Page 1

Title: Southern States –

LLS-I-2000, LLS-II-2000 and LLS-II-3000

Load and Line Switchers

TABLE OF CONTENTS

1.0 SCOPE.......................................................................................................................2

2.0 STANDARDS .............................................................................................................2

3.0 DESIGN REQUIREMENTS........................................................................................2

3.01 Service Conditions................................................................................................. 2

3.02 Ratings................................................................................................................... 2

3.03 Interrupter .............................................................................................................. 3

3.04 SF6 Gas System .................................................................................................... 3

3.05 Operating Mechanism............................................................................................ 3

4.0 DESIGN TESTS.........................................................................................................3

5.0 PRODUCTION TESTS...............................................................................................3

5.01 Mechanical Operations Test .................................................................................. 3

5.02 Leak Test............................................................................................................... 4

5.03 Resistance Test..................................................................................................... 4

5.04 Dielectric Test........................................................................................................ 4

6.0 SPARE PARTS ..........................................................................................................4

7.0 DOCUMENTATION REQUIREMENTS......................................................................4

7.01 Approval Drawings................................................................................................. 4

7.02 Final Drawings....................................................................................................... 4

7.03 Instruction Books ................................................................................................... 4

7.04 Additional Documentation...................................................................................... 5

8.0 SHIPPING and DELIVERY.........................................................................................5

9.0 WARRANTY...............................................................................................................5

10.0 ACCEPTABLE LOAD and LINE SWITCHER.............................................................5

Product Specification Guide

PAGE

Page 1 of 5 Publication No.: PSG-805-080109

Page 2

Title: Southern States –

LLS-I-2000, LLS-II-2000 and LLS-II-3000

Product Specification Guide

Load and Line Switchers

1.0 SCOPE

This specification covers the design, manufacture, and testing of outdoor load and line

switchers.

2.0 STANDARDS

All outdoor load and line switchers shall be designed, manufactured, assembled, and

tested in accordance with the latest applicable ANSI, NEMA, IEEE, and ASTM

standards and guidelines. If there are any conflicts between the ANSI, NEMA, IEEE, or

ASTM standards and this specification the specification shall govern.

3.0 DESIGN REQUIREMENTS

3.01 Service Conditions

The load and line switcher shall be suitable for outdoor installation in electric

power substations and on transmission line applications under the following

conditions:

3.01.01 Temperature

The load and line switcher shall perform in an ambient temperature

range of -40oC through +50oC.

3.01.02 Altitude

The load and line switcher shall perform at elevations up to 3,300 feet.

3.01.03 Additional Requirements

If any site specific service conditions not covered in sections 3.01.01 and

3.01.02 exist (e.g. extreme cold temperature installation, high altitude

installation, etc.) they will be defined in the quotation request.

3.02 Ratings

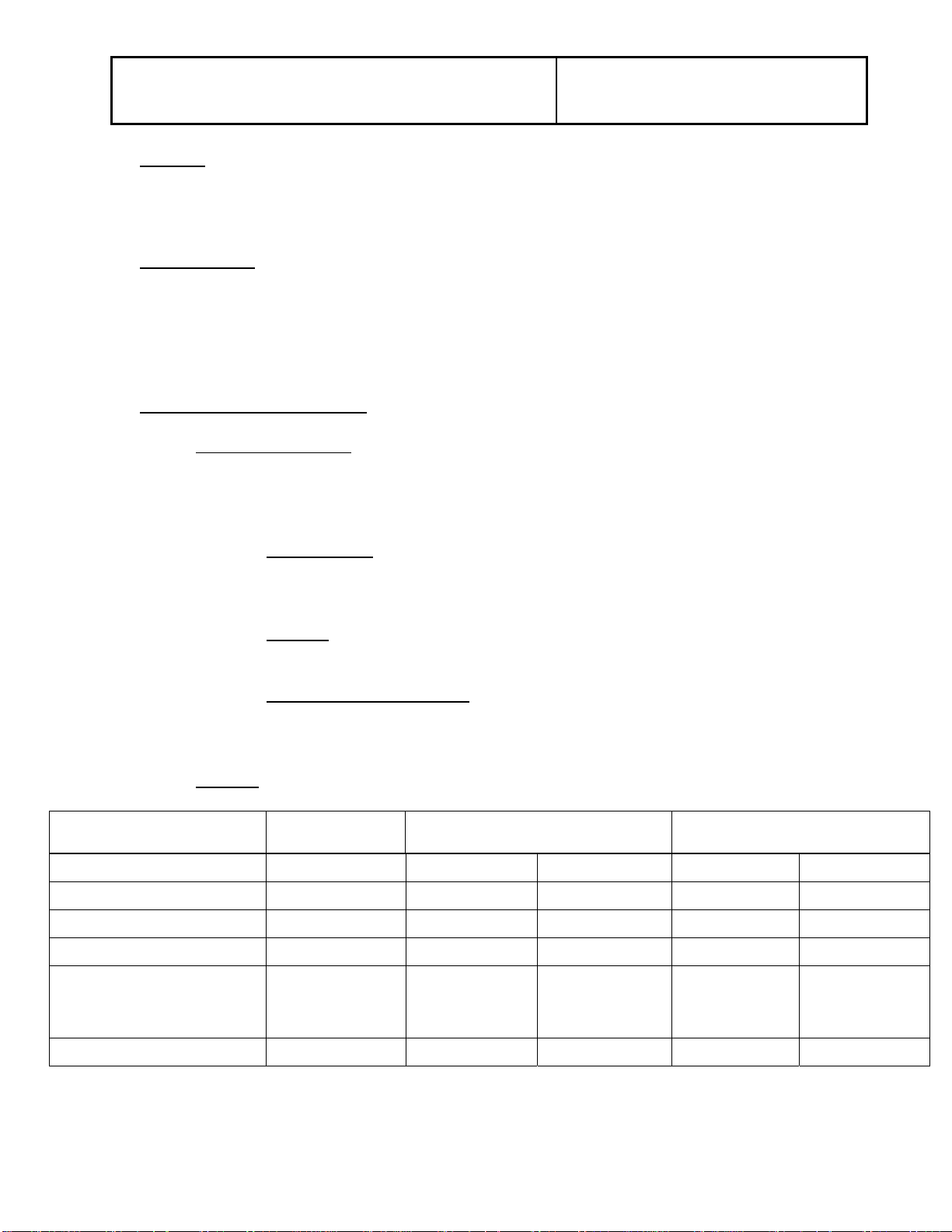

Design Characteristics LLS-I-2000 LLS-II-2000 LLS-II-3000

Maximum Voltage 38 kV – 72.5 kV 72.5 kV -170 kV 245 kV 72.5 kV -170 kV 245 kV

Load Breaking Capability 2000 A 2000 A 2000 A 3000 A 2000 A

Line Dropping Capability 300 A 300 A 200 A 300 A 200 A

Loop Splitting Capability 2000 A 2000 A 2000 A 3000 A 3000 A

55 psig at 20ºC

Nominal Operating Pressure 65 psig at 20ºC

Full Load Operations 2000 2000 2000 2000 2000

for 72.5 kV, 65

psig at 20ºC for

123 kV-170 kV

65 psig at 20ºC

55 psig at 20ºC

for 72.5 kV, 65

psig at 20ºC for

123 kV-170 kV

65 psig at 20ºC

Page 2 of 5 Publication No.: PSG-805-080109

Page 3

Title: Southern States –

LLS-I-2000, LLS-II-2000 and LLS-II-3000

Load and Line Switchers

3.03 Interrupter

The load and line switcher shall use SF6 single gap puffer interrupters. Vacuum

interrupters or multigap SF6 interrupters are unacceptable. Each interrupter shall

be housed in an ANSI 70 gray composite or epoxy insulator that will not degrade

when exposed to the sun’s UV rays. Fiberglass housed interrupters without

silicone outer coatings and porcelain housed interrupters are unacceptable.

3.04 SF6 Gas System

The gas system shall include the insulator and a color-coded, temperature

compensated density gauge that is visible from the ground.

A means for refilling the system in the field without disassembling the interrupter

must be provided. The device shall have a leak rate of less than 0.5% per year.

3.05 Operating Mechanism

Each interrupter shall be provided with a spring open mechanism and shall reset

itself when the switch is in the open position.

Product Specification Guide

4.0 DESIGN TESTS

The load and line switcher shall be design tested in accordance with IEEE Std. 1247-

1998, Standard for Interrupter Switches for Alternating Current Rated Above 1,000

Volts. The testing shall include dielectric tests, power tests, an environmental test, and

a mechanical endurance test. The dielectric tests shall include 60 Hz power frequency,

lighting impulse withstand, and visual corona. The power tests shall demonstrate the

capability to perform load breaking, line dropping, and loop splitting. The power tests

and the dielectric tests shall be performed at full voltage on the complete interrupter

assembly. Testing individual modules is not acceptable. The environmental test shall

demonstrate the load and line switcher’s capability to perform over a temperature range

of –40ºC to +50ºC. The load and line switcher shall be endurance tested to 2000

operations.

5.0 PRODUCTION TESTS

Each load and line switcher shall be fully assembled at the factory, adjusted, tested, and

timed per IEEE Std. 1247-1998. The tests shall include:

5.01 Mechanical Operations Test

There shall be at least 25 mechanical operations performed at the factory.

Timing tests shall be recorded.

Page 3 of 5 Publication No.: PSG-805-080109

Page 4

Title: Southern States –

LLS-I-2000, LLS-II-2000 and LLS-II-3000

Load and Line Switchers

5.02 Leak Test

An SF6 leak test shall be performed to confirm the leak rate is less than 0.5% per

year.

5.03 Resistance Test

5.03.01 Current Path Resistance Test

A micro-ohm resistance check shall be performed on each interrupter

using a 100 A DC source and the values shall be recorded.

5.04 Dielectric Test

5.04.01 Interrupter Dielectric Test

Each complete interrupter assembly shall pass a 60 Hz power frequency

withstand test for one minute.

6.0 SPARE PARTS

Product Specification Guide

No spare parts shall be required at the time of load and line switcher purchase. Stock

shall be maintained at the manufacturer and available for rush shipment in the event of

an emergency need.

7.0 DOCUMENTATION REQUIREMENTS

7.01 Approval Drawings

The manufacturer shall furnish approval drawings in AutoCAD .DWG format via

e-mail. The purchase order will designate the name and e-mail address of the

individual where the drawings should be forwarded. If there are no comments to

the approval drawings purchaser will respond via e-mail that drawings are

approved as submitted with no changes. If comments are required then one

copy of the drawings will be returned to the manufacturer within 10 days from the

date of transmittal marked “approved with comments as noted”.

7.02 Final Drawings

The manufacturer shall furnish final drawings in AutoCAD .DWG format via email. Unless otherwise specified in the purchase order, the final drawings will be

forwarded to the same individual that the approval drawings were sent to.

7.03 Instruction Books

The manufacturer shall furnish an electronic copy of each applicable instruction

book in Adobe Acrobat .PDF format via e-mail. Unless otherwise specified in the

purchase order, the instruction book(s) will be forwarded to the same individual

that the approval drawings were sent to.

Page 4 of 5 Publication No.: PSG-805-080109

Page 5

Title: Southern States –

LLS-I-2000, LLS-II-2000 and LLS-II-3000

Load and Line Switchers

7.04 Additional Documentation

One complete set of final drawings and one copy of each applicable instruction

book shall be shipped in a weatherproof envelope with each load and line

switcher.

8.0 SHIPPING and DELIVERY

Each interrupter shall be shipped fully pressurized with SF6, eliminating the need to pull

a vacuum on the interrupters in the field.

9.0 WARRANTY

All load and line switchers and their accessories furnished under this specification shall

be covered by a five-year warranty from date of shipment against failure due to design

or to defects in workmanship or material.

10.0 ACCEPTABLE LOAD and LINE SWITCHER

Product Specification Guide

Load and Line switchers, Type LLS-I or LLS-II, as manufactured by Southern States

are approved. Alternative products must meet or exceed this specification and be

approved for use by the USER prior to the bid date.

Page 5 of 5 Publication No.: PSG-805-080109

Loading...

Loading...