Spark modern fires LBS-OD 60-NG, LBS-OD 96-LP, LBS-OD 48-LP, LBS-OD 48-NG, LBS-OD 36-LP Owner's Operation And Installation Manual

...

S P A R K M O D E R N F I R E

S

LINEAR BURNER SYSTEM OUTDOOR

NATURAL GAS / PROPANE

OWNER’S OPERAT I O N AN D IN S T A L L A T IO N MAN UA L

We recommend that our products be installed

and serviced by professionals who are certified

in the U.S. by NFI (National Fireplace Institute).

Complies with

WARNING

or any other appliance.

shall not be stored in the vicinity of this

An LP-cylinder not connected for use

flammable vapors and liquids in the

Do not store or use gasoline or other

vicinity of this or any other appliance.

WARNING

Read the installation, operating and maintenance

instructions thoroughly before installing or servicing

this equipment.

Improper installation, adjustment, alteration, service,

or maintenance can cause injury or property damage.

DANGER

CARBON MONOXIDE

HAZARD

This appliance can produce

carbon

monoxide

which

has no odor.

Using it in an

enclosed space can kill you.

Never use this

appliance

in

an enclosed space as a

camper, tent,

car or home

.

DANGER

If you smell gas:

1. Shut off gas to appliance.

2. Extinguish any open flame.

3. If odor continues, keep away from the

appliance and immediately call your

gas supplier or fire department.

WARNING:

For Outdoor Use Only

INSTALLER:

Leave this manual with the appliance.

CONSUMER:

Retain this manual for future reference.

ANS Z21.97.CSA 2.41-2012 "Outdoor Decorative Gas Appliances",

CGA 2.17-M91(R2009) "Gas Fired Appliances for Use at High Altitudes"

Report # 321-F-07b-5

2

SAFETY

INFORMATION

WARNINGS

Natural Gas: Natural gas is odorless. An odor making agent is

added to the gas. The odor helps

you detect a gas leak. However,

the odor added to the gas can fade.

Gas may be present even though

no odor exists.

Make certain you read and understand all warnings. Keep this

manual for reference. It is your

guide to safe and proper operation

of this appliance.

1. This appliance, as supplied, is

only for use with the type of

gas indicated on the rating

plate.

3. Keep the appliance area clear

and free from combustible

materials, gasoline and other

flammable vapors and liquids.

4. Do not burn solid fuel in the

fireplace after installing the

appliance. Do not use this

appliance to cook food or

burn paper or other objects.

5.

Children and adults should be

alerted to the hazards of

materials

carefully supervised when

they are in the area of the

appliance.

8. The appliance, when installed,

must be electrically grounded

in accordance with local codes

or, in the absence of local

codes, with the National Elec-

ely

call a qualif

any part of the

under water.

10. Inspect the burner before each

LOCAL CODES

. Follow local codes.

* American National Standards

Institute, Inc., 1430

Broadway, New York,

NY 10018

* National Fire Protection

Association, Inc.,

Batterymarch Park, Quincy,

MA 02269.

WARNING:

Any change

to this appliance or its

controls can be dangerous.

IMPORTANT:

The appliance

should be inspected before

use and at least annually by

a quilified service person.

More frequent cleaning may

be required as necessary. It

is imperative that the control

compartment, burners and

circulating air passageways

of the appliance be kept clean.

DANGER: Carbon monoxide poisoning may lead

to death!

HIGH ALTITUDE

INSTALLATIONS:

7. Young children should be

should not be hung

from the appliance, or placed

on or near the app

liance.

6.

Clothing

or other flammable

high

surface temperatures and

should stay away to avoid

burns or clothing

ignition.

trical Code, ANSI/NFPA 70

or the Canadian Electrical

Code, CSA C22.1, if

applicable

.

The burner must be replaced

prior to the appliance being put

into operation if it is evident that

the burner is damaged.

Please

refer to "Illustrated parts List"

for the replacement burner part

number.

The appliance is rated for

installations up to 4500’ (1372 m)

above sea level. Above 4500’ the

appliance must be de- rated at the

factory for the appropriate altitude.

the

appliance. Only a qualified

service person should install,

service, or repair appliance.

11. Turn the appliance off and let

cool before servicing, installling, or repairing. Any guard

or other protective device

removed for servicing the

appliance must be replaced

prior to operating

ied

service techn ician to inspect

the room appliance and to

replace

control

system and any gas control

which has been

9.

Do not use appliance if any

part has been under water.

Imm ediat

2. When an appliance is for con nection to a fixed piping system,

the installation must conform

with local codes, or in the ab sence of local codes with the

National Fuel Gas Code, ANSI

Z223.1/NFPA 54, or

Interna-

tional Fuel Gas Code, Natural

Gas and Propane Installation

Code, CSA B149.1, or Pro-

pane Storage and Handling

Code, B149.2, as applicable.

use of LBS-OD.

In

the absence of local codes,

use the latest edition of The

National Fuel Gas Code ANSI

Z223.1/NFPA54 available from:

Install and use

LBSOD with

care

.

Carbon Monoxide Poisoning:

Early signs of carbon monoxide

poisoning resemble the flu, with

headaches, dizziness, or nausea. If

you have these signs, the

LBS-

OD

may not be working properly.

Get fresh air at once! Have the

LBSOD serviced.

Some people are

more affected by carbon

monoxide than others. These

include pregnant women, people

with heart or lung disease or

anemia, those under the influence

of alcohol, and those at high

altitudes.

3

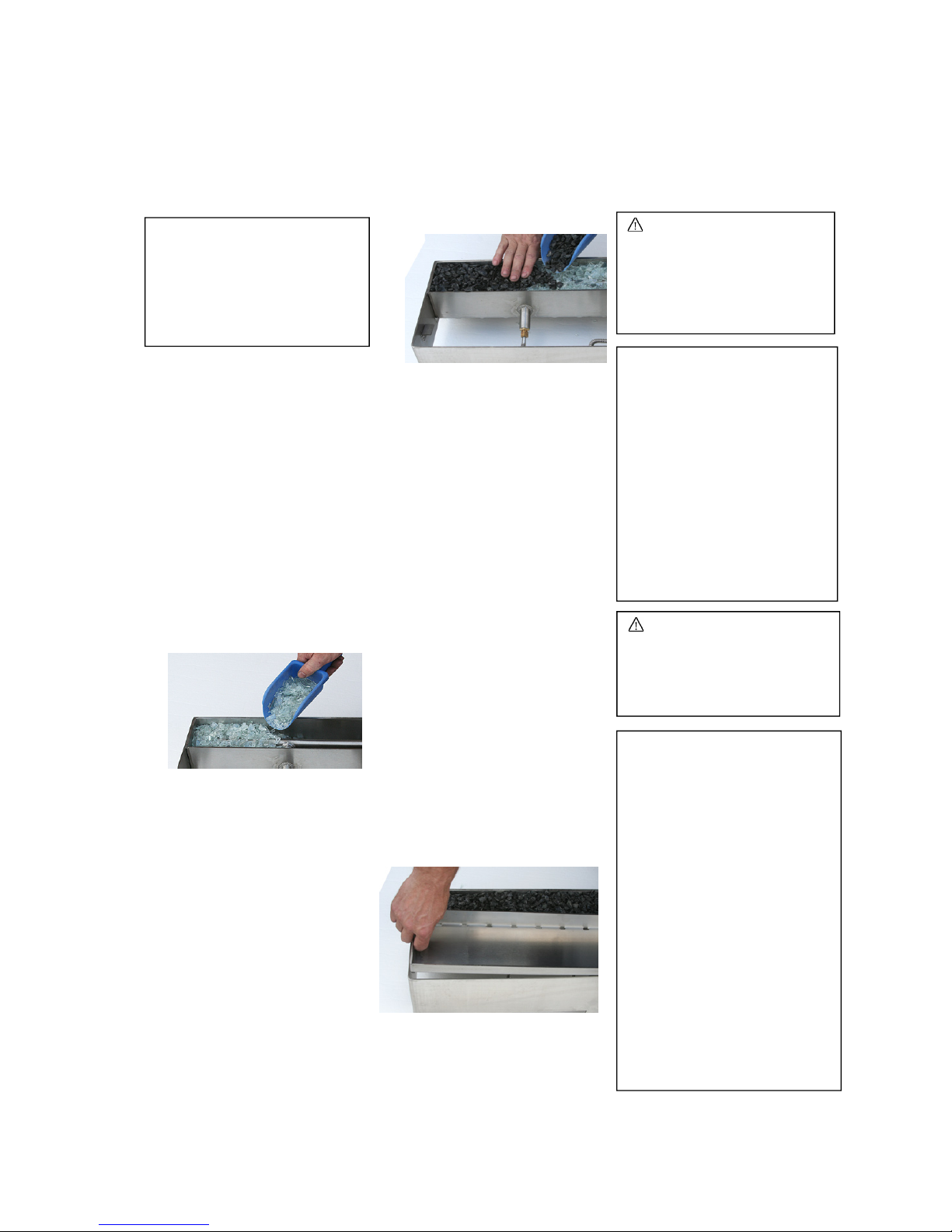

PRODUCT ASSEMBLY

2. Connect the Burner Assembly

to gas supply using supplied

flex connector and shutoff

valve.

3. Evenly fill the media

compartment with burner

media (broken tempered

glass) fully covering the

burner as shown on a picture.

If you are NOT planning to

add optional topping media,

then fill the media

compartment in full and

proceed to the step 5.

NOTE: If you are planning to

add some topping media

(optional colored glass or

lava rock), leave approximately ¾” not filled on top

of burner media and proceed

to the next step.

4. Place and evenly distribute

topping media (optional

colored glass or lava rock) on

top of burner media as shown

on a picture.

Make sure that pilot opening

is not blocked with excess of

media.

5. Carefully leak test all

connections following the

procedure on page 5.

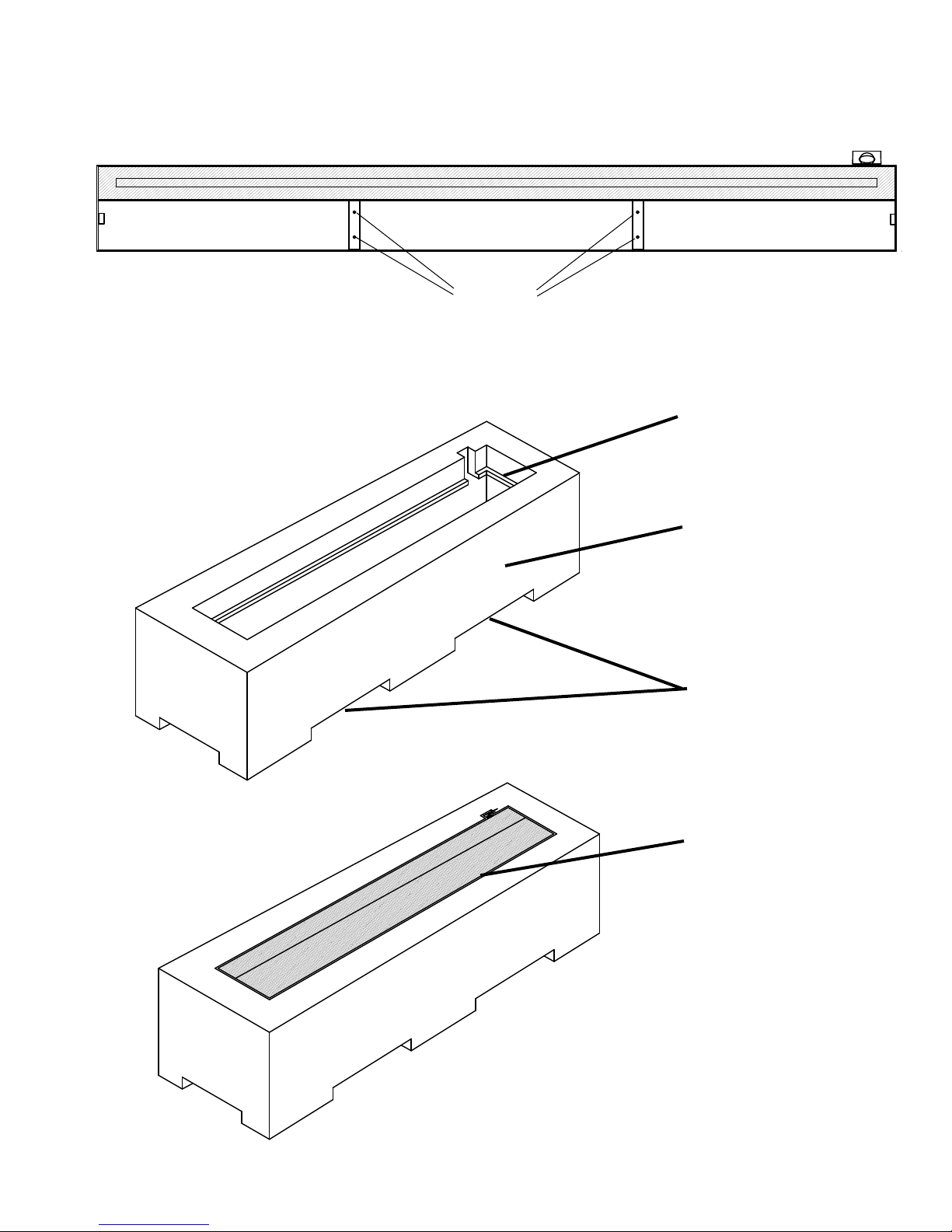

7. Cover manifold and valve

compartment of the Burner

Assembly with Front Cover.

8. Fill front cover tray with

topping media to desired

level.

INSTALLATION

CAUTION: Do not remove

the metal data plates

attached to the Linear

Burner System.

These plates contain

important information.

NOTICE: Installation and

repair should be done by a

qualified service person. The

appliance should be

inspected before use and at

least annually by a qualified

service person. More frequent cleaning may be

required as necessary. It is

imperative that control

compartment, burner and

circulating air passageways

of the appliance be kept

clean.

CLEARANCES TO

COMBUSTIBLE MATERIALS:

- Top……… 60” (153 cm)

- Short Side of the Unit

to Wall ……. . 9” (23 cm)

- Long Side of the Unit

to Wall …… 16” (41 cm)

No Thermal Floor Protection Required

Fuel pressure specification:

WARNING: Failure to position

the parts in accordance with

these diagrams or failure to

use only parts specially

approved with this appliance

may result in property

damage or personal injury.

WARNIN

G:

having the clear glass media

completely

covering

the burner!

Never light the

appliance

without

1. Remove Burner Assembly,

Front Cover and Burner

Media from packaging (see

Parts List, page

14).

6. Having free access to the

valve and manifold

compartment of the Burner

Assembly turn ON the

appliance following the

procedure on page

8.

Make sure the flame is even

along the burner and

appliance is fully operational

and safe for use. Turn OFF

the appliance and let it cool

before proceeding to the next

step.

Inlet

Nat. Gas

(NG)

Min:

4.5”

w.c.

Max:

10.5" w.c.

Inlet

Propane

(LP)

Min:

11.0”

w.c.

Max:

13.0" w.c.

Manifold (LP)

10.0” w.c.

Manifold (NG)

3.5” w.c.

IMPORTANT: LBS-OD 96 models must have the burner system

secured to the base in order to avoid warpage of the appliance!

Secure burner

to base here

LINEAR BURNER SYSTEM OUTDOOR

INSTALLATION (EXAMPLE)

Clearances to combustibles must be

maintained (see page 3).

Minimum 0.75" lip to

support appliance.

Non-combustible materials

only (complete structure).

Allow for air flow

from below

( min. 12 Sq. In. per

linear foot of burner).

4

Cover

(see Illustrated Par ts L ist, page 13)

NOTE:

Maintain minimum 0.25" gap

around appliance and pilot.

Linear Burner System can be installed on any

non-combustible materials. Above example is

not a requirement.

must be in place when appliance is not in use.

FIREPLACE INSTALLATION

CHECK GAS TYPE

Use proper gas type for the replace you are installing. If you have conicting gas type, do not install replace. See dealer where

you purchased the replace for proper replace for your gas type or conversion kit.

INSTALLING GAS PIPING TO FIREPLACE / BURNER SYSTEM LOCATION

WARNING

A qualified installer or service person must

connect appliance to gas supply. Follow all

local codes.

CAUTION

For propane/LP units, never connect fireplace directly to the propane/LP supply. This

burner system requires an external regulator (not supplied). Install the external regulator

between the burner system and propane/LP supply.

INSTALLATION ITEMS NEEDED

Before installing replace and burner system, make sure you have the items listed below.

• External regulator (supplied by installer) • Piping (check local codes) • Sealant (resistant to propane/LP gas)

• Equipment shutoff valve* • Test gauge connection* • Sediment trap (recommended)

• Tee joint • Pipe wrench

• approved exible gas line with gas connector (if allowed by local codes — not provided)

* A CSA design-certied equipment shutoff valve with

1

/8" NPT tap is an acceptable alternative to test gauge connection.

Purchase the CSA design-certied equipment shutoff valve from your dealer.

For propane/LP connections only, the installer must supply an external regulator. The external regulator will reduce

incoming gas pressure. You must reduce incoming gas pressure to between 11 and 13 inches of water. If you do not reduce

incoming gas pressure, burner system regulator damage could occur. Install external regulator with the vent pointing down as

shown in Figure

1. Pointing the vent down protects it from freezing rain or sleet.

External

Regulator

100 lb. (min)

Propane/LP

Supply Tank

Vent Pointing

Down

CAUTION

Use only new black iron or steel pipe. Internally

tinned copper or copper tubing can be used per

National Fuel Code, section 2.6.3, providing gas

meets hydrogen sulfide limits, and where permitted

by local codes. Gas piping system must be sized

to provide minimum inlet pressure (listed on data

plate) at the maximum flow rate (BTU/hr). Undue

pressure loss will occur if the pipe is too small.

When using copper or ex connectors use only ttings approved

for gas connections. The gas control inlet is 3/8" NPT.

Figure 1 - External Regulator with Vent Pointing Down

(Propane/LP Only)

5

A.G.A. Design-Certified

Manual Shutoff Valve

With 1/8” NPT Tap

Cap Pipe Nipple Tee Joint

Sediment Trap

3” Minimum

CONNECTING TO GAS

SUPPLY

Installation Items Needed

pliers

- sediment trap

- tee joints

- pipe wrench

Installation must include a manual

shutoff valve, union, and plugged

1/8” NPT tap. Locate NPT tap

within reach for test gauge hook

up. NPT tap must be upstream

from the appliance.

Apply pipe joint sealant lightly to

male threads. This will prevent

excess sealant from going into

pipe. Excess sealant in pipe could

result in a clogged burner injector.

Install sediment trap in supply line

as shown below. Locate sediment

trap where it is within reach for

cleaning and trapped matter is not

likely to freeze. A sediment trap

CHECKING GAS

CONNECTION

Test Pressures in Excess Of

1/2 psi (3.5 kPa)

Test Pressures Equal To or

Less Than 1/2 psi (3.5 kPa)

WARNING:

A qualified

service person must connect appliance to gas supply. Follow all local codes.

CAUTION:

Use only new,

black iron or steel pipe.

Internally tinned copper

tubing may be used in

certain areas. Use pipe of

1/2" diameter or greater to

allow proper gas volume to

Linear Burner System. If

pipe is too small, undue loss

of pres

WARNIN

G:

Test all gas

piping and connections for

leaks after installing or

servicing. Correct all leaks

at once.

WARNING:

Never use an

open flame to check for a

leak. Apply a mixture of

liquid soap and water on all

joints. Bubbles forming

show a leak. Correct all

leaks at once.

From Gas Meter

(5” W.C. to 10.5” W.C.

pressure)

The appliance and its individual

shutoff valve must be disconnected from the gas supply piping

system during any pressure testing

of that system at test pressures in

excess of ½ psi (3.5 kPa).

The appliance must be isolated

from the gas supply piping system by

closing its individual manual

shutoff valve during any pressure

testing of the gas supply piping

system at test pressures equal to or

less than ½ psi (3.5 kPa).

Approved Flexible

Gas

Connector

IMPORTANT

This appliance is not designed

for use with a non-disposable,

self-contained LP-gas supply

system! Do not use a gas hose

to connect the appliance to any

gas supply. Use approved

Flexible Gas Connectors.

6

Before installing the Outdoor

Fireplace, make sure you have all

items listed bellow:

- piping (check local codes)

- sealant

- manual shutoff valve

- adjustable (crescent) wrench or

traps moisture and contaminants.

This keeps them from going into

Outdoor Fire

place controls.

If sediment trap is not installed or

is installed wrong, unit may not

run properly.

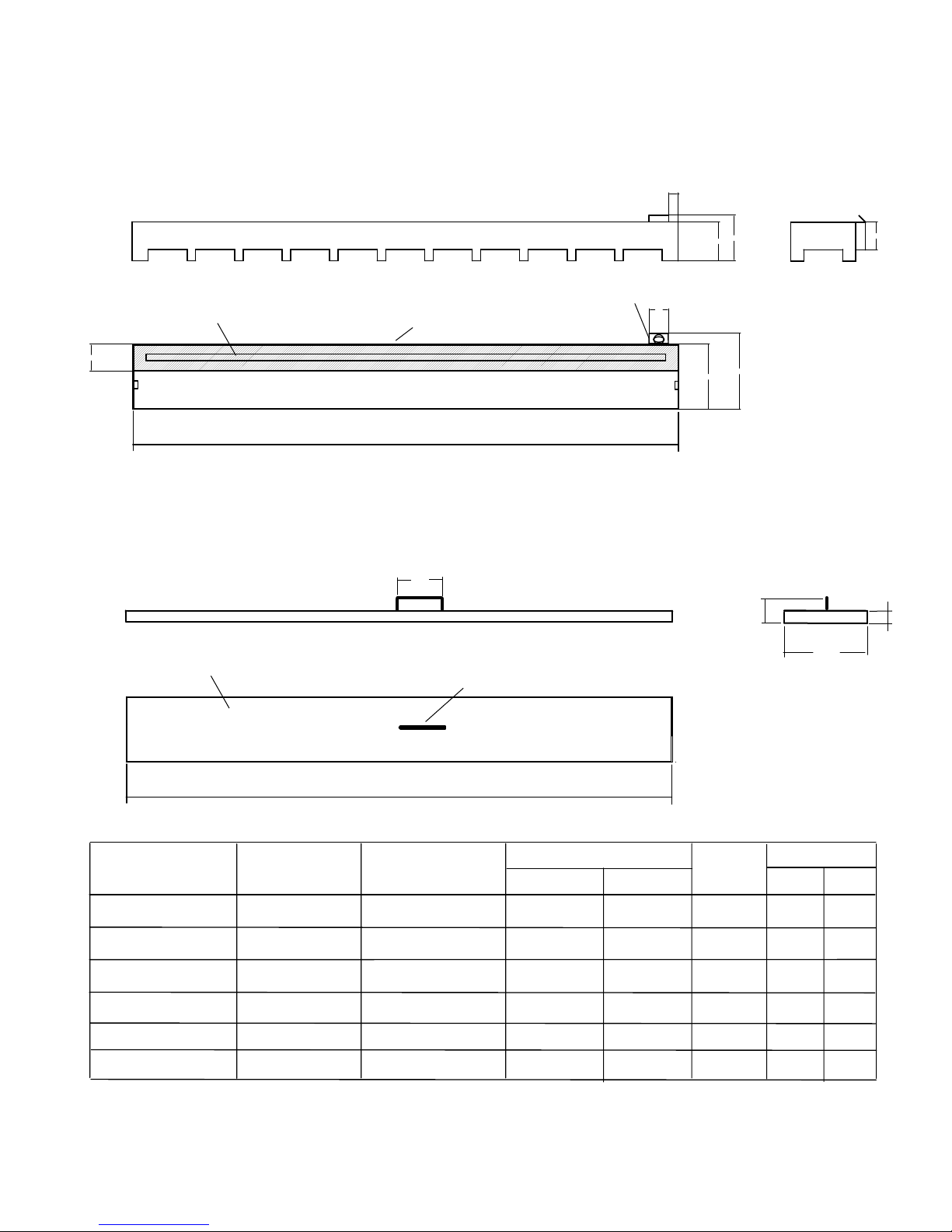

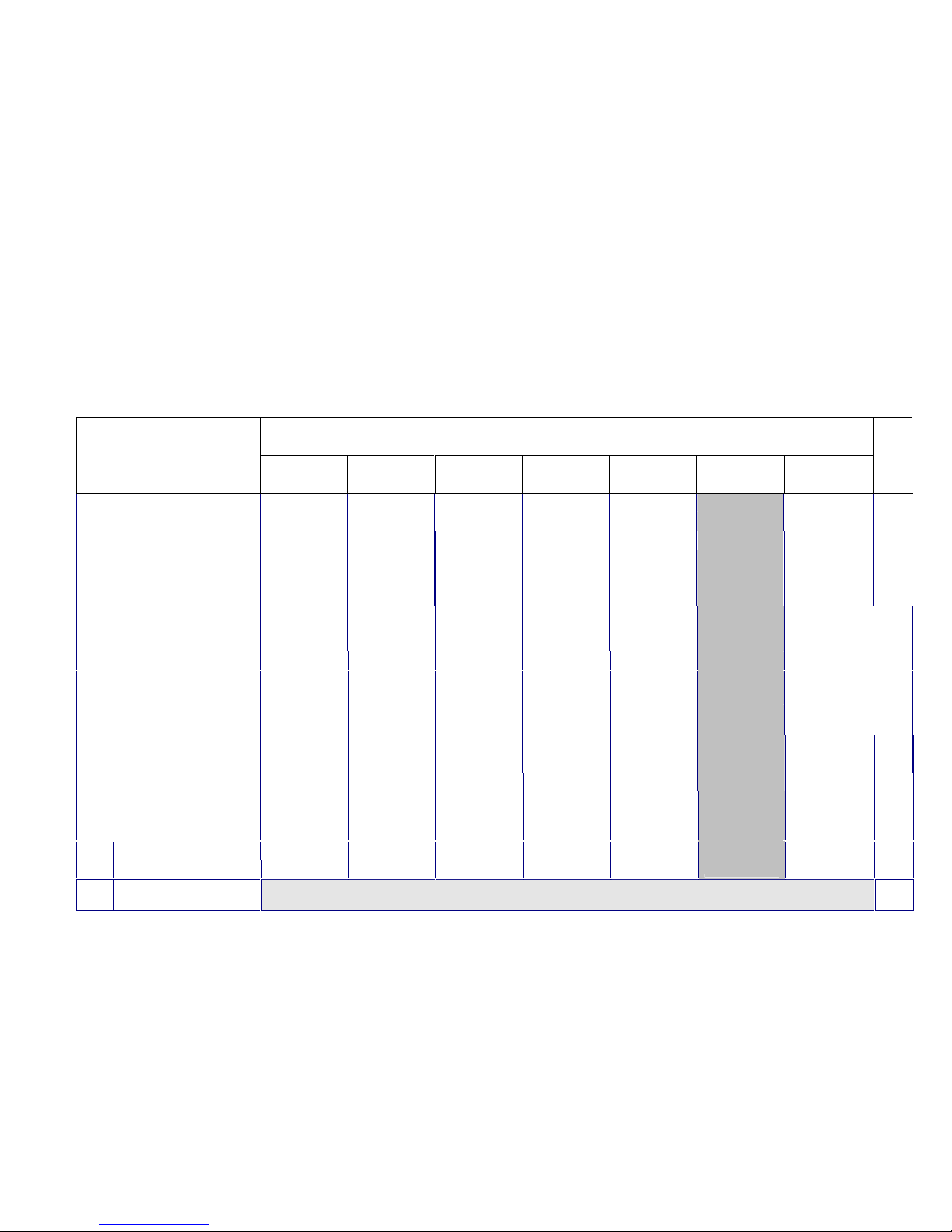

LINEAR BURNER SYSTEM OUTDOOR SPECIFICATIONS

BURNER DIMENSIONS

1.5"

7"

6"

PILOT

BURNER TUBE

4"

MEDIA BURNER TRAY

OVERAL WIDTH (W)

*

*

3"

11.5"

10"

4.25"

TOP COVER DIMENSIONS

4"

TOP COVER

2.5"

11.5"

WELD-ON HANDLE

1"

MODEL #

LBS-OD 24 - NG(LP)

LBS-OD 36 - NG(LP)

LBS-OD 48 - NG(LP)

LBS-OD 60 - NG(LP)

LBS-OD 72 - NG(LP)

LBS-OD 96 - NG(LP)

OVERALL

WIDTH

(W)

24"

36"

48"

60"

72"

96"

TOP COVER WIDTH (W+0.65")

BURNER TUBE

LENGTH

20"

32"

44"

56"

68"

92"

INPUT RATE (Btu/hr)

N.G. L.P.

41,000

61,000

82,000

102,000

116,000

142,000

33,500

54,000

72,000

90,000

110,000

146,500

# ORIF.

N.G. (L.P.)

2 (1)

3 (1)

4 (1)

5 (2

)

6 (2)

8 ( 2)

ORIF. SIZE

N.G. L.P.

44 49

44 4

4

3

38

43

43

43

36

41

35

3

7

LIGHTING INSTRUCTION

FOR YOUR SAFETY READ BEFORE OPERATING

LIGHTING FOR THE FIRST TIME

WARNING

Never use an open flame to check for gas leak.

If you do not follow these instruction exactly,

a fire or explosion may result causing property

damage, personal injury or loss of life.

A.This appliance is equipped with an ignition device which automatically lights the pilot. Do not try to light

the pilot by hand.

B. BEFORE OPERATING smell all around the appliance area for gas. Be sure to smell next to the oor because

some gas is heavier than air and will settle on the oor.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

C. Main gas valve in this appliance is not serviceable and does not have any control knobs or switches to operate.

Do not remove heat shields covering the valve and electronic devices; do not try to repair or modify the valve

as it may result in a fire or explosion. Call a qualified service technician if you have any safety concerns.

D. Do not use this appliance if any part of it has been under water. Immediately call a qualied service technician

to inspect the appliance and to replace any part of the control system and any gas control that has been under

water.

INITIAL LIGHTING

Purge air from the supply line as follows:

• Open main shutoff valve.

• Unscrew main pressure test point.

• Leave inlet test screw open until gas comes in.

• When gas is owing, tighten inlet screw immediately.

LEAK TESTING

1. Follow the pipe from the gas supply line connection to the gas valve. Check connection for leaks with soap

and water mixture.

DANGER

2. Next check for gas leaks at the burner with soap and water mixture.

3. Check the pilot for gas leaks with soap and water mixture.

8

L100001 35

APPROVED LEAK TESTING METHOD

9

LIGHTING FOR THE FIRST TIME

Continued

You may check for gas leaks with the following methods only:

WARNING

• Soap and water solution

• An approved leak testing spray

• Electronic sniffer

WARNING

If using a soap and water solution to test

for leaks, DO NOT spray solution onto

electronic parts.

DANGER

Never use an open flame to check for gas leak.

Check for gas leaks in each of the following locations:

• Pipe from the gas supply line connection to the gas valve

• Burner connections, pilot • Field made joints / gas shutoff valve

• All joints on valve and control body • Factory made joints, each joint and connection

NOTE: Remove any excessive pipe compound from

the connections. Excessive pipe compound can set

off electronic sniffers.

OPERATING INSTRUCTIONS

1. STOP! Read the safety information on previous page.

2. Turn off all electric power to the appliance.

3. Do not attempt to light the pilot by hand.

4. Remove Front Tray from the appliance (see Illustrated Parts List, page 14).

5. Turn the gas control manual valve to the full OFF position.

6. Wait five (5) minutes to clear out any gas. Then smell for gas, including near the floor.

If you smell gas, STOP! Follow "B" in the safety information (see page 7).

If you don't smell gas, go to the next step.

7. Turn the gas control manual valve to the ON position.

8. Plug supplied 7V DC adapter into 110V power outlet.

9. Connect the wire to the DC input plug at the unit.

10. Lift and remove Heat Shield covering electronic components inside of the unit

11. Locate Remote Receiver inside of the unit

of the Receiver is in "REMOTE"

(middle) position.

(see Illustrated Parts List, page 13).

12. Replace Heat Shield and then replace Front Tray.

WA

(see Illustrated Parts List, page 13).

Make sure that the slider switch

13. Read and follow instructions in how to set up and to use remote control described in supplied

"INSTALLATION AND OPERATING INSTRUCTIONS FOR SKYTECH MODEL: 1001 T/LCD-A"".

14. If the appliance will not operate, follow the instructions "To Turn Off Gas To Appliance" and call

your service technician or gas supplier.

T

Continued

TO TURN OFF GAS TO APPLIANCE

Unplug 7V DC adapter from the power outlet.

3. Turn the gas control manual valve to the full OFF position.

1. Turn off all electric power to the appliance if service is to be

performed.

2. If necessary, remove Front Tray from the appliance to access

manual shutoff valve on gas line.

4. If necessary, replace Front Tray.

10

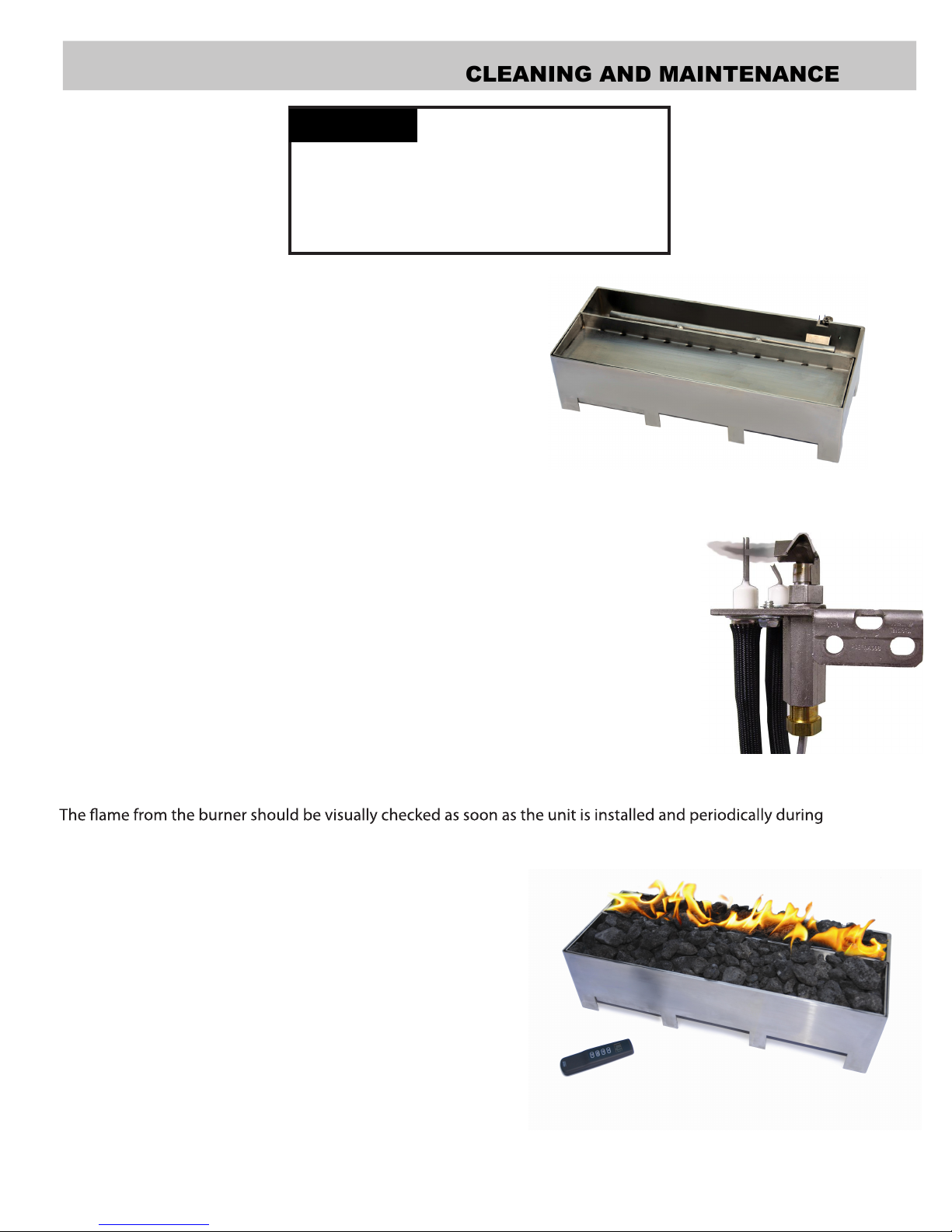

CLEANING AND MAINTENANCE

PILOT FLAME

The ames from the pilot should be visually checked as soon as the unit is installed

and periodically during normal operation. The pilot flame must always be present

when the fireplace is in operation or connected to the gas line with main shutoff

valve open and the IPS activated (powered). The pilot flame has two distinct

BURNER

1

flames, one engulfing the flame sensor and the other reaching to the main burner.

Pilot Flame

WARNING

Turn off gas before servicing fireplace. It

is recommended that a qualified service

technician perform these check-ups at the

beginning of each heating season.

BURNER, PILOT AND CONTROL COMPARTMENT

Keep the control compartment clean by vacuuming or brushing at

least twice a year. Make sure the burner porting, pilot air opening

and burner air opening are free of obstructions at all times.

normal operation.

Keep the appliance and its burner clean by vacuuming or brushing at

least twice a year. Make sure the burner porting and burner air

openings are free of obstructions at all times.

Inspect area around the burner. Remove any lint or foreign

material with a brush or vacuum.

The burner must be replaced prior to the appliance being put

into operation if it

refer to "Illustrated Parts List" for the replacement part number

specified by the manufacturer.

is evident that the burner is damaged. Please

11

TROUBLESHOOTING

WARNING: Turn off the unit

and let cool before servicing. Only

a qualified service person should

service and repair this appliance.

Note:

All troubleshooting items are listed in

order of operation.

OBSERVED PROBLEM POSSIBLE CAUSEREMEDY

Unit is smoking / sooting excessively

(

Note:

It is natural and unavoidable for

appliance sets to produce moderate

levels of carbon (soot) where flames

contact the media. This is especially true

Burner is excessively noisy

(

Note:

The movement and combustion of

gas will create low, unavoidable levels of

noise.)

Burner flame is too low or too high

Remote does not function

1. Poor fuel quality

2.Excessive flame impingement or blockage

3.Improper fuel/air mixture

1. Passage of air/gas across irregular surfaces

2. Excessive gas pressure on natural gas

units

1. Incorrect gas supply or pressure

2. Blocked burner orifice or burner manifold ports

3. Improper burner orifice size

1. Battery is not installed. Battery power

is low.

1.Contact local natural gas company

2.Separate the stones/media to allow

more flame passage

3.Remove any foreign items from the

flame pattern and/or check for proper

orifice sizing

1. Relieve any tight bends or kinks in gas

supply line

2.Check/reset gas regulator pressure

1. Check for proper gas supply pressure

2. Free burner orifice and manifold ports

of any burrs, paint, or other blockage

3. Verify proper burner orifice sizing (see

page 7)

1.Replace batteries in receiver and

remote control

12

Continued

OBSERVED PROBLEM

When ignitor button is pressed, there is

spark at pilot but no ignition

Burner does not light after pilot is lit

Delayed ignition burner

POSSIBLE CAUSE

1.Gas supply turned off or manual shutoff

valve closed shutoff valve

2.Air in gas lines when installed

3.Pilot adjustment screw closed

4.Pilot is clogged

5.Ignitor electrode broken

1.Burner orifice clogged

2.Inlet gas pressure is too low

3.Burner orifice diameter is too small

4.Flame sensor leads disconnected

1.Pilot flame needs adjusting

REMEDY

1.Turn on gas supply or open manual

2.Purge air from the supply line

(see page

3. Adjust pilot flame for approximately

1" blue flame

4.Clean pilot (see Cleaning and Mainte-

nance, page 1

5. Low gas pressure

1.Clean burner orifice

2.Contact local natural or propane/LP gas

company

3.Replace burner orifice

4.Reconnect leads

1.Adjust pilot flame for approximately

1" blue flame

8)

1) or replace pilot assembly.

WARNING: If you smell gas

• Shut off gas supply.

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in

your building.

• Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

Unit produces unwanted odors

IMPORTANT:

Cleaning supplies, paint, paint remover, cigarette smoke, cements and glues, new

carpet or textiles, etc., create fumes. These fumes may mix with combustion air

and create odors. These odors will disappear over time.

Gas odor even when Remote Control is

leaks in OFF position

Operating unit where impurities in air exist may create odors.

1. Gas leak. See Warning statement above.

1.Gas leak. See Warning statement above.

2. Main gas valve defective 2. Replace gas valve

1. Locate and correct all leaks.

1. Locate and c o r r e c t al l

13

ILLUSTRATED PARTS LIST

O W N E R ’ S O P E R A T I ON A N D I N S T A LL AT IO N M A NU A L

14

ILLUSTRATED PARTS LISTILLUSTRATED PARTS LIST

FOR PART DESCRIPTION SEE NEXT PAGE

16

18

15

14

1

8

5

2

3

4

6

7

9

10

11

12

13

17

ILLUSTRATED PARTS LIST

8

W130202

W130204

W130206

W130208

1

7

Valve

Heat

Shield

D400261

D400261

D400261

D400261

1

4

Burner Flex Connector C100009

R100080

R100080

R100080 1

1

PARTS LIST

Key

#

Part Description

Q-

ty

Valve Bracket

(NOT SHOWN)

Manifold complete

with Tubing Assembly

Continued on Next Page

This list contains replaceable parts used in your

Linear Burner System Outdoor (LBS-OD)

appliance

1

Burner Assembly

W110202

W110204

W110206

W110208

1

2

Main Gas Valve

R10002

6

R10002

6

R10002

6

R10002

6 1

3

Pilot Assembly

R10002

8

R10002

8

R10002

8

R10002

8 1

5 DFC

Wire Assembly

H100141

H100141

H100141

H100141

1

6

D400260

D400260

D400260

D400260

1

Part Number according to the LBS-OD Natuaral Gas model (and Propane/LP)

(W120202)

(W120204)

(W120206)

(W120208)

(R100027)

(R100027)

(R100027)

(R100027)

(R100029)

(R100029)

(R100029)

(R100029)

(C100009)

(C100009)

(C100009)

(C100009)

LBS-OD 24 LBS-OD36 LBS-OD 48 LBS-OD 60 LBS-OD 72 LBS-OD 96

W120203

(W120203)

W120205

(W120205)

R100026

(R100027)

R100026

(R100027)

R100028

(R100029)

R100028

(R100029)

(C100009)

C100009

(C100009)

R100080

H100141

H100141

D400260

D400260

D400261

D400261

W130203

W130205

All replacement parts should be ordered from your

retai

ler or from

Spark Modern Fires

at

1-

866-938-3846 or on-line at www.sparkfires.com

1

PARTS LIST

(CONTINUED)

Key

#

Part Description

Q-

ty

9

Orifice

R100044

R100043

Top Media

(MANY

TYPES AVAILABLE)

Burner

Media

(NOT

SHOWN)

This list contains replaceable parts used in your

Linear Burner System Outdoor (LBS-OD)

appliance

Part Number according to the

LBS-

OD model

12 Pilot Shield

D400267

D400267

D400267

D400267

1

13 Control Heat Shield

D400265

D400265

D400265

D400265

1

14 DFC Board

H100142

H100142

H100142

H100142

1

(R200061)

(Air Mixer for LP model)

(R200063)

(R200063)

(D400290)

(D400290)

(D400290)

(D400290)

(1)

LBS-OD 24 LBS-OD36 LBS-OD 48 LBS-OD 60 LBS-OD 72 LBS-OD 96

R100044

(R200062)

R100043

R100043

R100043

SEE PAGE 6

(R200064)

(R100062)

10 Front Tray D400234 D400254 D400253 D400209 D400217 D400210 1

11 Unit Cover D400272 D400273 D400274 D400275 D400276 D400278 1

(D400290)

D400267

D400267

(D400290)

D4002

65

D400265

H1

00142

H1

00142

H100150

H100150

H100140

H100140

17 6 Volt Battery Pack

H100150

H100150

H100150

H100150

1

18 7V 10mA DC adapter H100140

H100140

H100140

H100140

1

Remote Control

15

Remote Receiver

RCB-R RCB-R RCB-R RCB-R RCB-R RCB-R 1

1

6 RCB RCB RCB RCB RCB RCB 1

19

xxx xxx xxx xxx xxx xxx Pkg

20 F200503 F200503

F200503 F200503 F200503 F200503 Pkg

ILLUSTRATED PARTS LIST

SEE NEXT PAGE

FOR PART DESCRIPTION

ILLUSTRATED PARTS LIST

SEE NEXT PAGE

FOR PART DESCRIPTION

2

ILLUSTRATED PARTS LIST

SEE NEXT PAGE

FOR PART DESCRIPTION

ILLUSTRATED PARTS LIST

SEE NEXT PAGE

FOR PART DESCRIPTION

2

17

PSE-NA368

Pilot Assembly

6 Volt Battery Backup ( uses 4 pcs AA Batteries)

L100001 17

127(6

INSTALLATION RECORD

The installer should complete the form below that describes the details of the installation. Having this

written record of installation information available will greatly expedite trouble-shooting should any problem

arise with your fireplace. The installer should keep a duplicate of this form for their records. Accurate completion of this form is required for warranty coverage and for any technical support by Spark Modern Fires.

Date Purchased:

Purchaser/Dealer:

Installer:

Fireplace S/N on product ID tag:

Date Installed:

FUEL:

◯

Natural Gas

◯

◯

L.P. Propane

◯

Inlet Pressure Measured After Installation:

Manifold Pressure Measured After Installation:

High Fire:

In. W.C. Low Fire: In. W.C.

CONFIGURATION:

In. W.C.

ALTITUDE: Feet Above Sea Level

Was Fireplace Derated? ◯Yes ◯ No

If Yes To What Orifice Size?

Unusual Structure Near Appliance?

◯

Inside Corner

◯

Termination:

◯

Trees/Shrubs

◯

(Please Describe)

Prevalent Wind Conditions?

Other Installation Notes:

◯

◯

Other

SMF32011

LIMITED LIFETIME WARRANTY

The following components are warranted for life to the original owner, subject to proof of purchase: Linear

Burner Assembly.

BASIC WARRANTY

Spark Modern Fires warrants the components and materials in your gas appliance to be free from manufacturing

and material defects for a period of two years from date of installation. After installation, if any of the components manufactured by Spark Modern Fires in the appliance are found to be defective in materials or workmanship, Spark Modern Fires will, at its option, replace or repair the defective components at no charge to the original owner. Spark Modern Fires will also pay for reasonable labor cost incurred in replacing or repairing such components for a period of two years from date of installation. Any products presented for warranty repair must be

accompanied by a dated proof of purchase.

This Limited Lifetime Warranty will be void if the appliance is not installed by a qualified installer in accordance with installation instructions. The Limited Lifetime Warranty will also be void if the appliance is not ope-

rated and maintained according to the operating instructions supplied with the appliance, and does not extend to (1)

firebox/burner assembly damaged by accident, neglet, misuse, abuse, alterations, negligence of others, including the installation thereof by unqualified installers, (2) the costs of removal, reinstallation or transportation of

defective parts on the appliance, or (3) incidental or consequential damage. All service work must be performed

by an authorized service representative.

This warranty is expressly in lieu of other warranties, express or implied, including the warranty of merchantability of fitness for purpose and of all other obligations or liabilities. Spark Modern Fires does not assume for it

any other obligations or liabilities in connection with sale or use of the appliance. In states that do not allow limitations on how long an implied warranty lasts, or do not allow exclusion of indirect damage, those limitations of

exclusions may not apply to you. You may also have additional right not covered in the Limited Lifetime War-

ranty. Spark Modern Fires reserves the right to investigate any and all the claims against this Warranty and de-

cide upon method of settlement. For information about this warranty contact:

Spark Modern Fires

53 Chestnut Woods Rd.

Redding, CT 06896

U.S.A.

WARRANTY INFORMATION

KEEP THIS FOR WARRANTY

Model

Serial No.

Date Purchased

Always specify model and serial numbers when communicating with the factory.

Rev.7 08/2013

Loading...

Loading...