GB

Operating Manual

Stud welding device

SRM technology

BMK-8i

Stud welding gun PH-9 SRM12

PH-3N SRM

GB

Device numbers

We recommend registering the device numbers here so they can be quickly accessed if service is needed.

Operating manual

Document no.: P00158, 01-2016, translation of the original manual

(English: P00258)

All information in this document is the property of

Heinz Soyer Bolzenschweißtechnik GmbH.

Device Type Serial number

Stud welding device BMK-8i

Stud welding gun PH-9 SRM12

PH-3N SRM

Revision status

Document Created/modified Editor Date

Original Prepared DD 14.01.2016

Operating Manual Soyer Bolzenschweißtechnik 3

CONTENTS

1. General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1. Validity of the operating manual 6

1.2. Registered trademarks 6

1.3. Abbreviations and definitions 6

1.4. Declarations of conformity 7

1.5. Manufacturer 9

1.6. Instruction, training 9

1.7. Standards and directives 9

2. Important safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1. Safety alerts used 10

2.2. General safety instructions 11

2.3. Safety instructions for the working method 14

2.4. Personal protection equipment 15

2.5. Intended use of the stud welding device 16

2.5.1 Incorrect use 16

2.6. Intended use of the stud welding guns 16

2.6.1 Incorrect use 16

2.7. Operating company prerequisites 17

2.7.1 Requirements for personnel 17

3. Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4. Storage, shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5. Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6. Description of the BMK-8i stud welding device . . . . . . . . . . . . . . . . . . . . . . . 19

6.1. Type designation 19

6.2. Working method 19

6.2.1 Stud welding with SRM technology 20

6.2.2 Drawn arc stud welding technology with shielding gas 20

6.3. Overview of the controls 22

6.3.1 Display and setting area 24

6.4. Technical data of the BMK-8i stud welding device 25

6.5. Permitted stud welding guns 26

4 Operating Manual Soyer Bolzenschweißtechnik

CONTENTS

6.6. Cleaning the stud welding device 27

7. Description of the SRM stud chuck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.1. Setting the SRM stud chuck 28

8. Description of the PH-9 SRM12 stud welding gun . . . . . . . . . . . . . . . . . . . . . 30

8.1. Technical data of the PH-9 SRM12 stud welding gun 31

8.2. Replacing the SRM stud chuck in PH-9 SRM12 32

8.3. Replacing the SRM12 support pipe insert with PH-9 SRM12 34

8.4. Cleaning the stud welding gun 35

9. Description of the PH-3N SRM stud welding gun . . . . . . . . . . . . . . . . . . . . . . 36

9.1. Technical data of PH-3N SRM stud welding gun 37

9.2. Replacing the SRM stud chuck with PH-3N SRM 38

9.3. Cleaning the stud welding gun 40

10. Setup and connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

10.1. Requirements for the installation location 41

10.2. Connection of the stud welding device and the stud welding guns 42

10.2.1 Mains connection 42

10.2.2 Connecting the earth cable 42

10.2.3 Connecting the stud welding gun 43

10.2.4 Connecting the shielding gas supply 43

11. Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

11.1. Setting the welding parameters 47

11.1.1 Help tables for device setting 47

11.1.2 Setting the welding current and the welding time 49

11.1.3 Setting/deactivating the SRM current 50

11.1.4 Setting the gas preflow time 51

11.1.5 Setting the lift time (height of lift) in "Setup" mode 52

12. Welding operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

12.1. Carrying out welding 54

12.2. Notes on checking the quality of the weld 56

12.2.1 Visual inspection 56

12.3. Switching off the device 57

12.4. Weld defects and their causes 58

Operating Manual Soyer Bolzenschweißtechnik 5

CONTENTS

13. Maintenance and repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

14. Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

15. Warranty conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

General information

6 Operating Manual Soyer Bolzenschweißtechnik

1. General information

This operating manual contains important information and requirements for operating the devices. Keep the operating manual in a readily accessible location

close to the devices.

The term 'devices' in the operating manual refers to the stud welding device and

the stud welding gun.

Carefully read through the operating manual and the other documents contained

in the technical documentation. In particular, comply with the safety instructions

which are intended to help you recognise any residual risks and prevent hazards.

The drawings and diagrams in this operating manual help illustrate the content

and may vary slightly from the actual equipment.

The manufacturer reserves the right to make technical changes.

1.1 Validity of the operating manual

This operating manual applies to the following devices:

1.2 Registered trademarks

The following terms in this manual are marked with registered trademarks:

1.3 Abbreviations and definitions

Essential abbreviations or designations in this manual:

Stud welding device BMK-8i

Stud welding guns PH-9 SRM12

PH-3N SRM

SRM®: SRM stands for magnetic field stud welding and refers to welding

or stud welding in a radially symmetrical magnetic field.

SOYER®: Developments/technologies of Soyer GmbH.

HZ-1 threaded studs: SOYER universal studs with centring tip.

MF threaded studs: SOYER threaded stud with a reduced flange diameter

(MF stands for mini flange).

General information

Operating Manual Soyer Bolzenschweißtechnik 7

1.4 Declarations of conformity

The devices are built according to the generally accepted codes of practice.

i

Please note that significant modifications to the device can void the

declaration of conformity.

In addition, the manufacturer warranty coverage may be rendered invalid.

General information

8 Operating Manual Soyer Bolzenschweißtechnik

Stud welding device

Heinz Soyer Bolzenschweißtechnik GmbH

Inninger Straße 14

82237 Wörthsee

CE Declaration of Conformity

We herewith declare that the machine described in the following and the version available on the

market correspond in design and construction to the safety and health requirements of the listed

guidelines and standards. Any unauthorised modification to this machine automatically annuls this

declaration.

Designation of machine :

Stud welding device

Machine type :

BMK-8i

Machine no. : ______________________

Applicable EU directives : RoHS Directive (2011/65/EU)

Low Voltage Directive (2014/35/EU)

EMC Directive (2014/30/EU)

Applied harmonised : EN 60 974-1:2012

standards, in particular EN 60 974-10:2008

Applied national standards : DGUV Regulation 1

Date : 17 May 2016

Producer’s signature : ____________________

Signer’s function : Managing Director

General information

Operating Manual Soyer Bolzenschweißtechnik 9

1.5 Manufacturer

The manufacturer of the devices is:

Heinz Soyer Bolzenschweißtechnik GmbH

Inninger Straße 14

82237 Wörthsee

Tel.: 0049-8153-885-0

Fax: 0049-8153-8030

Mail: info@soyer.de

Web: www.soyer.de, www.soyer.com

1.6 Instruction, training

Soyer offers optional and individual instruction in the operation of the devices.

Soyer also offers training for customer-specific use of the devices.

Information about the scope and costs of instruction and training can be obtained

from Soyer GmbH.

1.7 Standards and directives

The following standards (among others) must be observed for carrying out stud

welding work and for the qualification of personnel:

• DIN EN ISO 14555 Welding - Arc stud welding of metallic materials

• DIN EN ISO 14732 Welding personnel - Qualification testing of welding operators and weld setters for mechanized and automatic welding of metallic materials

• DIN EN 60974-9 Arc welding equipment - Part 9: Installation and use

• DVS data sheet 0904 Practical tips - Arc stud welding

Important safety instructions

10 Operating Manual Soyer Bolzenschweißtechnik

2. Important safety instructions

Read the following chapters carefully and follow the safety instructions. If you are

uncertain or an instruction cannot be followed, please contact the manufacturer.

The devices have been built according to the generally accepted codes of practice and in compliance with, and application of, the usual and established safety

requirements. To achieve the maximum possible safety, it is essential that all of

the safety instructions in this operating manual are heeded and followed.

2.1 Safety alerts used

Warning signs are used in this document, depending on the potential danger of

the situation.

Safety and information symbols used in this manual

This safety alert indicates an imminently hazardous

situation which will result in serious injury or death.

This safety alert indicates a potentially dangerous

situation which could result in serious physical

injury or death.

This safety alert indicates a potentially hazardous

situation which could result in minor or moderate

injury.

This alert, without the triangle, is also used for

potentially hazardous situations which will result in

property damage.

Additional information indicating danger from electric current. The additional information is used in

conjunction with a warning sign.

Additional information on the risk of burns. The

additional information is used in conjunction with a

warning sign.

Do not touch the surface of the housing, danger of

electrocution.

Do not touch or open, danger for unauthorised persons.

Danger for persons with a heart pacemaker or

other medical implants.

The info sign is not a safety alert. It indicates important and useful information on the subject.

DANGER

!

WARNINGWARNING

!

CAUTIONCAUTION

!

i

Important safety instructions

Operating Manual Soyer Bolzenschweißtechnik 11

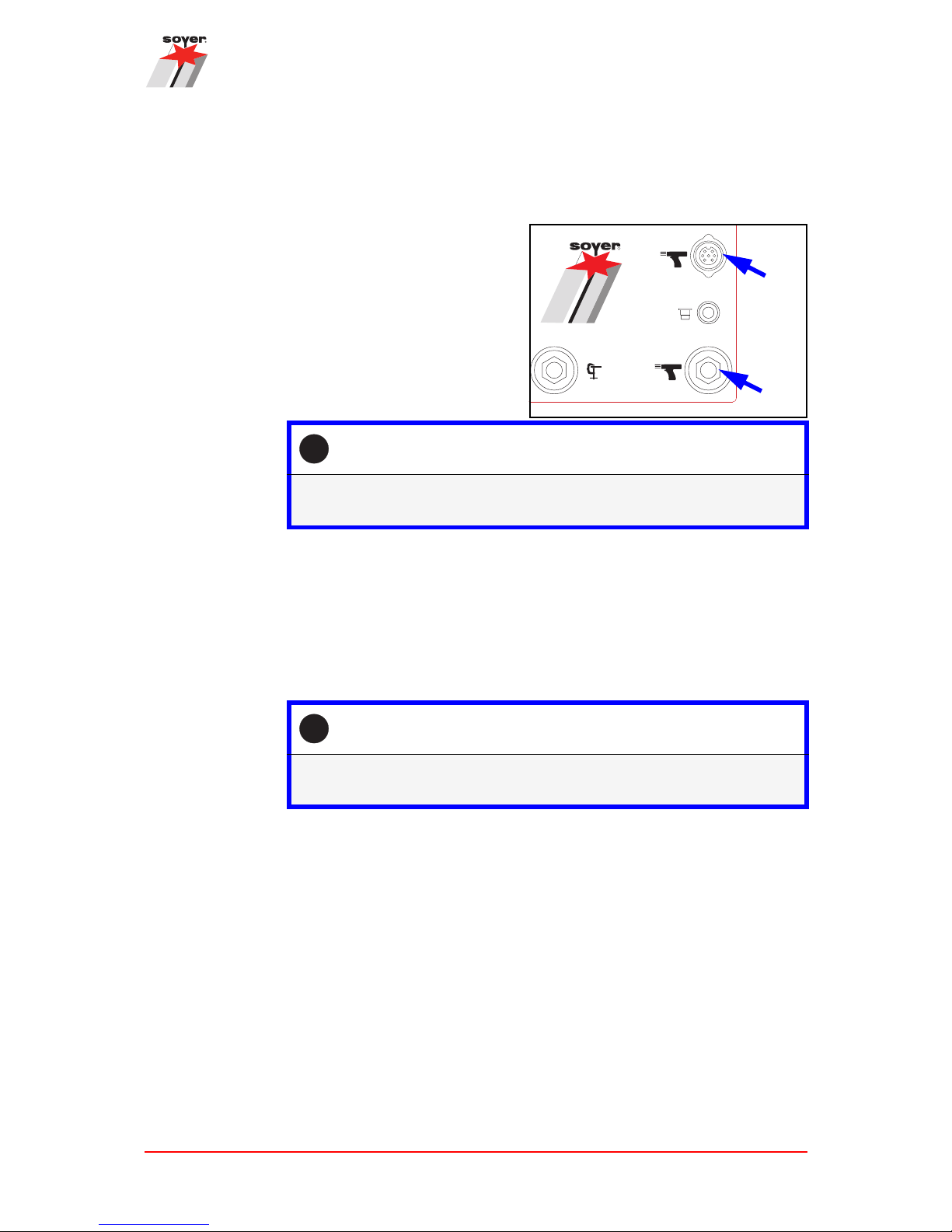

Safety instructions on the device

There may be warning stickers on the devices as additional warnings of danger.

The warning stickers are affixed by the manufacturer and must not be removed.

If a warning sticker is damaged and thus illegible, a new warning sticker must be

affixed immediately.

The warning stickers must be obtained from the manufacturer.

2.2 General safety instructions

DANGER

!

Danger due to electric current, general information

When working on current-carrying components, there is a danger to life from

electric current.

• Work on electrical or electronic modules may only be carried out by electrotechnically qualified personnel and carried out in line with the currently

applicable electrotechnical regulations.

• Protection equipment must not be manipulated or disabled. Protection

equipment includes, for example, the housing and housing cover, fuses

and device switches.

• If protection devices have to be removed for maintenance work, the device

must only be switched on again when all protection devices are mounted

again and their functionality has been checked.

• Starting the device with defective protection equipment is not allowed.

Repair or replace faulty protection equipment immediately. Unwanted

operation by a third party must be prevented.

Important safety instructions

12 Operating Manual Soyer Bolzenschweißtechnik

DANGER

!

Danger from electric current during maintenance and repair

When working on current-carrying components, there is a danger to life from

electric current.

• Work on electrical or electronic components must only be carried out by

electrical specialists from Soyer Bolzenschweißtechnik.

• Before working on the stud welding device, the mains switch of the device

must be switched off and the mains plug of the stud welding device disconnected.

• Before working on the stud welding gun, the supply cable to the stud welding device must be disconnected.

• If protection devices have to be removed for maintenance work, the device

must only be switched on again when all protection devices are mounted

again and their functionality has been checked.

DANGER

!

Danger from magnetic fields

Strong magnetic fields occur in the area of the device, which may affect the

operation of medical aids, causing a danger to life.

• Persons with electrical medical aids (such as pacemakers) must keep

away from the devices.

• The operating personnel must ensure that persons with medical aids keep

away from the devices.

DANGER

!

Danger of explosion from an inappropriate installation location in explosive atmospheres

The device is not designed for use in explosive zones.

• The device may not be installed and operated in explosive atmospheres.

Important safety instructions

Operating Manual Soyer Bolzenschweißtechnik 13

CAUTIONCAUTION

!

Danger of burns due to hot surfaces

Through the welding process, the workpieces and some parts of the welding

gun become so hot that touching them can lead to burns.

• Always use personal protective equipment.

• Before beginning work on hot parts of the device, check that they have

cooled down.

• Do not hold the gun tight in the welding area.

WARNINGWARNING

!

Danger of burns from hot welding spatter

Dangerous welding spatter can occur during the welding process.

• Always use personal protective equipment.

WARNINGWARNING

!

Danger of burns from hot welding spatter

Welding spatter or hot workpieces occurring due to the welding process can

result in a danger of burns.

• Do not store any inflammable and combustible materials in the welding

area.

Important safety instructions

14 Operating Manual Soyer Bolzenschweißtechnik

2.3 Safety instructions for the working method

WARNINGWARNING

!

Hazards due to incorrect working method

Hazards for operators and third parties can arise due to an incorrect working

method.

• Ensure sufficient stability and a dry installation location for the stud welding

device.

• Make sure not to knock over the stud welding device or to pull it down from

its emplacement with the cables of the gun.

• Make sure, especially with mobile use, of your own good stability during

welding.

• Do not hold the workpiece in your hands during welding. The workpiece

must be securely fixed during the welding process.

• Never wrap the gun lines around parts of your body (e.g. arm) as electric

fields can occur.

• If the gun is not put on properly or the gun settings are incorrect, a flash

can occur during welding. Do not look directly into the flash.

• The gun carries out lifting movements during the welding process. Do not

hold the gun tight in the area of moving parts.

Important safety instructions

Operating Manual Soyer Bolzenschweißtechnik 15

2.4 Personal protection equipment

The wearing of personal protective equipment is recommended when working

with the stud welding device.

WARNINGWARNING

!

Danger due to missing or incorrect personal protection kit

There is a danger of burns during stud welding, especially due to hot welding

spatter. A danger of blinding can also arise due to the occurrence of strong

arcs.

• Always wear suitable, closed protective clothing.

• The extent of the protective equipment depends on the respective occurrence and intensity of the welding spatter, arcs and/or noise. This varies

according to the basic material, stud material, stud size and required welding power.

• Heed the instructions concerning protective equipment in the following

overview.

Recommended personal protection equipment

Protective goggles

During welding, welding spatter and a flash occur. Wear

suitable safety goggles with side protection and protect

your eyes with filter protection if necessary.

Protective gloves

During welding, the workpieces and parts of the welding

gun become hot, as well as the occurrence of welding spatter. Wear suitable, non-combustible, heat-resistant protective gloves.

Protective clothing

Welding spatter occurs during welding. Wear suitable, noncombustible and, if necessary heat-resistant, protective

clothing.

Safety shoes

Welding spatter occurs during welding. Wear suitable, noncombustible, heat-resistant safety shoes.

Hearing protection

Depending on the welding device and the welding application, relatively loud welding noise can occur. Wear suitable

hearing protection.

Important safety instructions

16 Operating Manual Soyer Bolzenschweißtechnik

2.5 Intended use of the stud welding device

Pins and threaded studs from M3 - M8 (M6 and M8 preferred), made of steel and

stainless steel, can be welded using the SOYER BMK-8i stud welding device.

Special studs or diameters on request.

The stud welding device must only be operated with the welding guns described

in Chapter "6.4 Technical data of the BMK-8i stud welding device" on page 25.

The stud welding device must be operated within the technical specifications.

Only welding studs from Soyer (HZ-1 and MF types) must be welded.

The stud welding device supports the following welding processes:

• SRM welding (stud welding in a radially symmetrical magnetic field)

• Drawn arc stud welding with shielding gas

2.5.1 Incorrect use

Any use other than the intended use of the device is deemed to be non-intended.

Use other than intended use, unauthorised modification or manipulation of the device will void the Declaration of Conformity as well as all warranty claims against

the manufacturer.

2.6 Intended use of the stud welding guns

Pins and threaded studs from M3 to M12 and numerous different weld fasteners

according to DIN EN ISO 13918, made of steel, stainless steel, aluminium and

brass, can be welded with the SOYER stud welding guns described in this operating manual.

Special studs or diameters on request.

The operation of welding guns is only permitted with the stud welding devices described in the technical data of the gun.

The stud welding gun must be operated within the technical specifications.

2.6.1 Incorrect use

Any use other than the intended use of the welding gun is deemed to be contrary

to the intended use.

Use other than the intended use, unauthorised modification or manipulation of the

device will void the Declaration of Conformity as well as all warranty claims

against the manufacturer.

i

The maximum diameter and type of weldable studs can be limited by the

performance capacity of the stud welding device on which the gun is

operated.

Important safety instructions

Operating Manual Soyer Bolzenschweißtechnik 17

Misuse of the welding gun as a tool, e.g. as a hammer for checking the weld quality, is not permitted.

2.7 Operating company prerequisites

The operator of the device must ensure that the preconditions in this operating

manual are fulfilled for safe operation.

These include, for example, the conditions at the installation site, the official regulations on requirements for a safe workplace, the training of the operating personnel and qualified personnel in handling the device if necessary, fulfilment of

the prescribed maintenance work, and monitoring that the device is used in conformity with intended use.

The operating manual must be stored in the vicinity of the device.

The device operating company must ensure that the device is only used when all

protective equipment is present, active and undamaged.

2.7.1 Requirements for personnel

Operating personnel

The personnel responsible for operating the device in normal operation must be

familiar with the device and trained accordingly. They must have read and understood the operating manual. In addition, they must be capable of eliminating (or

minimising as far as possible) any possible remaining danger to themselves and

third parties when working with the device.

To retain this qualification, the safety training must be repeated at least once a

year. In the event of a fault or if maintenance becomes necessary, consult specially trained qualified personnel or the manufacturer.

Operators of stud welding equipment must have the expert knowledge for operating, correctly setting the equipment and for properly carrying out the welding.

If the welders have to be qualified for certification of welding, the

DIN EN ISO 14555 and DIN EN ISO 14732 standards must be observed.

Electrical and

electronic specialists

The following basically applies: Work on current-carrying elements may only be

performed by qualified electricians. The work must be carried out in line with the

applicable technical rules for electrotechnical devices.

i

All devices of Soyer Bolzenschweißtechnik GmbH must only be opened

by Soyer personnel or by personnel authorised by Soyer.

Transport

18 Operating Manual Soyer Bolzenschweißtechnik

3. Transport

When transporting the device, make sure it cannot be damaged. It must be protected against the effects of weather, especially moisture, through suitable packaging.

4. Storage, shutdown

Protect the device against dirt and humidity during storage or shutdown.

Protect the device against unauthorised access by third parties.

5. Disposal

Local environmental guidelines for disposal must be complied with.

Substances that are hazardous to water and the environment must be disposed

of in accordance with legal regulations.

Materials must be separated according to regulations where applicable.

Description of the BMK-8i stud welding device

Operating Manual Soyer Bolzenschweißtechnik 19

6. Description of the BMK-8i stud welding device

The main elements of the stud welding device are shown and the function described in the following.

6.1 Type designation

6.2 Working method

Pins and threaded studs from M3 - M8 (M6 and M8 preferred) made of steel and

stainless steel can be welded using the SOYER BMK-8i stud welding device.

Only welding studs from Soyer (HZ-1 and MF types) must be welded.

The BMK-8i working with SRM technology was specially developed for mobile

use.Thanks to SRM, the BMK-8i mobile welding device enables problem-free

welding, even in constrained positions.

The BMK-8i works on the basis of a compact inverter current source and delivers

a constant welding current up to 300 A with extremely short welding times. The

rectified mains voltage is converted into a high frequency voltage with a frequency

of 75 kHz by an Insulated Gate Bipolar Transistor-based (IGBT-based) inverter.

The energy is transferred by a high frequency transformer and rectified on the output side. As a result of the high control speed in combination with the integrated

SRM welding process of the BMK-8i, the reproducibility of the welds is increased

and the quality of the welding significantly improved.

The PH-9 SRM12 stud welding gun or the PH-3 SRM stud welding gun (via an

adapter) can be connected as a standard gun to the BMK-8i stud welding device.

Designation

Order number

Feature

BMK-8i

P01363

Mains voltage 230 V 1PH/N/PE

Description of the BMK-8i stud welding device

20 Operating Manual Soyer Bolzenschweißtechnik

6.2.1 Stud welding with SRM technology

The welding process recommended by Soyer for operating the BMK-8i is the patented SRM welding process (patent no.: 10 2004 051 389) in conjunction with the

also newly developed HZ-1 universal studs with flat front face and centring tip

(patent no.: 10 2006 016 553).

SRM means stud welding in a radially symmetrical magnetic field.

This innovative weld technology allows welds in a ratio of 1:10 of the sheet thickness to the stud diameter (previously 1:4) where the use of ceramic rings can be

dispensed with.

The versatile advantages of the SRM process provides completely new application options in the entire stud welding sector (additional information available at

www.srm-technology.de).

Functional principle

The advantages of the SRM welding process are:

• No bothersome weld bead

• Welding from constrained positions now also without ceramic ring

• Reduced weld penetration in the plate

• Lower energy consumption and reduced welding time

• No welding spatter

6.2.2 Drawn arc stud welding technology with shielding gas

For drawn arc stud welding with shielding gas, a gas mixture of 82% argon and,

for example, 18% CO2 (e.g. Corgon®18*) is used as an aid.

This shielding gas shields the weld point from the atmosphere and takes over the

weld pool backing at the same time. It also forms a concave fillet weld-shaped

weld bead with a metallic surface without discolouration, which reduces the risk

of corrosion and achieves better dynamic characteristics of the weld joint.

The stud tip touches the

workpiece and is lifted.

The arc is initiated.

The ignited arc is guided

by a magnetic field and

melts both joint parts

fully.

The stud immerses in

the very flat weld penetration zone and is solidly connected.

i

Further information on this subject can be found at www.soyer.de.

Description of the BMK-8i stud welding device

Operating Manual Soyer Bolzenschweißtechnik 21

When welding with shielding gas without any further aids, the formation of an exact bead in an accurately calibrated and reproducible version is not possible. Stud

welding with shielding gas can be carried out at considerably shorter distances as

there is no need to install and remove the ceramic rings for each welding process.

*) Corgon®18 is a gas mixture from Linde AG in D-82049 Höllriegelskreuth, Germany

i

Further information on this subject can be found at www.soyer.de.

Description of the BMK-8i stud welding device

22 Operating Manual Soyer Bolzenschweißtechnik

6.3 Overview of the controls

Figure 1: Overview of the device front

Item Designation

a Selection and display area with display and function keys (see Chap-

ter "6.3.1 Display and setting area" on page 24)

b Control cable connection of the gun

c Shielding gas connection of the gun, coupling socket KD 1/4

d Welding cable connection of the gun

e Connection of the earth cable

R

BMK-8i

S

+

SRM

GAS

[A]

[ms]

[A]

[s]

[ms]

GAS

SRM

>

>

>

>

www.soyer.com

a

e

b

c

d

Description of the BMK-8i stud welding device

Operating Manual Soyer Bolzenschweißtechnik 23

Figure 2: Overview of the back of the device

Item Designation

a Model plate

b Mains switch for switching the device on/off

c Mains connection cable

d Gas connection

e Carrying belt

a

b

d

c

e

Description of the BMK-8i stud welding device

24 Operating Manual Soyer Bolzenschweißtechnik

6.3.1 Display and setting area

Figure 3: Display and setting area

Item Designation

a Function selection

The following functions can be selected using the arrow keys:

• Welding current

• Welding time

• SRM current (deactivated at value 0 A, activated at value > 0 A)

• Gas preflow time (deactivated at value 0 s, activated at value > 0 s)

• Lift test (see Chapter "11.1.5 Setting the lift time (height of lift) in

"Setup" mode" on page 52)

The LED next to the selected function lights up.

b +/- keys

For setting the value of the selected function shown on the display.

c Display

The set values of the selected function are shown on the display.

d Display of the operating state

The following operating states are displayed during welding operation:

• Trigger button of the gun is pressed

• Gun is placed on the workpiece and ready for welding

•SRM is active

• Gas preflow is active

The LED next to the active operating state lights up.

+

SRM

GAS

[A]

[ms]

[A]

[s]

[ms]

GAS

SRM

>

>

>

>

a

b

d

c

Description of the BMK-8i stud welding device

Operating Manual Soyer Bolzenschweißtechnik 25

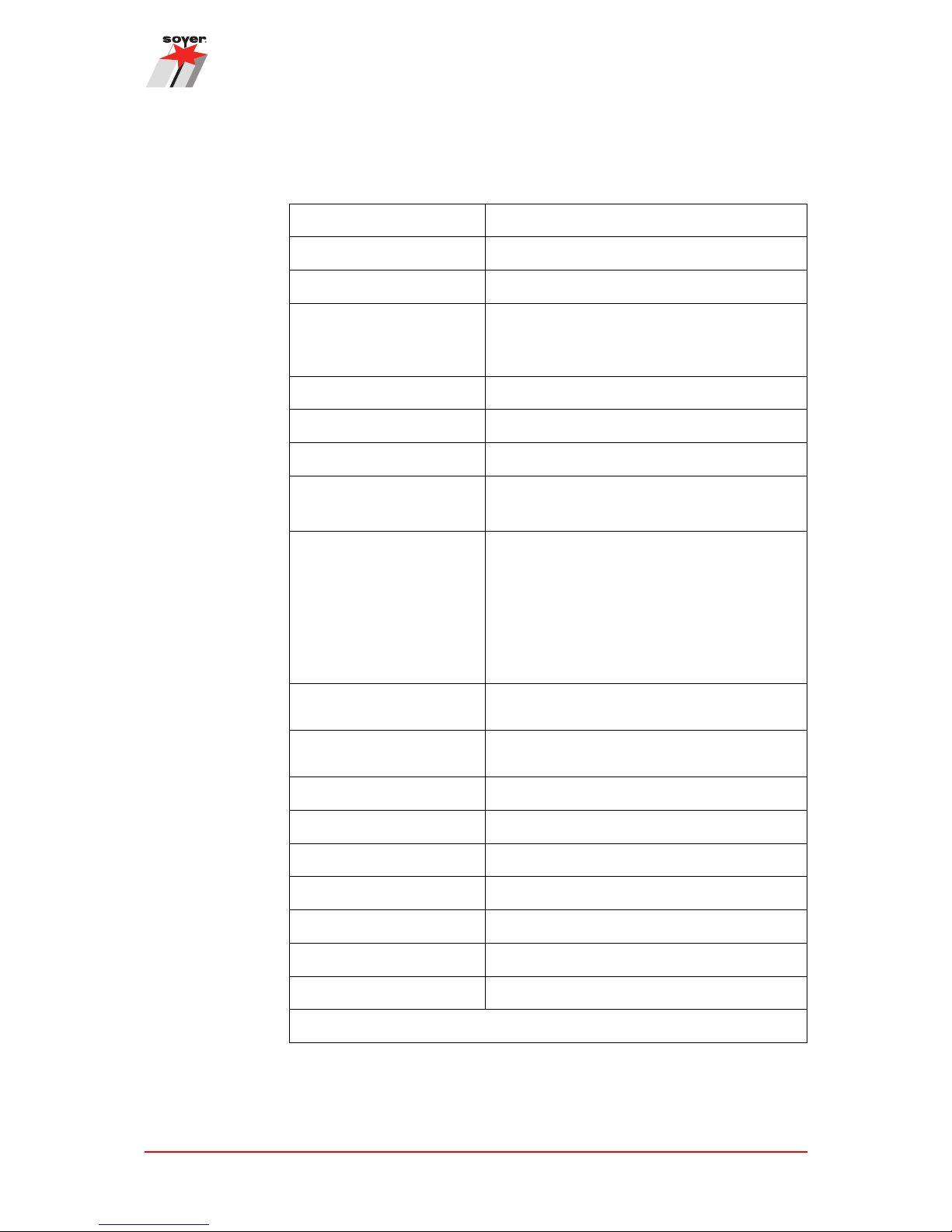

6.4 Technical data of the BMK-8i stud welding device

Designation BMK-8i stud welding device

Welding process Drawn arc stud welding (DA)

Standard gun PH-9 SRM12 stud welding gun

Welding area SOYER threaded studs, from M3 - M8 (M6 and

M8 preferred) HZ-1 and MF types

or nails Ø 2 - 4 mm (optional)

Current source Inverter technology

Welding current 100 - 300 A stud welding

Welding time 10 to 500 ms

Welding sequence Ø 6 mm to 6 studs/min

Ø 8 mm to 3 studs/min

Mains connection 1 x 230 volt (+10% -15%) - 50/60 Hz

16 AT or 16 AC characteristic

Note: The device must be slow-fused for the

full rating, i.e. 16 AT or 16 AC characteristic

(with circuit breakers) as otherwise the fuse

could be activated (in accordance with the

technical data ).

E-continuous current

(standby)

< 0.1 A/phase

E-continuous power

(standby)

15 VA

E-maximum current 60 A/phase at 1x230 volt (short-time duty)

No-load voltage < 30 V/DC

Protection class IP 21

Shielding gas connection Max. 12 l/min

Dimensions 95 x 210 x 320 mm (W x H x D)

Weight 9.5 kg without cable

Colour Blue

Subject to technical changes

Description of the BMK-8i stud welding device

26 Operating Manual Soyer Bolzenschweißtechnik

6.5 Permitted stud welding guns

(1): Possible with optional adapter plug and adapter cable.

WARNINGWARNING

!

Hazards due to wrong gun

Hazards for the operator can arise if the wrong welding gun is used.

• Only use the welding guns from Soyer permitted in the following.

i

The use of other guns or guns from another manufacturer will invalidate

the declarations of conformity and the warranties of Soyer.

Overview of permitted stud welding guns

Gun Comments

PH-9 SRM12 Standard gun

PH-3N SRM Connection adapter required (1)

Adapter plug for the gas connection: F06695/FA

Adapter cable for the control cable: F06694/FA

Description of the BMK-8i stud welding device

Operating Manual Soyer Bolzenschweißtechnik 27

6.6 Cleaning the stud welding device

Do not use aggressive cleaning agents for cleaning the device.

Make sure that cleaning waste is disposed of in an environmentally compatible

manner. Comply with the instructions of the cleaning agent manufacturer.

The frequency of cleaning depends on the conditions in which the stud welding

device is used.

DANGER

!

Hazards during cleaning

Improper cleaning of the stud welding device can endanger personnel.

• The device may only be cleaned by trained and qualified technicians.

• Prior to starting work, the stud welding device must be disconnected from

the mains and secured against being switched back on again.

• Work on electrical devices and modules may only be carried out by qualified electricians in accordance with the electrotechnical codes of practice.

• Cleaning agents must not get into the device.

CAUTIONCAUTION

device damage due incorrect cleaning

Improper cleaning can lead to damage of the device.

• No cleaning agents must get into the device.

• Do not use aggressive agents for cleaning.

Description of the SRM stud chuck

28 Operating Manual Soyer Bolzenschweißtechnik

7. Description of the SRM stud chuck

Each welding gun is provided with a stud chuck that matches the welding stud.

For the SRM welding process, there are:

Adjustable stud chucks:

• SRM stud chuck M6 - F05307

• SRM stud chuck M8 - F05215

• SRM stud chuck M10 - F05217*

• SRM stud chuck M12 - F05219*

* When using the stud chuck with the BMK-12i or BMK-16i devices.

The stud chuck in the gun must be installed/changed in accordance with the stud

diameter.

Adjustable stud chucks must be set to the stud length.

7.1 Setting the SRM stud chuck

SRM stud chucks must be set to the length of the welding stud and, if necessary,

to the gun size.

The standard stud chuck can hold studs up to a length of 60 mm.

i

Different stud diameters require different stud chucks.

When using studs with a length > 45 mm, the end stop screw must be

shortened.

Description of the SRM stud chuck

Operating Manual Soyer Bolzenschweißtechnik 29

Setting the stud

chuck

Setting the SRM stud chuck

Step 1: Select the stud chuck according to the required stud diameter.

Step 2: Insert the stud into the stud chuck.

Step 3: Set the end stop screw so that the

flange top edge of the stud, when it

is sitting on the screw, sits between

3 mm and 5 mm above the stud

chuck.

Step 4: Fix the end stop screw with the lock-

nut.

i

If the stud protrusion is more

than 5 mm, the required transverse magnetic field is

deflected sideways which can

lead to uncontrolled SRM welding.

The setting is complete.

3 - 5 mm

Description of the PH-9 SRM12 stud welding gun

30 Operating Manual Soyer Bolzenschweißtechnik

8. Description of the PH-9 SRM12 stud welding gun

Figure 4: PH-9 SRM12 stud welding gun

The gun has a lift magnet. Before welding, the stud is lifted by the lift magnet and

automatically lowered again for welding.

The height of the lift is also decisive for the weld result.

The lift height can be determined using the lift time with the aid of the stud welding

device. Also comply with Chapter "11.1.5 Setting the lift time (height of lift) in "Setup" mode" on page 52.

The height of lift is set using the adjusting wheel on the gun (see "Figure 4: PH-9

SRM12 stud welding gun").

Item Designation

a PH-9 SRM12 stud welding gun, with lift magnet

b Shielding gas cap with SRM technology

c Trigger button

d Current and control cables for connecting to the stud welding device.

e Adjustment wheel for setting the height of lift/lift time

f Gas insert for shielding gas cap SRM12

g SRM supply for connecting to the stud welding device.

h Gas supply for connecting to the stud welding device.

i Support pipe insert SRM12

a

d

c

b

e

f

h

g

i

Description of the PH-9 SRM12 stud welding gun

Operating Manual Soyer Bolzenschweißtechnik 31

The PH-9 SRM12 stud welding gun has a gas insert for each diameter of the stud

chuck:

• M6: F06738

• M8: F06739

• M10: F06740

• M12: F06741

The gas insert serves to optimise the gas flow and insulate the stud chuck from

the shielding gas cap.

.

8.1 Technical data of the PH-9 SRM12 stud welding gun

i

The PH-9 SRM12 stud welding gun must only be operated with the stud

welding devices specified in the technical data.

Technical data of the PH-9 SRM12 stud welding gun

Designation PH-9 SRM12 stud welding gun

Item no. P02276

Welding process • Drawn arc stud welding (DA)

• SRM welding process

Stud diameter M3 - M12 (depending on the stud welding device)

stud chuck SRM stud chuck

Stud length Standard to 60 mm, special lengths possible on

request and with special accessories

Stud welding devices The gun is approved for operation on the following

Soyer stud welding devices:

• BMK-8i

• BMK-12i

• BMK-16i when using the adapter:

Control cable adapter: F06770/FA

Earth cable adapter: F06771/FA

Gas adapter: F06772/FA

Weight 1.3 kg without cable

Subject to technical changes

Description of the PH-9 SRM12 stud welding gun

32 Operating Manual Soyer Bolzenschweißtechnik

8.2 Replacing the SRM stud chuck in PH-9 SRM12

Replacing the SRM stud chuck.

Step 1:

WARNING

WARNING

!

If the gun is connected to the stud welding device,

switch off the stud welding device.

Step 2: Set the stud chuck to the required stud (see Chapter "7.1 Setting

the SRM stud chuck" on page 28).

Step 3: Undo the union nut

Step 4: If there is still a stud chuck in the

gun, remove it.

i

Using pliers as an aid makes

removal easier.

Step 5: Remove the tripod with the shielding

gas cap.

Undo the four socket head screws.

Step 6: Change the gas insert according to

the required stud).

Gas inserts:

• Item no: M6 = F06738

• Item no: M8 = F06739

• Item no: M10 = F06740

• Item no: M12 = F06741

Description of the PH-9 SRM12 stud welding gun

Operating Manual Soyer Bolzenschweißtechnik 33

Step 7: Slide the tripod with the shielding

gas cap onto the gun.

Step 8: Slide the stud chuck to the end stop

in the spring piston in the gun.

Step 9: Hand-tighten the union nut.

Step 10: Insert a stud and check the stud

protrusion.

The stud/stud flange must protrude 1 - 1.5 mm out of the

shielding gas cap.

If necessary, correct the setting

of the stud chuck by shifting the

tripod.

Step 11: Tighten the four socket head screws.

The assembly is complete.

Replacing the SRM stud chuck.

1 - 1.5 mm

Description of the PH-9 SRM12 stud welding gun

34 Operating Manual Soyer Bolzenschweißtechnik

8.3 Replacing the SRM12 support pipe insert with PH-9 SRM12

It may be necessary to replace the support pipe insert due to heavy wear or impurity.

Item number for support pipe insert: F06748

Use original spare parts only.

Replacing the SRM12 support pipe insert.

Step 1:

WARNING

WARNING

!

If the gun is connected to the stud welding device,

switch off the stud welding device.

Step 2: Undo the two threaded pins on the

tripod housing.

Step 3: Remove the old support pipe insert

and install a new one.

Slide the new support ring up to the

end stop in the mounting.

i

When installing, make sure that

the support pipe insert and the mounting surface are

clean.

Step 4: Hand-tighten the two threaded pins

on the tripod housing.

The assembly is complete.

Description of the PH-9 SRM12 stud welding gun

Operating Manual Soyer Bolzenschweißtechnik 35

8.4 Cleaning the stud welding gun

Regularly free the gun and shielding gas cap of slag and weld spatt er using a s uitable tool.

The frequency of cleaning depends on conditions under which the stud welding

gun is used.

CAUTIONCAUTION

!

Risk of injury when cleaning

Welding spatter and slag can have sharp edges.

• Wear protective gloves when cleaning.

i

To prevent impurities from welding spatter and slag and to simplify

cleaning, we recommend using Soyer release spray (order number

M01464).

Description of the PH-3N SRM stud welding gun

36 Operating Manual Soyer Bolzenschweißtechnik

9. Description of the PH-3N SRM stud welding gun

Figure 5: PH-3N SRM stud welding gun

The gun has a lift magnet. Before welding, the stud is lifted by a magnet and automatically lowered again for welding.

The height of the lift is also crucial for the weld result.

The lift height can be determined using the lift time with the aid of the stud welding

device. Also comply with Chapter "11.1.5 Setting the lift time (height of lift) in "Setup" mode" on page 52.

The height of lift is set using the adjusting wheel on the gun.

Item Designation

a PH-3N SRM stud welding gun, gap welding gun with lifting magnet

b Shielding gas cap with SRM technology

c Trigger button

d Current and control cables for connecting to the stud welding device.

e Adjustment wheel for setting the height of lift/lift time

f SRM supply for connecting to the stud welding device.

g Gas supply for connecting to the stud welding device.

a

d

c

b

e

f

g

Description of the PH-3N SRM stud welding gun

Operating Manual Soyer Bolzenschweißtechnik 37

9.1 Technical data of PH-3N SRM stud welding gun

(*) With adapter plug, see technical data of stud welding device.

i

The PH-3N SRM stud welding gun must only be operated with the stud

welding devices specified in the technical data.

Technical data of PH-3N SRM stud welding gun

Designation PH-3N SRM stud welding gun

Item no. P02245

Welding process • Drawn arc stud welding (DA)

• SRM welding process

Stud diameter M3 - M12 (depending on the stud welding device)

Stud chuck SRM stud chuck and SRM nut holder

Stud length Standard to 60 mm, special lengths possible on

request and with special accessories

Stud welding devices The gun is approved for operation on the following

Soyer stud welding devices:

• BMK-8i (*)

• BMK-12i (*)

• BMK-16i

Weight 1.3 kg without cable

Subject to technical changes

Description of the PH-3N SRM stud welding gun

38 Operating Manual Soyer Bolzenschweißtechnik

9.2 Replacing the SRM stud chuck with PH-3N SRM

Replacing the SRM stud chuck.

Step 1:

WARNING

WARNING

!

Switch off the stud welding device if the gun is connected to the stud welding device.

Step 2: Set the stud chuck to the required stud (see Chapter "7.1 Setting

the SRM stud chuck" on page 28).

Step 3: Remove the tripod with the shielding

gas cap. To do so, undo the four

socket head screws.

i

It is not essential to remove the

tripod with the shielding gas

cap, but it makes the job easier.

Step 4: Undo the union nut

Step 5: If there is still a stud chuck in the gun, remove it.

Step 6: Slide the stud chuck to the end stop

in the spring piston in the gun.

Step 7: Hand-tighten the union nut.

Description of the PH-3N SRM stud welding gun

Operating Manual Soyer Bolzenschweißtechnik 39

Step 8: Insert a stud and check the stud

protrusion.

The stud/stud flange must protrude 1 - 1.5 mm out of the

shielding gas cap.

If necessary, correct the setting

of the stud chuck by shifting the

tripod.

Step 9: Fasten the tripod with the shielding

gas cap onto the gun.

Assembly is complete.

Replacing the SRM stud chuck.

1 - 1.5 mm

Description of the PH-3N SRM stud welding gun

40 Operating Manual Soyer Bolzenschweißtechnik

9.3 Cleaning the stud welding gun

Regularly free the gun and shielding gas cap of slag and weld spatt er using a s uitable tool.

The frequency of cleaning depends on conditions under which the stud welding

gun is used.

CAUTIONCAUTION

!

Danger of injury when cleaning

Welding spatter and slag can have sharp edges.

• Wear protective gloves when cleaning.

i

To prevent impurities from welding spatter and slag and to simplify

cleaning, we recommend using Soyer release spray (order number

M01464).

Setup and connection

Operating Manual Soyer Bolzenschweißtechnik 41

10. Setup and connection

10.1 Requirements for the installation location

The installation location for the stud welding device must be clean and dry. Ensure adequate ventilation of the stud welding device. Do not install the stud welding device in an unventilated room. There is a danger of overheating.

Ensure that the installation surface is level, clean and stable.

The installation location and workplace must comply with the legal requirements.

Ensure that the installation location has good accessibility all round for maintenance work.

Make sure that the stud welding device is not soiled by work causing dust (especially metal dust or swarf) in the immediate vicinity (e.g. from grinding work).

DANGER

!

Danger from humid installation location

There is a danger of electrocution if the stud welding device is operated in a

humid environment.

• The stud welding device must only be operated in dry rooms.

CAUTIONCAUTION

!

Danger from welding vapours

Health threatening vapours can occur depending on the material of the workpiece and/or welding stud.

• Where necessary, ensure suitable extraction of the welding vapours.

Setup and connection

42 Operating Manual Soyer Bolzenschweißtechnik

10.2 Connection of the stud welding device and the stud welding guns

10.2.1 Mains connection

After installation, connect the stud welding device to the power supply using the

mains plug. To do so, observe Chapter "6.4 Technical data of the BMK-8i stud

welding device" on page 25.

10.2.2 Connecting the earth cable

A secure earth connection must be

established between the workpiece

to which the studs are welded and

the stud welding device.

To do so, plug the earth cable into

the socket and turn the plug to the

right up to the end stop.

Then connect the earth cable to the

workpiece (ensure a conductive

connection).

i

When switching on the device, all LEDs on the front of the device light

up briefly.

R

BMK-8i

S

www.soyer.com

Setup and connection

Operating Manual Soyer Bolzenschweißtechnik 43

10.2.3 Connecting the stud welding gun

Only use the welding guns approved by the manufacturer. To do so, observe

Chapter "6.5 Permitted stud welding guns" on page 26.

Plug the welding cable into the

socket (a) and turn the plug to the

right up to the end stop.

Plug the control cable into the control cable socket (b) and tighten the

union nut.

10.2.4 Connecting the shielding gas supply

Prior to welding with shielding gas, a suitable gas supply must be established.

The gas connection on the back of the device is used for supplying gas to the stud

welding device via a pressure reducer (pressure reduction valve not included in

the scope of delivery).

i

Check whether the connection of the gun requires any special adapters

(see Chapter "6.5 Permitted stud welding guns" on page 26).

R

BMK-8i

www.soyer.com

a

b

i

The maximum permissible operating value for the shielding gas amount

is 12 l/min.

Setup and connection

44 Operating Manual Soyer Bolzenschweißtechnik

Example of a shielding gas cylinder with connection fittings (not included

in the scope of delivery).

Figure 6: Example of a gas supply

Item Designation

a Gas cylinder with shielding gas (for recommended mixtures, see

below)

b Main shut-off valve

c Pressure gauge for indicating the gas pressure in the gas cylinder

[bar]

d Gas flow rate meter [l/min] (pressure reduction valve)

e Shut-off valve for the gas connection hose of the stud welding device

f Gas connection hose of the stud welding device

g Valve for regulating the gas flow rate (maximum permissible gas

amount: 12 l/min)

a

b

d

c

e

g

f

Setup and connection

Operating Manual Soyer Bolzenschweißtechnik 45

Establishing the gas supply

Step 1: Check the gas cylinder, the connection fittings and the gas hose

with the connecting plugs for integrity and functionality.

Step 2: Connect the gas connection hose to the pressure reduction

valve of the gas cylinder and the stud welding device.

Step 3: Open the main valve of the gas cylinder and the shut-off valve of

the gas connection hose.

Step 4: Use the regulating valve to set a shielding gas flow rate of

approx. 4 - 5 l/min.

Step 5: Plug the shield gas hose of the gun into the stud welding device.

The gas supply is established.

BMK-8i

www.soyer.com

Setup and connection

46 Operating Manual Soyer Bolzenschweißtechnik

WARNINGWARNING

!

Danger from escaping gas

Numerous dangers can occur due to escaping gas, such as oxygen deprivation or line/gas cylinder whipping around.

• Make sure the gas cylinder is adequately secured against falling over and

damage.

• Make sure the gas cylinder, fittings and lines are always in a good condition.

• Make sure there is an adequate supply of fresh air when using, storing or

transporting the gas cylinder.

• Comply with the instructions of the gas/gas cylinder manufacturer.

• Carry out all necessary, prescribed checks of the gas cylinder, fittings and

lines.

• Safeguard the gas supply against unauthorised access.

i

The following shielding gas mixtures are recommended:

• 82% argon and 18% CO2 (preferred)

• 90% argon and 10% CO2

• 85% argon and 15% CO2

Settings

Operating Manual Soyer Bolzenschweißtechnik 47

11. Settings

The stud welding device and gun must be matched and adjusted for the respective processing.

11.1 Setting the welding parameters

How to set the welding parameters of the

• welding current

• welding time

•SRM current

• gas preflow time and

• lift time/height of lift

is explained in the following.

To achieve an optimum stud welding result, it is necessary to carry o ut some s ample welds with different settings.

The parameters to be set on the stud welding device also depend on the following

influencing factors:

• Material of the workpiece

• Thickness of the workpiece

• Material of the welding stud

• Diameter of the welding stud

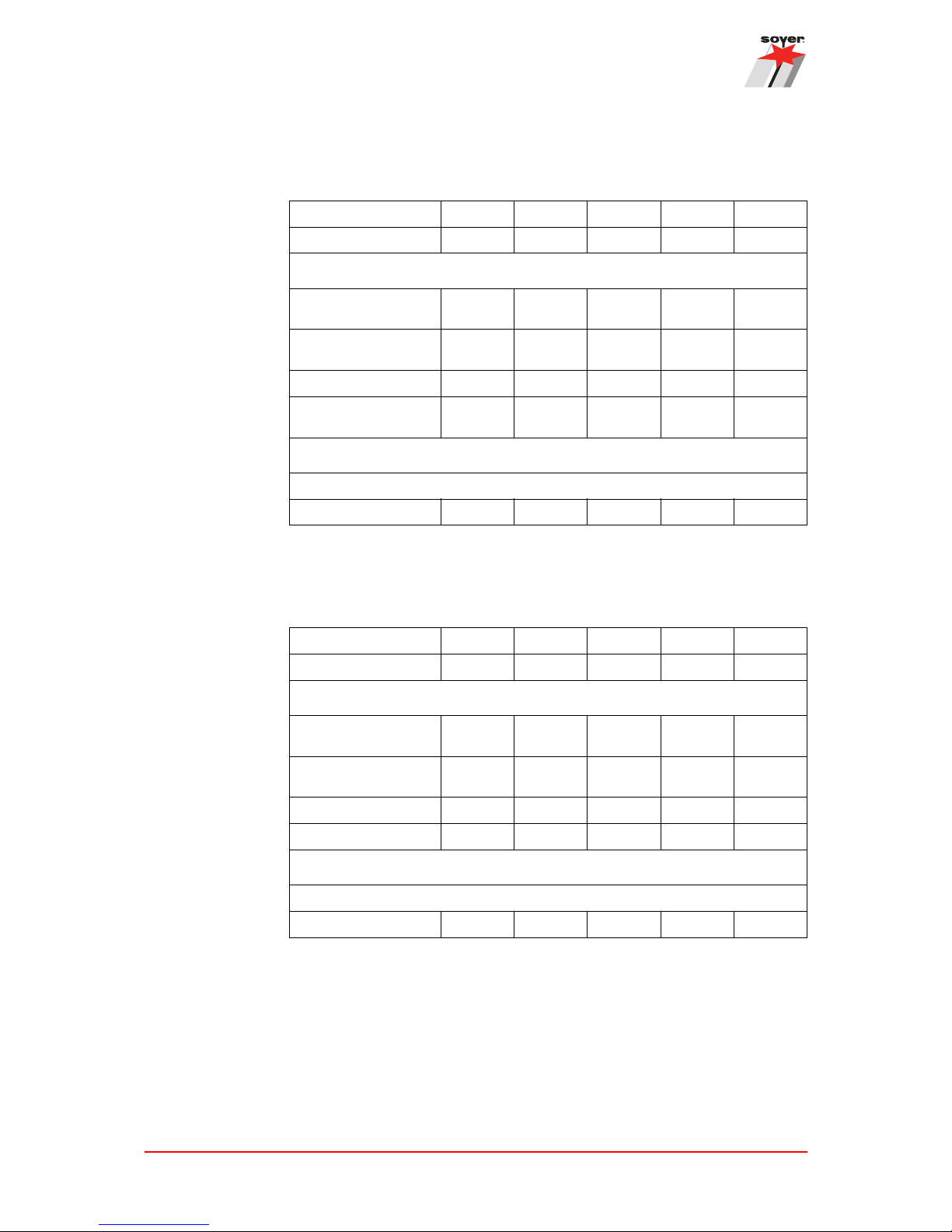

11.1.1 Help tables for device setting

The values given in the following table can be useful as guide values for an initial

sample weld.

How the respective settings are made is explained in later chapters.

Settings

48 Operating Manual Soyer Bolzenschweißtechnik

The values were determined using a 2 mm thick plate.

The values were determined using a 2 mm thick plate.

BMK-8i SRM welding parameters setting aid

PH-9 SRM12 gun

Stud material Steel 4.8 A2-50 Steel 5.8 Steel 8.8 A2-50

Stud thread - type M6-MF M6-MF M8-HZ-1 M8-HZ-1 M8-HZ-1

General welding parameters

Welding current, approx.

[A]

200 200 270 270 270

Welding time, approx.

[ms]

250 250 300 300 300

SRM current, approx. [A] 0.30 0.30 0.30 0.30 0.50

Gas preflow time, approx.

[s]

1.0 1.0 1.0 1.0 1.0

Lift time/Height of lift

Required height of lift approx.: 1 - 1.5 mm

Lift time, approx. [ms] 13.5 13.5 13.5 13.5 13.5

BMK-8i SRM welding parameters setting aid

PH-3N SRM gun

Stud material Steel 4.8 A2-50 Steel 5.8 Steel 8.8 A2-50

Stud thread - type M6-MF M6-MF M8-HZ-1 M8-HZ-1 M8-HZ-1

General welding parameters

Welding current, approx.

[A]

200 200 270 270 270

Welding time, approx.

[ms]

250 250 250 250 250

SRM current [A] 0.20 0.20 0.30 0.30 0.50

Gas preflow time [s] 1.0 1.0 1.0 1.0 1.0

Lift time/Height of lift

Required height of lift, approx.: 1 - 1.5 mm

Lift time, approx. [ms] 12.5 10.0 8.5 8.5 8.5

Settings

Operating Manual Soyer Bolzenschweißtechnik 49

11.1.2 Setting the welding current and the welding time

If you do not have specified values, the table in Chapter "11.1.1 Help tables for

device setting" on page 47 can be used as an aid for a basic setting.

Setting the welding current and the welding time

Step 1: Connect the device as described in Chapter "10.2 Connection of

the stud welding device and the stud welding guns" on page 42.

Step 2:

Use the ↑↓ arrow keys to

select the position for the

welding current setting.

The LED lights up if the selection is correct.

Step 3: Use the +/- keys to set the

required value for the welding

current on the display.

The welding current has been set.

Step 4: Use the ↑↓ arrow keys to

select the position for the

welding time setting.

The LED lights up if the selection is correct.

Step 5: Use the +/- keys to set the

required value for the welding

time on the display.

The welding time has been set.

+

[A]

[ms]

[A]

[s]

[ms]

GAS

SRM

>

>

>

>

+

SRM

GAS

+

[A]

[ms]

[A]

[s]

[ms]

GAS

SRM

>

>

>

>

+

SRM

GAS

Settings

50 Operating Manual Soyer Bolzenschweißtechnik

11.1.3 Setting/deactivating the SRM current

If you do not have specified values, the table in Chapter "11.1.1 Help tables for

device setting" on page 47 can be used as an aid for a basic setting.

If an SRM current value > 0 A is set, SRM is automatically activated during welding with the set current value. If the setting is 0 A, SRM is deactivated.

Setting/deactivating the SRM current

Step 1: Connect the device as described in Chapter "10.2 Connection of

the stud welding device and the stud welding guns" on page 42.

Step 2: Use the ↑↓ arrow keys to

select the position for the SRM

current setting.

The LED lights up if the selection is correct.

Step 3: Use the +/- keys to set the

required value for the SRM

current on the display.

The SRM current is

adjustable from 0 - 1500 mA

(display in A) in 50 mA steps

(0.05 A).

i

If the setting is "0", SRM is deactivated.

The SRM current has been set.

+

[A]

[ms]

[A]

[s]

[ms]

GAS

SRM

>

>

>

>

+

SRM

GAS

Settings

Operating Manual Soyer Bolzenschweißtechnik 51

11.1.4 Setting the gas preflow time

If you do not have specified values, the table in Chapter "11.1.1 Help tables for

device setting" on page 47 can be used as an aid for a basic setting.

The "Gas test" mode can be used to check that the shielding gas flows through

the shielding gas cap of the gun. As soon as the release knob on the gun is

pressed, shielding gas flows out of the shielding gas cap of the gun for the time

set in seconds. This means the gas lines can also be purged with shielding gas

before starting work.

Setting the gas preflow time

Step 1: Connect the device as described in Chapter "10.2 Connection of

the stud welding device and the stud welding guns" on page 42.

Step 2: Use the ↑↓ arrow keys to

select the position for the gas

preflow time setting.

The LED lights up if the selection is correct.

Step 3: Use the +/- keys to set the

required value (1-5 s) for the

gas preflow time on the display.

The gas preflow time has been set.

+

[A]

[ms]

[A]

[s]

[ms]

GAS

SRM

>

>

>

>

+

SRM

GAS

Settings

52 Operating Manual Soyer Bolzenschweißtechnik

11.1.5 Setting the lift time (height of lift) in "Setup" mode

For drawn arc welding guns, the weld stud is lifted for a defined height/time just

before the welding process and automatically lowered again during the welding

process.

As the height of lift of the stud is difficult to measure, the equivalent lift time is

specified on the stud welding device.

In the following setting of the lift time, the welding process is simulated in "Setup"

mode. The lifting and lowering of the stud is the same as during welding, only the

welding current is not activated.

Operating modes

• Setup mode: No welding is carried out when simulating a welding process.

• Operating mode (normal mode): Welding is carried out

WARNINGWARNING

!

Danger from incorrect operating mode

If the following adjustment work is not carried out in "Setup" mode but in operating mode, pressing the trigger button on the gun causes a weld to be carried

out.

• Make sure that "Setup" mode is activated for the lift test.

Setting the lift time/height of lift with the stud welding device

Step 1: Connect the device as described in Chapter "10.2 Connection of

the stud welding device and the stud welding guns" on page 42.

Switch on the device.

Step 2: Fit the gun with a welding stud.

Step 3: Use the ↑↓ arrow keys to

select the position for the lift

test.

The LED lights up if the selection is correct.

+

[A]

[ms]

[A]

[s]

[ms]

GAS

SRM

>

>

>

>

Settings

Operating Manual Soyer Bolzenschweißtechnik 53

Notes on "Setup" mode

• The setup process can be repeated as often as required. However, to avoid

the magnetic coil overheating, maintain a waiting time of approx. one second

between two test strokes.

Step 4: Set the gun on the workpiece and

press the trigger button on the gun

for the weld.

Make sure the green "Stud on workpiece" control lamp lights up before

triggering.

The currently set value for the lift

time in [ms] appears on the display.

The longer the lift time, the higher

the height of lift. Determining the correct lift time requires experience and some trials. Guide values for the correct lift time can be

found in Chapter "11.1.1 Help tables for device setting" on

page 47.

The lift time is changed using the adjustment ring on the welding gun for the

height of lift of the stud.

Step 5: Make sure the device is in operating mode by selecting one of

the three functions above (green LEDs).

Setting the lift time/height of lift with the stud welding device

SRM

GAS

Welding operation

54 Operating Manual Soyer Bolzenschweißtechnik

12. Welding operation

How welds are carried out and how any weld defects can be avoided are described in the following.

12.1 Carrying out welding

How a weld is carried out with the stud welding gun is described in the following.

DANGER

!

Danger from incorrect operation

During stud welding, many hazards can arise if the devices are not operated

correctly.

• Before operating the stud welding device, observe Chapter "2. Important

safety instructions" on page 10.

• If you have any problems understanding the operating manual, please

contact the manufacturer, Soyer.

• Before each use, check that the devices and the lines with the plugs are

intact.

Carrying out welding

Step 1: Before welding, observe Chapter "2. Important safety instruc-

tions" on page 10.

Step 2: Connect the gun to the stud welding device (see Chapter "10.2

Connection of the stud welding device and the stud welding

guns" on page 42).

Pay attention to any necessary connection adapters.

Step 3: Insert the matching stud chuck and a welding stud (see Chapter

"7. Description of the SRM stud chuck" on page 28).

Only use Soyer welding studs.

Step 4: Check the welding parameters (see Chapter "11. Settings" on

page 47).

Welding operation

Operating Manual Soyer Bolzenschweißtechnik 55

Step 5: Make sure the device is in

operating mode by selecting

one of the three above functions.

Step 6: Check that the welding points on the stud and workpiece are

bare metal.

Step 7: Press the gun onto the workpiece at an angle of 90°.

If the contact to the workpiece and the earth connection are correct, the second LED from the top lights up.

Step 8: Press the gun trigger button.

Welding is carried out. During welding, the LED

for the trigger button and (when activated

accordingly) the LEDs for SRM welding and the

shielding gas also light briefly.

i

During the welding process, hold the gun still and only

pull the gun vertically away from the welded stud after

completing the welding process. This prevents the stud

chuck widening and becoming damaged.

The welding process is now complete.

Carrying out welding

+

[A]

[ms]

[A]

[s]

[ms]

GAS

SRM

>

>

>

>

SRM

GAS

SRM

GAS

Welding operation

56 Operating Manual Soyer Bolzenschweißtechnik

12.2 Notes on checking the quality of the weld

If the SOYER stud welding system is used properly and the correct materials are

chosen, the strength of the weld joint (weld zone) is always higher than that of the

stud or the basic material.

The following production weld tests have been proven in practice:

• Visual inspection

• Bend test

Further information is given in the standard:

DIN EN ISO 14555 Welding - Arc welding of metallic materials or in the DVS d ata

sheets DVS 0904 Instructions for practice - Arc stud welding.

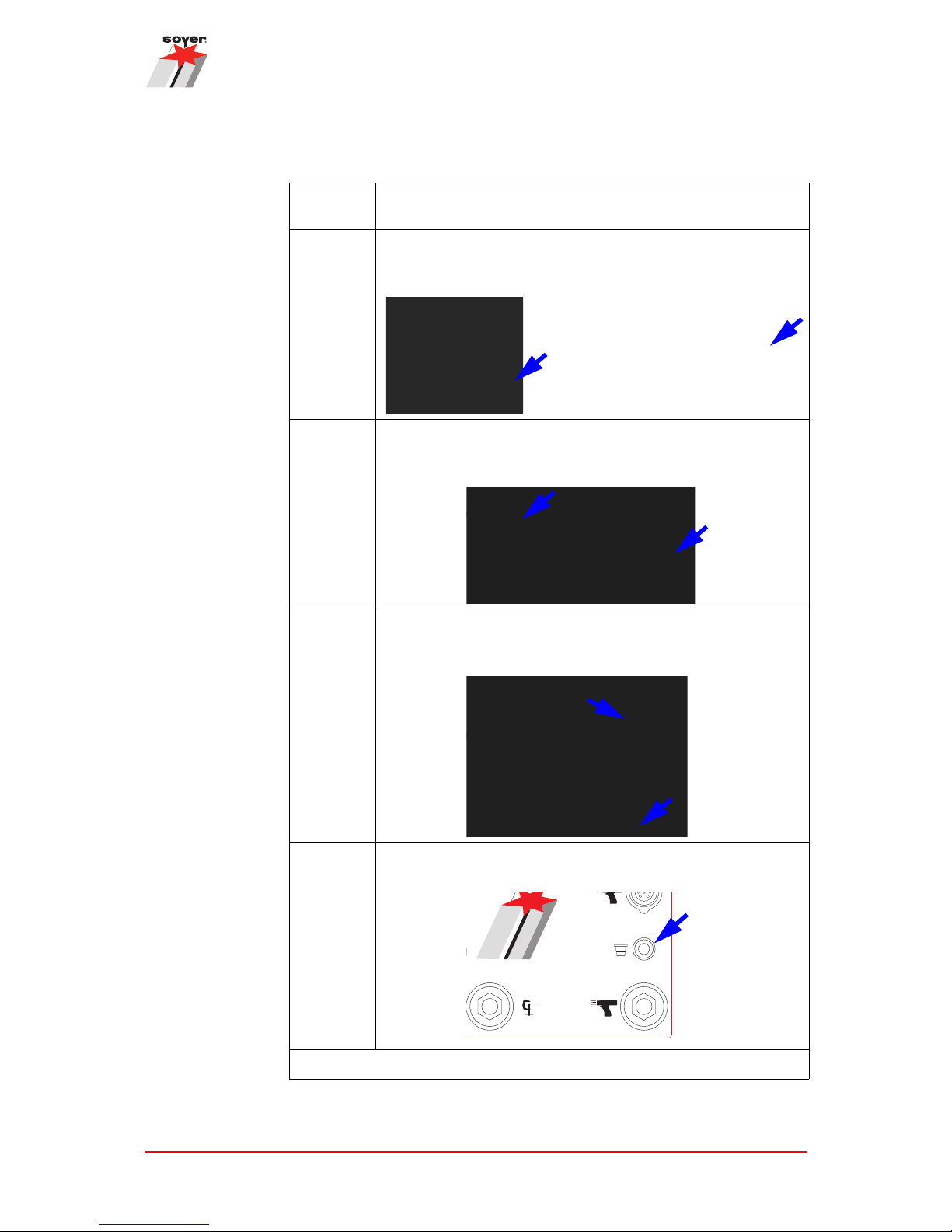

12.2.1 Visual inspection

Visual inspection is used for a rough check for major defects. The uniformity of

the weld is assessed here.

The following table serves as an aid for assessing a weld result.

Visual inspection

Welding image Note

Good weld joint.

Optimum setting.

Small weld bead, uniform, shiny and

closed.

Poor weld joint, e.g. due to excessive welding energy or immersion distance/lift too

low.

The stud is constricted at the weld joint. The

stud is only partly welded.

Poor weld joint, e.g. due to insufficient welding energy or immersion distance/lift too

low.

The weld bead is weak and unevenly

formed.

Welding operation

Operating Manual Soyer Bolzenschweißtechnik 57

12.3 Switching off the device

Switch off the stud welding device at the mains switch.

This also automatically switches off the connected welding gun.

Make sure that the stud welding device cannot be switched on and used by unauthorised persons.

Close the shut-off valves to the gas supply.

Poor weld joint, e.g. through arc blow out

effect, welding gun shaken or applied at a

slant.

The stud flange is not fully welded and has

visible defects. Undercuts are visible.

Visual inspection

Welding image Note

Welding operation

58 Operating Manual Soyer Bolzenschweißtechnik

12.4 Weld defects and their causes

The most common weld defects, their possible causes and how to troubleshoot

them are described in the following.

If the fault cannot be remedied as described, please contact Heinz Soyer Bolzenschweißtechnik GmbH.

Faults Possible cause and troubleshooting

The device cannot be

switched on.

• Check the mains supply fuses.

The device does not

weld, there is no (or

very little) spark formation.

The device is not connected to the mains or not switched on.

• Connect the device to the mains and switch it on. The LED displays light

up briefly when switching on.

The welding cable, control cable or gas hose are not correctly connected or

damaged.

• Connect the cables or gas hose correctly or examine for damage, replace

if necessary.

The connection plugs or sockets of the device are damaged.

• Have the plugs or sockets replaced by SOYER Customer Service.

Both earth cables are not (or not correctly) connected, or the earth clamps

are not fastened to the workpiece.

• Connect the earth cable, fasten the earth clamps to the workpiece.

The weld points or earth connection points on the workpiece are not bare

metal.

• Prepare the workpiece or studs.

The height of lift or the immersion depth is not set correctly.

• Set the height of lift or the immersion depth correctly in accordance with

the operating manual for the stud welding gun.

The gas flow rate is set too high, i.e. greater than 12 l/min (the arc is blown

out).

• Set the gas flow rate to a lower value.

The stud sits too loose in the stud chuck.

• Press the stud chuck together or reclamp.

Defect on the controller or on the welding gun.

• Notify SOYER Customer Service.

Welding operation

Operating Manual Soyer Bolzenschweißtechnik 59

The shielding gas

does not flow during

the welding process.

The gas cylinder is not (or is not correctly) connected to the device or the

valve, or the shut-off valve is not open.

• Connect the gas cylinder or open the valve or the shut-off valve.

The time for the gas preflow time is set to "0".

• Set the gas preflow time to the required preflow time.

The gas flow rate is set too low.

• Set the gas flow rate to 4 - 5 l/min with the regulating valve.

The solenoid valve in the device is soiled or defective.

• Contact Customer Service and have it replaced.

The stud does not lift,

there is no main current arc although the

"Stud on workpiece"

LED lights up.

The height of lift is not set correctly.

• Set the height of lift in accordance with operating manual for the stud

welding gun.

The controller of the device or the welding gun is defective. (The stud does

not lift despite correctly set height of lift).

• Notify SOYER Customer Service.

The stud lifts but the

main current is not

ignited.

The lift is too large.

• Set the lift in accordance with the operating manual for your welding gun.

The gas pressure is too high.

• Set the gas pressure to the specified value.

Faults Possible cause and troubleshooting

Welding operation

60 Operating Manual Soyer Bolzenschweißtechnik

Different weld results SRM current not set correctly

• Increase the SRM current parameter in steps and check if there is any

improvement.

Welding energy not set correctly.

• Adjust the welding energy.

Cable connections are too loose, there are transfer resistances.

• Check the proper seating of all cable connections and earth clamps.

Stud is too loose or not up to the end stop in the stud chuck.

• Press the stud up to the end stop, replace the stud chuck if necessary.

There is a magnetic arc blow out effect. The arc is pushed in a specific

direction

• Change the fastening of the earth clamps, place pieces of iron on the

edges or turn the welding gun.

The height of lift and/or the immersion depth are/is not set correctly.

• Set the height of lift and/or the immersion depth in accordance with the

operating manual for your welding gun.

Low quality studs with imprecise dimensions or poor surface quality have

been used.

• Only use Soyer welding studs.

The welding time and/or the gas flow rate are/is not set correctly.

• Set the welding time and/or the gas flow rate again.

Basic material is not suitable for welding.

• Use suitable material combinations.

One-sided beads are

formed at the same

points.

The formation of a bead is caused by magnetic arc blow out effect.The arc

is pushed in a specific direction

• Change the fastening of the earth clamps, place pieces of iron on the

edges or turn the welding gun.

The SRM current is set to 0 or is set too low.

• Increase the SRM current parameter in steps and check if there is any

improvement.

Very heavy spark formation,

stud flange almost

melted away.

Main current duration set too long.

• Re-adjust the time for the main current duration according to the table.

Welding current set too high.

• Re-adjust the welding current.

Faults Possible cause and troubleshooting

Welding operation

Operating Manual Soyer Bolzenschweißtechnik 61

Stud does not weld

with the entire flange

area, the strength of

the weld insufficient.

Main current duration set too short.

• Re-adjust the time for the main current duration according to the table.

Faulty earth connection.

• Check proper seating of the earth cable and earth clamps, tighten if necessary.

Excessive soiling of the workpiece surface.

• Clean the workpiece surface.

Front surface of the welding stud deformed.

• Use a new welding stud.

Stud protrusion beyond the stud chuck not set correctly.

• Set the distance between the stud chuck and the end of the weld stud to

3 - 5 mm.

Welding gun applied at a slant.

• Press the gun onto the workpiece at an angle of 90°.

Lift not set correctly.

• Adjust the lift.

The device switches

itself off.

The stud lift is not set correctly.

• Set the stud lift in accordance with the operating manual for the welding

gun and switch on the device.

The welding gun has been pulled off the workpiece during the main current.

• Switch the device back on.

The arc breaks off because the gas pressure is too high.

• Set the gas pressure to the specified value.

The surface of the workpiece has poor electrical conductance – the arc

breaks off.

• Grind off the surface.

Faulty mains supply.

• Check the mains supply fuses.

Fuse in the device defective

• Notify Customer Service.

Stud thread is burned. The stud chuck is worn out.

• Replace the stud chuck.

Faults Possible cause and troubleshooting

Maintenance and repair

62 Operating Manual Soyer Bolzenschweißtechnik

13. Maintenance and repair

The stud welding device and the stud welding guns must only be maintained and

repaired by Heinz Soyer Schweißtechnik GmbH or its authorised specialists.

14. Service

In the event of service, please contact:

Heinz Soyer Bolzenschweißtechnik GmbH

Inninger Straße 14

82237 Wörthsee

Tel.: 0049-8153-885-0

Fax: 0049-8153-8030

Mail: info@soyer.de

Please have the serial number at hand during service requests.

Alternatively, you can contact your respective Soyer representative. The contact

data is available on our web site at

www.soyer.de or

www.soyer.com (English)

15. Warranty conditions

The warranty period for commercial use or corresponding use is 12 months. In

the event of repair, we guarantee the elimination of deficiencies at the Etterschlag

factory. Wear parts are excluded.

The warranty claim expires if damage occurs through improper operation, repairs

or interventions by unauthorised persons as well as due to the use of accessories

and spare parts not intended on our system.

If third party welding studs are used, we accept no responsibility for the proper

functioning of the stud welder and the quality of the weld joint.

Warranty conditions

Operating Manual Soyer Bolzenschweißtechnik 63

Heinz Soyer Bolzenschweißtechnik GmbH

Inninger Straße 14

82237 Wörthsee

Tel.: 0049-8153-885-0

Mail: info@soyer.de

www.soyer.com

www.srm-technology.de

Loading...

Loading...