Page 1

IMPORTANT:

Before using, check that the spa pool has been connected

to a suitable weather protected outlet socket equipped with

a double poled isolating switch that meets the requirements

of the specification plate on the heater cover.

Introduction:

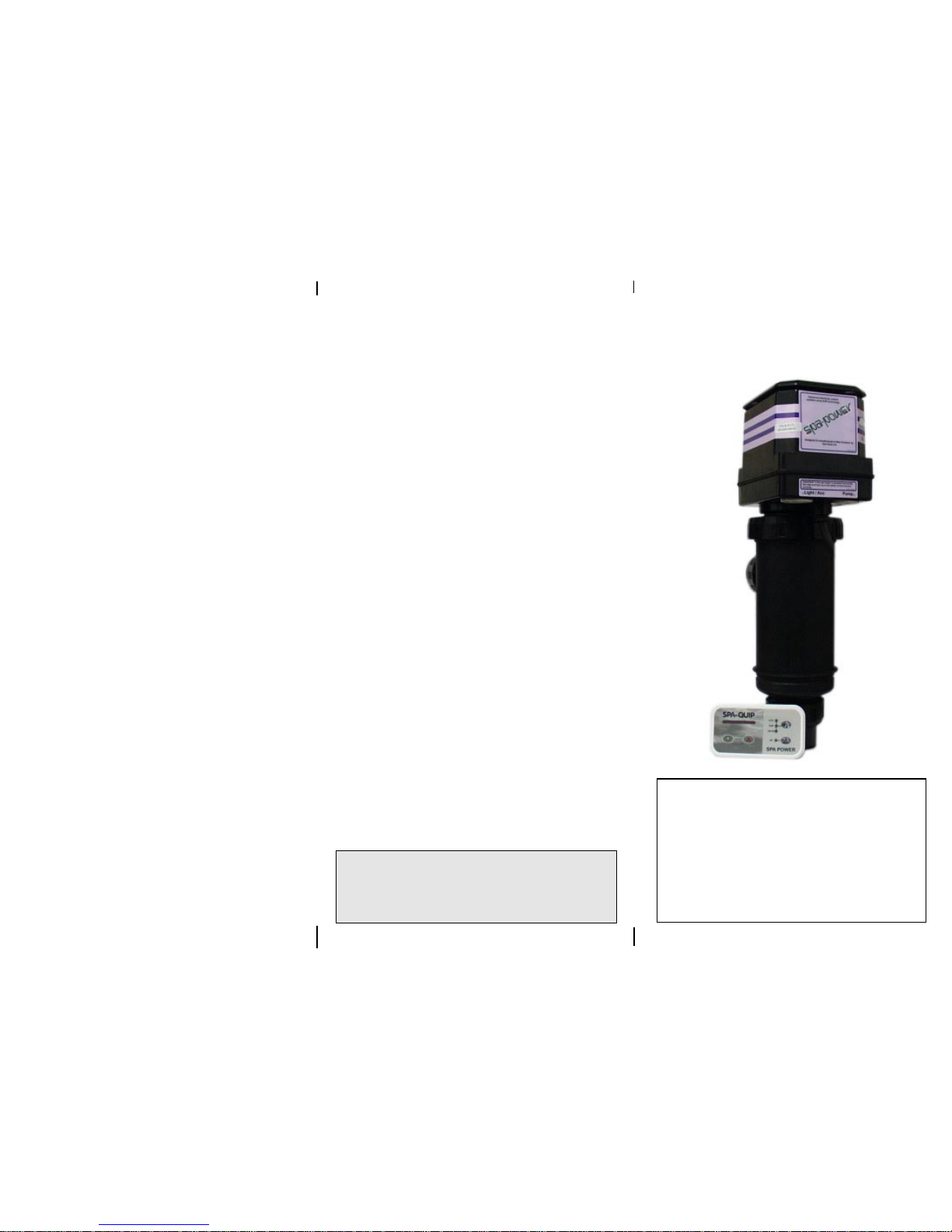

Congratulations on the purchase of a pool incorporating the

Spa Power 500 electronic controller. This controller has

been designed to offer more powerful accessories, superior

control and superior ease of use than other competing

controllers in its class. It makes use of an optimal

combination of proven, reliable technology and innovative

new sensor designs.

Quick operating instructions:

(1) Pump Mode button

Default state = auto mode on, pump and heater controlled

automatically to maintain pool temperature.

Three pushes on this button cycle the system as follows.

Push 1 = Auto off, pump on, heater automatically

controlled.

Push 2 = Auto off, pump off, heater off.

Push 3 = Auto on, pump and heater controlled

automatically.

(2) Aux/Air/Jets/Light button

Default state = off.

Two pushes of this button cycle the output as follows.

Push 1 = Output on.

Push 2 = Output off.

(3) Temperature setting - Bargraph display

Default setting = 37°C.

Holding down the up or down buttons adjusts the

temperature setting as follows (steady dot).

Up: increases setting 0.5°C per beep, 1.0°C per bargraph

dot.

Down: decreases setting 0.5°C per beep, 1.0°C per

bargraph dot.

Minimum setting = 31°C, maximum setting = 40.5°C.

(4) Temperature setting - Digital display

Default setting = 37°C.

Holding the increase or decrease button down will

automatically adjust the spa temperature setting. This

setting is then displayed on the digital readout.

Up: increases setting 0.5°C per beep.

Down: decreases setting 0.5°C per beep. Minimum

setting = 20°C, maximum setting = 40.5°C.

Clean up cycle:

If desired, a clean up cycle can be initiated after using the

pool so the water is well filtered and brought back up to

temperature if necessary. This is done by simply pushing

the pump mode button so the pump is on and the system

is not in auto mode. This will run the pump for a fixed

period of time (90 minutes) circulating the water through

the filter. The system will then return to auto mode and

maintain the temperature ready for the next time the pool

is used.

Auto Sanitising (filtration):

The Spa Power 500 monitors the amount of pump running

used in normal pool operation. If this is low then it

automatically runs the pump for an additional period to

maintain the filtration/sanitisation of the pool.

Aux/Air/Jets/Light button:

This control gives the user on/off control over an additional

pool accessory which may vary in different pool designs. In

some cases it may not be fitted. Operation is clearly

indicated by a coloured light on the panel. If left on, this

accessory will automatically switch off after a fixed time (30

minutes). Usually switching on this accessory will cause

the heater to switch off (loadshedding). This is in order to

keep the total power load within a safe level.

Up and Down Temperature Control buttons:

The Spa Power 500 gives the user direct control of the pool

temperature from the poolside panel. There is no need to

look under the pool for the temperature adjustment. To

adjust the temperature simply press the up or down

button on the panel until the display corresponds with the

desired temperature. There is a slight delay before the

buttons operate to reduce the risk of accidental

adjustment.

Pushing the Up and Down buttons together produces a

flashing temperature display which indicates the current

sensed temperature in the heater. This is not the pool

temperature, but when the pump is running it should

approximate the pool temperature. The pool temperature

will be maintained very close to the set temperature.

Detailed operating description:

Pump Mode button:

The Spa Power 500 controls the water pump and heater

automatically to maintain the water at the desired

temperature. The user can leave the system to look after

the pool and know it will be at the right temperature

whenever he/she wishes to use it.

The pump mode button allows the user to switch the

pump on or off as desired when using the pool. For safety

the heater is always automatically controlled. Automatic

operation is the default and the system returns to automatic

mode by itself at a fixed time (90 minutes) after the user

last pushed the pump mode button. Pushing the pump

mode button then leaves automatic mode and switches the

pump on. If the pump was already on in auto mode then it

will stay on.

Pushing the pump mode button again will switch the heater

and pump off. The pump will run for a few seconds to cool

the heater before switching off. One more push of the

pump mode button will return to automatic mode. These

operations are clearly indicated on the panel by coloured

lights.

Digital display

Bargraph display

1

2

1

4

3

2

Page 2

Self Diagnostic Error Codes:

The Spa Power 500 controller has extensive self

diagnosing abilities. In the event of a problem it will

indicate an error number according to the nature of the

problem. These are indicated by an alarm beeper beeping

out the error number and by either the bargraph

simultaneously flashing the corresponding dots up to the

error number or the digital display indicating the error

number The error numbers and their meanings are listed

below.

Error 1 (H2O) = PRIME FAILED

Primefailed is a special case. This is not necessarily a

problem with the Spa Power 500 itself, but indicates that no

water is being sensed in the heater. On the push of the

pump mode button the pump will run for 10 seconds to try

get water to the heater. If successful, normal operation will

resume. If unsuccessful Error 1 will be indicated again.

Error 2 = not used.

Errors 3-8 = are fatal errors.

Operation will stop and will not continue until the controller

is reset (switched off and on again at the main power).

Error 3 = STUCK BUTTON

This error indicates that one of the buttons in the control

panel is stuck or has been held down for more that one

minute. This may be caused by water getting into the

panel or by damage to the control panel.

Error 4 = NO WATER SENSOR

This error indicates a problem with the optical water

sensor in the heater. It may also be caused by the sensor

being disconnected inside the unit or by damage to the

sensor.

Error 5 = OVERTEMP

This error indicates that the digital temperature sensor in

the heater has detected a temperature of 45°C or more.

This is not necessarily a problem with the Spa Power 500

itself. It might be caused by excessive pump use during

very hot weather or by disconnection or failure of the pump

(no water flow).

Error 6 = KLIXON TRIPPED

This error indicates that the safety electromechanical over

temperature cut out on the heater has operated. This is

not necessarily a problem with the Spa Power 500 itself. It

might be caused by high temperatures during shipping,

e.g. in the back of a sealed truck, or it might be caused by

disconnection or failure of the pump. This cut out can be

reset by pushing the red reset rod in the controller.

Error 7 = STUCK RELAY

This error indicates a problem with the heater control

circuitry inside the unit.

Error 8 = NO TEMP DATA

This error indicates a problem with the digital temperature

sensor in the heater. It might be caused by the sensor

being disconnected inside the unit or by damage to the

sensor.

Installation:

1. The heater should be located:

(a) on the pressure side of the pump.

(b) before the filter on the return line and before

chlorinators and ozone injectors (if fitted).

(c) where it is accessible for maintenance and with

enough clear room to remove the control head

from the heater body.

2. The heating system must be installed in an enclosure

rated IP24, ie. it must be totally protected against water

from all directions.

3. All installations must comply with AS3100 and any

additional requirements of your local supply authority

including any relevant code of practice.

4. The heater body may be plumbed so the water can be

in either direction when mounted horizontally. If

mounted horizontally, the heater must be mounted with

its outlet sockets to the top so the safety water

detection circuits are effective. Please note label on

heater head which indicates correct side up.

5. Supply cord damage

If the supply cord of the equipment is damaged, it

must be replaced by a repair shop appointed by the

manufacturer because special purpose tools are

required.

SPA POWER 500

Spa-Quip (Australia) Pty Ltd

Unit 2A, 4 Hudson Ave

Castle Hill, NSW 2154 Australia

Phone: (02) 9634 5600 Fax: (02) 9634 5900

email: service@spa-quip.com.au

Spa-Quip Ltd

PO Box 302-114, North Harbour Post Shop

Auckland New Zealand

Phone: (09) 415 8622 Fax: (09) 415 8621

http://www.spa-quip.co.nz

email: inquiry@spa-quip.co.nz

OPERATING INSTRUCTIONS

Pt No 916309

Loading...

Loading...