EN

Operating

Instructions

Stud welding device BMS-9 ACCU

Stud welding gun PS-9K ACCU

EN

Device numbers

We recommend to enter the device numbers in the list so that they can be accessed quickly if servicing is required.

Device Type Serial number

Stud welding device BMS-9 ACCU

Battery BMS-9 ACCU

Stud welding gun PS-9K ACCU

Operating Instructions

Document no.: P00162, 04-2019, translation of the original instructions

(English: P00262)

All information in this document is the property of

Heinz Soyer Bolzenschweißtechnik GmbH.

Revision status

Document created/amended Editor Date

Original Created DD 03/05/2019

CONTENTS

1. General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1. Validity of the operating instructions 5

1.2. Declarations of conformity 5

1.3. Manufacturer 7

1.4. Instruction, training 7

1.5. Standards and directives 7

2. Important safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1. Warning signs used 8

2.2. General safety instructions 9

2.3. Personal protective equipment 12

2.4. Intended use of the stud welding device 13

2.4.1 Incorrect use 13

2.5. Intended use of the stud welding guns 13

2.5.1 Incorrect use 13

2.6. Operating company prerequisites 14

2.6.1 Prerequisites for personnel 14

3. Important safety instructions for battery operation . . . . . . . . . . . . . . . . . . . . 15

4. Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5. Storage, shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6. Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7. Description of the BMS-9 ACCU stud welding

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . device 19

7.1. Working method 19

7.1.1 Product features 20

7.1.2 Capacitor discharge stud welding 20

7.2. Overview of the controls 21

7.2.1 Displaying the operating states 22

7.2.2 Indication of the battery charging status on the device display 23

7.3. Charging and inserting the battery 24

7.4. Technical data of the BMS-9 ACCU stud welding device 28

7.5. Permitted stud welding guns 30

Operating Instructions Soyer Bolzenschweißtechnik 3

CONTENTS

7.6. Cleaning the stud welding device 30

8. Description of the PS-9K ACCU stud welding gun . . . . . . . . . . . . . . . . . . . . . 32

8.1. Technical data of the PS-9K ACCU stud welding gun 33

8.2. Cleaning of the stud welding gun 34

9. Description of the stud chuck. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9.1. Adjusting and inserting the adjustable stud chucks 35

10. Setup and connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

10.1. Requirements for the installation location 39

10.2. Connection of the stud welding device and the stud welding guns 40

10.2.1 Power supply 40

10.2.2 Switching the device on and off 40

10.2.3 Connecting the earth cable 40

10.2.4 Connecting the stud welding gun 42

11. Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

11.1. Adjusting the charging voltage on the stud welding device 43

12. Welding operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

12.1. Carrying out welding 45

12.2. Notes on checking the quality of the weld 46

12.2.1 Visual inspection 46

12.3. Welding defects and their causes 48

12.4. Malfunctions with an error message 49

13. Maintenance and repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

14. Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

15. Warranty conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4 Operating Instructions Soyer Bolzenschweißtechnik

1. General information

i

These operating instructions include important instructions and provisions for the

operation of the devices. Please keep the operating instructions at hand near the

devices.

In these operating instructions, the term “devices” refers to the stud welding

device and the stud welding gun.

Carefully read the operating instructions and any other documents contained in

the technical documentation. Pay particular attention to the safety instructions

which are intended to help you recognise any possible residual risks and prevent

hazards.

The drawings and illustrations in these operating instructions are for illustrative

purposes and may vary slightly from the actual equipment.

The manufacturer reserves the right to make technical changes.

General information

1.1 Validity of the operating instructions

These operating instructions apply to the following devices:

Stud welding device BMS-9 ACCU

Stud welding gun PS-9K ACCU

1.2 Declarations of conformity

The devices are designed and constructed in accordance with the general

accepted codes of practice.

Please note that significant changes to the device will cause the

declaration of conformity to become void.

Furthermore, the manufacturer's warranty may be rendered invalid.

Operating Instructions Soyer Bolzenschweißtechnik 5

General information

Heinz

Soyer Bolzenschweißtechnik GmbH

Inninger Straße 14

82237 Wörthsee

CE - Declaration of Conformity

We herewith declare that the design of the machine described below as well as in

the version marketed by us meets the safety and health requirements of the stated

guidelines and standards. Any modification of this machine without confirmation

shall automatically annul this declaration.

Designation of the machine

Stud welding device

Machine type

BMS

-9 ACCU

Machine no.

_____________________

Applicable EU guidelines

RoHS directive (2011/65/EU)

Low-voltage directive (2014/35/EU)

EMC directive (2014/30/EU)

Harmonised standards

applied, in particular

EN 60974

-1:2012

EN 60974

-10:2008

National regulations applied

DGUV direc

tive 1

Date 29 March 2019

Manufacturer

- signature

Function of the signatory

CEO

Stud welding device

6 Operating Instructions Soyer Bolzenschweißtechnik

1.3 Manufacturer

i

The manufacturer of the devices is:

Heinz Soyer Bolzenschweißtechnik GmbH

Inninger Straße 14

82237 Wörthsee

Phone: 0049-8153-885-0

Fax: 0049-8153-8030

Mail: info@soyer.de

Web: www.soyer.de, www.soyer.com

1.4 Instruction, training

General information

Soyer offers optional and individual instruction in the operation of the devices.

Moreover, Soyer offers training for customer-specific use of the

devices. The tutorial is available at:

https://youtu.be/QrYjCVNdRZk.

Information on the scope and costs of instruction and training can be

obtained from Soyer GmbH.

Also see our video instructions at

www.youtube.com/user/SoyerGmbH.

1.5 Standards and directives

The following standards, inter alia, must be observed for carrying out stud welding

work and for the qualification of personnel:

• DIN EN ISO 14555 Welding - Arc stud welding of metallic materials

• DIN EN ISO 14732 Welding personnel - Qualification testing of welding

operators and weld setters for mechanised and automatic welding of metallic

materials

• DIN EN 60974-9 Arc

• Technical Bulletin DVS 0903 Capacitor discharge stud welding with tip ignition

• Technical Bulletin DVS 0904 Instruction for practice - Arc stud welding

welding equipment - Installation and use

Operating Instructions Soyer Bolzenschweißtechnik 7

Important safety instructions

DANGER

!

WARNINGWARNING

!

CAUTIONCAUTION

!

2. Important safety instructions

Read the following chapters carefully and follow the safety instructions. Please

contact the manufacturer if you are uncertain or an instruction cannot be followed.

The devices have been constructed in accordance with the generally accepted

codes of practice and established and usual safety requirements were observed

and applied. In order to reach maximum safety, it is absolutely necessary to follow

and observe all safety instructions specified in these operating instructions.

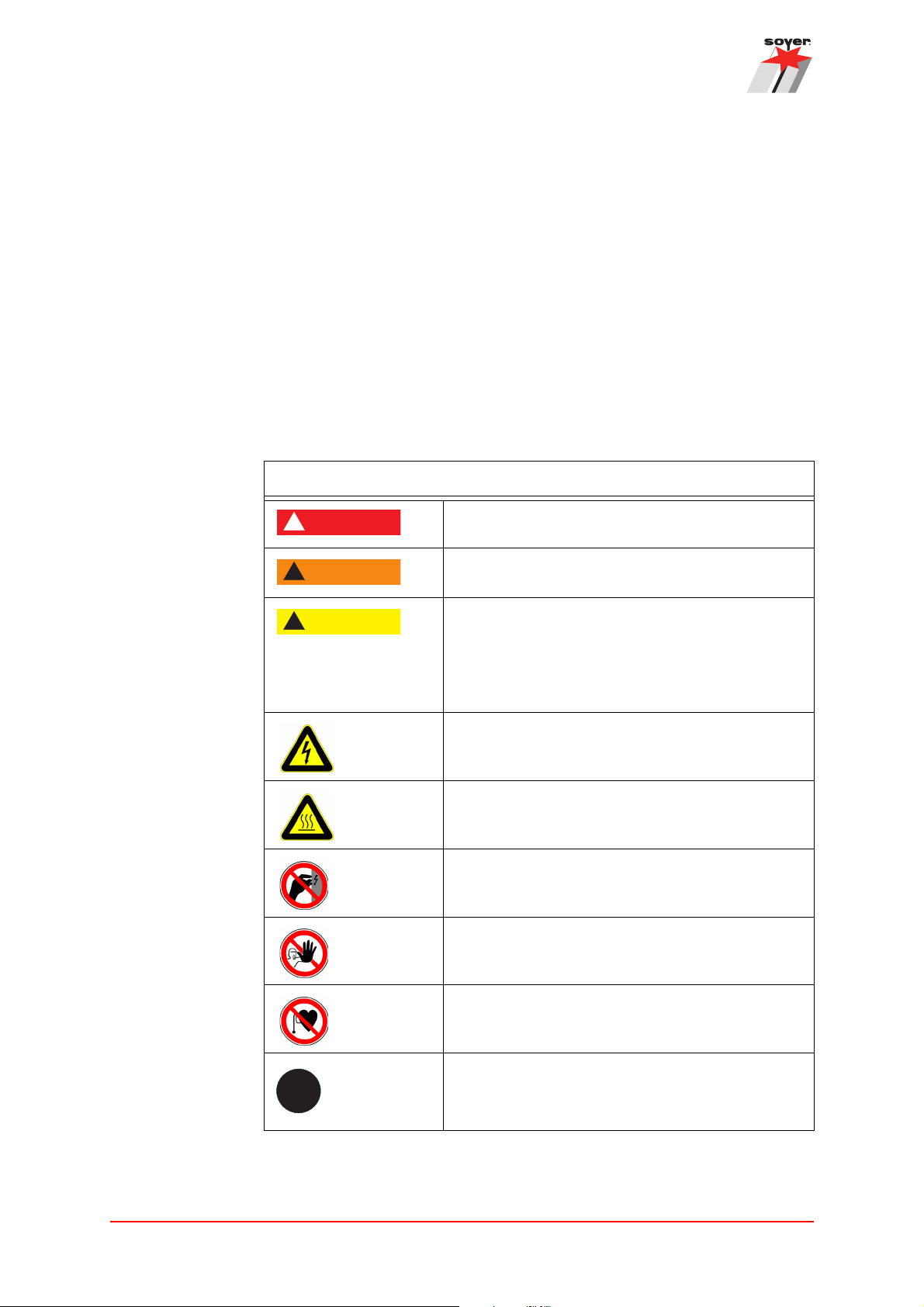

2.1 Warning signs used

Warning signs are used in this document, depending on the potential danger of

the situation.

Safety and information symbols used in this manual

This warning sign indicates imminent danger leading to severe injuries or death.

This warning sign indicates a potentially dangerous

situation that may lead to severe injuries or death.

This warning sign indicates a potentially dangerous

situation that may lead to minor injuries.

Without the warning triangle, this warning sign is

also used in the event of danger of material damage.

Additional sign indicating danger from electric current. The additional sign is used in connection with

a warning.

Additional sign indicating the danger of burns. The

additional sign is used in connection with a warning.

Do not touch the surface or the housing: Shock

hazard.

Do not touch or open, danger to unauthorised persons.

Danger to persons with medical implants such as

pacemakers.

The information sign is not a warning sign. It indicates important and useful information on the sub-

i

8 Operating Instructions Soyer Bolzenschweißtechnik

ject.

Important safety instructions

DANGER

!

Safety instructions

on the device

As an additional warning of danger, warning labels can be found on the devices.

Warning labels are affixed by the manufacturer and must not be removed. If a

warning label is damaged and thus illegible, a new warning label must be affixed

immediately.

Warning labels must be obtained from the manufacturer.

2.2 General safety instructions

Danger from electric current, general information

When working on live components, there is a danger to life from electric

current.

• Work on electric or electronic components may only be performe

tra

ined electrotechnical personnel in accordance with currently applicable

electrotechnical regulations.

d by

• Protection devices must not be manipulated or disabled. Protecti

vices include, for example, housing and housing cover, fuses or power

de

switches.

• If protection devices have to be removed for maintenance work, the device

may only be switched on again when all protection devices are ins

a

nd their functionality has been checked.

• Starting the device with faulty protection devices is not permitted. Fau

rotective devices must be repaired or replaced immediately. Un

p

eration by third parties must be prevented.

op

on

talled

lty

intentional

Operating Instructions Soyer Bolzenschweißtechnik 9

Important safety instructions

DANGER

!

DANGER

!

DANGER

!

Danger from electric current during maintenance and repair work

When working on live components, there is a danger to life from electric

current.

• Work on electric or electronic components may only be performe

tra

ined electrotechnical personnel of Soyer Bolzenschweißtechnik.

• Before performing any work on the stud welding device, the mains swi

f the device must be turned off and the mains plug must be disconnecte

o

e battery of battery-operated devices must be removed.

Th

• Before performing any work on the stud welding gun, the supply cables to

the stud welding device must be disconnected.

• If protection devices have to be removed for maintenance work, the device

may only be switched on again when all protection devices are ins

a

nd their functionality has been checked.

Danger from magnetic fields

In the area surrounding the device, strong magnetic fields which may influence medical auxiliary devices and therefore result in danger to life occur

during the welding process.

d by

tch

d.

talled

• Persons with electric medical aids (e.g. pacemakers) must stay away fr

the

devices.

• The operating personnel must ensure that persons with medical aids sta

ay from the devices.

aw

Danger of explosion from inappropriate operation sites in explosive

areas

The device is not designed for use in explosive areas.

• The device must not be installed and operated in explosive areas.

10 Operating Instructions Soyer Bolzenschweißtechnik

om

y

Important safety instructions

CAUTIONCAUTION

!

WARNINGWARNING

!

WARNINGWARNING

!

Danger of burns from hot surfaces

During the welding process, the workpieces and some parts of the welding

gun get so hot that touching them may cause burns.

• Always use personal protective equipment.

• Before working on hot parts of the device, check if they have cooled down.

Danger of burns from hot welding spatters

During the welding process, dangerous welding spatters may occur.

• Always use personal protective equipment.

Danger of fire from hot welding spatters

Welding spatters or hot workpieces occurring during the welding process may

cause danger of fire.

• Do not store combustible or highly flammable materials in the

ar

ea.

welding

Operating Instructions Soyer Bolzenschweißtechnik 11

Important safety instructions

WARNINGWARNING

!

2.3 Personal protective equipment

It is recommended to wear personal protective equipment when working with the

stud welding device.

Danger from missing or incorrect personal protective equipment

Stud welding may lead to danger of burns, especially due to hot welding spatters. Danger of blinding may also arise due to the occurrence of strong arcs.

• Always wear suitable and closed protective clothing.

• Type and extent of the required protective equipment depend on

tive occurrence of welding spatters and/or arcs. Both occurrences

respec

vary, depending on the basic material, stud material, stud size and t

quired welding performance.

re

• Please observe the following instructions for protective equipment.

Recommended personal protective equipment

Safety goggles

Welding spatters and a flash occur during the welding process. In order to protect your eyes, wear appropriate safety

goggles with side protection and a filter protector, if necessary.

Protective gloves

During the welding process, the workpieces and components of the welding gun get hot and welding spatters

occur. Wear appropriate, incombustible, heat-resistant protective gloves.

Protective clothing

the

he

12 Operating Instructions Soyer Bolzenschweißtechnik

Welding spatters occur during the welding process. Wear

appropriate, incombustible and, if necessary, heat-resistant

protective clothing.

Safety footwear

Welding spatters occur during the welding process. Wear

appropriate, incombustible, heat-resistant safety footwear.

Hearing protection

Relatively loud welding noises may occur, depending on

the welding device and the welding application. In that

case, wear appropriate hearing protection.

2.4 Intended use of the stud welding device

With the SOYER® BMS-9 ACCU capacitor discharge stud welding device, pins

and threaded studs from M3 to M8 as well as many different weld fasteners made

of steel, stainless steel, aluminium and brass can be welded in accordance with

DIN EN ISO 13918 (capacitor discharge).

Special studs or diameters upon request.

The stud welding device can only be operated with the welding guns described in

chapter “7.5 Permitted stud welding guns” on page 30.

The stud welding device must be operated within the scope of technical data.

2.4.1 Incorrect use

Any use of the device deviating from the intended use is considered as not intended.

Not intended use, unauthorised modification or manipulation of the device will

void the declaration of conformity and warranty claims against the manufacturer.

Important safety instructions

2.5 Intended use of the stud welding guns

With the SOYER® stud welding guns which are described in these operating

instructions, pins and threaded studs from M3 to M8 as well as many different

weld fasteners made of steel, stainless steel, aluminium and brass can be welded

in accordance with DIN EN ISO 13918 (capacitor discharge).

Special studs or diameters upon request.

The stud welding guns can only be operated with the stud welding devices which

are described in chapter “8.1 Technical data of the PS-9K ACCU stud welding

gun” on page 33.

The stud welding gun can only be operated within the scope of technical data.

2.5.1 Incorrect use

Every use of the welding gun deviating from the intended use is considered as not

intended.

Not intended use, unauthorised modification or manipulation of the device will

void the declaration of conformity and warranty claims against the manufacturer.

Misusing the gun as a tool, e.g. as a striking tool for checking the welding quality,

is not permitted.

Operating Instructions Soyer Bolzenschweißtechnik 13

Important safety instructions

i

2.6 Operating company prerequisites

The operating company of the device must ensure that the prerequisites described in these operating instructions for a safe operation of the device are met.

These include, for example, conditions at the installation location, regulatory requirements on a safe workplace, instruction of operating personnel and qualified

personnel in using the device, if applicable, compliance with required maintenance work as well as monitoring the intended use of the device.

These operating instructions must be stored in the vicinity of the device.

The operating company of the device must ensure that all protective devices are

present, active and intact before the device is used.

2.6.1 Prerequisites for personnel

Operating

personnel

Trained

electrotechnical

personnel

Persons authorised to operate the device must be familiar with the device and

trained accordingly. They must have read and understood these operating instructions. When working on the device, they must also be able to avert possible

residual danger to themselves or third parties or minimise them as far as possible.

To retain this qualification, safety training must be carried out at least once a year.

If necessary, specially trained personnel or the manufacturer must be consulted

in case of failure or for maintenance work.

Operators of stud welding devices must have technical expertise for operating

and adjusting the device properly as well as for properly carrying out weldings.

If welding personnel has to be qualified for certification of welding, the standards

DIN EN ISO 14555 and DIN EN ISO 14732 are to be observed.

In general: Works on live elements may only be performed by authorised electricians. This work must be performed in accordance with the applicable technical

rules for electrotechnical devices.

All devices of Soyer Bolzenschweißtechnik GmbH must only be opened

by personnel of Soyer or personnel authorised by Soyer.

14 Operating Instructions Soyer Bolzenschweißtechnik

Important safety instructions for battery operation

WARNINGWARNING

!

3.

Important safety instructions for battery operation

These operating instructions describe the operation of a stud welding device

which is operated by a lithium-based high-performance battery.

The battery consists of several connected individual cells.

Due to the very high energy density and the technical design of these batteries,

the batteries must be handled very carefully.

Hazards due to improper battery handling

Improper handling and use of a battery may lead to electric shocks, skin irritations, chemical burns, fire or explosion.

• For safe handling and operation, the following instructions and recommendations must be strictly observed.

General safety information

• Do not disassemble, open or shred batteries.

• Store batteries out of the reach of children and unauthorised persons.

• Do not expose batteries to heat or fire. Avoid storage in direct sunlight.

• Do not short-circuit batteries.

• Do not store batteries in a hazardous manner in a box or drawer where they

can short-circuit each other or can be short-circuited by other conductive materials.

• Do not expose batteries to mechanical impact.

• Only remove the battery from its original packaging right before it is used.

• If a cell is leaking, the fluid must not come into contact with the skin or the e

If

contact has occurred, please rinse the affected area with plenty of water

co

nsult a physician.

• Only use chargers which are especially designed for this type of battery.

• Always observe the polarity labels plus (+) and minus (-) on the batteries a

evices. Proper use must be ensured.

d

• Do not use rechargeable batteries, cells or other batteries which are not designed for the use in combination with the device.

• If the connections of batteries are soiled, clean them using a dry, clean cloth.

• Keep batteries clean and dry at all times.

• Batteries must be charged before use. Always use the proper charger and observe the manufacturer’s instructions for correct charging.

• Do not charge batteries for an extended period if they are not used.

• Do not charge batteries at temperatures below 0 °C.

• The batteries may only be used in the SOYER® devices for which they are intended.

yes.

and

nd

Operating Instructions Soyer Bolzenschweißtechnik 15

Important safety instructions for battery operation

• If possible, batteries should be removed from devices, if the devices are not in

use for several weeks.

• Never use or store batteries and devices with inserted battery in an exp

nvironment or in an environment with highly flammable substances.

e

• Ambient temperature during operation of the device: -20 °C to +50 °C.

Maintenance

• Regularly check whether the battery is in clean and dry condition.

• Use a clean and dry cloth to remove dirt.

Safe storage

losive

• Always store batteries in a clean and dry place. Ideally store the batteries a

r

oom temperature as a maximum or in colder environments (e. g. fridge).

• Admissible temperature during storage: -20 °C to +60 °C (recommended: 0

to +20 °C).

• Do not store batteries in discharged condition. The residual capacity should be

at least 50 - 80%.

• Check stored batteries every 2 - 3 months and charge them, if required, t

event deep discharge which results in the destruction of the battery.

pr

Handling of defective batteries and disposal

• Always dispose of batteries in an environmentally compatible way in accordance

with applicable local provisions. Consult the local waste disposal company.

• Never dispose of batteries in household waste.

• Do not dispatch batteries. If a battery is defective, please contact co. Soyer.

• Do not touch any leaking fluid with bare hands. Collect the fluid and dispos

o

f it in the correct manner. Wear goggles and protective gloves.

Dealing with battery malfunctions

Abnormal battery performance such as incorrect charging or unusually long

charging times, noticeable sudden power loss, unusual LED messages or leaking

fluids can indicate a battery defect.

t

°C

o

e

• In case of obvious or suspected battery malfunctions, please consu

e of co. Soyer.

servic

16 Operating Instructions Soyer Bolzenschweißtechnik

lt the

Important safety instructions for battery operation

Measures in case of battery fire

• Do not touch the burning battery, not even with protective gloves. A

ery is extremely hot due to plasma formation!

batt

• In case of battery fire, remove all flammable objects around the burning batter

a

nd call the fire brigade, if required.

• Ensure sufficient ventilation to ensure that hazardous and explosive vapou

ca

n escape.

• In case of significant smoke development, please leave the room immediately.

• In case of respiratory tract irritation, consult a physician.

• Do not fight battery fire with water. Powder extinguishers and fire blankets only

serve to extinguish surrounding fires but are not an effective method to fight

the battery fire.

burning

rs

y

Operating Instructions Soyer Bolzenschweißtechnik 17

Transport

i

i

i

4. Transport

When transporting the device, make sure that it cannot be damaged. Appropriate

packaging can protect the device against weathering effects, especially moisture.

Do not dispatch the battery. Please observe chapter “3. Important safety

instructions for battery operation” on page 15.

5. Storage, shutdown

6. Disposal

During storage or shutdown, make sure to protect the device against dirt and

humidity.

Protect the device against unauthorised access by third parties.

For the storage of the battery, please observe chapter “3. Important

safety instructions for battery operation” on page 15.

Local environmental directives must be observed when disposing of the device.

Water-endangering as well as environmentally hazardous substances are to be

disposed of in accordance with legal regulations.

If applicable, materials must be separated according to regulations.

For the disposal of the battery, please observe chapter “3. Important

safety instructions for battery operation” on page 15.

18 Operating Instructions Soyer Bolzenschweißtechnik

Description of the BMS-9 ACCU stud welding device

a

c

b

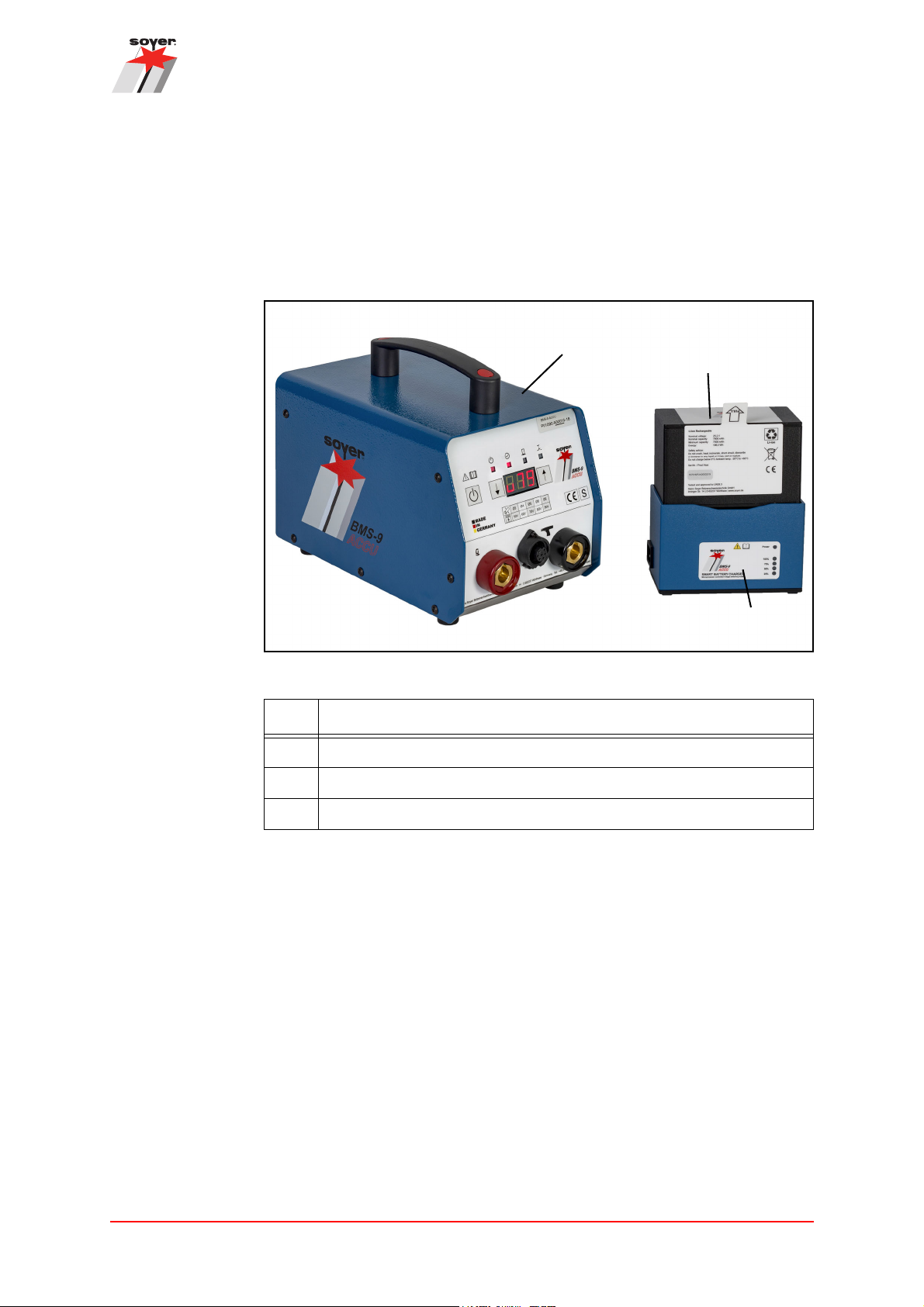

7. Description of the BMS-9 ACCU stud welding

de

vice

The main elements of the stud welding device and its features are described in

the following.

Figure 1: BMS-9 ACCU stud welding device

Item Designation

7.1 Working method

The welding capacitors with a capacity of 200 Millifarad are charged with up to

99 V using the energy from the battery (24 V). The charging unit corresponds to

a state-of-the-art inverter power source. The welding power is output exclusively

by the welding capacitors.

With the SOYER® BMS-9 ACCU stud welding device, pins and threaded studs

from M3 to M8 as well as many different weld fasteners made of steel or stainless

steel can be welded in accordance with DIN EN ISO 13 918 (capacitor discharge).

Welding of weld fasteners made of aluminium and brass is also possible.

a BMS-9 ACCU stud welding device

b Battery

c Battery charger

Operating Instructions Soyer Bolzenschweißtechnik 19

Description of the BMS-9 ACCU stud welding device

i

7.1.1 Product features

• Power supply via high performance battery

• Inverter switching power supply for maximum welding power

• High performance with a compact design and a low weight

• Automatic storage of the charging voltage

• Short charging cycles to increase productivity

• Precise digital display of the charging voltage

• Monitoring of all functions via a clear function display field

7.1.2 Capacitor discharge stud welding

The SOYER® BMS-9 ACCU stud welding device operates according to the

principle of capacitor discharge with tip ignition.

This system uses the sudden discharge of a capacitor bank to generate arc

energy.

Functional principle

The stud tip is placed

into contact with the

workpiece.

For more information on this subject, please visit: www.soyer.com.

The ignited arc creates

a melt zone on the stud

and the metal sheet.

The stud is immersed in

the weld pool. The

material solidifies and

the stud is permanently

welded.

20 Operating Instructions Soyer Bolzenschweißtechnik

7.2 Overview of the controls

Heinz Soyer Bolzenschweißtechnik GmbH · Inninger Str. 14 · D-82237 Wörthsee · Germany · Tel.: +49 8153 885-0 · www.soyer.com

R

BMS-9

Ø3

Ø4

Ø5

Ø6

Ø8

50V 60V 70V 80V 90V

S

MADE

IN

GERMANY

ab

h

dec

f

i

g

Description of the BMS-9 ACCU stud welding device

Figure 2: Overview of the front panel

Item Designation

Power key button for turning the device on/off

a

b Selection table with reference values for easy matching of the

required charging voltage to the stud diameter.

c Function key, reduce displayed charging voltage

d Display of operating states, see chapter “7.2.1 Displaying the operat-

ing states” on page 22.

e Function key, increase displayed charging voltage

f Display

g Socket for the connection of the earth cable

h 7-pin connection socket for the control cable

i Socket for the connection of the welding cable

Operating Instructions Soyer Bolzenschweißtechnik 21

Description of the BMS-9 ACCU stud welding device

ab dc

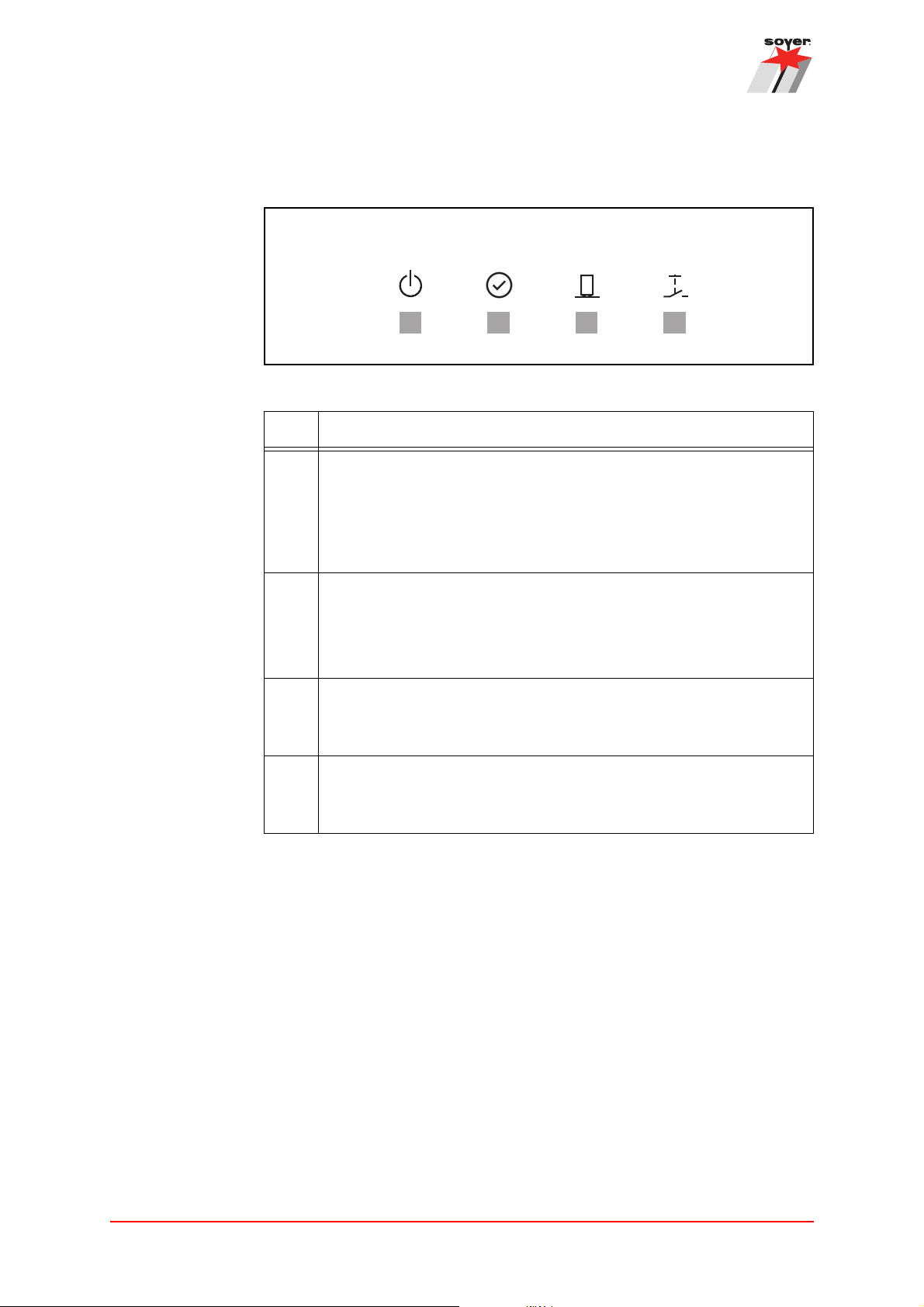

7.2.1 Displaying the operating states

Figure 3: Operating states

Item Designation

a Ready

In normal operation, the LED lights up when the stud welding device

is ready for operation in normal mode.

When the LED flashes, the device is in standby mode to save battery

power. When the gun is operated, the device starts up again.

b Indication of the charging voltage

The LED lights up as soon as the set charging voltage has been

reached.

After the welding process, the LED is off.

c Stud on workpiece

The LED lights up when the earth terminal is connected and the stud

touches the workpiece.

d Release

The LED lights up when the trigger button on the welding gun is

pressed.

22 Operating Instructions Soyer Bolzenschweißtechnik

Description of the BMS-9 ACCU stud welding device

7.2.2 Indication of the battery charging status on the device display

Figure 4: Indication of the battery charging status (70% in the example)

On the device display, the charging status of the battery is displayed.

It is displayed as a capital “A” followed by the charging status in percent.

You see this when you switch on the device directly after the charging voltage

(which is displayed as a small “u” followed by the voltage in volt).

Operating Instructions Soyer Bolzenschweißtechnik 23

Description of the BMS-9 ACCU stud welding device

a

b

c

d

e

7.3 Charging and inserting the battery

The BMS-9 ACCU is operated exclusively by a battery. Please ensure that the

device battery is always charged and ready for operation.

To charge the battery, you need the dedicated original charger (SOYER® article

number F07051/FA).

Figure 5: Charger

Item Designation

aCharger

b Connection socket for the mains cable.

c Charging contacts for the battery.

d The Power LED is illuminated if the charger is connected to the

mains.

e

Charging status indicators for the current charging status of the battery.

24 Operating Instructions Soyer Bolzenschweißtechnik

Description of the BMS-9 ACCU stud welding device

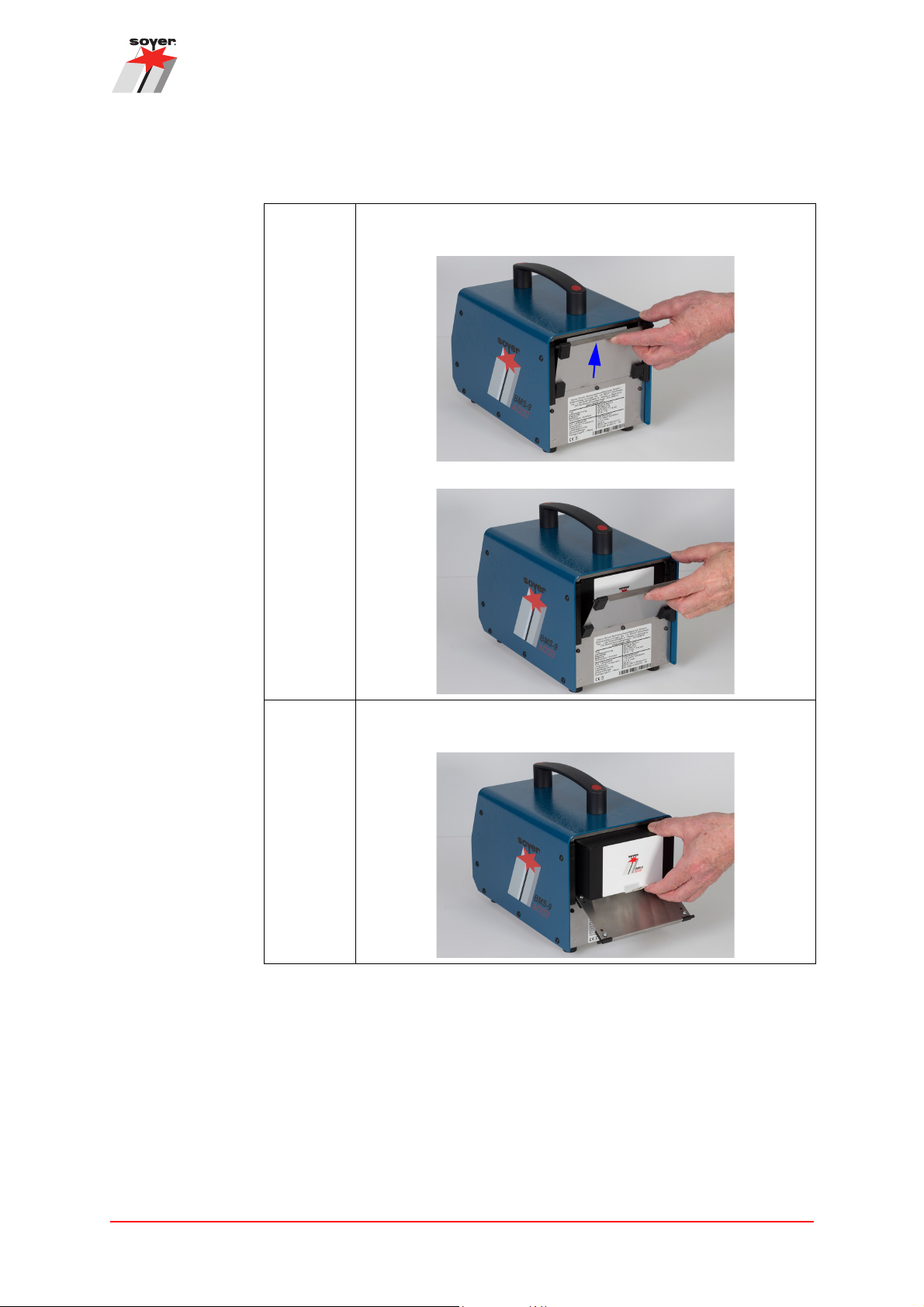

Removing, charging and inserting the battery

Step 1:

To remove the battery, pull the cover flap up to open it.

Step 2: Pull out the battery.

Operating Instructions Soyer Bolzenschweißtechnik 25

Description of the BMS-9 ACCU stud welding device

i

a

a

Removing, charging and inserting the battery

Step 3: Place the battery on the charging station. Ensure that the battery

is positioned correctly on the charging contacts (a).

Step 4:

Charge the battery until the 100% charging status indicator (a) of

the charger is illuminated.

Remove the battery from the charger when it is fully

charged. The charger is not suitable as a permanent

storage location for the battery.

26 Operating Instructions Soyer Bolzenschweißtechnik

Description of the BMS-9 ACCU stud welding device

i

a

Removing, charging and inserting the battery

Step 5: Push the charged battery into the device to the stop.

Ensure correct orientation so that the device contacts can

engage with the battery. If the labelling on the battery is properly

oriented to be read (a), the position is correct.

If the battery cannot be pushed completely into the

device, check the orientation and the contacts.

Step 6:

The exchange of the battery is complete.

Close the cover flap.

Operating Instructions Soyer Bolzenschweißtechnik 27

Description of the BMS-9 ACCU stud welding device

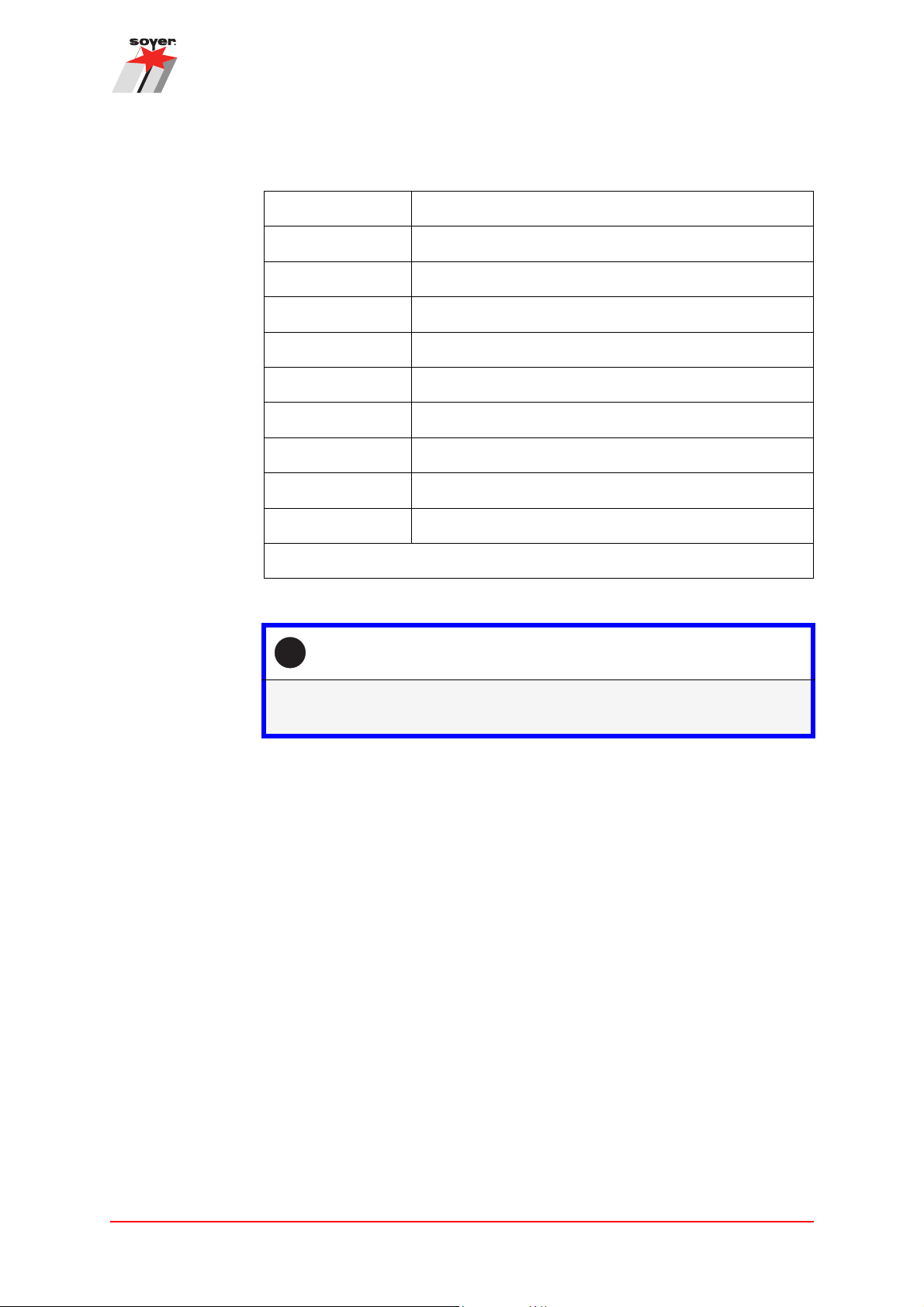

7.4 Technical data of the BMS-9 ACCU stud welding device

Stud welding device:

Designation BMS-9 ACCU stud welding device

Welding procedure

Standard gun PS-9K ACCU

Welding area M3 - M8 or Ø 3 - 8 mm for steel, stainless steel,

Power source Capacitor bank 200,000 μF

Charging voltage 40 - 99 V infinitely variable up/down

Welding sequence Ø6 mm: 10 studs/min

Power supply Battery

Cooling method S, or passive by convection

Protection class IP 23

Dimensions 180 x 235 x 300 mm (w x h x d)

Weight approx. 7.2 kg with inserted battery

Colour RAL 5009 azure blue

Capacitor discharge stud welding

aluminium and brass (aluminium and brass limited,

depending on the respective requirements)

Ø 3 mm: 20 studs/min

Subject to technical changes

Battery charger:

Designation Battery charger for BMS-9 ACCU

Mains connection Wide-range power supply 100 - 240 V, 50/60 Hz

Power output 28.8 V, 2 A

Protection class IP 30

Dimensions 83 x 96 x 152 mm (w x h x d)

Weight approx. 0.5 kg including mains cable

Colour RAL 5009 azure blue

Article number F07051/FA

Subject to technical changes

28 Operating Instructions Soyer Bolzenschweißtechnik

Description of the BMS-9 ACCU stud welding device

i

Battery:

Designation Battery for BMS-9 ACCU stud welding device

Type Lithium-ion

Rated voltage 25.2 V

Rated capacity 7800 mAh

Minimum capacity 7500 mAh

Energy 196.5 Wh

Dimensions 89 x 77 x 142 mm (w x h x d)

Weight approx. 1.2 kg

Colour RAL 5009 azure blue

Article number F07016/FA

Subject to technical changes

Please also observe chapter “3. Important safety instructions for battery

operation” on page 15.

Operating Instructions Soyer Bolzenschweißtechnik 29

Description of the BMS-9 ACCU stud welding device

WARNINGWARNING

!

i

DANGER

!

7.5 Permitted stud welding guns

Permitted stud welding gun: PS-9K ACCU

Hazards due to wrong gun

Hazards for the operator may occur when a wrong welding gun is used.

• Only use welding guns hereinafter permitted by Soyer.

The use of other guns or guns from another manufacturer will invalidate

the declarations of conformity and warranties of Soyer.

7.6 Cleaning the stud welding device

Dangers during cleaning

Improper cleaning of the stud welding device can endanger personnel.

• The device may only be cleaned by trained specialists.

• Before any cleaning work is done, the stud welding device must be disconnected from the main power supply and secured against accidental switchon. The battery of battery-operated devices must be removed.

• Work on electrical devices and components may only be performe

skilled e

lectricians in accordance with electrotechnical regulations.

d by

• Make sure that no liquids get into the device.

Do not use aggressive detergents for cleaning the device.

Please make sure that any cleaning waste is disposed of in an environmentally

safe manner. Please observe the instructions of the detergent manufacturer.

30 Operating Instructions Soyer Bolzenschweißtechnik

Description of the BMS-9 ACCU stud welding device

CAUTIONCAUTION

Damage to the device due to incorrect cleaning

Incorrect cleaning may cause damage to the device.

• Make sure that no liquids get into the device.

• Do not use aggressive detergents for cleaning the device.

The frequency of cleaning depends on the operating conditions of the stud welding device.

Operating Instructions Soyer Bolzenschweißtechnik 31

Description of the PS-9K ACCU stud welding gun

i

a

d

c

b

8. Description of the PS-9K ACCU stud welding gun

Figure 6: PS-9K ACCU stud welding gun

Item Designation

a PS-9K ACCU stud welding gun, contact gun without lifting magnet

b Support tube

c Release button

d Power and control cable for connection with the stud welding device.

Due to a projection on the support tube and a spring in the gun, the stud of this

gun is pressed firmly to the workpiece (contact gun).

The stud is not lifted before welding.

The PS-9K ACCU stud welding gun may only be operated with the stud

welding devices specified in the technical data.

32 Operating Instructions Soyer Bolzenschweißtechnik

Description of the PS-9K ACCU stud welding gun

8.1 Technical data of the PS-9K ACCU stud welding gun

Technical data of the PS-9K ACCU stud welding gun

Designation PS-9K ACCU stud welding gun (contact gun)

Item no. P02162

Welding procedure Capacitor discharge stud welding

Stud diameter M3 - M8

Stud chuck Adjustable

Stud length Adjustable stud chuck up to a maximum of 35 mm

Longer stud lengths with optional accessory possible

Stud welding device The gun is approved for operation on the following

SOYER® stud welding device:

• BMS-9 ACCU

Weight 2.3 kg

Subject to technical changes

Operating Instructions Soyer Bolzenschweißtechnik 33

Description of the PS-9K ACCU stud welding gun

CAUTIONCAUTION

!

i

8.2 Cleaning of the stud welding gun

On a regular basis, remove slag and welding spatters from the gun and the

support tube using a suitable tool.

The frequency of cleaning depends on the operating conditions of the stud

welding gun.

Risk of injury during cleaning

Welding spatters and slag can be sharp-edged.

• Wear protective gloves when cleaning.

• Please switch off or disconnect the stud welding device before cleaning the

stud welding gun.

We recommend the use of SOYER® separating spray in order to prevent

impurities from welding spatters and slag and to simplify the cleaning

process.

34 Operating Instructions Soyer Bolzenschweißtechnik

9. Description of the stud chuck

i

In principle, every welding gun is provided with a stud chuck that matches the

welding stud. Adjustable stud chucks must be set to the corresponding stud

length.

9.1 Adjusting and inserting the adjustable stud chucks

Adjustable stud chucks must be adjusted to the length of the welding stud and, if

necessary, to the gun size.

The standard stud chuck can hold studs with a length of up to 35 mm.

The adjustment of the stud chuck is shown using the example of the PS-9 gun.

The adjustment is carried out in the same way for other gun types.

Description of the stud chuck

Adjusting the

stud chuck

For welding guns with a short housing

(e. g. PS-1K or PS-9K ACCU), it may be

necessary to shorten the stop screw of

longer welding studs.

When the adjusting screw is too long, the stud

chuck cannot be fully plugged into the gun or

the stud lift cannot be properly executed during welding.

Adjusting an adjustable stud chuck

Step 1: Select the stud chuck according to the required stud diameter.

Step 2: Insert the stud into the stud chuck.

Operating Instructions Soyer Bolzenschweißtechnik 35

Description of the stud chuck

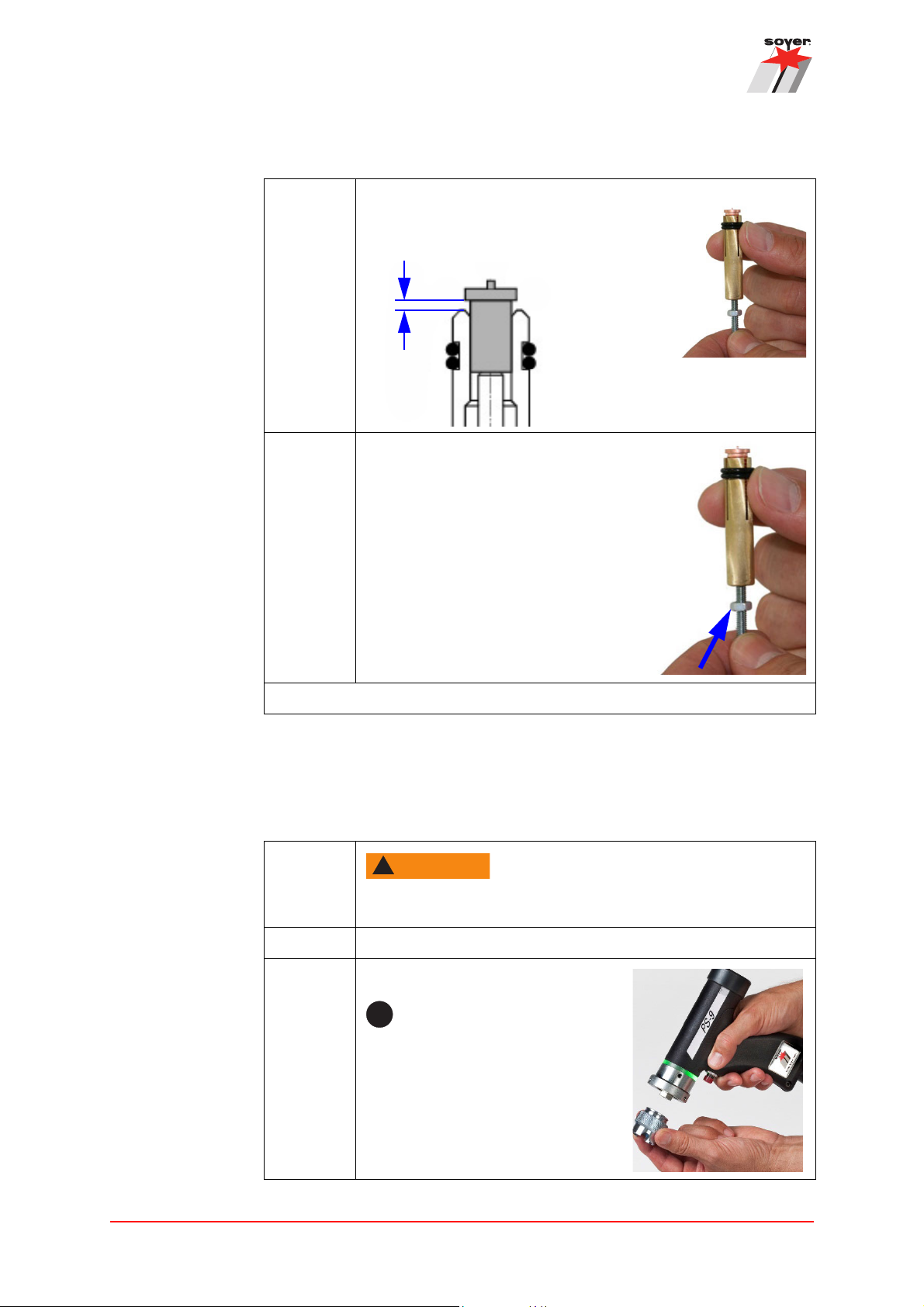

1.5 - 3 mm

WARNING

!

i

Adjusting an adjustable stud chuck

Step 3: Adjust the stop screw so that the top

Step 4: Fix the stop screw with the lock nut.

of the flange of the stud sits between

1.5 mm and 3 mm above the stud

chuck when it touches the screw.

Installation of the

stud chuck

The adjustment is complete.

The installation of the stud chuck is shown using the example of the PS-9 gun.

The installation of the stud chuck into other gun types is carried out in the same

way.

Installation of the adjustable stud chuck.

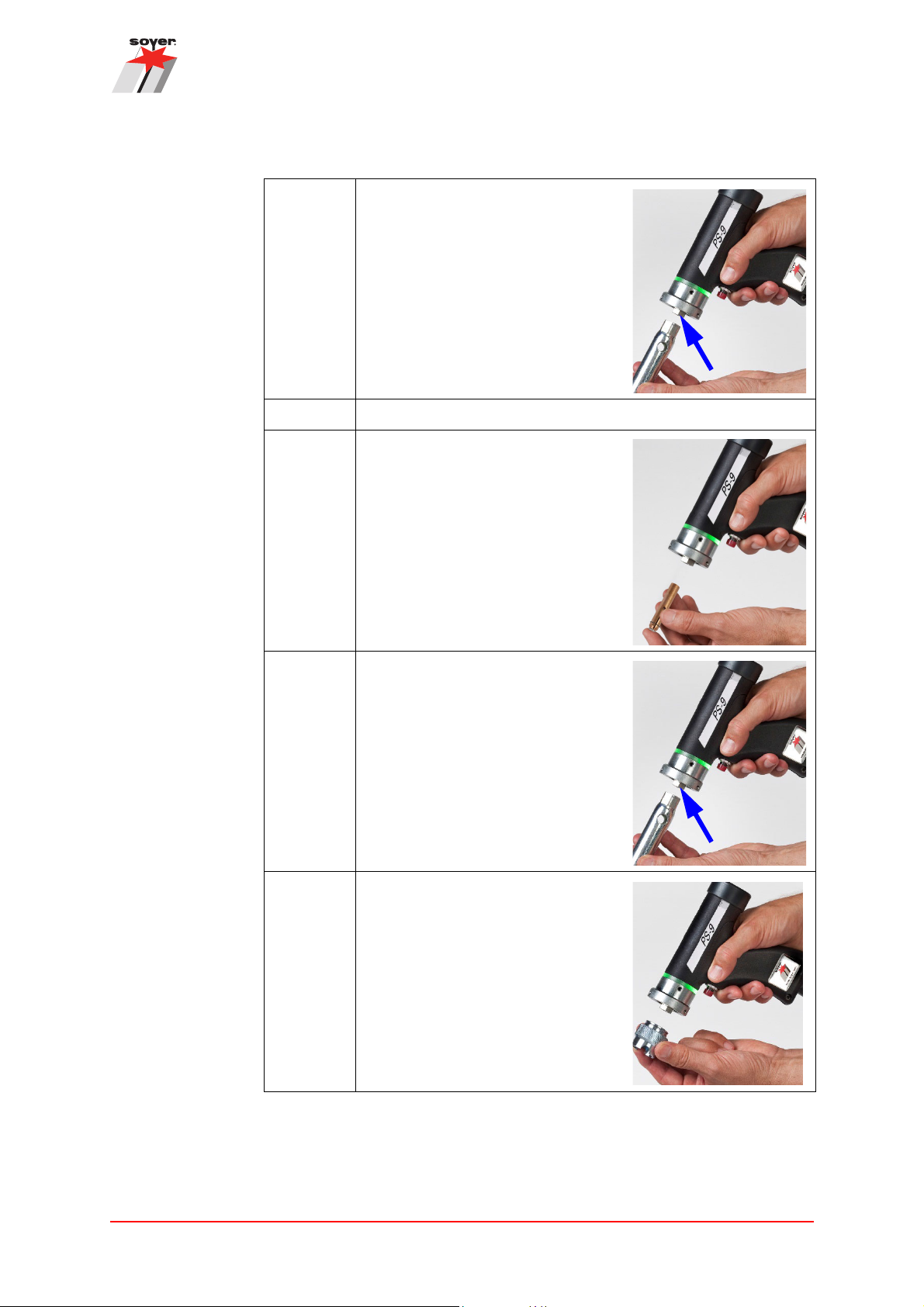

Step 1:

Step 2: Set the stud chuck to the required stud.

Step 3: Remove the gun support tube.

WARNING

Switch off the stud welding device when the gun is

connected to it.

It is not mandatory to remove

the support tube, however this

makes use easier.

36 Operating Instructions Soyer Bolzenschweißtechnik

Description of the stud chuck

Installation of the adjustable stud chuck.

Step 4: Undo the union nut

Step 5: If there is still a stud chuck in the gun, remove it.

Step 6: Slide the stud chuck up to the stop

into the spring piston of the gun.

Step 7: Hand-tighten the union nut.

Step 8: Plug the support tube onto the gun.

Operating Instructions Soyer Bolzenschweißtechnik 37

Description of the stud chuck

1.5 - 3 mm

Installation of the adjustable stud chuck.

Step 9: Insert a stud and check

The assembly is complete.

the stud protrusion.

The stud / stud flange

must protrude 1.5 - 3 mm

from the support tube.

If applicable, correct the

setting of the stud chuck

(see chapter “ Adjusting

the stud chuck” on

page 35).

38 Operating Instructions Soyer Bolzenschweißtechnik

10. Setup and connection

DANGER

!

CAUTIONCAUTION

!

10.1 Requirements for the installation location

The installation location for the stud welding device must be clean and dry.

Observe the permissible temperatures in chapter “7.4 Technical data of the BMS9 ACCU stud welding device” on page 28. Ensure that ventilation for the

stud welding device is sufficient. Do not install the stud welding device in an

unventilated room. There is a danger of overheating.

Ensure that the installation surface is flat, clean and stable.

The installation location and workplace must comply with legal requirements.

Ensure that the installation location has a good accessibility for maintenance

work.

Make sure that the stud welding device cannot be soiled by dust (especially metal

dust or chips) caused by work in the immediate surroundings (e.g. grinding work).

Setup and connection

Danger from humid operation site or mobile use

There is a danger of electrocution when operating the stud welding device in a

humid environment.

• The stud welding device should only be operated in a dry environment.

• The battery charger should only be operated stationary and in closed and

dry rooms. Mobile use is not permissible.

Danger from welding vapours

Vapours that are dangerous to health may occur, depending on the material of

the workpiece and/or the welding stud.

• Ensure suitable suction of welding vapours, if necessary.

Operating Instructions Soyer Bolzenschweißtechnik 39

Setup and connection

Heinz Soyer Bolzenschweißtechnik GmbH · Inninger Str. 14 · D-82237 Wörthsee · Germany · Tel.: +49 8153 885-0 · www.soyer.com

R

BMS-9

Ø3Ø4Ø5

Ø6

Ø8

50V 60V 70V 80V 90V

S

MADE

IN

GERMANY

10.2 Connection of the stud welding device and the stud welding guns

10.2.1 Power supply

The BMS-9 ACCU stud welding device is operated exclusively by a battery. For

the use of the battery, please observe chapter “7.3 Charging and inserting the battery” on page 24.

10.2.2 Switching the device on and off

Use the power key button to switch the stud welding device

on or off.

• Switching on the device: Push key button once briefly.

• Switching off the device: Push key

• Switching off the device if the device is in standby mode: Push key button

twice briefly (the device switches to normal operation first and then off).

Ensure that the stud welding device cannot be switched on and used by unauthorised persons.

button once briefly.

10.2.3 Connecting the earth cable

A secure earth connection must be established between the workpiece onto which

the studs are welded and the stud welding

device.

Insert the earth cable into the socket and

turn the plug to the right up to the stop.

Then connect the earth cable to the workpiece (ensure a conductive connection).

Then attach the earth clamps to the workpiece so that the welding gun is positioned

in the centre of the connecting line of the two earth clamps. This guarantees a

symmetrical current distribution around the stud as well as good welding results.

Difficult areas are weldings on the edge of the workpiece or great inhomogeneities in material thickness, i.e. the sheet thickness varies by a few millimetres or

additional material is welded or riveted to the material. This also includes stud

welding on vertical sections.

In order to achieve good welding results, c arry ou t sever al test weldings under different conditions. Simply change the position of the earth clamps or turn the welding gun, for example.

40 Operating Instructions Soyer Bolzenschweißtechnik

Blow effect

Setup and connection

Blow effect due to earth connection or workpiece geometry

Blow effect Explanation

Symmetrical earth connection

Ideal condition, stud is located in the centre

of the two earth connections.

Asymmetrical earth connection

The arc is deflected to the side where there

is a lower current density.

Workpiece geometry

Additional workpiece masses disturb the

arc symmetry.

Operating Instructions Soyer Bolzenschweißtechnik 41

Setup and connection

Heinz Soyer Bolzenschweißtechnik GmbH · Inninger Str. 14 · D-82237 Wörthsee · Germany · Tel.: +49 8153 885-0 · www.soye

R

BMS-

Ø3Ø4Ø5

Ø6

Ø8

50V 60V 70V 80V 90V

S

MADE

IN

GERMANY

a

b

10.2.4 Connecting the stud welding gun

Only use the welding guns approved by the manufacturer. See chapter “7.5 Permitted stud welding guns” on page 30.

Plug the welding cable into the socket (a) and

turn the plug to the right up to the stop.

Plug the control cable into the control cable

socket (b) and tighten the union nut.

42 Operating Instructions Soyer Bolzenschweißtechnik

11. Settings

i

B

Ø3

Ø4

Ø5

Ø6

Ø8

50V 60V 70V 80V 90V

MADE

IN

GERMANY

The stud welding device and the stud welding gun must be matched and adjusted

for the respective work.

11.1 Adjusting the charging voltage on the stud welding device

In the following, it is described how the charging voltage is adjusted.

In order to achieve an optimal stud welding result, carrying out some test welds

with different settings is necessary.

The charging voltage to be set on the stud welding device depends, among

others, on the following influencing factors:

• Material of the workpiece

• Thickness of the workpiece

• Material of the welding stud

• Diameter of the welding stud

At the stud welding device you find a support table with reference values for

charging voltages for the corresponding stud diameter.

Settings

The support table is intended to determine a suggested value for a

charging voltage which is approximately required to weld a stud with the

selected diameter according to experience. This value serves as a

guideline and normally has to be adjusted based on test welds using the

arrow keys.

The value which is set using the arrow keys is saved and remains

unchanged until a new value is entered even if the device is switched

off.

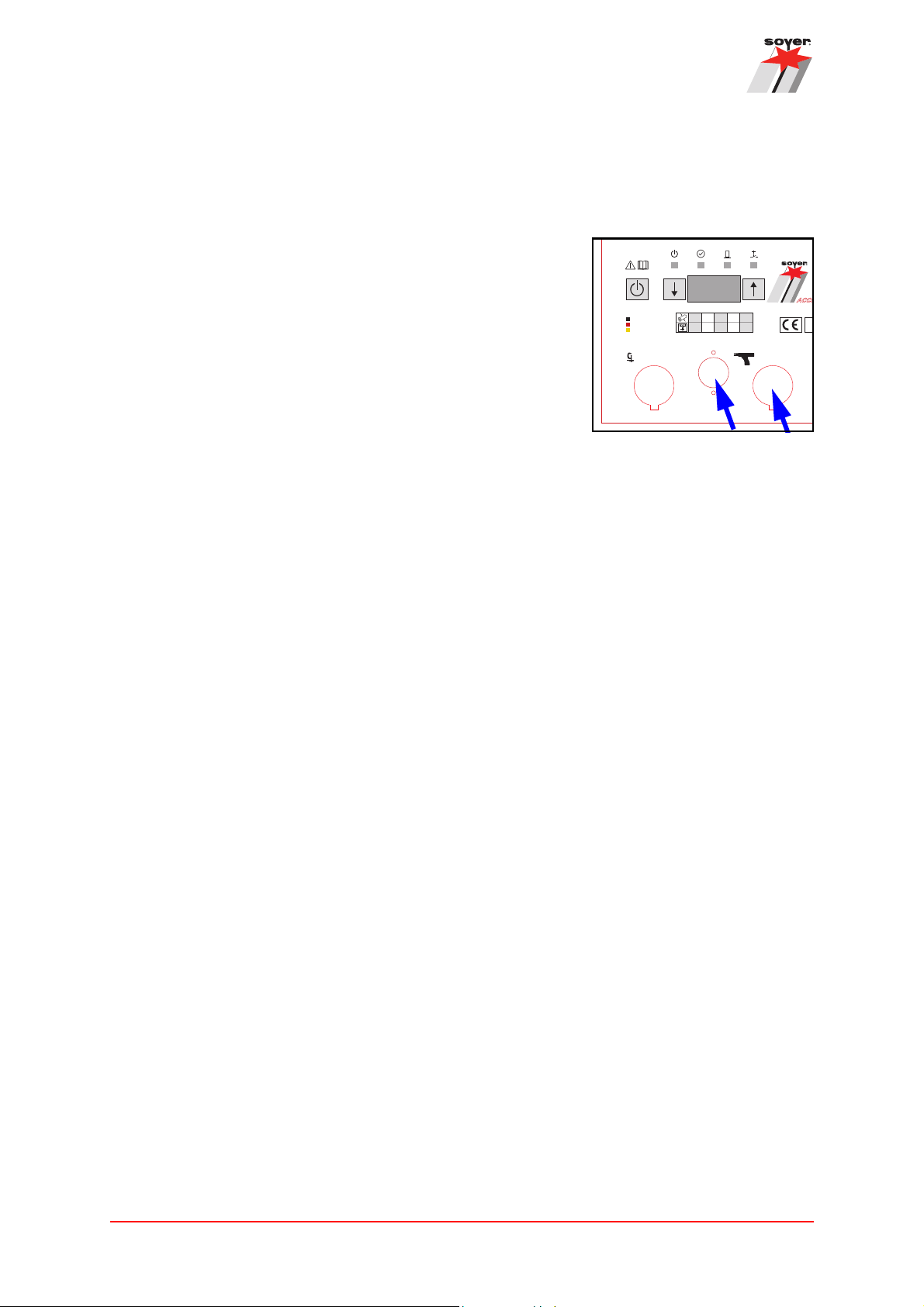

Adjusting the charging voltage

Step 1: Connect the device as described in chapter “10.2 Connection of

the stud welding device and the stud welding guns” on page 40.

Step 2: Use the table at the

stud welding device

to determine the

required charging

voltage for the relevant stud diameter.

Operating Instructions Soyer Bolzenschweißtechnik 43

Settings

i

Adjusting the charging voltage

Step 3: On the display, a

charging voltage value

will be displayed in [V].

Use the arrow keys

to increase or decrease the value, if required.

The charging voltage is adjusted.

The adjusted value is saved and remains unchanged even after

switching the device off and back on again.

↑↓

44 Operating Instructions Soyer Bolzenschweißtechnik

12. Welding operation

DANGER

!

In the following, it is described how weldings are carried out and how possible

welding errors can be avoided.

12.1 Carrying out welding

In the following, it is described how weldings are carried out with a stud welding

gun.

Danger from incorrect operation

During stud welding, incorrect operation of the devices may cause many

dangers.

Welding operation

• Before using the stud welding device, see chapter “2. Important safety

instructions” on page 8.

• If you have any problems understanding the operating instructions, contact

the manufacturer, Soyer.

Carrying out welding

Step 1: Before welding, see chapter “2. Important safety instructions” on

page 8

Step 2: Connect the gun to the stud welding device (see chapter “10.2

Connection of the stud welding device and the stud welding

guns” on page 40).

Step 3: Insert the appropriate stud chuck and a welding stud (see chap-

ter “8. Description of the PS-9K ACCU stud welding gun” on

page 32 and chapter “9. Description of the stud chuck” on

page 35).

Only use SOYER® welding studs.

Step 4: Check the charging voltage (see chapter chapter “11.1 Adjusting

the charging voltage on the stud welding device” on page 43).

Step 5: Ensure that the welding points on the stud and workpiece are

metallically bright.

Operating Instructions Soyer Bolzenschweißtechnik 45

Welding operation

i

Carrying out welding

Step 6: Press the gun onto the workpiece at an angle of 90 degrees.

When using a contact gun, press it firmly against the spring

force.

Step 7: Push the release button of the gun.

Welding is carried out.

During the welding process, hold the gun steadily and

only remove it vertically from the welded stud after the

welding process is finished. By doing so, widening or

damaging the stud chuck is avoided.

The welding process is finished.

12.2 Notes on checking the quality of the weld

If the SOYER® stud welding equipment is handled correctly and the correct

materials are selected, the strength of the welding joint (welding zone) is always

higher than the strength of the stud or the base material.

In practice, the following production control tests have proved successful:

• Visual inspection

• Bend test

For further information, see standard:

DIN EN ISO 14555 Arc stud welding of metallic materials or Technical Bulletin

DVS 0904 Instruction for practice - Arc stud welding.

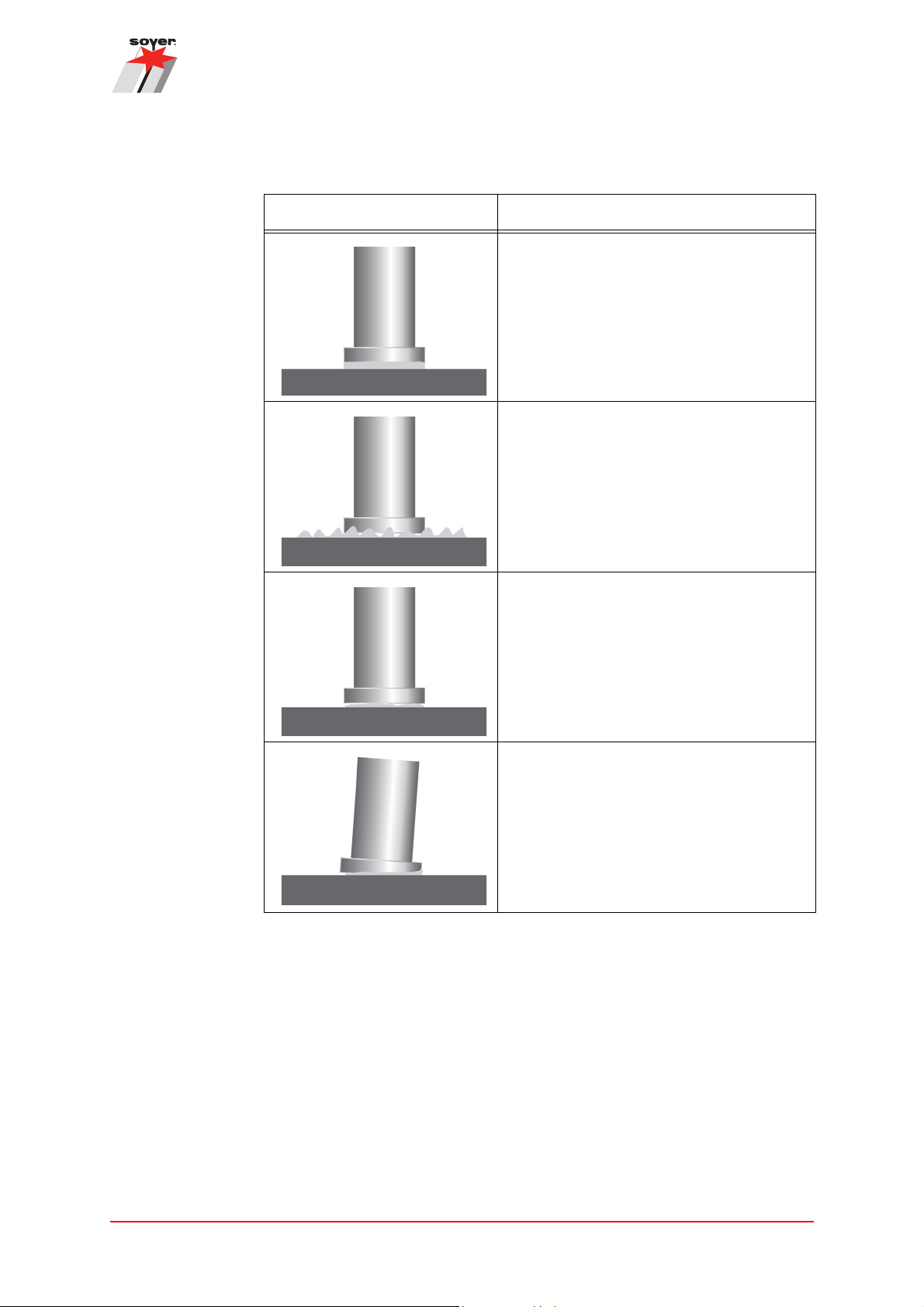

12.2.1 Visual inspection

The visual inspection serves as a rough check for major defects. The uniformity

of the weld is assessed.

The following table serves as an aid for the assessment of the welding result:

46 Operating Instructions Soyer Bolzenschweißtechnik

Visual inspection

Welding image Note

Welding operation

Good welding joint.

Optimum setting.

Even, bright and closed welding bead.

Poor welding joint, e.g. because the welding energy is too high or the immersion distance / lift is too small.

Poor welding joint, e.g. because the welding energy is too low or the lift is too short.

The welding bead is weak and unevenly

formed.

Poor welding joint, e.g. due to a blow effect

or a welding gun that was shaken or applied

at a slant.

The stud flange is not welded completely

and has visible imperfections. Undercuts

are visible.

Operating Instructions Soyer Bolzenschweißtechnik 47

Welding operation

12.3 Welding defects and their causes

In the following, the most common welding errors, possible causes and troubleshooting are described.

Please contact Heinz Soyer Bolzenschweißtechnik GmbH if a problem cannot be

solved.

Error Possible cause and troubleshooting

Device does not weld,

no sparking

Scorched stud thread Stud is too loose in the stud chuck.

Varying welding results

with unchanged settings

Stud welding device is not switched on or battery is empty.

• When switching on the device, the red indicator light “Ready” must

light up.

• Charge battery, if required.

Welding points or earth connection points on the workpiece are not

metallically bright. The LED display “Stud on workpiece” does not light

up (see chapter “7.2.1 Displaying the operating states” on page 22).

• Prepare the workpiece or stud. Grind connection points to a bright

metal finish.

• Press or retighten the stud chuck.

Stud chuck is worn.

• Exchange stud chuck.

Stud is too loose or not fully inserted into the stud chuck.

• Push in the stud until stop.

• If necessary, exchange the stud chuck.

Welding studs manufactured inaccurately.

• Only use SOYER® welding studs.

Stud is not welded to the

whole flange surface,

strength of the welding is

insufficient

48 Operating Instructions Soyer Bolzenschweißtechnik

Contamination on the surface of the workpiece is too heavy.

• Clean or grind the surface of the workpiece to a bright metal finish.

The front surface of the welding stud is deformed.

• Use new welding studs.

• Only use SOYER® welding studs

The welding gun was placed in tilted position.

• Position the welding gun evenly.

12.4 Malfunctions with an error message

DANGER

!

Dangers during troubleshooting

During troubleshooting, various dangers may occur.

Welding operation

• All devices of Soyer

by personnel of Soyer or personnel authorised by Soyer.

• For troubleshooting, the device must be disconnected from the main power

supply and secured against accidental switch-on. The battery of batteryoperated devices must be removed.

When there is a stud welding device malfunction, an error message (code) appears on the display.

Error

code

E01 Battery is empty. Charge or exchange battery.

E03 The thyristor is short-circuited. The thyristor is defective, please contact our

Description Possible cause

Bolzenschweißtechnik GmbH must only be opened

service.

E04 Excess temperature of the electronic

equipment.

E05 Capacitors are not being charged. • Gun not removed from stud after welding.

Operating Instructions Soyer Bolzenschweißtechnik 49

During high welding sequences, the device may

be exposed to an increased ambient temperature

(>45°C) or direct sunlight.

The device does not start again, even if the temperature decreases. In this case, switch off and on

again.

• Welding capacitor faulty (leakage current).

• Charging current source faulty.

Maintenance and repair

13. Maintenance and repair

Maintenance and repair of the stud welding device and the stud welding guns

should only be performed by Heinz Soyer Bolzenschweißtechnik GmbH or

authorised specialists.

14. Service

If servicing is required, please contact:

Heinz Soyer Bolzenschweißtechnik GmbH

Inninger Straße 14

82237 Wörthsee

Phone: 0049-8153-885-0

Fax: 0049-8153-8030

Email: info@soyer.de

Please have the serial number ready during service requests.

Alternatively, you can also contact your respective Soyer agent. Contact information can be found on our website at

www.soyer.de or

www.soyer.com (English)

50 Operating Instructions Soyer Bolzenschweißtechnik

15. Warranty conditions

The warranty period for commercial or equal use is 12 months. If repair is required, we guarantee the correction of the defects at the Etterschlag plant.

Wearing parts are excluded.

The warranty claim shall expire if damage is caused through improper operation,

repairs or interventions are undertaken by unauthorised persons and accessories

and spare parts are used that are not intended for our system.

When using welding studs from external manufacturers, we do not assume any

warranty for proper function of the stud welder and the quality of the welding joint.

Warranty conditions

Operating Instructions Soyer Bolzenschweißtechnik 51

Heinz Soyer Bolzenschweißtechnik GmbH

Inninger Straße 14

82237 Wörthsee

Tel.: 0049-8153-885-0

Mail: info@soyer.de

Loading...

Loading...