Southland SWB43170 User Manual

Operator’s Manual

Walk Behind Blower

43 cc, 2 Cycle

Look inside for:

Page

Safety Definitions 2

Important Safety Information 3-5

Product Specifications 6

Parts & Features 6

Assembly 7-8

Operation 9-11

Maintenance 12

Storage 13

Troubleshooting 14

Technical Service 14

Warranty 15

MODEL Nos. SWB43170

IMPORTANT:

Thank you for purchasing this Southland® Walk Behind Blower.

This manual provides complete instructions for safely operating and maintaining your Blower. Read and save these

instructions. Refer to this manual each time before using your Blower.

Record the following for future reference:

Mfg. Date Code: ____________________

Date of Purchase: Attach a copy of your sales receipt.

Consumer Toll Free Number: 1-800-737-2112

Refer to the website for electronic manual and parts book.

www.southlandpowerequipment.com

WARNING

CONTAINS LEAD. May be harmful if eaten or chewed. May generate dust containing lead. Wash hands after use. Keep out

of reach of children.

WARNING

This product can expose you to chemicals including lead, which is known to the State of California to cause cancer and birth

defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

If you have a question or problem...

CALL TOLL FREE: 1-800-737-2112

KEEP THIS MANUAL FOR FUTURE REFERENCE

04/11/2019 Printed in China A204148

Safety Definitions

CHOKE/

COLD

START

RUN/

WARM

START

6x

PRIMER BULB

ON

UNDER SIDE

6x

PRIMER BULB

ON

UNDER SIDE

• Save these instructions

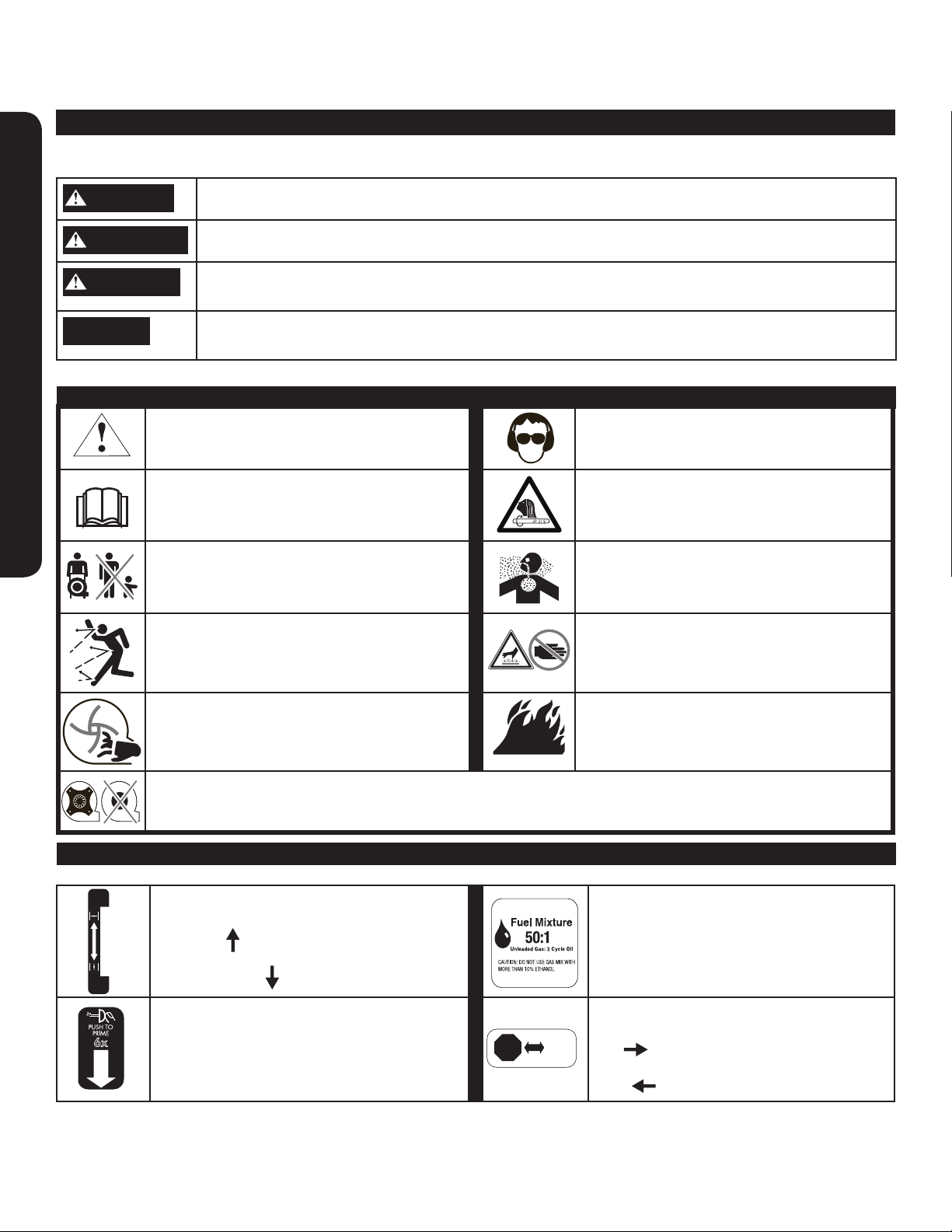

Safety Alert Symbols

Important Safety Information

The following symbols are used on the product and in this manual to alert the operator of potential safety hazards.

Read them carefully, and understand their meaning.

DANGER

WARNING

CAUTION

NOTICE

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor/moderate injury or

equipment/property damage.

Indicates a situation which may result in equipment / property damage or may relate to general safety

messages.

The following symbols can be found on your blower. Carefully read and understand their meaning.

Safety Warning Symbols

Look for this symbol to point out important safety precautions. It means: Attention! Become Alert! Your Safety

Is Involved.

Read operator’s manual before operating this machine.

Failure to follow directions could result in serious injury.

Do not use if children or bystanders are present.

Unit will blow objects and debris at high speeds. Never

stand in front of discharge chute. Never allow discharge

chute to point toward bystanders, pets, or valuable

property.

Wear eye protection complying with ANSI Z87.1 and

hearing protection.

To prevent entanglement, always wear protective hair

covering to contain long hair.

Engine exhaust contains carbon monoxide, an odorless

and deadly gas. NEVER run unit indoors or in a poorly

ventilated area.

Do NOT touch hot muffler or cylinder. These parts are

extremely hot from operation and may remain hot for a

short time after operation.

There are rotating blades inside the blower which can

cause serious injury. Keep hands out of intake and

discharge openings. Never insert foreign objects such as

sticks or tools into the intake guards or discharge chute.

Do NOT operate machine without shields, guards, and safety devices (e.g. intake guard) in place and working.

Control and Operating Symbols

Choke Control:

Cold Start

Run/Warm Start

Fuel Primer:

Press 6 times

STOP

To reduce risk of fire, clean spilled gas and oil and keep

unit free from debris. Gasoline is extremely flammable.

Allow machine to cool completely before refueling.

Fuel Mixture:

50:1

(Unleaded Gas : 2 Cycle Oil)

Ignition Switch:

ON/

ON

RUN

OFF

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2019 MAT Engine Technologies, LLC

ENG - 2

Important Safety Information

• Save all instructions

RESPONSIBILITY OF OPERATOR

1. Carefully read and follow these safety instructions. Failure to do so can result in serious injury.

2.

Know your product. Read and understand this manual before use. Compare the illustrations to unit. Learn location

and function of all controls. Thoroughly understanding the unit before use will result in the best performance and safety.

3. Follow all instructions when assembling the unit. If the unit was purchased in assembled condition, the operator must

check the unit carefully to make sure it was assembled according the instructions in the manual before use.

4. Regularly inspect the blower. Make sure parts are not bent, damaged, or loose.

5. Use this equipment for its intended purpose only.

6. Operate the unit only with guards, shields, and other safety items in place and working correctly.

7. Service the unit only with authorized or approved replacement parts.

8. Complete all unit maintenance and adjustments according to the instructions in this manual.

- Look for this symbol to point out important safety precautions. It means: “ Attention! Become Alert! Your Safety Is

Involved.”

WARNING

To prevent accidental starting when setting up, transporting, adjusting or making repairs, always disconnect spark plug

wire and put wire where it cannot contact the spark plug.

PREPARATION SAFETY

WARNING

• Read, understand, and follow all instructions on the machine and in this manual. Be thoroughly familiar with the

controls and the proper use of the blower before starting. Know how to stop the engine quickly.

• Familiarize yourself with all the safety and operating decals on this equipment.

CAUTION

• Blower will propel debris at high speed and can cause damage. Before use, check that area is free from breakable

objects, such as house windows, auto glass, greenhouses, etc.

• Check that all nuts and bolts are tight and equipment is in good condition.

OPERATION SAFETY

WARNING

• Keep area of operation clear of all bystanders, particularly small children and pets.

• Never allow children or young teenagers to operate the walk behind blower. Only allow responsible individuals, who

are familiar with the instructions, to operate the blower.

WARNING

• Do not operate the blower while under the inuence of alcohol, drugs, or other medication which can cause drowsiness

or affect your ability to operate this machine safely.

• Do not use this machine if you are mentally or physically unable to operate the machine safely.

• This equipment was designed specically for the purpose of blowing leaves and debris. Do NOT use this equipment

for any other purpose.

• Always wear ANSI compliant safety goggles or safety glasses with side shields when operating blower to protect your

eyes from foreign objects, which can be thrown from the unit.

• Wear appropriate clothing such as a long sleeved shirt or jacket. Also wear long trousers or slacks. Do NOT wear

shorts. Do NOT wear loose clothing, which could get caught in this equipment.

• Always wear work gloves and sturdy footwear such as leather work shoes or short boots. These will protect ankles and

shins from small sticks, splinters, and other ying debris, and improve traction.

Important Safety Information

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2019 MAT Engine Technologies, LLC

ENG - 3

Important Safety Information (Continued)

• Save all instructions

• It is advisable to wear protective headgear to protect against being struck by small ying particles, or being struck by

Important Safety Information

low hanging branches, twigs, or other objects, which may be unnoticed by the operator.

WARNING

• There are rotating blades inside blower which can cause serious injury. NEVER place hand or anything else in the

intake or discharge openings when machine is running.

WARNING

• Do NOT operate without shields and guards (such as the intake guard) in place and secure.

• Do not stand or put your hand in front of the discharge opening. Always pay attention to the direction of the discharge

opening. Never allow discharge opening to point towards bystanders, pets, or valuable property.

• Exercise extreme caution when operating on or crossing gravel drives, walks, or roads. Stay alert for hidden hazards or trafc.

WARNING

• Exercise caution to avoid slipping or falling. Always be sure of your footing; keep a rm hold on the handle and walk;

never run. Never operate the blower at high transport speeds on slippery surfaces.

• Look behind and use care when backing.

• Never operate the blower without good visibility or light.

DANGER

• Do not run the engine indoors or inside a closed area. The exhaust fumes are dangerous, containing CARBON

MONOXIDE, an ODORLESS AND DEADLY GAS.

• Never leave the blower unattended when the engine is running. Stop the engine and make sure all moving parts have

stopped. Remove the wire from the spark plug.

• If the blower should start to vibrate abnormally, stop the engine, disconnect the spark plug wire and prevent it from

touching the spark plug. Check immediately for the cause. Vibration is generally a warning of trouble.

• Watch for holes, ruts, bumps, or other rough ground. Tall grass can hide obstacles.

• Never pick up or carry machine when engine is running.

FUEL SAFETY

WARNING

• Gasoline is extremely ammable, and gasoline vapors can explode if ignited. Handle with care. Allow engine to cool at

least 2 minutes before refueling.

• Wash skin or clothes immediately if they come in contact with gasoline.

• Use an approved container.

• Check fuel supply before each use, allowing space for expansion as the heat of the engine and/or sun can cause fuel

to expand.

• Fill fuel tank outdoors with extreme care. Never ll fuel tank indoors. Never ll fuel tank while machine is in a vehicle.

• Never remove gas cap or add fuel with the engine running. Allow engine to cool completely before refueling.

WARNING

• Do not smoke while refueling.

• After refueling, replace fuel tank cap securely and wipe up spilled fuel.

• Never store fuel or blower with fuel in the tank inside a building where fumes may reach an open ame.

STORAGE SAFETY

•

Always refer to the operator’s manual instructions for important details if the blower is to be stored for an extended period.

• Never store the blower with fuel in the fuel tank inside a building where ignition sources are present such as water

heaters, space heaters, clothes dryers, etc.

• To reduce re hazard, keep blower free of grass, leaves, or other debris build-up.

• Allow the engine to cool before storing in any enclosure.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2019 MAT Engine Technologies, LLC

ENG - 4

Important Safety Information (Continued)

• Save all instructions

REPAIR, MAINTENANCE, AND ADJUSTMENT SAFETY

• After striking a foreign object, stop the engine. Remove the wire from the spark plug and keep the wire away from the

plug to prevent accidental starting. Thoroughly inspect the blower for any damage. If damaged, have the equipment

repaired by a trained technician before restarting and operating.

WARNING

• Stop the engine before cleaning, repairing, or inspecting the unit. Make sure all moving parts have stopped. Let the

engine cool, disconnect the spark plug wire and move it away from the spark plug.

• Never attempt to make any adjustments while the engine is running.

• Keep the blower in safe working condition. Check all fasteners at frequent intervals for proper tightness.

• When servicing or repairing the blower, do not tip the machine over or up unless specically instructed to do so in this

manual. Service and repair procedures can be done with the blower in an upright position. Some procedures will be

easier if the machine is lifted on a raised platform or working surface.

• Use only original equipment or authorized replacement parts.

WARNING

• Never tamper with safety devices. Check their proper operation regularly.

• Do not change the engine governor setting or over-speed engine.

• Clean and replace safety and instruction decals as necessary.

• To guard against engine over-heating, always have engine air lter mounted and clean.

CHILDREN SAFETY

WARNING

• Tragic accidents can occur if the operator is not alert to the presence of children. Children are often attracted to the

blower and the leaf clearing activity.

• Keep children out of the area of operation and under the watchful care of a responsible adult.

• Never assume that children will remain where you last saw them.

• Be alert and turn blower off if children enter the area.

• Before and while moving backwards, look behind and down for small children.

• Never allow children to operate the blower.

• Use extra care when operating near blind corners, shrubs, trees, or other objects that may obstruct vision.

Important Safety Information

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2019 MAT Engine Technologies, LLC

ENG - 5

Specifications

• Save all instructions

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43cc, 2 Cycle

Maximum Air Flow . . . . . . . . . . . . . . . . .170 MPH/520 CFM

Fuel Tank Capacity. . . . . . . . . . . . . . . . . . . . .28 oz (810 ml)

Fuel Type ..............Unleaded Gasoline - 87 Octane

or Higher

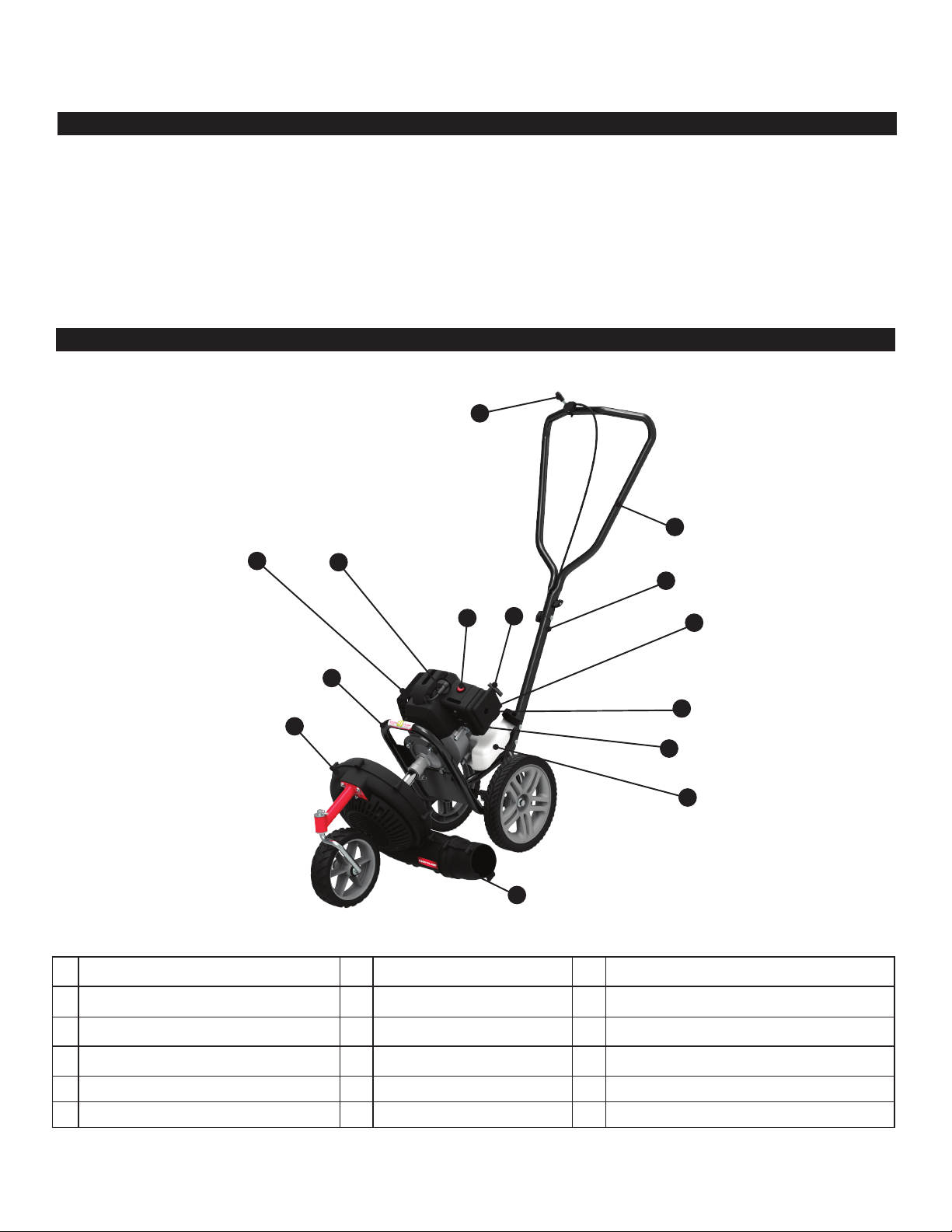

Parts & Features

14

13

2-Cycle Oil Type. . . . . . . . . . . . . .2-Cycle Oil That Meets or

Exceeds JASO-FC Specifications

Fuel Mixture . . . . . . . . . . . . . . . 50:1 (Gasoline: 2-Cycle Oil)

Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . NGK-BPMR6A

CHAMPION-CJ8 or Equivalent

Net Weight . . . . . . . . . . . . . . . . . . . . . . . . . . 28 lbs. (13 kg.)

10

4

3

7

6

5

1

9

2

1. Blower Assembly 7. Recoil Starter Handle 13. Spark Plug

2. Discharge Nozzle 8. Choke 14. Muffler

3. Middle Handle 9. Fuel Primer Bulb

4. Upper Handle 10. Throttle Lever

8

12

11

5. Front Handle 11. Fuel Tank

6. On/Off Ignition Switch 12. Air Filter Cover

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2019 MAT Engine Technologies, LLC

ENG - 6

Assembly

• Save all instructions

If you need assistance or find any parts missing,

CALL TOLL FREE: 1-800-737-2112.

WARNING

Read and follow the assembly instructions. Do not discard any parts or materials until the unit is assembled.

References to the right or left side of the blower are from the viewpoint of the operator’s position behind the blower.

WARNING

Do not operate blower if it is damaged or not completely and correctly assembled.

WARNING

Before doing any assembly or maintenance to the unit, remove the wire from the spark plug.

WARNING

Always wear ANSI compliant safety glasses with side shields while assembling the blower.

Parts Included With the Packaged Blower

• Operator’s Manual

• Upper and Middle Handles

• Blower Assembly with Tube

• Discharge Nozzle

• 50:1 2-Cycle Engine Oil (2.6 Fluid Ounces)

• Spark Plug Wrench and 5mm Hex Wrench

• (2) Wheel Assemblies

• (2) Wheel Hex Bolts

• (4) Washers For Wheel Bolts

• (2) Plastic Wing Nuts (For Attaching Handles)

• (2) Saddle Bolts (For Attaching Handles)

• (2) Hex Flange Screws, M6 x 35 (For Attaching

Lower Handle)

• (2) Hex Lock Nuts, M6 (For Attaching Lower Handle)

WARNING

Do not operate blower if it is damaged or not securely and fully assembled.

Tools Needed for Assembly

• 10 mm wrench or adjustable wrench

• 12 mm socket or open wrench

Unpacking

1. Remove components from carton.

2. Remove foam and corrugated protection

Handle Assembly

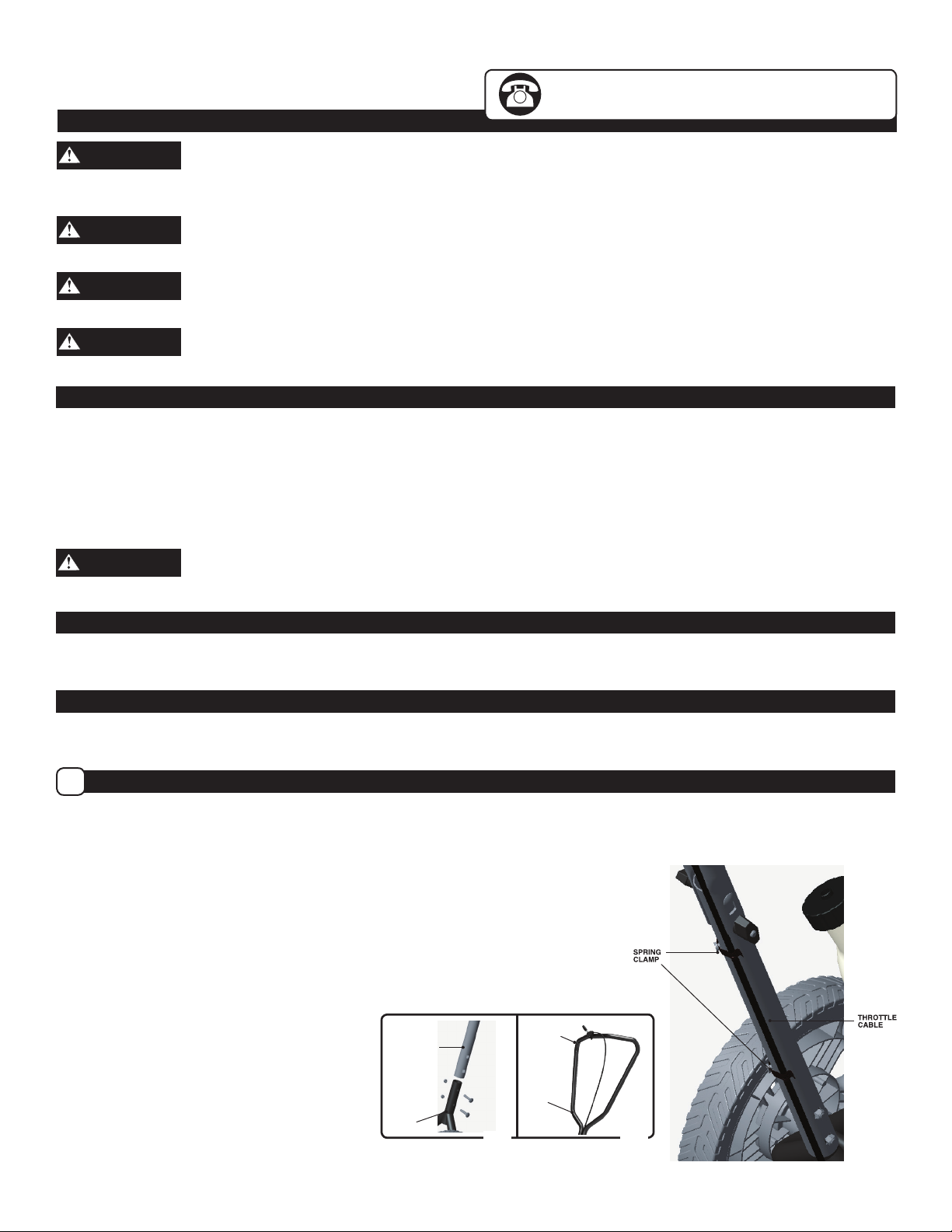

A

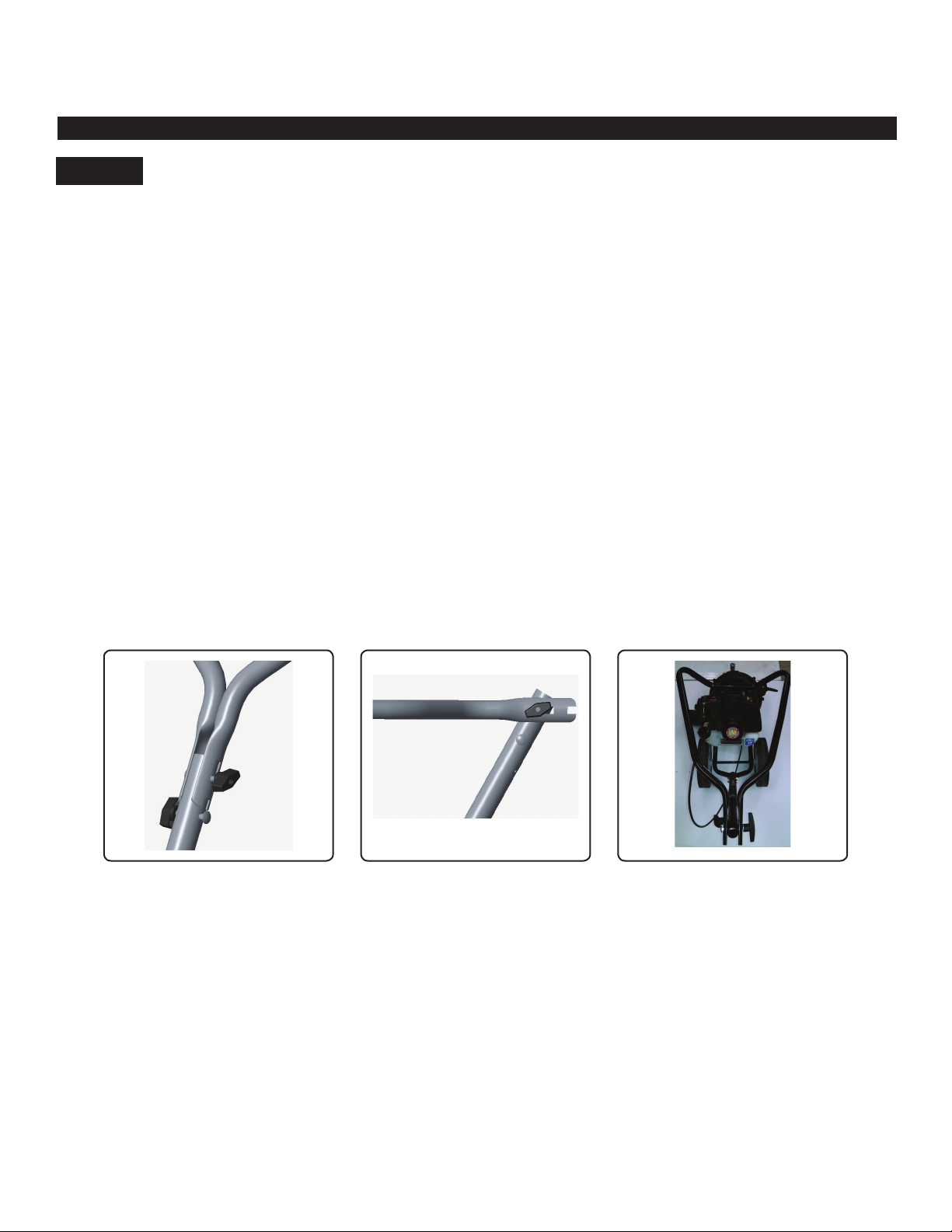

1. Install straight round middle handle to lower handle

and secure using two M6 x 35 hex bolts and locknuts. (Fig. 1)

2. Route throttle cable through legs of upper handle. Install upper handle

to middle handle and secure using two saddle bolts and plastic knobs. Install saddle

bolts from opposing sides so plastic knobs will not interfere with each other. Orient

handle so the “V” shape is upward. Tighten knobs securely.

3. Secure throttle cable to the underside of the middle

handle using the two spring clamps which have been

installed at the factory. (Fig. 3) Inspect throttle cable to

assure generous loops. Do not kink cable.

MIDDLE

HANDLE

(Fig. 2)

UPPER

HANDLE

MIDDLE

HANDLE

LOWER

HANDLE

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2019 MAT Engine Technologies, LLC

ENG - 7

Fig. 1

Fig. 2

Fig. 3

Assembly (Continued)

• Save all instructions

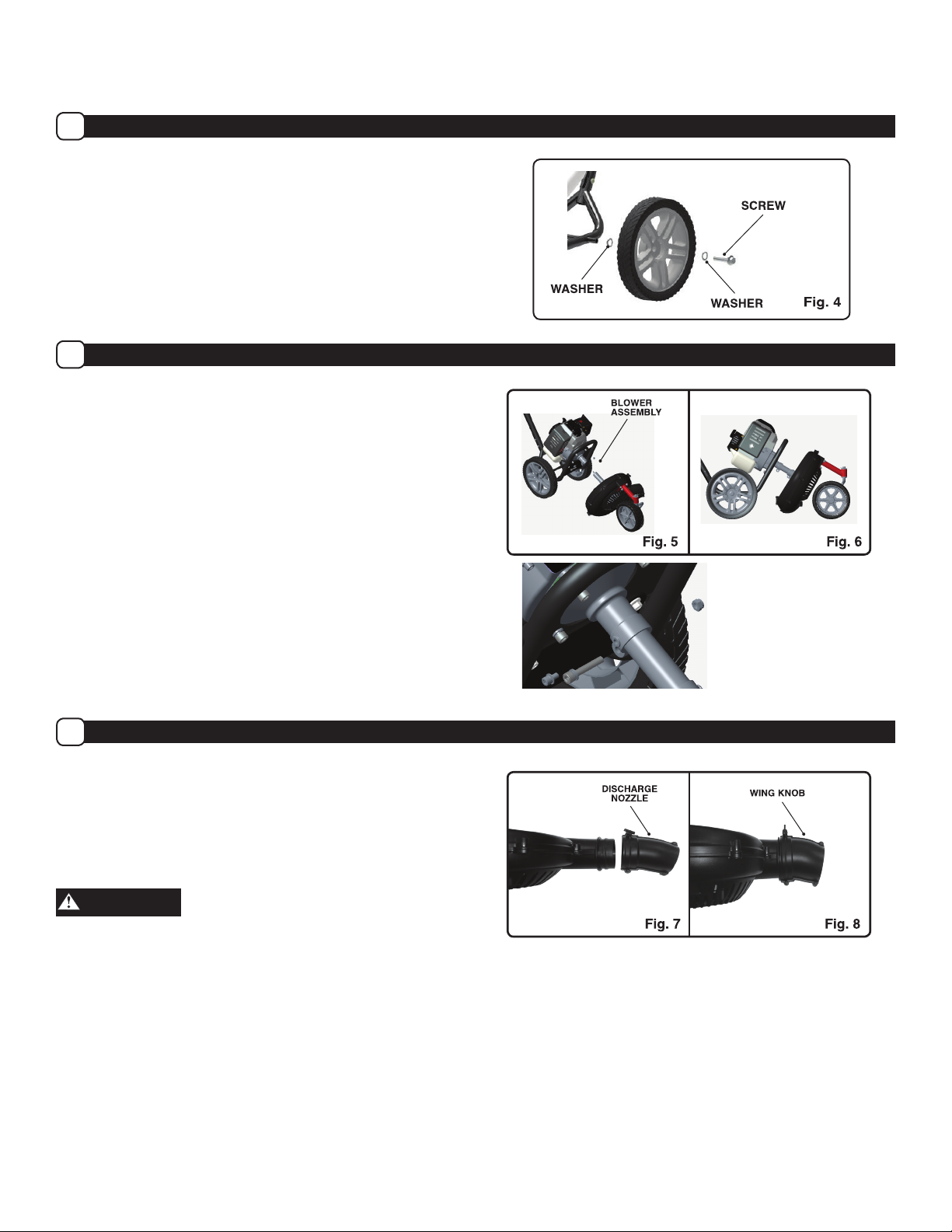

Wheel Assembly

B

1. Install the wheels to the frame using the provided hex

screws and washers. Install one washer on the inside

and one washer on the outside of each wheel.

Tighten to 9-13 ft. lbs. (12-18 Nm) torque using a

12 mm wrench. (Fig. 4)

Blower Assembly

C

1. Install the tube end of the blower assembly

into the engine clutch housing. It may be necessary

to rotate the blower assembly slightly to align the shafts.

Rotate the installed tube so the index screw opening

in the housing matches the hole in the blower assembly

tube. Install the socket head screw (M6 x 12) with the

provided hex wrench. Tighten securely. (Fig. 5)

2. Set the unit on a flat hard surface. The swivel wheel

should sit flat and perpendicular to the surface. Tighten

the clamp screw (M6 x 25) securely. Try to rotate the

tube within the housing. If you can rotate the tube,

tighten the clamp screw additionally. Repeat if

necessary. (Fig. 5 & 6)

Discharge Nozzle Assembly

D

1. Push discharge nozzle onto the Blower housing

outlet. (Fig. 7 )

2. Rotate nozzle so it discharges slightly towards the

front. (Fig. 8)

3. Hand tighten the wing knob to lock into position.

WARNING

Do not operate the Blower without the discharge

nozzle assembled.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2019 MAT Engine Technologies, LLC

ENG - 8

Operation

• Save all instructions

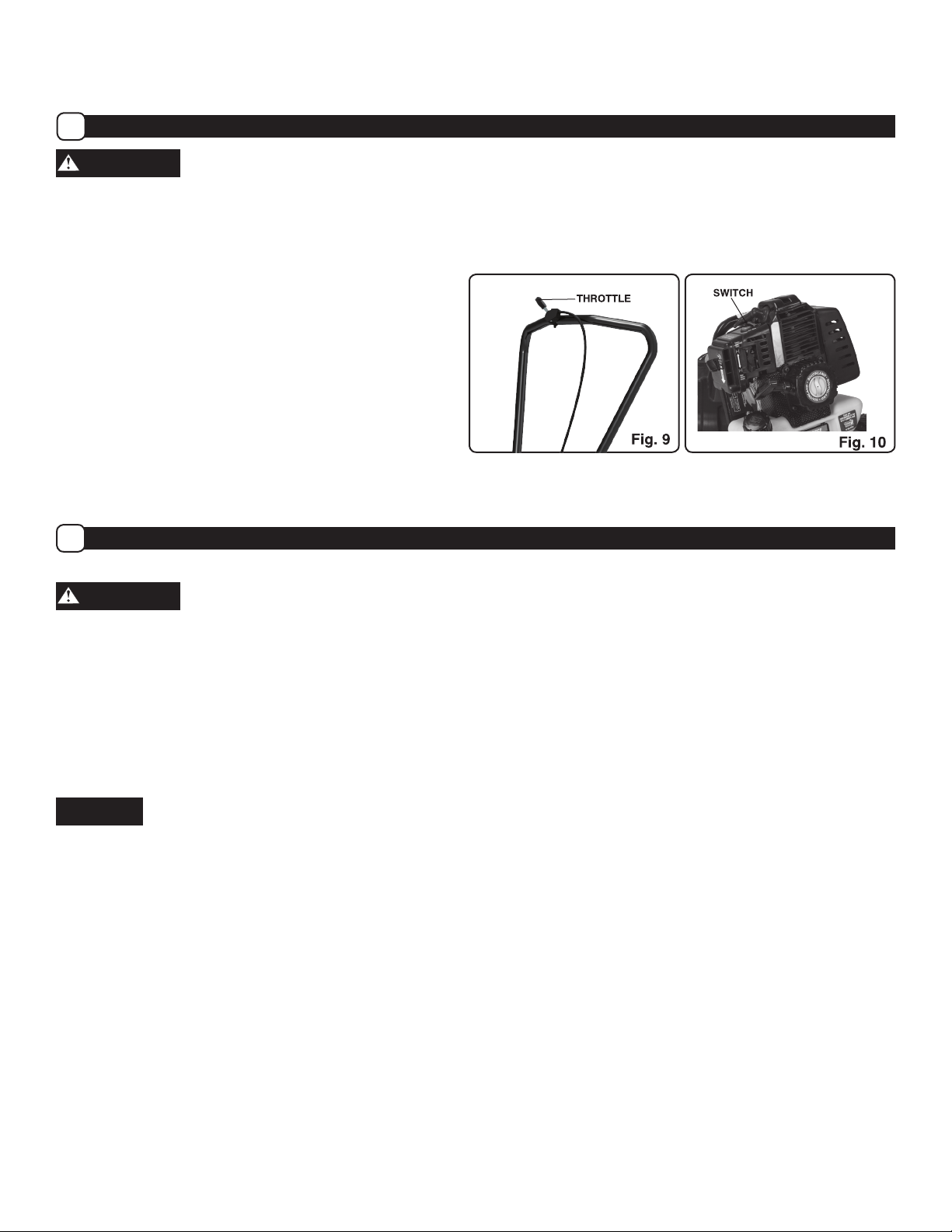

Control Identification and Use

A

WARNING

Thoroughly inspect the area where the Blower is to be used and remove all foreign objects. Your equipment can throw

small objects at high speed causing personal injury or property damage.

Keep all children and bystanders at least 50 ft (15 m) away when operating. Stop machine if anyone enters the area.

1. Throttle:

The throttle is located on the upper handle.

Rotating the lever downward will increase the engine

speed. Rotating the lever to the up-most position will

return to idle speed. (Fig. 9)

2. Start/Stop Switch:

An ignition switch is located on the engine shroud.

The switch must be in the “on” position for the engine

to run. Moving the switch to the “off” position will stop

the engine. (Fig. 10)

Before Starting the Engine

B

Mixing Fuel / 2-Cycle Oil

WARNING

Do not smoke or allow smoking near fuel or the Blower. Mix and pour fuel outdoors WHERE THERE ARE NO SPARKS

OR FLAMES.

The 2-cycle engine on your Blower requires that fuel and

2-cycle engine oil be pre-mixed before adding to the

blower’s fuel tank. To mix the fuel/ 2-cycle oil:

1. Use fresh unleaded gasoline with an octane rating

of 87 or higher. Do not use gasoline containing more

than 10% ethanol.

NOTICE

Use of gasoline containing more than 10% ethanol can

damage Blower. Use of non-ethanol gasoline is best.

We recommend the continuous use of a fuel additive/

stabilizer to counteract the effects of ethanol. These

additives also prolong the shelf life of gasoline.

2. Always use 2-cycle oil that meets or exceeds

JASO – FC specifications and is intended for mixing at

a fuel/oil ratio of 50:1

5. Follow instructions on 2-cycle oil container for mixing

fuel. Mix gasoline and 2-cycle oil at a ratio of 50:1.

A mixture with a 50:1 ratio is obtained by mixing

1 gallon (4 liters) of gasoline with 2.6 ounces of oil

(77 ml). After adding oil to gasoline, shake container

momentarily to ensure proper mixing.

6. Mix only enough fuel for your immediate needs.

Do not store pre-mixed fuel.

7. Stop engine and allow to cool before refueling.

8. To fill the Blower’s fuel tank with the gasoline/oil

mixture, place the Blower upright on the ground or on

a sturdy bench and wipe any debris from around

the fuel cap.

9. Remove fuel cap slowly and use a funnel to pour the

mixture into the tank, and replace the fuel cap.

3. Do not use automotive or 2-cycle marine outboard oil.

These will damage your Blower’s engine and void

the warranty.

4. Always mix the gasoline and 2-cycle oil in a container

approved for gasoline. Never mix fuel directly in the

blower’s fuel tank.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2019 MAT Engine Technologies, LLC

ENG - 9

10. Avoid spilling fuel or oil. Wipe up all fuel spills.

11. Move at least 10 ft (3 m) away from fueling site

before starting engine.

Operation (Continued)

• Save all instructions

Before Starting the Engine (Continued)

C

WARNING

Keep all bystanders, especially CHILDREN, away during operation.

IMPORTANT: This unit’s engine exhaust system is equipped with a spark-arresting muffler. Tampering with or removing

the spark-arrestor violates section 4442 of the California Public Resources Code as well as other applicable state and

federal law.

NOTE: When the weather gets cold, please allow the engine to warm up at idle for longer period of time, before engaging to

RUN/WARM START position.

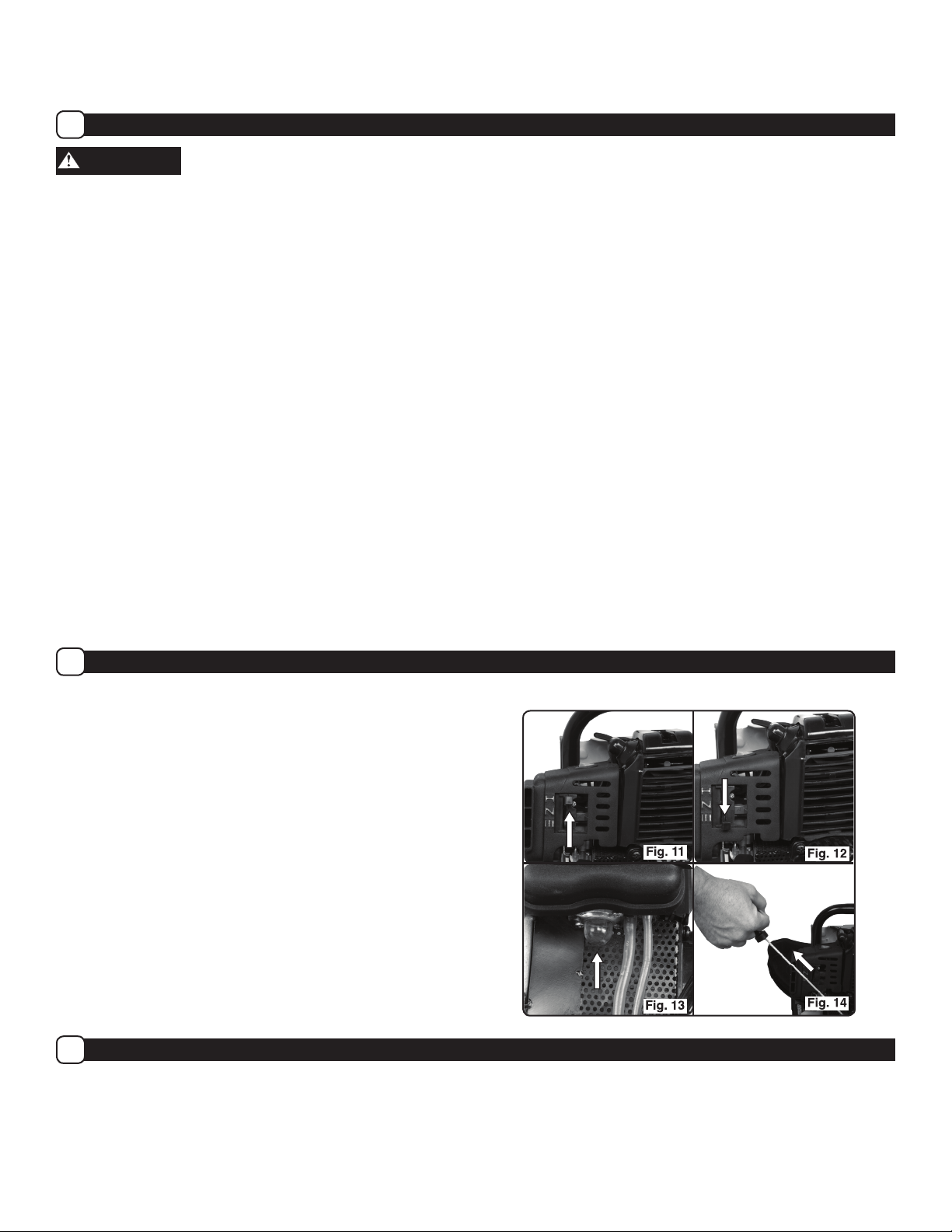

Cold Starting The Engine:

1. Place the Blower on a flat surface.

2. Move the ignition switch to the “ON” position.

3. Move the choke lever up to the “COLD

START” position. (Fig. 11)

4. Press the primer bulb slowly 6 times. (Fig. 13)

5. Pull the recoil starter handle sharply until the engine

starts and runs. (Fig. 14)

6. After engine starts and runs for 10-15 seconds, move

choke lever to “RUN/WARM START” position. (Fig. 12)

Starting Engine

D

NOTE: If the unit still doesn’t start, refer to the TROUBLESHOOTING section of this manual. Starting A Flooded Engine.

Starting A Flooded Engine:

1. Place the Blower on a flat surface.

2. Move the ignition switch to the “ON” position.

3. Move the choke lever to “RUN/WARM START”

position. (Fig. 12)

Warm Starting The Engine:

1. Place the Blower on a flat surface.

2. Move the ignition switch to the “ON” position.

3. Move the choke lever to “RUN/WARM

START” position. (Fig. 12)

4. Pull the recoil starter handle sharply until the

engine starts and runs. (Fig. 14)

4. Fully Rotate the throttle lever downward and pull the

starter handle repeatedly until engine starts and runs.

This could require pulling the starter handle many times,

depending on how badly the unit is flooded. (Fig. 14)

5. If the engine still does not start, allow the unit to sit for

about 30 minutes, and repeat step 1-4.

Stopping the Engine

E

1. Rotate the throttle lever to the up-most position and allow the engine to idle for a few moments.

2. Move the Ignition Switch to the “OFF” position.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2019 MAT Engine Technologies, LLC

ENG - 10

Operation (Continued)

• Save all instructions

How to Adjust the Vertical Flow Angle

F

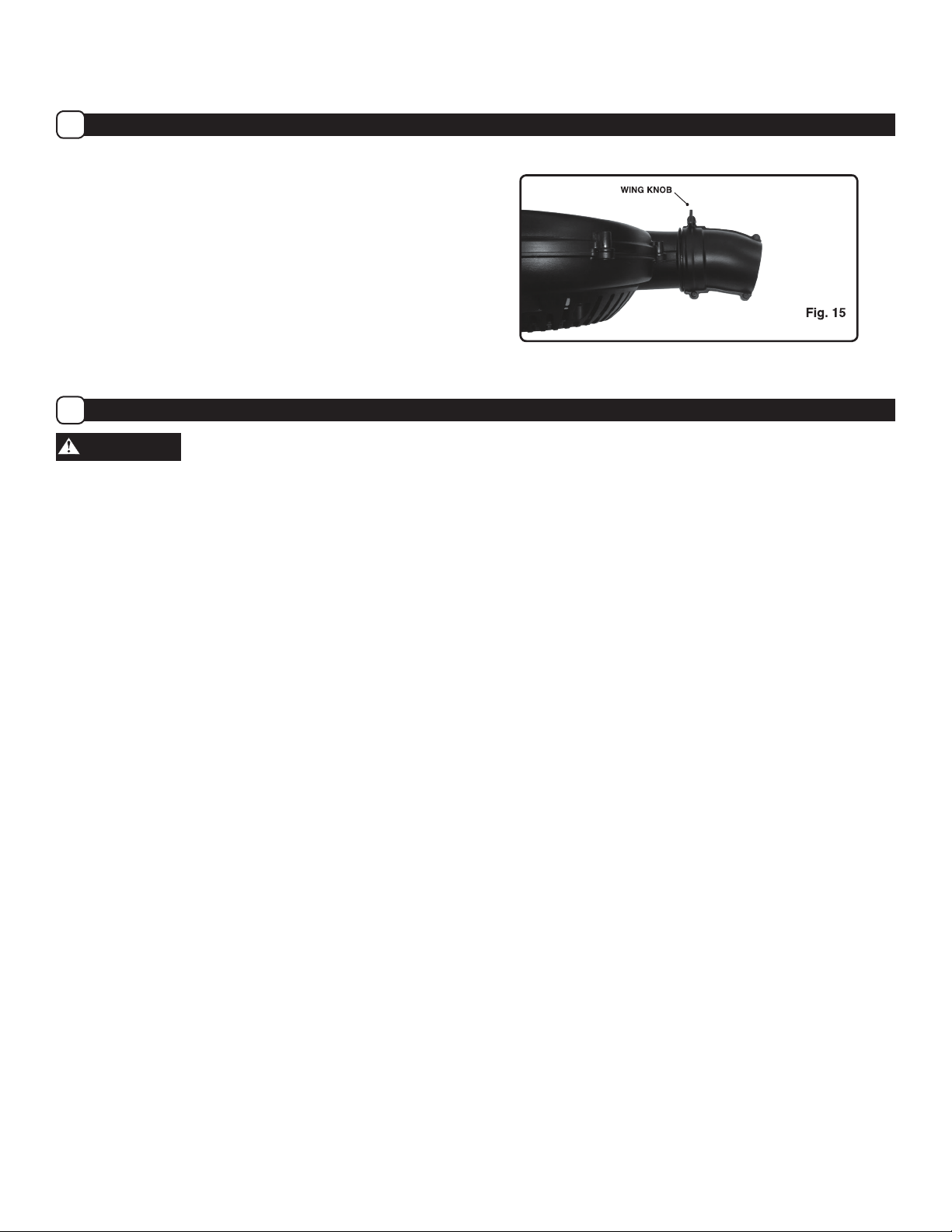

2. The airflow can be directed up or down by loosening

the discharge nozzle wing knob and rotating the nozzle

in the desired direction. Tighten wing knob. (Fig. 15)

Tips for Using your Walk Behind Blower

G

WARNING

Read the Operator’s manual. Know location and functions

of all controls. Keep all safety devices and shields in place.

Never allow children or uninstructed adults to operate the

blower. Keep bystanders away from machine. Keep away

from the fan intake opening and discharge chute, as the

fan is rotating and can cause severe injury.

• Blowing leaves is best performed when conditions are dry.

• To clear a very large and/or heavy pile of leaves, make

two passes: First point the directional adjustment

upward to move the top of the pile. Then point the

directional adjustment downward to move the base of the pile.

• When clearing leaves, always pay attention to natural

wind direction and blow the leaves the same direction as

the natural wind.

• To clear a small area, corral the leaves in the center by

circling several times around the perimeter of the area.

• To clear a large area, move the leaves from one side to

the other by making back and forth passes.

• Before starting a clearing project, plan how the leaves

will be collected and disposed.

• Check and clean air intake grille if leaves accumulate

and decreased performance is noticed.

• A drag chain is provided to dissipate any static charges

that may be generated during use. Be sure chain is

present and in contact with ground.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2019 MAT Engine Technologies, LLC

ENG - 11

Routine Maintenance

• Save all instructions

WARNING

Disconnect the spark plug before performing maintenance.

Air Filter

A

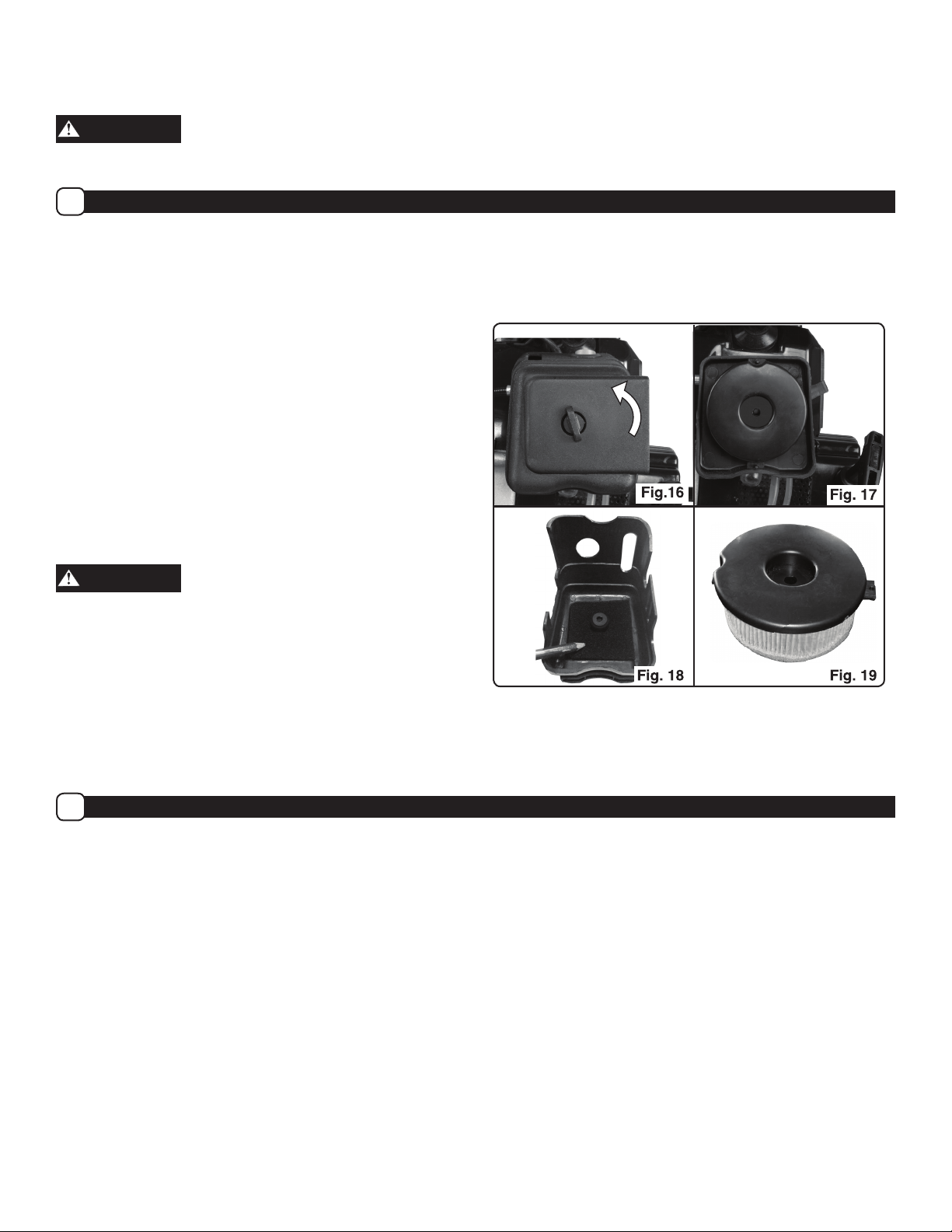

Your Blower has been equipped with two air filters inside the housing. Accumulated debris and dust in the air filter will

reduce engine performance, increase fuel consumption and increases the risk of engine damage. Clean the air filters

every 5 hours of operation. It may be necessary to clean the air filter more often in dry conditions due to a large amount

of airborne debris.

1. Before removing air filter cover, brush away any loose

dirt or debris on and around the pre-filter located in

the outer filter housing.

2. Remove air filter by unscrewing the retaining fastener.

(Fig. 16)

3. Remove and clean foam filter. (Fig. 18)

•

Light surface dust can readily be removed by

tapping the filter.

• Heavy deposits should be washed out in soap

and water. Squeeze out any remaining water and

allow the filter to completely dry.

WARNING

Never clean filter in gasoline or other flammable solvents.

4. Add four drops of thin oil to the foam filter, squeeze

out excess and replace.

5. Remove the paper air filter element. (Fig 19) Clean

filter by gently tapping it on a flat surface. If very dirty,

replace with a new filter.

6. Reassemble the air filter element and air filter cover.

Spark Plug

B

Inspect the spark plug after every 10-15 hours of use; adjust spark plug gap and replace spark plug as necessary.

Replace spark plug every year to maintain engine performance and easy starting.

To inspect or replace the spark plug:

1. Remove the insulated spark plug boot.

2. Use the spark plug wrench to remove the spark plug,

by turning counter-clockwise.

3. Clean and adjust the spark plug gap to

0.024 – 0.028 inches (0.6 - 0.7 mm).

5. Install the spark plug finger tight in the cylinder head,

then tighten firmly with the spark plug wrench.

6. Attach the insulated spark plug boot.

4. Replace any worn plug with a recommended

replacement (see PRODUCT SPECIFICATIONS)

Clean and adjust the spark plug gap to

0.024 – 0.028 inches (0.6 - 0.7 mm).

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2019 MAT Engine Technologies, LLC

ENG - 12

Storage

• Save all instructions

NOTICE

To prevent fuel gum deposits and corrosion in the Blower’s

carburetor and fuel system, it is highly recommended to

use a fuel additive / stabilizer formulated for ethanol fuels.

Follow the stabilizer manufacturer’s instructions. Run the

engine at least 5 minutes after adding stabilizer.

1.

Allow engine to cool and empty the fuel tank before

storing or transporting in vehicle. Use up remaining fuel

in the carburetor by starting the engine and letting it run

until it stops. Squeeze primer bulb several times to purge

fuel from the carburetor.

2. When not in use, store Blower indoors in a dry

location. Store Blower in a locked area out of the

reach of children.

3. Store unit and fuel in area where fuel vapors cannot

reach sparks or open flames from water heaters,

electric motors or switches, furnaces, etc.

4. When preparing the Blower for storage or when

Blower will not be used for 30 days or more:

a. Inspect and clean the Blower thoroughly.

b. Lightly oil all external metal surfaces.

c. Remove the spark plug, place a few drops of

2-cycle engine oil into the cylinder. Pull the

recoil starter several times to distribute the oil.

Replace the spark plug.

d. Inspect and clean air filter as required.

5. The upper handle can be folded to reduce the

storage space required. To fold, loosen but do not

remove the upper two knobs retaining the saddle

screws. Remove the throttle cable from the two spring

clamps and move to left side of unit. Pull the upper

handle to the rear which will dis-engage the connector,

and fold the upper handle forward being careful not to

kink the throttle cable. Reassemble in the

reverse manner.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2019 MAT Engine Technologies, LLC

ENG - 13

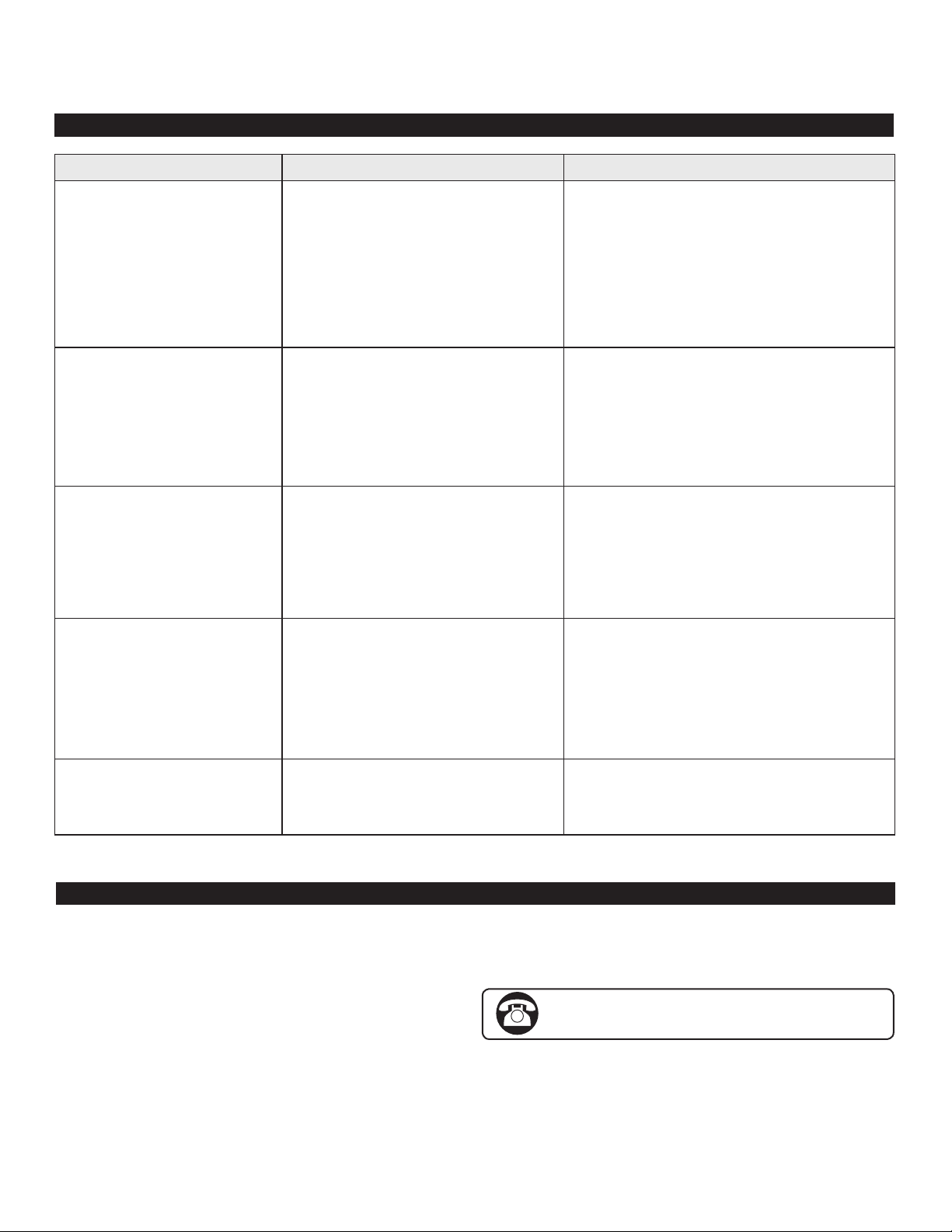

Troubleshooting

• Save all instructions

PROBLEM POSSIBLE CAUSE(S) SOLUTION(S)

Engine will not start. 1.

Ignition Switch in the “OFF” position.

2. Engine flooded.

3. Fuel Tank empty.

4. Spark Plug not firing.

5. Fuel not reaching carburetor.

6. Carburetor requires adjustment.

1. Move ignition switch to the ON position.

2. See Starting a Flooded Engine in

OPERATION section.

3. Fill tank with correct fuel mixture.

4. Replace Spark Plug.

5. Check for kinked or split fuel line; repair

or replace.

6. Contact a qualified service center.

Engine will not accelerate,

lacks power or stalls.

Engine smokes excessively. 1. Fuel mixture incorrect.

Engine runs hot. 1. Fuel mixture incorrect.

Engine will not idle properly. 1. Carburetor requires adjustment.

1. Air filter dirty.

2. Spark plug fouled.

3. Carburetor requires adjustment.

4. Carbon build-up on muffler outlet

screen.

5. Compression low.

2. Air filter dirty.

3. Carburetor requires adjustment.

2. Spark Plug incorrect.

3. Carburetor requires adjustment.

4. Carbon build-up on muffler outlet

screen.

5. Engine air inlet covered

with debris.

2. Crankshaft seals worn.

3. Compression low.

1. Clean air filter.

2. Clean or replace plug.

3. Contact a qualified service center.

4. Contact a qualified service center.

5. Contact a qualified service center.

1. Empty Fuel Tank and refill with correct fuel

mixture.

2. Clean or replace air filter.

3. Contact a qualified service center.

1. See Mixing Fuel / 2-Cycle Oil in

OPERATION section.

2. Replace with correct Spark Plug.

3. Contact a qualified service center.

4. Contact a qualified service center.

5. Clean engine cooling air inlet.

1. Contact a qualified service center.

2. Contact a qualified service center.

3. Contact a qualified service center.

Technical Service

You may have further questions about assembling, operating, or maintaining this Blower. If so, you can contact our

Technical Service Department at 1-800-737-2112 (English only).

You may also write to:

METL Corporate Office - CORRESPONDENCE ONLY

ATTN: Technical Service – METL

6700 Wildlife Way

Long Grove, IL 60047

When contacting the Technical Service Department, have ready:

• Your Name

• Your Address

• Your Phone Number

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2019 MAT Engine Technologies, LLC

ENG - 14

• Model Number of Product

• Date of Purchase

(include copy of receipt for written requests)

If you need assistance or have any questions, CALL

TOLL FREE: 1-800-737-2112.

Loading...

Loading...