Southland SHB25170.1 User Manual

Operator’s Manual

Gasoline Powered Blower

25cc, 2 Cycle

MODEL No. SHB25170.1

Look inside for:

Page

Safety Definitions 1

Important Safety Information 2-4

Product Specifications 5

Parts & Features 5

Assembly 5-6

Operation 7-8

Routine Maintenance 8

Storage 9

Troubleshooting 10

Technical Service 10

Warranty 10-16

IMPORTANT:

Thank you for purchasing this Southland® Blower.

Read and understand all warnings and instructions in this manual before operating this tool. Improper use of this

tool can cause severe injury or death. Keep this manual for future reference.

Record the following for future reference:

Mfg. Date Code : __________________

Date of Purchase: Attach a copy of your sales receipt.

Consumer Toll Free Number: 1-800-737-2112

Refer to the website for electronic manual and parts book.

www.southlandpowerequipment.com

WARNING

Engine exhaust, some of its constituents, and certain product components contain or emit chemicals known to the

State of California to cause cancer and birth defects or other reproductive harm.

CALIFORNIA PROPOSITION 65 WARNING

If you have a question or problem...

CALL TOLL FREE: 1-800-737-2112

KEEP THIS MANUAL FOR FUTURE REFERENCE

11/20/2015 Printed in the China A203447

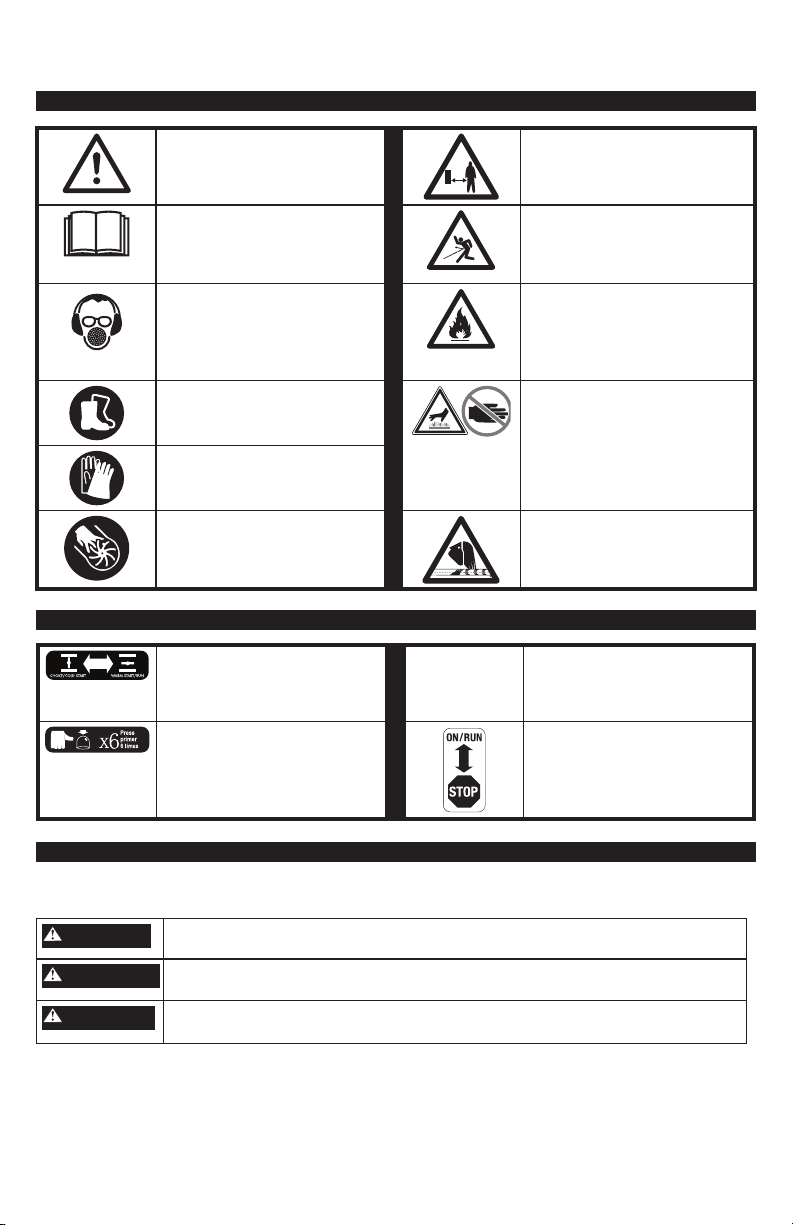

Safety Definitions

• Save all instructions

Safety Warning Symbols:

WARNING! Your safety is involved.

Read these instructions carefully.

Always wear eye protection that meets

or exceeds the requirements of ANSI

Z87.1.

Wear hearing protection.

Wear breathing protection.

Wear safety footwear. Extremely hot surface. Do not touch

Wear safety gloves.

Rotating impeller blades can cause

severe injury.

Control and Operating Symbols:

Choke Control:

Cold Start

Run/Warm Start

Fuel Primer:

Press 6 times.

Keep all bystanders at least 50 ft.

50 ft

15 m

(15 m) away.

This equipment can throw small objects

at high speed causing personal injury.

Inspect area where used and remove

all foreign objects.

Fuel is flammable. Handle with care.

a hot muffler, gear box or cylinder,

you may get burned. These parts

get extremely hot from operation and

remain hot for a short time after the unit

is turned off.

To prevent entanglement, always wear

protective hair covering to contain

long hair.

Fuel Mixture:

50:1

(Unleaded Gas : 2 Cycle Oil)

Ignition Switch:

ON - Engine Run

OFF - Engine Stop

Safety Alert Symbols:

The symbols below identify important safety information in this manual. Become familiar with these symbols and

the warnings associated with these symbols.

DANGER

WARNING

CAUTION

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2015 MAT Engine Technologies, LLC

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury or equipment/damage property.

ENG - 2

Important Safety Information

• Save all instructions

BEFORE OPERATING BLOWER

1. READ AND UNDERSTAND ALL INSTRUCTIONS BEFORE OPERATING BLOWER.

WARNING

Read and follow all warnings and safety instructions. Failure to do so can result in serious injury to you or bystanders.

2. Avoid Dangerous Environments

a. Do not operate Blower while under the influence of alcohol, medications, or drugs.

b. Do not operate Blower when you are tired.

c. Do not use this Blower if you are mentally or physically unable to operate safely.

3. Inspect Blower for damaged parts, and make sure all fasteners and guards are in place and secure. Replace

any damaged parts.

4. Dress properly when operating Blower.

a. Always wear heavy long pants, boots, gloves, and a long-sleeve shirt.

b. Do not wear loose clothing or jewelry that can get caught in the rotating parts of the Blower.

c. Always wear gloves and substantial foot wear when working outside.

d. Always wear protective hair covering to contain long hair.

5. Always wear a face or dust mask if operation is dusty.

6. Always wear eye protection that meets or exceeds the requirements of ANSI Z87.1.

7. Always wear hearing protection which meets or exceeds ANSI standards.

8. Thoroughly inspect the area where the Blower is to be used and use rakes and booms to loosen debris

before use.

WARNING

Your equipment can throw small objects at high speed causing personal injury or property damage.

WARNING

This product contains chemicals known to the State of California to cause cancer or birth defects, or other

reproductive harm.

Important Safety Information

WHILE OPERATING BLOWER

1. Stay alert. Use common sense. Watch what you are doing.

2. Do not operate Blower if it is damaged or not securely and fully assembled.

3. Only well instructed adults should operate Blower. Never allow children to operate Blower.

4. Keep children away. Keep all bystanders at least 50 feet (15 meters) away.

5. Do not point the Blower nozzle in the direction of people or pets.

6. Use only for blowing yard debris. Use only on ground surfaces. Do not use Blower for any job except that for which it

is intended.

7. Maintain your balance and proper footing at all times. Do not overreach.

8. Always keep engine on the right hand side of your body.

9. Do not force Blower. It will do the job better and with less likelihood of a risk of injury at the rate for which it was designed.

DANGER

10. Never start or run the unit inside a closed room or building; breathing exhaust fumes can kill.

CAUTION

Prolonged exposure to vibrations through use of gasoline powered hand tools could cause blood vessel or nerve

damage in fingers, hands, and joints of people prone to circulation disorders or abnormal swellings. Extensive use

in cold weather has been linked to blood vessel damage in otherwise healthy people. If symptoms occur such as

numbness, pain, loss of strength, change in skin color or texture, or loss of feeling in the fingers, hands, or joints,

discontinue the use of this tool and seek medical attention.

WARNING

To reduce the risk of fire and burn injury, handle fuel with care. It is highly flammable.

FUEL SAFETY

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2015 MAT Engine Technologies, LLC

ENG - 3

Important Safety Information

• Save all instructions

1. Mix and pour fuel outdoors WHERE THERE ARE NO SPARKS OR FLAMES.

Important Safety Information

2. Use a container approved for gasoline.

3. Do not smoke or allow smoking near fuel or the Blower.

4. Avoid spilling fuel or oil. Wipe up all fuel spills and let the unit dry before using.

5. Move at least 10 feet (3 meters) away from fueling site before starting engine.

6. Stop engine and allow to cool before removing fuel cap. Remove fuel cap slowly. Do not refuel a hot engine.

Do not refuel a running engine.

MAINTENANCE & STORAGE OF BLOWER

WARNING

1. Stop the engine, and disconnect the spark plug before performing maintenance.

2. Maintain Blower with care. Inspect Blower periodically. If Blower is not working properly or damaged, have it

repaired by a qualified service center.

3. Check for misalignment of moving parts, binding of moving parts, broken parts, mounting, and any other

condition that may affect its operation.

4. Keep guards in place and in working order.

5. A guard or other part that is damaged should be properly repaired or replaced by a qualified service center.

6. Use only genuine Southland® replacement parts and accessories. Use of any non-Southland® parts or

accessories could lead to injury, damage to the unit, and will void your warranty.

7. Do not remove or modify any parts. Removing or modifying parts could lead to injury, damage the Blower, and

will void the warranty.

8. Keep handles dry, clean, and free from oil and grease.

9. Allow engine to cool. Empty the fuel tank. Push primer bulb multiple times to remove remaining fuel from

carburetor and empty fuel tank again. Use up remaining fuel by starting the engine and letting it run until it stops.

10. When not in use, store Blower indoors in a dry location. Store Blower above the reach of children or in a locked

area out of the reach of children.

11. Store unit and fuel in area where fuel vapors cannot reach sparks or open flames from water heaters, electric

motors or switches, furnaces, etc.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2015 MAT Engine Technologies, LLC

ENG - 4

Product Specifications

• Save all instructions

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 cc, 2 cycle

Idle Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . 4,000 RPM

Peak Air Velocity . . . . . . . . . . . . . . . . . . . . . . . . 170 mph

Air Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . .400 CFM

Fuel Tank Capacity . . . . . . . . . . . . . 20 fl oz US (600 ml)

Fuel Type .....Unleaded Gasoline – 89 Octane or higher

2-Cycle Oil Type ...... 2-Cycle Oil that meets or exceeds

. . . . . . . . . . . . . . . . . . . . . . . . JASO – FC Specifications

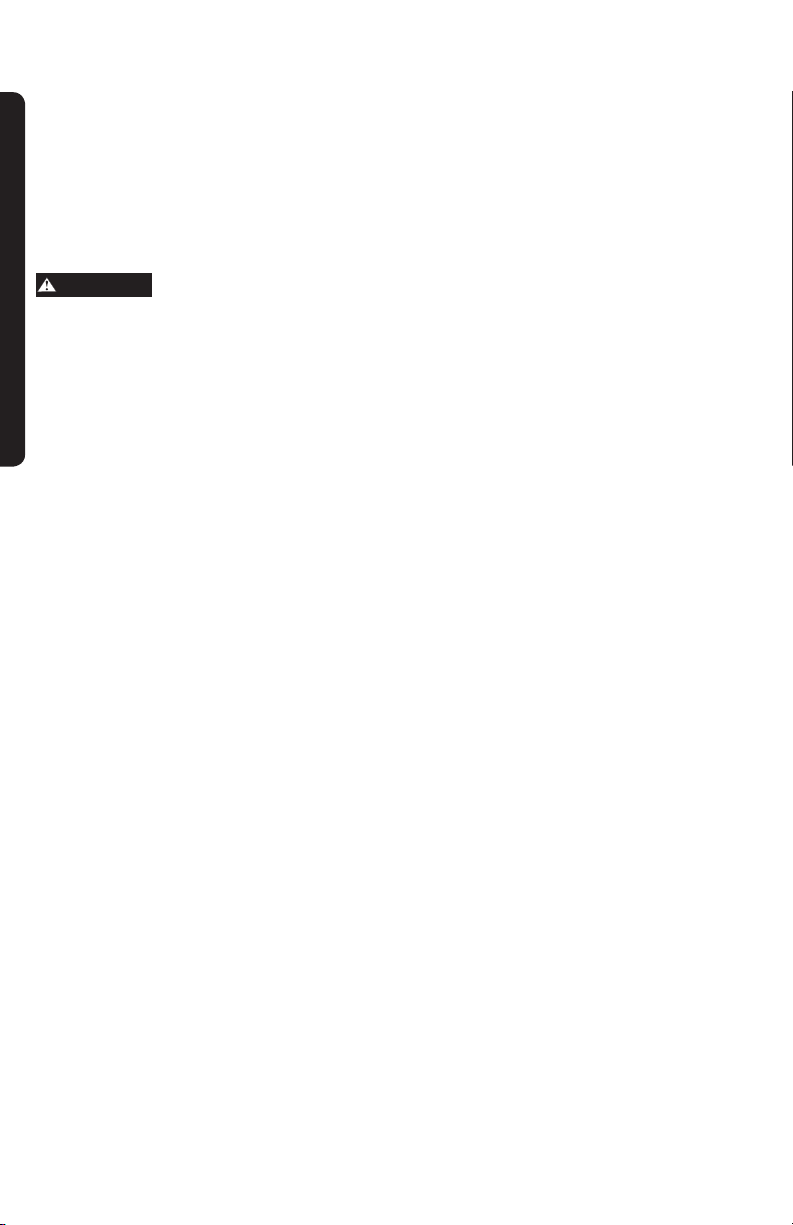

Parts & Features

Fig. 1

13

6

11

4 5

1

2

8

3

9

10

12

7

Fuel Mixture .............50:1 (Gasoline: 2-Cycle Oil)

Sound Pressure Values . . . . . . . . . . . . . . . . . . . . . . 79dB

Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . .Torch L8RTC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . NGK - BPMR7A

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .CHAMPION - CJ7Y

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . or equivalent

Net Weight . . . . . . . . . . . . . . . . . . . . . . . 11.5 lbs (5.2 kg)

14

1. Ignition Switch 8. Spark Plug

2. Handle 9. Fuel Primer Bulb

3. Engine 10. Choke

4. Upper Tube 11. Fuel Cap

Lower Tube

5.

6. Recoil Starter Handle 13. Throttle Lever

7. Fuel Tank

12. Air Filter Cover

14. Nozzle

Assembly

Parts Included With The Packaged Blower

• Upper Tube (1)

• Lower Tube (1)

• Nozzle, High Speed (1)

If you need assistance or find any parts

missing, CALL TOLL FREE: 1-800-737-2112

• Screwdriver with Spark Plug Wrench

• 2-Cycle Engine Oil (2.6 fl oz US / 77 ml)

• Operator’s Manual

WARNING

Do not operate Blower if it is damaged or not securely and fully assembled.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2015 MAT Engine Technologies, LLC

ENG - 5

Assembly (Continued)

• Save all instructions

Blower Assembly

WARNING

Blower tube installation affects both Blower balance and

performance. The tube and nozzle must be installed

correctly.

Never use the Blower without the upper and lower tubes

correctly fitted to the Blower.

WARNING

Rotating impeller blades can cause severe injury! Stop

the engine before installing or removing the Blower

tubes. Never perform any maintenance or assembly

procedures on this Blower while the engine is running.

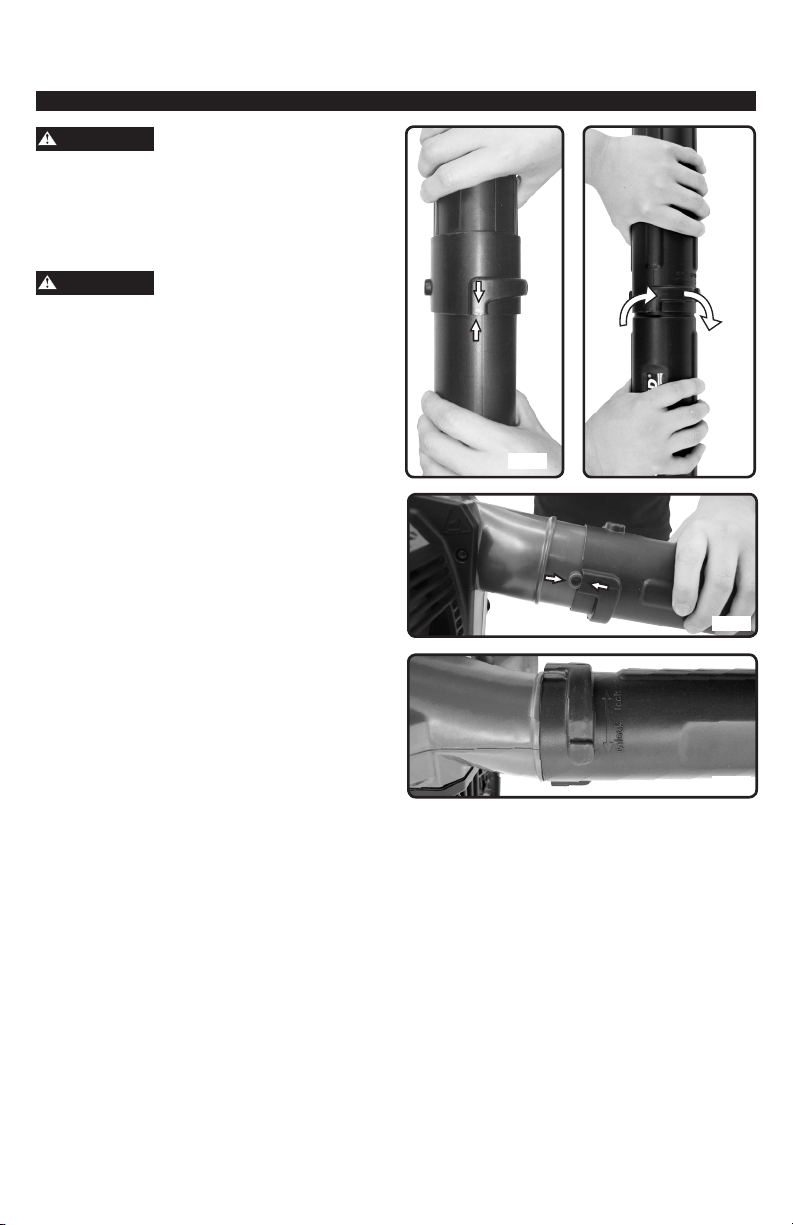

1. Align the arrow on the upper tube with the arrow

on the lower tube. (Fig. 2 ).

2. Slide the lower tube to the upper tube.

3. Turn the lower tube clockwise until a click is reached

to secure the lower tube to the upper tube. (Fig. 3)

4. Align the arrow on the upper tube with the arrow on

the Blower outlet. (Fig.4)

5. Slide the upper tube to the Blower outlet.

6. Turn the upper tube clockwise until a click is

reached to secure the upper tube to the Blower

outlet. (Fig.5)

Fig. 2

Fig. 3

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2015 MAT Engine Technologies, LLC

ENG - 6

Fig. 4

Fig.5

Operation

• Save all instructions

Before Starting Engine:

A

Mixing Fuel / 2-Cycle Oil

WARNING

Do not smoke or allow smoking near fuel or the Blower. Mix and pour fuel outdoors WHERE THERE ARE NO

SPARKS OR FLAMES.

The 2-cycle engine on your Blower requires that fuel

and 2-cycle engine oil be pre-mixed before adding to

the Blower’s fuel tank. To mix the fuel/ 2-cycle oil:

1. Use fresh unleaded gasoline containing no more

than 10% ethanol with an octane rating of 89 or higher.

2. Always use 2-cycle oil that meets or exceeds JASO

– FC specifications and is intended for mixing at a

fuel/oil ratio of 50:1.

3. Do not use automotive or 2-cycle marine outboard oil.

These will damage your Blower’s engine and void

the warranty.

4. Always mix the gasoline and 2-cycle oil in a

container approved for gasoline. Never mix fuel

directly in the Blower’s fuel tank.

5. Follow instructions on 2-cycle oil container for

mixing fuel. Mix gasoline and 2-cycle oil at a ratio

Starting Engine:

B

WARNING

You MUST make sure the tubes are secure before

using the unit.

Cold Starting The Engine

1. Place the Blower on a flat surface.

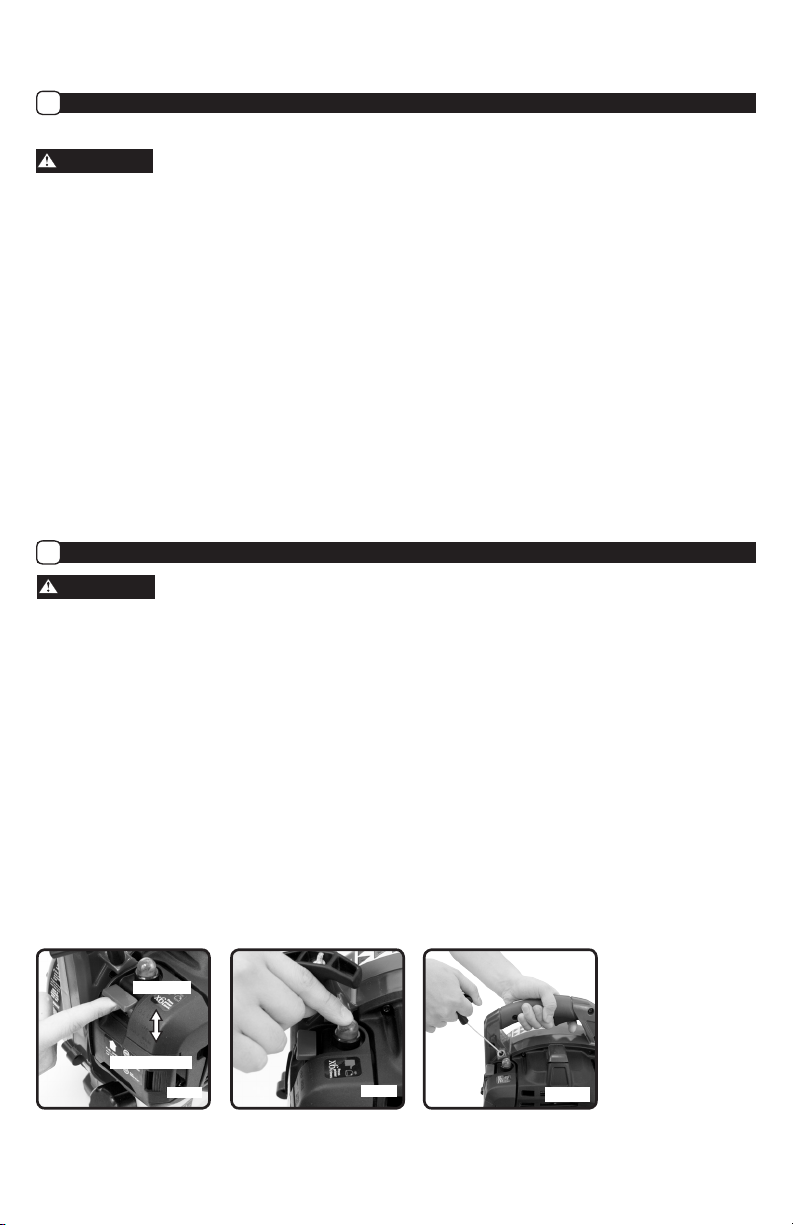

2. Move the Choke Lever upwards to the “COLD

START” position (Fig. 7).

3. Press the Primer Bulb slowly 6 times or until bulb

fills with fuel (Fig. 8).

4. Pull the recoil starter handle sharply while

squeezing throttle lever until the engine starts and

runs. If engine fails to start after 4 pulls, move choke

lever to HALF CHOKE position and retry. (Fig. 9)

5. After engine starts, move choke lever to “HALF CHOKE” position, release throttle and engine will idle

and warm up. After approximately one minute,

squeeze throttle lever to full speed position and

move choke to “RUN/WARM START” position.

of 50:1. A mixture with a 50:1 ratio is obtained by

mixing 1 gallon (4 liters) of gasoline with 2.6 ounces

of oil (77 ml). After adding oil to gasoline, shake

container momentarily to ensure proper mixing.

6. Mix only enough fuel for your immediate needs.

Do not store pre-mixed fuel.

7. Stop engine and allow to cool before refueling.

8. To fill the Blower’s fuel tank with the gasoline/ oil

mixture, place the Blower upright on the ground

or on a sturdy bench and wipe any debris

from around the fuel cap.

9. Remove fuel cap slowly and use a funnel to pour the

mixture into the tank, and replace the fuel cap.

10. Avoid spilling fuel or oil. Wipe up all fuel spills.

11. Move at least 10 feet (3 meters) away from fueling

site before starting engine.

NOTE: When the weather gets cold, please allow the

engine to warm up at idle for longer period of time, (up

to 3 minutes) before engaging to “RUN/WARM

START” position.

Warm Starting The Engine

1. Place the Blower on a flat surface.

2. With the Choke Lever in the “RUN/WARM START”

position, pull the Recoil Starter Handle sharply until

the engine starts and runs.

COLD START

RUN/WARM START

Fig. 7

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2015 MAT Engine Technologies, LLC

Fig. 8

ENG - 7

Fig. 9

Operation (Continued)

• Save all instructions

Starting Engine:

B

Starting A Flooded Engine

1. Place the Blower on a flat surface.

2. With the Choke Lever in the “RUN/WARM START”

position, hold the Throttle Lever fully depressed and

pull the starter handle repeatedly until engine starts

and runs. This could require pulling the starter handle

many times, depending on how badly the unit is flooded.

3. If the engine still does not start, allow the unit to sit

for about 30 minutes, and repeat steps 1-3.

If the unit still doesn’t start, refer to the

TROUBLESHOOTING section of this manual or:

Stopping the Blower:

C

1. Release the Throttle Lever and allow the engine to idle for a few moments.

2. Move the Ignition Switch to the “STOP” position.

If you need assistance or have any

questions, CALL TOLL FREE: 1-800-737-2112

Routine Maintenance

• Save all instructions

WARNING

Disconnect the spark plug before performing maintenance except for carburetor adjustments.

Air Filter:

A

Accumulated debris and dust in the air filter will reduce engine performance, increase fuel consumption, and

increases the risk of engine damage. Clean the air filter every 5 hours of operation.

1. Before removing Air Filter Cover, brush away any

loose dirt or debris on and around the filter cover.

2. To remove Air Filter Cover, press on its sides and lift off

(Fig. 10).

3. Remove and clean foam filter.

• Light surface dust can readily be removed by

tapping the filter.

• Heavy deposits should be washed out in soap and

water. Squeeze out any remaining water and allow

the filter to completely dry.

WARNING

Never clean filter in gasoline or other flammable solvents.

4. Add a drop of thin oil to the filter and replace it.

Fig. 10

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2015 MAT Engine Technologies, LLC

ENG - 8

Routine Maintenance (Continued)

• Save all instructions

Spark Plug:

B

Inspect the spark plug after every 10-15 hours of use; adjust spark plug gap and replace spark plug as necessary.

Replace spark plug every year to maintain engine performance and easy starting.

To inspect or replace the Spark Plug:

1. Remove the insulated spark plug boot.

2. Use the spark plug wrench to remove the Spark

Plug, by turning counter-clockwise.

3. Clean and adjust the spark plug gap to 0.024 –

0.028 in. (0.6 - 0.7mm).

4. Replace any worn plug with a recommended

replacement (see PRODUCT SPECIFICATIONS).

5. Install the Spark Plug finger tight in the cylinder

head, then tighten firmly with the spark plug wrench.

6. Replace the insulated spark plug boot.

Storage

1. Allow engine to cool and empty the fuel tank before

storing or transporting in vehicle. Use up remaining

fuel in the carburetor by starting the engine and

letting it run until it stops. Push primer until no more

fuel is in the fuel line.

2. When not in use, store Blower indoors in a dry

location. Store Blower above the reach of children or

in a locked area out of the reach of children.

3. Store unit and fuel in area where fuel vapors cannot

reach sparks or open flames from water heaters,

electric motors or switches, furnaces, etc.

NOTE: To prevent fuel gum deposits in the Blowers carburetor and fuel system, it is acceptable to use fuel conditioner.

Follow the conditioner manufacturer’s instructions. Run the engine at least 5 minutes after adding conditioner.

4. When preparing the Blower for storage or when

Blower will not be used for 30 days or more:

a. Inspect and clean the Blower thoroughly.

b. Lightly oil all external metal surfaces.

c. Remove the spark plug, place a few drops

of 2-cycle engine oil into the cylinder. Pull the

recoil starter several times to distribute the oil.

Replace the spark plug.

d. Inspect and clean air filter as required.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2015 MAT Engine Technologies, LLC

ENG - 9

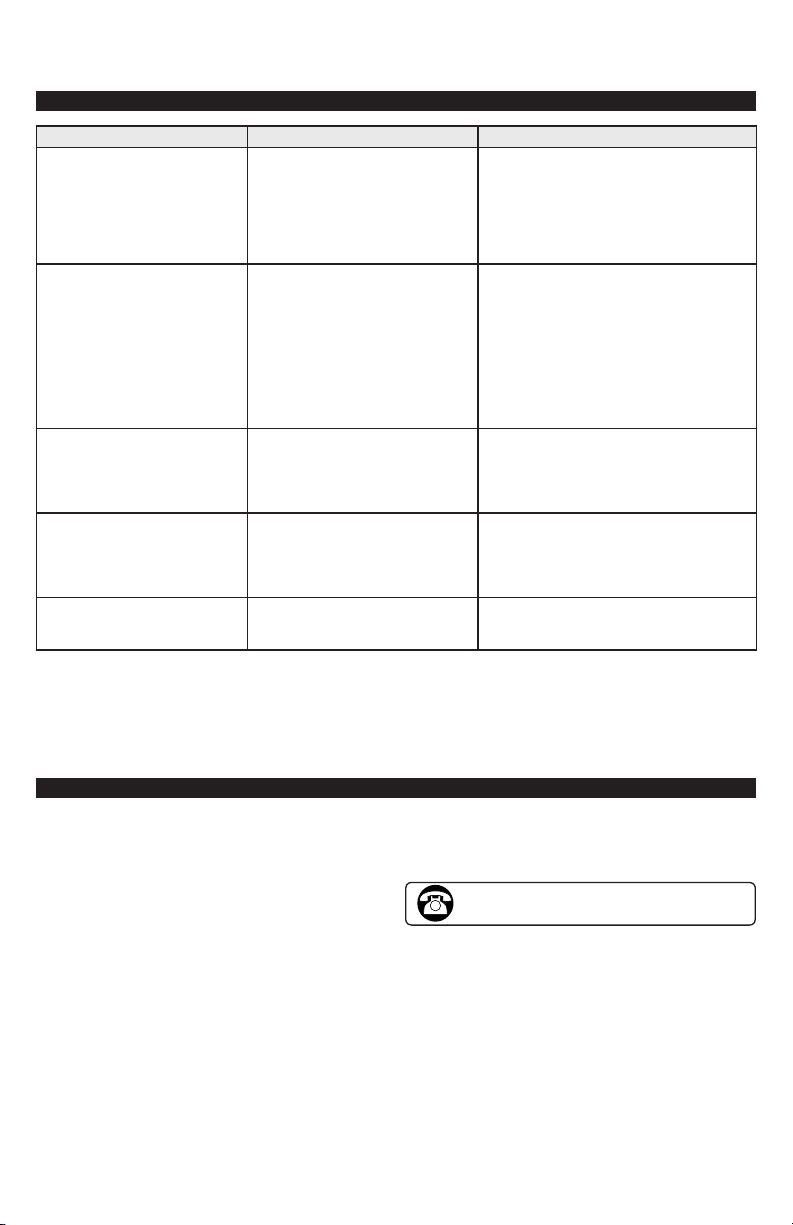

Troubleshooting

• Save all instructions

PROBLEM POSSIBLE CAUSE(S) SOLUTION(S)

Engine will not start. 1. Engine flooded.

Engine will not accelerate, lacks

power or stalls.

Engine smokes excessively. 1.

Engine runs hot. 1. Fuel mixture incorrect.

Engine will not idle properly. 1. Carburetor requires adjustment.

2. Fuel Tank empty.

3. Spark Plug not firing.

4. Fuel not reaching carburetor.

5. Carburetor requires adjustment.

1. Engine has not reached operating

temperature.

2. Choke lever in the “cold start” position.

3.

Fuel not reaching carburetor.

4. Air filter dirty.

5. Spark plug fouled.

6. Carburetor requires adjustment.

7. Carbon build-up on muffler outlet

screen.

8. Compression low.

Choke lever in the “cold start” position.

2. Fuel mixture incorrect.

3. Air filter dirty.

4. Carburetor requires adjustment.

2. Spark Plug incorrect.

3. Carburetor requires adjustment.

4. Carbon build-up on muffler outlet

screen.

2. Crankshaft seals worn.

3. Compression low.

1. See Starting a Flooded Engine in

OPERATION section.

2. Fill tank with correct fuel mixture.

3. Replace Spark Plug.

4. Check for kinked or split fuel line; repair or

replace. Check fuel filter.

5. Contact a qualified service center.

1.

Allow engine to idle and warm up until full

operating speed can be attained.

2. Move choke lever to the “warm start/run” position.

3.

Check for kinked or split fuel line; repair or

replace.

4. Clean air filter.

5. Clean or replace plug

6. Contact a qualified service center.

7. Contact a qualified service center.

8. Contact a qualified service center.

1.

Move choke lever to the “warm start/run” position.

2. Empty Fuel Tank and refill with correct fuel

mixture.

3. Clean or replace air filter.

4. Contact a qualified service center.

1. See Mixing Fuel with 2-Cycle Oil in

OPERATION section.

2. Replace with correct Spark Plug.

3. Contact a qualified service center.

4. Contact a qualified service center.

1. Contact a qualified service center.

2. Contact a qualified service center.

3. Contact a qualified service center.

Technical Service

You may have further questions about assembling, operating, or maintaining this Blower. If so, you can contact our

Technical Service Department at 1-800-737-2112 (English only).

You may also write to:

CORRESPONDENCE ONLY:

MAT Engine Technologies, LLC

ATTN: Technical Service – METL

6700 Wildlife Way

Long Grove, IL 60047

When contacting the Technical Service Department,

have ready:

• Your Name

• Your Address

• Your Phone Number

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2015 MAT Engine Technologies, LLC

ENG - 10

If you need assistance or have any questions,

CALL TOLL FREE: 1-800-737-2112

• Model Number of Product

• Date of Purchase (include copy of receipt for written requests)

Warranty

• Save all instructions

Southland® Blower Limited Warranty

A

Always specify model number when contacting the factory.

We reserve the right to amend these specifications at any time without notice. The only warranty applicable is our standard written

warranty. We make no other warranty, expressed or implied. MAT Engine Technologies, LLC warrants this Blower and any parts

thereof, to be free from defects in material and workmanship for one year (90 days for reconditioned unit) from the date of first

purchase from an authorized dealer, provided that the product has been properly maintained and operated in accordance with all

applicable instructions. This warranty is extended only to the original retail purchaser. The bill of sales or proof of purchase must

be presented at the time a claim is made under this warranty. This warranty does not cover commercial, industrial, or rental usage,

nor does it apply to parts that are not in original condition because of normal wear and tear, or parts that fail or become damaged

as a result of misuse, accident, lack of proper maintenance, tampering, or alteration. Travel, handling, transportation, and

incidental costs associated with warranty repairs are not reimbursable under this warranty and are the responsibility of the owner.

To the full extent allowed by the law of the jurisdiction that governs the sale of the product, this express warranty excludes any

and all other expressed warranties and limits the duration of any and all implied warranties, including warranties of merchantability

and fitness for a particular purpose to one year from the date of first purchase, and MAT Engine Technologies, LLC’s liability is

hereby limited to the purchase price of the product and MAT Engine Technologies, LLC shall not be liable for any other damages

whatsoever including indirect, incidental, or consequential damages. Some states / provinces do not allow limitation of how long

an implied warranty lasts or an exclusion or limitation of incidental or consequential damages, so the above limitation of damages

may not apply to you. This warranty provides the original purchaser with specific rights.

For information regarding those rights, please consult the applicable state / provincial laws.

MAT Engine Technologies, LLC

ATTN: Technical Service – METL

6700 Wildlife Way

Long Grove, IL 60047

1-800-737-2112

Federal and California Emissions Control Warranty Statement

B

This MAT Engine Technologies, LLC (

Southland® Model No. Regulatory Agency

SHB25170.1

To the extent there is any conflict between this Emissions Control Warranty and the

Warranty shall apply except where the

Please read your warranty rights and obligations carefully. Some sections of the warranty may not apply to the specific

model you purchased. Unless specifically noted otherwise, the terms below shall apply to all Southland® products

covered within this manual.

State of California:

The California Air Resources Board and MAT Engine Technologies, LLC (METL) are pleased to explain the emissions

control system’s warranty on your small off-road engine (SORE). In California, new SOREs must be designed, built and

equipped to meet the State’s stringent anti-smog standards. METL must warrant the emissions control system on your SOREs

for the periods of time listed below provided there has been no abuse, neglect or improper maintenance of your SOREs.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2015 MAT Engine Technologies, LLC

METL

) outdoor power equipment engine complies with the emissions regulations of:

United States Environmental Protection Agency (“U.S. EPA”) and the State of

California

METL

METL

Limited Warranty may provide a longer warranty period.

YOUR WARRANTY RIGHTS AND OBLIGATIONS

Limited Warranty, this Emissions Control

ENG - 11

Warranty (Continued)

• Save all instructions

Other U.S States / Territories:

In other areas of the Unites States, your outdoor power equipment engine must be designed, built and equipped so as to

conform at the time of sale to U.S. EPA emissions standards for small off-road spark ignition engines at or below 19 kilowatts.

All of the United States:

Your emission control system may include parts such as the carburetor or fuel-injection system, fuel lines, the ignition system,

and catalytic converter. Also included may be hoses, belts, clamps, connectors and other emission-related assemblies.

Where a warrantable condition exists, METL will repair your small off-road engine at no cost to you including diagnosis, parts and labor.

Manufacturer’s Warranty Coverage:

The emissions control system is warranted for one year. If any emissions-related part on your engine is defective, the part will

be repaired or replaced by METL.

Owner’s Warranty Responsibilities:

• As the SORE owner, you are responsible for the performance of the required maintenance listed in your proprietor’s manual.

METL recommends that you retain all receipts covering maintenance on your SORE, but METL cannot deny warranty solely

for the lack of receipts or for your failure to ensure the performance of all scheduled maintenance.

• As the SORE owner, you should however be aware that METL may deny your warranty coverage if your SORE or a part has

failed due to abuse, neglect, improper maintenance or unapproved modifications.

• You are responsible for presenting your SORE to a distribution center or service center authorized by METL as soon as the

problem exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty

coverage, you should contact METL customer service:

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2015 MAT Engine Technologies, LLC

ENG - 12

If you need assistance or have any questions,

CALL TOLL FREE: 1-800-737-2112

Warranty (Continued)

• Save all instructions

Defects Warranty Coverage:

METL warrants to the original purchaser and each subsequent purchaser that the small off-road engine (SORE) (1) has been

designed, built and equipped so as to conform with all applicable regulations; and (2) is free from defects in materials and

workmanship that cause the failure of a warranted part to conform with those regulations as may be applicable to the terms

and conditions stated below.

(a) The warranty period begins on the date the engine is first purchased. The warranty period is one year.

(b) Subject to certain conditions and exclusions as stated below, the warranty on emissions related parts is as follows:

(1) Any warranted part that is not scheduled for replacement as required maintenance in your Operator’s Manual is

warranted for the warranty period stated above. If the part fails during the period of warranty coverage, the part will

be repaired or replaced by METL according to Subsection (4) below. Any such part repaired or replaced under

warranty will be warranted for the remainder of the period.

(2) Any warranted part that is scheduled only for regular inspection in your Operator’s Manual is warranted for the

warranty period stated above. Any such part repaired or replaced under warranty will be warranted for the remaining

warranty period.

(3) Any warranted part that is scheduled for replacement as required maintenance in your Operator’s Manual is

warranted for the period of time before the first scheduled replacement date for that part. If the part fails before the

first scheduled replacement, the part will be repaired or replaced by METL according to Subsection (4) below.

Any such part repaired or replaced under warranty will be warranted for the remainder of the period prior to the first

scheduled replacement point for the part.

(4) Repair or replacement of any warranted part under the warranty provisions herein must be performed at a

warranty station at no charge to the owner.

(5) Notwithstanding the provisions herein, warranty services or repair will be provided at all of our distribution centers

that are franchised to service the subject engines.

(6) The engine owner must not be charged for diagnostic labor that leads to the determination that a warranted part is

in fact defective, provided that such diagnostic work is performed at a warranty station.

(7) METL is liable for damages to other engine components proximately caused by a failure under warranty of any

warranted part.

(8) Throughout the engine warranty period stated above, METL will maintain a supply of warranted parts sufficient to

meet the expected demand for such parts.

(9) Any replacement part may be used in the performance of any warranty maintenance or repairs and must be

provided without charge to the owner. Such use will not reduce the warranty obligations of METL.

(10) Add-on or modified parts that are not exempted by the California Air Resources Board may not be used. The use of

any non-exempted add-on or modified parts by the original or subsequent purchaser will be grounds for disallowing

a warranty claims. METL will not be liable to warrant failures of warranted parts caused by the use of a non-

exempted add-on or modified part.

(11) The manufacturer issuing the warranty shall provide any documents that describe that warranty procedures or

policies within five working days or requested by the California Air Resources Board.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2015 MAT Engine Technologies, LLC

ENG - 13

Warranty (Continued)

• Save all instructions

Emission Warranty Parts List:

The repair or replacement of any warranted part otherwise eligible for warranty coverage may be excluded from such warranty

coverage if METL demonstrates that the engine has been abused, neglected, or improperly maintained, and that such abuse,

neglect, or improper maintenance was the direct cause of the need for repair or replacement of the part. That notwithstanding,

any adjustment of a component that has a factory installed, and properly operating, adjustment limiting device is still eligible

for warranty coverage. The following emissions warranty parts list is covered.

(1) Fuel Metering System:

(a) Gasoline carburetor assembly and its internal

components (if so equipped)

(b) Fuel filter (if so equipped)

(c) Carburetor gaskets

(d) Fuel pump (if so equipped)

(2) Air Induction System including:

(a) Intake pipe/manifold

(b) Air cleaner

(3) Ignition System including:

(a) Spark plug

(b) Ignition module/coil

(4) Catalytic Muffler Assembly (if so equipped) including:

(a) Muffler gasket

(b) Exhaust manifold

(5) Crankcase Breather Assembly including:

(a) Breather connection tube.

(6) Miscellaneous items Used in Above Systems including:

(a) Switches

(b) Hoses, belts, connectors, and assemblies.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2015 MAT Engine Technologies, LLC

ENG - 14

Warranty (Continued)

• Save all instructions

California Evaporative Emission Control Warranty Statement

C

YOUR WARRANTY RIGHTS AND OBLIGATIONS

Applies to Model SHB25170.1:

The California Air Resources Board and METL are pleased to explain the evaporative emission control system’s warranty

on your small off-road engine (SORE). In California, new SOREs must be designed, built and equipped to meet the State’s

stringent anti-smog standards. METL must warrant the evaporative emission control system on your SOREs for the period of

time listed below provided there has been no abuse, neglect or improper maintenance of your SOREs.

Your evaporative emission control system may include parts such as: carburetors, fuel tanks, fuel lines, fuel caps, valves,

canisters, filters, vapor hoses, clamps, connectors, and other associated components.

Manufacturer’s Warranty Coverage:

This evaporative emission control system is warranted for one year. If any evaporative emission-related part on your

equipment is defective, the part will be repaired or replaced by METL.

Owner’s Warranty Responsibilities:

• As the SORE owner, you are responsible for performance of the required maintenance listed in your proprietor’s manual.

METL recommends that you retain all receipts covering maintenance on your SOREs, but METL cannot deny warranty solely

for the lack of receipts.

• As the SORE owner, you should however be aware that METL may deny you warranty coverage if your SOREs or a part

have failed due to abuse, neglect, or improper maintenance or unapproved modifications.

• You are responsible for presenting your SOREs to distribution center or service center authorized by METL as soon as the

problem exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty coverage,

you should contact METL customer service:

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2015 MAT Engine Technologies, LLC

ENG - 15

If you need assistance or have any questions,

CALL TOLL FREE: 1-800-737-2112

Loading...

Loading...