

12

edge brick, middle

13

edge brick, right

14

baffle plate

pos. name

1

base brick, right

2

base brick, middle right

3

base brick, middle left

4

base brick, left

5

side wall brick, right

6

rear wall brick, right

7

rear wall brick, middle bottom

8

rear wall brick, middle top

9

rear wall brick, left

10

baffle plate right

11

baffle plate left

5.1.5. ARTE Bh

Chamotte must be assembled strictly in numerical order!

5.1.6. VARIA 2L-80h

Chamotte must be assembled strictly in numerical order!

53

5

1

2

3

4

5

6

7

8

9

10

11

1

2

3

4

5

6

7

8

9

10

11

pos. name

1

base brick, left

2

base brick, middle left

3

base brick, middle right

4

base brick, right

5

side wall brick, left

6

rear wall brick, left

7

rear wall brick, middle bottom

8

rear wall brick, middle top

9

rear wall brick, right

10

baffle plate left

11

baffle plate right

pos. name

1

base brick, right

2

base brick, middle right

3

base brick, middle left

4

base brick, left

5

side wall brick, right

6

rear wall brick, right

7

rear wall brick, middle bottom

8

rear wall brick, middle top

9

rear wall brick, left

10

baffle plate right

11

baffle plate left

5.1.7. VARIA 2R-80h

Chamotte must be assembled

strictly in numerical order!

5.1.8. VARIA 2L-100h

Chamotte must be assembled

strictly in numerical order!

54

1

2

3

4

5

6

7

8

9

10

11

1

2

3

4

5

6

pos. name

1

base brick, left

2

base brick, middle left

3

base brick, middle right

4

base brick, right

5

side wall brick, left

6

rear wall brick, left

7

rear wall brick, middle bottom

8

rear wall brick, middle top

9

rear wall brick, right

10

baffle plate left

11

baffle plate right

pos. name

1

base brick, front left

2

base brick, rear left

3

base brick, front right

4

base brick, rear right

5

side wall brick, left

6

side wall brick, right

5.1.9. VARIA 2R-100h

Chamotte must be assembled

strictly in numerical order!

5.1.10. VA RI A B - F D h

Chamotte must be assembled strictly in numerical order!

55

1

2

4

3

7

6

5

1

2

4

3

5

6

7

8

9

5.1.11. A R T E 3R L-60h

Chamotte must be assembled strictly in numerical order!

5.1.12. ARTE 3RL-8 0 h

Chamotte must be assembled strictly in numerical order!

pos. name

1

base brick, front left

2

base brick, front right

3

base brick, rear left

4

base brick, rear right

5

rear wall brick, bottom

6

rear wall brick, top

7

baffle plate

pos. name

1

base brick, front left

2

base brick, front right

3

base brick, rear left

4

base brick, rear right

5

rear wall brick, right

6

rear wall brick, bottom

7

rear wall brick, top

8

rear wall brick, left

9

baffle plate

56

1

2

5

6

7

9

8

4

3

5.1.13. ARTE 3RL-100h

Chamotte must be assembled strictly in numerical order!

pos. name

1

base brick, front left

2

base brick, front right

3

base brick, rear left

4

base brick, rear right

5

rear wall brick, right

6

rear wall brick, bottom

7

rear wall brick, top

8

rear wall brick, left

9

baffle plate

1

2

3

4

6

5

7

5.1.14. ARTE U-50h-2016

Chamotte must be

assembled strictly

in numerical order!

pos. name

1

base brick, left

2

base brick, right

3

rear wall brick, bottom

4

rear wall brick, top

5

baffle plate, center

6

baffle plate, left

7

baffle plate, right

57

8

6

9

7

5

2

3

4

1

5.1.15. ARTE U-70h-2016

Chamotte must be

assembled strictly

in numerical order!

pos. name

1

base brick, rear left

2

base brick, rear right

3

base brick, front right

4

base brick, front left

5

rear wall brick

6

baffle plate, rear left

7

baffle plate, rear right

8

baffle plate, front left

9

baffle plate, front right

58

2

1

4

3

10

8

6

11

9

7

5

5.1.16. ART E U-90h-2016

Chamotte must be

assembled strictly

in numerical order!

pos. name

1

base brick, rear left

2

base brick, rear right

3

base brick, front left

4

base brick, front right

5

rear wall brick

6

baffle plate, rear left

7

baffle plate, rear right

8

baffle plate, center left

9

baffle plate, center right

10

baffle plate, front left

11

baffle plate, front right

59

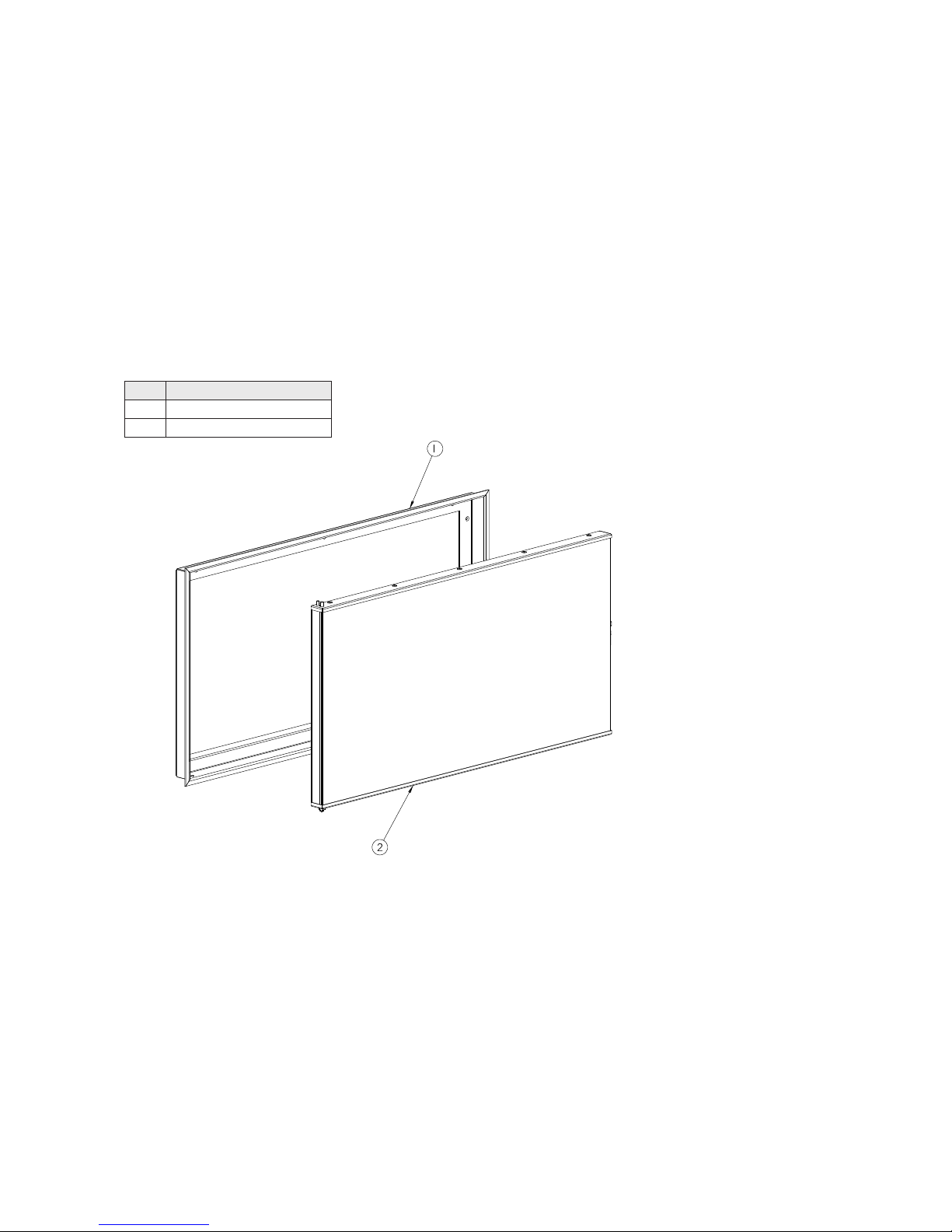

5.2. DOOR REMOVAL / INSTALLATION

WARNING

BURNING YOUR APPLIANCE WITH THE DOORS OPEN OR AJAR CREATES

A FIRE HAZARD THAT MAY RESULT IN A HOUSE AND/OR CHIMNEY FIRE.

DO NOT STRIKE OR SLAM DOOR.

NEVER REMOVE THE DOOR WHEN THE APPLIANCE IS HOT.

pos. name

1

cage nut M6

2

hood sheet

3

hexagon bolt M6x12

4

hexagon nut M6

5

cheese head cap screw M5x8

6

cheese head cap screw M6x25

7

cheese head cap screw M6x10

8

cheese head cap screw M8x35

9

pulley

10

door frame sheet

11

guide bar, left

12

guide bar, right

13

door frame sheet, bottom

14

air guide sheet

single faced

Example shown: Varia M100h

60

pos. name quantity SAP

1

pulley 1 -

2

flange bearing BG FL 1 2 1007754

3

cage nut M6 12 -

4

countersunk bolt M6x12 8 -

5

cheese head cap screw M6x10 4 -

6

cheese head cap screw M5x8 6 -

7

cheese head cap screw M5x8 12 -

8

set screw M10x8 1 -

9

set screw with point M5x10 3 -

10

cheese head cap screw M6x14 4 -

11

washer 12x6,4x1,6 4 -

12

pan-head screw M5x12 2 -

13

hood sheet, front 1 -

14

air guide sheet 1 -

15

door frame sheet, bottom 1 -

16

hood sheet, left 1 -

17

guide bar, right 1 -

18

guide bar, left 1 -

19

angle, right 1 -

20

angle, left 1 -

21

support 1 -

22

air duct sheet 1 -

23

weight rod 1 -

two sided

Example shown: Varia 2L-100h

61

pos. name quantity SAP

1

flange bearing assembly, on ball bearings 2 1019702

2

cage nut M6 8 -

3

pressure screw M8x10 2 -

4

hexagon bolt M6x12 4 -

5

hexagon nut M6 2 -

6

cheese head cap screw M5x8 7 -

7

cheese head cap screw M6x10 4 -

8

cheese head cap screw M6x25 2 -

9

cheese head cap screw M6x14 4 -

10

washer 12x6,4x1,6 4 -

11

set screw M5x10 2 -

12

pulley, right 1 1019066

13

pulley, left 1 1019088

14

door frame sheet 1 -

15

hood sheet 1 -

16

door frame sheet, bottom 1 -

17

guide bar, left 1 -

18

guide bar, right 1 -

19

sealing strip 1 -

20

weight rod 1 -

double sided, front

Example shown: Varia B-FDh

62

pos. name quantity SAP

1

roller fitting 1 -

2

frame 1 -

double sided, back

Example shown: Varia B-FDh

63

pos. name

1

hood sheet, left

2

hood sheet, right

3

hood sheet, front

4

weight shaft sheet, right

5

weight shaft sheet, left

6

lock flap

7

angle, rear left

8

angle, rear right

9

angle, front right

10

angle, front left

11

guide bar, right

12

guide bar, left

13

angle, bottom right

14

weight rod

15

angle, top left

16

angle, top right

17

angle, bottom left

18

pulley

19

pulley, small

20

inspection port

21

flange bearing assembly, on ball bearings

22

cage nut M6

23

cage nut M6

24

washer 6,4

25

countersunk bolt M5x10

26

countersunk bolt M3x8

27

cheese head cap screw M6x10

28

cheese head cap screw M6x14

29

cheese head cap screw M5x8

30

set screw M10x8

31

hexagon bolt M10x35

32

door frame sheet

three sided

Example shown: Arte 3RL100h

64

DO NOT POKE OR STIR THE LOGS WHILE THEY ARE BURNING. USE ONLY

FIRELOGS THAT HAVE BEEN EVALUATED FOR THE APPLICATION IN

FIREPLACE AND REFER TO FIRELOG WARNINGS AND CAUTION MARKINGS ON PACKAGING PRIOR TO USE.”

WARNING

AVOID BURN RISK. REMOVE OPERATIONAL TOOL AFTER USE!!!

WARNING

THE USE OF THE PROTECTIVE GLOVE IS MANDITORY!!!

Your Spartherm product is designed with the most advanced technology. The appliance is extremely airtight. It has an exclusive direct outside air supply (optional kit),

a safety feature designed to prevent spillage, and to keep your house free of carbon

monoxide, in case of a down drafting chimney or an internal negative pressure.