Page 1

FAN-PWM-V3

Instructions

Page 2

www.spalusa.com

1

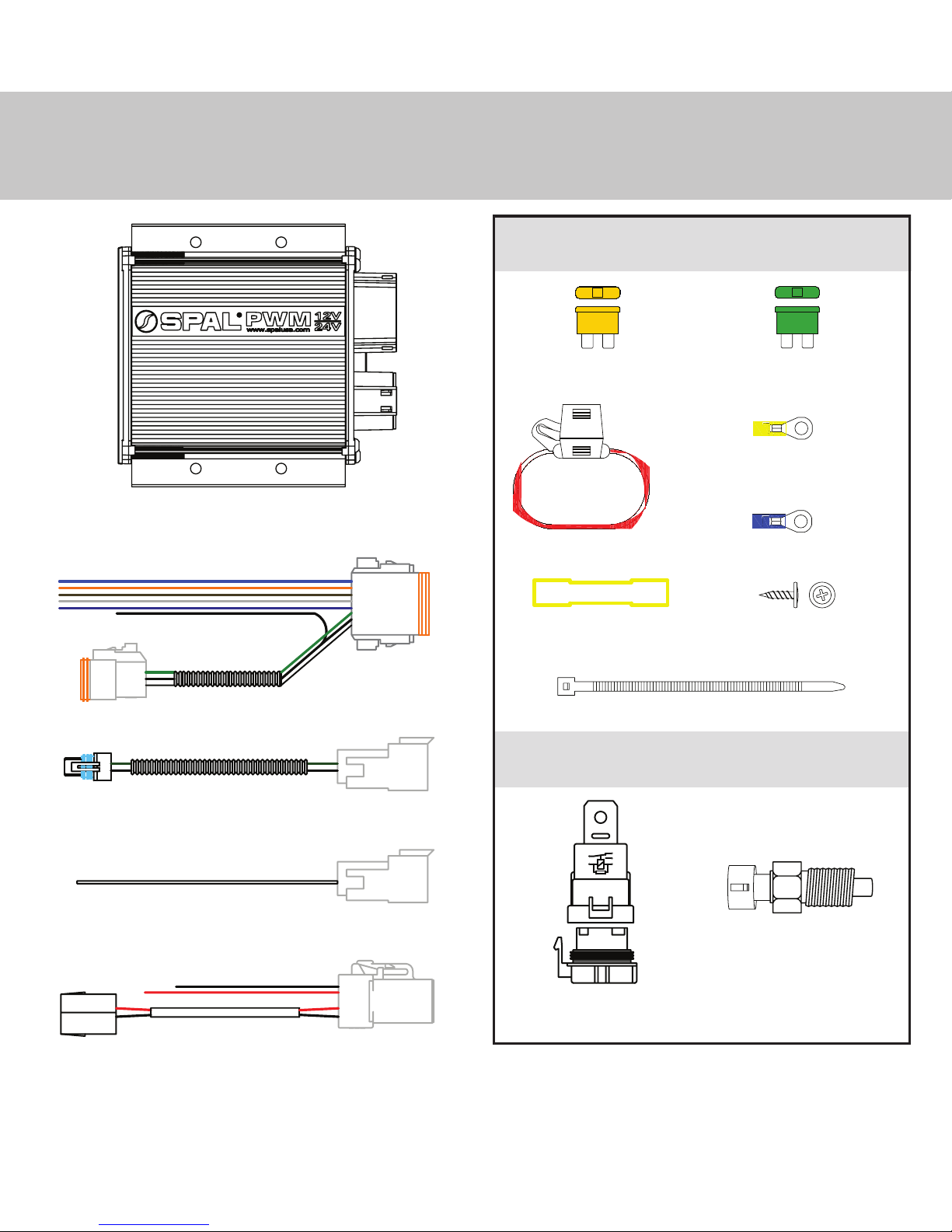

Parts Included In Kit

FA N-PWM CONTROLLER

HARDWARE BAG

INSTRUCTION BOOKLET

20 AMP FUSE

20

BCU+

FAN-PWM-V3 Controller (1)

MAIN HARNESS

FA N-PWM CONTROLLER

ITEMS INCLUDED IN KIT

HARDWARE BAG

INSTRUCTION BOOKLET

FUSE HOLDER

20 AMP FUSE

30 AMP FUSE

YELLOW RING CONNECTORS (2)

30

20

BCU+

DT06-3S

C B

Main Harness (1)

MAIN HARNESS

SPAL TEMP SENSOR HARNESS

FA N-PWM CONTROLLER

ITEMS INCLUDED IN KIT

HARDWARE BAG

INSTRUCTION BOOKLET

FUSE HOLDER

20 AMP FUSE

30 AMP FUSE

YELLOW RING CONNECTORS (2)

BLUE RING CONNECTORS

(2)

YELLOW BUTT CONNECTOR

(1)

30

20

BCU+

BA

DT06-3S

C B

SPAL Temp Sensor Harness (1)

OEM TEMP SENSOR HARNESS

MAIN HARNESS

SPAL TEMP SENSOR HARNESS

FA N-PWM CONTROLLER

ITEMS INCLUDED IN KIT

HARDWARE BAG

INSTRUCTION BOOKLET

FUSE HOLDER

20 AMP FUSE

30 AMP FUSE

YELLOW RING CONNECTORS (2)

BLUE RING CONNECTORS

(2)

YELLOW BUTT CONNECTOR

(1)

SELF TAPPING SCREWS

(4)

30

20

BCU+

BA

DT06-3S

C B

OEM Temp Sensor Harness (1)

OEM TEMP SENSOR HARNESS

MAIN HARNESS

POWER HARNESS

SPAL TEMP SENSOR HARNESS

FA N-PWM CONTROLLER

ITEMS INCLUDED IN KIT

HARDWARE BAG

INSTRUCTION BOOKLET

ZIP TIES

(12)

FUSE HOLDER

20 AMP FUSE

30 AMP FUSE

YELLOW RING CONNECTORS (2)

BLUE RING CONNECTORS

(2)

YELLOW BUTT CONNECTOR

(1)

SELF TAPPING SCREWS

(4)

30

20

BCU+

BA

DT06-3S

C B

Power Harness (1)

Hardware Bag

Fuse Holder (1)

Yellow Butt

Connector (1)

Self Tapping

Screws (4)

Zip Ties (12)

86

87

87a

85

30

FRH

OPTIONAL ITEMS

20

BCU+

20 Amp Fuse (1) 30 Amp Fuse (1)

86

87

87a

85

30

SPAL SENSOR

FRH

OPTIONAL ITEMS

30

20

BCU+

86

87

87a

85

30

SPAL SENSOR

FRH

OPTIONAL ITEMS

30

20

BCU+

Yellow Ring Connectors (2)

86

87

87a

85

30

SPAL SENSOR

FRH

OPTIONAL ITEMS

BCU+

Blue Ring Connectors (2)

86

87

87a

85

30

SPAL SENSOR

FRH

OPTIONAL ITEMS

BCU+

86

87

87a

85

30

SPAL SENSOR

FRH

OPTIONAL ITEMS

BCU+

86

87

87a

85

30

SPAL SENSOR

FRH

OPTIONAL ITEMS

BCU+

86

87

87a

85

30

SPAL SENSOR

FRH

30

20

Optional Equipment

86

87

87a

85

30

FRH

(Fan Relay Harness)

SPAL Sensor

86

87

87a

85

30

Page 3

www.spalusa.com

2

Suggested Fuse Values

PULLER # PUSHER # DESCRIPTION AIRFLOW (CFM) RECOMMEDNED FUSE

9”

30102061 30102053 9” High Performance Fan / Paddle Blade 740 25

30100392 30100381 9” Fan 590 10

10”

30102057 30102058 10” High Performance / Paddle Blade 1120 25

30100360 30100374 10” Fan 650 10

11”

30102052 ------------- 11” Dual High Performance Fan / Pull 2780 30/Per Motor

30102054 30102040 11” High Performance Fan / Paddle Blade 1360 30

30101500 30101502 11” Medium Profile Fan 970 15

30100364 30100365 11” Fan 810 10

12”

30102130 ------------- 12” High Performance Dual Fan / Curved Paddle 3170 30/Per Motor

30102029 30102030 12” High Performance Fan / Curved Blade 1450 30

30102038 30102025 12” High Performance Fan / Paddle Blade 1640 30

30101504 30101505 12” Medium Profile Fan 1230 20

30100375 30100384 12” Fan 870 10

13”

30102044 30102045 13” High Performance Fan / Curved Blade 1640 30

30101507 30101508 13” Medium Profile Fan 1250 20

30100398 30100399 13” Fan 1030 10

14”

30102041 30102055 14” High Performance Fan / Striaght Blade 1650 30

30102042 30102056 14” High Performance Fan / Curved Blade 1780 30

30101509 30101510 14” Medium Profile Fan 1280 20

30100385 30100382 14” Fan 960 10

16”

30102113 ------------- 16” Extreme Performance Fan / Pull 2315 30

30102036 30102082 16” High Performance Fan / Straight Blade 2035 30

30102082 ------------- 16” High Performance Fan / Paddle Blade 1880 30

30102048 30102049 16” High Performance Fan 2025 30

30101516 30101517 16” Medium Profile Fan 1610 20

30100400 30100401 16” Fan 1300 15

Page 4

www.spalusa.com

3

New Features of 3rd Generation PWM

**WHY THIS MAY BE IMPORTANT FOR YOU**

• Ability to reset to any one of 3 preset temperature ranges when using FAN-PWM-TS sensor

• Smart fan diagnostics detects stalled or over current fans to prevent module damage

• New 16 bit MCU for increased resolution on temperature sensor input

• Primary fan low power starts to reduce the current spike on electrical system

• Onboard status LED and status output for vehicle interior status light

• Quality Deutsch IPD connectors on the premium harness made in USA

• Silicone rubber button membrane and case seals for improved durability

• Improved AC input timing to minimize fan operation during defrost cycles

• Single unit capable of use with both 12VDC and 24VDC systems

In an effort to add features and improve quality of the FAN-PWM the functionality of the

unit may impede previous ‘creative’ installations of FAN-PWM’s.

• A brushed DC motor MUST be connected to the fan output or the unit will report an

error code. Possible use with very low power (<4A) fans and non SPAL products may

also cause fan not found error code. SPAL USA will not guaranty this products function-

ality with NON SPAL fans as too often specications are unknown.

• Over current protection means that the output will SHUT DOWN if the measured fan

continuous run current increases above 30A for extended periods. If running a fan ap-

proaching this amount of current draw (>25A), SPAL USA recommends that the installa-

tion also include a status light so the operator will be aware of fan status. See page 8 for

status light wiring.

• Because of timing sequences on the AC input wire when using a manual override

switch there will be a delay before the fan turns on/off with the switch.

Page 5

www.spalusa.com

4

Introduction / Overview

Congratulations on your purchase of the SPAL FAN-PWM! Due to the various in-

stallation congurations, please carefully read the entire manual before installing

the FAN-PWM. This SPAL Electric Fan Controller (FAN-PWM) will vary the speed

of the fan based on engine temperature by using Pulse Width Modulation tech-

nology. A second fan can be added but requires the use of an additional relay to

control the secondary fan (SPAL part number FRH). The secondary fan will not be

variable speed; it will be ON/OFF only.

Because the FAN-PWM was designed to alter the speed of the fan, SPAL USA

suggests setting the High 10° to 20° above the thermostat rating and setting the

Low at least 10° below the High.

Instruction Manual Highlights

Wiring 15 - 19

Programming 11 - 14

Trouble Shooting 21 - 24

Frequently Asked Questions (FAQ) 25 - 26

Page 6

www.spalusa.com

5

Operation

The FAN-PWM is equipped with 2 LED’s: a ‘STAT’ LED and a ‘FAN’ LED.

‘STAT’ LED will be lit when the unit is powered on, system checks are OK, and

the fans are not running.

The 3 color ‘FAN’ LED indicates when the fan output is active, and is also used

during programming. Each color represents the following: AMBER for temperatures above LOW, RED for temperatures above HIGH, and GREEN when the

A/C input has been activated.

When the Low temperature setting is reached, the ‘FAN’ LED will light AMBER,

and the fan will run at 50% or ½ speed. The fan will then gradually increase

in speed as the engine temperature rises. If the high temperature setting is

reached, the ‘FAN’ LED will light RED, and the fan will now be running at full

speed. (continued next page)

Front View of PWM

ENTR PRG STAT FAN

Page 7

www.spalusa.com

6

Operation

(continued)

Mounting

The SPAL FAN-PWM is water resistant and can be mounted in the engine bay or

inside the vehicle. Keep the controller away from high heat sources such as the

engine exhaust. Above the wheel well, on the radiator support, or rewall are

good examples of proper locations.

When the ‘FAN’ LED lights RED, a negative output will be sent on the gray wire.

This gray wire can be used to trigger a fan relay, an indicator light, etc. If you are

using dual fans with the recommended wiring setup (refer to pages 18/19) your

2nd fan will turn on full speed at this time.

If the cooling system is able to lower the coolant temperature approximately 5°

below the High setting, the ‘FAN’ LED will turn from RED to AMBER and the fan

will slow in speed; at this time the second fan output will stop as well. If the cooling system is able to continue to lower the coolant temperature to approximately

5° degrees below the low setting, the ‘FAN’ LED will turn off, the ‘STAT’ LED will

light GREEN, and the fan will stop completely.

Page 8

www.spalusa.com

7

Temperature Sensor Connection

The FAN-PWM can be used with most vehicle’s original temperature sensor

circuits and aftermarket electric temp gauges. This eliminates the need for an

additional sensor. Some older cars’ sensors (as those circa the 1970’s) may not

work. If you experience problems, please call our technical support line for assistance 1-800-454-7725.)

Vehicles With known issues:

• Ford modular engine’s coolant/head temp (4.6/5.4L) range switching @ ~200 degrees

• GM Duramax (could be other new GM also) multi range switching @ ~160 degrees

With these sensors the same voltage will exist at multiple temperatures. If you

set the controller above the switching point of the sensor range it will technically work. The problem is that the fan will turn on at cold startup initially, turn

off, before coming on again at the proper temperature.

• Please see the PROGRAMMING section on pages 11-14.

• If using this type of sensor, the SPAL FAN-PWM must be programmed to your desired

temperature points as the default settings will not be properly calibrated.

Note: Both large and small gauge ground wires must be grounded.

Single Fan: Please see SINGLE FAN WIRING instructions on Page 16 and 17.

Dual Fan: A dual fan set-up requires a Fan Relay Harness (SPAL part number

FRH) to power the secondary fan. Please see DUAL FAN WIRING

instructions on Page 18 and 19

Connecting To A Factory OEM Temperature Sensor

Page 9

www.spalusa.com

8

Temperature Sensor Connection

If your vehicle is not equipped with an OEM temperature sensor, you can purchase a SPAL temperature sensor (SPAL part number FAN-PWM-TS) that plugs

directly into the fan controller harness. This sensor should be located in the engine for optimal performance.

• When using the SPAL temperature sensor, the fan controller has a factory

preset with a Low setting of ~190° and High setting of ~205°.

• If different settings are required, please see the PROGRAMMING section

on pages 11-14.

Optional Status Output

The FAN-PWM provides a negative output for an external device such as a LED

(not provided) to be used to remotely show the status of the system. With the

vehicle’s ignition on, the status output will indicate the following:

• No output: All checks OK, fan not running

• Output on: Fan output is active (fan could be running low to high speed)

• Blinking output: Indicates an error code; watch ‘STAT’ LED on module for

error code (See page 21)

STA T US LIGHT/LED

- STA T US OUTPUT (BROWN)

+ 12VDC IGNITION POWER

12V

SPAL Temperature Sensor (FAN-PWM-TS)

Page 10

www.spalusa.com

9

AIR CONDITIONING INPUT (BLUE)

AIR CONDITIONING COMPRESSOR

GROUND

+12VDC WHEN A/C ON

A/C Wiring Diagram

Air Conditioning Input

The FAN-PWM has a built in 15 second delay for ON and a 30 second delay for

OFF with the Air Conditioning Input. After the A/C compressor has turned ON,

the fan will not go to HIGH until after a 15 second delay. After the A/C turns off,

the fan will stay on HIGH for 30 seconds before resuming normal operation.

1. If your A/C system does not have a trinary switch, connect the Blue wire

directly to the +12V wire of the air conditioning compressor or a wire within

your HVAC system that is powered only when the A/C is engaged. As a

result any time the compressor is engaged and or the A/C is activated, the

fan(s) will run at 100% with ‘FAN’ LED lit GREEN.

Page 11

www.spalusa.com

10

Air Conditioning Input

(continued)

2. If your A/C system has a trinary switch, you may use it to trigger your

cooling fans. This is the preferred way to control your cooling fans as the

fan operation is based on the pressure of the coolant in the A/C system.

Though the A/C pump may not be running, the pressure of the A/C system

may require operation of the cooling fans to properly cool the A/C condenser.

A

IR CONDITIONING COMPRESSOR

Blue Wire from FA N-PWM

A/C

Thermostat

Existing wire(s) from

evaporator wiring harness

Y

T

B

A

T

E

R

Ground

+12VDC

FUSE

5A

A/C TRINARY DIAGRAM

Page 12

Programming

ENTR PRG STAT FAN

‘Stat’ LED (Green):

• On when FAN-PWM is powered from the ignition input. Fan(s) are not on.

• Blinking indicates an error code. See page 21 for error codes.

3 Color ‘Fan’ LED:

• RED: High temperature setting has been reached.

• Fan(s) run at High speed.

• AMBER: Low temperature setting has been reached.

• Fan starts at half-speed and increases until High temperature setting is

reached.

• GREEN: Indicates Air Conditioning has been powered ON.

• Fan(s) run at full speed.

www.spalusa.com

11

Page 13

www.spalusa.com

12

When programming the FAN-PWM the fan will turn off automatically to allow

quicker warm-up of coolant temperature. If at anytime you enter programming

mode by mistake, repeatedly press the PRG button until the unit returns to

normal status.

1. Press and Hold down PRG button for 5 seconds.

2. Fan will stop running and the ‘FAN’ LED will be slowly blinking AMBER.

3. Warm engine up to desired LOW temperature and press ENTR button

to program LOW.

4. The ‘STAT’ LED will blink once and the ‘FAN’ LED will turn RED and be

blinking slowly.

5. Warm engine up to desired HIGH temperature and press ENTR button

to set HIGH.

6. The ‘STAT’ LED will blink once then ‘FAN’ LED will turn GREEN and be

blinking slowly.

7. Press the PRG button once to EXIT programming.

Programming

(continued)

Setting Both The Low & High Temperature

Page 14

www.spalusa.com

13

Programming

(continued)

1. Press and Hold down PRG button for 5 seconds.

2. Fan will stop running and ‘FAN’ LED will be slowly blinking AMBER.

3. Press PRG button once.

4. ‘FAN’ LED will be slowly blinking RED.

5. Warm engine up to desired HIGH temperature and press ENTR button to

set HIGH.

6. The ‘STAT’ LED will blink once then the ‘FAN’ LED will be slowly blinking

GREEN.

7. Press PRG button once to EXIT programming.

Setting The High Temperature Only:

Setting The Low Temperature Only

1. Press and Hold down PRG button for 5 seconds.

2. Fan will stop running and the ‘FAN’ LED will be slowly blinking AMBER.

3.

Warm engine up to desired LOW temperature and press ENTR to set LOW.

4. The ‘STAT’ LED will blink once and the ‘FAN’ LED will turn RED and be

blinking slowly.

5. Press PRG button 2 times to EXIT programming.

Page 15

www.spalusa.com

14

Programming

(continued)

The FAN-PWM has 3 default programs for use with the SPAL temperature sensor (FAN-PWM-TS).

Selecting The Desired Preset

1. Hold down PRG button for 5 seconds.

2. FAN will stop running and ‘FAN’ LED will be slowly blinking AMBER.

3. Press PRG button 2 times.

4. ‘FAN’ LED will slowly blink GREEN.

5. Press ENTR button once for Preset 1. ‘STAT’ LED will ash once.

Press ENTR button again for Preset 2. ‘STAT’ LED will ash twice.

Press ENTR button again for Preset 3. ‘STAT’ LED will ash three times.

6. Once desired preset has been reached Press PRG button to exit

programming mode.

Preset 1 has a LOW temp of 170° and a HIGH temp of 185°.

Preset 2 has a LOW temp of 190° and a HIGH temp of 205°.

Preset 3 has a LOW temp of 205° and a HIGH temp of 220°.

Page 16

www.spalusa.com

15

Wiring

Wire Color Harness Wire Connection

RED FAN/PWR Fan Positive with Fan Connector to Primary Fan

WHITE FAN/PWR Fan Negative with Fan Connector to Primary Fan

RED FAN/PWR +12VDC Power Directly to Battery

BLACK FAN/PWR Ground

PURPLE MAIN Not Used

ORANGE MAIN

Switched Ignition (+12VDC when vehicle is running)

GRAY MAIN

Secondary Fan Output (negative trigger for relay)

BLUE MAIN Air Conditioning Input (+12VDC when A/C

compressor is ON

BROWN MAIN Status Output (negative output for Light/LED)

WHITE OEM SENSOR OEM Temperature Sensor (Variable Voltage 0-5

HARNESS VDC)

BLACK SPAL SENSOR SPAL Temperature Sensor with connector

HARNESS

GREEN SPAL SENSOR SPAL Temperature Sensor with connector

HARNESS

YELLOW

FRH

+12VDC Directly to Battery

RED FRH Secondary Fan Positive

GRAY FRH

PWM Secondary Fan Output (Gray wire from FAN-PWM)

ORANGE FRH Switched Ignition (+12VDC when vehicle is running)

BLACK FRH Chassis Ground

Optional Second Fan Relay (FRH)

Page 17

www.spalusa.com

16

Wiring

(continued)

OEM TEMP SENSOR

(WHITE)

VA RIABLE VOLTA GE +

GROUND

SINGLE FAN OEM SENSOR

Y

T

B

A

T

E

R

FUSE

GROUND

(BLACK)

+12VDC (RED)

MAX. 30 AMP

FUSE

FA N/PWR HARNESS

C B

AIR CONDITIONING INPUT (BLUE) SEE PA GE 9

STA TUS OUTPUT (BROWN) SEE PA GE 8

SWITCHED IGNITION (ORANGE)

(GRAY) NOT USED

MAIN HARNESS

(PURPLE) NOT USED

GROUND (BLACK)

Single Fan OEM Sensor

Page 18

www.spalusa.com

17

Wiring

(continued)

SINGLE FAN SPAL SENSOR

Y

T

B

A

T

E

R

FUSE

GROUND

(BLACK)

+12VDC (RED)

MAX. 30 AMP

FUSE

FA N/PWR HARNESS

C B

AIR CONDITIONING INPUT (BLUE) SEE PAGE 9

STAT US OUTPUT (BROWN) SEE PA GE 8

SWITCHED IGNITION (ORANGE)

(GRAY) NOT USED

MAIN HARNESS

(PURPLE) NOT USED

SPAL TEMP SENSOR HARNESS

SPAL SENSOR

GROUND (BLACK)

Single Fan SPAL Sensor

Page 19

www.spalusa.com

18

Wiring

(continued)

C B

FAN POSITIVE (RED)

86

87

87a8530

Y

T

B

A

T

E

R

FUSE

AIR CONDITIONING INPUT (BLUE) SEE PA GE 9

GROUND

GROUND

STAT US OUTPUT (BROWN) SEE PA GE 8

SWITCHED IGNITION (ORANGE)

(BLACK)

+12VDC (RED)

FAN HARNESS

SECONDARY FAN OUTPUT (GRAY)

SWITCHED IGNITION (ORANGE)

+12VDC (YELLOW)

2ND FAN RELAY

PA RT # (FRH)

MAX. 30 AMP

FUSE

MAX. 30 AMP

FUSE

NOT USED (PURPLE)

OEM TEMP SENSOR (WHITE)

VA RIABLE

VOLTAGE +

GROUND

DUAL FAN OEM SENSOR

MAIN HARNESS

FAN/PWR

HARNESS

FUSE

GROUND (BLACK)

Dual Fan OEM Sensor

Page 20

www.spalusa.com

19

Wiring

(continued)

C B

FAN POSITIVE (RED)

86

87

87a

85

30

Y

T

B

A

T

E

R

FUSE

AIR CONDITIONING INPUT (BLUE) SEE PA GE 9

GROUND

GROUND

STAT US OUTPUT (BROWN) SEE PA GE 8

SWITCHED IGNITION (ORANGE)

(BLACK)

+12VDC (RED)

FAN HARNESS

SECONDARY FAN OUTPUT (GRAY)

SWITCHED IGNITION (ORANGE)

+12VDC (YELLOW)

2ND FAN RELAY

PA RT # (FRH)

MAX. 30 AMP

FUSE

MAX. 30 AMP

FUSE

NOT USED (PURPLE)

DUAL FAN SPAL SENSOR

MAIN HARNESS

FAN/PWR

HARNESS

FUSE

SPAL TEMP SENSOR HARNESS

SPAL SENSOR

GROUND (BLACK)

Dual Fan SPAL Sensor

Page 21

www.spalusa.com

20

Manual Fan Override Switch

This will allow your cooling fan to run anytime the override switch is ON.

WARNING: There is a 15 second delay after you ip the switch ON and a 30 second delay after you ip the switch OFF. After you turn the switch ON the FAN(s)

will go to Full speed after the 15 second delay. The FAN(s) will stay on high until

the 30 second delay is complete. If the switch is turned ON and OFF repeatedly

the delay will restart after the last time the switch was turned ON or OFF.

**SPAL USA suggests this override switch also trigger the electric water pump

relay. This will allow a single override switch to control both the fan and electric water pump.**

Note: 1. The fan will continue to run indenitely if the switch is not shut off.

2. When running for extended periods of time, the voltage should be

monitored as to not overly discharge the vehicle’s battery.

Y

T

B

A

T

E

R

BLUE A/C INPUT WIRE

+12VDC

TO BATTERY +12VDC

MANUAL FA N OVERRIDE

SWITCH

Page 22

Troubleshooting

To reset or restore the FAN-PWM back to its original settings, press and hold

both the ENTR and PRG buttons down for 10 seconds. The ‘STAT’ LED will blink

5 times

Resetting Or Restoring FAN-PWM Back To Factory Defaults

Number of Blinks on ‘Stat’ LED

1

2

3

4

Blinking LED Code Explanations

CODE 1: Sensor Input Not Found

The FAN-PWM is not sensing a connection to a temperature sensor. Verify connections to the temperature sensor. If using an OEM sensor, verify correct temperature sensor wire is being tapped. See info under High and Low Program

Data Error for more information on sensor issues. If using SPAL sensor did you

cut the sensor harness connector off? If the sensor connector is cut off then you

have to splice the white wire to the green wire. If you have hooked the system

to a switch instead of a gauge type sender this error will occur once the switch

reaches its activation temp. Primary and secondary fan will run during this error

condition.

www.spalusa.com

21

Error Description

Code 1:

Code 2:

Code 3:

Code 4:

Page 23

www.spalusa.com

22

Troubleshooting

(continued)

CODE 2: Fan Not Found Or Fan Speed Error

The FAN-PWM is not sensing a fan or the fan is not functioning properly. Verify

the connections and operation. A brushed DC motor MUST be connected to the

fan output or the unit will report an error code. Possible use with very low power

(<4A) fans and non SPAL products may also cause Fan Not Found Error code.

SPAL USA will not guarantee this product’s functionality with non SPAL fans as

too often specications are unknown.

CODE 3: High & Low Program Data Error

You will need to reprogram the High and Low temperature settings on the FANPWM. If you are using the SPAL temperature sensor then you can reprogram

using one of the default settings. Temperature sensor issues are addressed as

follows.

1. Using a SPAL Temperature Sensor (FAN-PWM-TS)

a. Your LOW and HIGH settings are too close in temperature, either

move your LOW lower or the HIGH higher. A MINIMUM of 10°

AT THE SENSOR between the two points is recommended.

b. Possible bad wire connection. Double check all connections and

repeat the programming sequence.

(continued next page)

Page 24

Troubleshooting

(continued)

CODE 3: High & Low Program Data Error (continued)

2. Using Factory Coolant Temperature Sensor (OEM) or Electric Water

Temperature Gauge

a. Sensor prole not compatible with current LOW/HIGH values.

Depending on the application a minimum spread of 10°to 15° may not

be sufcient. This is more prevalent with older factory water tempera ture gauges. The voltage difference between the HIGH and LOW

temperature settings must be .1 Volt or higher.

b. White wire not connected to proper wire on vehicle. Typically on a 2

wire coolant temp sensor, one wire will be a chassis ground while the

other will vary in voltage with temperature. The white wire must be

connected to the wire which varies in voltage.

c. Connection was made to a temperature SWITCH not a sensor. The

FAN-PWM will not function connected to a switch (such as our 185-TS)

that is used to turn on a relay or warning light. The sensor type must

be for a gauge or a coolant temp sensor for a fuel injection computer.

d. Wiring from the sensor to the gauge or computer is faulty. The white

wire is a passive input and it must be connected in parallel with the

original circuitry designed for that specic sensor.

www.spalusa.com

23

Page 25

www.spalusa.com

24

Troubleshooting

(continued)

e. There are some 2 stage computer sensors which vary in voltage in 2

steps. These sensors drop in voltage until they reach a certain

temperature (example 200°) then the engine raises the power level

suddenly to have another similar drop in voltage. You might be able to

program the FAN-PWM to work within ONE of these stages. But as a

side effect, it will work also in the other stage which means the fan may

operate when not necessarily needed. For complete proper operation

in this case you will need to use a SPAL temperature sensor.

CODE 3: High & Low Program Data Error (continued)

CODE 4: Module Over Current Error

Over current protection means that the output will SHUT DOWN if the measured fan continuous run current increases above 30A for extended periods. If

running a fan that is approaching this amount of current draw (>25A), SPAL USA

recommends that the installation also include a status light so the operator will

be aware of the fan status.

Page 26

FAQ

After programming the Low and High temperature settings make sure you are

not pressing the ENTR button when ‘FAN’ LED is Blinking GREEN. If the ENTR

button is pressed after programming, the FAN-PWM is set to a factory default

setting erasing your previous settings.

My Temperature Settings Are Not Staying Programmed.

My Fan Stays On All The Time

FAN-PWM Dosen’t Turn On

1. Check fuses

2. Check battery and ignition wires for power

3. Check both ground connections. Make sure the small and large gauge

black wires are connected to ground

www.spalusa.com

25

1. DO NOT ground the “primary” fan to the chassis. If the fan’s negative

on the rst fan is wired to a chassis ground, then the fan will be on. Wire

the primary fan’s negative to the FAN-PWM fan negative. The FAN-PWM

variable speed control is through the negative side.

2. Is the A/C override hooked up? Check the power input to the Blue wire

and verify that it is only receiving a + 12 VDC when the A/C is on.

3. Is the small black wired hooked to a good ground source? If there is no

ground on that wire the PWM will run on high speed with the red LED on

5 seconds after the ignition is switched on.

Page 27

www.spalusa.com

26

FAQ

(continued)

1. Check relay wiring

2. Conrm ground signal from FAN-PWM on Gray wire when on High

3. Verify fan is working properly by grounding the gray wire from the relay

and turning the ignition on, fan should run at this time.

Second Fan Will Not Turn On

1. After the A/C or manual switch is turned on, there is a 15 second delay

before the FAN-PWM will override into High Mode.

2. Verify there is + 12 Volts going to the Blue wire when A/C or switch is

turned on.

Fan Does Not Go Into High Mode Immediately After

The A/C or Manual Override Is Turned On

Fans Stays In High Mode After Turning Off The

A/C Or Switch

1. After the A/C or switch is turned off, there is a 30 second delay before the

FAN-PWM will resume its normal variable speed operation.

2. Verify there is no power present on the Blue wire when the A/C or switch

is turned off.

For optional wiring diagrams, including 2-speed fans - visit www.spalusa.com,

or contact tech support at 1-800-454-7725 - email tech@spalusa.com

Page 28

03_08-109-FanPWM1s

SPAL Limited Warranty

SPAL USA warrants this product to be free from defects in material and workmanship for a period of eighteen (18) months from the date of sale of the original purchaser. SPAL USA will repair this product free of charge if, in the judgment of SPAL USA it has been proven defective within the warranty period. The

product should be returned, at the customer expense, to the location of original

purchase. This warranty does not cover any expenses incurred in the removal

and/or reinstallation of the product.

This warranty does not apply to any product damaged by improper installation,

misuse, abuse, improper line voltage, re, ood, lightning, or other acts of God,

or a product altered or repaired by anyone other than SPAL USA.

This warranty is in lieu of other warranties, expressed or implied, including any

implied warranty of merchantability. No person is authorized to assume for

SPAL USA any other liability concerning the sale of this product.

*IMPORTANT - KEEP YOUR RECEIPT WITH THIS WARRANTY STATEMENT!

If you have other questions about the installation of the FAN-PWM contact

SPAL USA tech support at 1-800-454-7725 or email tech@spalusa.com.

Additional information and updates can be found on at www.spalusa.com.

www.spalusa.com

Loading...

Loading...