Page 1

FOR FUTURE REFERENCE

WARNING: Improper installation, adjustment, alteration, service

$9.00

Please complete this information

and retain this manual for the life

of the equipment.

MODEL #

SERIAL #

DATE PURCHASED

OWNER'S MANUAL

INSTALLATION

USER'S GUIDE

SERVICE

PARTS

IMPORTANT

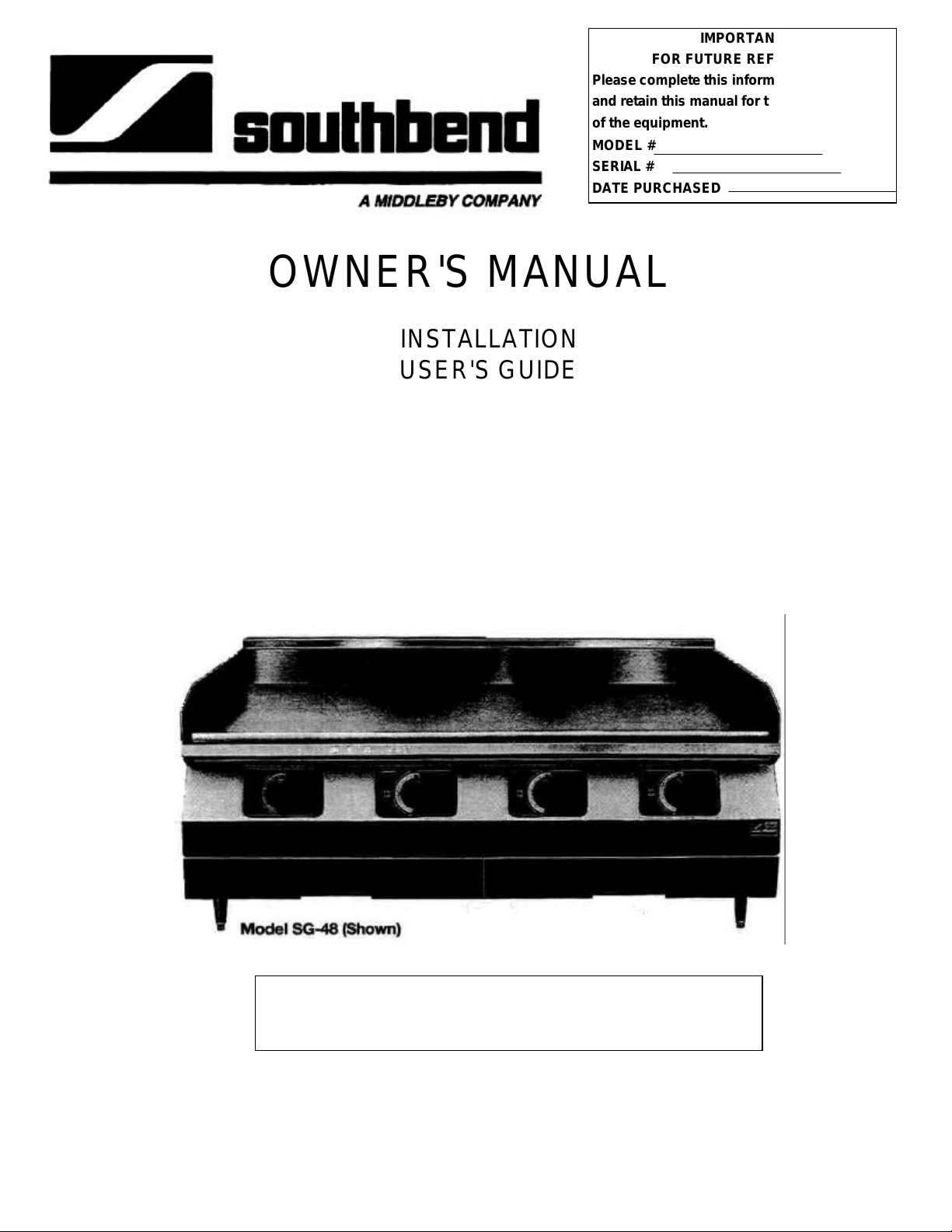

COUNTER GRIDDLE

MODELS: SG-24, SG-24E; SG-36, SG-36E

SG-48, SG-48E; SG-60, SG-60E

SG-72, SG-72E

or maintenance can cause propertydamage, injury or death . Read

the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

1100 Old Honeycutt Road • Fuquay, NC 27526 • (919) 552-9161 • FAX (919) 552-9798 • (800) 348-2558

Middleby Corp. Service Hot Line (800) 238-8444

COUNTER GRIDDLE

(Manual Section BP)

Page 2

RETAIN THIS MANUAL FOR FUTURE REFERENCE

WARNING

NOTICE

POST IN PROMINENT LOCATION, THE EMERGENCY TELEPHONE

NUMBER OF YOUR LOCAL GAS SUPPLIER AND INSTRUCTIONS TO

BE FOLLOWED IN THE EVENT YOU SMELL GAS.

Instructions to be followed in the event the user smells gas shall be obtained by consulting

the local gas supplier. If the smell of gas is detected, immediately call the emergency

phone number of your local Gas Company. They will have personnel and provisions

available to correct the problem.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS AND LIQUIDS

IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

NOTICE

This product is intended

for commercial use only.

NOT FOR HOUSEHOLD USE.

EQUIPMENT MUST BE KEPT FREE

AND CLEAR OF COMBUSTIBLES

WARNING

AT ALL TIMES.

Southbend (manufacturer) reserves the right to change

specifications and product design without notice. Such

revisions do not entitle the buyer to corresponding changes,

improvements, additions or replacements for previously

purchased equipment.

WARNING

Warranty will be void and the manufacturer is relieved of all liability IF...

(A) Service work is performed by other than a qualified technician

OR...

(B) Other than Genuine Southbend replacement parts are installed.

WARNING

DO NOT OBSTRUCT THE FLOW OF COMBUSTION

AND VENTILATION AIR TO AND FROM YOUR GAS

COOKING EQUIPMENT.

Page 3

Congratulations! You have just purchased one of the finest pieces of heavy-duty, commercial cooking equipment on the market

today.

You will find that your new equipment, like all Southbend equipment, has been designed and manufactured to some of the

toughest standards in the industry — those of Southbend. Each piece of Southbend equipment has been carefully engineered

and designs have been verified through laboratory tests and field installations in some of the more strenuous commercial

cooking applications. With proper care and field maintenance, you will experience years of reliable, trouble -free operation from

your Southbend equipment. To get the best results, it's important that you read this manual carefully.

TABLE OF CONTENTS:

SECTION ONE - INSTALLATION

Specifications 1

Installation 2

SECTION TWO - USER'S GUIDE

Warranty 1

Operation 2

Maintenance 5

SECTION THREE - SERVICE

Adjustments 1

Troubleshooting 3

SECTION FOUR - PARTS

Parts List 2

INSPECT FOR SHIPPING DAMAGE

All containers should be examined for damage before and during unloading. The freight carrier has assumed

responsibility for its safe transit and delivery. If equipment is received damaged, either apparent or concealed,

a claim must be made with the delivering carrier.

A) Apparent damage or loss must be noted on the freight bill at the time of delivery. It must then be signed

by the carrier representative (Driver). If this is not done, the carrier may refuse the claim. The carrier can

supply the necessary forms.

B) Concealed damage or loss if not apparent until after equipment is uncrated, a request for inspection must

be made to the carrier within 15 days. The carrier should arrange an inspection. Be certain to hold all

contents plus all packaging material.

1100 Old Honeycutt

Road Puquay, NC

27526 (919) 552-9161

FAX (919) 552-9798

(800) 348-2558

Page 4

COUNTER GRIDDLE

USER'S GUIDE

LIMITED WARRANTY

Southbend warrants that the equipment, as supplied by the factory to the original purchasers, is free from defects in materials

and workmanship. Should any part thereof become defective as a result of normal use within the period and limits defined

below, then at the option of Southbend such parts will be repaired or replaced by Southbend or its Authorized Service Agency.

This warranty is subject to the following conditions:

If upon inspection by Southbend or its Authorized Service Agency it is determined that this equipment has not been used in an

appropriate manner, has been modified, has not been property maintained, or has been subject to misuse or misapplication,

neglect, abuse, accident, damage during transit or delivery, fire, flood, riot or Act of God, then this warranty shall be void.

Specifically excluded under this warranty are claims relating to installation; examples are improper utility connections and

improper utilities supply. Claims relating to normal care and maintenance are also excluded; examples are calibration of

controls, and adjustments to pilots and burners.

Equipment failure caused by inadequate water quality is not covered under warranty. WATER QUALITY must not exceed the

following limits: Total Dissolved Solids (TDS) - 60 PPM (Parts Per Million). Hardness - 2 Grains or 35 PPM, PH Factor - 7.0 to

7.5. Water pressure 30 PSI minimum, 60 PSI maximum. Boiler maintenance is the responsibility of the owner and is not

covered by warranty.

This equipment is intended for commercial use only. Warranty is void if equipment is installed in other than commercial

application.

Repairs under this warranty are to be performed only by a Southbend Authorized Service Agency. Southbend can not be

responsible for charges incurred from other than Authorized Southbend Agencies.

THIS WARRANTY MUST BE SHOWN TO AN AUTHORIZED SERVICE AGENCY WHEN REQUESTING IN-WARRANTY

SERVICE WORK. THE AUTHORIZED SERVICE AGENCY MAY AT HIS OPTION REQUIRE PROOF OF PURCHASE.

This warranty does not cover services performed at overtime or premium labor rates nor does Southbend assume any liability

for extended delays in replacing or repairing any items in the equipment beyond the control of Southbend. "Southbend shall

not be liable for consequential or special damages of any nature that may arise in connection with such product or part."

Should service be required at times which normally involve overtime or premium labor rates, the owner shall be charged for

the difference between normal service rates and such premium rates.

In all circumstances, a maximum of one hundred miles in travel and two and one half hours (2.5) travel time shall be allowable.

In all cases the closest Southbend Authorized Agency must be used.

The actual warranty time periods and exceptions are as follows:

This warranty only covers product shipped into the 48 contiguous United States and Hawaii, one year labor, one year parts

effective from the date of original purchase. There will be no labor coverage for equipment located on any island not

connected by roadway to the mainland.

Exceptions to standard warranty, effective within above limitations:

Glass Windows, Door Gaskets, Rubber Seals, Light Bulbs, Ceramic Bricks,

Sight Glasses, Cathodic Descalers or Anodes............................................. 90 days material and labor

Stainless Steel Fry Pot.............................4 years extended material warranty on fry pot only—no labor

Stainless Steel Open Top Burners ............... 4 years extended material warranty on burners only — no labor

Pressure Steam Boiler Shell.................. Prorated 4 years extended warranty on boiler shell only — no labor

Boiler shells which have not been properly maintained will not be covered by warranty.

In all cases parts covered by a five year warranty will be shipped FOB the factory after the first year.

Our warranty oh all replacement parts which are replaced in the field by our Authorized Service Agencies will be limited to

three months on labor, six months on materials (parts) effective from the date of installation. See LIMITED WARRANTY REPLACEMENT PARTS for conditions and limitations.

If the equipment has been changed, altered, modified or repaired by other than a qualified service technician during or after

the one year limited warranty period, then the manufacturer shall not be liable for any damages to any person or to any

property which may result from the use of the equipment thereafter.

"THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS, AND CONSTITUTES THE ENTIRE

LIABILITY OF SOUTHBEND. IN NO EVENT DOES THE LIMITED WARRANTY EXTEND BEYOND THE DURATION OF

ONE YEAR FROM THE EFFECTIVE DATE OF SAID WARRANTY."

USER’S GUIDE

COUNTER GRIDDLE

SECTION TWO — USER'S

GUIDE

PAGE 1

Page 5

JOB___________ ITEM # ___________

Southbend Thermostatic Counter Griddles

OPTIONS:

o

o

COUNTER GRIDDLE

Gas, Heavy Duty

MODELS: SG-24, SG-36, SG-48, SG-60, SG-72

offer unsurpassed performance, combining

proven control systems with Southbend quality

and durability.

Standard Features:

• One inch thick polished rolled steel plate with

• Stainless steel front and sides.

• Flame failure safety device—Standard.

• 3/4" rear gas connection and pressure

Capabilities:

• Independent thermostatic controls for precise

• 30,000 BTU burner every 12".

• Extremely uniform heat distribution across surface.

• Unsurpassed combustion efficiency.

Cleanability:

• 4" NSF approved legs.

• Spatula width grease trough.

• Hidden grease drawer with large capacity.

• Stub back interlocks with splash guard rear

A MIDDLEBY COMPANY

4" high rear and side splash guards.

regulator.

temperature settings between 150'Fand450"F.

to eliminate spills between plate and stub

back.

Model SG-48 — Stainless steel front and sides standard.

o

Stainless steel stand

o

Stainless steel Intermediate shelf for

o

Casters for stand

o

2" Insulator base

o

Stainless rear and bottom

o

Fully or partially grooved griddle plate

Hard chrome griddle plate surface

5/8” Thick polished steel plate

• INQUIRE TO FACTORY FOR SPECIAL OR

CUSTOM REQUIREMENTS

We reserve the right to change specifications and

product design without notice. Such revisions do not

entitle the buyer to corresponding changes,

improvements, additions or replacements for

previously purchased equipment. Southbend has a

policy of continuous product research and

improvement.

All Units:

Stainless steel front and sides standard. Rear

and bottom panels are aluminized steel. A 5"

stainless steel stub back is include at no charge.

Reinforced double wall sides are fully

insulated.

Technical Data

Unit dimensions, utility information, construction

specifications and miscellaneous information is

listed on the reverse side.

Warranty

One year parts and labor warranty at no extra

charge from the date of purchase.

1100 Old Honeycutt Road

Fuquay, NC 27526

(919)552-9161

FAX (919) 552-9798

(800) 348-2558 Page CL-01

Page 6

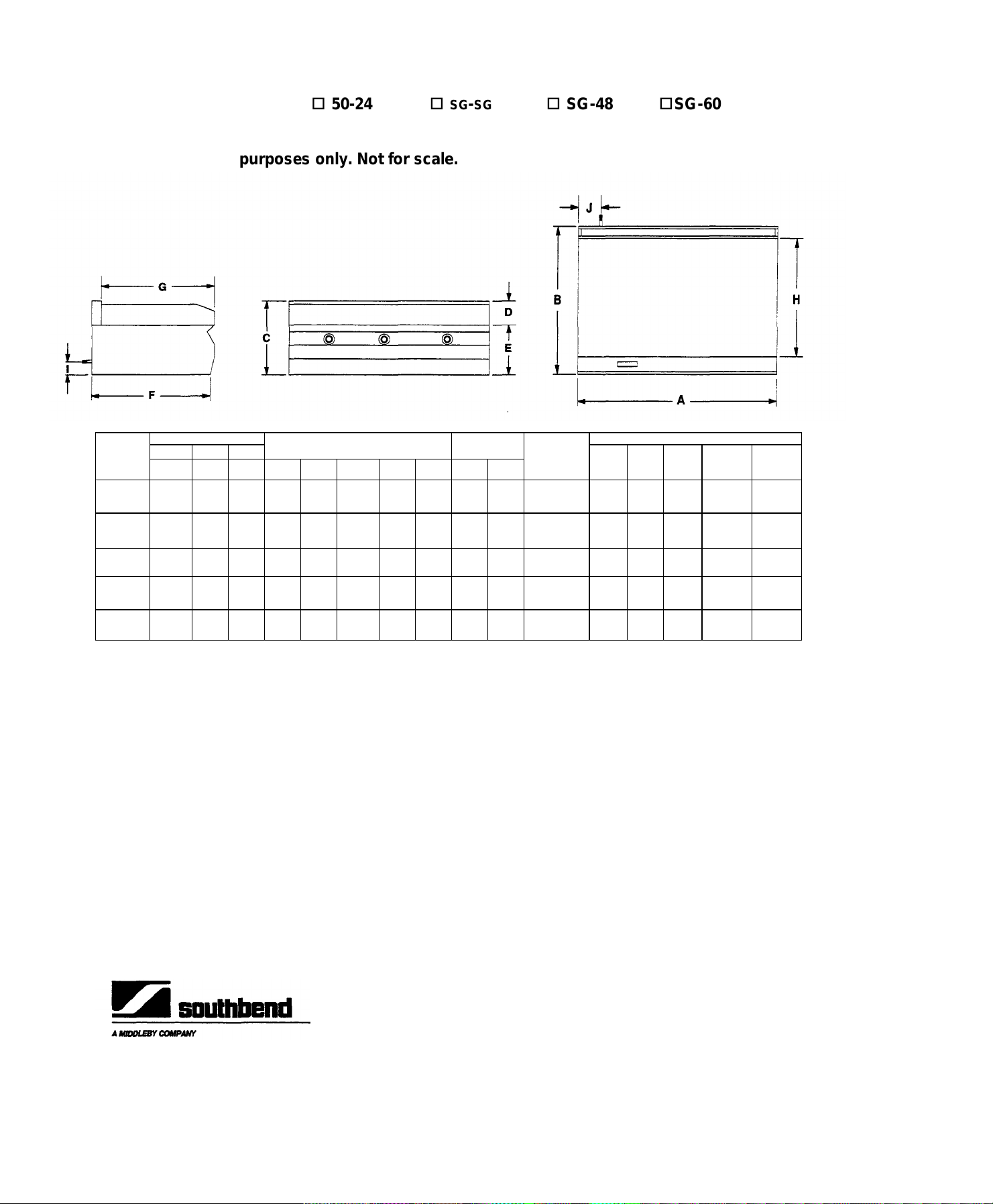

MODELS: o 50-24 o SG-SG o SG-48 oSG-60 o SG-72

EXTERIOR

CRATE SIZE

1100

Old Honeycutt Road

For dimensional purposes only. Not for scale.

MODELS

o SG-24

o SG-36

o SG-48

o SG-60

o SG-72

Width Depth Height

A B C D E F G H I J

24"

30"

18"

5"

5"

5"

5"

5"

13"

(330)

13"

(330)

13"

(330)

13"

(330)

13"

(330)

(610)

36"

(914)

48"

(1219)

60"

(1524)

72"

(1829)

(762)

30"

(762)

30"

(762)

30"

(762)

30"

(762)

(457)

18"

(457)

18'

(457)

18"

(457)

18"

(457)

(127)

(127)

(127)

(127)

(127)

287/8”

(733)

287/8”

(733)

287/8”

(733)

287/8”

(733)

287/8”

(733)

27 ¾ ‘

(704)

27 ¾ ‘

(704)

27 ¾ ‘

(704)

27 ¾ ‘

(704)

27 ¾ ‘

(704)

PERFORMANCE SPECIFICATIONS:

BTU Rating: Each burner rated 30,000 BTU/hour "natural" and "propane"

gas. 2 burners on 24" wide models for total of 60,000 BTU/hour, 3 burners

on 36" wide models for total of 90,000 BTU/hour, 4 burners on 48" wide

models for total of 120,000 BTU/hour, 5 burners on 60" wide models for

total of 150,000 BTU/hour, 6 burners on 72" wide models for total of

180,000 BTU/hour.

Preheat Time: Approximately 25 minutes to 350T.

INSTALLATION SPECIFICATIONS:

Free Standing Models: Required operating pressures are 4" W.C. for

"natural" gas and 10" W.C. for "propane" gas. 3/4TMPT rear gas with pressure regulator is standard.

Flex Hose: Use only a commercial flex hose. The I.D. should not be

smaller than the I.D. of the pipe from the unit to which it is connected.

24"

(610)

24"

(610)

24"

(610)

24"

(610)

24"

(610)

3/4" GAS

CONNECTION

2 3/8”

(60)

2 3/8”

(60)

2 3/8”

(60)

2 3/8”

(60)

2 3/8”

(60)

BURNERS

(BTUea.)

1 ¾”

(45) 2 (30,000)

1 ¾”

(45)

1 ¾”

(45) 4 (30,000)

1 ¾”

(45) 5 (30,000)

1 ¾”

(45) 6 (30,000)

3

(30,000)

Width Depth Height

31"

39"

39"

39"

39"

(991)

39"

(991)

24"

(610)

24"

(610)

24"

(610)

24"

(610)

24"

(610)

(787)

55"

(1397)

55"

(1397)

67"

(1702)

80"

(1702)

(991)

(991)

(991)

Cubic

Volume

16.8cu.ft.

.47 cu. m.

28.9cu.ft

.81 cu. m.

28.9cu.ft.

.81 cu. m.

36.3cu.ft.

1.1 cam.

43.3cu.ft.

1.3 cam.

CONSTRUCTION BIDDING SPECIFICATIONS:

Cabinet: Front, sides, and 5" riser are all stainless steel. Rear and bottom

panels are aluminized steel. Reinforced double wall sides are fully insulated.

Griddle Plate: One inch thick polished rolled steel plate.

Gas/Heat Control Systems: Each foot of griddle is heated by a "U"-

shaped burner. Each burner is controlled by a thermostatic gas valve for

independent temperature control. One standing pilot services up to 4

burners. Each pilot is equipped with a flame failure safety device. 3/4" rear

gas with pressure regulator is standard. Units over 48" wide are

constructed of two bodies.

Approvals: A.G.A. and C.G.A. design certified, N.S.F. listed.

Crated

Weight

305 lbs.

445 lbs.

545 Ibs.

705 Ibs.

890 lbs.

Southbend, in line with its policy to continually improve its products, reserves the right to change materials or specifications without notice.

INTENDED FOR COMMERCIAL USE ONLY. NOT FOR HOUSEHOLD USE.

PageCL-02 Printed in U.S.A. 1/94 FormCL01/02

Fuquay, NC 27526

(919)552-9161

FAX (919) 552-9798

(800)348-2558

Page 7

COUNTER GRIDDLE

INSTALLATION

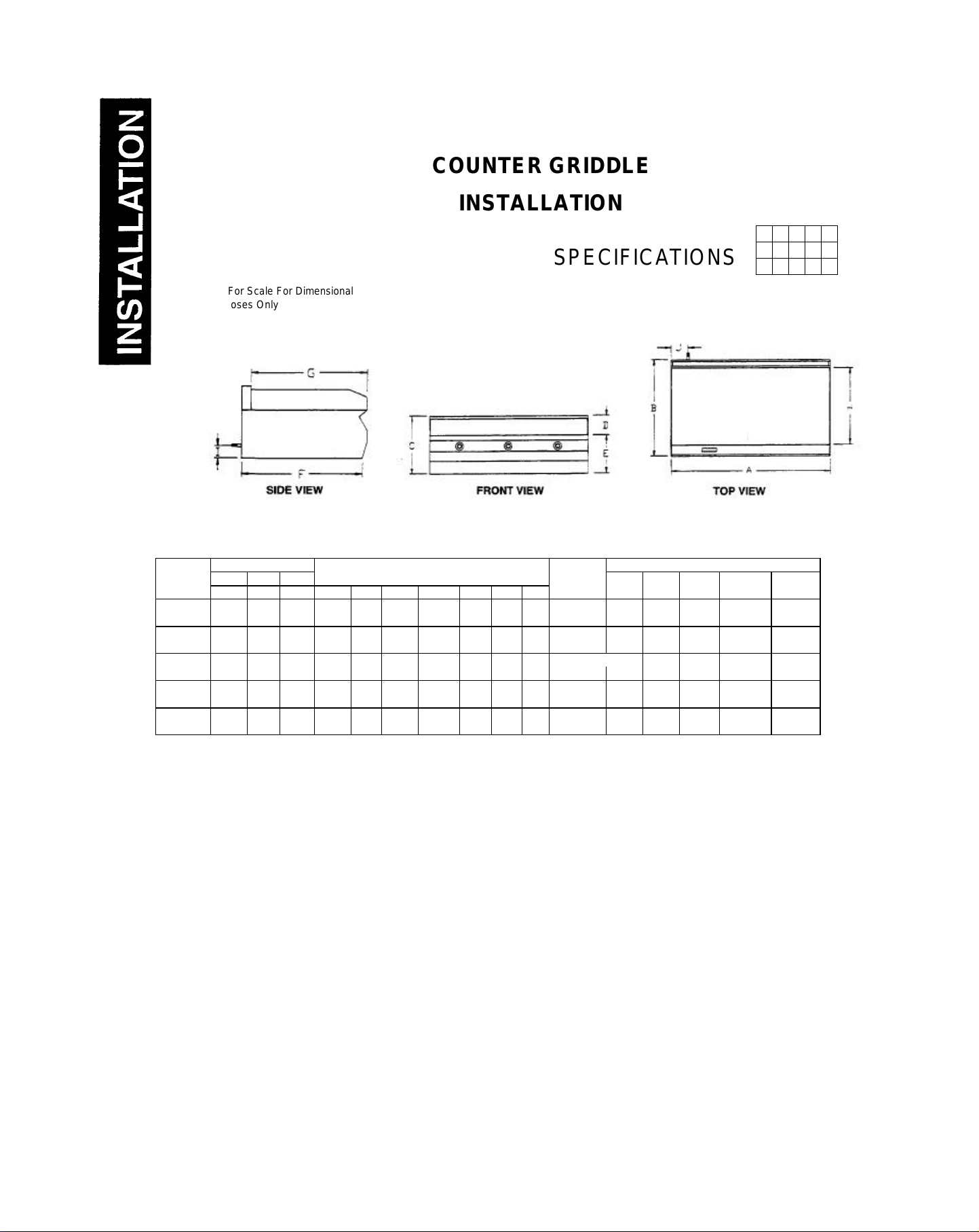

Not For Scale For Dimensional

Litho in U.S.A.

COUNTER GRIDDLE SECTION

SPECIFICATIONS

Purposes Only

DIMENSIONS: ( ) = Millimeters

MODELS

? SG-24 24" 30" 18" 5" 13" 28 7/8" 27 7/8' 24" 23/8" 13/4"

? SG-24E (610) (762) (457) (127) (330) (733) (704) (610) (60) (45) (30,000) (787) (991) (610) .47 cu. m.

? SG-36 36" 30" 18" 5" 13" 28 7/8" 277/8' 24" W 13/4"

? SG-36E (914) (762) (457) (127) (330) (733) (704) (610) (60) (45) (30.000) (1397) (991) (610) .81 cu. m.

? SG-48 48" 30" 18" 5" 13" 28 7/8" 277/8' 24" 23/8" 13/4"

? SG-48E (1219) (762) (457) (127) (330) (733) (704) (610) (60) (45) (30.000) (1397) (991) (610) .81 cu. m.

? SG-60 60" 30" 18" 5" 13" 28 7/8" 277/8' 24" 23/8" 13/4"

? SG-60E (1524) (762) (457) (127) (330) (733) (704) (610) (60) (45) (30,000) (1702) (991) (610) 1.1 cu. m.

? SG-72 72" 30* 18" 5" 13" 28 7/8" 277/8' 24" 23/8" 13/4"

? SG-72E (1829) (762) (457) (127) (330) (733) (704) (610) (60) (45) (30.000) (1702) (991) (610) 1.3 cu. m.

EXTERIOR CRATE SIZE

Width Depth Height

A B C D E F G H I J

3/4" GAS

CONNECTION

BURNERS

(BTU ea.)

Width Depth Height

2 31" 39" 24" 16.8cu.ft.

3 55- 39" 24" 28.9cu.ft.

4 55" 39" 24" 28.9 cu. ft.

5 67" 39" 24" 36.3 cu. ft.

6 80" 39" 24" 43.3 cu. ft.

Cubic

Volume

Crated

Weight

305 Ibs.

445 Ibs.

545 Ibs.

705 Ibs.

890 Ibs.

PERFORMANCE SPECIFICATIONS:

BTU Rating: Each burner rated 30,000 BTU/hour "natural"

and "propane" gas. 2 burners on 24" wide models for total of

60,000 BTU/hour, 3 burners on 36" wide models for total of

90,000 BTU/hour, 4 burners on 48" wide models for total of

120,000 BTU/hour, 5 burners on 60" wide models for total of

150,000 BTU/hour, 6 burners on 72" wide models for total of

180,000 BTU/hour. Preheat Time: Approximately 13 minutes

to 350°F.

INSTALLATION SPECIFICATIONS:

Free Standing Models: Required operating pressures are 4"

W.C. for "natural" gas and 10" W.C. for "propane" gas. 3/4"

NPT rear gas with pressure regulator is standard.

Flex Hose: Use only a commercial flex hose. The I.D. should

CONSTRUCTION BIDDING

SPECIFICATIONS:

Cabinet: Front, sides, and 5" riser are all stainless steel. Rear

and bottom panels are aluminized steel. Reinforced double

wall sides are fully insulated. Griddle Plate: One inch thick

polished rolled steel plate.

Gas/Heat Control Systems: Each foot of griddle is heated by

a "U"-shaped burner. Each burner is controlled by a

thermostatic gas valve for independent temperature control.

One standing pilot services up to 4 burners. Each pilot is

equipped with a flame failure safety device. 3/4" rear gas with

pressure regulator is standard. Units over 48" wide are

constructed of two bodies.

Approvals: A.G.A. and C.G.A. design certified, N.S.F. listed.

not be smaller than the I.D. of the pipe from the unit to which it

is connected.

Southbend, in line with its policy to continually improve its products, reserves the right to change materials or

specifications without notice.

INTENDED FOR COMMERCIAL USE ONLY. NOT FOR HOUSEHOLD USE.

ONE — INSTALLATION

PAGE 1

2-94

Page 8

INSTALLATION

WARNING: THESE PROCEDURES MUST BE FOLLOWED BY QUALIFIED

GENERAL:

THE UNIT, WHEN INSTALLED, MUST CONFORM WITH LOCAL CODES, OR IN THE ABSENCE OF LOCAL

CODES, WITH THE NATIONAL FUEL GAS CODE, ANSI Z223.1-LATEST EDITION.

THE UNIT, WHEN INSTALLED, MUST BE ELECTRICALLY GROUNDED AND COMPLY WITH LOCAL

CODES, OR LN THE ABSENCE OF LOCAL CODES, WITH THE NATIONAL ELECTRICAL CODE ANSFNFPA

70-LATEST EDITION.

CANADIAN INSTALLATION MUST COMPLY WITH CAN/CGA-B149.1 NATURAL GAS INSTALLATION

CODE, CODE CAN/CGA-B 149.2 PROPANE INSTALLATION CODE, AND CSA C22.1 CANADIAN

ELECTRICAL CODE PARTS I, OR LOCAL CODES.

These models are design certified for operation on Natural or Propane gases.

The appliance should be connected ONLY to the type of gas for which it is equipped. All Southbend equipment is

adjusted at the factory. Check type of gas on serial plate in the compartment behind the front panel, on inside

Right Lining.

NOTE: Each Counter Griddle is a complete unit with an individual 3/4" NPT supply connection at the rear. An

adequate gas supply is imperative. Undersized or low pressure lines will restrict the volume of gas required for

satisfactory performance. A Pressure regulator, which is provided with each unit, is set to maintain a 4" W.C.

manifold pressure for natural gas and a 10" W.C. manifold pressure for propane gas. However, to maintain

these conditions the pressure on the supply line, when all units are operating simultaneously, should not drop

below 7" W.C. for natural gas of 11" W.C. for propane gas.

Counter Griddle units, a 3/4" NPT gas supply connection is located at the right side of rear, when you are facing rear of

the unit.

If applicable, the vent line from the gas appliance pressure regulator shall be installed to the outdoors in accordance with

local codes or, in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1-LATEST EDITION and

CANADIAN INSTALLATION MUST COMPLY WITH CAN/CGA-B149.1 NATURAL GAS INSTALLATION

CODE, CODE CAN/CGA-B149.2 PROPANE INSTALLATION CODE. A 1/8" pressure tap is located on the manifold

of each unit.

All pipe joints should be tested for leaks with a soap and water solution before operating the unit. The test pressure should

not exceed 14" W.C.

CAUTION: THIS APPLIANCE AND ITS INDIVIDUAL SHUTOFF VALVE MUST BE DISCONNECTED FROM

THE GAS SUPPLY PIPING SYSTEM DURING ANY PRESSURE TESTING OF THE SYSTEM AT TEST

PRESSURES IN EXCESS OF 1/2 PSIG (3.45 kPa).

THIS APPLIANCE MUST BE ISOLATED FROM THE GAS SUPPLY PIPING SYSTEM BY CLOSING ITS

INDIVIDUAL MANUAL SHUTOFF VALVE DURING ANY PRESSURE TESTING OF THE GAS SUPPLY

PIPING SYSTEM AT TEST PRESSURES EQUAL TO OR LESS THAN 1/2 PSIG (3.45 kPa).

PERSONNEL OR WARRANTY WILL BE VOIDED.

INSTALLATION

EXHAUST FANS AND CANOPIES:

An adequate ventilation system is required for the Southbend counter line. The minimum canopy hood dimensions are

outlined as follows:

It is recommended that a canopy extend 6" past appliance and be located 6' 6" from the floor. Filters should be

installed at an angle of 45 degrees or more with the horizontal. This prevents dripping grease and facilitates

collecting the run-off grease in a drip pan, usually installed with a filter. A strong exhaust fan tends to create a

negative pressure condition in the room and may interfere with burner performance, extinguish pilot flames, or

result in poor cooking performance.

To avoid a negative pressure condition, return air must be brought into the room to replenish the air being

removed by the ventilation hood.

This can be accomplished by one of two ways:

A. Return air may be introduced into the room through the heating, ventilation, and air conditioning (HVAC)

system.

B. Return air may come from within the hood itself by using fans internal to the hood system.

NOTE: Return air from fans MUST NOT BLOW DOWN GRIDDLE FLUE OR DIRECTLY ON GRIDDLE

SURFACE.

COUNTER GRIDDLE SECTION

ONE — INSTALLATION

PAGE 2

Page 9

INSTALLATION

In case of unsatisfactory performance on any appliance, check with the exhaust fan in the "OFF" position. Do this

only long enough to check equipment performance. Then turn hood back on and let it run to remove any exhaust that

may have accumulated during the test.

WALL EXHAUST FAN: Should be installed at least 2 feet above the vent opening at the top of the backsplash.

All units must be installed in such a manner that the flow of combustion and ventilation air are not obstructed.

Provisions for an adequate air supply must also be provided.

PROPER VENTILATION IS THE OWNER'S RESPONSIBILITY. ANY PROBLEM DUE

TO IMPROPER VENTILATION WOULD NOT BE COVERED BY WARRANTY.

Local codes regarding installation vary greatly from one area to another. The National Fire Protection Association,

Inc. states in its NFPA 96 latest edition that local codes are "authority having jurisdiction" when it comes to

requirements for installation of equipment. Therefore, installations should comply with all local codes.

TO INSTALL COUNTER MODEL GRIDDLE:

1. Inspect for shipping damage as outlined in front of manual.

2. Cut banding straps and remove corrugated box from griddle.

3. Before cutting banding material holding griddle to wooden skid, move unit as near to the place of installation

as possible.

4. Cut banding strap holding griddle to wooden skid.

5. Locate box marked Legs and box marked Regulator. A gas

pressure regulator is supplied with each Counter griddle and

legs are supplied when unit is ordered with legs. If these

items are not received, contact your Southbend

Sales Representative. Please have your model

and serial numbers ready when you call.

NOTE: If your griddle is to be installed

with legs, proceed to Step 6. If your

griddle is to be installed flat on a

counter or on a stand, move to section

titled "OPTIONAL INSTALLATION."

6. Lift griddle from front left and right

comers and tilt back to about 45° angle.

7. Install NSF approved legs supplied with

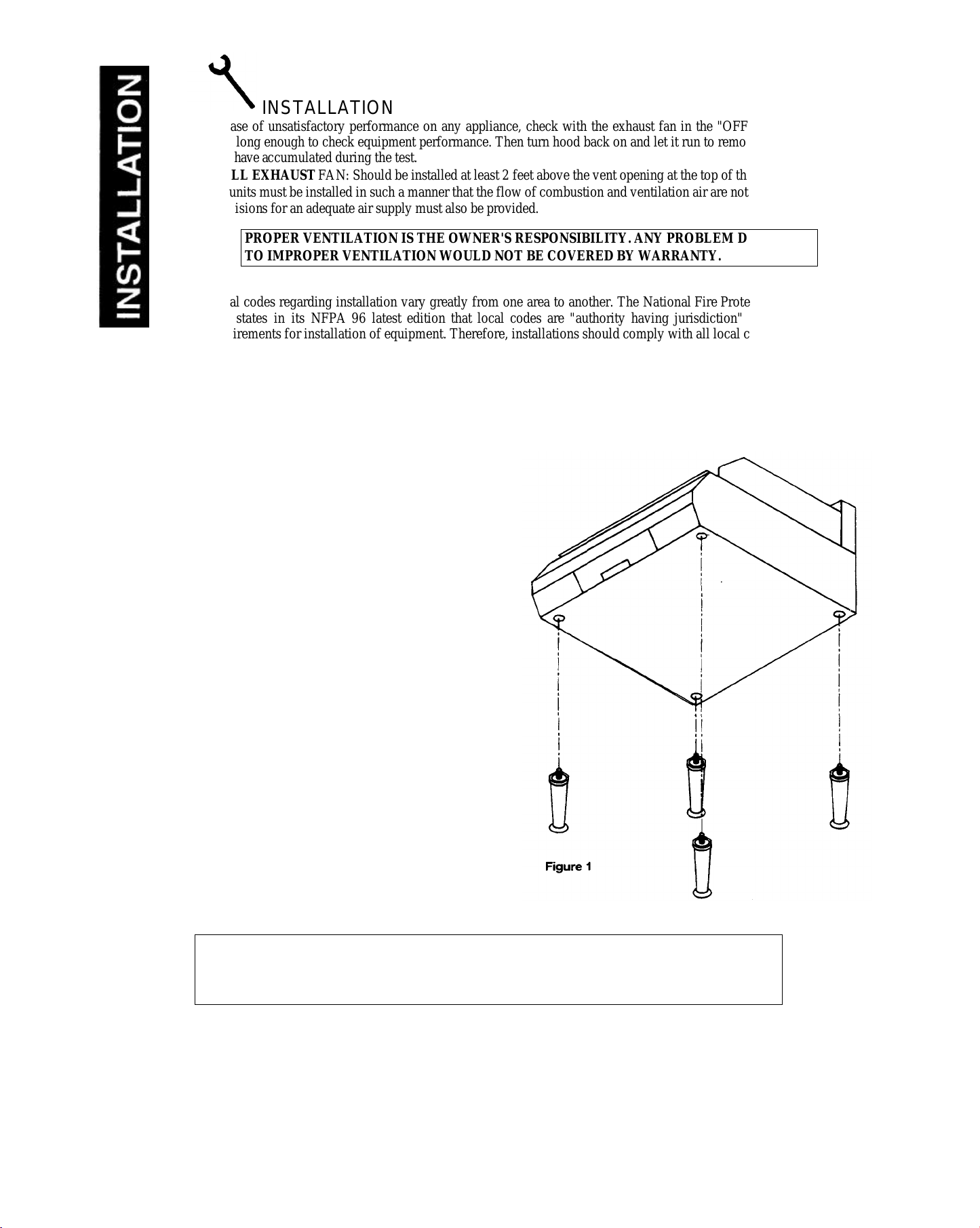

griddle. Refer to Figure 1 (below).

8. After installing legs on front of griddle base,

SLOWLY lower griddle till the front of

griddle rests on legs.

9. Lift rear of griddle at left and right

comers and install rear legs.

NOTE: If it is necessary to prop griddle up to install legs, support griddle from sides, NOT the

COUNTER GRIDDLE SECTION

ONE — INSTALLATION

PAGE 3

center. Griddle MUST ALWAYS BE LIFTED AND MOVED FROM ENDS — NEVER LIFT

FROM CENTER.

Lithe in U.S.A.

2-94

Page 10

INSTALLATION

ALL MODELS

0 IN. 0

IN.

WARNING: If Griddle is to be installed without legs, the surface the griddle will rest upon must be made of

2.

top using G.E. or Dow Corning RTV or

INSTALLATION

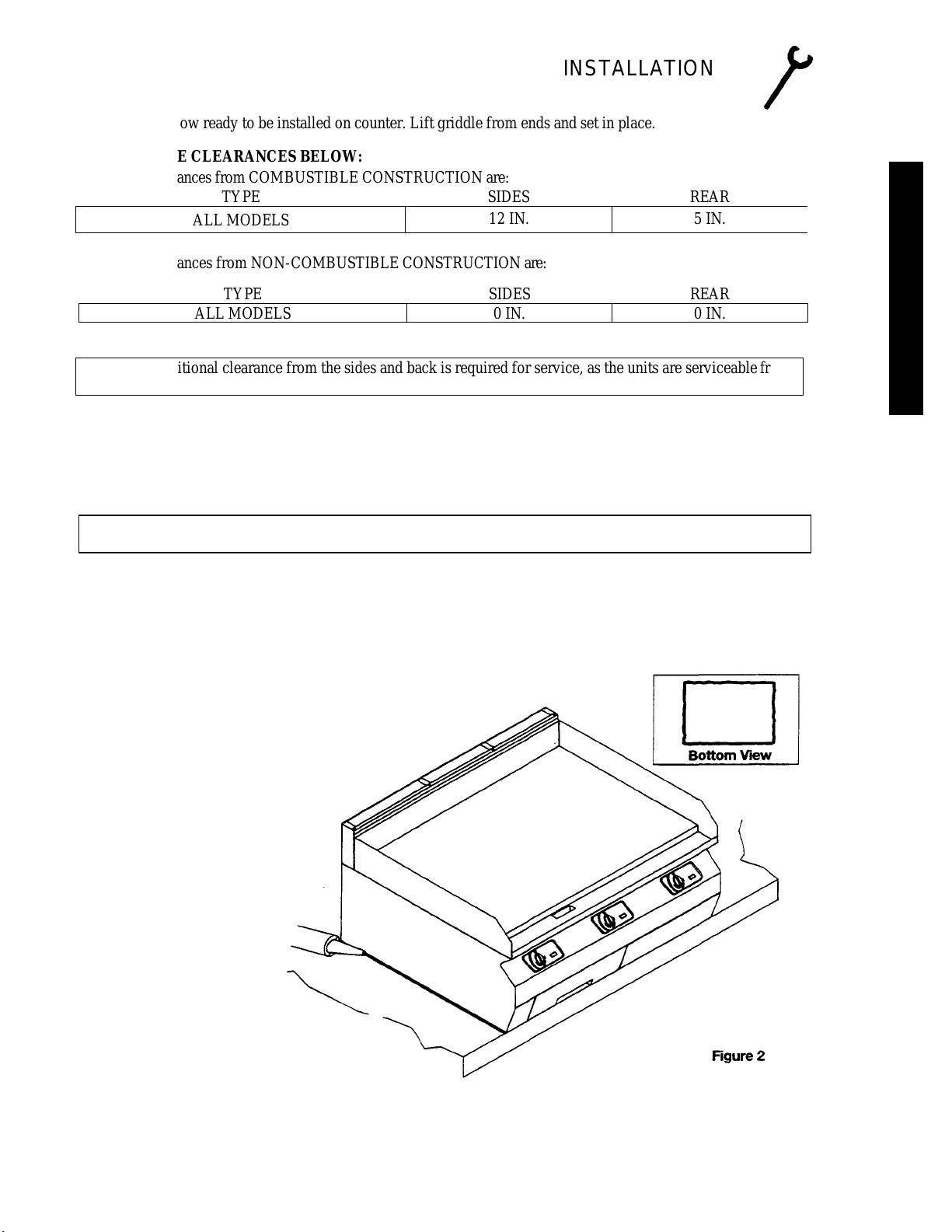

10. Griddle is now ready to be installed on counter. Lift griddle from ends and set in place.

PLEASE NOTE CLEARANCES BELOW:

Minimum clearances from COMBUSTIBLE CONSTRUCTION are:

TYPE SIDES REAR

ALL MODELS

Minimum clearances from NON-COMBUSTIBLE CONSTRUCTION are:

TYPE SIDES REAR

NOTE: No additional clearance from the sides and back is required for service, as the units are serviceable from the

front.

11. Adjust bottom of legs to level griddle.

CAUTION: ONLY NON-COMBUSTIBLE COUNTERS ARE TO BE USED TO SUPPORT THESE UNITS.

OPTIONAL INSTALLATION:

12 IN. 5 IN.

NON COMBUSTIBLE MATERIAL. Follow all local codes.

TO INSTALL WITHOUT LEGS:

1. After uncrating and inspecting for shipping damage, lift griddle from ends and place on non-combustible

surface. NOTE: NEVER LIFT GRIDDLE FROM CENTER. GRIDDLE MUST BE LIFTED FROM ENDS.

After setting griddle in place, make your gas supply connection.

(Refer to GAS CONNECTION, Section 1, Page 11.)

3. After making gas connection, seal griddle to counter

equivalent. (NOTE: Consult local code for

exact requirements.) A small bead of

RTV around edge of griddle

bottom should be adequate. Refer

to Figure 2 below.

SECTION ONE — INSTALLATION

COUNTER GRIDDLE

PAGE 4

Page 11

INSTALLATION

COUNTER GRIDDLE

Litho in U.S.A.

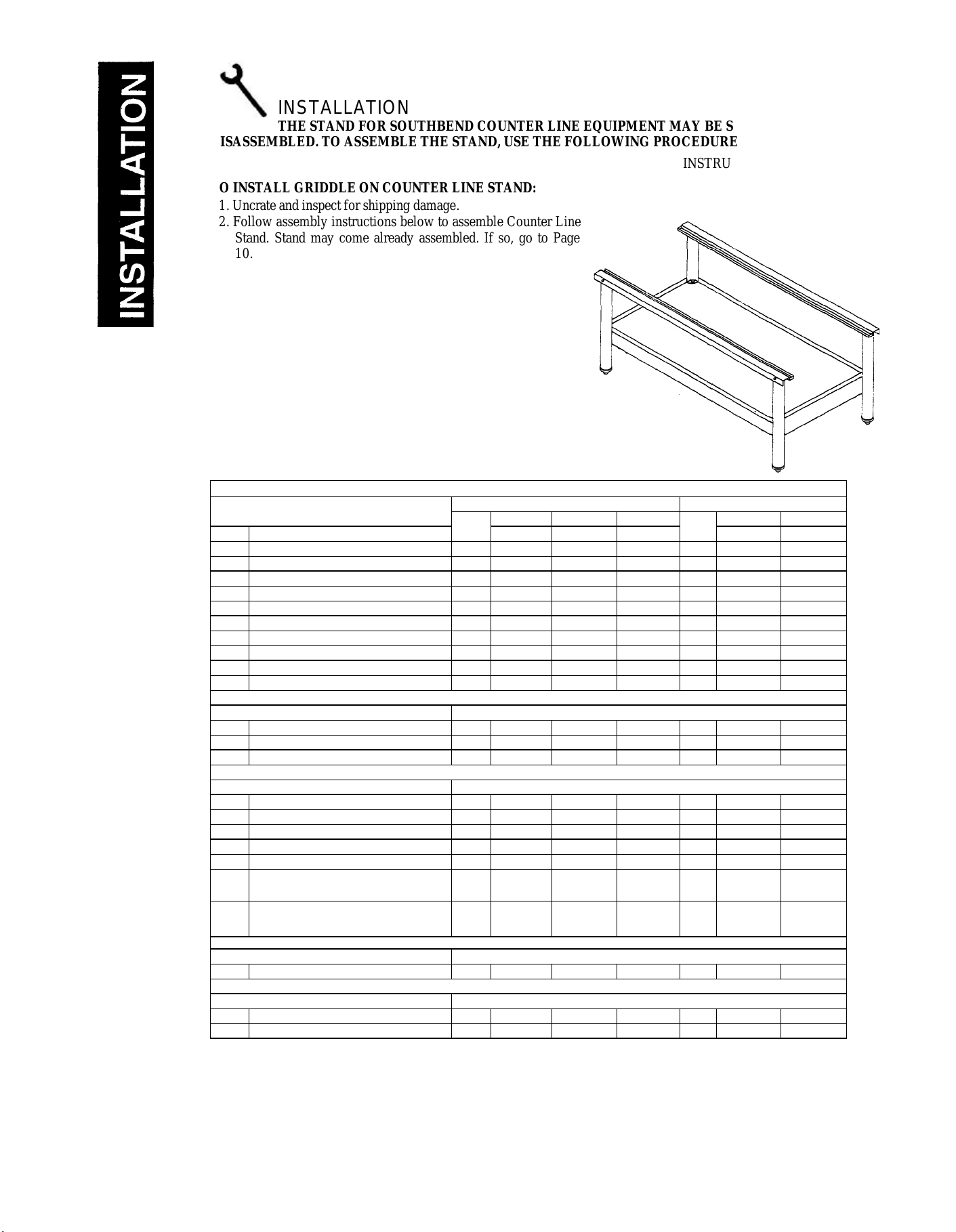

THE STAND FOR SOUTHBEND COUNTER LINE EQUIPMENT MAY BE SHIPPED

DISASSEMBLED. TO ASSEMBLE THE STAND, USE THE FOLLOWING PROCEDURES.

INSTRUCTIONS P/N 1173737

TO INSTALL GRIDDLE ON COUNTER LINE STAND:

1. Uncrate and inspect for shipping damage.

2. Follow assembly instructions below to assemble Counter Line

Stand. Stand may come already assembled. If so, go to Page

10.

ASSEMBLY INSTRUCTIONS FOR SOUTHBEND

COUNTER LINE STAND

SCL-24, SCL-36, SCL-48, SCL-60, SCL-72

PARTS LIST FOR SOUTH BEND COUNTER LINE STANDS

PARTS FOR STAND

ITEM DESCRIPTION

A Bottom brace/Lt & Rt side 2 1173709 1173709 1173709 4 1173709 1173709

B Bottom brace/front & rear 2 1173710 1173723 1173724 4 1173728 1173729

C Leg bracket 4 1173707 1173707 1173707 8 1173707 1173707

D Comer brace 4 1173706 1173706 1173706 8 1173706 1173706

E ¼ " Lock washer 16 1146500 1146500 1146500 32 1146500 1146500

F ¼” - 20 x11/2 Hex head bolt 16 1146200 1146200 1146200 32 1146200 1146200

G ¼ " - 20 Acorn nut 16 1164827 1164827 1164827 32 1144827 1144827

H ¼ " - 20 x1 ¼ Hex head bolt 8 1146203 1146203 1146203 16 1146203 1146203

I Front & rear top support 2 1173721 1173720 1173722 2 1173879 1173880

J ¼ " - 20 x 5/8 Hex head bolt 4 1146518 1146518 1146518 6 1146518 1146518

ITEM

QTY

MODELS MODELS

SCL-24 SCL-36 SCL-48 SCL-60 SCL-72

P/N P/N P/N

ITEM

QTY

P/N P/N

PARTS FOR STAND WITH LEGS

K Left leg assembly 2 1173590 1173590 1173590 2 1173590 1173590

L Right leg assembly 2 1173589 1173589 1173589 2 1173589 1173589

M Center leg assembly

PARTS FOR STAND WITH CASTERS

N Left caster leg assembly 2 1173592 1173592 1173592 2 1173592 1173592

O Right caster leg assembly 2 1173591 1173591 1173591 2 1173591 1173591

P Center caster leg assembly

Q Caster with lock 2 1174264 1174264 1174264 2 1174264 1174264

R Caster with out lock 2 1174263 1174263 1174263 4 1174263 1174263

Caster package composed 1 1174265 1174265 1174265

(2) of Item Q & (2) of Item R

Caster package composed

(2) of Item Q & (4) of Item R

PARTS FOR STAND WITH SHELF

S Shelf 1 1173717 1173718 1173719 2 1173881 1173882

STAND MOUNT PARTS SENT WITH UNIT

T Mount angle 2 1173725 1173726 1173727 2 1173733 1173878

U #10 x ½ Sheet metal screw 4 1146304 1146304 1146304 6 1146304 1146304

2 1173731 1173731

2 1173732 1173732

1 1173708 1173708

SECTION ONE — INSTALLATION

PAGE 5

2-94

Page 12

INSTALLATION

INSTALLATION

ASSEMBLY PROCEDURE FOR SCL-24, SCL-36, & SCL-48

1. Remove from carton two (2) item "A" bottom brace left and right side, and two (2) item "B" bottom brace

front and rear, and position as shown in Figure 1. Position one (1) item "D" comer brace into each comer

matching prepunched holes on the bottom inside flange of bottom braces.

2. Locate leg bracket item "C," and insert into comer being sure bracket flanges are engaged into open hem of

bottom braces.

3. Using 1/4 - 20 x 1/2 hex head bolts item T," and 1/4 lock washers item "E" along with 1/4 - 20 acorn nut item

"G," secure comer brace to bottom brace on all four comers.

NOTE: Check to be sure leg brackets are still in proper position, and outside comers are square. Only hand tighten

bolts for now.

4. Attach left leg assembly item "K," as shown in Figure 2, and right leg assembly item "L" to frame using ¼ -20 x 1 ¼

hex bolts item "H" from inside of frame. Repeat Step 4 for back side of stand.

NOTE: When installing leg assemblies be sure to have single threaded insert facing outside on the front and rear of

stand. Still only hand tighten bolts for now.

5. Now check the assembled stand, make sure that all legs are straight and all comers are square. Finish tightening all

bolts but do not over tighten.

COUNTER GRIDDLE

SECTION ONE — INSTALLATION

PAGE 6

Page 13

INSTALLATION

INSTALLATION

COUNTER GRIDDLE SECTION

*6. When stand requires casters simply substitute left caster leg assembly Item "N" for Item "K" and right caster leg

assembly Item "O" for Item "L." Screw in casters with lock Item "Q" into front caster leg assemblies, and casters

with out lock Item "R" into rear caster leg assemblies.

*7. Install optional shelf Item "S" between leg assemblies. Down flange on shelf will be to front side of stand. No

mounting screws are necessary. See Figure 3.

8. Position top front and rear support item "I" over leg assemblies as shown in Figure 4. Secure into legs assemblies

with ¼ - 20 x 5/8 hex head bolts Item "J."

*NOTE: Instructions 6 and 7 applied only to those units with optional shelf and casters.

ONE — INSTALLATION

PAGE 7

Litho in U.S.A.

2-94

Page 14

INSTALLATION

ASSEMBLY PROCEDURE FOR SCL-60 & SCL-72

1. Remove from carton four (4) Item "A" bottom brace left and right side, and four (4) item "B" bottom

brace front and rear, and position as shown in Figure 5. Position one (1) item "D" corner brace into each

comer matching prepunched holes on the bottom inside flange of bottom braces.

2. Locate leg bracket Item "C" and insert into corner being sure bracket flanges are engaged into open hem of

bottom braces.

3. Using ¼ -20 x ½ hex head bolts Item "F," and 1/4 lock washers item "E" along with ¼ -20 acorn nut item "G,"

secure corner brace to bottom brace on all eight corners.

INSTALLATION

NOTE: Check to be sure leg brackets are

still in proper position, and outside

comers are square. Only hand

tighten bolts for now.

4. Attach left leg assembly item "K," as

shown in Figure 6, right leg assembly

item "L," and center leg assembly item

"M" to frame using V, - 20 x 1/< hex

bolts item "H" from inside of frame.

Repeat Step 4 for back side of stand.

NOTE: When installing leg assemblies be

sure to have single threaded insert

facing outside on the front and rear

of stand. Still only hand tighten

bolts for now.

5. Now check the assembled stand, make

sure that all legs are straight and all comers are square. Finish tightening all bolts but do not over tighten.

COUNTER GRIDDLE SECTION

ONE—INSTALLATION

PAGE 8

Page 15

INSTALLATION

INSTALLATION

COUNTER GRIDDLE

Litho in U.S.A.

*6. When stand requires casters simply substitute left caster leg assembly item "N" for item "K," right caster leg

assembly item "O" for item "L," and center caster leg assembly item T" for item "M." Screw in casters with lock

item "Q" into left and right front caster leg assemblies, and casters without lock item "R" into rear caster leg

assemblies, and front center caster leg assembly.

*7. Install optional shelves item "S" between leg assemblies. Down flange on shelves will be to front side of stand.

No mounting screws are necessary. See Figure 7.

8. Position top front and rear su_pport item "I" over leg assemblies as shown in Figure 8. Secure into leg assemblies

with V* - 20 x %. hex head bolts item "J."

*NOTE: Instructions 6 and 7 applied only to those units with optional shelf and casters.

SECTION ONE — INSTALLATION

PAGE 9

2-94

Page 16

INSTALLATION

WARNING:

WARNING:

MOUNTING INSTRUCTIONS FOR SCL-24, SCL-36,

SCL-48, SCL-60, SCL-72

Stands for Counter Line are made to hold one or more units. When using the stand, the 4" legs on a Counter Top Unit are

not used. To mount a unit on a stand use the following procedure.

1. Mount angle support brackets item T" to unit using #10 x Yi sheet metal screws item "IT provided as shown in Figure

9. Mounting holes are prepunched for angle mounting.

2. Once brackets are attached, set unit on stand, making sure angle brackets are inserted into top front and rear supports.

No additional attachment is required.

INSTALLATION

For an appliance equipped with casters, the installation shall be made with a connector that

complies with the standard for connectors for movable gas appliances, ANSI Z21.69-1987, CANI

6.10-88, and a quick disconnect device that complies with the standard for quick-disconnect

devices for use with gas fuel, ANSI Z21.41-1978, and addenda, Z21.41a.l981, Z21.41b.l983 and

CANI 6.9 M79. Adequate means must be provided to limit the movement of the appliance

without depending on the connector and the quick-disconnect device or its associated piping to

limit the appliance movement.

If disconnect of this restraint is necessary to remove the appliance for cleaning, etc., reconnect it

when the appliance is moved to its originally installed position.

NOTE: Adequate restraining means must be attached to rear of appliance when installed. Installation must conform to

local codes as applicable.

SECTION ONE — INSTALLATION

COUNTER GRIDDLE

PAGE 10

Page 17

INSTALLATION

INSTALLATION

COUNTER GRIDDLE SECTION

Litho in U.S.A.

GAS CONNECTIONS

1. Each griddle is a complete unit with an individual 3/4" NPT supply connection at the rear. A 3/4" manual gas

shutoff valve is recommended at the gas supply inlet for complete shutdown. Standard pipe fittings are required.

2. The regulator shipped with the unit must be installed at the gas supply inlet. Be sure regulator is connected so that

the gas flow is in the same direction as the arrow on the bottom of the regulator. Refer to Figure 3.

3. The manifold pressure must be maintained at the pressure marked on the serial plate; 4" W.C. for natural gas and

10" W.C. for propane gas.

4. If applicable, the vent line from the gas appliance pressure regulator shall be installed to the outdoors in

accordance with local codes or, in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1-

1988.

NOTE: Be sure all control valves are in the "OFF" position before making gas connection.

OPTIONAL BOTTOM GAS CONNECTIONS

1. Field convertible - no additional parts necessary

A) Remove items 1,2,3,4.

B) Re-install.

ONE — INSTALLATION

PAGE 11

2-94

Page 18

OPERATION

Before turning main gas supply on, make sure all control valves are in the "OFF" position.

USER’S GUIDE

COUNTER GRIDDLE

Litho in U.S.A.

All units are adjusted at the factory. On new installations start up with the top burner of the unit(s) furthest from the gas

input to the manifold. This will purge the system of air. Turn gas supply "ON."

1. Models:

A. Models: SG series

Unit is set with each burner at 30,000 BTU/hour at the factory prior to shipment, and should bum reasonably

close to the desired flame. Natural gas manifold pressure is 4" W.C. Propane gas manifold pressure is 10"

W.C.

2. Pilot Lighting and Relighting Instructions - All Units without "E" suffix: ie Models SG.

A. Turn thermostat controls and power switch, if equipped, to OFF.

B. Remove grease drawer, raise pull button on safety valve handle and turn to OFF. Wait 5 minutes. Refer to

Figure 1.

C. Turn safety valve handle to PILOT, depress button, light pilot and hold for 45 seconds or until pilot remains

lit. Refer to Figure 2.

D. Turn safety valve handle to ON and power switch, if equipped, to ON. Refer to Figure 3.

E. If pilot is extinguished or gas is interrupted, repeat above.

F. For complete shutdown turn burner thermostats and power switch, if equipped, to OFF. Remove grease

drawer- Raise pull button on safety valve handle and turn to OFF.

NOTE: With pilot lit and safety valve handle rotated to the ON position, the runner tube will light. The runner tube

stretches across the burner compartment and carries the flame from the single pilot to all the burners. The

runner tube will be lit as long as there is a pilot and the safety valve is in the ON position.

3. Burner Operations

A. After the pilot light is lit and the safety valve handle is in the ON position, turn the burner thermostat

valves to the desired setting and verify burner ignition through the view port.

SECTION TWO — USER'S GUIDE

PAGE 2

2-94

Page 19

OPERATION

Pilot Lighting Instructions: SG-Series Models with an "E" Suffix: ie all models SB-_E

A. Turn burner control valve to OFF.

B. Remove grease drawer. Power switch must be in OFF position.

C. To light pilot, place power switch to ON position. Observe pilot flame ignition through slot in front panel.

Replace grease pan back.

D. Turn burner control valve to desired settings.

E. If pilot is extinguished or gas is interrupted, repeat above.

F. For complete shutdown turn burner control valve to OFF. Remove grease drawer. Power switch must be

in OFF position. Replace grease drawer.

NOTE: In the event of power failure, no attempt should be made to operate the appliance during prolonged

power failure outage.

MAINTENANE

WARNING:

ADJUSTMENTS AND SERVICE WORK MAY BE PERFORMED ONLY BY A QUALIFIED TECHNICIAN WHO IS EXPERIENCED IN, AND KNOWLEDGEABLE WITH,

THE OPERATION OF COMMERCIAL GAS COOKING EQUIPMENT. HOWEVER,

TO ASSURE YOUR CONFIDENCE, CONTACT YOUR AUTHORIZED SERVICE

AGENCY FOR RELIABLE SERVICE, DEPENDABLE ADVICE OR OTHER

ASSISTANCES, AND FOR GENUINE FACTORY PARTS.

USER’S GUIDE

GRIDDLES:

New griddles should be carefully tempered and maintained to avoid possible cracking and/or warping. To break in a

new griddle, first wipe it clean. Next, light all the griddle burners and turn them to 200° F for one hour. Then,

gradually bring griddle to frying temperature. Next, spread three or four ounces of beef suet or, as a substitute baking

soda, to season it. Never allow water on a hot griddle and never wash it with soap and water.

Use a Norton Alundum Griddle Brick to clean griddle. Always remember to heat griddle slowly because quick heat

may cause costly damage. Griddle plates cannot be guaranteed against damage due to carelessness. Neve r place

utensils on griddle. Do not overheat griddle above 550°F, as this will cause warpage or breakage.

Do not use any type of steel wool. Small particles may be left on the surface and get into food products.

WARNING:

DO NOT CLEAN SPATULA BY HITTING THE EDGE ON THE GRIDDLE PLATE.

SUCH ACTION WILL ONLY CUT AND PIT THE GRIDDLE PLATE, LEAVING IT

ROUGH AND HARD TO CLEAN.

COUNTER GRIDDLE SECTION

TWO — USER'S GUIDE

PAGE 3

Page 20

MAINTENANCE

USER’S GUIDE

EXTERIOR

STAINLESS STEEL: To remove normal dirt, grease, or product residue from stainless steel that operates at low

temperatures, use ordinary soap and water (with or without detergent) applied with a sponge or cloth. Dry thoroughly

with a clean cloth.

To remove grease and food splatter or condensed vapors that have baked on the equipment, apply cleanser to a damp

cloth or sponge and rub cleanser on the metal in the direction of the polishing lines on the metal. Rubbing cleanser as

gently as possible in the direction of the polished lines will not mar the finish of the stainless steel. NEVER RUB

WITH A CIRCULAR MOTION. Soil and burnt deposits which do not respond to the above procedures can usually be

removed by rubbing the surface with SCOTCH-BRITE scouring pads or STAINLESS scouring pads. DO NOT USE

ORDINARY STEEL WOOL as any particles left on the surface will rust and further spoil the appearance of the finish.

NEVER USE A WIRE BRUSH, STEEL SCOURING PADS (EXCEPT STAINLESS), SCRAPER, FILE OR OTHER

STEEL TOOLS. Surfaces which are marred collect dirt more rapidly and become more difficult to clean. Marring also

increases the possibility of corrosive attack.

TO REMOVE HEAT TINT: Darkened areas sometimes appear on stainless steel surfaces where the area has been

subjected to excessive heat. These darkened areas are caused by thickening of the protective surface of the stainless

steel and are not harmful. Heat tint can normally be removed by the foregoing, but tint which does not respond to this

procedure calls for a vigorous scouring in the direction of the polish lines using SCOTCH-BRITE scouring pads or a

STAINLESS scouring pad in combination with a powered cleanser. Heat tint action may be lessened by not applying,

or by reducing, heat to equipment during slack periods.

WARNING:

UNDER NO CIRCUMSTANCES IS GRIDDLE TO BE USED FOR HEATING STOCK

POTS. SUCH USE AUTOMATICALLY VOIDS THE WARRANTY.

COOL DOWN: At the end of each use allow griddle to cool normally. After griddle has cooled, coat griddle surface

with a light film of cooking oil to protect the surface from.moisture.

NEVER COOL GRIDDLE BY APPLYING ICE OR WATER TO GRIDDLE SURFACE.

DAMAGE DUE TO MISUSE IS NOT COVERED BY THE WARRANTY.

COUNTER GRIDDLE SECTION

TWO — USER'S GUIDE

PAGE 4

WARNING:

Litho in U.S.A.

2-94

Page 21

COUNTER GRIDDLE

SERVICE

SERVICE

ADJUSTMENTS

WARNING:

ADJUSTMENTS AND SERVICE WORK MAY BE PERFORMED ONLY BY A

QUALIFIED TECHNICIAN WHO IS EXPERIENCED IN, AND KNOWLEDGEABLE

WITH, THE OPERATION OF COMMERCIAL COOKING EQUIPMENT. HOWEVER,

TO ASSURE YOUR CONFIDENCE, CONTACT YOUR AUTHORIZED SERVICE

AGENCY FOR RELIABLE SERVICE, DEPENDABLE ADVICE OR OTHER

ASSISTANCES, AND FOR GENUINE FACTORY PARTS.

WARNING

Warranty will be void and the manufacturer is relieved of all liability IF...

(A) Service work is performed by other than a qualified technician OR...

(B) Other than Genuine Southbend replacement parts are installed.

Before making any adjustment, make sure unit is connected to the type of gas for which it is

equipped. Check for type of gas on serial plate.

.The manifold pressure on natural gas should be 4" W.C.,

Propane gas manifold pressure should be 10" W.C. The

pressure should be measured at the manifold tap with all

equipment full on.

PILOT ADJUSTMENTS:

A. Remove the pilot adjust cover screw located at the

pilot gas outlet on safety valve. Refer to Figure 4.

B. Using a screwdriver, turn pilot adjusting screw to the

right to decrease or left to increase the size of the pilot

flame. (Flame should cover thermocouple tip,

approximately 1/2".)

C. Replace pilot adjustment cover screw.

BURNER ADJUSTMENTS:

A. Turn burner valve to full ON position. (NOTE: If

griddle is cold, wait 5 minutes before making

adjustments.)

B. Loosen screw which holds the sheet metal air shutter.

C. If the flame is blowing or lifting off the burner ports,

close air shutter on front of burner until a stable

flame is obtained.

D. If the flame is yellow tipping, open the air shutter until a stable flame is obtained.

E. Tighten the set screw which holds the air shutter.

SECTION THREE — SERVICE

COUNTER GRIDDLE

PAGE 1

Page 22

ADJUSTMENTS

Litho in U.S.A.

COUNTER GRIDDLE SECTION

THERMOSTAT CALIBRATION

A. To Check Calibration:

1. Turn thermostats to the

300°F marking. See

Figure 5.

SERVICE

2. After burners have been on a minimum of 1 hour (if cold or 30 minutes if already hot when set at 300°F) place a reliable

thermometer or thermocouple with test instruments in the center of the griddle and over the center of each burner. See

Figure 6.

3. Continue to check temperatures at 5 minute intervals, until you have two readings that are within 30° of each other.

4. The control should only be recalibrated if your reading is not within 30 degrees of the dial setting (300°F).

THREE — SERVICE

PAGE 2

2-94

Page 23

ADJUSTMENTS

B. To Recalibrate Thermostat:

This control has been carefully calibrated at the factory. That is, it is so adjusted to match the actual

griddle temperatures. Field calibration is seldom necessary and it should NOT be done unless considerable

experience with cooking and temperatures definitely proves that the control is not maintaining the temperatures to

which the dial is set.

1. When recalibrating, check temperatures as instructed in previous section.

2. Set temperature indicator knob to 300°F marking.

3. Remove indicator knob j from dial stem kand insert dial stem k back on thermostat. Refer to Figure 7.

SERVICE

4. Insert screwdriver through center of dial stem k into the calibration stem slot land push calibration stem l

inward. NOTE: DO NOT TURN SCREW ON CALIBRATION STEM.

5. While holding calibration stem l in with screwdriver, look for indicator mark m on dial stem k. Refer to Figure

7A.

6. Locate indicator mark that points closest to 300°F.

7. Rotate this indicator mark untill it points to the actual temperature you are reading off of the temperature

sensing device you placed in center of grill.

8. Release pressure on calibration stem l.

9. Reinstall knob l and turn thermostat to 300°F and check temperature again at 5 minute intervals.

10. If the griddle will not adjust to within 30°F this means that the sensing bulb is inoperative and the control

should be replaced.

COUNTER GRIDDLE

SECTION THREE — SERVICE

PAGE 3

Page 24

SERVICE

Litho in U.S.A.

TROUBLE SHOOTING:

Problem Look for -

Unit will not heat up - Main gas supply is "OFF"

Burners produce excessive carbon deposits - Incorrect gas type or orifice size

SERVICE

Pilot produces excessive carbon deposits - Pilot gas not adjusted properly

Burner will not come on - Safety valve in "Pilot" position

Pilot will not stay lit - Pilot was not adjusted properly

COUNTER GRIDDLE SECTION

THREE — SERVICE

PAGE 4

- Pilot not lit

- Safety valve not "ON"

- Incorrect supply pressure

- Incorrect burner air mixer adjustment

- Burner orifice out of alignment with burner

- Incorrect orifices

- Incorrect pilot orifice

- Pilot out

- Clogged burner - charge ports

- Clogged or dirty orifice

- Draft condition

- Improper ventilation systems

- Air in gas line

- Valve end of thermocouple corroded or loose

- Pilot shield needs to be moved closer to pilot

- Improper gas pressure

- Incorrect gas supply size (not enough volume)

2-94

Page 25

COUNTER GRIDDLE

PARTS

PARTS

WARNING

INSTALLATION OF OTHER THAN GENUINE SOUTHBEND PARTS WILL VOID THE

WARRANTY OF THIS EQUIPMENT.

The serial plate is located behind the front panel, on inside right lining. There is also an Identification Plate mounted on

the left side of the front valve panel that will supply model and serial number.

Replacement parts may be ordered either through a Southbend Authorized Parts Distributor or a Southbend Authorized

Service Agency.

When ordering parts, please supply the Model Number, Serial Number, Part Number, Description, plus Finish, Type of

gas and Electrical Characteristics as applicable.

For parts not listed, consult a Southbend Authorized Parts Distributor or Southbend Authorized Service Agency. If

necessary, please consult Southbend Parts Department for assistance.

Models: SG-24,SG-24E

SG-36, SG-36E

SG-48, SG-48E

SG-60, SG-60E

SG-72, SG-72E

Suffix "E" indicates Electronic Ignition.

REPLACEMENT PARTS INDEX: see pages

Legs and Insulated Bases 2

Manifold and Runner Tube Parts 3

Body Parts SG Series 4-5

Thermostat Pilots and Controls 6-7

Rear Gas Piping and Regulators 8

Electronic Ignition Parts 9

Wiring Diagram For "E" Suffix 10

COUNTER GRIDDLE

SECTION FOUR — PARTS

PAGE 1

Page 26

PARTS

LEG AND INSULATED BASES

ITEM PART NO. DESCRIPTION 24 36 48 60 72

1 1163561 4" Leg (single) 4 4 4 8 8

2 1173884 Insulator Front 24" 1

3 1173883 Insulator Side 2 2 2 2 4

* 1173888 Insulator Base Assembly 1

* 1173889 Insulator Base Assembly

* 1173890 Insulator Base Assembly

* 1173891 Insulator Base Assembly

+ 1146304 Screw #10x1/2 Truss Head 4 4 4 4 8

1173885 Insulator Front 36"

1173886 Insulator Front 48"

1173887 Insulator Front 60"

1172857 Set of 4 Legs 1 1 1 1 2

1

1

• Includes 2 Sides — 1 Front and 4 Screws.

• + Not shown.

COUNTE GRIDDLE Litho in U.S.A.

SECTION FOUR- PARTS 2-94

PAGE 2

1

1

1

1

2

Page 27

PARTS

MANIFOLD AND RUNNER TUBE PART

ITEM PART NO. DESCRIPTION 24 36 48 60 72

1 1174358 Runner Tube Assembly 24" 1

2 1174374 Manifold Pipe Weld Assembly 24" 1

3 1058468 Orifice Spud, NAT 1

4 1147007 Pipe Plug 1/8" 1 1 1 2 2

1174362 Runner Tube Assembly 36"

1174364 Runner Tube Assembly 48"

1174378 Manifold Pipe Weld Assembly 36"

1174382 Manifold Pipe Weld Assmembly48"

1058465 Orifice Spud, NAT

1058456 Orifice Spud, NAT

1058474 Orifice Spud, Propane 1

1058470 Orifice Spud, Propane

1058468 Orifice Spud, Propane

1

1

1

1

1

1

1

1

1

1 2

1

1 2

1

1 2

1

1 2

COUNTER GRIDDLE

SECTION FOUR — PARTS

PAGE 3

Page 28

PARTS

COUNTER GRIDDLE

Litho in U.S.A.

SECTION FOUR — PARTS

PAGE 4

2-94

Page 29

PARTS

BODY PARTS SG SERIES

ITEM PART NO. DESCRIPTION SG 24 SG 36 SG 48 SG 60 SG 72

1 1174443-01 Griddle Assembly 24" 1

1 1174445-01 Griddle Assembly 36"

2 1172224 Grease Chute Weld Assembly 1 1 2 2 2

3 1174415 Control Panel Assembly 24" 1

4 1174417 Poly Cover Thermostat 2 3 4 5 6

5 1173690 Body Side Left 1 1 1 2 2

6 1173691 Body Side Right 1 1 1 2 2

7 1166662 Insulation 2 2 2 4 4

8 1173600 Side Liner, Left 1 1 1 2 2

9 1173601 Side Liner, Right 1 1 1 2 2

10 1174410 Rue Riser Front, 24" 1

11 1174402 Flue Riser Side 2 2 2 4 4

12 1174409 Flue Riser Center Support 1 2 3 5 6

13 1174403 Flue Riser Back, 24" 1

14 1174398 Grease Drawer Assembly 1 1 2 2 2

15 1174395 Lower Cover, Side 2 1 2 3 2

16 1174396 Lower Cover, Side Right 36"

17 1174466 Lower Cover Support, Left 1 1 2 2 2

18 1174394 Lower cover Support, Right 1 1 2 2 2

19 1174670 Grease Drawer Slide 2 2 4 4 4

20 1174350 Bottom Main 24" 1

21 1173676 Body Bottom Back, 24" 1

22 1174348 Leg Support, Right 1 1 1 2 2

23 1174346 Leg Support, Left 1 1 1 2 2

24 1174470 Body Bottom Support

25 1174440 Grease Chute Support 1 1 2 2 2

26 1174367 Top Front Support, 24" 1

27 1174468 Flue Diverter 2 3 4 5 6

28 1174357 Burner Rest 2 3 4 5 6

29 1174356 Burner Divider 1 2 3 3 4

30 1174353 Burner Box Bottom, 24" 1

1174355 Burner Box Bottom, 48" 1

1174447-01 Griddle Assembly 48"

1174449-01 Griddle Assembly 60"

1174451-01 Griddle Assembly 72"

1174419 Control Panel Assembly 36"

1174421 Control Panel Assembly 48"

1174411 Rue Riser Front, 36"

1174412 Flue Riser Front, 48"

1174413 Flue Riser Front, 60"

1174414 Flue Riser Front, 72"

1174405 Flue Riser Back, 36"

1174407 Flue Riser Back, 48"

1174397 Lower Cover, Center 48"

1174351 Bottom Main 36"

1174352 Bottom Main 48"

1173678 Body Bottom Back, 36"

1173680 Body Bottom Back, 48"

1174368 Top Front Support, 36"

1174369 Top Front Support 48"

1174354 Burner Box Bottom, 36"

1

1

1

1

1

1

1

1 1 2 2

1

1

1

1

1

1

1

1

1

1

1

1

1 2

1

1

1 2

1 2

1

1 2

1

1 2

1

1 2

1

1 2

COUNTER GRIDDLE

SECTION FOUR — PARTS

1

1

Page 30

PARTS

Litho in U.S.A

COUNTER GRIDDLE

SECTION FOUR — PARTS

PAGE 6

2-94

Page 31

PARTS

THERMOSTATS. PILOTS AND CONTROLS

ITEM PART NO. DESCRIPTION

1 1174341 "J"BURNER 2 3 4 5 6

2 1008737 Hood Orifice, NAT 2 3 4 5 6

1008752 Hood Orifice, Propane 2 3 4 5 6

3 1174370 Orifice Support Bar 2 3 4 5 6

4' 1148306 Orifice Body Fitting 2 3 4 5 6

5 1174393 Tube 3/8 Manifold to T Stat 2 3 4 5 6

6 1166150 Brass Elbow 2 3 4 5 6

7 1174337 Griddle Thermostat 2 3 4 5 6

8 1174366 Pilot Bracket 1 1 1 2 2

9 1173574 Pilot Body 1 1 1 2 2

10 1174423 Pilot Orifice, NAT 1 1 1 2 2

1174424 Pilot Orifice, Propane 1 1 1 2 2

11 1174467 Pilot Shield 1 1 1 2 2

12 1174371 Tube 1/4" Pilot to Safety 1 1 1 2 2

13 1161521 Thermocouple 36" Long 1 1 1 2 2

14 1173700 Manifold Pipe Support 1 1 1 2 2

15 1174384 Manifold Elbow Weld Assembly 1 1 1 2 2

16 1160008 Brass Elbow 2 2 2 4 4

17 1174392 Tube 5/8 Feed to Manifold 1 1 1 2 2

18 1174340 Combination Safety Valve 1 1 1 2 2

19 1174338 Thermostat Dial Stem 2 3 4 5 6

20 1173645 Indicator Knob 2 3 4 5 6

SG

24

SG

36

SG

48

SG

60

SG

72

* 1148306 Jam Nut Used with Orifice Body Fitting 2 3 4 5 6

COUNTER GRIDDLE

SECTION FOUR — PARTS

PAGE 7

Page 32

PARTS

COUNTER GRIDDLE

Litho in U.S.A.

For Rear Gas Connection

SECTION FOUR — PARTS

PAGE 8

SG REAR GAS PIPING AND REGULATOR

ITEM PART NO. DESCRIPTION

1 1147305 Pipe TEE 3/4" x 3/4" x 1/2"

2 1167381 Pipe Nipple 3/4" x 7" 1 1 1 1 1

3 1174594 Tee Plate Weld Assembly 1 1 1 2 2

4 1147011 Pipe Plug 3/4" 1 1 1 2 2

5 1147116 Bushing 3/4" x 1/2" 1 1 1 3 3

6 P9158 Brass Connector 1/2 x 5/8cc 1 1 1 2 2

7 1174601 Upper Tube 1 1 1 2 2

8 1174389 Cross Feed Tube - - - 1 1

9 1160205 Regulator NAT Gas 1 1 1 1 1

10 1146801 Pipe Nipple 1"x 2" 0 0 0 1 1

1160206 Regulator Propane Gas 1 1 1 1 1

SG

24

SG

36

SG

48

SG

60

1 1

SG

72

2-94

Page 33

PARTS

SGE ELECTRONIC IGNITION PARTS - USED ON ALL MODELS WITH SUFFIX "E"

ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION

1 1174807 Control Box Body 15 1174812 Tube 5/8" (90 Degrees)

2 1174806 Control Box Front 16 1146803 Nipple Black 3/4" x 3"

3 1161675 Wire Snap Bushing 1/2" 17 1174384 Manifold Elbow Weld Assembly

4 1165699 Plug, Nylon, 94V-2 4 Pin 18 1173700 Manifold Pipe Support

5 1170343 Rocker Switch DPST (ON-OFF) 19 1174810 Dual Pilot Valve w/Solenoid

6 1174813 Spark Ignition Pilot Module 20 1162957 Molded Plug and Cord

7 1172277 Transformer 21 1174808 Tube 1/4" (Pilot)

8 1172285 Strain Relief Bushing 22 1174817 Spark Ignition Cable

9 1167381 Black Pipe Nipple 3/4" x 7" 23 1174814 Spark Ignition Pilot

10 1174594 Tee Plate Weld Assembly 24 1174423 Pilot Orifice, NAT

11 1147011 Pipe Plug Black 3/4"

12 1147116 Bushing 3/4" to 1/2" 25 1174822 Wire Bundle

13 P9158 Connector Brass 1/2m x 5/8cc 26 1163054 Adhesive Label "ON"

14 1174809 Tube 5/8" (Offset)

1174424 Pilot Orifice, Propane

* 1174815 Spark Ignition Schematic

* Not Shown on Diagram.

COUNTER GRIDDLE

SECTION FOUR — PARTS

PAGE 9

Page 34

PARTS

COUNTER GRIDDLE

Litho in U.S.A.

SECTION FOUR — PARTS

PAGE 10

2-94

Page 35

A MIDDLEBY COMPANY

Convection Ovens Ranges Steam Kettles Under Fired Broilers

Cook & Hold Convection Ovens Fryers Tilting Braising Pans Salamander Broilers

Bake & Roast Ovens Special & Custom Equipment Cooker/Mixer Kettles Cheese Melters

Pizza Ovens Convection Steamers Floor Model Broilers Counter Top Broilers & Griddles

Page 36

COUNTER GRIDDLE

1100

Old Honeycutt

PART NUMBER

1174442

- 2-94

A product with the Southbend name incorporates the best in durability and low

maintenance. We all recognize however, that replacement parts and occasional

professional service may be necessary to extend the useful life of this unit.

When service is needed, contact a Southbend Authorized Service Agency, or

your dealer. To avoid confusion, always refer to the model number, serial

number, and type of your unit.

Road Fuquay.NC 27526

(919)552-9161 FAX

(919) 552-9798

(800)348-2558

Loading...

Loading...