Southwest Specialty Products Sonoran Unvented 36 User Manual

11

SOUTHWEST FIREBIRD MFG

SAVE THIS BOOK

This book is valuable. In addition to instructions for installing and

maintaining this fireplace, it contains information that will enable

you to obtain replacement parts or optional accessory items when

needed. Keep it with your other important papers.

FOR USE ONLY WITH LISTED GAS-FIRED UNVENTED DECORATIVE ROOM

HEATER NOT TO EXCEED 40,000 BTU/H. “ DO NOT BUILD A WOOD FIRE”

SONORAN UNVENTED Model 36/42/48

INSTALLATION INSTRUCTIONS

PREFABRICATED MODULAR MASONRY- UNVENTED

SONORAN 36/42/48TO BE USED WITH UNVENTED GAS LOGS.

CHECK LOCAL CODES

BEFORE INSTALLATION

Carefully review the instructions supplied with the decorative type unvented

room heater for the minimum fireplace size requirement .

DO NOT INSTALL AN APPLIANCE IN THIS FIREBOX UNLESS THIS FIREBOX

MEETS THE MINIMUM DIMENSIONS REQUIRED FOR THE INSTALLATION.

WARNING: If the information in this manual is not followed exactly, a fire or

explosion may cause damage, personal injury or loss of life.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrical switches; do not use any phone in your building.

Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

instructions.

If you can not reach your gas supplier, call the fire department.

MANUFACTURED BY

Southwest Firebird Inc. OMNI-Test Laboratories, Inc.

4646 Menaul N.E. LISTED

Manufactured by

Southwest Firebird Manufacturing Inc.

4646 Menaul N.E. OMNI- Test Laboratories, Inc

Albuquerque NM 87110 LISTED

FACTORY-BUILT FIREPLACE

Test UL 127, ANSI Z21.91 Standard

22

INTRODUCTION

THIS FIREPLACE IS NOT INTENDED TO BE USED AS A PRIMARY SOURCE OF HEAT

NOTE: Installation and repair should be done by a qualified installer familiar with fireplaces. The fireplace system

should be inspected and cleaned before use and periodically thereafter, especially during the heating season, to

prevent the excessive build-up of soot and creosote and to ensure a safe operating system.

BEFORE YOU BEGIN

Before beginning the installation of your Unvented Fireplace, read these instructions through completely.

The Southwest Firebird Manufacturing Inc. warranty will be voided by, and Southwest Firebird Manufacturing Inc.

disclaims any responsibility for the following actions:

A) Modification of the fireplace or any of the components manufactured by Southwest Firebird Manufacturing Inc.

unless otherwise permitted by Southwest Firebird Manufacturing Inc.

B) The use of a fireplace insert or any other component part not approved by Southwest Firebird Manufacturing Inc.

in combination with a Southwest Firebird Manufacturing Inc. fireplace.

C) Installation and/or operation in a manner other than instructed in this manual.

D) The burning of anything other than the type of gas approved for use in this gas Unvented Fireplace.

The installation must conform with local codes or, in the absence of local codes, with the National Fuel Gas Code

ANSI Z2231.1-1988./NFPA 54.

.

Model Sonoran Unvented 36/42/48 is intended and approved for installation in either residential homes or buildings of

standard construction.

This model is not for use in mobile homes.

DO NOT INSTALL THIS UNVENTED ASSEMBLY IN SLEEPING QUARTERS.

This model's serial number and other specific rating information may be found on the OMNI-Test Laboratories, Inc.

RATING PLATE located inside the fireplace opening.

This Southwest Firebird Manufacturing Inc fireplace and its approved components are safe when installed according to this

installation manual and operated as recommended by Southwest Firebird Manufacturing Inc. Unless you use Southwest

Firebird Inc. approved components tested for this fireplace, YOU MAY CAUSE A FIRE HAZARD!

SELECTING LOCATION

PROPER INSTALLATION is the most important step in ensuring a safe and continuous operation of this fireplace.

This fireplace complies with UL 127 as a FACTORY-BUILT FIREPLACE, and is tested and listed by OMNI-Test

Laboratories, Inc.

To determine the safest and most efficient location for your Unvented Fireplace, you must take into consideration the

following guidelines:

1. The location must allow for all proper clearances (see Page 4).

2. Consider a location where heat output would not be affected by drafts, air conditioning ducts, windows or doors.

3. A location that minimizes modifications on existing framing will make installation easier.

A flush installation is recommended where living space is limited or at a premium. Check local codes for any restrictions.

Projected installations can extend any distance into the room. A projection may be ideal for a new addition on an existing,

finished wall.

Corner installations make use of space that may not normally be used and provides a wider and more efficient range for

radiant heat transference. An internal wall installation provides a discreet option for room separation and can also be ideal

as an addition to existing wall.

33

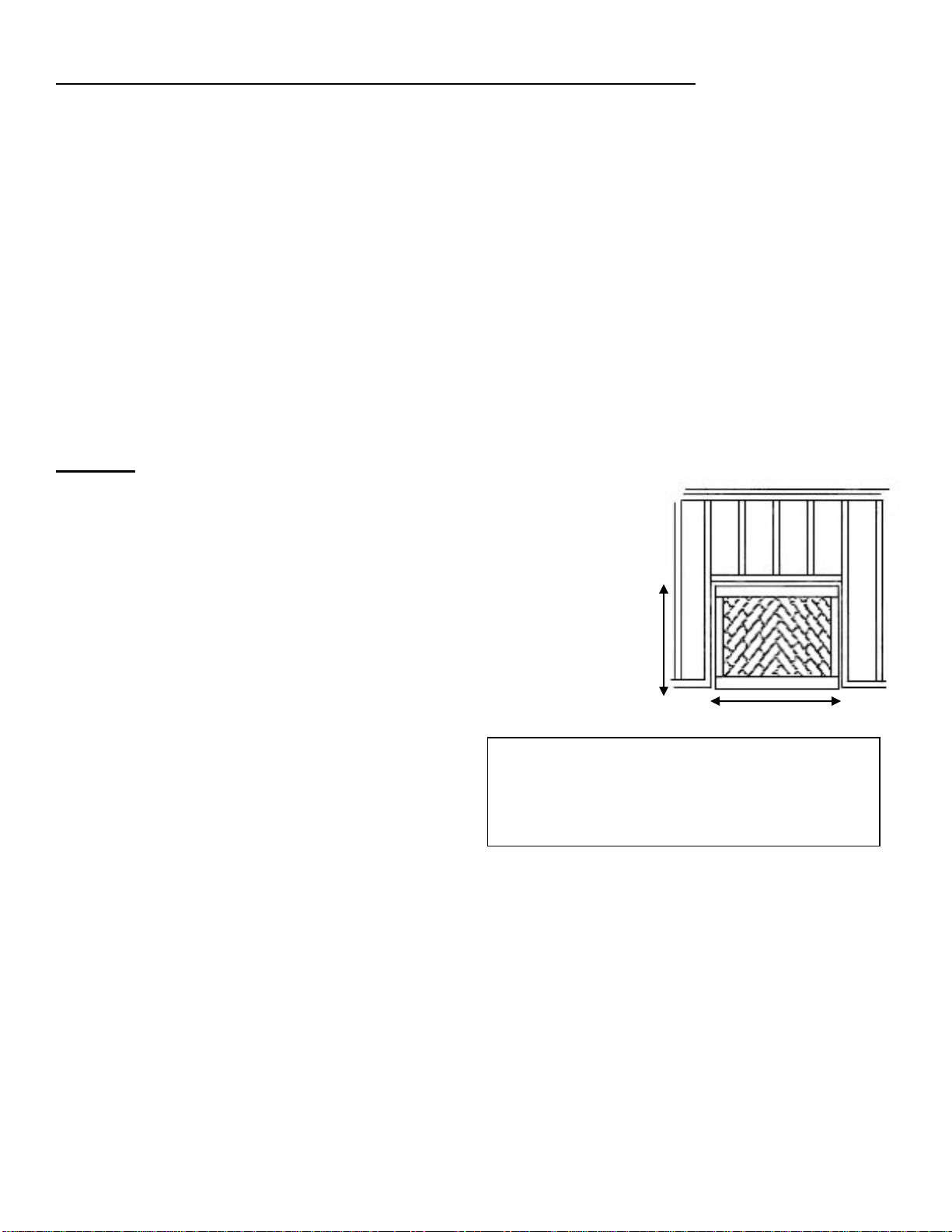

FRAMING DIMENSIONS

Widths A

Height B

Depth

Sonoran 36

44”

39”

27”

Sonoran 42

Sonoran 48

50”

56”

39’

39”

27”

27”

B

A

IN SELECTING A LOCATION, THE FOLLOWING PRECAUTIONS MUST BE OBSERVED;

1. Install in an area providing ventilation and adequate combustion air.

2. Due to high temperatures, the Unvented Fireplace should be located out of traffic and away from furniture

and draperies.

3. NEVER obstruct the front opening of the Unvented Fireplace or the flow of combustion and ventilation air. Keep

control compartments accessible.

4. Do not locate in the vicinity where gasoline or other flammable liquids may be stored. The Unvented Fireplace area

must be kept clear and free from these combustible materials.

5. DO NOT INSTALL THIS UNVENTED ASSEMBLY IN SLEEPING QUARTERS.

Preparation for Firebox Assembly

Tools Needed: 4” plastic putty knife or metal drywall knife.

Metal scraper or painter’s tool.

4” disposable coarse paint brush.

Carpenters square.

4’ level.

Optional Tool: SWF assembly jig system. (Frame & Straps.)

FRAMING

Construct framing using dimensions applicable to your particular installation.

If the fireplace is installed on a combustible material, the bottom heat shield is required

with 4” clearance to combustible with 1 ¼” airspace. Framing height is a minimum of

55”. Construct framing using dimensions shown depending on your particular

installation.

A 36" long 1/2” NPT SCHD 40 flexible gas line complying with the National Fuel Gas

Code ANSI Z223.1-1988/NFPA 54, may be run from the regulator to the exterior of the

Unvented Fireplace for access to your incoming 1/2" NPT black iron gas line or you

may route incoming gas line directly to the regulator.

The incoming gas line may be routed towards the Unvented

Fireplace either from the left hand or right hand sides of the

Unvented Fireplace's outer surround. Remove the gas line

cover plate from the Unvented Fireplace's outer surround at

the location to be used. Remove insulation from inside the

gas line conduit sleeve. Run gas line through until regulator

can be reached.

A sediment trap should be included between incoming gas line and regulator connection.

The sediment trap must extend a minimum of 3" down below the center of the incoming pipe.

Prepare incoming black iron gas line with Teflon tape or pipe joint compound (check with local codes as to the use of

Teflon tape).

Compounds used on threaded joints of gas piping shall be resistant to the action of Liquefied Petroleum (LP or Propane),

and should be applied lightly to ensure excess sealant does not enter the gas line.

Complete your gas installation by connecting incoming gas line to regulator. Secure all joints tightly with wrench but do not

over-tighten. If a flexible gas line is used, take care not to kink connector.

Repack insulation in and around the conduit sleeve and flexible gas line.

Loading...

Loading...