Spartan Tool URBAN WARRIOR SKID MOUNT JETTER, 75720010, Ultimate Urban Warrior Skid Mount Sewer Jetter, 75730010 Product Manual

FOR T OUGH CUSTOMERS.

SINCE 1943

PRODUCT MANUAL

Urban Warrior

Skid Mount Sewer Jetter

Spartan Tool LLC | 1506 West Division Street | Mendota, IL 61342

order by phone 800.435.3866 order online SpartanTool.com

© 2018 Spartan Tool LLC

Part #75720010

Contents

WARNINGS ............................................................................................................4

FEATURES .............................................................................................................5

DESCRIPTION—COMPONENTS .........................................................................................6

DESCRIPTION—CONTROLS ............................................................................................11

eController Functions ......................................................................................................... 11

Corona Display ............................................................................................................... 12

Push Buttons and Indicating Lights ............................................................................................ 12

Navigation Bullets ............................................................................................................ 13

HP Hose Reel Mode ........................................................................................................... 13

Management Mode ........................................................................................................... 13

Hose Counter (if equipped) ................................................................................................... 14

Tachometer .................................................................................................................. 14

Remote Control ............................................................................................................... 15

SAFETY INSTRUCTIONS ...............................................................................................16

IMPORTANT SYMBOLS ................................................................................................18

MECHANICAL OPERATION .............................................................................................19

Check Before Departure ...................................................................................................... 19

Placement of Urban Warrior ................................................................................................... 19

Prior to Starting the Urban Warrior ............................................................................................ 19

Starting the Engine ........................................................................................................... 20

Electric Hose Reel Pivot Locking Device ........................................................................................ 21

Hydraulic Reel Control ........................................................................................................ 22

High Pressure Hose Guide ..................................................................................................... 22

ECONTROLLER OPERATION ............................................................................................23

Management Mode ........................................................................................................... 23

Emergency Stop Test .......................................................................................................... 24

Battery Indication ............................................................................................................. 24

RIOMOTE® CONTROL OPERATION ......................................................................................24

2

OPERATING INSTRUCTIONS ...........................................................................................25

Cleaning a Drain Line ......................................................................................................... 25

Stop Spraying ................................................................................................................ 26

Care of the HP Hose ........................................................................................................... 26

Cold Weather Operation ...................................................................................................... 26

Cleaning a Wall, Terrace, or Floor .............................................................................................. 27

Secure After High-Pressure Cleaning .......................................................................................... 27

ECONTROLLER ERRORS ................................................................................................28

Emergency Stop .............................................................................................................. 28

Engine Temperature .......................................................................................................... 28

Heat Exchanger High Temperature ............................................................................................ 28

Hydraulic Oil High Temperature ............................................................................................... 29

Oil Level ...................................................................................................................... 29

Coolant Level ................................................................................................................. 29

Battery Charge ............................................................................................................... 30

Run Dry ...................................................................................................................... 30

Service Interval ............................................................................................................... 30

MAINTENANCE .......................................................................................................31

Daily Maintenance ............................................................................................................ 31

Minor Service ................................................................................................................. 32

Hydraulic System ............................................................................................................. 33

Extensive Periodic Maintenance ............................................................................................... 34

Maintenance Schedule ........................................................................................................ 34

TECHNICAL SPECIFICATIONS ..........................................................................................35

TROUBLESHOOTING ..................................................................................................37

APPENDIX A: ENGINE CONTROL MODULE .............................................................................39

APPENDIX B: MACHINE DIMENSIONS ..................................................................................40

APPENDIX C: ACCESSORIES ...........................................................................................41

3

Warnings

• Read the safety and operating instructions before using any Spartan Tool product. Drain and sewer cleaning can be dangerous if

proper procedures are not followed and appropriate safety gear is not utilized. Read the engine owners’ manual for instructions and

safety precautions on engine operation.

• Gasoline is extremely flammable and is explosive under certain conditions.

• Refuel in a well ventilated area with the engine stopped. Do not smoke or allow flames or sparks in the area where the engine is

refueled or where gasoline is stored.

• Do not overfill the fuel tank (there should be no fuel in the filler neck). After refueling, make sure the tank cap is closed properly

and securely.

• Explosive fuel can cause fires and severe burns. Fuel is flammable and its vapors can ignite. Store fuel only in approved containers, in

well ventilated, unoccupied buildings. Do not fill the fuel tank while the engine is hot or running, since spilled fuel could ignite if it

comes in contact with hot parts or sparks from ignition. Do not start the engine near spilled fuel. Never use fuel as a cleaning agent.

• Before starting unit, be sure to wear personal protective equipment such as safety goggles or face shield and protective clothing

such as gloves, coveralls or raincoat, rubber boots with metatarsal guards, and hearing protection.

• Ensure the jet hose has been placed in the pipe (minimum of 6 feet suggested) before engaging the water pressure to prevent the

hose from coming out of the pipe prematurely and causing injury.

• Always shut off the water pressure before pulling the hose out of the pipe. Mark the hose a minimum of 6 feet from the end to help

ensure the hose is not accidentally pulled out of the pipe while still under pressure. Shut off the water pressure when the hose mark

is encountered.

CAUTION: Portions of the system can still be under pressure even if the unit is not operating.

• Never point the wash gun at anyone while operating the unit. Injury may result.

• Drains and sewer can carry bacteria and other infectious micro-organisms or materials which can cause death or severe illness. Avoid

exposing eyes, nose, mouth, ears, hands, and cuts and abrasions to waste water or other potentially infectious materials during drain

and sewer cleaning operations. To further help protect against exposure to infectious materials, wash hands, arms and other areas

of the body, as needed, with hot, soapy water and, if necessary, flush mucous membranes with water. Also, disinfect potentially

contaminated equipment by washing such surfaces with a hot soapy wash using a strong detergent.

• For any questions, contact Spartan Tool at the address shown below.

CONTACT US

Spartan Tool LLC

1506 West Division Street

Mendota, IL 61342

800.435.3866

SpartanTool.com

4

SPECS

• Pipe Sizes: up to 18" diameter

• Max Water Pressure: 3,000 psi

• Max Water Flow: 19 GPM

• Water Capacity: 160 gallons

• Unit Weight: 1,200 lbs (empty)

• Overall Size: 52/"L x 49"W x 49/"H

• Warranty: (1) year limited

FEATURES

• 50 HP Kubota Gasoline Engine

Features

• P52 Speck/Giant Triplex Pump

• eControl: LCD screen and easy-to-use jog-wheel for single click operation of machine

• LED dispay and warning lights provide machine status at a glance

• Pressure can be continuously adjusted with accessible handwheel

• Hose length counter

• Remote control

• 1/2" x 360' of Maxflow HP hose

• 115' of supply hose

• Pivoting 180° hose reel, hydraulically operated with freewheel system

• Powder coated steel frame

SAFETY

• Run dry protection with override ability

• Automatic engine shutdown protection for high water temperature, engine temperature, low engine oil, or low engine coolant

• Electric reel latching mechanism for easy pivoting and safety

5

Description—Components

15

20

3

2

14

1

22

27

9

19

10

13

12

11

8

16

1. High-pressure hose on reel

2. Supply hose on reel

3. Supply hose valve

4. eController

5. Hose holder

6. Hose guide

7. High-pressure (HP) valve

8. Supply pipe

9. Water lter

10. Drain valve

6

11. Pressure regulator

12. Pressure gauge

13. Supply hose holder

14. Pivot Locking Device

15. Supply hose reel lock

16. Water lter valve

17. HP pump

18. Hydraulic oil reservoir

19. Pulsator valve

20. Water tank level indicator

21. Water tank

22. Fuel tank

23. Engine

24. Battery

25. ECM (Engine Control Module)

26. Hydraulic Hose Reel Speed

Control

27. Nozzle holders

28. Catalytic converter

Description—Components

21

4

20

22

5

1

14

9

2

12

11

8

19

1. High-pressure hose on reel

2. Supply hose on reel

3. Supply hose valve

4. eController

5. Hose holder

6. Hose guide

7. High-pressure (HP) valve

8. Supply pipe

9. Water lter

10. Drain valve

27

11. Pressure regulator

12. Pressure gauge

13. Supply hose holder

14. Pivot Locking Device

15. Supply hose reel lock

16. Water lter valve

17. HP pump

18. Hydraulic oil reservoir

19. Pulsator valve

20. Water tank level indicator

16

10

21. Water tank

22. Fuel tank

23. Engine

24. Battery

25. ECM (Engine Control Module)

26. Hydraulic Hose Reel Speed

Control

27. Nozzle holders

28. Catalytic converter

7

Description—Components

15

21

25

22

24

27

3

7

26

6

12

18

11

17

8

19

9

16

10

1. High-pressure hose on reel

2. Supply hose on reel

3. Supply hose valve

4. eController

5. Hose holder

6. Hose guide

7. High-pressure (HP) valve

8. Supply pipe

9. Water lter

10. Drain valve

8

11. Pressure regulator

12. Pressure gauge

13. Supply hose holder

14. Pivot Locking Device

15. Supply hose reel lock

16. Water lter valve

17. HP pump

18. Hydraulic oil reservoir

19. Pulsator valve

20. Water tank level indicator

21. Water tank

22. Fuel tank

23. Engine

24. Battery

25. ECM (Engine Control Module)

26. Hydraulic Hose Reel Speed

Control

27. Nozzle holders

28. Catalytic converter

1

Description—Components

27

9

19

12

11

13

8

2

21

23

10

16

1. High-pressure hose on reel

2. Supply hose on reel

3. Supply hose valve

4. eController

5. Hose holder

6. Hose guide

7. High-pressure (HP) valve

8. Supply pipe

9. Water lter

10. Drain valve

11. Pressure regulator

12. Pressure gauge

13. Supply hose holder

14. Pivot Locking Device

15. Supply hose reel lock

16. Water filter valve

17. HP pump

18. Hydraulic oil reservoir

19. Pulsator valve

20. Water tank level indicator

28

21. Water tank

22. Fuel tank

23. Engine

24. Battery

25. ECM (Engine Control Module)

26. Hydraulic Hose Reel Speed

Control

27. Nozzle holders

28. Catalytic converter

9

Description—Components

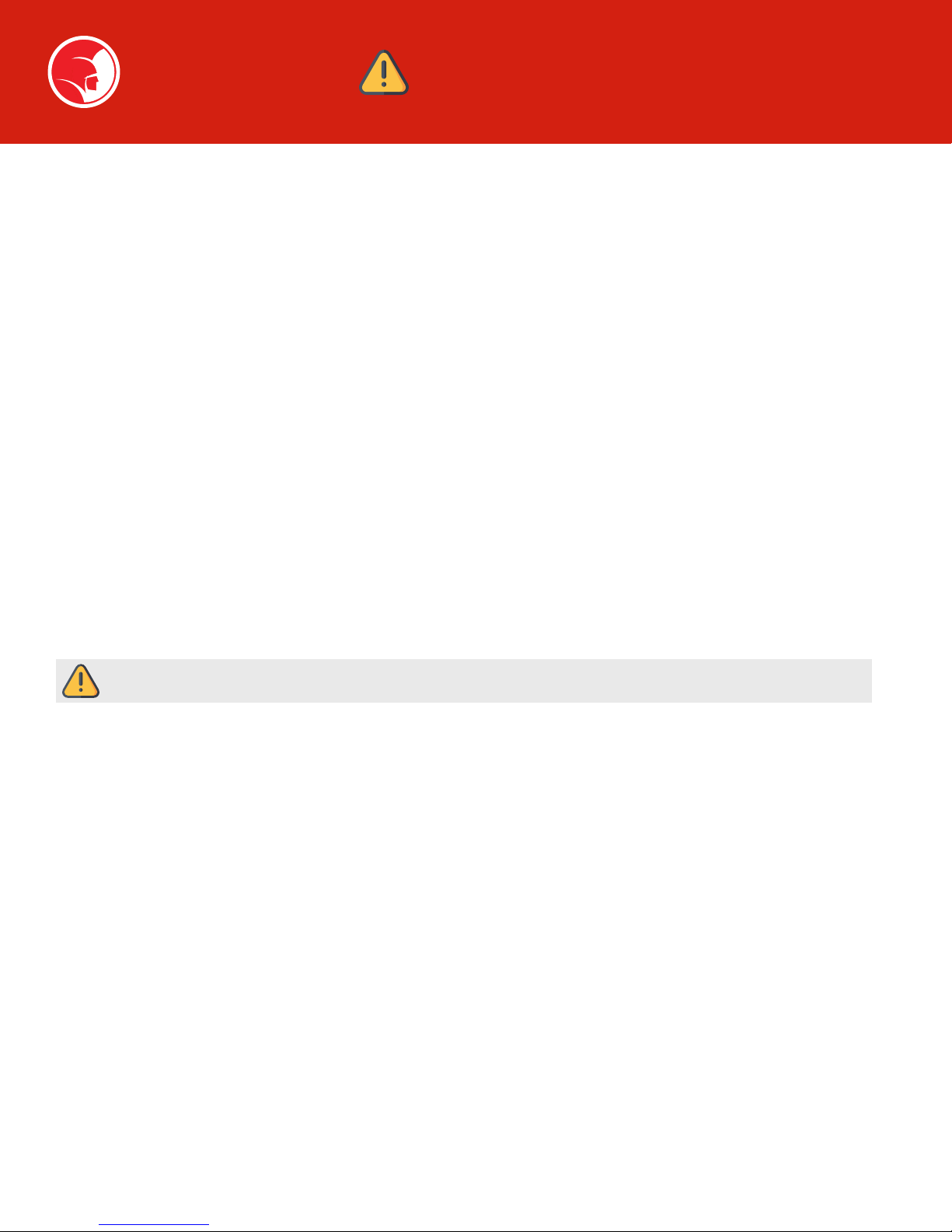

CONTROLS AND INDICATIONS

Corona

Function icon

Navigation bullets

Pointer

Engine LED

Engine On button

Navigator dial

Vacuum LED

Emergency stop

Tachometer

High pressure spray LED

High pressure spray button

Vacuum button

Key switch

(o / manual / Riomote)

10

Description—Controls

ECONTROLLER FUNCTIONS

Spartan Tool provides several options on the Urban Warrior skid mount sewer jetter. As a result, there are multiple eControl

configurations to accommodate the features available on any particular unit.

This section of the manual will cover available functions of the Two Function eController and the Three Function eController.

The two figures below identify the Two Function and Three Function eController.

2 FUNCTION ECONTROLLER

The two function remote is identified by the two

blue function indicators at the top of the LCD

display.

The two functions are:

• Home function

• Maintenance function

3 FUNCTION ECONTROLLER

The three function remote is identified by the three

blue function indicators at the top of the LCD

display.

The three functions are:

• Home function

• HP hose reel control

• Management function

11

Description—Controls

The Corona on the eController is normally off (gray).

CORONA DISPLAY

Blue corona indicates

set to Riomote Control

Red corona indicates

eController error

See page 27 (eController

Errors) for alarm functions

PUSH BUTTONS AND INDICATING LIGHTS

The Engine On light/button indicates the status and

controls the starting of the engine. (See page 19, Starting

the Engine, for more information.)

The High Pressure Spray light/button indicates the status

and controls the high pressure spray valve. (See page 24,

Cleaning a Drain Line, for more information.)

The Blue LED above each button will blink when the

corresponding function is available. (The engine is ready to start or

high pressure spray is available.)

The Blue LED above each button will light solid when the

corresponding function is active. (The engine is running or the high

pressure spray valve is open.)

Orange corona indicates

pre-start functions or

one of two error conditions:

• Run dry (no water

in tank)

• Error oil level

Insert key

Position 1

(manual control)

Position 2

(remote control)

12

Description—Controls

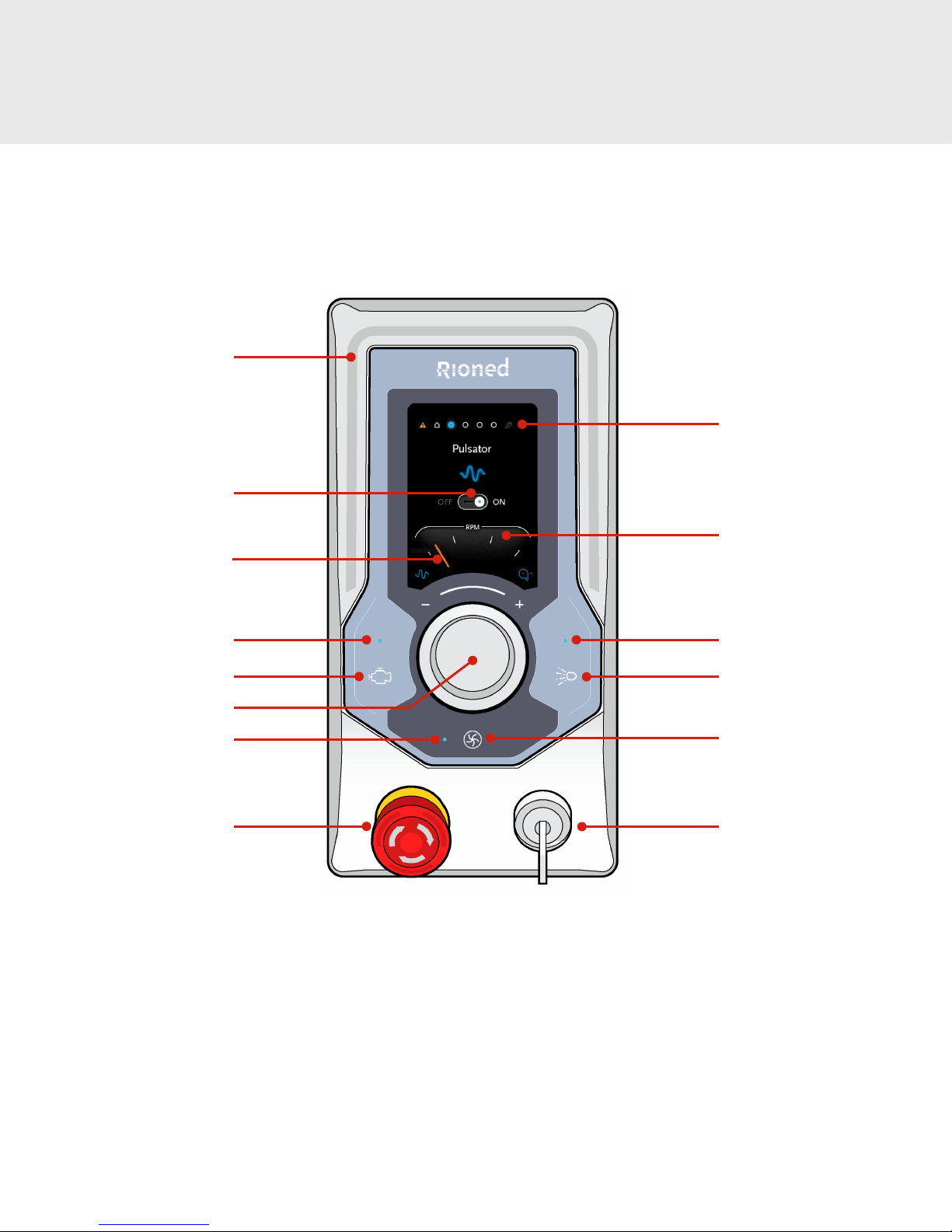

NAVIGATION BULLETS

The navigation bullets have two general states: Passive (gray) Active (blue)

Depending on the user’s location in the menu, one bullet is on display, or in the case of a pop-up eController error, all navigation bullets

disappear. (See page 27, eController Errors, for a list of pop-up displays.)

Features in navigation bullets are in specified order, if applicable:

Home

Error

Management

HP Hose

Reel

ECONTROLLER FUNCTIONS

HP Hose Reel Mode

When the eController is set to HP Hose Reel the LCD displays the

hose position and the up/down control positions. The hose reel is

actuated by rotating the Navigator dial clockwise to select down and

counter clockwise to select up. Depress the Navigator dial to select

the action.

The speed of the hydraulic drive using the eController is controlled

by adjusting the speed control unit which throttles the hydraulic flow

to the reel drive hydraulic motor. (See page 21, Rewind Hose Using

Hydraulic Reel.)

The Error navigation icon is only visible and can

be navigated when an error is applicable.

The Home navigation icon is the default position

and normally displays engine run time and HP

hose counter.

Hydraulic Speed Control

Management Mode

When the eController is set to Management Mode, the LCD displays a menu of three functions that can

be selected by rotating the Navigator dial and activated by depressing the navigation knob.

• Software Version displays the current version of the controller software.

• Service Interval displays the days and run hours until maintenance is required.

• Hose Counter displays the length of hose off the HP hose reel.

13

Description—Controls

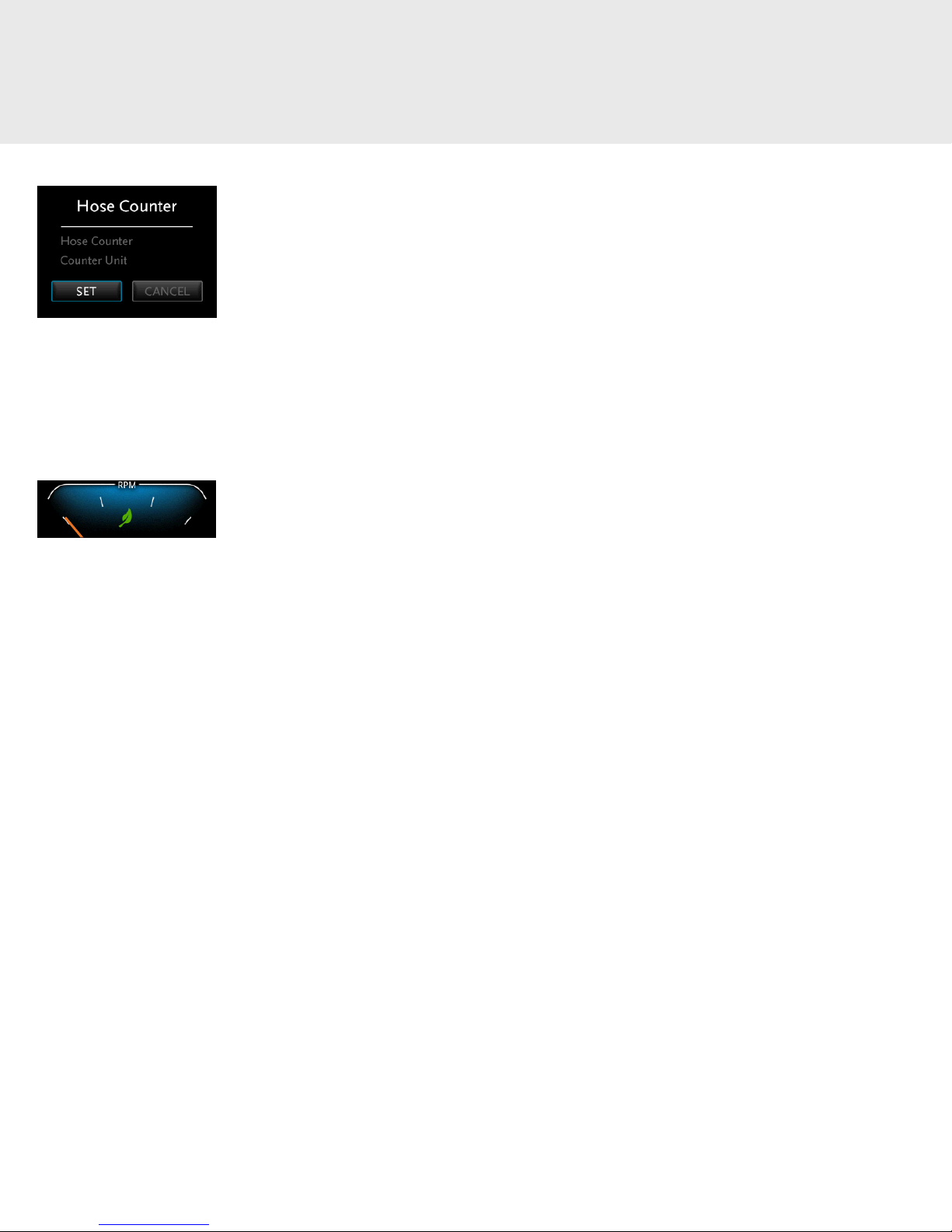

Hose Counter (if equipped)

When the eController is set to Hose Counter mode, the LCD displays a menu of two functions that can

be selected by rotating the Navigator dial and activated by depressing the navigation knob.

• Hose Counter allows the user to select on or off.

• Counter Unit allows the user to select meters or feet.

Tachometer

The pointer indicates the engine’s current RPM.

14

REMOTE CONTROL

Hand-Held Remote Sender

Description—Controls

Hose UP/DOWN

(9-channel option)

Engine speed SLOW

Spray valve OFF

Engine OFF

Battery indication

Emergency stop

Engine speed FAST

Spray valve ON

Engine START

Remote pairing

The Riomote® radio remote control consists of a large waterproof and shockproof hand-held

sender and a unit-mounted receiver. The system is provided with separate batteries (8 hours per

charge) and is supplied with a battery charger. The Riomote® radio remote control is available in

7-channel and 9-channel models dependent on the functions available on the eController.

UNIT-MOUNTED RECEIVER

15

Safety Instructions

WARNING: Read the Operator’s Manual thoroughly before using any Spartan Tool product.

Drain and sewer cleaning can be dangerous if proper procedures are not followed. Know the proper

operation, correct applications for your Spartan Tool products

EMERGENCY STOP

This machine is equipped with an Emergency Stop. By operating the Emergency Stop, the machine will shut down. Do not use this

button for normal stopping. Only use it when dangerous situations occur. After use, remove the danger and then rotate the Emergency

Stop button clockwise to be able to start up again. Ensure the Emergency Stop can always be reached.

PRESSURE REGULATOR

The Pressure Regulator functions to ensure that the working pressure never gets too high. It functions like a safety valve, relieving

water to the storage tank to reduce pressure in the HP hose line.

PERSONAL PROTECTIVE EQUIPMENT

The following personal protective equipment should be worn by personnel operating or working with the Urban Warrior:

• Ear protection

• Protective safety glasses or goggles

• Gloves (recommended)

• Waterproof work clothing (recommended)

• Spray boots for use with the spray gun (recommended)

WORK AREA

The following precautions must be observed when establishing a work area for use of the Urban Warrior:

• Clearly mark the work area.

• Maintain a minimum distance of 20 feet from the work area.

• Remove all loose materials from inside the work area.

• Never spray from an unstable surface (ladder, boat, scaffold, etc.).

• Never use in a confined space (closed room).

• Ensure there are no combustible materials in the area.

• The area must be adequately ventilated to prevent accumulation of carbon monoxide.

• DO NOT use corrosive chemicals in conjunction with Spartan Tool sewer jetters. Only environmentally-approved chemicals should

be introduced into drain lines.

16

Safety Instructions

GENERAL PRECAUTIONS

• Do not let the machine operate without supervision.

• Keep children and animals away from the machine.

• DO NOT spray on humans or animals. If the skin is penetrated, immediately seek medical attention.

• Prevent damage from debris or flying parts.

• Avoid spraying near electrical connections and other electric components if you are cleaning with a spray gun.

• Never block the controls in any way.

• Put personal protective equipment on BEFORE you start the machine.

• Ensure that the spray nozzle does not leave the drain.

SAFETY STICKERS

1. Safety glasses, hard hats , and hearing protection are required

2. Safety shoes are required

3. Be familiar with the user’s manual

4. Hand protection is required

5. Wear protective clothing against caustic material

6. No eating or drinking

7. Slipping hazard

8. Pinching hazard (hand injury)

9. Rotating machinery

10. Warning, machine auto start

17

Important Symbols

PRESSURE GAUGE

Operating Zone Danger Zone

The mechanical relief in the

unloader valve will prevent

pressure from exceeding

3000 PSI.

WARNING If the unit fails to maintain pressure within the operating zone, contact Spartan Tool

Customer Service at 800.435.3866 or by email at CustomerService@SpartanTool.com.

18

Mechanical Operation

CHECK BEFORE DEPARTURE

Before you drive away with the vehicle, check the following:

1. The high-pressure hose has been inserted into the hose holder (5) and secured with

the locking pin.

2. The high-pressure hose reel is locked with the clutch engaged (30) (see page 21)

and the manual hydraulic hose reel control lever is in the neutral position, or the

eController is not in Hose Reel mode. (See page 21, Hydraulic Hose Reel Control, for

more information.) The HP reel swing arm is locked in place with latch.

3. The supply hose is connected to the supply hose holder (19). The supply hose reel is

locked by means of the reel locking device (15).

4. If temperatures are below freezing, the water tank should be emptied and the piping

system drained and flushed with antifreeze. (See page 25, Cold Weather Operation, for

more information.)

5. The vehicle is now ready for departure.

PLACEMENT OF URBAN WARRIOR

1. Put the vehicle at the desired location and set the parking brake.

2. Block the tires if using on an incline or uneven surface.

3. Mark the working area by establishing barriers to prevent inadvertent access to the

work area.

PRIOR TO STARTING THE URBAN WARRIOR

5

15

19

1. Ensure there is adequate fuel in the fuel tank (22) for the intended task.

2. Ensure the water filter (9) is clean. Clean the filter, if necessary.

3. Check that the supply valve (16) to the water filter is open.

4. Check that the high-pressure valve (7) at the HP hose reel is closed.

5. Fill the water tank via the supply pipe (8) or the supply hose.

(The maximum water temperature is 55°C.)

6. Loosen the control wheel of the pressure regulator (11) (rotate

counter-clockwise).

7. Attach the jetting

nozzle onto the

high-pressure hose.

7

22

11

9

8

16

19

Mechanical Operation

STARTING THE ENGINE

IMPORTANT! The machine is equipped with an Emergency Stop. By

operating this Stop, the machine will shut down. Do not use this button for

normal stopping. Only use when dangerous situations occur. After use, rotate the

Emergency Stop clockwise to be able to start again. Make sure the Emergency

Stop can always be reached.

CAUTION! Put on protective safety goggles and ear protection

before starting the machine.

1. Put the key in the eController key switch.

2. Turn the key clockwise to position 1, Manual Control on.

• Work Safe is displayed for 2 seconds.

• Icon Manual Control on is displayed for 2 seconds.

• Then the main menu is displayed.

3. Check the Error icon.

• If the error icon is visible, then check the eController Error

icon. (See page 27 for a description of eController Errors.)

20

Mechanical Operation

38

39

4. If the error icon is not visible, depress the Engine On button for two seconds.

• After 5 seconds, the engine starts.

• With the engine running, the blue Engine LED light (38) and the Engine On light (39) is

displayed for 2 seconds.

• The main menu on the eController is displayed after 5 seconds.

5. Increase (clockwise) or decrease (counter clockwise) RPM by turning the Navigator dial.

6. Depress the Navigator dial to display the Navigation Bullet menu.

• Let the engine warm up. After 3 minutes, the machine is ready for use.

• Press the Engine On button (39) to adjust RPMs with the Navigator dial.

ELECTRIC HOSE REEL PIVOT

LOCKING DEVICE

There are two locking mechanisms associated with the high

pressure hose reel arm.

1. Electric Push Button

2. Manual Pull Cable

1

2

21

Mechanical Operation

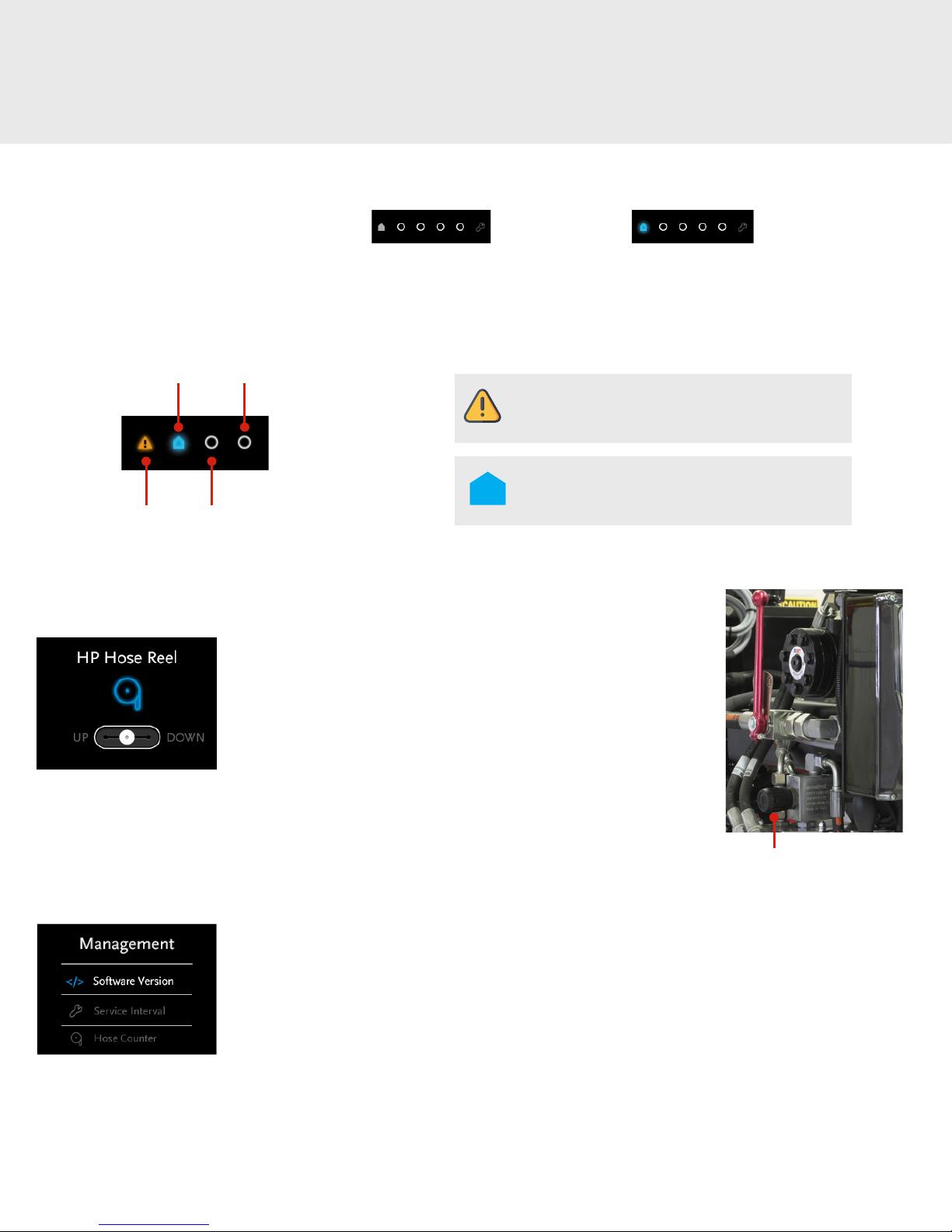

HYDRAULIC REEL CONTROL

The hydraulic control lever is spring loaded to default to the Neutral

Position (A) where the hose reel is locked by the hydraulic actuator.

• Pushing the control lever up (position B) will actuate the hydraulic

motor to wind the hose onto the reel.

• Pushing the control lever down (position C) will actuate the hydraulic

motor to unwind the hose off the reel.

• Due to the proportional functioning of this valve you can control the

speed of the reel by movement of the lever away from the center

position (A).

• Pushing the control level into position D, (a maintaining position) will

allow the hose reel to move without the aid of the hydraulic motor. This

allows the hose to unwind as the high pressure hose nozzle works its

way through a drain line.

A clutch assembly (30) on the HP hose reel drive unit can be disengaged to

allow the hose reel to free wheel for pulling the hose off the reel manually.

The hydraulic speed control knob (26) can be adjusted to control

the range of speed when using the hydraulic reel control lever. (This feature

is only available on model equipped with the 9-channel remote.)

(if equipped)

26

9-channel remote

30

For 5-channel remote with

WARNING! Never block the Hydraulic Hose Reel lever and always control it with one hand while

guiding the high-pressure hose by means of the hose guide.

HIGH PRESSURE HOSE GUIDE

The purpose of the High-Pressure Hose Guide (6) is to guide the HP hose

onto and off of the hose reel.

• Put the end of the HP hose through the opening of the hose guide (6).

• Moving the hose guide right and left guides the hose evenly on the

hose reel.

manual hydraulic valve

D

B

A

C

6

22

eController Operation

MANAGEMENT MODE

Management Mode functions to display the current software version, required service intervals, and the

hose reel counter.

1. Rotate the Navigator dial to set the navigation bullet to the last position, Management.

2. Depress the Navigator dial to activate the Management function.

• The Navigation bullet extinguishes.

• The Management underline illuminates.

3. Once the Management function is activated, the three menu options are displayed which include:

Software version, Service interval and Hose counter.

4. Each menu item can be displayed by selecting the item with the Navigator dial and depressing the dial

to activate the selection.

23

Riomote® Control Operation

RIOMOTE® CONTROL

The Riomote® remote control provides the ability to operate the high pressure machine jetter from a

distance. There are multiple versions of the remote control based on the available functions of the machine.

Corona

EMERGENCY STOP TEST

Check that the emergency stop works before working with

the Riomote® control. Proceed as follows:

1. Insert the key into the eController key switch.

2. Turn the key to position 2, Remote Control on.

• Work Safe is displayed for 2 seconds.

• Riomote® Control on is displayed continuously.

• Corona illuminates blue and is blinking.

3. Switch the Riomote® control on.

• Press and hold the Start button on the Riomote® to

link the Riomote® with the Urban Warrior.

• Release the Start button when the blue corona

stops blinking.

• Corona illuminates continuous blue when the

Riomote® control is in contact with the receiver.

4. Start the engine using Engine Start button on the

Riomote® control.

5. Depress the Stop button to exercise the Emergency

Stop function.

BATTERY INDICATION

If the Battery indicator on the Riomote control lights

continuously, the battery must be recharged.

NOTE! The engine will

shut down if the remote is

out of range or the battery

loses charge.

Battery

indicator

eController

key switch

1

2

Emergency stop

Engine start

Start

NOTE! If the engine does NOT stop by using the Riomote® control, contact Spartan Tool

Customer Service.

24

Operating Instructions

CLEANING A DRAIN LINE

1. Attach a suitable nozzle onto the high-pressure hose.

2. With the hose reel out of gear (Position D, page 21), pull the hose through the hose

guide (6) to facilitate guiding the hose.

3. The hose can be unwound short distances with the hydraulic hose reel out of gear.

4. Put the nozzle into the drain to be cleaned (a minimum of 6 feet).

5. Rotate the pressure regulator (11) clockwise to increase pressure to the desired

value on the pressure gauge (12).

6. Open the high-pressure valve (7).

7. Depress the high pressure on button

(35).

• Water begins spraying out of the

nozzle at the end of the hose.

• High pressure LED (33) lights blue.

• High Pressure On is displayed on the

eController screen for 2 seconds.

• After 5 seconds, Main Menu is

displayed on the eController screen.

12

11

8. Increase or decrease engine RPM by

turning the Navigator dial.

9. The hose will now unwind and work its

way into the drain line.

10. When possible, jet the drain line from

the low end to the high end of the pipe.

6

7

11. Check for water draining away as an

indication that the blockage has been

cleared in the drain line.

12. When the blockage has been cleared,

continue to flush the pipe while

rewinding the high-pressure hose.

33

35

Navigator dial

25

Operating Instructions

ATTENTION! Ensure that the spraying nozzle does not leave the drain while spraying.

Water under high pressure may cause severe injury.

STOP SPRAYING

Depress the high pressure button (35) to shut the high pressure valve.

• The high pressure LED (33) extinguishes.

• High Pressure O appears on the eController display for 2 seconds.

• Water spray at hose nozzle stops.

• Engine RPM decreases.

• Close the high pressure valve (7).

33

35

CARE OF THE HP HOSE

• Always clean the hose after use.

• Ensure there are no sharp objects near the hose.

• Ensure vehicles do not cross over the hose.

IMPORTANT! Rewind hose onto reel under pressure to avoid crushing. If machine has run out

of water, ensure hose is unwound before pressurizing.

COLD WEATHER OPERATION

Your high-pressure device may freeze up in cold weather and temperatures below 32°F. A number of safety precautions must be taken.

Additional preparations before departure:

1. Drain the water tank by opening the drain valve.

2. When all the water has been removed or drained, remove the water filter.

3. Clean the filter and mount it in opposite order.

4. Close the drain valve.

5. Remove the nozzle/gun from the HP hose.

6. Antifreeze unit with optional Antifreeze System.

26

CLEANING A WALL, TERRACE, OR FLOOR

CAUTION! Before using a spray gun, set the jetter pressure below the maximum spray gun

pressure (+/- half the maximum spray gun pressure). Do this prior to starting the engine. Once the

engine is running, jetter pressure can be increased by turning the HP regulator handwheel to the

working pressure. DO NOT exceed the green band pressure on the pressure gauge.

1. Attach the spray gun (B) onto the high-pressure hose.

2. Disengage the clutch and completely unroll the high pressure hose.

3. Attach the spray lance gun (C), securing the quick coupling tightly.

4. Open the manual HP valve (7).

Operating Instructions

7

5. Depress the High Pressure On button.

6. Throttle up the engine speed by rotating the Navigator dial clockwise.

7. Rotate the pressure regulator hand wheel (11) clockwise until the desired

operating pressure is reached when the spray gun is open.

11

SECURE AFTER HIGH-PRESSURE CLEANING

1. Depress the high pressure button (35) to shut the high-pressure valve and throttle

down the engine.

2. Close the manual high pressure valve (7).

B C

34

35

3. Depress the Engine On button (34) for more than 1 second to stop the engine.

4. Rewind the hose.

IMPORTANT! Rewind hose onto reel under pressure to avoid crushing. If machine has run out

of water, ensure hose is unwound before pressurizing.

27

eController Errors

EMERGENCY STOP

1. The Emergency Stop icon illuminates on the eController when the Emergency Stop

button is depressed.

• Engine stops

• High pressure valve closes

• Pulsator valve closes (if equipped)

• Hose reel switches off

2. Operation can only be restarted after rotating the Emergency Stop button to release it.

ENGINE TEMPERATURE

1. The Engine Temperature icon illuminates when high engine temperature is detected

(240° F).

• Engine stops

• High pressure valve closes

• Pulsator valve closes (if equipped)

• Hose reel switches off

2. The operator can acknowledge the alarm display by depressing the Navigator dial in

Manual Mode.

3. Operation can only resume after engine temperature has cooled to clear the alarm.

HEAT EXCHANGER HIGH TEMPERATURE

1. The Heat Exchanger High Temperature icon illuminates when high temperature is

detected.

• Engine stops

• High pressure valve closes

• Pulsator valve closes (if equipped)

• Hose reel switches off

28

2. The operator can acknowledge the alarm display by depressing the Navigator dial in

Manual Mode.

3. Operation can only resume after heat exchanger temperature has cooled.

eController Errors

HYDRAULIC OIL HIGH TEMPERATURE

1. The Hydraulic Oil Temperature icon illuminates when high hydraulic oil temperature

is detected.

• Engine stops

• High pressure valve closes

• Pulsator valve closes (if equipped)

• Hose reel switches off

2. The operator can acknowledge the alarm display by depressing the Navigator dial in

Manual Mode.

3. Operation can only resume after the hydraulic oil temperature has cooled.

OIL LEVEL

1. The Oil Level icon illuminates when low engine oil level is detected.

• Engine stops

• High pressure valve closes

• Pulsator valve closes (if equipped)

• Hose reel switches off

2. The operator can override the alarm display by depressing the Navigator dial in Manual

Mode and continue operation.

COOLANT LEVEL

1. The Coolant Level icon illuminates when low engine coolant level is detected.

• Engine stops

• High pressure valve closes

• Pulsator valve closes (if equipped)

• Hose reel switches off

2. The operator can acknowledge the alarm display by depressing the Navigator dial in

Manual Mode.

3. The operator must refill the coolant level in order to restart the engine.

29

eController Errors

BATTERY CHARGE

1. The Battery Charge icon illuminates when low battery voltage is detected.

• Engine stops

• High pressure valve closes

• Pulsator valve closes (if equipped)

• Hose reel switches off

2. The operator can override the alarm display by depressing the Navigator dial in Manual

Mode and continue operation.

RUN DRY

1. The Run Dry icon illuminates when low level is detected in the water tanks.

• Engine stops

• High pressure valve closes

• Pulsator valve closes (if equipped)

• Hose reel switches off

2. The operator can override the alarm display by depressing the

Navigator dial in Manual Mode and continue operation.

3. The High-Pressure LED starts blinking when the run dry is active.

The override remains active as long as the Navigator dial is depressed.

SERVICE INTERVAL

1. The Service Interval icon illuminates when any of the maintenance intervals have

been exceeded. The error is also listed under the Management function on the

eController.

• Engine stops

• High pressure valve closes

• Pulsator valve closes (if equipped)

• Hose reel switches off

30

2. After running 360 days or 250 hours (whichever comes first), the error message is

displayed.

3. The operator can override the message by depressing the Navigator dial in Manual

Mode.

4. The message will reappear the next time the machine is started.

Maintenance

CAUTION! Always stop the engine first and depressurize the system before servicing or

repairing the machine. To depressurize the system, open the manual HP valve. If the spray gun is

attached, you must also pull the trigger to release the pressure.

DAILY MAINTENANCE

Check Oil Levels

• Check all oil levels once a week (engine oil, HP water pump oil, hydraulic oil).

• Add oil if necessary (see page "MOTOR" on page 35, Technical Specications, Motor).

• If oil level has dropped, this implies a leak in the system. In this case, check all gaskets, couplings, and hydraulic hoses in

the system.

• Immediately repair damage and fill the system with the correct oil.

NOTE! During the break-in period, oil consumption may be greater than usual.

Engine Oil Hydraulic Oil HP Water Pump Oil

Clean the Water Filter

1. Close the water lter valve (16).

2. Unscrew the cap from the lter piece (9).

3. Clean the filter and associated parts. After cleaning, assemble

the parts in reverse order.

9

4. Open the water lter valve (16).

5. Check for leakage.

16

31

Maintenance

MINOR SERVICE

Minor service must be carried out every 250 working hours (or at least once every 6 months) and includes the following parts of

the machine:

1. Drive and Engine

• Change the oil in the engine.

• Replace the oil filter.

• Clean the air filter.

• Replace the fuel filter.

• Check tension of the V-belt and increase tension if necessary.

• Check the condition of the battery.

• Check the torque of attachment bolts for the engine and tighten as necessary.

2. Carriage

• Lubricate all mechanical moving parts in the system. Check that all nuts and bolts have been correctly tightened.

3. Pump system

a. Cleaning the high-pressure control system:

• With the manual high-pressure valve closed, the pressure gauge should NOT indicate any pressure due to recirculation

through the unloader valve.

• If the spray gun is connected and closed, the pressure gauge should NOT indicate any pressure due to recirculation through

the unloader valve.

• If the pressure gauge does indicate a pressure, this implies a leakage in the system or the pop-off valve on the unloader valve

may be dirty or damaged. (Contact Spartan Tool Customer Service for assistance.)

• If leakage is suspected, stop the machine, unscrew the hose coupling and clean or replace the pop-off valve on the unloader.

Also, check the condition of the O-ring and gasket. (Contact Spartan Tool Customer Service for assistance.)

b. Regularly clean the high-pressure control system:

• Carefully remove all dirt.

• Proper maintenance will increase the service life of this part.

c. Changing the pump oil:

• Change the pump oil in the high-pressure pump after every 500 working hours (or at least once a year).

32

HYDRAULIC SYSTEM

IMPORTANT! Renew the hydraulic oil at least once a year!

1. Replace the hydraulic fluid in the reel drive system.

2. Check hydraulic oil level before each use. If level is not sufficient proceed as follows:

a. Stop the machine.

b. Ensure the unit is on a level surface.

c. Remove the dipstick (A) from the oil tank (B).

d. Clean the dipstick with a lint-free rag.

e. Put the dipstick back into the oil tank.

f. Remove the dipstick and check the oil on the dipstick is between maximum and minimum (C).

g. Fill oil, if necessary.

h. Return and tighten the dipstick to the oil tank.

Maintenance

A

B

Maximum

Minimum

D

To let the oil out of the reservoir, unscrew the drain plug (D) and catch the oil in a drain pan.

C

B

D

A

33

Maintenance

EXTENSIVE PERIODIC MAINTENANCE

Have the high-pressure machine checked and maintained on a regular basis by a Spartan Tool technician.

MAINTENANCE SCHEDULE

Check oil levels Before each use

Clean water filter Before each use

Clean carriage Weekly

Service engine Every 250 working hours or at least once every 6 months

Lubricate moving parts Every 250 working hours or at least once every 6 months

Clean pressure regulator Every 250 working hours or at least once every 6 months

Renew pump oil Every 500 working hours or once a year

Renew oil hydraulic system Once a year

Decalcify suction valves Once a year

Decalcify pressure valves Once a year

Puncture nozzle holes Before each use

Replace parts immediately if there is wear or defect.

34

Technical Specifications

GENERAL SPECIFICATIONS

Description Unit

Dimensions See "Appendix B, Machine Dimensions" on page 40

Water tank capacity ~80 gal. per tank

Fill medium Water (H20) maximum

Temperature medium 132° F

Total length of high-pressure hose ~360 ft.

Diameter of high-pressure hose ½" (NW13)

Total length of supply hose 115 ft.

Diameter of supply hose ¾" (NW19)

Hydraulic oil type Hestia 46 (Replace once a year)

Hydraulic oil tank capacity 5 liters

Maximum hydraulic temperature 80° C

Pressure regulator ULH 262-2H

Year of construction See name plate on frame

MOTOR

Description Unit

Type Kubota WG1605

Number of cylinders 4

Power 37 kW (50 HP)

Fuel Unleaded Gasoline

Fuel tank ~8 gal.

Cooling Water cooled via heat exchanger

Weight 270 lbs.

Battery 45AH 300A

Engine oil 10W30 API/SF-CC or better

Engine oil capacity 1.59 gal.

Normal coolant—engine is protected to -18° F.

Special coolant—engine is protected to -36° F.

35

Technical Specications

PUMP

Description Unit

Type Speck P52

Maximum pressure See name plate on frame

Maximum output See name plate on frame

Weight 120 lbs.

Maximum water temperature 60° C / 140° F

Gear oil GX 80W90

Gear oil capacity 118 fl. oz.

36

Troubleshooting

FAILURE REASON SOLUTION

Machine has run out of fuel. Add fuel.

Replace the defective fuse and restart

Main or secondary fuse blown.

Battery voltage too low. Charge or replace the battery.

engine. If problem repeats, contact

Spartan Tool Customer Service.

Engine does not start or stops abruptly.

The high-pressure pump does not

produce the required pressure.

Emergency stop activated.

Insufficient level in the water tank (for

cooling system).

Engine coolant level low.

Temperature of engine coolant too high. Let the machine cool down.

Water tank empty. Fill the water tank.

Supply valve to water filter closed. Open the supply valve.

Water filter clogged.

Air in the high-pressure pump.

Suction valves blocked.

V-belt not sufficiently tightened. Tighten the V-belt; replace if necessary.

Suction valves worn out. Contact Spartan Tool Customer Service.

Water level in tank too low.

Water supply valve not sufficiently

opened.

Rotate the emergency stop button in

order to be able to start up again.

Fill the water tank and let the machine

cool down. When cooled, the machine can

be started again.

Fill the cooling system at the expansion

tank.

Stop the machine and clean the water

filter.

Allow the machine to run a few minutes.

The failure will normally disappear. If not,

contact Spartan Tool Customer Service.

Carefully loosen the valves and de-scale

them, if necessary.

Stop the engine, refill the tank and restart

engine.

Open the supply valve completely.

Pressure varies.

Water filter clogged. Stop the machine and clean the filter.

Pump sucks air.

Nozzle clogged.

Pressure valves dirty or worn.

Pump gasket worn out. Stop the machine and replace gasket.

Pump v-belts slip. Stop the machine and tighten the belts.

Ceramic plungers in the pump damaged. Contact Spartan Tool Customer Service.

Pressure control clogged or internally

damaged.

Stop the machine and check all hoses and

couplings for leakage.

Stop the machine and clean the nozzle

(clean the nozzle holes).

Stop the machine. Check the condition

of the pressure valves. Clean or replace

them.

Contact Spartan Tool Customer Service.

37

Troubleshooting

FAILURE REASON SOLUTION

Handle in wrong position. Put the handle into the correct position.

Hydraulic tank almost empty.

Attachment bolt for control lever of

Hydraulic reel does not wind the hose.

No reaction from the Riomote controller.

Warning signal after short working time. Battery discharged / defective.

hydraulic system is loose.

Working pressure set too low. Increase the working pressure, if possible.

Hydraulic tank return filter dirty.

Hydraulic system damaged. Contact Spartan Tool Customer Service.

No current.

Transmitter is not on.

Transmitter out of reach from receiver.

Refill the tank. Check the system for

leakage.

Fasten the bolt and put the lever into the

correct position.

Switch off the machine and clean the

return filter.

Recharge the battery.

Use new battery.

Contact points are dirty.

Check fuses.

Contact Spartan Tool Customer Service if

problem is frequent or ongoing.

Activate the transmitter (link to the

receiver).

Put the machines closer together. Move

transmitter closer.

Charge or replace the Riomote® battery.

Check the terminal connections.

Transmitter indications are good but

functions are not executed.

Certain functions are not executed.

Emergency stop pushed in. Unlock emergency stop.

Receiver has no current. Check / replace fuses.

No radio connection. Check functions of control lights.

Receiver is faulty. Contact Spartan Tool Customer Service.

Interruption in electric current.

Check all plugs. Plug in and push. Check

control lights if functions are indicated.

38

APPENDIX A

Engine Control Module

The Engine Control Module (ECM) consists of two major functions.

The function of the Engine Safety Protection Panel is to monitor engine parameters to alert the operator to any abnormal conditions

requiring attention as well as any operating limits that may be exceeded requiring the machine to be immediately shut down. Once the

engine is started, the ECM has primary control of the engine providing prealarms, alarms and safety shutdowns.

This attachment provides the operator with information necessary to understand the operation of the Engine Safety Precautions Panel.

The diagram below identies the indications available on the Engine Safety Protection Panel which will be explained on the

subsequent pages.

INDICATOR LAMPS AND ENGINE CONTROL UNIT INDICATIONS

Coolant

Temperature

Battery

Voltage

Fuel rate

Menu Enter

Engine

Fault

Lamp

Engine

Alarm

Lamp

Engine

RPM

Air Intake

Temp

Total

Hours

Throttle

Up

Throttle

Down

39

APPENDIX B

A-A ( 1 : 10 )

A A

2

3

4

5

6

7

94 0

1

40

1

40

80

8

0

68 2

5

0

6

1

2

11 2

9

66

0

279 381

1866

589

1277

1194

1240

1338

Machine Dimensions

40

APPENDIX C

Accessories

Part Number Description Qty.

79824700 Open Nozzle 1

79824600 Closed Nozzle 1

77799800 Handgun Assembly 1

77800600 Hose Guard Assembly, 2" 1

79873500 Anti-Turnaround Pipe Assembly 1

75729115 7-Channel Riomote® Control 1

75729145 9-Channel Riomote® Control 1

75729146 Riomote® Battery Charger 1

75729116 Riomote® Battery 1

75728000 Urban Series Antifreeze System 1

75729130 1/2" x 360' Maxflow Hose 1

75729120 HP Hose Reel Swivel Seal 1

75729105 HP 3-Way Ball Valve 1

41

Notes

YOUR URBAN WARRIOR

Unit Serial Number

Engine Serial Number Pump Serial Number

42

Notes

43

FOR T OUGH CUSTOMERS.

SINCE 1943

CONTACT US

Spartan Tool LLC

1506 West Division Street

Mendota, IL 61342

800.435.3866

SpartanTool.com

75720010MAN-1810

Loading...

Loading...