Dura-Dock Dock Lift

Owner’s Manual

(DDL 5-59M, DDL6-59M & DL8-59M)

Model:

Serial Number:

Date placed in

service:

SOUTHWORTH PRODUCTS CORP.

P.O. Box 1380, Portland, ME 04104-1380

Telephone: 800-743-1000 • 207-878-0700

Fax: 207-797-4734

www.SouthworthProducts.com

Southworth Products DDL Dock Lift ManualFebruary 19, 2019

Contents

1 Introduction .................................................................................................................................... 4

1.1 Responsibilities of Owner and Users.................................................................................. 4

1.2 Responsibilities of Operators .............................................................................................. 5

2 Safety .............................................................................................................................................. 6

2.1 Safety Alert Symbols ............................................................................................................ 7

2.2 Signal Words ......................................................................................................................... 7

2.3 Safety Devices ....................................................................................................................... 7

3 Labeling .......................................................................................................................................... 7

3.1 Label Location Diagram ....................................................................................................... 8

4 Installation...................................................................................................................................... 9

4.1 External Power Unit .............................................................................................................. 9

4.2 Pit Installation........................................................................................................................ 9

4.3 Typical Pit Plan .................................................................................................................... 10

4.4 Recommended Pad Plan .....................................................................................................11

4.5 Alternative Pad Plan ........................................................................................................... 12

4.6 General Installation ............................................................................................................. 13

5 Operation...................................................................................................................................... 14

5.1 Loading ................................................................................................................................ 15

6 Maintenance & Repair ................................................................................................................. 15

6.1 Maintenance Devices .......................................................................................................... 16

6.2 Periodic Maintenance ......................................................................................................... 17

6.2.1 Weekly Maintenance ................................................................................................... 17

6.2.2 Monthly Maintenance ................................................................................................. 17

6.2.3 Six Months................................................................................................................... 17

6.3 Relieving Hydraulic Pressure ............................................................................................ 18

6.4 Replacement Parts .............................................................................................................. 19

7 Troubleshooting .......................................................................................................................... 19

8 Electrical Information .................................................................................................................. 21

8.1 Wiring Schematic ................................................................................................................ 21

8.2 Control Panel ....................................................................................................................... 22

9 Hydraulic Information ................................................................................................................. 23

9.1 Hydraulic Fluid Specications ........................................................................................... 23

9.2 Hydraulic Schematic ........................................................................................................... 23

9.3 Hydraulic Power Unit .......................................................................................................... 23

9.4 Hose Specications ............................................................................................................ 23

Southworth Products DDL Dock Lift Manual

2

9.5 Hydraulic Arrangements .................................................................................................... 24

9.5.1 Standard Hydraulic Arrangement ............................................................................. 24

9.5.2 Alternative Hydraulic Arrangement .......................................................................... 24

10 Warranty & Contact Information .............................................................................................. 25

This label (Part No. 10095524) is required by California law.

For more information visit: www.P65Warnings.ca.gov

This lift is design and manufactured in accordance with

ANSI standard MH29.1 – “The Safety Requirements for

Industrial Scissors Lifts”.

Southworth ProductsDDL Dock Lift Manual DDL Dock Lift Manual

3

1. Introduction

1.1 Responsibilities of Owner and Users

Basic Principles - Owners/users shall apply sound principles of safety, training, inspection,

maintenance, and expected operating environment. It shall be the responsibility of the owner/user

to advise the manufacturer where deection may be critical to the application.

Manuals - Owners/users shall keep and maintain a copy of the operating and maintenance

manual(s) and ensure its availability to operating and maintenance personnel.

Inspection and Maintenance - It shall be the responsibility of the users to inspect and maintain

the industrial scissors lift as required to ensure proper operation. The frequency of inspection

and maintenance shall be based upon the manufacturer’s recommendations and be compatible

with operating conditions and the severity of the operating environment. Machinery that is not in

proper operating condition shall be immediately removed from service until repaired. Maintenance

and repairs shall be made by a qualied person and the repairs shall be in conformance with the

manufacturer’s recommendations.

Maintenance Safety Precautions - Before adjustments and repairs are started on the machine,

the following precautions shall be taken as applicable:

1. Remove the load from the load enclosure.

2. Lower the platform to the full down position.

3. Relieve system pressure from all circuits before loosening or removing any components.

4. All controls in the “off’ position and all operating features secured from inadvertent motion

by brakes, blocks, or other means.

5. Disconnect power and follow established owner/user lockout/tag out policies.

6. Follow precautions and directions as specied by the manufacturer.

Replacement Parts - When parts or components are replaced, they shall be replaced with parts

or components approved by the original manufacturer.

Maintenance Training - The user shall ensure only qualied personnel inspect and maintain the

machine in accordance with the manufacturers recommendations.

Operator Training - An owner/user, who directs or authorizes an individual to operate the

machine shall ensure that the individual has been:

1. Trained in accordance with the manufacturer’s operating manual.

2. Made aware of the responsibilities of operators as outlined in section 1.4 of this manual.

3. Retrained, if necessary, based on the owners/user’s observation and evaluation of the

operator.

Modications and additions shall not be performed without the manufacturer’s prior written

approval. Where such authorization is granted, capacity, operation, and maintenance instruction

plates, tags, or decals shall be changed accordingly.

Southworth Products DDL Dock Lift Manual

4

1.2 Responsibilities of Operators

Basic Principles - Operators shall apply sound principles of safety and good judgment in

the application and operation of the machine with consideration given to its intended use

and expected operating environment. Since the operator is in direct control of the machine,

conformance with good safety practices is the responsibility of the operator. The operator shall

make decisions on the use and operation with due consideration for the fact that his or her own

safety as well as the safety of other personnel on or near the machine is dependent on those

decisions.

1. General Training - Only personnel who have received general instructions regarding the

inspection, application and operation of machine, including recognition and avoidance of

hazards associated with their operation, shall operate the machine. Such topics covered

shall include, but not necessarily be limited to, the following issues and requirements:

2. A pre-start inspection

3. Responsibilities associated with problems or malfunctions affecting the operation of the

machine.

4. Factors affecting stability

5. The purpose of placards and decals

6. Workplace inspection

7. Safety rules and regulations

8. Authorization to operate

9. Operator warnings and instructions

10. Actual operation of the machine. Under the direction of a qualied person, the trainee shall

operate the machine for a sufcient period of time to demonstrate prociency in actual

operation of the machine.

Pre-start Inspection - Before use each day or at the beginning of each shift, the machine shall

be given a visual inspection and functional test including but not limited to the following:

1. Operating and emergency controls

2. Safety devices

3. Hydraulic system leaks

4. Electrical cables and wiring harness

5. Loose or missing parts

6. Nameplates, precautionary and instructional markings and/or labeling

7. Guarding system

8. Items specied by the manufacturer

Problem or Malfunctions - Any problems or malfunctions that affect the safety of operations shall

be repaired prior to the use of the machine.

Before Operations - The operator shall:

1. Read and understand the manufacturer’s operating instruction(s) and user’s safety rules or

have them explained

2. Understand all labels, warnings, and instructions displayed on the machine or have them

explained.

Southworth ProductsDDL Dock Lift Manual DDL Dock Lift Manual

5

Workplace Inspections - Before the machine is used and during use, the operator shall check

the area in which the machine is to be used for possible hazards such as, but not limited to:

1. Bumps, oor obstructions and uneven surfaces

2. Overhead obstructions and electrical hazards

3. Presence of unauthorized persons

4. Other possible unsafe conditions as noted in the operating manual.

Operator Warnings and Instructions - The operator shall ensure the operation of the machine

is in compliance with the following:

Guarding system - Guarding shall be installed and positioned, and access gates or openings

shall be secured per the manufacturer’s instructions.

Distribution of load - The load and its distribution on the platform shall be in accordance with the

manufacturer’s rated capacity for that specic conguration.

Maintaining overhead clearance - The operator shall ensure that adequate clearance is

maintained from overhead obstructions and energized electrical conductors and parts.

Point of Operation - The operator shall not place any part of their body under the platform.

Precaution for moving equipment - When other moving equipment or vehicles are present,

special precautions shall be taken to comply with the safety standards established for the

workplace.

Reporting problems or malfunctions - The operator shall immediately report to a supervisor

any problem(s) or malfunction(s) that become evident during operation. The operator shall ensure

all problems and malfunctions that affect the safety of operations are repaired prior to continued

use.

Capacity limitation - Rated capacity shall not be exceeded when loads are transferred to the

load enclosure.

Work area - The operator shall ensure the area surrounding the machine is clear of personnel

and equipment before lowering the load enclosure.

Securing the machine - The operator shall comply with the means and procedures provided to

protect against use by an unauthorized person(s).

Altering safety devices - Safety devices shall not be altered or disabled.

Modications or alterations of the machine or the fabrication and attaching of frameworks or the

mounting of attachments to the machine or the guarding system shall only be accomplished with

prior written permission of the manufacturer.

Assistance to the operator - If an operator encounters any suspected malfunction or any hazard

or potentially unsafe condition relating to capacity, intended use or safe operation the operator

shall cease operation of the machine and request further instruction from the owner/user.

Problems or malfunctions - Any problem(s) or malfunction(s) that affect the safety of operations

shall be repaired prior to the use of the machine.

2. Safety

All personnel installing, operating, and maintaining this machine shall read and understand this

manual. For questions or concerns contact the manufacturer.

This machine shall be installed, operated, and maintained by trained and/or qualied personnel

only.

Southworth Products DDL Dock Lift Manual

6

2.1 Safety Alert Symbols

A BCD

A symbol that indicates a hazard. It is composed of an equilateral triangle surrounding an

exclamation mark. The safety alert symbol is only used on hazard alerting signs. It is not used on

safety notice and safety instructions signs.

A – For use with DANGER signal word; (safety white triangle, safety red exclamation mark, safety

red background)

B – For use with WARNING signal word; (safety black triangle, safety orange exclamation mark)

C – For use with CAUTION signal word; (safety black triangle, safety yellow exclamation mark)

D – For use with DANGER, WARNING, or CAUTION signal words; (safety yellow triangle with a

safety black border and safety black exclamation mark

2.2 Signal Words

Indicates a hazardous situation that, if not avoided, will result in death

or serious injury.

Indicates a hazardous situation that, if not avoided, could result in

death or serious injury.

Indicates a hazardous situation that, if not avoided, could result in

minor or moderate injury.

Indicates information considered important, but not hazard-related

(e.g., messages relating to property damage).

2.3 Safety Devices

This machine is equipped with devices and features to protect the operator and nearby personnel

from severe injury or death. These features and devices shall be installed and functioning

correctly during operation.

This machine is equipped with beveled toe guards on the platform, which meet the requirements

of ANSI MH 29.1 and requirements for pit installation.

3. Labeling

This machine has labeling to indicate potential hazards this machine may pose when operating

and/or maintaining the machine. All labels must be legible. If any label is missing, damaged, or

otherwise illegible contact the manufacturer for replacement labels.

Southworth ProductsDDL Dock Lift Manual DDL Dock Lift Manual

7

3.1 Label Location Diagram

BK-LD TAG SOUTHWORTH

5900158

Southworth Products DDL Dock Lift Manual

8

4. Installation

Installation of this machine shall be performed by trained and/ or qualied personnel

only. The owner/ installer is responsible obtaining any necessary permissions and/ or

permits. Follow all applicable codes and ordinances. Read and understand all safety and

installation information in this manual.

Before installation, remove all shipping materials and verify all components on the packing

list were received. Inspect the machine, all components, wiring and electrical connections,

hydraulic hoses and ttings for damage. If components are missing or damage is found contact

the manufacturer before continuing installation. If not being installed in a pit see Typical and

Alternative Pad Plan sections

To avoid death or serious injury:

• Pinch points and Crush Hazards exist when moving and transporting the machine.

Do not enter under any equipment while moving or transport. Keep hands, feet, and

loose clothing away from moving equipment.

• This machine must be installed on a solid, stable, level surface or machine will be

unstable and can lead to injury. Do not install on asphalt or other unstable surface.

• Never enter beneath the platform unless the machine is unloaded and secured

against lowering using the maintenance device. See Maintenance Devices section.

Use appropriate lifting device to lift the machine. Use a load spreader

to lift the machine. Lift the machine using the provided lifting eye-bolts

only. Do not lift the machine by the platform.

This machine must be properly secured to the oor/ ground before

operation or the machine may be damaged.

High Voltage: Electrical service and installation must be performed by

trained and/ or qualied personnel. Lock-out/ tag-out the power source

before installation.

Electric motors create sparks. Do not install the power unit in an area

where ammable gases may be present.

4.1 External Power Unit

External power units should be placed within thirty feet (hose length) of the machine to avoid

excess pressure drops. External power units must be protected from moisture and weather.

4.2 Pit Installation

Do not install this machine in a pit unless the machine has been

designed for such installation. Shear points exist and can cause severe

injury.

Platforms traveling below oor level may require guarding in

accordance with ANSI MH 29.1. Guarding must be installed before

operation.

This machine is equipped with beveled toe guards which meet the MH

29.1 guarding requirements.

1. Verify that the pit dimensions match the pit plan.

2. Verify that pit is clear of tools and other debris before lowering the machine into the pit.

3. Follow General Installation instructions to complete the installation.

Southworth ProductsDDL Dock Lift Manual DDL Dock Lift Manual

9

4.3 Typical Pit Plan

3" X 3" X 1/4" ANGLE BY

CONDUIT ENTRY CAN BE

IN PIT. (BY CONTRACTOR)

•

•

•

PIT CONTRACTOR. ALL

CORNERS TO BE

SECURELY WELDED. PIT

MUST BE SQUARE (

ACROSS CORNERS.

3/4" LAG HOLES

LAG WITH

SLEEVE ANCHORS

(BY INSTALLER)

PLATFORM

WIDTH

+1-1/2"

5/8" MIN.

FROM ANY DIRECTION

INCLUDING ENTRY FROM

1/2")

BOTTOM OF PIT SUMP.

COUPLINGS FOR

HYDRAULIC

CONNECTIONS

PLATFORM LENGTH + 1-1/2"

2" CONDUIT

1 1/2"

STEP REQUIRED FOR BRIDGE

PLATE HINGE CLEARANCE

BRIDGE

PLATE

WIDTH

+1/2"

BRIDGE PLATE

LENGTH + 1/2"

CROSS HATCHING INDICATES AREAS OF

BASE FROM THE MUST BE SHIMMED AND

OR GROUTED AFTER LEVELING OF THE

BASE FRAME TO ENSURE PROPER BASE

FRAME SUPPORT.

CONDUIT RUN IS REQUIRED FOR ROUTING

OF HYDRAULIC HOSES AND ELECTRICAL

WIRING UNLESS ALTERNATIVE

ARRANGEMENTS ARE REQUESTED.

2" ELECTRICAL CONDUIT USED WHEN 1/2"

HYDRAULIC HOSE, VENT LINE, AND

ELECTRICAL LEADS ARE TO BE INSTALLED

FROM POWER UNIT TO LIFT (BY PIT

CONTRACTOR).

CONCRETE ANCHORS TO

1/2" X 6" LOCATED

BE

12" O.C. WITH ONE 3"

FROM EACH END.

CONCRETE BEHIND CURB

ANGLES MUST BE WELL

COMPACTED WITH NO

VODIS

8" BOLLARDS

STEEL PIPE FILLED

WITH CONCRETE

(BY CONTRACTOR)

CENTER LINE OF

BOLLARDS TO BE

ALIGNED WITH

FRONT OF PIT

48"

1/2"

LOW

6"

3"

HEIGHT

+1/2"

36"

1/2" SHIM

UNDER EACH

LAG PLATE FOR

PROPER DRAINAGE

PIT DRAIN AS REQUIRED TO

PREVENT STANDING WATER

Southworth Products DDL Dock Lift Manual

10

4.4 Recommended Pad Plan

PIPE

96" PAD

NOTES:

ON PAD (BY CONTRACTOR)

Use of a sump/drain for proper drainage and a conduit run for hydraulic/ electrical routing

in pad is recommended. If no sump/drain and conduit run is provided see Alternative Pad

Plan .

FOR MODEL DDL5-59

WITH 72"X96" PLATFORM

7 1/2"

54"

BASE

72"

PAD

FRAME

57"

ANCHORS

7 1/2"

HINGE END OF BASE

86" BASE FRAME

CONDUIT ROUTE CAN BE

FROM ANY DIRECTION

INCLUDING FROM BOTTOM

OF PIT SUMP

COUPLINGS FOR

HYDRAULIC

CONNECTIONS

4X LAG WITH

(MINIMUM) SLEEVE

ANCHORS

5/8"

78" LAGS

12"

12"

2" CONDUIT

5"

6"

THROW OVER

PLATE AREA

ROLLER END

6"

CROSS HATCHING INDICATES AREAS OF •

BASE FRAME THAT MUST BE SHIMMED

AND/OR GROUTED AFTER LEVELING OF THE

BASE FRAME TO ENSURE PROPER BASE

FRAME SUPPORT.

CONDUIT RUN IS RECOMMENDED FOR •

ROUTING OF HYDRAULIC HOSES AND

ELECTRICAL WIRING.

2" ELECTRICAL CONDUIT USED WHEN 1/2" •

HYDRAULIC HOSE, VENT LINE, AND

ELECTRICAL LEADS ARE TO BE INSTALLED

FROM POWER UNIT TO LIFT (BY

CONTRACTOR).

SURFACE MUST BE

SMOOTH AND LEVEL

2° SLOPE GRADE

AWAY FROM PAD

CONCRETE PAD MUST BE

WELL COMPACTED WITH

NO VOIDS

6"

3"

CENTER LINE OF BUMPER

POSTS TO BE ALIGNED WITH

EDGE OF PAD

36"

5"

9"

8" STEEL

2X

FILLED WITH

CONCRETE TYP.

(BY CONTRACTOR)

48"

8"

36"

PAD DRAIN AS REQUIRED TO

PREVENT STANDING WATER

Southworth ProductsDDL Dock Lift Manual DDL Dock Lift Manual

11

4.5 Alternative Pad Plan

ON

96" PAD

NOTES:

FOR MODEL DDL5-59

If sump/drain is not used lift will require 1/2” shims under the lag plates to allow proper

water drainage. The base frame must be shimmed and/or grouted according to the pad

plan to ensure the base frame is properly supported. Hydraulic connections are to be

made at the couplings on the roller end of the base frame.

WITH 72"X96" PLATFORM

7 1/2"

54"

BASE

57"

ANCHORS

FRAME

7 1/2"

72"

PAD

IF SUMP IS NOT USED, THE BASE FRAME •

MUST BE RAISED 1/2" TO ALLOW FOR

PROPER WATER DRAINAGE.

CROSS HATCHING INDICATES AREAS OF •

BASE FRAME THAT MUST BE SHIMMED

AND/OR GROUTED AFTER LEVELING OF THE

BASE FRAME TO ENSURE PROPER BASE

FRAME SUPPORT.

IF CONDUIT RUN IN PAD IS NOT USED FOR •

HYDRAULIC ROUTING CONNECTIONS ARE

TO BE MADE AT COUPLINGS ON ROLLER

END OF BASE FRAME.

HINGE END OF BASE

4X LAG WITH

(MINIMUM) SLEEVE

ANCHORS

5/8"

86"

78"

CENTER LINE OF BUMPER

POSTS TO BE ALIGNED WITH

EDGE OF PAD

5"

9"

6"

THROW OVER

PLATE AREA

ROLLER END

COUPLINGS FOR

HYDRAULIC

CONNECTIONS. FOR

MACHINES MOUNTED

PADS WITH NO CONDUIT

ROUTING PROVIDED.

6"

8" STEEL PIPE

2X

FILLED WITH

CONCRETE TYP.

(BY CONTRACTOR)

SURFACE MUST BE

SMOOTH AND LEVEL

2° SLOPE GRADE

AWAY FROM PAD

Southworth Products DDL Dock Lift Manual

CONCRETE PAD MUST BE

WELL COMPACTED WITH

NO VOIDS

12

48"

8"

36"

4.6 General Installation

1. Attach a chain or lifting strap, with an appropriate load spreader, to the main lifting eyes.

The chain or strap must pull on the lifting eyes vertically.

2. Using an appropriate lifting device, carefully move the machine into position.

USE LOAD SPREADER SO THAT CHAIN/

STRAPS PULLS VERTICALLY ON LIFTING

EYES

INSTALL EYE BOLTS INTO SECOND SET OF

HOLES TO MANUALLY RAISE THE PLATFORM

(OFF PLATFORM CENTERLINE)

3. Remove the lifting eyes and install them into the second set of holes. The second set of

holes have a nut welded to the bottom of the platform and are used to manually raise the

platform for access during installation. Reattach the chain or strap.

LIFTING EYE POSITION FOR

MOVING ENTIRE MACHINE

(ALONG PLATFORM CENTERLINE)

Eye bolts must be removed from holes securing the platform to the base

frame (holes along platform center line) before attempting to raise the

platform.

4. Using the eyes bolts, raise the platform and engage the maintenance device. See the

Maintenance Devices section. Ensure the roller end of the platform is not is not lifted off

of the upper rollers.

5. Remove the eye bolts and save them for future use, if needed.

6. Ensure the machine is level. If necessary use shims beneath the lag plates. All load bearing

points of the base frame must be fully supported by using grout beneath the base frame.

An improperly supported base frame can cause excess wear and/or

permanent damage to the machine.

FRONT ROLL-OVER SUPPORT

LAG PLATES (ALL

FOUR CORNERS)

ROLLER TRACKS (BOTH SIDES)

SIDE ROLL-OVER

SUPPORT (BOTH SIDES)

CROSS HATCHING INDICATES AREAS THAT

NEED TO BE SHIMMED AND/OR GROUTED,

ONCE LEVELED.

Southworth ProductsDDL Dock Lift Manual DDL Dock Lift Manual

13

HINGE END

7. Anchor the machine using appropriate anchors.

8. Clear the hydraulic lines by ushing with compressed air.

Hydraulic lines must be clear of debris before connecting or damage

may occur when the unit is powered.

If hoses & electrical wiring are not routed through conduit, hoses and

wiring must be protected from damage by other means.

9. Make all hydraulic connections according the hydraulic schematic.– See Hydraulic

Information section for specications and schematics.

10. Make all electrical connections according the wiring schematic.– See Electrical

Information section for specications and schematics.

11. If applicable, install and anchor ramp.

12. Install handrails and snap cables/ chains.

13. Check all hydraulic hoses and connections, wiring and electrical connections, and other

components for proper installation and damage.

14. Cycle the lift to test function. If platform does not begin to raise after a few seconds, see

Troubleshooting section.

ALL HANDRAILS MUST BE

INSTALLED AND SECURED

BEFORE PERSONNEL MAY

RIDE ON LIFT

THROW OVER PLATE

MUST BE IN RAISED

POSITION BEFORE

RAISING OR LOWERING

THE PLATFORM

ALL SNAP CHAINS/CABLES

MUST BE SECURED

BEFORE PERSONNEL MAY

RIDE ON LIFT

5. Operation

Before operating this machine, read and understand this manual. Inspect the machine for

excessive wear and/ or damage. If excessive wear or damage is found, remove the machine

from service and contact maintenance personnel. Inspect all precautionary labeling. If any

label is missing or illegible contact the manufacturer for replacement labels. Ensure area is free of

debris.

Before raising or lowering, raise throw over plate(s) and bridge plate(s)

to avoid damaging the plate(s).

Southworth Products DDL Dock Lift Manual

14

To avoid death or serious injury:

• Only trained and/or qualied personnel shall operate this machine.

• Personnel are not permitted on the platform during operation unless handrails and

snap chains/cables are installed.

• Loads that may shift during operating must be secured before operating.

• Keep hands, feet, and loose clothing away from moving parts.

• Do not enter beneath the platform until the load has been removed and the machine

has been secured against lowering with the maintenance device(s).

• Do not load or unload the machine while moving.

• The load’s center of mass must be centered on the platform. Uneven or off center

loading may cause excessive wear or permanent damage.

• During operation, operator must be in view of the machine at all times.

When not in use the platform is to be in the fully lowered position.

To raise the machine, press and hold the UP button on the controls. Release the button when

the platform is at the desired height.

To lower the machine, press and hold the DOWN button on the controls. Release the button

when the platform is at the desired height.

5.1 Loading

All loads should be centered on the platform. Uneven loading can lead to excessive wear or

damage. Always secure loads that may roll or shift during travel.

6. Maintenance & Repair

To avoid death or serious injury:

• Only trained and/ or qualied personnel shall perform maintenance or repair of this

machine.

• Pinch points exist, keep hands, feet, and loose clothing away from moving parts.

• Always use appropriate Personal Protective Equipment when performing and

maintenance or repair.

• Disconnect and lock out electrical supply before performing any maintenance or

repair

• Do not adjust the hydraulic pressure relief valve. This valve is pre-set and

adjustment may cause the machine to fail.

• Before performing maintenance or repair to the hydraulic components, relieve

pressure in the hydraulic system. See Relieving Hydraulic Pressure section.

• Pressurized uids can penetrate skin and cause severe injury. Do not use hands or

other body parts to detect hydraulic leaks.

• Do not enter beneath the platform until the load has been removed and the machine

is secured against lowering with the maintenance device(s). See Maintenance

Devices section.

Southworth ProductsDDL Dock Lift Manual DDL Dock Lift Manual

15

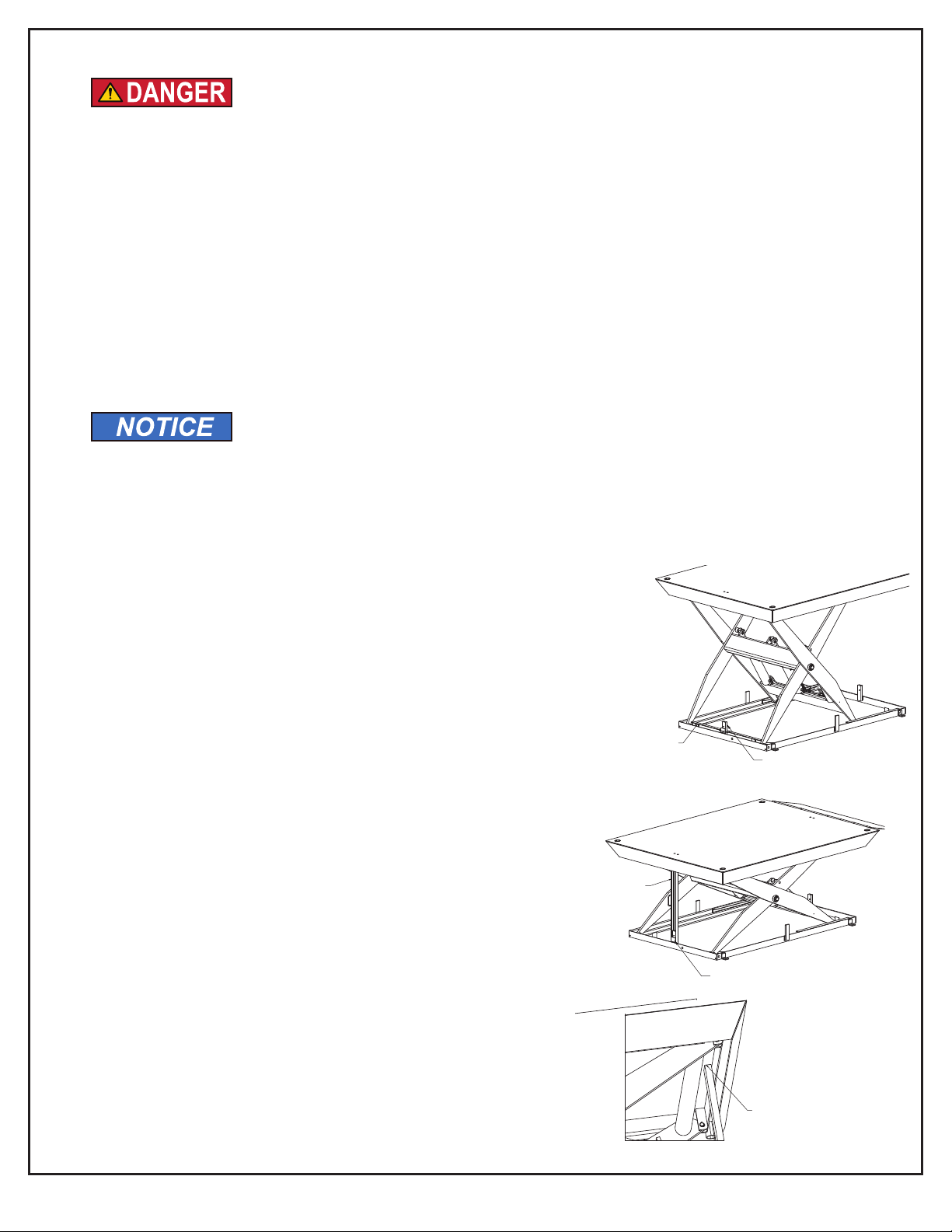

6.1 Maintenance Devices

To avoid death or serious injury:

• DO NOT enter beneath the platform until load has been removed and the machine is

secured against lowering using the supplied maintenance device(s).

• The supplied maintenance device(s) are designed to support the weight of

an UNLOADED machine only. Failure to remove the load before engaging

the maintenance devices may result in failure and allow the machine to fall

unexpectedly.

Before performing any maintenance or repair:

1. Remove any load on the platform of the machine.

2. Verify that all personnel and debris are clear of the work area.

3. Raise the lift to the fully raised position.

4. Engage maintenance device as shown in the diagram.

When engaged the maintenance device must rest on the underside of

the platform. Damage may occur if the maintenance device is resting on

the structural reinforcements. Maintenance device to be used on hinge

end of machine only.

5. Slowly lower the machine until the weight of the machine is supported by the maintenance

device(s). Continue to hold the down button for ve to ten seconds after the platform stops

to relieve hydraulic system pressure.

6. Disconnect electrical supply and

lock out the machine to prevent

unintended actuation of the

machine.

7. After maintenance or repair is

complete, verify all tools, debris,

and personnel are clear of the area.

Clean up any spills. Re-energize the

machine.

RAISE THE PLATFORM TO THE FULLY 1.

RAISED POSITION

REMOVE THE MAINTENANCE DEVICE 2.

FROM THE STOWED POSITION AND

PLACE THE END OVER THE POST.

LOWER THE PLATFORM UNTIL 3.

RESTING ON THE MAINTENANCE

DEVICE. WHEN ENGAGED, THE

MAINTENANCE DEVICE MUST REST ON

THE UNDERSIDE OF THE PLATFORM.

DAMAGE MAY OCCUR IF

MAINTENANCE DEVICE IS RESTING ON

STRUCTURAL REINFORCEMENTS

MAINTENANCE DEVICE STOWED

HINGE END

POST

8. Raise the machine to the fully raised

position.

9. Disengage the maintenance device

and stow the maintenance device.

MAINTENANCE DEVICE ENGAGED

10. Lower the machine to the fully

lowered position.

11. Test for proper operation.

Southworth Products DDL Dock Lift Manual

16

HINGE END

POST

WHEN ENGAGED, THE

MAINTENANCE DEVICE MUST

REST ON THE UNDERSIDE OF

THE PLATFORM. DAMAGE MAY

OCCUR IF MAINTENANCE

DEVICE IS RESTING ON

STRUCTURAL

REINFORCEMENTS

6.2 Periodic Maintenance

Before each use ensure area is clear of debris and sump/drain is clear. Inspect the machine

for excessive wear or damage and ensure all precautionary labeling is legible. Inspect railings,

verify cables/chains are in place and in good condition. Verify push button switch and cord are

functioning and are not damaged.

6.2.1. Weekly Maintenance

• Inspect leg rollers, center pivot pins and bushings, and leg hinge pins and bushings for

excessive wear or damage. Repair or replace as necessary.

• Inspect machine for loose of broken fasteners. Repair or replace as necessary.

• Inspect labeling. If any label is damaged or otherwise illegible contact the manufacturer

for replacement labels.

6.2.2. Monthly Maintenance

• Perform Weekly Maintenance.

• Apply a light oil or PTFE lubricant to non-greased pivot points or rollers.

• Inspect the appearance of the hydraulic uid. The uid should be transparent and clear

of debris.

• Inspect all hydraulic hoses and ttings. Repair or replace as necessary.

• Inspect all electrical wiring and connections. Repair or replace as necessary.

• Inspect limit switches, if applicable. Repair, replace, or adjust as necessary.

6.2.3. Six Months

• Perform Monthly and Weekly maintenance.

• Inspect the hydraulic cylinder and return line. If excessive uid exists in the vent line,

the cylinder may need to be repacked or replaced.

• Change hydraulic uid. Clean the suction screen and vent cap. Replace pressure line or

return line lter element (if equipped).

PULL CABLE

RAILINGS (BOTH SIDES)

HYDRAULIC

CYLINDER PINS

(EACH CYLINDER)

MAINTENANCE

DEVICE

(STOWED)

CENTER PIVOT

PINS/BUSHINGS

(BOTH SIDES)

SNAP CABLES

(BOTH ENDS OF

PLATFORM)

THROW OVER

PLATE

PLATFORM

UPPER/LOWER

ROLLERS

(BOTH SIDES)

HYDRAULIC POWER UNIT

UPPER/LOWER LEG HINGE

PINS/BUSHINGS (BOTH SIDES)

Southworth ProductsDDL Dock Lift Manual DDL Dock Lift Manual

17

BASE FRAME

HYDRAULIC

CYLINDERS

6.3 Relieving Hydraulic Pressure

MOTOR

CONTROL PANEL

If the machine is operating normally, hydraulic system pressure can be relieved by lowering the

platform to the fully lowered position or on maintenance device and continuing to hold the down

button for ve to ten seconds.

If the platform is raised and will not lower:

Crush Hazard – Do not enter under the platform.

Remove load before performing any maintenance or repair.

Disconnect and lockout electrical power before performing maintenance

or repair.

Failure to securely block the platform from lowering will allow the

platform to fall uncontrolled when system pressure is relieved, causing

severe injury or death - use only supplied maintenance device.

High pressure uid can cause severe injury or death. Always use proper

personal protective equipment when performing any maintenance or

repair.

1. Thread the lifting eyes into holes on the platform for manually raising the platform (holes off

the center line of the platform). See General Installation Section numbers 1-5.

2. Attach chains/ straps and load spreader to the lifting eyes.

3. Using an appropriate lifting device, slowly pull the chains/ straps until they are taught and

will support the platform when hydraulic pressure is relieved. If the platform is not in the

fully raised position, continue to pull the platform up until it reaches the fully raised position.

Platform weight: approximately 2000 lb.

When lifting the platform by the lifting eyes, ensure cable/chain/straps

pull vertically on the lifting eyes.

4. Ensure platform is secured and will not fall as hydraulic pressure is relieved.

5. Carefully and slowly loosen the hydraulic tting on the input side of the adjustable ow

control shown in the diagram to relieve system pressure. Use an appropriate, clean,

container to catch hydraulic uid in the hoses. Use an oil absorbent to clean up any spills.

Uncontaminated uid can be reused.

6. Engage the maintenance device. - See Maintenance Devices section.

7. Slowly lower the platform until resting on the maintenance device.

DOWN SOLENOID/ VALVE

PUMP

DISCONNECT

HYDRAULIC HOSE

FROM THIS FITTING

TO RELIEVE SYSTEM

PRESSURE

ADUJUSTABLE DOWN

FLOW CONTROL

Southworth Products DDL Dock Lift Manual

18

6.4 Replacement Parts

Southworth Products has carefully chosen the components in your lift to be the best available

for the purpose. Replacement parts should be identical to the original equipment. Southworth

Products will not be responsible for equipment failures resulting from the use of incorrect

replacement parts or from unauthorized modications of the machine.

Southworth Products will gladly supply you with replacement parts for your Southworth Products

lift. With your order, please include the model number and the serial number of the lift. You

can nd these numbers on the name plate, which is located on the crossbar at the base of the

cylinder(s). When you are ordering parts for a cylinder, also include the cylinder number. This is

stamped on the base of the cylinder housing.

To order replacement parts, please call the Parts Department. See Warranty & Contact

Information section. Parts are shipped subject to the following terms:

• FOB factory

• Returns only with the approval of our parts department.

• Payment net 30 days (except parts covered by warranty).

• Freight collect (except parts covered by warranty).

• The warranty for repair parts is 30 days from date of shipment.

Parts replaced under warranty are on a “charge-credit” basis. We will invoice you when we ship

the replacement part, then credit you when you return the worn or damaged part, and we verify

that it is covered by our warranty. Labor is not covered under warranty for Parts orders.

7. Troubleshooting

PROBLEM POSSIBLE CAUSE CHECK

Load too heavy Make sure the load does not exceed the rated

capacity.

Power unit not receiving

power.

Hand controls may be

malfunctioning or may not be

receiving power.

Motor contactor may be

malfunctioning.

Lift will not raise

Motor may be turning in wrong

direction.

Hydraulic Fluid low With lift in fully lowered position the uid level

Lift has reached it upper limit. Upper limit switch may need to be adjusted

Verify that the power unit is receiving power. See

Electrical Information Section.

Verify that the controls are receiving power

and are functioning correctly. See Electrical

Information Section.

Verify motor contactor is functioning. See

Electrical Information Section.

Swap any two phases of the motor power leads.

should be approximately 3/4” from the top of the

tank.

Motor voltage too low Supply voltage must be ± 10% of the rated

voltage at the motor terminals.

Tank vent plugged Make sure vent plug on hydraulic tank is

installed and not blocked.

Southworth ProductsDDL Dock Lift Manual DDL Dock Lift Manual

19

PROBLEM POSSIBLE CAUSE CHECK

Suction lter is clogged Clean suction lter.

Lift will not raise

Lift fails to hold

(Drifts down)

Lift will not lower

Vacuum leak in the suction

line

Check all ttings and hoses for damage or loose

connections.

Down valve may be energized Check wiring to down valve and solenoid valve.

Missing coupling between

motor and pump (if

applicable).

Pressure relief valve is

activated.

Check to make sure the coupling between the

pump and motor has been installed.(Machines

manufactured before September 2012).

If there is a loud squealing noise the pressure

relief valve may be activated. – Contact

Customer Service for assistance.

External Hydraulic leak Inspect all hoses, connections, and cylinders for

leaks.

Down valve may be leaking

internally.

Remove the down valve and inspect for debris

which may be preventing it from closing.

Contact Customer Service for procedure.

Down valve may be energized Check the solenoid with a volt meter.

Cylinder may be leaking Check for uid leaks.

Down valve may not be

energized

Down Flow control may need

Check for power to the solenoid valve with a volt

meter while pressing the down button.

Adjust down ow control as needed.

to be adjusted

Lift raises too

slowly

Lift lowers too

slowly

Voltage may be low Check voltage at motor. Supply voltage must

be ± 10% of the rated voltage at the motor

terminals.

Suction lter, breather cap, or

Remove necessary components and clean.

pressure line may be clogged

Pump may be overheating

Check uid level and viscosity.

due to insufcient oil

Down valve may not be fully

opening or may be partially

Remove the down valve and clean. - Contact

Customer Service for procedure.

blocked or stuck closed.

Flow control may need to be

Adjust the ow control as necessary.

adjusted

Pressure relief valve is

activated.

If there is a loud squealing noise the pressure

relief valve may be activated. – Contact the

manufacturer for assistance.

Southworth Products DDL Dock Lift Manual

20

8. Electrical Information

M1

1

2

3

5

Sol

DOWN VALVE

SOLENOID

2

HPU MOTOR

STARTER

M1

OL

2

3

5

L1

L1

L3

L2

FUSED DISCONNECT

(BY OTHERS)

208/230/380/

415/460/575V

3 PHASE

50/60 Hz

L2

L3

1

1

UP

DOWN

4

UP LIMIT

OPTIONAL

4

CONNECT ACCORING TO

CORRECT SUPPLY VOLTAGE

1T3

1T2

1T1

MTR

HYDRAULIC

POWER UNIT

MOTOR

L1

1FU

L3

2FU

2

1

3FU

NOTE:

UP LIMIT SWITCH IS OPTIONAL. IF UP LIMIT SWITCH

IS ABSENT, WIRE 3 RUNS DIRECTLY TO THE COIL ON

THE MOTOR CONTACTOR.

Control Voltage: 24/1/60 Motor: 3.2 HP

Primary Voltage Phase Frequency Full Load Amp Required Supply Fusing

460 3 60 4 6 AMP

230 3 60 8 12 AMP

208 3 60 8.4 12 AMP

Other motor and hydraulic power unit options are available. If your machine was supplied

with a motor other than the one described here contact the manufacturer for more

information.

8.1 Wiring Schematic

Southworth ProductsDDL Dock Lift Manual DDL Dock Lift Manual

21

8.2 Control Panel

T2

1

3-BL4-WHT

3-BL

X2 XF

FU2

T3

APPLICABLE CODES.

FU3

T1

H1

230V

H3

460V

H2

208V

H4

A1 A2

L1 L2

L3

L1

L3

4

2

G

2

T1

1-RED

T2

T3

NOTE:

GROUND CONNECTIONS NOT SHOWN. FOR

GROUND CONNECTIONS USE SUPPLED

GOUNDING TERMINAL. ENSURE ALL

ELECTRICAL COMPONENTS AND MACHINE

ARE PROPERLY GROUNDED ACCORDING TO

NC

95

CORRECT SUPPLY

FU1

CONNECT L1 TO

208/230/460-3-60 SUPPLY VOLTAGE - SEE

96

ELECTRICAL INFORMATION SECTION

1 2 3 4 5 6

VOLTAGE

(FROM FUSED DISCONNECT - BY CUSTOMER)

JUMPER "A"

ENSURE PROPER FUSES ARE

USED AND OVERLOAD RELAY

IS ADJUSTED FOR

RESPECTIVE PRIMARY

VOLTAGE - SEE ELECTRICAL

INFORMATION SECTION.

GROUNDING

TERMINAL

TERMINAL BLOCK

DOWN

VALVE

MOTOR

CONTROLS

2

5-WHT

5

OPTIONAL UPPER TRAVEL LIMIT SWITCH

(NC) OR PROXIMTY SWITCH(NO) HELD

CLOSED WHEN SCISSORS LEGS IS IN FRONT

OF IT. OPENS AS LEG ROTATES OUT OF

SENSE RANGE.

IF NOT PROVIDED WIRE 3 CONNECTS TO A1

ON MOTOR CONTACTOR VIA THE TERMINAL

BLOCK, REMOVE WIRE 4.

Southworth Products DDL Dock Lift Manual

22

9. Hydraulic Information

9.1 Hydraulic Fluid Specications

This machine is supplied with Conoco Ecoterra Hydraulic Fluid.

Do not substitute! Conoco Ecoterra Hydraulic oil is not compatible with

oils containing Zinc. Mixing will result in poor machine performance,

could damage hydraulic components, and will lessen the environmental

benets gained by using Conoco Ecoterra Hydraulic Oil.

9.2 Hydraulic Schematic

9.3 Hydraulic Power Unit

ADJUSTABLE FLOW

CONTROL

PRESSURE LINE

TO LIFT

9.4 Hose Specications

TO VENT LINE

CONNECTION ON LIFT

MOTOR

DOWN SOLENOID/ VALVE

PUMP

RESERVOIR

(CAPACITY: APPROXIMATELY

2.4 US GAL.)

REMOVE PLUG AND REPLACE WITH VENT

LINE ELBOW AND CONNECT VENT LINE BETWEEN

LIFT VENT LINE FITTING AND THIS ELBOW.

Minimum operating pressure rating 3,000 psi, 12,000 psi burst pressure.

Pressure hose is optional. Units supplied with 25 feet of vent line and

the hydraulic power unit vent line connection elbow if pressure hose not

purchased other wise the vent line comes in the same length as the

pressure hose.

CONTROL PANEL

BREATHER

VENT LINE

ELBOW FOR

RESERVOIR

Southworth ProductsDDL Dock Lift Manual DDL Dock Lift Manual

23

9.5 Hydraulic Arrangements

37 1/2

9/16-18

& VENT LINES

HYDRAULIC PRESSURE

EXCESS FLOW

37 1/2 9/16-18

COUPLINGS FOR

VENT

LINES

PROTECTOR

HYDRAULIC CYLINDERS

PRESSURE LINE

PUSH-TO-CONNECT

FITTING FOR VENT

LINE

ROLLER END

HINGE END

9.5.1. Standard Hydraulic Arrangement

Applicable when machine is installed in a pit/pad with an under lift

conduit run for routing hydraulic hoses and electrical wiring.

HYDRAULIC CYLINDERS

VENT

LINES

HINGE END

PUSH-TO-CONNECT

FITTING FOR VENT

LINE

COUPLINGS FOR PRESSURE

& VENT LINE CONNECTIONS

FROM HPU

PRESSURE LINE

9.5.2. Alternative Hydraulic Arrangement

Applicable when machine is installed in a pit/pad without an under lift

conduit run for routing hydraulic hoses and electrical wiring.

ROLLER END

EXCESS FLOW

PROTECTOR

Southworth Products DDL Dock Lift Manual

24

10. Warranty & Contact Information

Southworth Products warrants this product to be free from defects in material or workmanship for

the duration of the warranty period. Warranty periods vary and begin on the date of shipment. For

specic warranty information, contact Southworth Products with the machine’s serial number.

Any claim for breach of this warranty must be received in writing by Southworth Products within

the warranty period. Warranties shall not cover failure or defective operation, caused by misuse,

misapplication, negligence or accident, exceeding recommended capacities, or any alteration

or repair of the item purchased which has not been authorized by Southworth Products. Except

as set forth herein, Southworth Products makes no other warranties, express or implied,

including THE WARRANTIES OF MERCHANTABILITY AND OF FITNESS FOR A PARTICULAR

PURPOSE, all of which ARE HEREBY EXCLUDED.

Southworth Products meets the labeling requirements of California’s Proposition 65. Southworth

Products makes no warranty or representation with respect to the compliance of any product with

other State or local safety or product standard codes and any failure to comply with such codes

shall not be considered a defect of material or workmanship under this warranty. Southworth

Products shall not be liable for any direct or consequential damages arising out of such noncompliance.

Southworth Products’ obligations under any warranty or for any other damages which may arise

under any sale, agreement, or contract, are limited to the replacement or repair of defective

components at its factory or another location at Southworth Products’ discretion. This is buyer’s

sole remedy under any such warranty, sale, agreement, or contract. Southworth Products will not

be liable for consequential, incidental, exemplary, or punitive damages of any kind resulting from

a breach of any warranty that it has provided or for breach of any term of any sale, agreement, or

contract. Any warranty may be altered only in writing by Southworth Products.

SOUTHWORTH PRODUCTS CORP.

P.O. Box 1380, Portland, ME 04104-1380

Telephone: 800-743-1000 • 207-878-0700

Fax: 207-797-4734

www.SouthworthProducts.com

Southworth ProductsDDL Dock Lift Manual DDL Dock Lift Manual

25

Loading...

Loading...