Spartan Tool URBAN WARRIOR SKID MOUNT JETTER, 75720010, Ultimate Urban Warrior Skid Mount Sewer Jetter, 75730010 Product Manual

FOR T OUGH CUSTOMERS.

SINCE 1943

PRODUCT MANUAL

Urban Warrior

Skid Mount Sewer Jetter

Spartan Tool LLC | 1506 West Division Street | Mendota, IL 61342

order by phone 800.435.3866 order online SpartanTool.com

© 2018 Spartan Tool LLC

Part #75720010

Contents

WARNINGS ............................................................................................................4

FEATURES .............................................................................................................5

DESCRIPTION—COMPONENTS .........................................................................................6

DESCRIPTION—CONTROLS ............................................................................................11

eController Functions ......................................................................................................... 11

Corona Display ............................................................................................................... 12

Push Buttons and Indicating Lights ............................................................................................ 12

Navigation Bullets ............................................................................................................ 13

HP Hose Reel Mode ........................................................................................................... 13

Management Mode ........................................................................................................... 13

Hose Counter (if equipped) ................................................................................................... 14

Tachometer .................................................................................................................. 14

Remote Control ............................................................................................................... 15

SAFETY INSTRUCTIONS ...............................................................................................16

IMPORTANT SYMBOLS ................................................................................................18

MECHANICAL OPERATION .............................................................................................19

Check Before Departure ...................................................................................................... 19

Placement of Urban Warrior ................................................................................................... 19

Prior to Starting the Urban Warrior ............................................................................................ 19

Starting the Engine ........................................................................................................... 20

Electric Hose Reel Pivot Locking Device ........................................................................................ 21

Hydraulic Reel Control ........................................................................................................ 22

High Pressure Hose Guide ..................................................................................................... 22

ECONTROLLER OPERATION ............................................................................................23

Management Mode ........................................................................................................... 23

Emergency Stop Test .......................................................................................................... 24

Battery Indication ............................................................................................................. 24

RIOMOTE® CONTROL OPERATION ......................................................................................24

2

OPERATING INSTRUCTIONS ...........................................................................................25

Cleaning a Drain Line ......................................................................................................... 25

Stop Spraying ................................................................................................................ 26

Care of the HP Hose ........................................................................................................... 26

Cold Weather Operation ...................................................................................................... 26

Cleaning a Wall, Terrace, or Floor .............................................................................................. 27

Secure After High-Pressure Cleaning .......................................................................................... 27

ECONTROLLER ERRORS ................................................................................................28

Emergency Stop .............................................................................................................. 28

Engine Temperature .......................................................................................................... 28

Heat Exchanger High Temperature ............................................................................................ 28

Hydraulic Oil High Temperature ............................................................................................... 29

Oil Level ...................................................................................................................... 29

Coolant Level ................................................................................................................. 29

Battery Charge ............................................................................................................... 30

Run Dry ...................................................................................................................... 30

Service Interval ............................................................................................................... 30

MAINTENANCE .......................................................................................................31

Daily Maintenance ............................................................................................................ 31

Minor Service ................................................................................................................. 32

Hydraulic System ............................................................................................................. 33

Extensive Periodic Maintenance ............................................................................................... 34

Maintenance Schedule ........................................................................................................ 34

TECHNICAL SPECIFICATIONS ..........................................................................................35

TROUBLESHOOTING ..................................................................................................37

APPENDIX A: ENGINE CONTROL MODULE .............................................................................39

APPENDIX B: MACHINE DIMENSIONS ..................................................................................40

APPENDIX C: ACCESSORIES ...........................................................................................41

3

Warnings

• Read the safety and operating instructions before using any Spartan Tool product. Drain and sewer cleaning can be dangerous if

proper procedures are not followed and appropriate safety gear is not utilized. Read the engine owners’ manual for instructions and

safety precautions on engine operation.

• Gasoline is extremely flammable and is explosive under certain conditions.

• Refuel in a well ventilated area with the engine stopped. Do not smoke or allow flames or sparks in the area where the engine is

refueled or where gasoline is stored.

• Do not overfill the fuel tank (there should be no fuel in the filler neck). After refueling, make sure the tank cap is closed properly

and securely.

• Explosive fuel can cause fires and severe burns. Fuel is flammable and its vapors can ignite. Store fuel only in approved containers, in

well ventilated, unoccupied buildings. Do not fill the fuel tank while the engine is hot or running, since spilled fuel could ignite if it

comes in contact with hot parts or sparks from ignition. Do not start the engine near spilled fuel. Never use fuel as a cleaning agent.

• Before starting unit, be sure to wear personal protective equipment such as safety goggles or face shield and protective clothing

such as gloves, coveralls or raincoat, rubber boots with metatarsal guards, and hearing protection.

• Ensure the jet hose has been placed in the pipe (minimum of 6 feet suggested) before engaging the water pressure to prevent the

hose from coming out of the pipe prematurely and causing injury.

• Always shut off the water pressure before pulling the hose out of the pipe. Mark the hose a minimum of 6 feet from the end to help

ensure the hose is not accidentally pulled out of the pipe while still under pressure. Shut off the water pressure when the hose mark

is encountered.

CAUTION: Portions of the system can still be under pressure even if the unit is not operating.

• Never point the wash gun at anyone while operating the unit. Injury may result.

• Drains and sewer can carry bacteria and other infectious micro-organisms or materials which can cause death or severe illness. Avoid

exposing eyes, nose, mouth, ears, hands, and cuts and abrasions to waste water or other potentially infectious materials during drain

and sewer cleaning operations. To further help protect against exposure to infectious materials, wash hands, arms and other areas

of the body, as needed, with hot, soapy water and, if necessary, flush mucous membranes with water. Also, disinfect potentially

contaminated equipment by washing such surfaces with a hot soapy wash using a strong detergent.

• For any questions, contact Spartan Tool at the address shown below.

CONTACT US

Spartan Tool LLC

1506 West Division Street

Mendota, IL 61342

800.435.3866

SpartanTool.com

4

SPECS

• Pipe Sizes: up to 18" diameter

• Max Water Pressure: 3,000 psi

• Max Water Flow: 19 GPM

• Water Capacity: 160 gallons

• Unit Weight: 1,200 lbs (empty)

• Overall Size: 52/"L x 49"W x 49/"H

• Warranty: (1) year limited

FEATURES

• 50 HP Kubota Gasoline Engine

Features

• P52 Speck/Giant Triplex Pump

• eControl: LCD screen and easy-to-use jog-wheel for single click operation of machine

• LED dispay and warning lights provide machine status at a glance

• Pressure can be continuously adjusted with accessible handwheel

• Hose length counter

• Remote control

• 1/2" x 360' of Maxflow HP hose

• 115' of supply hose

• Pivoting 180° hose reel, hydraulically operated with freewheel system

• Powder coated steel frame

SAFETY

• Run dry protection with override ability

• Automatic engine shutdown protection for high water temperature, engine temperature, low engine oil, or low engine coolant

• Electric reel latching mechanism for easy pivoting and safety

5

Description—Components

15

20

3

2

14

1

22

27

9

19

10

13

12

11

8

16

1. High-pressure hose on reel

2. Supply hose on reel

3. Supply hose valve

4. eController

5. Hose holder

6. Hose guide

7. High-pressure (HP) valve

8. Supply pipe

9. Water lter

10. Drain valve

6

11. Pressure regulator

12. Pressure gauge

13. Supply hose holder

14. Pivot Locking Device

15. Supply hose reel lock

16. Water lter valve

17. HP pump

18. Hydraulic oil reservoir

19. Pulsator valve

20. Water tank level indicator

21. Water tank

22. Fuel tank

23. Engine

24. Battery

25. ECM (Engine Control Module)

26. Hydraulic Hose Reel Speed

Control

27. Nozzle holders

28. Catalytic converter

Description—Components

21

4

20

22

5

1

14

9

2

12

11

8

19

1. High-pressure hose on reel

2. Supply hose on reel

3. Supply hose valve

4. eController

5. Hose holder

6. Hose guide

7. High-pressure (HP) valve

8. Supply pipe

9. Water lter

10. Drain valve

27

11. Pressure regulator

12. Pressure gauge

13. Supply hose holder

14. Pivot Locking Device

15. Supply hose reel lock

16. Water lter valve

17. HP pump

18. Hydraulic oil reservoir

19. Pulsator valve

20. Water tank level indicator

16

10

21. Water tank

22. Fuel tank

23. Engine

24. Battery

25. ECM (Engine Control Module)

26. Hydraulic Hose Reel Speed

Control

27. Nozzle holders

28. Catalytic converter

7

Description—Components

15

21

25

22

24

27

3

7

26

6

12

18

11

17

8

19

9

16

10

1. High-pressure hose on reel

2. Supply hose on reel

3. Supply hose valve

4. eController

5. Hose holder

6. Hose guide

7. High-pressure (HP) valve

8. Supply pipe

9. Water lter

10. Drain valve

8

11. Pressure regulator

12. Pressure gauge

13. Supply hose holder

14. Pivot Locking Device

15. Supply hose reel lock

16. Water lter valve

17. HP pump

18. Hydraulic oil reservoir

19. Pulsator valve

20. Water tank level indicator

21. Water tank

22. Fuel tank

23. Engine

24. Battery

25. ECM (Engine Control Module)

26. Hydraulic Hose Reel Speed

Control

27. Nozzle holders

28. Catalytic converter

1

Description—Components

27

9

19

12

11

13

8

2

21

23

10

16

1. High-pressure hose on reel

2. Supply hose on reel

3. Supply hose valve

4. eController

5. Hose holder

6. Hose guide

7. High-pressure (HP) valve

8. Supply pipe

9. Water lter

10. Drain valve

11. Pressure regulator

12. Pressure gauge

13. Supply hose holder

14. Pivot Locking Device

15. Supply hose reel lock

16. Water filter valve

17. HP pump

18. Hydraulic oil reservoir

19. Pulsator valve

20. Water tank level indicator

28

21. Water tank

22. Fuel tank

23. Engine

24. Battery

25. ECM (Engine Control Module)

26. Hydraulic Hose Reel Speed

Control

27. Nozzle holders

28. Catalytic converter

9

Description—Components

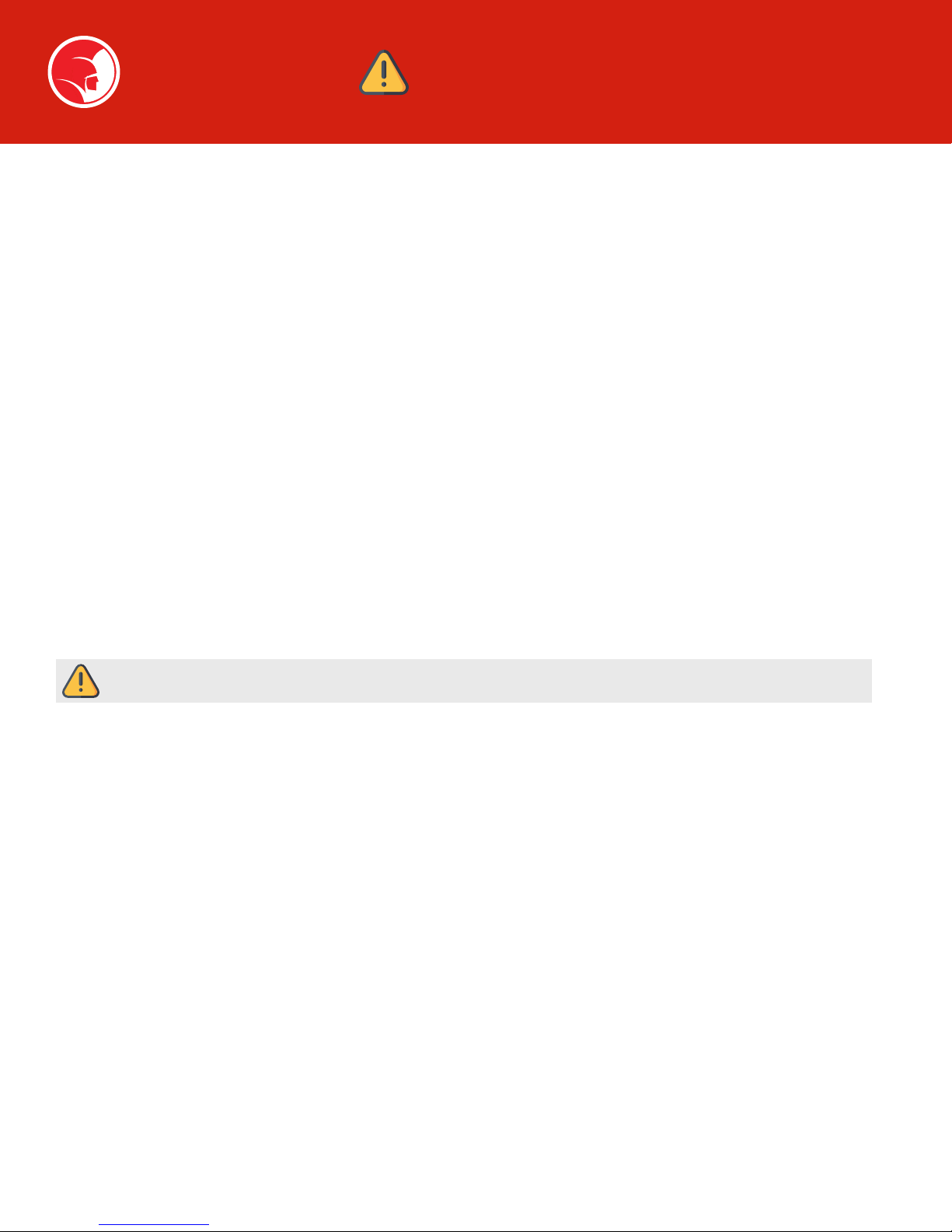

CONTROLS AND INDICATIONS

Corona

Function icon

Navigation bullets

Pointer

Engine LED

Engine On button

Navigator dial

Vacuum LED

Emergency stop

Tachometer

High pressure spray LED

High pressure spray button

Vacuum button

Key switch

(o / manual / Riomote)

10

Description—Controls

ECONTROLLER FUNCTIONS

Spartan Tool provides several options on the Urban Warrior skid mount sewer jetter. As a result, there are multiple eControl

configurations to accommodate the features available on any particular unit.

This section of the manual will cover available functions of the Two Function eController and the Three Function eController.

The two figures below identify the Two Function and Three Function eController.

2 FUNCTION ECONTROLLER

The two function remote is identified by the two

blue function indicators at the top of the LCD

display.

The two functions are:

• Home function

• Maintenance function

3 FUNCTION ECONTROLLER

The three function remote is identified by the three

blue function indicators at the top of the LCD

display.

The three functions are:

• Home function

• HP hose reel control

• Management function

11

Description—Controls

The Corona on the eController is normally off (gray).

CORONA DISPLAY

Blue corona indicates

set to Riomote Control

Red corona indicates

eController error

See page 27 (eController

Errors) for alarm functions

PUSH BUTTONS AND INDICATING LIGHTS

The Engine On light/button indicates the status and

controls the starting of the engine. (See page 19, Starting

the Engine, for more information.)

The High Pressure Spray light/button indicates the status

and controls the high pressure spray valve. (See page 24,

Cleaning a Drain Line, for more information.)

The Blue LED above each button will blink when the

corresponding function is available. (The engine is ready to start or

high pressure spray is available.)

The Blue LED above each button will light solid when the

corresponding function is active. (The engine is running or the high

pressure spray valve is open.)

Orange corona indicates

pre-start functions or

one of two error conditions:

• Run dry (no water

in tank)

• Error oil level

Insert key

Position 1

(manual control)

Position 2

(remote control)

12

Description—Controls

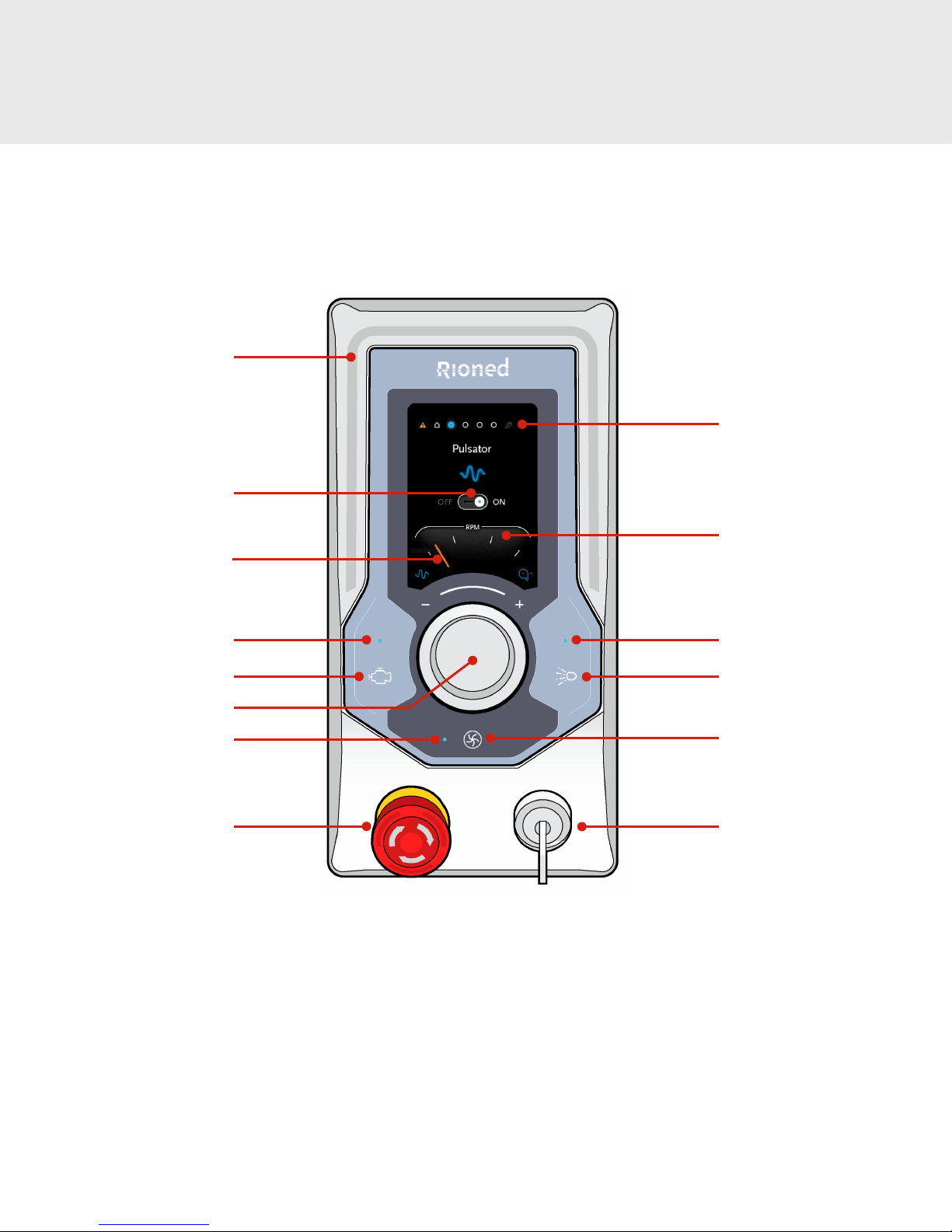

NAVIGATION BULLETS

The navigation bullets have two general states: Passive (gray) Active (blue)

Depending on the user’s location in the menu, one bullet is on display, or in the case of a pop-up eController error, all navigation bullets

disappear. (See page 27, eController Errors, for a list of pop-up displays.)

Features in navigation bullets are in specified order, if applicable:

Home

Error

Management

HP Hose

Reel

ECONTROLLER FUNCTIONS

HP Hose Reel Mode

When the eController is set to HP Hose Reel the LCD displays the

hose position and the up/down control positions. The hose reel is

actuated by rotating the Navigator dial clockwise to select down and

counter clockwise to select up. Depress the Navigator dial to select

the action.

The speed of the hydraulic drive using the eController is controlled

by adjusting the speed control unit which throttles the hydraulic flow

to the reel drive hydraulic motor. (See page 21, Rewind Hose Using

Hydraulic Reel.)

The Error navigation icon is only visible and can

be navigated when an error is applicable.

The Home navigation icon is the default position

and normally displays engine run time and HP

hose counter.

Hydraulic Speed Control

Management Mode

When the eController is set to Management Mode, the LCD displays a menu of three functions that can

be selected by rotating the Navigator dial and activated by depressing the navigation knob.

• Software Version displays the current version of the controller software.

• Service Interval displays the days and run hours until maintenance is required.

• Hose Counter displays the length of hose off the HP hose reel.

13

Description—Controls

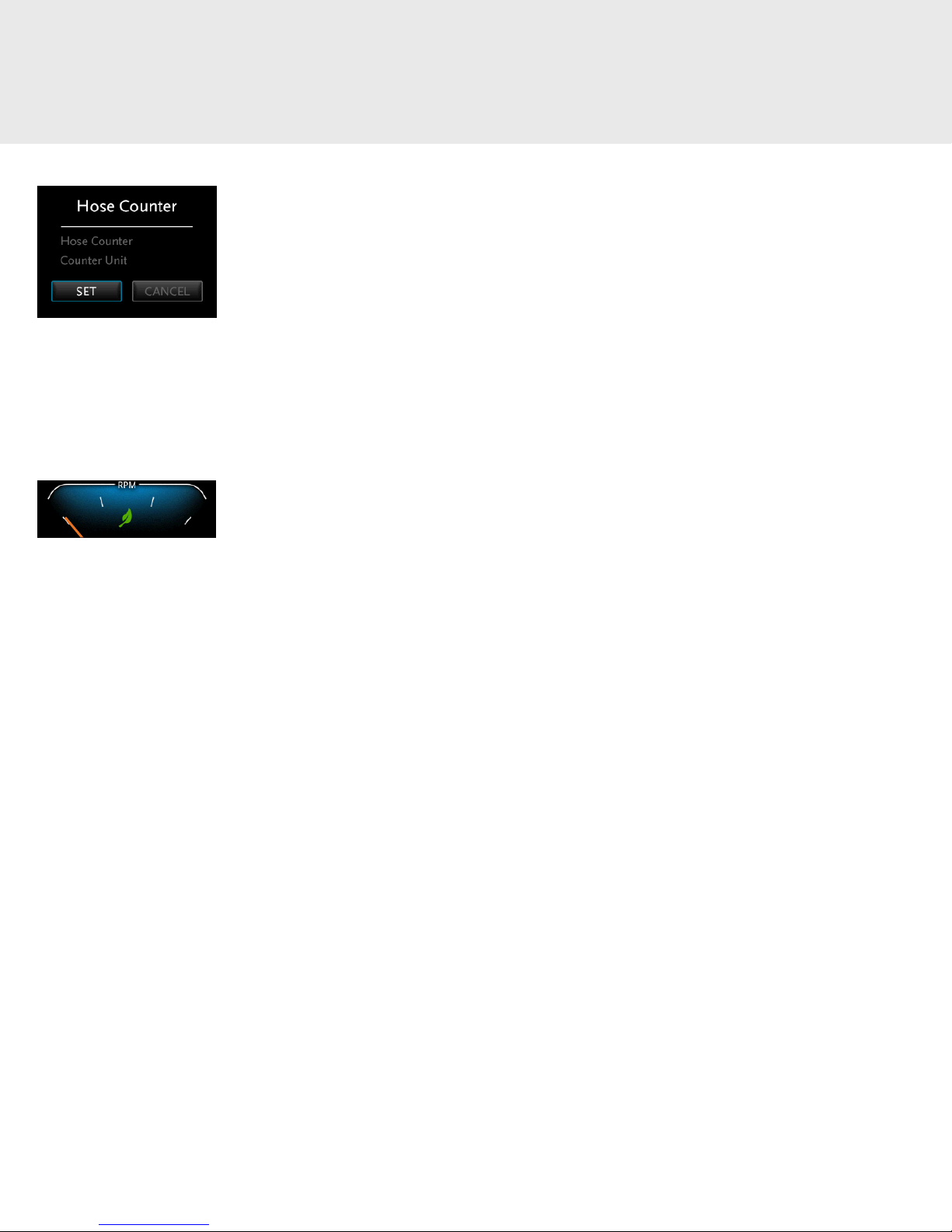

Hose Counter (if equipped)

When the eController is set to Hose Counter mode, the LCD displays a menu of two functions that can

be selected by rotating the Navigator dial and activated by depressing the navigation knob.

• Hose Counter allows the user to select on or off.

• Counter Unit allows the user to select meters or feet.

Tachometer

The pointer indicates the engine’s current RPM.

14

Loading...

Loading...