Southland SELS60 User Manual

Operator’s Manual

6 TON ELECTRIC

LOG SPLITTER

Look inside for:

Page

Safety Definitions ............................2

Important Safety Information ..................3-5

Product Specifications ........................6

Controls & Features ..........................6

Safety Decals ...............................7

Assembly ..................................8

Preparation for Operation......................8

Operation ..................................9

Maintenance..............................10-11

Transporting ............................... 11

Troubleshooting ............................ 12

Technical Service ........................... 12

Slope Guide ............................... 13

Warranty ................................. 14

Record the following for future reference:

Mfg. date code: __________________

Date of purchase: ________ Attach a copy of your sales receipt.

Consumer toll free number: 1-800-737-2112

Model No. SELS60

Refer to the website for electronic manual and parts book.

www.southlandpowerequipment.com

IMPORTANT:

Thank you for purchasing this Southland® Log Splitter. This manual provides complete instructions for

safely operating and maintaining your Log Splitter. Read and save these instructions. Refer to this manual each time before

using your Log Splitter.

WARNING: CONTAINS LEAD. May be harmful if eaten or chewed. May generate dust containing lead. Wash hands after use.

Keep out of reach of children.

WARNING: This product can expose you to chemicals including lead, which is known to the State of California to cause can-

cer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

If you need assistance or have any questions,

CALL TOLL FREE: 1-800-737-2112

KEEP THIS MANUAL FOR FUTURE REFERENCE

07/12/2018 Printed in China A203548

Safety Definitions

• Save all instructions

Safety Alert Symbols:

The symbols below identify important safety information in this manual. Become familiar with these symbols

and the warnings associated with them.

DANGER

WARNING

CAUTION

NOTICE

Safety Warning Symbols:

The following symbols can be found on your Log Splitter. Carefully read and understand their meaning.

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

Indicates a practice not related to personal injury which, if not avoided, may result in

property damage.

Look for this symbol to point out important safety precautions. It means: Attention! Become

Alert! Your Safety Is Involved.

Read, understand and follow operator’s manual before operating this machine. Failure to

follow directions could result in serious injury.

Electric shock hazard! Disconnect electrical power before making adjustments, or performing

maintenance on Log Splitter.

Electric shock hazard! Do not use in wet or rainy conditions. Use only approved outdoor

extension cords with a grounding pin.

Keep bystanders, pets and children at least 10 feet away from the machine while it is in

operation. Stop machine if anyone enters the area.

Avoid hand injury! Keep hands away from wedge, ram and other moving parts.

Check for hydraulic fluid leaks by passing a piece of paper or cardboard underneath or over the

area of the leak. Do not check for leaks with your hand. Fluid escaping from the smallest hole,

under pressure, can have enough force to penetrate the skin resulting in tissue damage and

cause serious injury or death.

Do not operate or transport the Log Splitter on slopes greater than 5 degrees. Block wheels to

prevent movement.

Hydraulic cylinder and other components can become very hot. Avoid contact. Wear gloves

when operating Log Splitter.

Personal Safety Symbols:

Wear heavy-duty protective gloves when operating this product.

Wear eye and ear protection complying with ANSI Z87.1.

Wear protective footwear when operating this product.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

Important Safety Information

• Save all instructions

Responsibility of Operator:

1. Carefully read and follow these safety instructions. Failure to do so can result in serious injury.

2.

Know your product. Read and understand this manual before use. Compare the illustrations to machine.

Learn location and function of all controls. Thoroughly understanding the unit before use will result in the

best performance and safety.

3. Follow all instructions when assembling the unit. If the unit was purchased in assembled condition, the

operator must check the machine carefully to make sure it was assembled according the instructions in the

manual before use.

4. Regularly inspect the Log Splitter. Make sure parts are not bent, damaged, or loose.

5. Use this equipment for its intended purpose only. The intended purpose is to split wood for use in replaces.

6. Operate the machine only with guards, shields, and other safety items in place and working correctly.

7. Service the machine only with authorized or approved replacement parts.

8. Complete all unit maintenance and adjustments according to the instructions in this manual.

- Look for this symbol on your Log Splitter to point out important safety precautions.

It means: “ Attention! Become Alert! Your Safety Is Involved.”

WARNING

Do not use Log Splitter in wet or in rainy conditions due to risk of electrical hazard. Electrical shock may result.

WARNING

The Log Splitter is capable of amputating or crushing hands and ngers. Read and follow all warnings and

safety instructions on the Log Splitter and in this manual. Failure to do so can result in serious injury or death to

you or bystanders.

WARNING

In order to avoid electrical or crushing hazard when setting up, transporting, adjusting or making repairs,

always disconnect plug from electrical source.

Training Safety:

1. Read, understand and follow the operating and service instruction manual carefully. Be thoroughly familiar

with the controls and the proper use of the equipment. Know how to stop the machine and disengage the

controls quickly.

2. Never allow children to operate the equipment. Never allow adults to operate the equipment without

proper instruction.

3. Keep bystanders, pets and children at least 10 feet (3 m) from the machine while it is in operation. Stop

the machine if anyone enters the area.

4. Keep in mind that the operator or user is responsible for accidents or hazards occurring to other people,

their property and themselves.

Preparation Safety:

1. Thoroughly inspect the area where the Log Splitter is to be used and remove all foreign objects.

2. Operate only on level ground to ensure machine stability. Do not operate or transport Log Splitter on

slopes greater than 5 degrees. It is recommended that the Log Splitter be placed on a stable, flat and level

work platform approximately 24-30 inches high. Always use two adults to lift the unit.

3. Do not operate the equipment without wearing adequate outer garments and safety goggles. Avoid

loose-fitting clothes or jewelry and use protective footwear that will improve footing on slippery surfaces.

Wear leather work gloves. Wear protective hair covering to contain long hair, preventing it from getting

caught in the Log Splitter.

4. During operation, foreign objects can be ejected and can result is severe eye damage. Always wear safety

glasses with side shields or safety goggles during operation and while performing an adjustment or repair.

Always use eye protection which is marked to comply with ANSI Z87.1.

5. Never use in an explosive atmosphere. Normal sparking of the motor could ignite fumes or flammable dust.

6. Never attempt to make any adjustments while the motor is connected to an electrical source.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

Important Safety Information (Continued)

• Save all instructions

Hydraulic Safety:

WARNING

Hydraulic fluid may be under high pressure or may be hot and can cause personal injury. Read, understand and

follow the following safety precautions.

1. The hydraulic system of the Log Splitter requires careful inspection. Wear eye protection and gloves prior

to inspection.

2. Hydraulic uid may be under high pressure or may be hot and can cause personal injury.

3. Escaping hydraulic uid can create a re hazard and ignite if exposed to an ignition source.

4. Check for hydraulic uid leaks by passing a piece of paper or cardboard underneath or over the area of

the leak.

5. Do NOT check for leaks with your hand.

6. Fluid escaping from the smallest hole, under pressure, can have enough force to penetrate the skin resulting

in tissue damage and cause serious injury or death. Machine operation should stop until any detected leak

is repaired.

7. Seek professional medical attention IMMEDIATELY if injured by escaping hydraulic uid. Serious infection or

reaction can develop if medical treatment is not administered immediately.

8. Do NOT adjust the hydraulic valve. The pressure relief valve on the Log Splitter is preset at the factory. Only

a qualied service technician should perform this adjust.

Electrical Safety:

Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole receptacles that accept the Log

Splitter’s plug. When using the Log Splitter at a considerable distance from the power source, use an extension

cord heavy enough to carry the electrical current that the Log Splitter will draw. An undersized extension

cord will cause a drop in line voltage, resulting in a loss of power and causing the motor to overheat. Use the

information provided below to determine the minimum wire size required in an extension cord. Only round

jacketed cords listed by Underwriter’s Laboratories (UL) should be used. Only use extension cords of 50 feet

or less.

Cord Length In Feet Minimum Wire Size (A.W.G.)*

25’ ..............................................................................................................................................................14 gauge

50’ ..............................................................................................................................................................12 gauge

*A.W.G. = American Wire Gauge

When working with the tool outdoors, use an extension cord that is designed for outside use. This is indicated

by the letters WA (weather approved) on the cord’s jacket. Before using an extension cord, inspect it for loose

or exposed wires and cut or worn insulation.

WARNING

Keep the extension cord clear of the working area. Position the cord so that it will not get caught on lumber, Log

Splitter or other obstructions. Failure to do so can result in serious personal injury.

WARNING

Check extension cords before each use. If damaged, replace immediately. Never use the Log Splitter with a damaged

cord. Touching the damaged area could cause electrical shock resulting in serious injury.

Electrical Connection:

This Log Splitter is powered by a precision built electric motor. It should be connected to a power supply that is

120 volts, 60 hz, AC only (normal household current). Do not operate this tool on direct current (DC). The power

supply circuit must be a 12 gauge wire - 20 amp circuit.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

Important Safety Information (Continued)

• Save all instructions

Grounding Instructions:

This tool is equipped with an electric cord having an equipment-grounding conductor and a grounding plug. The plug

must be plugged into a matching outlet that is properly installed and grounded in accordance with all local codes and

ordinances. Do not modify the plug provided. If it will not t the outlet, have the proper outlet installed by a

qualied electrician. Improper connection of the equipment-grounding conductor can result in a risk of electric

shock. The conductor with insulation having an outer surface that is green with or without yellow stripes is the

equipment-grounding conductor. If repair or replacement of the electric cord or plug is necessary, do not

connect the equipment-grounding conductor to a live terminal. Check with a qualied electrician or service

personnel if the grounding instructions are not completely understood, or if in doubt as to whether the tool is

properly grounded. Repair or replace a damaged or worn cord immediately.

Operation:

1. Do NOT put hands near moving parts. Contact with the splitting wedge can amputate ngers and hands.

2. Never allow bystanders within 10 feet of the machine while running. Keep children and pets away.

3. Never operate the machine without proper guards, plates or other safety protective devices in place.

4. Keep your hand away from splits that occur during the splitting operation. These may close suddenly and

crush or amputate fingers and hands. Do not remove jammed logs with your hands.

5. Exercise caution to avoid slipping or falling. Maintain a work space clean of wood and debris.

6. Stop motor and disconnect from electric power source when leaving the operating position, and when

making any repairs, adjustments and inspections.

7. Take all possible precautions as recommended by the manufacturer when leaving the machine unattended.

Stop the engine, do not leave the unit unattended until all moving parts have come to a complete stop.

8. Do not overload the machine by attempting to split any material beyond manufacturer’s recommendation.

9. Use only attachments and accessories approved by the manufacturer of the machine.

10. Never operate the machine without good visibility or light. Do not operate at night.

11. Do not operate the machine while under the influence of alcohol or any drugs that can affect your ability to

safely operate the splitter.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

Specifications

• Save all instructions

Unit Weight ............................................105 lbs (48 kg)

Ram Force ........................................................... 6 Ton

Cycle Time ................................................. 18 Seconds

Wedge Size .............................. 5 Inch Hardened Steel

Gear Pump ................................................ Singe Stage

Max Log Length......................................... 20.5 Inches

Max Log Diameter ....................................... 10 Inches*

Electrical Requirement ....................... 120V AC - 60Hz

Hydraulic Oil Type ......... Shell Tellus 22, Mobil DTE10,

ARAL Vitam GF 22, BP Energol HLP-HM22

Hydraulic Fluid Max ............... Approximately 3.5 Liters

Max Hydraulic Pressure ................................ 3480 PSI

Ambient Operating Temperatures ...............14° - 100°F

(-10° to 38°C)

* Maximum Log Diameter is an approximate. Actual maximum log diameter is dependent upon log shape,

consistency, wood type and internal moisture.

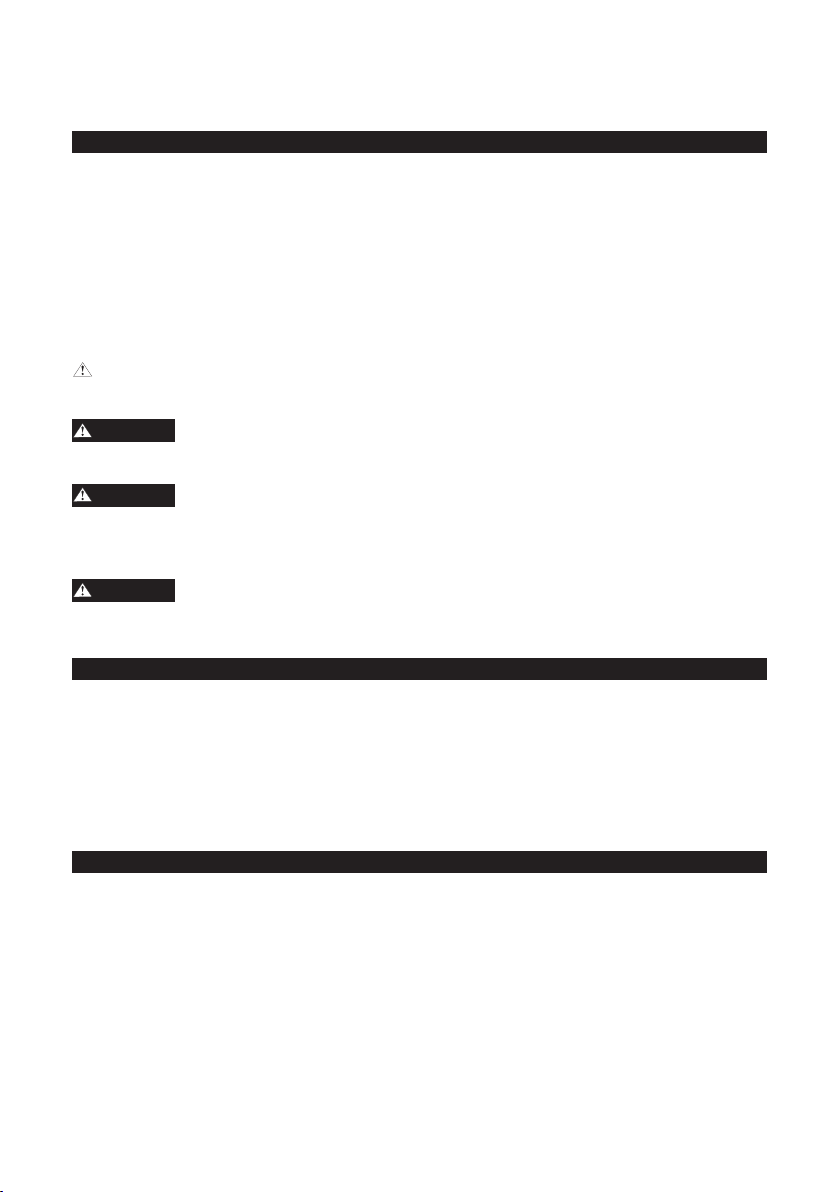

Controls & Features

Read, understand and follow this owner’s manual

before operating the equipment. Familiarize yourself

with the location and function of the controls and

features. (Fig 1)

1. Motor Switch - Depress switch to electrically

activate the electric motor. Upon release, the

switch will return to an off position.

2. Hydraulic Control Lever - Controls the forward

and backward movement of ram.

3. 5 Inch Wedge - Splits and separates the log.

4. Ram - Pushes the log into the wedge.

5. Vent Screw - Loosen to prevent buildup of

internal air pressure. Tighten after use and

when moving to prevent leakage.

6. Hydraulic Pump - Pumps the hydraulic oil

through the system.

7. Support Leg - Supports the Log Splitter

while operating.

8. Handles - For moving the Log Splitter.

9. Oil Drain and Fill Port - For adding or removing

hydraulic fluid.

10. Reset Button - Detects overload and disables

motor. Push to reset.

11. Stroke Limiter - Reduces the return stroke for use

with shorter logs.

12. Pressure Limiting Screw - Factory set. Do NOT

adjust.

12

2

1

4

7

9

3

10

6

11

8

5

Fig 1

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

Safety Decals

NOTICE

• Save all instructions

This Log Splitter has been designed and manufactured to provide you with the safety and reliability you would

expect from an industry leader in outdoor power equipment manufacturing.

Although reading this manual and the safety instructions it contains will provide you with the necessary basic

knowledge to operate this equipment safely and effectively, we have placed several safety labels on the

Log Splitter. This is to help remind you of the important information and warn you of specific hazards while

operating the machine.

These important safety labels are illustrated below, and are shown here to help familiarize you with the

location and content to the safety messages you will see as you perform normal splitting operations.

Please review these labels now. If you have any questions regarding their meaning or how to comply with

these instructions, reread the “Important Safety Information” sections or contact your local dealer.

Should any of the safety labels become unreadable because of being worn, faded or otherwise damaged

during the use of your Log Splitter, please contact your local authorized dealer to order replacement label. The

safety labels are easily applied, and will act as a constant visual reminder to you and others who may use the

equipment. Following the safety instructions is necessary for safe, effective operation of your Log Splitter.

- Before use, loosen vent screw three turns.

- After use and before moving, retighten vent screw

to avoid leakage.

CRUSH HAZARD

To avoid injury:

Keep arms

and hands

away from

moving parts.

If you need assistance or have any questions,

CALL TOLL FREE: 1-800–737-2112

READ AND FOLLOW

OPERATING INSTRUCTIONS

BEFORE USING LOG SPLITTER.

IMPACT OR PINCH HAZARD

- Keep bystanders at least 10 feet

away.

- Only one person should operate and

load the log splitter, staying within

the designated operating zone.

To Split Wood: Depress motor switch and move control lever downward. Release for return.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

ELECTRIC

SHOCK

HAZARD

- Disconnect from

power before

servicing.

- Do not use in

wet or damp

conditions.

Assembly

• Save all instructions

Unpacking Instructions:

CAUTION

Read, understand and follow all instructions for assembly and operation. Failure to properly assemble this

equipment could result in serious injury to the user or bystanders, or cause equipment damage.

Set the shipping crate on a solid, flat surface and carefully remove the lid. Use two adults and take all parts

out of the shipping crate and inspect the components to ensure there are no missing pieces before starting to

assemble the Log Splitter.

Carton Contents:

• Frame assembly

• (2) Wheel assemblies

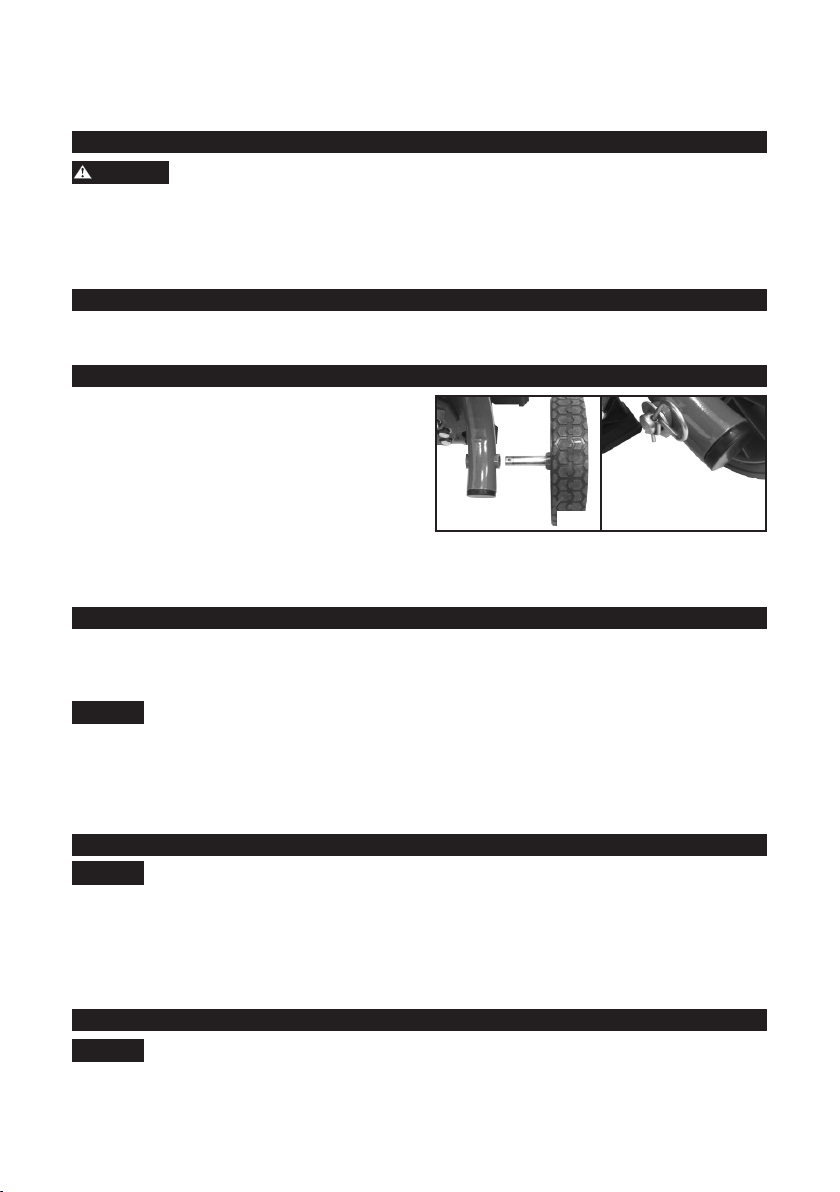

Wheel Assembly:

1. Insert wheel pin through wheel, washer, tube

bushing and secure with hairpin cotter.

Repeat for second wheel. (Fig 2-3)

2. Insert hub cap by pressing into wheel until it

is secured.

• Hardware pack

• Owner’s manual

• (2) Hub caps

Fig 2 Fig 3

Preparation for Operation

• Save all instructions

Before Using the Log Splitter:

NOTE: Before operating the Log Splitter, the vent screw MUST ALWAYS BE LOOSENED THREE TURNS until air

can move in and out of the oil tank smoothly. Air flow through the vent screw hole should be detectable during

log splitter operations. Before moving the Log Splitter, make sure the vent screw is tightened to avoid oil leakage.

NOTICE

Failure to loosen the vent screw will keep the air inside the hydraulic reservoir sealed and it will be compressed.

This compressed air will damage the seals of the hydraulic system and may cause permanent damage to the

Log Splitter.

Assure the power cord is routed away from all moving parts and sharp edges and is not under the support legs

of the Log Splitter.

Checking Hydraulic Fluid Level:

NOTICE

The Log Splitter is filled with hydraulic fluid at the factory, but check the level prior to each use.

1. Make sure the Log Splitter is unplugged.

2. Using the handle, stand the Log Splitter on

the end near the wheels.

3. Unscrew oil drain bolt with dipstick to

remove it, wipe clean and reinsert the bolt

with dipstick.

Maximum Pressure Limiting Screw:

4. Remove the dipstick and check to see if the

oil is between the two grooves.

5. If additional fluid is required, fill with fresh

hydraulic oil until the level is between the

two grooves of the dipstick.

6. Replace and tighten the dipstick bolt.

NOTICE

Do NOT adjust the maximum pressure limiting screw. The maximum pressure was set at the factory by

qualified mechanics using professional instruments. Unauthorized resetting may result in serious injury or

damage to the Log Splitter.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

Operation

• Save all instructions

Controlling the Log Splitter:

NOTE: The operator zone is when the operator is positioned at the rear of the Log Splitter near the control lever.

This Log Splitter is equipped with a control system that requires use of both hands of the operator. The left

hand controls the hydraulic control lever while the right hand controls the push button on/off switch. The Log

Splitter will not operate if either control is not simultaneously engaged. Only after the hydraulic control lever is

released will the log ram return backward to the starting position.

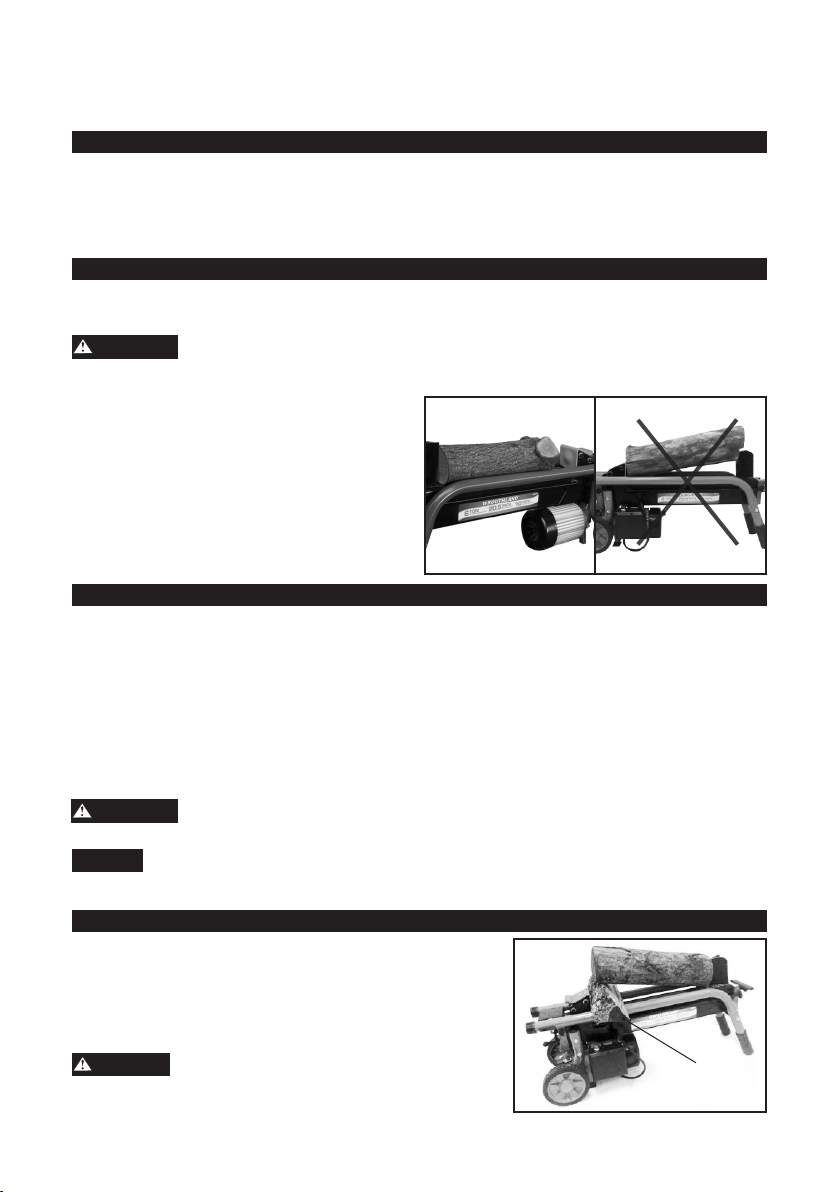

Splitting Wood:

Place the log lengthwise on the Log Splitter and split in the direction of the grain. Using the right hand, push

down and hold the push button on/off switch. Using the left hand, push down and hold the hydraulic control

lever. Once the wood is split, release both controls. The ram will auto return to the starting position. (Fig 4)

WARNING

Impact Hazard! Log may suddenly split and eject. Stay clear of the projected wood.

If the Log Splitter stalls while trying to split a log, retract

the ram, rotate the log by 90o to see whether it can be

split in a different direction. If you are not able to split

the log, this means that its hardness or structure

exceeds the capacity of the machine and the log

should be discarded.

Always set the log rmly on the log retaining tubes and

log cradle. Make sure the log does not twist, rock or slip

while being split. Do not elevate the log on the wedge.

This may result in machine damage. (Fig 5)

Use of the Stroke Limiter:

Split the log in the direction of its grain. Do not place log across the Log Splitter for splitting. It may be

dangerous and may seriously damage the machine. Do not attempt to split 2 pieces of logs at the same time.

If the wood to be split is consistently shorter than 20.5 inches in length, you can use the stroke limiter to

control the starting distance between the ram and the wedge.

To adjust: With the ram fully extended, release the motor switch while continuing to hold down the hydraulic

control lever. Have a second person loosen the adjustable knob and slide the stroke limiter to the desired

postion. With the knob oriented so it faces away from the unit, tighten the knob. Release the hydraulic control

lever only after the second person has secured the knob and moved away from the Log Splitter. The ram will

now stop at a position which requires less travel until it engages the log.

WARNING

Pinch Hazard! Keep hands and finger clear of all moving parts.

NOTICE

At the end of the stroke or if the units stalls, do not continue to engage both controls simultaneously for more

than 5 seconds. After this time interval, the oil will overheat and the machine could be damaged.

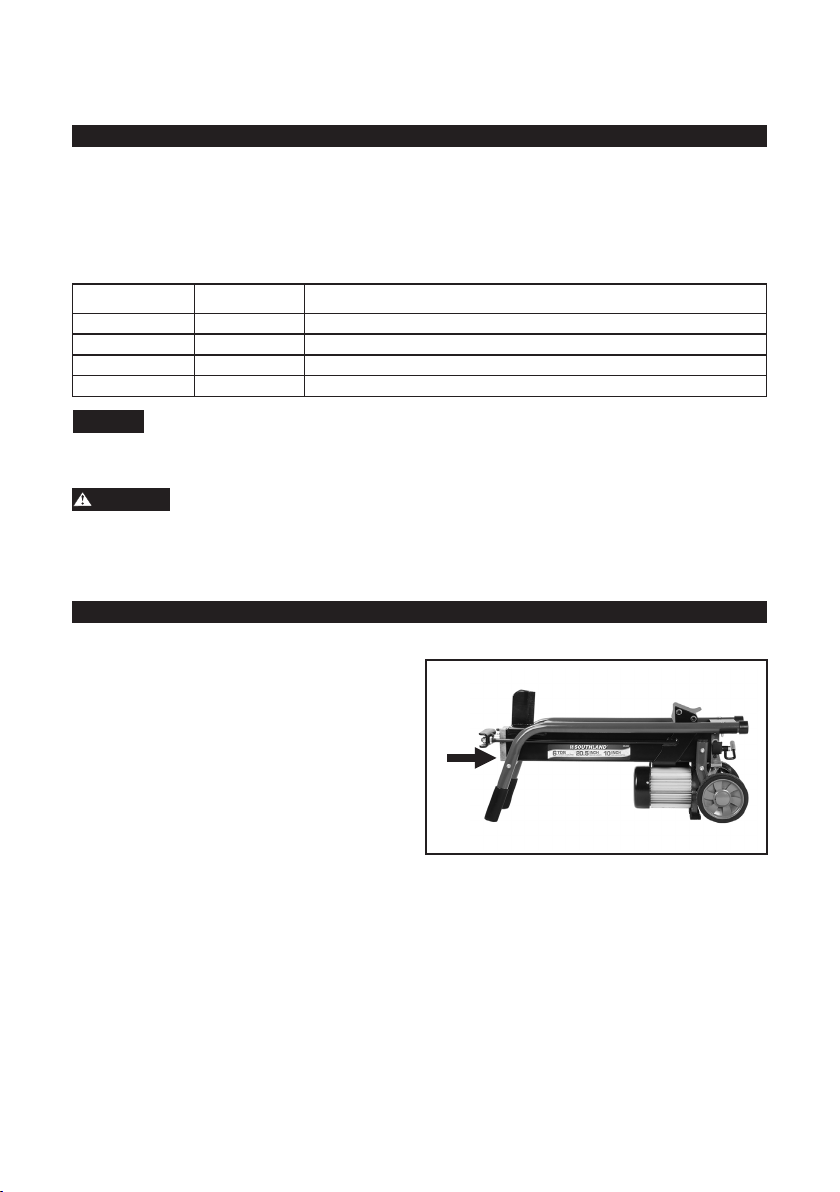

Freeing a Jammed Log:

1. Release both controls.

2. After the ram completely retracts, insert a wood wedge

under the jammed log. (Fig 6)

3. Using the ram, slowly push the wood wedge completely

under the jammed log.

4. Repeat above procedure with sharper slope wedge woods

until the log is completely freed.

CAUTION

The jammed log may suddenly disengage. Maintain a safe distance

away from the log during this operation.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

Correct Incorrect

Fig 4

Wood Wedge

Fig 5

Fig 6

Maintenance

• Save all instructions

Performing Maintenance:

• Before performing maintenance, the Log Splitter must be placed in maintenance mode. Disconnect from

electrical power source and move the control lever forward and backwards to relieve the hydraulic pressure

before performing any maintenance, make sure all guards, shields and safety features are put back in place

before operating the Log Splitter.

• Periodically check all fasteners for tightness and leaks.

• Annually clean and lightly lubricate all moving parts or when needed.

• Use a glossy enamel spray paint to touch up scratched or worn painted metal surfaces.

What When Method

Hydraulic uid Each use Check uid level and add as required.

Nuts and bolts Each use Check for loose bolts, tighten before operating.

Beam Each use Check for debris and freedom of movement.

Moving parts Each use Clear debris from Log Splitter.

NOTICE

If a part needs replacement, only use GENUINE parts that meet the manufacturer’s specications.

Replacement parts that do not meet specications may result in a safety hazard or poor operations.

CAUTION

• Always wear safety glasses with side shields or goggles marked to comply with ANSI Z87.1 prior to

performing maintenance.

• Wear nitrile gloves prior to performing maintenance involving hydraulic oil.

• When performing maintenance, if it is necessary to lift the unit, use two adults.

Replacing Hydraulic Oil:

NOTE: Replace the hydraulic oil in the Log Splitter after every 150 hours of use. Take following steps to replace it.

1. Make sure the Log Splitter is unplugged.

2. Unscrew oil drain bolt with dipstick to remove it.

3. Turn the Log Splitter on the support leg side over a

container to drain the hydraulic oil.

4. Lift the Log Splitter by the motor end.

5. Rell with hydraulic oil with 3.7 liters (118 oz) and

use type dened in the specications table on

page 6.

6. Clean the surface of dipstick on the oil drain bolt and put it back into the oil tank while keeping the Log Splitter

vertically.

7. Make sure the level of the relled oil is just between the two grooves around the dipstick.

8. Clean the oil drain bolt before replacing it. Make sure they are tightened to avoid leakage before placing the

Log Splitter horizontally.

NOTE: Periodically check the oil level and ll as necessary to ensure it is between the two grooves around

the dipstick.

NOTE: See recommended hydraulic oil types on page 6 under “Specication” section.

Fig 7

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

Maintenance (Continued)

• Save all instructions

Sharpening the Wedge:

After using the Log Splitters for some time, sharpen the wedge of the Log Splitter using a fine-toothed file and

smooth any burrs or crushed area along the cutting edge.

Storage:

• Before storing make sure the Log Splitter is clean and dry.

• Store equipment in a clean, dry area. Store machine away from sparks, open ames, pilot lights, heat and

other ignition sources.

• Lightly lubricate all Log Splitter surfaces and moving parts to prevent rust. (see “Maintenance”)

• Store indoors or protected area during severe weather and winter months.

Transporting

• Save all instructions

Transporting the Log Splitter:

Always place the Log Splitter on a protective mat when transporting to protect against damage to vehicle.

Remove from vehicle immediately upon arrival at your destination.

Always use two adults to load or unload the Log Splitter. Tighten the vent screw before moving or transporting

to prevent uid leakage. When transporting the Log Splitter in a vehicle, trailer, etc., make sure the vent screw is

tightened and the unit is secured with straps to prevent tipping. Use care when driving to prevent tipping the unit

over in the vehicle. Damage can occur to the Log Splitter or surrounding items if the Log Splitter is tipped.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

Troubleshooting

• Save all instructions

Problem and Solutions:

PROBLEM POSSIBLE CAUSE(S) SOLUTION(S)

Fails to split logs. 1. Log is improperly positioned.

2. The sizes or hardness of the

log exceeds the capacity of the

machine.

3. Wedge cutting edge is blunt.

4. Oil leaks.

5. Unauthorized adjustment

was made to the maximum

pressure limiting screw. Lower

pressure rating was set.

1. Refer to “Log Splitter Operation”

section (page 9) for perfect log loading.

2. Reduce the log sizes before splitting.

3. Refer to “Sharpening Wedge“ section

(page 10) to sharpen the cutting edge.

4. Locate leak(s) and contact the dealer.

5. Contact the dealer.

The ram moves unsteady,

makes an unfamiliar noise or

vibrates excessively.

Oil leaks around cylinder ram

or from other points.

Electric motor will

not run.

1. Lack of hydraulic oil and/or

excessive air in the hydraulic

system.

1. Air sealed in hydraulic system

while operating.

2. Vent screw is not tightened

before moving the Log Splitter.

3. Oil drain bolt with dipstick is

not tight.

4. Hydraulic control valve

assembly and/or seal(s) worn.

1. Motor has encountered

overload and activated the

reset button.

1. Check oil level for possible oil refilling.

2. Contact the dealer.

1. Loosen vent screw by 3 to 4 rotations

before operating the Log Splitter

2. Tighten the vent screw up before

moving the Log Splitter.

3. Tighten the oil drain bolt with dipstick.

4. Contact the dealer.

1. Push the reset button when motor has

cooled.

Technical Service

• Save all instructions

Contact Information:

You may have further questions about assembling, operating, or maintaining this Log Splitter. If so, you can

contact our Technical Service Department at 1-800-737-2112 (English only).

You may also write to:

METL Corporate Office - CORRESPONDENCE ONLY

ATTN: Technical Service – METL

6700 Wildlife Way

Long Grove, IL 60047

When contacting the Technical Service Department, have ready:

• Your Name

• Your Address

• Your Phone Number

• Model Number of Product

• Date of Purchase (include copy of receipt for written requests)

If you need assistance or have any questions,

CALL TOLL FREE: 1-800-737-2112.

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

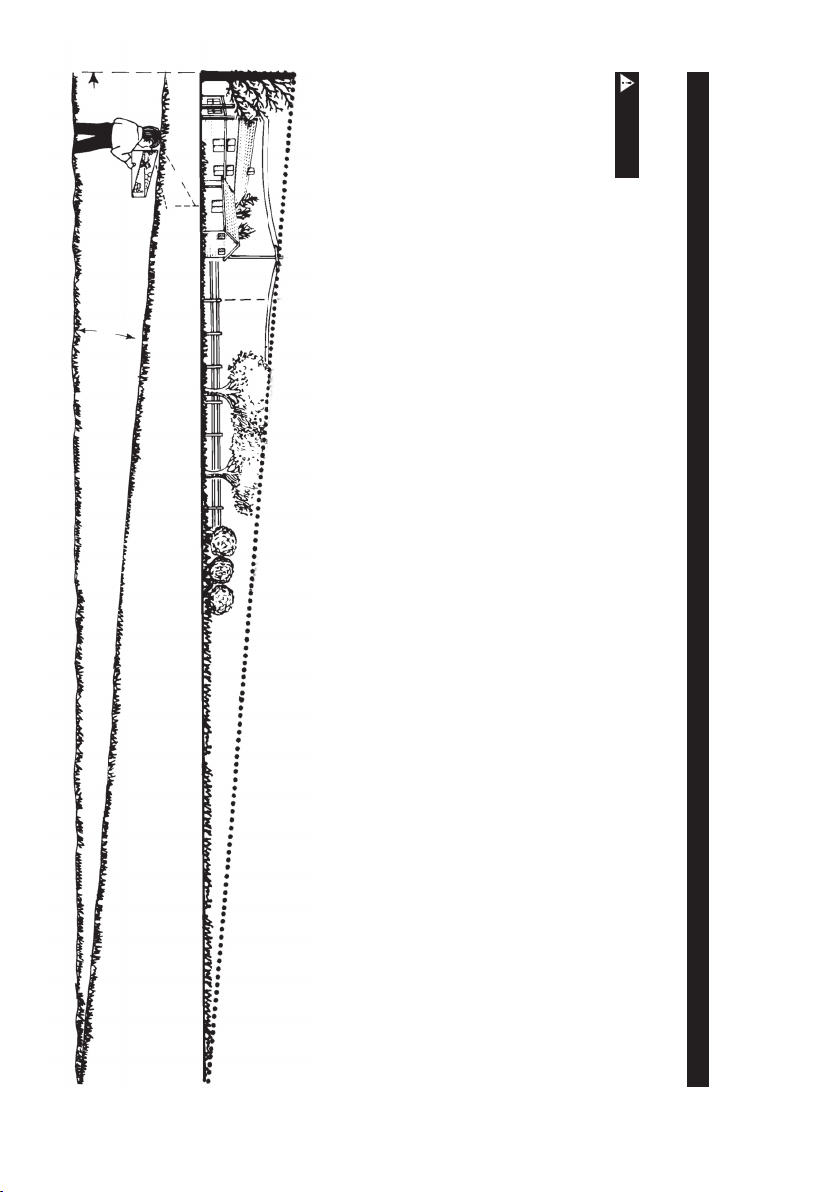

5 DEGREES

5 DEGREES

FOLD ALONG DOTTED LINE

when operating on or near slopes and obstructions.

Slope Guide

• Save all instructions

Sight and hold this guide level with a vertical tree, a corner of a structure, a power line pole, or a fence. Use this guide and do not split wood on a slope greater than

5 degrees. A 5 degree slope is a hill that increases in height at approximately 1.7 feet every 10 feet.

Use extreme care at all times and avoid sudden turns or maneuvers. Follow other instructions in this manual for safety in splitting wood on slopes. Use extra care

WARNING

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

Loading...

Loading...