Southwest Microwave 330 Users Manual

Southwest Microwave, In c.

Security Systems Division

INTREPID™

MicroWave 330

A DIGITAL MICOWAVE

OUTDOOR PERIMETER INTRUSION DETECTION SYSTEM

MicroWave 330 Installa tion

and Operation Manual

Version 0

Trademark Notice and Certifications

INTREPID™, MicroPoint™ and MicroTrack™ are registered trademarks of Southwest Microwave, Inc.

Copyright 1995 and 2012 Southwest Microwave, Inc. All rights Reserved.

FCC Notice

MicroWave 330 is classified as a field disturbance sensor.

This device complies with FCC Rules Part 15.245. Operation is subject to the following two conditions:

This device may not cause harmful interference and this device must accept interference received, including

interference that may cause undesired operation.

Notice: changes or modifications not expressly approved by Southwest Microwave, Inc. could void the

user’s authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

RoHS Compliant

Radiation Safety

The allowable standard minimum of safe radiation exposure level in the United States as established by the

American National Standards Institute is 10mW/cm

1mW/cm

approximately.0186mW/cm

2

. The average Southwest Microwave sensor surface radiation level (when in operation) is

2

or 1/50 of the proposed lower standard. This level rapidly dissipates at

distances from the unit. For example, at one meter, the figure reduces to .0012mW/cm

proposed level.

Copyright Southwest Microwave, Inc. May 2012

Southwest Microwave, Inc.

9055 South McKemy Street

Tempe, Arizona 85284-2946

Tel: (480) 783-0201

Fax: (480) 783-0401

Email: infossd@southwestmicrowave.com

Web: www.southwestmicrowave.com

2

. There is currently a proposal to drop this limit to

2

or 1/800 of the

2 Version 0

INTREPID™ MicroWave 330 S oftware

Southwest Microwave, Inc. thanks you for your purchase of the INTREPID MicroWave 330 Digital Microwave

Intrusion Link. Please refer to the Universal Installation Service Tool II (UIST II) for the software setup of this

sensor.

One disk is required to setup the system. It is called:

Universal Installation Service Tool II (UIST II)

This software is used to configure and set-up the system as well as being used for maintenance and

troubleshooting the system.

Software provided by Southwest Microwave, Inc. is subject to the license agreement terms of the individual

product. A copy of the license agreement is available by contacting Southwest Microwave, Inc.

3 Version 0

Table of Contents

1. Introduction ................................................................................................................................................ 5

2. Hardware .................................................................................................................................................... 5

2.1 MicroWave 330 Link ............................................................................................................................ 5

2.2 Optional Power Supplies ...................................................................................................................... 6

2.3 Oprional Accessories ............................................................................................................................ 6

3. Principles of Operation and Detection ..................................................................................................... 6

3.1 Description ............................................................................................................................................ 6

3.2 Range of Operation ............................................................................................................................... 7

3.3 Overlaps ................................................................................................................................................ 8

3.3.1 High Security Overlaps ................................................................................................................... 9

3.4 Transmitter Block Diagram .................................................................................................................. 9

3.5 Receiver Block Diagram ..................................................................................................................... 10

3.6 Specifications ...................................................................................................................................... 11

4. Installation Instructions .......................................................................................................................... 13

4.1 Location of MicroWave 330 ............................................................................................................... 13

4.1.1 Required Area ................................................................................................................................ 13

4.1.2 Terrain ........................................................................................................................................... 14

4.1.2.1 Terrain in High Security Applications .................................................................................... 14

4.1.3 Physical Protection ........................................................................................................................ 15

4.1.4 Best Security .................................................................................................................................. 15

4.2 Mounting of MicroWave 330 ............................................................................................................. 16

5. Modes of Operation ................................................................................................................................. 18

5.1 Free Running Mode ............................................................................................................................ 18

5.2 Tethered Mode .................................................................................................................................... 19

6. Wiring ....................................................................................................................................................... 20

6.1 Power Supply Wiring ......................................................................................................................... 20

6.2 Communications Wiring ..................................................................................................................... 21

6.3 Tethered Wiring .................................................................................................................................. 21

6.4 Synchronized Wiring .......................................................................................................................... 22

6.5 Remote Test ........................................................................................................................................ 23

7. Terminals, Switches and Indicators ....................................................................................................... 24

7.1 MicroWave 330T Transmitter ............................................................................................................ 24

7.1.1 Channel Select Switch ................................................................................................................... 24

7.1.2 External / Internal Modu la tion Switch ................................................................................... ....... 24

7.2 MicroWave 330R Receiver ................................................................................................................ 25

7.2.1 Address Switch .............................................................................................................................. 26

7.1.2 Audio Alarm Switch ...................................................................................................................... 26

7.2.3 Communications Ports ................................................................................................................... 26

8. Connecting the Transmitter and Receiver ............................................................................................. 26

8.1 MicroWave 330T Transmitter Connections ....................................................................................... 26

8.2 MicroWave 330R Receiver Connections ........................................................................................... 27

9. Alignment and Testing ............................................................................................................................ 27

10. Preventive Maintenance .......................................................................................................................... 28

11. Limited Warranty .................................................................................................................................... 29

12. Returning Equipment under Warranty ........................................................................................

13. Returning Equipment fro Non-Warranty Repair ................................................................................. 30

14. Replacement Parts ................................................................................................................................... 30

......... 29

4 Version 0

1.0 Introduction

The MicroWave 330 is part of the INTREPID™ Series II family of products. It is digital microwave field

disturbance sensor providing perimeter protection for open areas, gates, entryway, walls and rooftop

applications. It provides volumetric detection of human intruders with minimal environmental nuisance alarms.

Advanced digital signal processing (DSP) allows continuous monitoring of intrusion alarm and tamper switch

status, received signal strength for path fault and detection parameters. A system controller such as the Relay

Control Module II (RCM II), Control Module II (CM II), Graphic Control Module II (GCM II), Perimeter

Security Manager (PSM) or SDK (Software Development Kit) is required to poll and configure alarm sources

from MicroWave 330 for annunciation.

MicroWave 330 operates at K-band (24.125 GHz) frequency, achieving superior performance to X-band

sensors. Because K-band is 2.5 times higher the X-band, the multipath signal generated by an intruder is more

focused, and detection of slow-moving intruders is correspondingly better. At K-band frequency, the unit also

has low susceptibility to outside interference from air/seaport radar or other microwave systems.

MicroWave 330 communicates with other INTREPID Series II devices using RS422 communications. This

communication can be done over 22 or 24 gauge stranded shielded twisted pair wire (max 5,000 feet [1,500m]

between devices) or with fiber optic devices. The address of each MicroWave 330 is set by a dip switch on the

receiver circuit board.

MicroWave 330 operates from 10.5 to 60 VDC @ 2.5 Watts with a minimum startup current of 250mA. The

operating currents with standard power supplies are: 12 VDC @ 125mA (Tx) / 208mA (Rx), 24 VDC @ 63mA

(Tx) / 104mA (Rx) and 48 VDC @ 32mA (Tx) / 52mA (Rx).

2.0 Hardware

2.1 MicroWave 330 Digital Microwave Link

Each MicroWave 330 Digital Microwave Link includes a MicroWave 330 Transmitter, Microwave 330

Receiver and two MB62 Universal Mounting Brackets as shown in Figure 1.

MicroWave 330 dimensions are 10.6 in diameter (270mm) and 10.125 in (257mm) front to back (from radome

face to mounting bracket). Each unit weighs 4.5 lbs (2.041kg).

Figure 1 – MicroWave 330 Hardware

5 Version 0

2.2 Optional Power Su pplies

12 VDC power supply: Model PS13 Power Supply operates from 85-246VAC, 47-63Hz and furnishes 13.6

VDC at up to 2.8A. Power supplies contain automatic switchover and battery charging circuitry for optional

standby batteries of up to 25AH. Temperature rated from 14° to 122° F (-10° to 50° C). UL, ETS, EMC, CE,

RoHS compliant.

12 VDC power supplies: Model PS40 Power Supply operates from 120 VAC, 50-60Hz, 0.5A and furnishes

13.7 VDC at up to 1.6A. Model PS41 Power Supply operates from 220 VAC, 50-60Hz, 0.25A. Both contain

automatic switchover and battery charging circuitry for optional standby batteries of up to 25AH and are fused

on both input and output for maximum protection. Temperature rated from -40° to 150° F (-40° to 66° C).

24 VDC power supply: Model 78B1064 operates from 120VAC to provide 24VDC at 5A with 6.5AH battery

backup. Includes; indoor enclosure 15 x 11 x 4 in. (381 x 280 x 102mm). Temperature rated from 32° to 122° F

(0° to 50° C).

48 VDC power supplies: Model PS48 operates from 120VAC to provide 48VDC at 3A. Includes; indoor

enclosure 14 x 12 x 4 in. (356 x 305 x 102mm). Model PS49 operates from 220VAC to provide 48VDC at 3A.

This supply does not include enclosure. Temperature rated from 32° to 122° F (0° to 50° C).

from 32° to 122° F (0° to 50° C). UL, CSA, TUV, CE compliant.

Temperature rated

2.3 Optional Accessories

MB65 Mounting Bracket: Model MB65 is a heavy duty, position locking non corrosive mounting bracket for a

4 inch (102mm) O.D. post.

RS14 Radome: Model RS14 is a shielded radome used to add additional RFI/EMI protection for Microwave

330 transmitter or receiver.

48C15529-A01 Enhanced Reflector: Model 48C15529-A01 is an optional reflector to provide a shorter “dead

zone” to MicroWave 330 transmitter and receiver. This option reduces maximum range to 400 feet (122m).

02A15483-A01 Radome Latch Kit: Model 02A15483-A01 replaces the 6 radome screws for quicker access to

the sensor electronics. Two kits are required for each MicroWave 330 Digital MicroWave Link.

JB70A: Lightning/Surge Protection module protects the data communications and power lines. Includes;

enclosure with terminal strips for wire connections.

3.0 Principles of Operation and Detection

3.1 Description

The MicroWave 330 Transmitter radiates amplitude modulated K-band energy that travels to the MicroWave

330 Receiver where it is detected. A microprocessor and proprietary algorithms provide powerful Digital Signal

Processing to recognize the unique bi-static digital signatures of intruders walking, jumping, running or crawling

through the detection field. Targets are classified and scored in real time at each sensor and stored in the

receiver’s flash memory. When an intruder approaches the beam the energy at the receiver changes in signal

amplitude directly related to the targets size and density allowing the sensor to discriminate between targets.

MicroWave 330 will alarm on average sized humans walking, running or crawling on hands and knees through

the detection pattern. Field adjustments can provide alarm on larger or smaller targets, depending on the specific

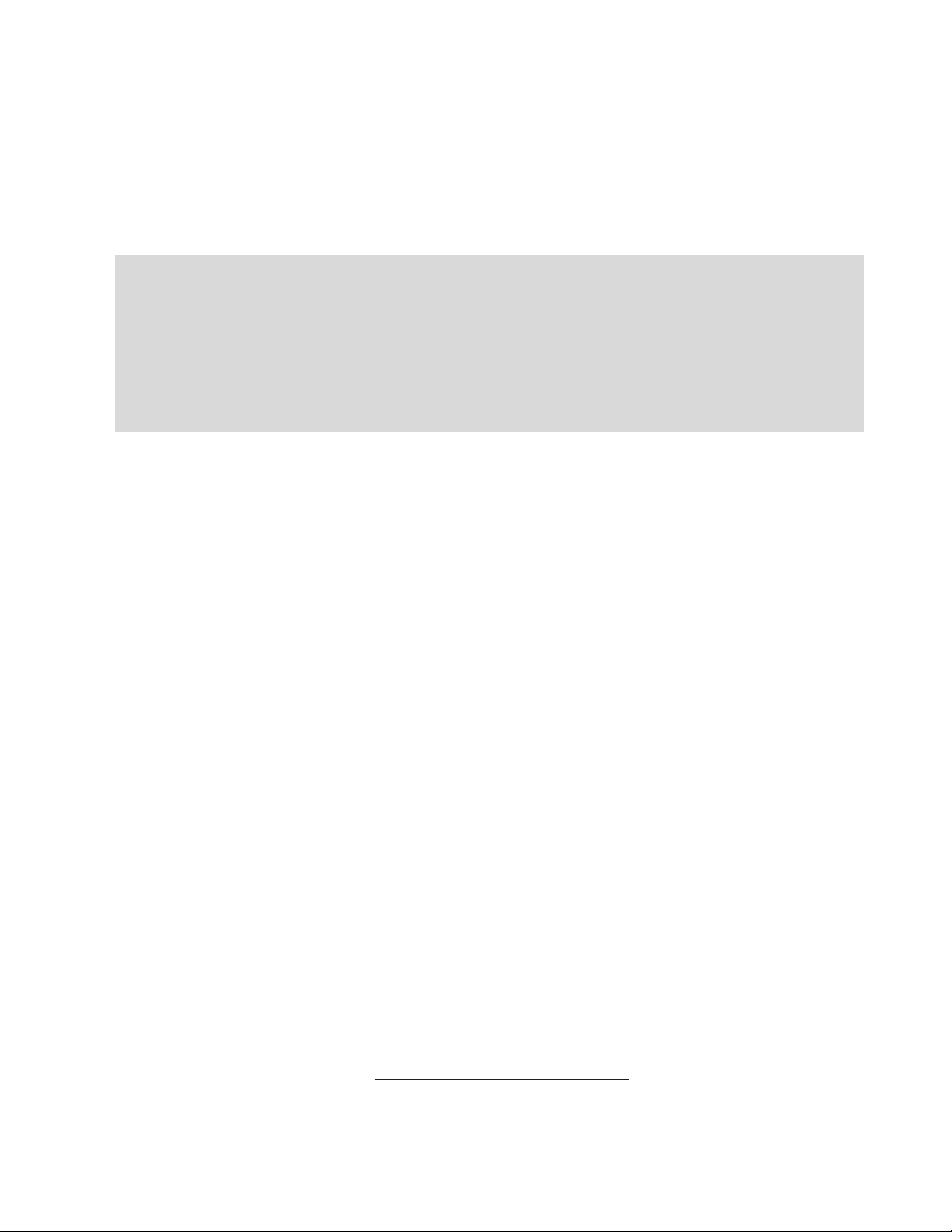

site requirements. Operation of MicroWave 330 is illustrated in Figure 2.

6 Version 0

Figure 2 – Operation of MicroWave 330 Link

3.2 Range of Operation

A single MicroWave 330 may cover a distance of 800 feet (244m). The receiver is equipped with automatic gain

control (AGC), which automatically adjusts receiver for the distance to be covered and sets the Path Fault

parameter.

Typical maximum width protection pattern of MicroWave 330 is shown in Figure 3 for mounting height of 2.5

feet (.76m) above smooth earth.

maximum and Receiver “Sensitivity” control is set to maximum

Figure 4 illustrates how pattern width varies with Transmitter-Receiver distance and sensitivity setting. Actual

patterns will vary somewhat with site topography and surface condition. Generally, lower mounting height or

rougher surface will increase pattern width. For example, if the total link distance is 500 feet (152.4m) and the

sensitivity adjustment set to mid-point, Figure 4 indicates the detection pattern width to be 7.5 feet (2.3m).

Maximum width will be when Transmitter-Receiver distance is at

Figure 3 – Typical Maximum Horizontal Pattern

Figure 4 – Typical Maximum Horizontal Pattern

7 Version 0

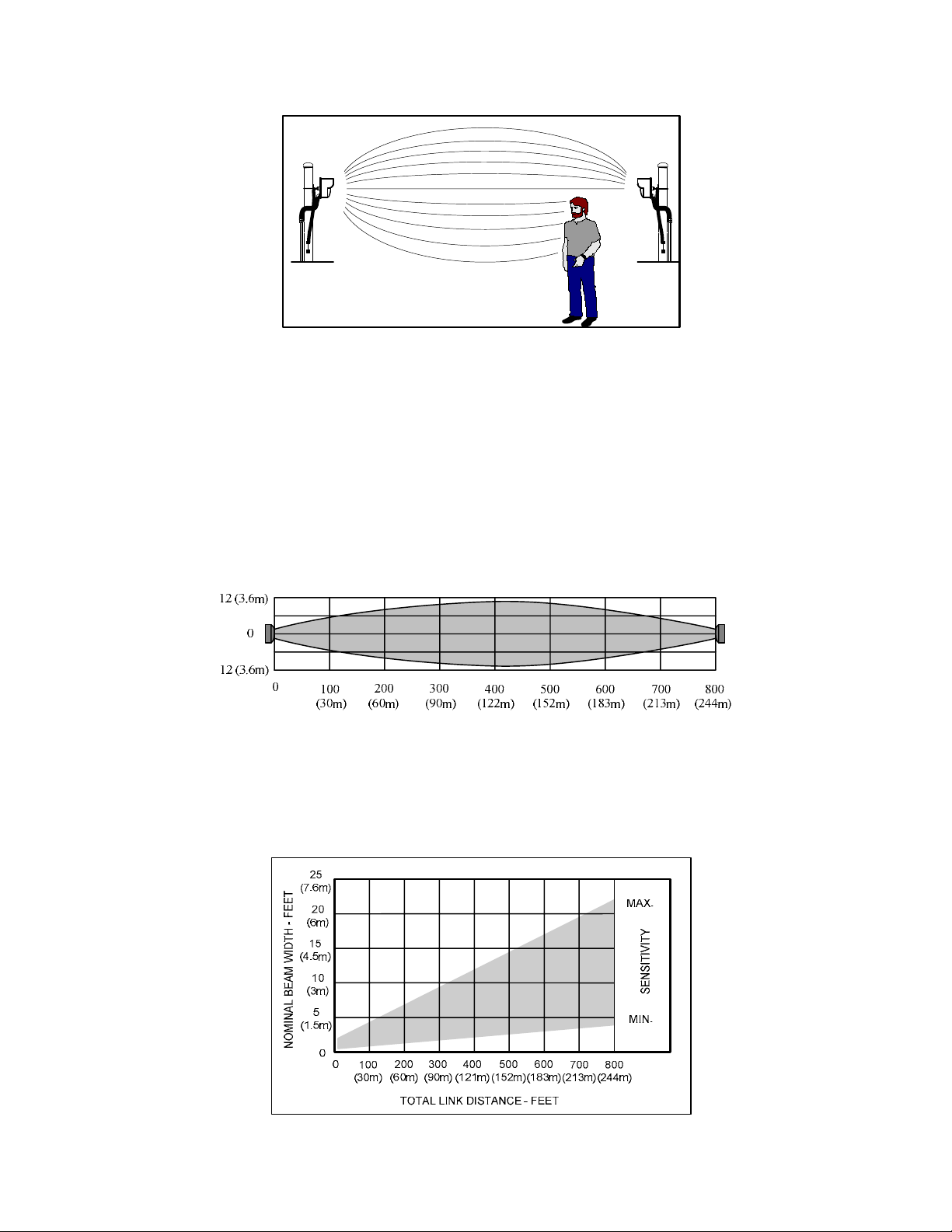

Vertical protection pattern will also depend upon Transmitter-Receiver distance, mounting height and

“Sensitivity” setting. Actual patterns will vary somewhat with site topography and surface condition. Typical

pattern height is 50 to 75% of pattern width. Approximate vertical protection pattern is shown in Figure 5. For

example, at 50 feet (15m) with minimum sensitivity the pattern height is 5 feet (1.5m).

25

(7.6m)

20

(6m)

350

MAX.

MIN.

400

(121m)

SENSITIVITY

15

(4.5m)

10

(3m)

5

(1.5m)

NOMINAL BEAM HEIGHT - FEET

0

0

50

(15m)

100

(30m)

(45m)

150

200

250

(60m)

(76m)

DISTANCE - FEET

300

(90m)

(107m)

Figure 5 – Typical Vertical Pattern

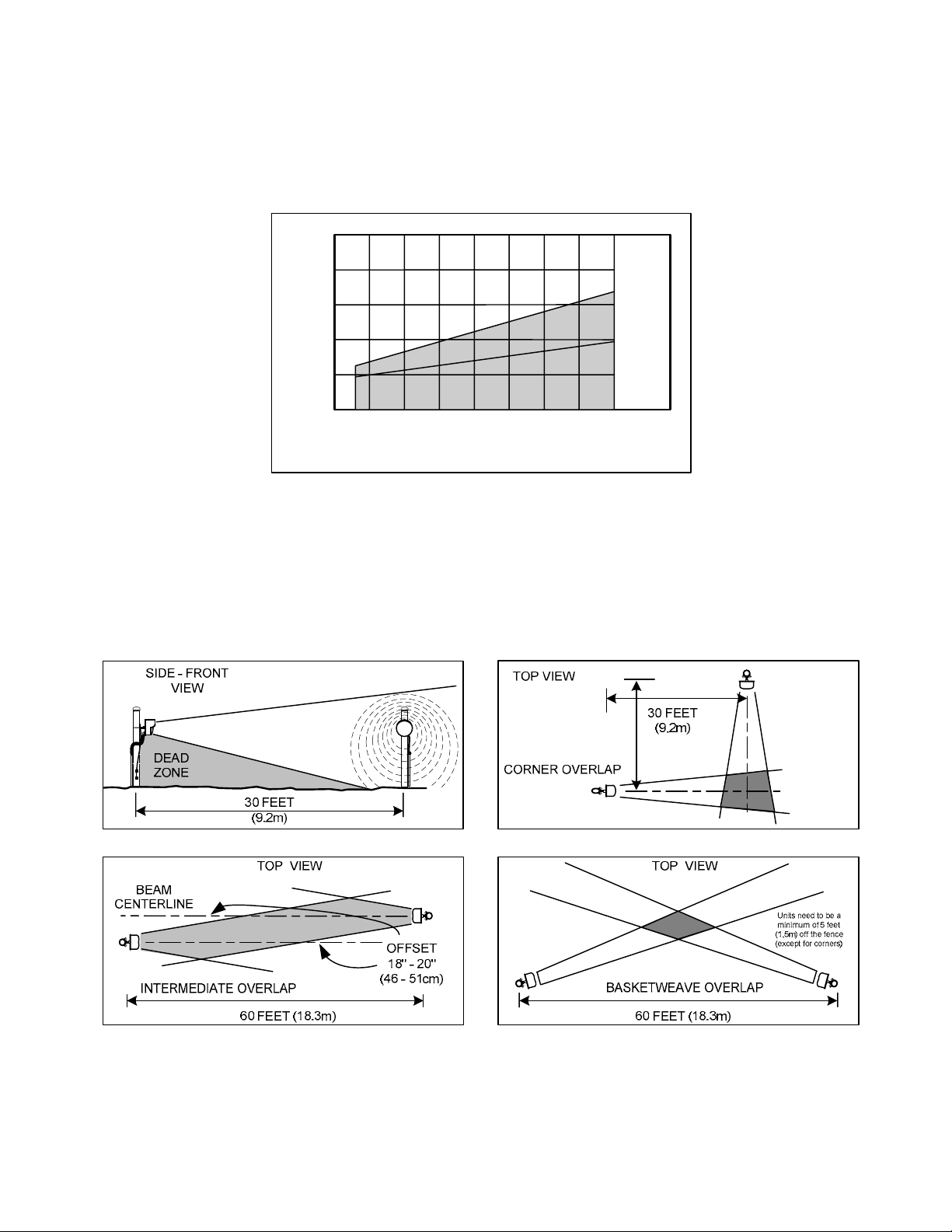

3.3 Overlaps

Protection pattern below centerline will tend to fill area between beam centerline and ground except for a “dead

zone” immediately in front of and below Transmitter and Receiver. This zone is best protected by overlapping

links at ends and corners as shown in Figures 6.

Figure 6 – Overlaps and Dead Zone

Corner overlaps should be 30 feet (9.2m) minimum. Intermediate or in line overlaps should be 60 feet (18.3m)

minimum with a beam centerline offset of 18 to 20 inches (46-51cm). Basket weave overlaps should be 60 feet

(18.3m) minimum and a minimum of 5 feet (1.5m) off the fence (except for corners).

8 Version 0

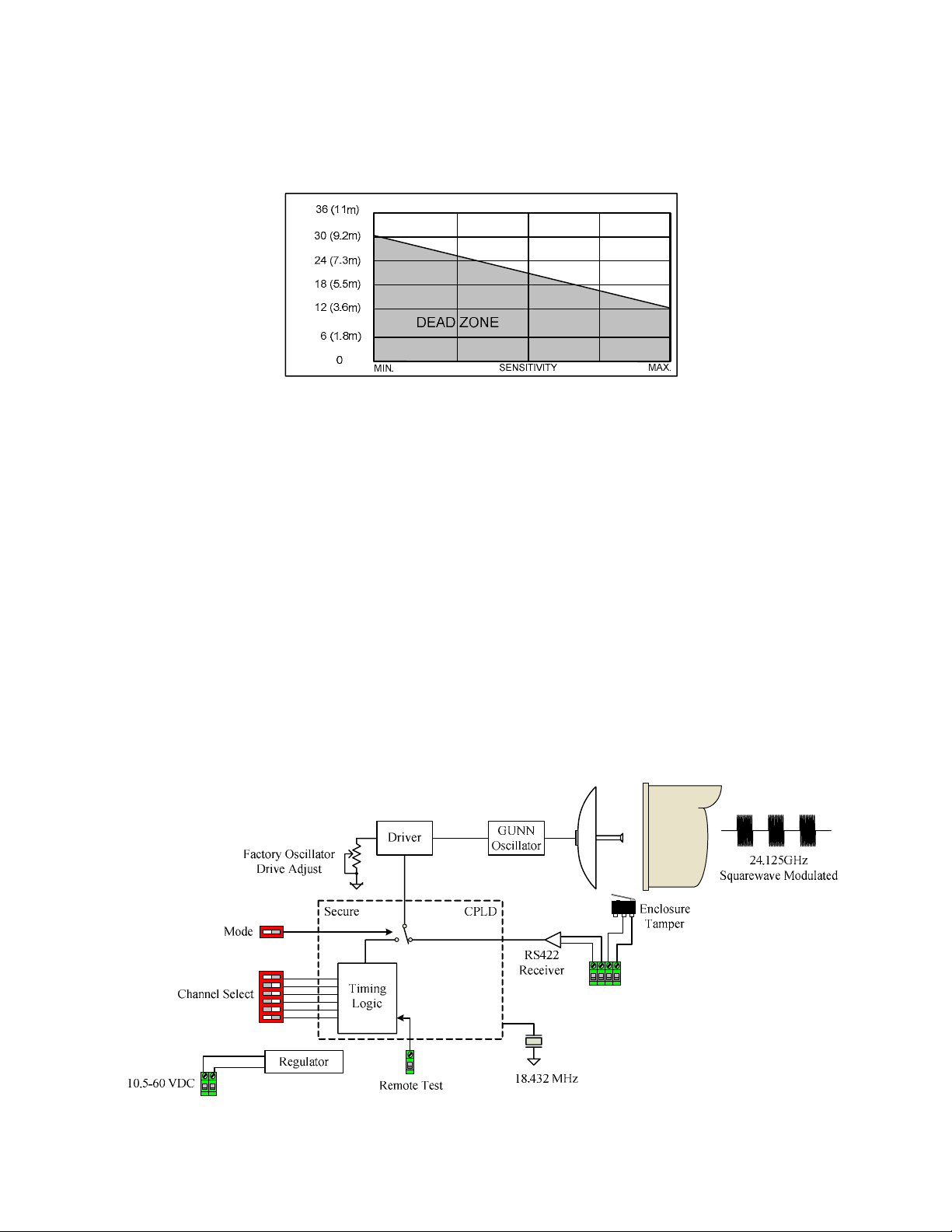

Figure 7 shows amount of overlap required to detect against hands and knees crawling intruders, as a function of

“Sensitivity” setting. It is always recommended to keep the sensitivity setting at the lowest possible value to

minimize nuisance alarms but maintaining a high probability of detection.

DEAD ZONE - FEET

Figure 7 – Sensitivity vs Dead Zone

3.3.1 High Security Overlaps

For maximum-security applications where detection of prone “commando style” crawl is required, the

intermediate over-lap should be 60 feet (18.3m) minimum with parallel beam centerline offset of 18 inches

(46cm) maximum. The corner overlaps should be 30 feet (9.2m) minimum. Terrain flatness should be no more

than plus three inches or minus three inches deviation from a plane drawn between the transmitter and receiver.

The zone length (Transmitter to Receiver) should not exceed 400 feet (122m).

High security applications also use stacked link configurations to meet site requirements. A stacked link may

consist of two or more MicroWave 330 links or used in combination with the Model 300B link which operates

at X-band frequency of 10.525 GHz. A stacked link greatly reduces the dead zone and increases PD.

3.4 Transmitter Block Diagram

MicroWave 330T Transmitter consists of two major subassemblies – RF Assembly and Transmitter Circuit

Board. A block diagram is shown in Figure 8.

Slave

Tamper

Modulation

Figure 8 – MicroWave 330 Transmitter

9 Version 0

The RF assembly consists of a Gunn oscillator, which generates K-band microwave energy and the parabolic

antenna system. The Transmitter circuit board contains voltage regulator and modulation circuit to drive the

microwave oscillator and a secure CPLD. Modulation frequency in Free Run Mode is selected from one of six

channels (A, B, C, D, E, and F) by a dip switch on the Transmitter Circuit Board.

The CPLD is responsible for the generation of the asynchronous modulation frequencies when the “Mode”

switch is set to “Internal” position and also for determining the quality of the signal provided on the tether when

the “Mode” switch is set to “External” position.

A “Test” terminal is provided on the Transmitter Circuit Board. Application of 5.0 to 14.0 VDC will cause

Transmitter to turn off and illuminate the red “Channel Error” LED, generating a test alarm at receiver. A green

LED on Transmitter Circuit Board indicates that power is on.

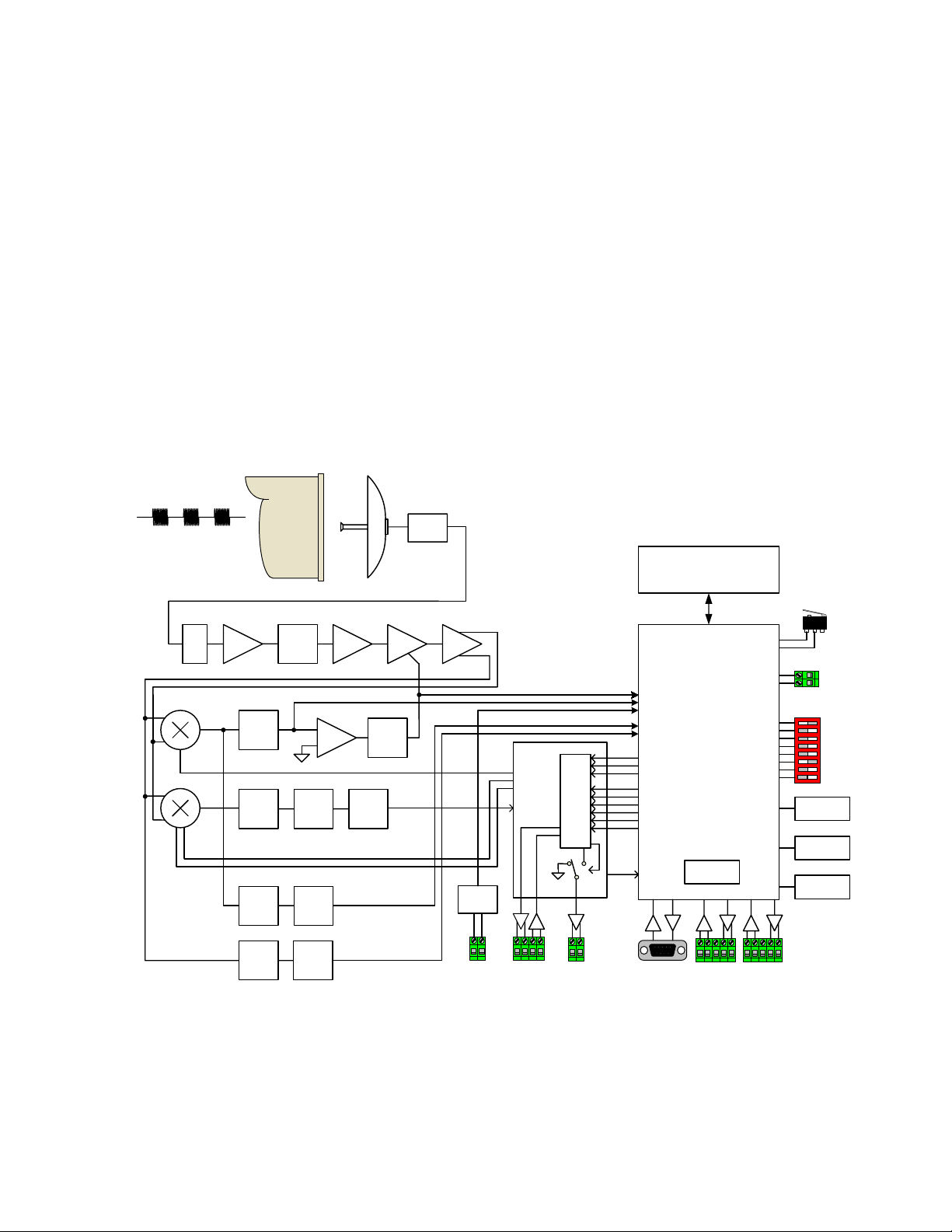

3.5 Receiver Block Diagram

MicroWave 330R Receiver consists of two major subassemblies – RF Assembly and Receiver Circuit Board. A

block diagram is shown in Figure 9.

Cavity

Det.

24.125Ghz

Squarewave Modulated

Low Noise

Bias

30dB

+

-

+

5

LPF

1

LPF

HPF

HPF

BPF

~

~

~

th

st

Level

Shift

Jam

Wrong

Channel

+

-

18.432 MHz

VCXO

AGC

+

-

∫

Secure

CPLD

TX +

TX -

Sync

RX -

RX +

Logic

Timing

TX +

TX -

Channel

Modulation

CLK

(Q)

(I)

Power

Supply

10.5-60VDC

Figure 9 – MicroWave 330 Receiver

CLK

Secu re

Align (ADC)

Target (ADC)

PS (ADC)

RS232

Configuration

Port

Memory

(optional)

CPU

Watchdog

TX +

TX -

Com 1

RS422

Alarm

Network

Enclosure

Tamper

External

Tamper

HI

LO

Node Address

BDM

Reset

RTC

TX +

TX -

Gnd

RX -

RX +

Gnd

Com 2

RS422

Alarm

Network

RX -

RX +

10 Version 0

Loading...

Loading...