Page 1

$6.00

southbend

A MIDDLEBY COMPANY

OWNER'S MANUAL

INSTALLATION

USER'S GUIDE

SERVICE

PARTS

IMPORTANT

FOR FUTURE REFERENCE

Please complete this

information and retain this

manual for the life of the

equipment.

MODEL #__________________

SERIAL #__________________

DATE PURCHASED__________

GAS CHAR BROILERS

MODELS: SCB-24 SCBC-24

SCB-36 SCBC-36

SCB-48 SCBC-48

SCBC60

(Includes all models with suffixes, R, A, AR)

These instructions should be read thoroughly before attempting installation. Installation and

Start Up should be performed by a qualified service technician. The Manufacturer,

Southbend (Head Office: 1100 Old Honeycutt Rd., Fuquay-Varina, North Carolina 27526),

informs you that unless the installation instructions for the above described Southbend

product are followed and performed by a qualified service technician, (a person experienced

in and knowledgeable concerning the installation of commercial gas and/or electrical cooking

equipment) then the terms and conditions of the Manufacturer's Limited Warranty will be

rendered void and no warranty of any kind shall apply.

If the equipment has been changed, altered, modified or repaired by other than a qualified

service technician during or after the 12-month limited warranty period, then the

manufacturer shall not be liable for any incidental or consequential damages to any person

or to any property which may result from the use of the equipment thereafter. Some States

do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion thereto may not apply to you.

In the event you have any questions concerning the installation, use, care, or service of the

product, write Customer Service Department, Southbend, 1100 Old Honeycutt Rd., Fuquay Varina, North Carolina 27526.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death. Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

CHAR BROILERS

(Manual Section BR)

Page 2

Congratulations! You have just purchased one of the finest pieces of heavy-duty, commercial cooking equipment on the market

A MIDDLEBY COMPANY

1100 Old Honeycutt Road

today.

You will find that your new equipment, like all Southbend equipment, has been designed and manufactured to some of the

toughest standards in the industry — those of Southbend. Each piece of Southbend equipment has been carefully engineered and

designs have been verified through laboratory tests and field installations in some of the more strenuous commercial cooking

applications. With proper care and field maintenance, you will experience years of reliable, trouble -free operation from your

Southbend equipment. To get the best results, it's important that you read this manual carefully.

TABLE OF CONTENTS:

SECTION ONE - INSTALLATION

Specifications ......................................…………...... 1

Installation .....................................……………........ 2

SECTION TWO - USER'S GUIDE

Warranty.........................................…………….......

Operation....................................……………............

Maintenance............................…………........... . ....

SECTION THREE - SERVICE

Adjustments ..................................……............ .... .. 1

Troubleshooting .............................…....................... 2

SECTION FOUR - PARTS

Parts List.......................................……..................... 1

1

2

4

CAUTION: POST IN PROMINENT LOCATION INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION SHALL BE OBTAINED

FROM LOCAL GAS SUPPLIER.

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

INTENDED FOR COMMERCIAL USE ONLY. NOT FOR HOUSEHOLD USE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

KEEP AREA AROUND APPLIANCES FREE AND CLEAR FROM COMBUSTIBLES.

IN THE EVENT A GAS ODOR IS DETECTED. SHUT DOWN EQUIPMENT AT THE MAIN

SHUTOFF VALVE AND CONTACT THE LOCAL GAS COMPANY OR GAS SUPPLIER FOR

SERVICE.

southbend

Fuquay, NC 27526

(919) 552-9161

FAX (919) 552-9798

(800) 348-2558

Page 3

GAS CHAR BROILER

USER'S GUIDE

LIMITED WARRANTY

Southbend warrants that the equipment, as supplied by the factory to the original purchasers, is free from defects in materials

and workmanship. Should any part thereof become defective as a result of normal use within the period and limits defined

below, then at the option of Southbend such parts will be repaired or replaced by Southbend or its Authorized Service Agency.

This warranty is subject to the following conditions:

If upon inspection by Southbend or its Authorized Service Agency it is determined that this equipment has not been used in an

appropriate manner, has been modified, has not been properly maintained, or has been subject to misuse or misapplication,

neglect, abuse, accident, damage during transit or delivery, fire, "flood, riot or Act of God, then this warranty shall be void.

Specifically excluded under this warranty are claims relating to installation; examples are improper utility connections and

improper utilities supply. Claims relating to normal care and maintenance are also excluded; examples are calibration of

controls, and adjustments to pilots and burners.

Equipment failure caused by inadequate water quality is not covered under warranty. WATER QUALITY must not exceed the

following limits: Total Dissolved Solids (TDS) - 60 PPM (Parts Per Million). Hardness - 2 Grains or 35 PPM, PH Factor

- 7.0 to 7.5. Water pressure 30 PSI minimum, 60 PSI maximum. Boiler maintenance is the responsibility of the owner and is not

covered by warranty.

This equipment is intended for commercial use only. Warranty is void if equipment is installed in other than commercial

application.

Repairs under this warranty are to be performed only by a Southbend Authorized Service Agency. Southbend can not be

responsible for charges incurred from other than Authorized Southbend Agencies. THIS WARRANTY MUST BE SHOWN TO AN

AUTHORIZED SERVICE AGENCY WHEN REQUESTING IN-WARRANTY SERVICE WORK. THE AUTHORIZED SERVICE

AGENCY MAY AT HIS OPTION REQUIRE PROOF OF PURCHASE. This warranty does not cover services performed at

overtime or premium labor rates nor does Southbend assume any liability for extended delays in replacing or repairing any items

in the equipment beyond the control of Southbend. "Southbend shall not be liable for consequential or special damages of any

nature that may arise in connection with such product or part." Should service be required at times which normally involve

overtime or premium labor rates, the owner shall be charged for the difference between normal service rates and such premium

rates. In all circumstances, a maximum of one hundred miles in travel and two and one half hours (25) travel time shall be

allowable. In all cases the closest Southbend Authorized Agency must be used. The actual warranty time periods and exceptions

are as follows:

This warranty only covers product shipped into the 48 contiguous United States and Hawaii, one year labor, one year parts

effective from the date of original purchase. There will be no labor coverage for equipment located on any island not connected

by roadway to the mainland. Exceptions to standard warranty, effective within above limitations:

Glass Windows, Door Gaskets, Rubber Seals, Light Bulbs, Ceramic Bricks,

Sight Glasses, Cathodic Descalers or Anodes ..…......………………………………………...................... 90 days material and labor

Stainless Steel Fry Pot.....................…………….…………………... .4 years extended material warranty on fry pot only — no labor

Stainless Steel Open Top Burners..………….………………...........4 years extended material warranty on burners only — no labor

Pressure Steam Boiler Shell .......…………………………........ Prorated 4 years extended warranty on boiler shell only — no labor

In all cases parts covered by a five year warranty will be shipped FOB the factory after the first year. Our warranty on all

replacement parts which are replaced in the field by our Authorized Service Agencies will be limited to three months on labor, six

months on materials (parts) effective from the date of installation. See LIMITED WARRANTY

- REPLACEMENT PARTS for conditions and limitations.

If the equipment has been changed, altered, modified or repaired by other than a qualified service technician during

or after the one year limited warranty period, then the manufacturer shall not be liable for any damages to any person

or to any property which may result from the use of the equipment thereafter.

"THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS, AND CONSTITUTES THE ENTIRE

LIABILITY OF SOUTHBEND. IN NO EVENT DOES THE LIMITED WARRANTY EXTEND BEYOND THE DURATION

OF ONE YEAR FROM THE EFFECTIVE DATE OF SAID WARRANTY."

Boiler shells which have not been properly maintained will not be covered by warranty.

SECTION TWO — USER'S GUIDE

CHAR BROILER

PAGE 1

Page 4

GAS CHAR BROILERS

SERVICE

ADJUSTMENTS

WARNING:

ADJUSTMENTS AND SERVICE WORK MAY BE PERFORMED ONLY BY A QUALIFIED

TECHNICIAN WHO IS EXPERIENCED IN, AND KNOWLEDGEABLE WITH, THE

OPERATION OF COMMERCIAL COOKING EQUIPMENT. HOWEVER, TO ASSURE YOUR

CONFIDENCE, CONTACT YOUR AUTHORIZED SERVICE AGENCY FOR RELIABLE

SERVICE, DEPENDABLE ADVICE OR OTHER ASSISTANCES, AND FOR GENUINE

FACTORY PARTS.

Before making any adjustment, make sure unit is connected to the type of gas for which it is equipped. Check for type of gas on

serial plate.

The manifold pressure on natural gas should be 6" W.C. for free standing units, 6" W.C. for sectional type broilers, and 4" W.C.

for counter type broilers. Propane manifold pressure should be 10" W.C. for all.

PILOT ADJUSTMENTS:

ALL PILOT FLAMES SHOULD BE STABLE AND NOT CARBON PRODUCING.

All pilots are adjustable by turning the slotted screw on the pilot valve located through the front panel, at the manifold. Each

burner incorporates an individual pilot burner.

BURNER ADJUSTMENT:

ALL BURNER FLAMES SHOULD BE STABLE BLUE WITHOUT BLOWING OR YELLOW TIPPING.

1. Turn valve to full on position.

2. Loosen screw which holds the sheet metal air shutter.

3. If the flame is blowing or lifting off of the ports, close air shutter on front of burner until a stable flame is obtained.

4. If the flame is yellow tipping, open the air shutter until a stable flame is obtained.

5. Tighten the set screw which holds the air shutter.

SECTION THREE — SERVICE

CHAR BROILERS

PAGE 1

Page 5

not turn on

A. Only some ranges in a bat

tery —

Incorrect orifices.

produce excessive carbon

—

Primary air not adjusted properly.

B. Counter model produces

—

Same as above.

excessive carbon deposits

not come on

—

Pilot out.

stay ignited

—

Clogged orifice.

—

Improper ventilation system.

SERVICE

CHAR BROILERS

Litho in U.S.A

.

TROUBLE SHOOTING:

Problem Look for —

A. All ranges in battery will — Main gas supply to ranges is "OFF."

B. Counter model will not turn. — Same as above.

A. All ranges produce excessive —

carbon deposits — Incorrect supply pressure.

B. Counter model produces — Same as above.

excessive carbon deposit.

deposits (burners)

Incorrect gas type supplied to battery.

(burners).

Only some pilots produce — Pilot gas not adjusted properly.

excessive carbon deposits — Incorrect pilot orifice.

Burner will — Manual valve in "OFF" position.

Top section pilot will not — Pilot gas not adjusted properly.

— Clogged burner charge port.

— Draft condition.

— Air in gas line.

SECTION THREE — SERVICE

PAGE 2

11-92

Page 6

southbend

A MIDDLEBY COMPANY

Convection Ovens Ranges Steam Kettles Under Fired Broilers

Cook & Hold Convection Ovens Fryers Tilting Braising Pans Salamander Broilers

Bake & Roast Ovens Special & Custom Equipment Cooker/Mixer Kettles Cheese Melters

Pizza Ovens Convection Steamers Floor Model Broilers Counter Top Broilers & Griddles

Page 7

GAS CHAR BROILERS

9161

A MIDDLEBY COMPANY

A product with the Southbend name incorporates the best in durability and low

maintenance. We all recognize however, that replacement parts and occasional

professional service may be necessary to extend the useful life of this unit. When

service is needed, contact a Southbend Authorized Service Agency, or your dealer.

To avoid confusion, always refer to the model number, serial number, and type of

your unit.

southbend

1100 Old Honeycutt Road

Fuq Fuquay-Varina. NC 27526

PART NUMBER 1173265 Rev. 11-92

(919)552FAX (919) 552-9798

(800) 348-2558

Page 8

S E R V I C E

southbend B•U•L•L•E•T•I•N

TO: Southbend Parts & Service Distributors

FROM: Thomas S. Enyeart- CFSP

Director Product Service

DATE: February 5, 1994 BULLETIN #9430

SUBJECT: Valve Change- Floor Model Char Broilers – Propane Gas.

Models SCB-24, SCB-36, SCB-48 and all same with suffix - R

Please insert this Bulletin with the #1173265 Gas Char Broiler owners

manual in the BR- Broiler & Cheese Melters section of your master

Southbend Manual.

Effective December, 1993 Serial #94A and thereafter

Floor Model Char Broiler Valves have been changed. Changing from the old

style to the new style for the first time requires a new knob. The kit is

available for the first time change only. After the original change or on new

style units the valve only can be changed.

DISCONTINUED PART:

1176750 Valve

This part will be available until existing stock is depletedapproximately 18 months. Then it will be obsolete and no longer

available.

NEW PARTS:

1176009 Valve -Hi Low- Propane Gas

When replacing 1076750 for the first time use:

4440401 Valve Replacement Kit- Propane Gas

This kit consists of: (all parts also available individually)

1176009 Valve-Hi Low- Propane Gas

1166011 Valve Knob

NOTE: The new valve can only be used for Propane Gas

For Natural Gas See Bulletin 9429- Part numbers 1176008 &

4440402.

The old valve used a 1160532 Valve Knob which is still available.

1100 Old Honeycutt Rd. • Fuquay-Varina, NC 27526 • (919) 552-9161 • (800) 348-2558 • Fax (919) 552-9798

Parts Service Hotline (800) 54 RANGE (800-547-2643)

Page 9

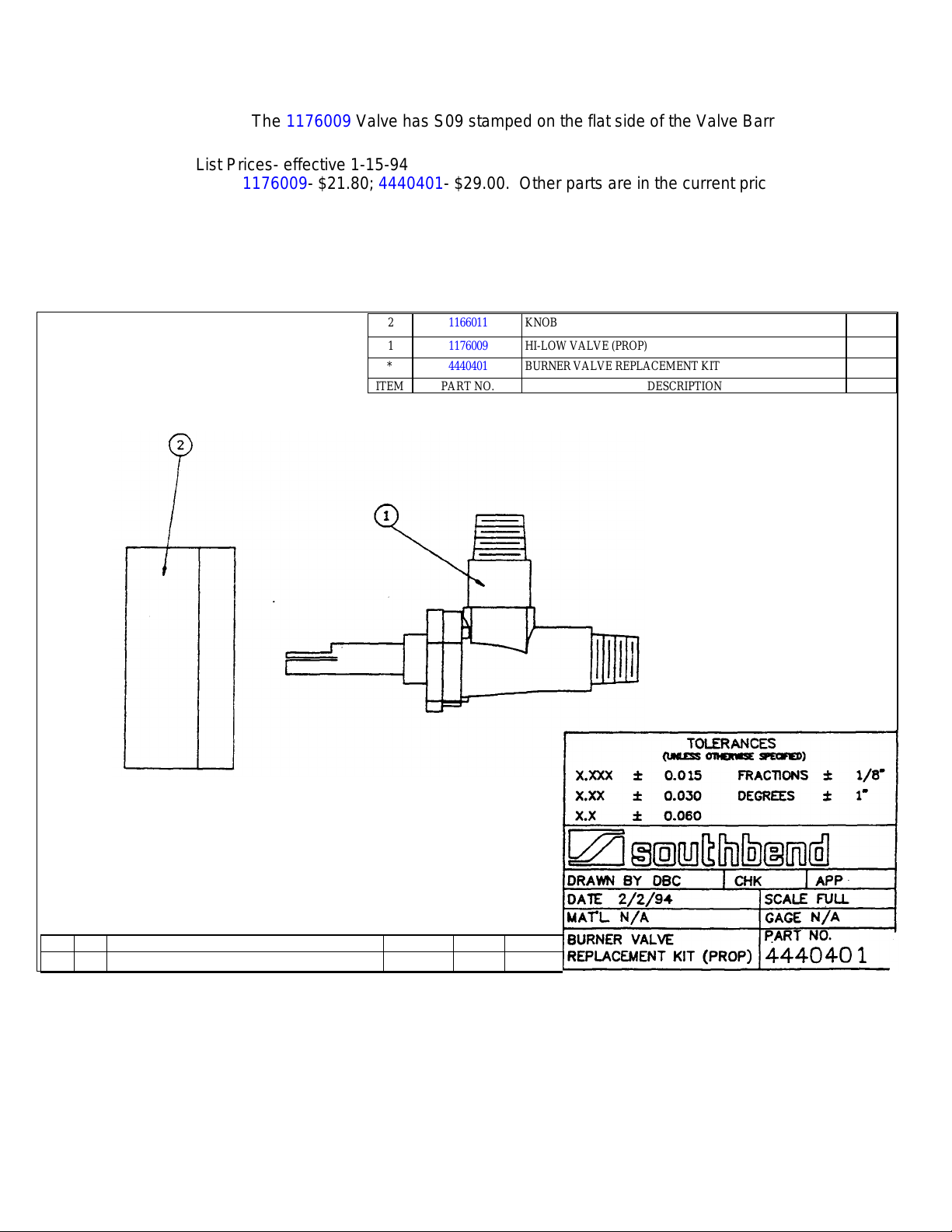

The 1176009 Valve has S09 stamped on the flat side of the Valve Barrel.

ITEM PART NO.

DESCRIPTION

Qty.

List Prices- effective 1-15-94

1176009- $21.80; 4440401- $29.00. Other parts are in the current price list.

TE/dy

2 1166011 KNOB 1

1 1176009 HI-LOW VALVE (PROP) 1

* 4440401 BURNER VALVE REPLACEMENT KIT *

ACAD SIZE A DWGDO NOT HAND ALTER

REV SYM

DRAWING RELEASED

2/2/94

REVISION DATE BY

DBC 94-30

ECN

Page 10

S E R V I C E

southbend B•U•L•L•E•T•I•N

TO: Southbend Parts & Service Distributors

FROM: Thomas S. Enyeart- CFSP

Director Product Service

DATE: February 5, 1994 BULLETIN #9429

SUBJECT: Valve Change- Floor Model Char Broilers – Natural Gas.

Models SCB-24, SCB-36, SCB-48 and all same with suffix - R

Please insert this Bulletin with the #1173265 Gas Char Broiler owners

manual in the BR- Broiler & Cheese Melters section of your master

Southbend Manual.

Effective December, 1993 Serial #94A and thereafter

Floor Model Char Broiler Valves have been changed. Changing from the old

style to the new style for the first time requires a new knob. The kit is

available for the first time change only. After the original change or on new

style units the valve only can be changed.

DISCONTINUED PART:

1076750 Valve

This part will be available until existing stock is depletedapproximately 18 months. Then it will be obsolete and no longer

available.

NEW PARTS:

1176008 Valve -Hi Low- Natural Gas

When replacing 1076750 for the first time use:

4440402 Valve Replacement Kit- Natural Gas

This kit consists of: (all parts also available individually)

1176008 Valve-Hi Low- Natural Gas

1166011 Valve Knob

NOTE: The new valve can only be used for Natural Gas

For Propane Gas See Bulletin 9430- Part numbers 1176009 &

4440401.

The old valve used a 1160532 Valve Knob which is still available.

1100 Old Honeycutt Rd. • Fuquay-Varina, NC 27526 • (919) 552-9161 • (800) 348-2558 • Fax (919) 552-9798

Parts Service Hotline (800) 54 RANGE (800-547-2643)

Page 11

The 1176008 Valve has S08 stamped on the flat side of the Valve Barrel.

ITEM PART NO.

DESCRIPTION

Qty.

List Prices- effective 1-15-94

1176008- $21.80; 4440402- $29.00. Other parts are in the current price list.

TE/dy

2 1166011 KNOB 1

1 1176008 HI-LOW VALVE (NAT) 1

* 4440402 BURNER VALVE REPLACEMENT KIT *

ACAD SIZE A DWGDO NOT HAND ALTER

REV SYM

DRAWING RELEASED

2/2/94

REVISION DATE BY

DBC 94-30

ECN

Page 12

S E R V I C E

southbend B•U•L•L•E•T•I•N

TO: Southbend Parts & Service Distributors

FROM: Thomas S. Enyeart- CFSP

Director Product Service

DATE: February 5, 1994 BULLETIN #9428

SUBJECT: Valve Change- Floor Model Char Broilers – Propane Gas.

Models SCBC-24, SCBC-36, SCBC-48 and all same with

suffix - R

Please insert this Bulletin with the #1173265 Gas Char Broiler owners

manual in the BR- Broiler & Cheese Melters section of your master

Southbend Manual.

Effective December, 1993 Serial #93L and thereafter

Counter Char Broiler Valves have been changed. Changing from the old

style to the new style for the first time requires a new knob. The kit is

available for the first time change only. After the original change or on new

style units the valve only can be changed.

DISCONTINUED PART:

1163552 Valve

This part will be available until existing stock is depletedapproximately 2 years. Then it will be obsolete and no longer

available.

This part was also used on Cheese Melters. See bulletin 9425 & 9426.

NEW PARTS:

1176011 Valve -Hi Low- Propane Gas

When replacing 1163552 for the first time use:

4440399 Valve Replacement Kit- Propane Gas

This kit consists of: (all parts also available individually)

1176011 Valve-Hi Low- Propane Gas

1099121 3/8 CC Nut

1099122 3/8 Ferrule

NOTE: The new valve can only be used for Propane Gas

1100 Old Honeycutt Rd. • Fuquay-Varina, NC 27526 • (919) 552-9161 • (800) 348-2558 • Fax (919) 552-9798

Parts Service Hotline (800) 54 RANGE (800-547-2643)

Page 13

For Natural Gas see Bulletin #9427, Part numbers 1176010 & 4440400.

ITEM PART NO.

DESCRIPTION

Qty.

Both valves use #1173645 Valve Knob.

The 1176011 Valve has S11 stamped on the flat side of the Valve Barrel.

List Prices- effective 1-15-94

1176011- $23.80; 4440399- $26.00; 1099122-$1.00. Other parts are in the

current price list.

TE/dy

3 1099121 3/8 CC NUT

2 1099122 3/8 FERRULE 1

1 1176011 VALVE HI-LOW (PROPANE) 1

* 4440399 BURNER VALVE REPLACEMENT KIT *

REV SYM

DRAWING RELEASED

2/2/94

REVISION DATE BY

DBC 94-30

ACAD SIZE A DWGDO NOT HAND ALTER

ECN

Page 14

S E R V I C E

southbend B•U•L•L•E•T•I•N

TO: Southbend Parts & Service Distributors

FROM: Thomas S. Enyeart- CFSP

Director Product Service

DATE: February 5, 1994 BULLETIN #9427

SUBJECT: Valve Change- Floor Model Char Broilers – Natural Gas.

Models SCBC-24, SCBC-36, SCBC-48, SCBC-60, and all same

with suffix - R

Please insert this Bulletin with the #1173265 Gas Char Broiler owners

manual in the BR- Broiler & Cheese Melters section of your master

Southbend Manual.

Effective December, 1993 Serial #93L and thereafter

Counter Char Broiler Valves have been changed. Changing from the old

style to the new style for the first time requires a new knob. The kit is

available for the first time change only. After the original change or on new

style units the valve only can be changed.

DISCONTINUED PART:

1163552 Valve

This part will be available until existing stock is depletedapproximately 2 years. Then it will be obsolete and no longer

available.

This part was also used on Cheese Melters. See bulletin 9425 & 9426.

NEW PARTS:

1176010 Valve -Hi Low- Natural Gas

When replacing 1163552 for the first time use:

4440400 Valve Replacement Kit- Natural Gas

This kit consists of: (all parts also available individually)

1176010 Valve-Hi Low- Natural Gas

1099121 3/8 CC Nut

1099122 3/8 Ferrule

NOTE: The new valve can only be used for Natural Gas

1100 Old Honeycutt Rd. • Fuquay-Varina, NC 27526 • (919) 552-9161 • (800) 348-2558 • Fax (919) 552-9798

Parts Service Hotline (800) 54 RANGE (800-547-2643)

Page 15

TE/dy

For Propane Gas see Bulletin #9428, Part numbers '176008 &

4440402.

Both valves use #1173645 Valve Knob

The 1176010 Valve has S10 stamped on the flat side of the Valve

Barrel.

List Prices- effective 1-15-94

1176010- $23.80; 4440400- $26.00.; 1199122- $1.00. Other parts are in the

current price list.

Page 16

S E R V I C E

southbend B•U•L•L•E•T•I•N

TO: Southbend Parts & Service Distributors

FROM: Thomas S. Enyeart- CFSP

Director Product Service

DATE: February 5, 1994 BULLETIN #9403

SUBJECT: Correction/ Clarification of Gas Pressure Regulators used on

Char Broilers. Models SCB & SCBC.

Please insert this Bulletin with the #1173265 Gas Char Broiler owners

manual in the BR- Broiler section of your master Southbend Manual.

When the owners manual was printed there was an error on pressure

regulator usage. The following corrects this error and clarifies the usage.

For Sectional (Front Manifold) Char Broilers – Models SCB-24, 36, 48

#1167782 Pressure Regulator – 1” – Natural Gas – Set at 6”wc

#1167783 Pressure Regulator – 1” – Propane Gas – Set at 10”wc

For Counter Char Broilers – Models SCBC-24, 36, 48, 60

#1160205 Pressure Regulator – ¾” Natural Gas – Set at 5”wc

#1160206 Pressure Regulator – ¾” Propane Gas – Set at 10”wc

Note: Part #1160205 is used on other units and is a Mandatory Distributor

Stock Part.

TE/dy

1100 Old Honeycutt Rd. • Fuquay-Varina, NC 27526 • (919) 552-9161 • (800) 348-2558 • Fax (919) 552-9798

Parts Service Hotline (800) 54 RANGE (800-547-2643)

Page 17

GAS CHAR BROILER

A

B

H

J

(457)

(737)

(559)

(991)

(737)

(559)

(991)

.81

cu. m.

(457)

(737)

(559)

(991)

?SCBC

-

24AR

(

737)

(559)

(991)

(737)

(559)

(991)

(330)

(737)

(559)

( ) =

Millimeters

( )=

Millimeters

INSTALLATION

FRONT MANIFOLD AND FREE STANDING TYPES

Floor Model Units - Models SCB-24, 36, 48 SPECIFICATIONS

SIDE VIEW FRONT VIEW TOP VIEW

DIMENSIONS:

EXTERIOR 1 ¼” MAN.PIPE 1" REAR GAS

MODEL

WIDTH

DEPTH

C D E F G

TOTAL

I

CK.TOP

K L M N

SCB24

SCB-24R

SCB-36

SCB-36R

SCB-48

SCB-4R

24"

(610)

36"

(914)

48”

(1219)

36"

(914)

36-

(914)

36"

(914)

—

—

—

31¾”

(806)

31¾”

(806)

31¾”

(806)

33"

(838)

33"

(838)

33"

(838)

3"

(76)

3"

(76)

3”

(76)

COUNTER UNITS - Models SCBC-24, 36, 48, 60

SIDE VIEW FRONT VIEW TOP VIEW

DIMENSIONS:

MODEL

? SCBC-24

? SCBC-24R

? SCBC-36

?SCBC-36R

?SCBC-48

?SCBC-48R

?SCBC-24A

?SCBC-36A

?SCBC-36AR

?SC8C-48A

?SCBC-48AR

?SCBC-60A

?SCBC-60AR

EXTERIOR CRATE SIZE

WIDTH DEPTH HEIGHT

A B C D E F G H 1 J

24"

(610)

36”

(914)

48”

(1219)

24”

(610)

36”

(914)

48"

(1219)

60"

(1524)

30"

(762)

30"

(762)

30"

(762)

30”

(762)

30"

(762)

30"

(762)

30”

(762)

18”

18”

(457)

18”

18”

(457)

18”

(457)

18”

(457)

18"

(457)

5"

(127)

5"

(127)

5”

(127)

5”

(127)

5”

(127)

5"

(127)

5"

(127)

Cooking

Surface

13”

(330)

13"

(330)

13"

(330)

13”

(330)

13”

(330)

13”

13"

(330)

29"

29"

29"

29"

29"

29"

29"

(737)

27 7/8”

(708)

27 7/8”

(708)

27 7/8”

(708)

27 7/8”

(708)

27 7/8”

(708)

27 7/8”

(708)

27 7/8”

(708)

17"

(430)

17"

(430)

17"

(430)

22"

22"

22”

22”

22"

22"

22"

(559)

36"

(914)

36"

(914)

36"

(914)

¾” Gas

Connection

2 3/8”

(60)

2 3/8”

(60)

2 3/8”

(60)

2 3/8”

(60)

2 3/8”

(60)

2 3/8”

(60)

2 3/8”

(60)

6"

(152)

6"

(152)

6"

(152)

1 ½”

(38)

1 ½”

(38)

1 ½”

(38)

1 ½”

(38)

1 ½”

(38)

1 ½”

(38)

1 ½”

(38)

30"

(762)

30"

(762)

30"

(762)

Burners

(BTU ea)

2ea.

(40.000)

3ea.

(40,000)

4ea.

(40.000)

2ea.

(36,000)

3ea.

(36.000)

4ea.

(36.000)

5ea.

(36.000)

33¾”

(857)

33¾”

(857)

33¾”

(857)

WIDTH DEPTH HEIGHT

31"

(787)

55"

(1397)

55"

(1397)

31"

(787)

55"

(1397)

55"

(1397)

67"

(1702)

39"

39-

39"

39"

39"

39"

(991)

39"

(991)

33½”

(851)

33½”

(851)

33½”

(851)

24"

(610)

24"

(610)

24"

(610)

24"

(610)

24”

(610)

24”

(610)

24"

(610)

SECTION ONE — INSTALLATION

14"

14"

14"

CUBIC

VOLUME

16.8 cu. ft.

.47 cu. m.

28.9cu.ft.

28.9cu.ft.

.81 cu.m.

16.8cu.ft.

.47 cu. m.

28.9cu.ft.

.81 cu. m.

28.9cu.ft.

.81 cu.m.

2½”

(63)

2½”

(63)

2½”

(63)

(356)

(356)

(356)

CHAR BROILERS

CRATED

WEIGHT

240 Ibs. 109.1 kg.

200 Ibs. 90.9kg.

350 Ibs. 159.1kg.

290 Ibs. 131.8kg.

425 Ibs. 193.2kg.

345 Ibs. 156.8 kg.

240 Ibs. 109.1 kg.

200 Ibs. 90.9kg.

350 Ibs. 159.1kg.

290 Ibs. 131.8kg.

425 Ibs. 193.2kg.

345 Ibs. 156.8kg.

PAGE 1

Page 18

INSTALLATION

WARNING: THESE PROCEDURES MUST BE FOLLOWED BY QUALIFIED PERSONNEL OR

WARRANTY WILL BE VOIDED.

GENERAL:

The installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1 - Latest Edition. Canadian installation must comply with CAN/CGA-B 149.1 Natural Gas

Installation Code, Code CAN/CGA-B 149.2 Propane Installation Code.

These models are design certified for operation on Natural or Propane gases.

The appliance should be connected ONLY to the type of gas for which it is equipped. All Southbend equipment

is adjusted at the factory.

NOTE: Check type of gas on serial plate.

Models: SCB-Series - serial plate located left front comer on bottom inside lower compartment.

Models: SCBC-Series - remove front control panel. Serial plate attached in the center on the compartment

front shield to unit.

NOTE: Each SCB-Series Broiler is a complete unit with an individual W NPT manifold across its entire width.

Units can be batteried by joining the unions at the ends of the manifolds. This manifold is not equipped

directly with a pressure regulator. However, the manifold must be connected with an adequately sized gas

appliance pressure regulator adjusted to supply a pressure to this manifold as marked on the serial plate; 6"

W.C. for natural gas and 10" W.C. for propane gas. In addition, the pressure regulator must meet the

following requirements:

1. The pressure regulator installed should be certified by a nationally recognized testing agency.

2. The regulator must have a maximum regulation capacity for the total connected load.

3. The regulator must have a pressure adjustment range to allow adjustment to the manifold pressure on the

appliance rating plate.

4. Unless the manifold pressure of all connected appliances is the same, a separate regulator must be supplied

for each unit(s) to indicate unit or units having differing manifold pressures.

5. If applicable, the vent line from the gas appliance pressure regulator shall be installed to the outdoors in

accordance with local codes or, in the absence of local codes, with the National Fuel Gas Code, ANSI Z23.1 Latest Edition. Canadian installation must comply with CAN/CGA-B 149.1 Natural Gas Installation Code,

Code CAN/CGA-B149.2 Propane Installation Code.

An adequate gas supply is imperative. Undersized or low pressure lines will restrict the volume of gas required for

satisfactory performance. A steady supply pressure, between 7" W.C. and 8" W.C. for natural gas and 11" W.C.

and 12" W.C. for propane gas is recommended. With all units operating simultaneously, the manifold pressure on

all units should not show any appreciable drop. Fluctuations of more than 25% on natural and 10% on propane

gas will create pilot problems and affect burner operating characteristics. Contact your gas company for correct

supply line sizes.

As an option, the unit may be supplied with a rear gas connection. The pipe size of this connection is one inch.

Unless otherwise specified, this connection is welded to the right side of the manifold.

NOTE: Each SCBC-Series Counter Broiler is a complete unit with an individual ¾” NPT supply connection at

the rear. An adequate gas supply is imperative. Undersized or low pressure lines will restrict the volume of gas

required for satisfactory performance. A pressure regulator, which is provided with each unit, is set to maintain

a 4" W.C. manifold pressure for natural gas and a 10" W.C. manifold pressure for propane gas. However, to

maintain these conditions the pressure on the supply line, when all units are operating simultaneously, should

not drop below 7" W.C. for natural gas or 11” W.C. for propane gas.

A 1/8” pressure tap is located on the manifold of each unit.

All pipe joints should be tested for leaks with a soap and water solution before operating the unit. The test

pressure should not exceed 14" W.C.

CAUTION: THIS APPLIANCE AND ITS INDIVIDUAL SHUTOFF VALVE MUST BE DISCONNECTED

FROM THE GAS SUPPLY PIPING SYSTEM DURING ANY PRESSURE TESTING OF THAT

SYSTEM AT TEST PRESSURES IN EXCESS OF 112 PSIG (3.45 kPa).

THIS APPLIANCE MUST BE ISOLATED FROM THE GAS SUPPLY PIPING SYSTEM BY CLOSING

ITS INDIVIDUAL MANUAL SHUTOFF VALVE DURING ANY PRESSURE TESTING OF THE GAS

SUPPLY PIPING SYSTEM AT TEST PRESSURES EQUAL TO OR LESS THAN 112 PSIG (3.45

kPa).

CHAR BROILERS

SECTION ONE — INSTALLATION

PAGE 2

Litho in U.S.A.

11-92

Page 19

INSTALLATION

WARNING: THESE PROCEDURES MUST BE FOLLOWED BY QUALIFIED PERSONNEL

OR WARRANTY WILL BE VOIDED.

EXHAUST FANS AND CANOPIES:

Canopies are set over ranges, ovens, etc., for ventilation purposes. It is recommended that a canopy extend 6" past appliance

and be located 6'6" from the floor. Filters should be installed at an angle of 45 degrees or more with the horizontal. This

prevents dripping grease and facilitates collecting the run-off grease in a drip pan, usually installed with a filter. A strong

exhaust fan tends to create a vacuum in the room and may interfere with burner performance or may extinguish pilot flames.

Fresh air openings approximately equal to the fan area will relieve such vacuum. In case of unsatisfactory performance on any

appliance, check with the exhaust fan in the "OFF" position.

WALL EXHAUST FAN: Should be installed at least 2 feet above the vent opening at the top of the backsplash.

NOTE: Be sure to inspect and clean ventilation system according to the ventilation equipment manufacturers instructions.

CLEARANCES

Minimum clearances from combustible construction are: (Canadian installations only)

MODEL TYPE SIDES REAR

FLOOR MODELS 12 IN. 6 IN.

COUNTER MODELS 12 IN. 6 IN.

Minimum clearances from non-combustible construction are: )

MODEL TYPE SIDES REAR

ALL MODELS 0 IN. 0 IN.

WARNING: All units must be installed in such a manner that the flow of combustion and ventilation air are not obstructed.

Provisions for an adequate air supply must also be provided. Do not obstruct the front of the unit at the top by the control

panel.

NOTE: No additional clearance from the sides and back is required for service, as the units are serviceable from the front.

FOR FLOOR MODELS - LEGS OR OPTIONAL CASTERS:

1. A set of legs or casters are packed in the unit. A threaded receptacle is

fastened to the base frame at each corner. Each leg or caster has a similar

mating thread.

2. Raise unit sufficiently to allow legs or casters to be screwed into the

receptacles. For safety, "shore up" and support the unit with an adequate

blocking arrangement strong enough to support the load.

3. Lower unit gently. Never drop or allow the unit to fall.

4. The legs or casters can be adjusted to overcome an uneven floor.

5. After the unit has been leveled, tighten the lock nuts.

WARNING: For an appliance equipped with casters, the installation shall be made with a connector that complies with the

standard for connectors for movable gas appliances, ANSI Z21.69-1987, CAN/CGA-6.10-88 and a quick-disconnect device

that complies with the standard for quick-disconnect devices for use with gas fuel, ANSI Z21.41-1978, and addenda,

Z21.41a.l981, Z21.41b.l983 and CAN/CGA-6.10-88. Adequate means must be provided to limit the movement of the

appliance without depending on the connector and the quick-disconnect device or its associated piping to limit the appliance

movement.

WARNING: Appliances equipped with casters have been installed with a restraint to limit their movement to prevent damage

to the gas supply connecting system. If disconnection of this restraint is necessary to move the appliance for cleaning, etc.,

reconnect it when the appliance is moved to its originally installed position.

SECTION ONE — INSTALLATION

CHAR BROILERS

PAGE 3

Page 20

INSTALLATION

CHAR BROILERS

Litho in U

-

S.A.

WARNING: THESE PROCEDURES MUST BE FOLLOWED BY QUALIFIED PERSONNEL

OR WARRANTY WILL BE VOIDED.

TO INSTALL COUNTER MODELS:

1. Seal to counter top with sealer such as G.E. or DOW Coming RTV type sealant. (Consult local code for exact

requirements.)

INSTRUCTIONS: To install Legs on Counter Models

1. Remove the BASIC Unit from the container.

2. CAREFULLY place the unit on its BACK.

3. Four NSF approved LEGS are packed with the unit.

4. REF: Sketch below:

A threaded RECEPTACLE (R) is attached to the underside of the bottom, at each corner.

Each leg has a threaded STUD (S).

Tighten the stud on each leg into a receptacle. Secure with a wrench on the hexagon section of the leg.

Each leg has its own NSF approved leveling FOOT (L). By adjusting these feet, the proper combination can be

achieved whereby the unit will be level and steady.

CAUTION: ONLY NON-COMBUSTIBLE COUNTERS ARE TO BE USED TO SUPPORT THESE UNITS

GAS CONNECTION:

On all threaded connections, the pipe joint compound must be approved for use with natural and LP gas. L

INDIVIDUAL UNITS:

1. Remove valve panel.

2. Use a long spirit level four ways; across the front top rail and rear collar plate, and along each edge.

3. A. For units that will not use the rear gas connection, connect the gas supply to the right or left side of

the manifold. Be sure to cap the unused side and the rear gas inlet.

B. For units that will use the rear gas connection, the gas supply to the unit will be made at the right

rear. Be certain both ends of the manifold are capped.

C. For counter units, a ¾” NPT gas supply connection is located at the right side of rear, when you are

facing rear of the unit.

4. Turn off all burner valves.

5. Turn on gas supply and immediately check all gas connections for leaks. Use soapy water only. Never use

an open flame.

6. Put valve panel back onto the unit.

7. Proceed to "MOUNTING SHELF OR BACKSPLASH INSTALLATION INSTRUCTIONS," if

applicable.

SECTION ONE — INSTALLATION

PAGE 4

11-92

Page 21

INSTALLATION

WARNING: THESE PROCEDURES MUST BE FOLLOWED BY QUALIFIED PERSONNEL

OR WARRANTY WILL BE VOIDED.

ASSEMBLY OF BATTERY - FLOOR MODEL UNITS:

1. Position the center range of the battery and carefully level unit. Use a long spirit level four ways; across front

top rail and the rear collar plate, and along each edge.

2. Remove all valve panels. Mark, so they will be returned to their respective unit.

3. Bring up adjacent units, level by same method and by using the center unit as reference. Match front rails and

rear collar plates. When battery is set on a masonry base and legs are not used, shims may be used. Special

attention should be given to Fry Top ranges to allow proper drainage on griddles.

4. Where Spreader Plates are installed, refer to Sectional Battery Component Assembly Instructions supplied

with each unit.

5. Connect units together by mating the unions. Make unions just HAND TIGHT at this time.

6. Starting at the center and working toward the ends, tighten each union gradually, going from one to another,

until all are finally tight. A special thin wrench, which fits the union nut, is provided with each battery, or a

chain wrench can be used.

7. Connect gas supply at right, left, or both ends. When a Spreader Plate with a "Tee" connection is inserted in a

battery, the gas supply may be connected at this point. Ranges with rear connections may also be used in this

respect. If five or more units are battened, more than one supply line should be used. Each supply line should

have a readily accessible, approved hand shutoff valve.

8. "Open" ends of the manifold must be capped.

9. Turn off all burner valves.

10. Turn on gas supply and immediately check all the unions for leaks. USE SOAPY WATER ONLY FOR

TESTING ON ALL GASES. NEVER USE AN OPEN FLAME TO CHECK FOR GAS LEAKS.

11. When entire gas system has been proved, turn off gas supply during additional installation.

12. A filler to cover the "gap" between the range fronts and tops is provided. Refer to Sectional Battery

Component Assembly Instructions supplied with each unit.

ASSEMBLY OF COUNTER MODELS:

1. Each Char Broiler is a complete unit with an individual %" NPT supply connection at the rear. A %" manual

gas shutoff valve is recommended at the gas supply inlet for complete shutdown. Standard pipe fittings are

required.

2. The regulator shipped with the unit must be installed at the gas supply inlet. Be sure regulator is connected so

that the gas flow is in the same direction as the arrow on the bottom of the regulator.

3. The manifold pressure must be maintained at the pressure marked on the serial plate; 4" W.C. for natural gas

and 10" W.C. for propane gas.

4. If applicable, the vent line from the gas appliance pressure regulator shall be installed to the outdoors in

accordance with local codes or, in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1Latest Edition. Canadian installation must comply with CAN/CGA-B 149.1 Natural Gas Installation Code,

Code CAN/CGA-B149.2 Propane Installation Code.

WARNING: IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN THE EQUIPMENT AT

THE MAIN SHUTOFF VALVE AND CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

CHAR BROILERS

SECTION ONE — INSTALLATION

PAGE 5

Page 22

INSTALLATION

1.

Front panel "A" is fastened with

CHAR BROILERS

Litho in U.S.A.

WARNING: THESE PROCEDURES MUST BE FOLLOWED BY QUALIFIED PERSONNEL

OR WARRANTY WILL BE VOIDED.

ASSEMBLY OF FREE STANDING MODELS:

1. Each Char Broiler is a complete unit with an individual 1" NPT supply connection at the rear. A 1" manual ga s shutoff

valve is recommended at the gas supply inlet for complete shutdown. Standard pipe fittings are required.

2. The regulator shipped with the unit must be installed at the gas supply inlet. Be sure regulator is connected so that the gas

flow is in the same direction as the arrow on the bottom of the regulator.

3. The manifold pressure must be maintained at the pressure marked on the serial plate; 6" W.C. for natural gas and 10" W.C.

for propane gas.

4. If applicable, the vent line from the gas applia nce pressure regulator shall be installed to the outdoors in accordance with

local codes or, in the absence of local codes, with the National Fuel Gas Code, ANSI 7333.1-Latest Edition. Canadian

installation must comply with CAN/CGA-B149.1 Natural Gas Installation Code, Code CAN/CGA-B149.2 Propane

Installation Code.

MOUNTING BACKSPLASH

INSTALLATION

INSTRUCTIONS

six (6) sheet metal screws.

Remove screws and panel will

come loose.

2. Remove nuts and lock washer

from collar plate studs "C" on

unit.

3. Lower the backsplash on to unit

allowing studs "C" to enter holes

in the shelf bracket. Secure shelf

bracket "B" with nuts and lock

washers that were removed in

instruction No. 2.

Fig. 1

NOTE: BACKSPLASH WILL POSSIBLY

BE MOUNTED ON SCBCs.

FRONT FILLER MOUNTING PROCEDURE

FIG 2. - FLAT-TYPE FRONT FILLER

(#1692 Black, #1692SS Stainless Steel)

APPLICATION: Char Broiler battened to a Fryer or Cabinet Based Unit.

MOUNTING PROCEDURE:

Align filler equally spaced over each unit. Drill securing holes with a #38

drill, using pre-punched holes in filler as a guide and secure with #4 x 3/8

sheet metal screws.

Fig. 2

WARNING: TUBULAR GAS LINES ARE LOCATED ON THE LEFT SIDE OF THE STANDARD

OVEN BASE UNITS BEHIND THE FILLER SECURING SCREW AREA. IF HOLES NEED TO

BE DRILLED, CARE MUST BE TAKEN AND INSPECTION MADE TO ENSURE GAS LINES

ARE NOT PUNCTURED.

WARNING: IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN THE EQUIPMENT AT

THE MAIN SHUTOFF VALVE AND CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

SECTION ONE — INSTALLATION

PAGE 6

11-92

Page 23

INSTALLATION

WARNING: THESE PROCEDURES MUST BE FOLLOWED BY QUALIFIED PERSONNEL

OR WARRANTY WILL BE VOIDED.

Fig. 3

APPLICATION: Char Broiler batteried with a Standard Oven Base

APPLICATION: Char Broiler on Left batteried with a

MOUNTING PROCEDURE:

If mounting holes are pre-drilled, remove screws, attach filler and secure with same screws. If mounting holes are not predrilled, or if pre-drilled holes do not align properly, drill holes using an 11/64” (.171 dia.) drill and secure with #10 x ½

slotted truss head sheet metal screws.

FIG. 3 - L.TYPE FRONT FILLER

Unit.

(#1146101 Black, #1146103 Stainless Steel for

Oven Base Unit on Right)

(#1146100 Black, #1146102 Stainless Steel for

Oven Base Unit on Left)

Convection Oven Base Unit on the Right.

(#1167010 Black, #1167011 Stainless Steel)

Fig. 4

FIG. 4 - L-TYPE FRONT FILLER

(#1166951 Black, #1166952 Stainless

Steel for Convection Oven Base Unit on left)

APPLICATION: Convection Oven Base Unit on left

and Char Broiler on right.

MOUNTING PROCEDURE

1. RIGHT SIDE OF THE CONVECTION OVEN BASE UNIT AT CONTROL PANEL - Loosen the two screws on the

right side of the front filler panel. Align the two slots in the front filler with the two screws. Push filler in until it is flush

with the front of the front filler panel and retighten the two screws.

2. For Standard Oven Base Units and Convection Oven Base Units being batteried against the Convection Oven Base Unit

right side, the factory will supply the single unit type left front trim. P/N 1136006 Black and 1136007 Stainless Steel for

Standard Sectional Units and P/N 1166809 Black and 1166810 Stainless Steel for Convection Oven Sectional Units.

3. Slide adjacent unit up against Convection Oven Sectional and forward up against front filler.

NOTE: For Cabinet Base Units

Left Front Trim Not Req'd.

WARNING: TUBULAR GAS LINES ARE LOCATED ON THE LEFT SIDE OF THE STANDARD

OVEN BASE UNITS BEHIND THE FILLER SECURING SCREW AREA. IF HOLES NEED TO BE

DRILLED, CARE MUST BE TAKEN AND INSPECTION MADE TO ENSURE GAS LINES ARE

NOT PUNCTURED.

WARNING: IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN THE EQUIPMENT AT

THE MAIN SHUTOFF VALVE AND CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

SECTION ONE — INSTALLATION

CHAR BROILERS

PAGE 7

Page 24

INSTALLATION

1172406

Drain Cabinet

Char Broiler

Fig. 5

Right Side Show

END TRIM MOUNTING PROCEDURE (Fig. 5)

(Left Side Opposite)

APPLICATION: Sectional Battery Units with Capped Manifold.

(#1072501 Black, #1072503 Stainless Steel Left End Trim)

(#1072500 Black, #1072502 Stainless Steel Right End Trim)

(#1073399 End Pipe Cap)

NOTE: Sectional type units are normally shipped with requested optional end trim attached to body side.

1. Position end trim to the underside of the front rail, tight against front and top.

2. Using the pre-punched holes in the end trim as a guide, drill (3) 1/8" (.125 dia.) holes and secure with (3) ff8 x % sheet

metal screws.

Slip-on filler will be supplied to seal unit top to unit top in case of spillage.

Types of fillers supplied will be:

Top fillers, except "U" channel range to range filler will be labeled to identify adjoining unit usage.

PART NUMBER UNIT ON LEFT

1172399 Char Broiler

1172401 Char Broiler

1172403 Char Broiler

1172405 Char Broiler

1172407 Char Broiler

1172495 Char Broiler

1172400 Any Range

1172402 Fryer 14"

1172404 Fry Top Range

1172408 Battery Type Broiler

1172496 Fryer 18"

CHAR BROILERS

SECTION ONE — INSTALLATION

PAGE 8

TOP FILLERS FOR BATTERY INSTALLATIONS

Char Broiler to Range Char Broiler to Drain Cabinet

Char Broiler to Fryer Battery Type Broiler to Char Broiler

Char Broiler to Fry Top Range

UNIT ON RIGHT

Any Range

Fryer 14"

Fry Top Range

Drain Cabinet

Battery Type Broiler

Fryer 18"

Char Broiler

Char Broiler

Char Broiler

Char Broiler

Char Broiler

Litho in

U.S.A. 11-92

Page 25

INSTALLATION

FRONT RAIL

GRATE

24 1 36 1

FLEX BROILER CONFIGURATIONS

SUPPORT

24" — 1172204

36" — 1172205

48" — 1172206

*NOTE: Maximum number of griddles per Char Broiler are:

OPTIONAL GRIDDLE MAY BE USED IN TWO WAYS AS FOLLOWS:

1. Placed on top of grids.

2. In place of two grids.

Unit Width

(in.) Griddles

48 2

60 2

Number of

CHAR BROILERS

SECTION ONE — INSTALLATION

PAGE 9

Page 26

OPERATION

CHAR BROILERS

Litho in U.S.A.

WARNING: THESE PROCEDURES MUST BE FOLLOWED BY QUALIFIED PERSONNEL

OR WARRANTY WILL BE VOIDED.

WARNING: For an appliance equipped with casters, the installation shall be made with a connector that complies with the

standard for connectors for movable gas appliances, ANSI Z21.69-1987, CAN/CGA -6.10-88 and a quick-disconnect device

that complies with the standard for quick-disconnect devices for use with gas fuel, ANSI Z21.41-1978, and addenda,

Z21.41a.l981, Z21.41b.l983 and CAN/CGA-6.10-88. Adequate means must be provided to limit the movement of the

appliance without depending on the connector and the quick-disconnect device or its associated piping to limit the appliance

movement.

WARNING: Appliances equipped with casters have been installed with a restraint to limit their movement to prevent

damage to the gas supply connecting system, if disconnection of this restraint is necessary to move the appliance for

cleaning, etc., reconnect it when the appliance is moved to its originally installed position.

Before turning main gas supply on, make sure all control valves are in the "OFF" position.

All units are adjusted at the factory. On new installations start up with the top burner of the unites) furthest from

the gas input to the manifold. This will purge the system of air. Turn gas supply "ON."

1. Models:

A. Models: SCB-Series

Unit is set with each burner at 40,000 BTU/hour at the factory prior to shipment, and should bum

reasonably close to the desired flame. Natural gas manifold pressure is 6" W.C. Propane gas manifold

pressure is 10" W.C.

B. Models: SCBC-Series

Unit is set with each burner at 40,000 BTU/hour at the factory prior to shipment, and should bum

reasonably close to the desired flame. Natural gas manifold pressure is 4" W.C. Propane gas manifold

pressure is 10" W.C.

C. Models: SCBC-Series with suffixes A, AR

Unit is set with each burner at 36,000 BTU/hour at the factory prior to shipment, and should burn

reasonably close to the desired flame. Natural gas manifold pressure is 4" W.C. Propane gas manifold

pressure is 10" W.C.

2. Pilot Lighting Instructions:

A. Set pilot valve with screwdriver to provide ½” flame by turning counterclockwise.

B. Light each pilot with match or taper.

C. Turn desired burner valve "ON."

D. To shut down, turn burner valve to "OFF." If pilot shutdown is desired, turn pilot valve(s) clockwise until

tight.

E. Do not attempt to relight for 5 minutes after shutdown.

3. The main burner flame should be 1" to 1 ½” high on natural gas and approximately ½” to 5/8” on propane

gas. Air can be adjusted by opening or closing air shutter slightly. See "ADJUSTMENTS."

4. Reinstall grate support, drip shield, grates and ceramics or on radiant model the radiants. On ceramic models

make sure ceramics are placed at random, not more than one layer thick, and with grates covered as

completely as possible. Turn flames on full for 15-20 minutes; bottom of ceramics should glow red. Once

preheated, the low valve setting should maintain cooking temperatures.

SECTION TWO — USER'S GUIDE

PAGE 2

CAUTION: IF YOU SMELL GAS DURING THE LIGHTING PROCEDURE, IMMEDIATELY SHUT

OFF THE GAS SUPPLY UNTIL THE LEAK HAS BEEN CORRECTED.

11-92

Page 27

OPERATION

5. Putting Broiler Into Use:

A. Heating — Be sure all standing pilots are lit. Turn on the number of burners desired to the full "ON" position. After

15-20 minutes flame can be turned back to maintain enough heat to keep the bottom of the coals or radiants hot.

These ceramic coals or radiants will be at broiling temperature throughout, giving off the radiant heat which is so

necessary to provide fast broiling.

B. Adjustment of Top Broiler Grid — To tilt, pull upon the back of the grid to place it in the tilt position. Normal

broiling position is the tilted position, and we recommend that this be used most of the time. The tilt angle allows the

fats rendered off during broiling of steaks, chops and hamburgers to run off into grease trough, thus eliminating

excess flaring of fats and accompanying smoke. The flat position should be used for heating on the top, or for continuous hot dog or sausage work. Fats dripping down into the fire will burn up on the meat and help to give it that

"special" flavor that is not only desirable but should occur. Steaks and chops, being fattier than other meats, will

naturally have the most flaring up. The angle will drain off sufficient fats to eliminate severe flares while providing

desirable broiling results.

C. Broiling:

Once the fire is hot enough, put your steak on the broiler. .. make sure both sides of the steak are seared to retain

maximum juice. This fast cooking is one of the secrets of successful steak broiling and gives your steaks that special

"outdoor" flavor. A 1 "-thick, rare steak should take approximately 8 minutes; adjust your timing according to

thickness of steak and amount of doneness required.

The Char Broiler is designed so that the rear 2/3 of the broiler grid is much hotter than the front 1/3. Use this to your

advantage — broil rare meats at the back quickly; medium and well-done meats close to the front, more slowly.

Remember, to cook meat properly you must have two essential things: Time and Heat — your Char Broiler gives

you a choice of heat intensity — you choose your own timing.

If you have several steaks to be finished in different degrees of doneness, move the finished rare steaks to the very

front where they will stay warm without cooking while medium and well-done steaks are finishing.

These suggestions apply equally to other food products. We sincerely hope that this information will be helpful to

you in the successful and profitable use of your broiler, and we are happy to have this opportunity of serving you.

SECTION TWO — USER'S GUIDE

CHAR BROILERS

PAGE 3

Page 28

MAINTENANCE

Litho in U.S.A.

WARNING:

ADJUSTMENTS AND SERVICE WORK MAY BE PERFORMED ONLY BY A QUAU. FIED

TECHNICIAN WHO IS EXPERIENCED IN, AND KNOWLEDGEABLE WITH, THE

OPERATION OF COMMERCIAL GAS COOKING EQUIPMENT. HOWEVER, TO ASSURE

YOUR CONFIDENCE, CONTACT YOUR AUTHORIZED SERVICE AGENCY FOR RELIABLE

SERVICE, DEPENDABLE ADVICE OR OTHER ASSISTANCES, AND FOR GENUINE

FACTORY PARTS.

CLEANING BROILER TOP GRID:

Daily — Brush regularly with a wire brush followed by wiping with a cloth, to prevent accumulation of carbon.

The grids should be cleaned regularly since this is where the rendered fat from the broiling operation runs off. If

accumulation of carbon develops here, the fats will drip from the points of carbon instead of running all the way

down to the end of the grid into the grease trough. To expect the best performance, your equipment must be

maintained in good condition, and cleaned daily. Naturally, the periods for this care and cleaning depend on the

amount and degree of usage.

Weekly — The grid should be removed at least weekly and scrubbed thoroughly. Done regularly this is an easy

job, but if neglected strong methods must be used to get it clean.

CLEANING CAST-IRON GRATES AND CERAMIC COALS:

(MODELS WITHOUT R SUFFIX)

The cast-iron grates receive the greatest amount of wear due to the extreme heat required for char broiling. Tb

insure longest possible life, coals and grates should be removed every few days, clinkers removed, and grates

brushed.

CAUTION: DO NOT OVERLOAD WITH COALS - ONE LAYER PLACED AT RANDOM IS

SUFFICIENT.

When grates become too badly warped they should be replaced.

CLEANING RADIANTS: (MODELS WITH R SUFFIX)

The radiants receive a great amount of wear due to excessive heat and drippings from cooking. Clean the radiants

every few days by placing in dishwasher.

CLEANING BURNERS:

Burners should be cleaned weekly. Remove and clean with wire brush. If burner ports are clogged, ream with stiff

wire. Due to intense heat it's possible burners will warp. Warped burners should be replaced immediately.

CLEANING CRUMB TRAY AND GREASE PAN:

There are 2 pans in the bottom of the unit. One is to catch grease (in the far left-hand comer of the broiler) and the

other is to catch crumb drippings from the broiler. The large pan, or crumb tray, should be removed every couple

of days and washed thoroughly. The small pan, or grease drawer, should be removed frequently to empty

accumulated grease and avoid overflow. This should be done while warm so that the grease is in a liquid state. The

shield over the grease protects it from the intense radiant heat, avoiding a fire hazard. When these pans are out it's

a good idea to wipe out the interior of the unit with a warm soapy cloth to prevent grease and carbonization

buildup. As with anything else, proper care, maintenance and cleaning will add months and years to the life of the

equipment, and eliminate costly delays because of breakdown.

CHAR BROILERS

SECTION TWO — USER'S GUIDE

PAGE 4

11-92

Page 29

MAINTENANCE

GRIDDLES:

New griddles should be carefully tempered and maintained to avoid possible cracking and/or warping. To break in a new

griddle, first wipe it clean. Next, light all the griddle burners and turn them low for one hour. Then, gradually bring griddle to

frying temperature. Next, spread three or four ounces of beef suet or, as a substitute baking soda, to season it. Never allow

water on a hot griddle and never wash it with soap and water.

Use a Norton Alundum Griddle Brick to clean griddle. Always remember to heat griddle slowly because quick heat may cause

costly damage. Griddle plates cannot be guaranteed against damage due to carelessness. Never place utensils on griddle. Do not

overheat griddle above 550°F, as this will cause warpage or breakage.

Do not use any type of steel wool. Small particles may be left on the surface and get into food products.

WARNING:

DO NOT CLEAN SPATULA BY HITTING THE EDGE ON THE GRIDDLE PLATE. SUCH

ACTION WILL ONLY CUT AND PIT THE GRIDDLE PLATE, LEAVING IT ROUGH AND

HARD TO CLEAN.

EXTERIOR

BLACK BAKED ENAMEL: Allow equipment to cool somewhat after use and wash exterior with a hot, mild

detergent or soap solution; particularly clean off all grease deposits. Dry thoroughly with a dry cloth.

STAINLESS STEEL: To remove normal dirt, grease, or product residue from stainless steel that operates at low

temperatures, use ordinary soap and water (with or without detergent) applied with • a sponge or cloth. Dry thoroughly

with a clean cloth.

To remove grease and food splatter, or condensed vapors, that have baked on the equipment, apply cleanser to a

damp cloth or sponge and rub cleanser on the metal in the direction of the polishing lines on the metal. Rubbing

cleanser, as gently as possible, in the direction of the polished lines will not mar the finish of the stainless steel.

NEVER RUB WITH A CIRCULAR MOTION. Soil and burnt deposits which do not respond to the above

procedure can usually be removed by rubbing the surface with SCOTCH-BRITE scouring pads or STAINLESS

scouring pads. DO NOT USE ORDINARY STEEL WOOL as any particles left on the surface will rust and further

spoil the appearance of the finish. NEVER USE A WIRE BRUSH, STEEL SCOURING PADS (EXCEPT

STAINLESS), SCRAPER, FILE OR OTHER STEEL TOOLS. Surfaces which are marred collect dirt more

rapidly and become more difficult to clean. Marring also increases the possibility of corrosive attack. Refinishing

may then be required.

To Remove Heat Tint: Darkened areas sometimes appear on stainless steel surfaces where the area has been

subjected to excessive heat. These darkened areas are caused by thickening of the protective surface of the

stainless steel and are not harmful. Heat tint can normally be removed by the foregoing, but tint which does not

respond to this procedure calls for a vigorous scouring in the direction of the polish lines using SCOTCH-BRITE

scouring pads or a STAINLESS scouring pad in combination with a powdered cleanser. Heat tint action may be

lessened by not applying, or by reducing, heat to equipment during slack periods.

SECTION TWO — USER'S GUIDE

CHAR BROILERS

PAGE 5

Page 30

GAS CHAR BROILERS

PARTS

PARTS

WARNING:

INSTALLATION OF OTHER THAN GENUINE SOUTHBEND PARTS WILL VOID THE

WARRANTY ON THIS EQUIPMENT.

ON FLOOR MODELS:

The serial plate is located as follows:

Model SCB Series — Left front comer on bottom inside lower compartment.

Model SCBC Series — Remove front control panel. Serial plate is attached in the center on the compartment front shield.

ON COUNTER MODELS:

The serial plate is located behind the front control panel centered on the unit.

Replacement parts may be ordered either through a Southbend Authorized Parts Distributor or a Southbend Authorized Service

Agency.

When ordering parts, please supply the Model Number, Serial Number, Part Number, Description, plus Finish, Type of Gas and

Electrical Characteristics, as applicable.

For parts not listed, consult a Southbend Authorized Parts Distributor or Southbend Authorized Service Agency. If necessary,

please consult Southbend Parts Department for assistance.

CONTROLS/RELATED PARTS

PART

NUMBER

1176750 Gas Valve 2 3 4

1163552 Gas Valve

1160532 Valve Knob 2 3 4

1173645 Valve Knob

1172185 Burner 2 3 4

1008737 Burner Orifice — Natural Gas #37 2 3 4

1008732 Burner Orifice — Natural Gas #32

1008749 Burner Orifice — Propane Gas 049 2

1161263 Pilot — Natural Gas 2 3 4 2 3 4

1161262 Pilot — Propane Gas 2 3 4 2 3 4

1173222 Pilot Shield 2 3 4 2 3 4

1148306 Orifice Fitting 2 3 4 2 3 4

1148301 Jam Nut for Orifice Fitting 2 3 4 2 3 4

1172215 Burner Supply Tube 2 3 4

1173628 Burner Supply Tube

1172489 Pilot Supply Tube 2 3 4

1173629 Pilot Supply Tube

1173641 Control Panel Polypanel

1167782 1" Pressure Regulator — Natural* 1 1 1

1160205 ¾” Pressure Regulator — LP

1167783 1" Pressure Regulator — Natural* 1 1 1

1160206 ¾” Pressure Regulator — LP

DESCRIPTION SCB-24 SCB-36 SCB-48 SCBC-24 SCBC-36 SCBC-48

2 3 4

2 3 4

2 3 4

2 3 4

2 3 4

2 3 4

2 3 4

1 1 1

1 1 1

* NOTE: For Free Standing, Floor Model Units only: Front Manifold units do not come equipped with regulator.

They have to be ordered separately and sized according to the installation.

SECTION FOUR — PARTS

CHAR BROILERS

PAGE 1

Page 31

* Maximum usage per unit.

CHAR BROILERS

Litho in U.S.A.

PARTS

BROILING SECTION PARTS

PART

NUMBER

1172781 Standard Top Grid 4 6 8 4 6 8

117278 Nickel Plated Top (Fish) Grid - Optional 4 6 8 4 6 8

1172427 Drip Shield — Ceramic Units Only 2 3 4 2 3 4

1172777 Grate — Ceramic Units Only 4 6 8 4 6 8

1173193 Ceramics — 5 Ib. Bag — Ceramic Units Only 2 3 4 2 3 4

1172217 Radiant — Radiant Units Only 2 3 4 2 3 4

1172343 Optional Griddle Accessory 1* 1* 2* 1* 1* 2*

2690 Grease Drawer 1 1 1

1173695 Grease Drawer

1172449 Dirt Tray - 24" & 48" 1 2

1173656 Dirt Tray - 24" & 48"

1172450 Dirt Tray - 36"

1173657 Dirt Tray - 36"

1172204 Grate Support Assy. 24" 1

1172205 Grate Support Assy. 36"

1172206 Grate Support Assy. 48”

1172440 Left SS Removable Splash Guard 1 1 1 1 1 1

1172439 Right SS Removable Splash Guard 1 1 1 1 1 1

1172434 Rear 24" SS Removable Splash Guard 1

1172435 Rear 36" SS Removable Splash Guard

1172436 Rear 48" SS Removable Splash Guard

1172443 Top Grid Support 24" (attaches to collar plate) 1

1172444 Top Grid Support 36" (attaches to collar plate)

1172445 Top Grid Support 48" (attaches to collar plate)

1172213 Top Filler — Left (for Free Standing) 1 1 1

1172214 Top Filler — Right (for Free Standing) 1 1 1

DESCRIPTION SCB-24 SCB-36 SCB-48 SCBC-24 SCBC-36 SCBC-48

1

1

1

1

1

1

1

1 1 1

1

1

1

1

1

1

1

1

2

1

1

1

BODY PARTS

PART

NUMBER

1173241 Left SS Door Panel w/hinge — 24" 1

1173248 Right SS Door Panel w/hinge — 24" 1

1173252 Left SS Door Panel w/hinge — 36" or 48" 1 1

1173250 Right SS Door Panel w/hinge — 36" or 48" 1 1

12849 Chrome Knob for Door 2 2 2

1164132 Door Striker 2 2 2

1164133 Door Catch 2 2 2

1172418 Rear Collar Plate — 24" 1

1173649 Rear Collar Plate — 24" 1

1172419 Rear Collar Plate - 36" 1

1173650 Rear Collar Plate - 36" 1

1172420 Rear Collar Plate - 48" 1

1173651 Rear Collar Plate - 48"

1172384 SS Valve Panel 24" 1

1173638 SS Valve Panel 24"

1172386 SS Valve Panel 36" 1

1173639 SS Panel 36" 1

1172388 SS Valve Panel 48"

1173640 SS Valve Panel 48" 1

1172159 Left Body Side - Black 1 1 1

1172157 Right Body Side — Black 1 1 1

1172160 Left Body Side — Stainless 1 1 1

1173682 Left Body Side — Stainless 1 1 1

1172158 Right Body Side — Stainless 1 1 1

1173683 Right Body Side — Stainless

DESCRIPTION SCB-24 SCB-36 SCB-48 SCBC-24 SCBC-36 SCBC-48

1

1 1 1

1

SECTION FOUR — PARTS

PAGE 2

11-92

Loading...

Loading...