Page 1

Installation and Operation Manual

For Gas Fryers

NO OPTIONS/ST AND ALONE

Covering Models

SB14,SB14R,SB18

ENGLISHFRANCAISESPANOL

Southbend A Middleby Corporation Company 1 100 Old Honeycutt Road, Fuquay-V arina, NC 27526

(919) 762-1000 phone (919) 552-9798 fax

L20-394 Rev 0 (04/12) www.southbend.com

Page 2

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE

FOR YOUR SAFETY

DO NOT store or use gasoline or other flammable vapors or liquids in the vicinity of this or

any other appliance.

WARNING

Improper installation, alteration, service or maintenance can cause property damage, injury

or death. Read the installation, operating and maintenance instructions thoroughly before

installing or servicing this equipment.

TO THE PURCHASER

Post in a prominent location the instructions to be followed in the event that an operator smells gas. Obtain this

information from your local gas supplier.

WARNING

There is an open flame inside the fryer. The unit may get hot enough to set near by materials on fire. Keep the

area around the fryer fr ee from combustibles.

WARNING

DO NOT supply the fryer with a gas that is not indicated on the data plate. If you need to convert the fryer to

another type of fuel, contact your dealer.

WARNING

DO NOT use an open flame to check for gas leaks!

WARNING

Wait 5 minutes before attempting to relight the pilot to allow for any gas in the fryer to dissipate.

WARNING

Never melt blocks of shortening on top of the burner tubes. This will cause a fire, and void your warranty.

WARNING

Water and shortening DO NOT mix. Keep liquids away from hot shortening.

Dropping frozen liquid food into the hot shortening will cause violent boiling.

WARNING

Ensure that the fryer can get enough air to keep the flame burning correctly. If the flame is starved for air, it can

give off a dangerous carbon Monoxide gas. Carbon monoxide is a clear odorless gas that can cause suffocation.

WARNING

A cooker equipped with casters and a flexible gas line, must be connected to the gas supply with a quick

disconnect device. This quick disconnect must comply with ANSI Z24.41. To limit the movement of the cooker

without depending on the connector or quick disconnect, a restraining cable must also be installed.

L20-394 rev 0 (04/12)

Page 3

CHECKING YOUR NEW FRYER

Your new fryer has been carefully packed into one crate. Every effort has been made to ensure that your fryer is delivered

to you in perfect condition. As you unpack your new fryer, inspect each of the pieces for damage. If something is damaged,

DO NOT sign the bill of lading. Contact the shipper immediately, the shipper is only responsible for 15 days after delivery.

Check the packing list enclosed with your fryer to ensure that you have received all of the parts to the fryer. If you are missing

any parts, contact the dealer from whom the fryer was purchased.

CAUTION

To prevent equipment damage, don't tilt the fryer onto any two of it's casters or pull the unit by the flue vents.

Leg/Caster Installation and Adjustment

Installing the legs and leveling the fryer is done with a 7/16" wrench, socket, and a large pair of water pump pliers. The legs/

casters must be installed to provide the necessary height to meet sanitation requirements and assure adequate air supply to

the burner. Attach the legs by performing the following procedure.

a. Lay the fryer on its side being careful not to damage the flue by pulling on it. Protect the outside of the fryer with

cardboard or a drop cloth when laying it down.

b. Attach each leg/caster with the hex head cap screws supplied with the fryer. Each leg/caster requires four 1/4 20 x 5/8" cap screws.

c. Mount the screws from the inside of the fryer with the nut on the outside. The nuts have lock washers attached

to them, therefore it is not necessary to use lock washers.

d. When all four legs/casters are mounted, stand the unit up being careful not to put too much weight on any one

leg/caster. Adjust the height and level the fryer by adjusting the leveling devices on the leg/caster with the water

pump pliers.

e. On units with casters, move the fryer to the desired location and lock the wheels using the locking devices on

the front of the casters.

ENGLISH

WARNING

The fryer must be properly restrained to prevent movement or tipping. This restraint must prevent the fryer from

movements that would splash hot liquids on personnel, which could cause severe burns or injuries.

Always wear oil proof gloves when moving or handling equipment or hot liquids.

Installation Clearances

The fryer needs clearance around it for proper operation. Adequate clearances allow for servicing and proper burner operation.

The clearances shown below are for cooker installation in combustible and noncombustible construction.

Combustible Non-Combustible

Construction Construction

Back 6" 0"

Sides 6" 0"

Floor - Combustible 9" 9" (Needed for Combustion)

Counter top must be constructed of a non-combustible material for SG14C counter top fryer installations.

Gas Connection

Your fryer will give you peak performance when the gas supply line is of sufficient size to provide the correct gas flow. The

gas line must be installed to meet the local building codes or National Fuel Gas Code ANSI Z223.1 Latest Edition. In Canada,

install the fryer in accordance with CAN/CGA-B149.1 or .2 and local codes. Gas line sizing requirements

can be determined by your local gas company by referring to National Fuel Gas Code, Appendix C, Table C-4 (natural gas)

and Table C-16 (propane). The gas line needs to be large enough to supply the necessary amount of fuel to all appliances

without losing pressure to any appliance.

WARNING

NEVER supply the fryer with a gas that is not indicated on the data plate. Using the incorrect gas type will cause

improper operation. If you need to convert the fryer to another type of fuel, contact your dealer.

L20-394 rev 0 (04/12)

1

Page 4

Fuel Types - Each fryer is equipped to work with one type of fuel. The type of fuel with which the appliance is intended to

operate is stamped on the data plate attached to the inside of the door.

NOTICE

NEVER use an adaptor to make a smaller gas supply line fit the cooker connection. This may

not allow proper gas flow for optimum burner operation, resulting in poor cooker performance.

Quick Disconnect Gas Connection

Gas fryers equipped with casters must be installed with connectors that comply with the Standard for Connectors for Movable

Gas Appliances, ANSI Z223.1 Latest Edition, and Addenda Z21.69A Latest Edition. This connection should include a quick

disconnect device that complies with the Standard for Quick Disconnect Devices for Use With Gas Fuel , ANSI Z223.1 Latest

Edition. When installing a quick disconnect you must also install a means for limiting the movement of the fryer. This device

will prevent the gas line or the quick disconnect from being strained. The restraining device should be attached to the cooker

on the back panel.

Fuel Supply Line Leak and Pressure Testing

The fuel supply system must be tested before the fryer is used. If the fuel line is going to be tested at a pressure greater than

(>)1/2 PSIG (3.45 kPa), make sure that the fryer is disconnected from the fuel line. If the fuel line is to be tested at a pressure

equal to or less than (<) 1/2 PSIG (3.45 kPa), the fryer can be connected but the unit's gas valve must be shut. Test all gas

line connections for leaks with a solution of soap and water when pressure is applied.

ELECTRICAL CONNECTION

The electrical service used by the fryer must comply with local codes. If there are no local codes that apply, refer to the National

Electrical Code (NEC), ANSI/NFPA 70 to install the service. In Canada refer to CSA Standard C22.1 and local codes. Wiring

diagrams are provided inside the fryer control box.

Ventilation and Fire Safety Systems

Your new fryer must have proper ventilation to function safely and properly. Exhaust gas temperatures can reach as high

as 1000°F. Therefore, it is very important to install a fire safety system. Your ventilation system should be designed to allow

for easy cleaning. Frequent cleaning of the ventilation system and the fryer will reduce the chances of fire. Table 1-2 provides

a list of reference documents that provide guidance on ventilation and fire safety systems. This table is not necessarily

complete. Additional information can be obtained from the CSA-International, 8501 East Pleasant Valley Road, Cleveland,

OH 44131.

Excessive ventilation causes drafts, which will interfere with the proper operation of the pilot and the burner. Leave at

least 18 inches of open space between the fryer's flue vent opening and the intake of the exhaust hood.

CAUTION

Ensure that your ventilation system does not cause a down draft at the fryer's flue opening.

Down drafts will not allow the fryer to exhaust properly and will cause overheating which may

cause permanent damage. Damage caused by down drafts will not be covered under

equipment warranty. NEVER allow anything to obstruct the flow of combustibles or

ventilation exiting from the fryer flue. DO NOT put anything on top of the flue area.

NOTICE

NEVER connect the blower directly to the flue openings. The direct flow of air will cause poor

temperature recovery, poor ignition, inefficient operation of the fryer, and could extinguish

the pilot.

Gas Line Requirements

A properly installed gas supply system will deliver 7.0 ± 2.0" w.c. natural gas (12.0 ± 2.0" w.c. LP) to all appliances

connected to the line, operating at full demand.

L20-394 rev 0 (04/12)

NOTICE

Do NOT exceed 13.5” W.C. pressure as damage may occur to the gas valve.

2

Page 5

LIGHTING INSTRUCTIONS

a. Fill kettle before lighting.

b. Turn combination gas valve knob to “PILOT” position.

c. Depress valve knob and light pilot. W ith pilot burning, hold knob depressed for 60 seconds.

d. Release knob, pilot should remain lit.

e. DO NOT TURN COMBINA TION GAS V AL VE KNOB TO THE “ON” POSITION UNTIL VESSEL IS FULL OF

W A TER OR SHOR TENING. TURNING THE KNOB TO “ON” WITH VESSEL EMPTY WILL DAMAGE THE

VESSEL OR COMPONENTS AND VOID W ARRANTY.

f. Relighting - wait 5 minutes before attempting to relight the pilot to allow for any gas in the fryer to dissipate.

Initial Cleaning

When the fryer is shipped, many of its parts are covered with a thin coat of oil for protection. Before the fryer is ready for

cooking it must be cleaned. This will remove the oil coating and any foreign matter that may have accumulated during storage

and shipment. Perform the cleaning as described below.

a. Fill the vessel with water.

b. Turn the fryer gas valve knob to the “ON” position. Allow the fryer to bring the water to a low boil and add one

packet of Pitco fryer cleaner or a mild, low sudsing detergent and allow water to continue to boil for a minute,

making sure water does not boil over.

c. Turn the gas valve knob to the “PILOT” position and allow fryer to soak with the hot water for 15 minutes.

NOTICE

Do not leave the fryer unattended during cleaning. Never let the water level go below the "Min

Level" mark on the back of the tank.

d. Using the fryer cleaning brush, scrub the inside of the fryer to remove protective coating.

e . When cleaning is complete, turn the gas valve knob to the “OFF” position and drain the water into a container

suitable for hot water and dispose of it.

f. When the tank has cooled, rinse it thoroughly with cool water. Continue to rinse the tank until the cleaner has

been rinsed, thoroughly from the tank.

g. Using a clean dry cloth, wipe out all of the water. Be very thorough removing the water, because any residual

water will cause hot oil to splatter out of the fryer. Close the drain valve and remove container.

ENGLISH

CAUTION

Mild steel tanks must be wiped down/coated with oil to keep the tank from rusting.

h. Now that the tank is clean, you are ready to fill and operate the fryer. Refer to instructions on adding shortening

to the fryer.

DAILY CLEANING

should be performed to maintain peak operation and appearance.

a . Wipe up any shortening that spills onto the exterior of the fryer. This should be done with a clean soft cloth

while the oil is still warm.

b. Use warm water with a mild detergent to clean surfaces. Be careful not to get water in the shortening and to

remove any detergent from the fry tank.

c. Use a nonabrasive scouring powder or pad to clean stains if necessary.

d. Perform the weekly boil out cleaning of your fryer described below.

WEEKLY FRYER CLEANING

This cleaning should include a complete draining of the fryer and a boil out.

a . You will need a container large enough to hold 1 1/2 times the oil in one tank. This container should also be

able to withstand 400

b. Shut fryer gas system OFF completely before performing procedures to ensure unit does not come on during

any part of the cleaning operation.

c. Drain the oil from the fryer and discard or save for reuse. Remove tube rack/mesh tube screens and remove any

large debris from the bottom of the fry tank. Once clean, return tube rack/mesh screens to the fry tank. Close

the drain valve and fill the fry tank with water and noncaustic detergent.

d . Relight gas system pilot, following the lighting instructions.

0

F oil temperatures.

L20-394 rev 0 (04/12)

3

Page 6

e. Turn the fryer gas valve knob to the “ON” position. Allow the fryer to bring the water to a low boil and add

one packet of Pitco fryer cleaner or a mild, low sudsing detergent and allow water to continue to boil for a minute,

making sure water does not boil over.

f.. Turn the gas valve knob to the “PILOT” position and allow fryer to soak with the hot water for 15 minutes.

g. Using the fryer cleaning brush, scrub the inside of the fryer to remove protective coating.

h. When cleaning is complete, turn the gas valve knob to the “OFF” position and drain the water into a container

suitable for hot water and dispose of it.

i. When the tank has cooled, rinse it thoroughly with cool water. Continue to rinse the tank until the cleaner has

been rinsed, thoroughly from the tank.

j. Using a clean dry cloth, wipe out all of the water. Be very thorough removing the water, because any residual

water will cause hot oil to splatter out of the fryer. Close the drain valve and remove container.

k. Now that the tank is clean, you are ready to fill and operate the fryer. Refer to instructions on adding shortening

to the fryer.

W ARNING

Gas units installed with casters must have a restraining device. This device must be connected at all times that the

fryer is connected to the gas supply . If it is disconnected for any reason, it must be r econnected.

Thermostat Calibration Check

NOTICE

Thermostat calibration requires that the temperature of the fryer be raised above boiling.

Therefore, you will need to drain the water from the fryer and fill it with oil. Before removing

the water, perform the initial cleaning of the fryer. Cleaning the fryer now will prevent you

from having to drain the oil and refill with water later.

To perform the calibration check detailed below you will need a digital thermometer.

a . Place the tip of the thermometer in the shortening approximately 1" above the temperature sensors.

b. Set the thermostat at 325°F and wait for the temperature reading on the thermometer to rise. As the temperature

rises toward 325°F watch the thermometer closely.

c. If the shortening temperature reaches 350°F and the burners DO NOT turn off, turn the thermostat down. Keep

lowering the thermostat setting until the burners go out.

If the burners do not turn off at the lowest thermostat setting, the thermostat could be

d. Let the fryer cycle 4 to 6 times before checking the temperature. Compare the thermometer temperature against

the thermostat setting. If the values are more than 5°F apart, calibrate the thermostat using the appropriate

calibration procedure in this manual.

THERMOSTAT CALIBRATION

Millivolt thermostats

a. Set the thermostat dial to 325o F.

b. Remove the thermostat dial by pulling the knob straight out. DO NOT rotate the dial.

c. Hold the outside of the shaft so it does not move. Use the tip of a small, flat tip screw driver to scrape away

the sealing compound from the adjustment screw.

d. Turn the adjustment screw clockwise to lower the temperature setting and counterclockwise to raise the

temperature. One quarter turn changes the temperature approximately 25o F.

e. Turn the adjustment until the burners turn on at 325o F . Replace the knob and allow the fryer to cycle 4 to 6

times. Check the temperature of the thermometer against the thermostat dial. If it is greater than 5o F differ

ence, repeat the calibration procedure.

f. When the calibration is correct, remove the thermometer and replace the tube screen.

CAUTION

defective. Contact your representative immediately.

Filling the fryer with liquid shortening

L20-394 rev 0 (04/12)

a . Make sure the drain valve is completely closed.

b . Fill the fryer with oil to the "Oil Level" line marked on the back of the tank.

4

Page 7

Filling the Fryer With Solid Shortening

a . Make sure the drain valve is completely closed.

b. Remove the screen covering the tubes.

c . Cut the shortening into cubes no larger than 1". ALWAYS pack the shortening below, between, and on top

of the burner tubes. DO NOT leave any large air gaps. Use care when packing the solid shortening in the tank.

DO NOT bend or break the temperature sensor probes. If these are damaged the fryer will not function properly.

d. Once the fryer is packed with shortening, the shortening must be melted.

e. To melt shortening, manually pulse the burners ON and OFF using the thermostat until the shortening is liquidized

enough to cover the heat tubes. This will protect the tank and components from damage and extend the life

of the oil.

Fryer Shut-Down

There are two shutdown modes of fryer operation, STANDBY and COMPLETE. The standby mode removes the ability for

the fryer's main burners to cycle. Complete shutdown turns off the gas supply to the fryer. Shut down the fryer by:

STANDBY Turn the thermostat to OFF. Turn the gas valve clockwise to the PILOT position. The cooker is now in Standby

and can remain this way for only brief periods of time. NEVER leave the cooker in standby overnight.

COMPLETE To completely shut down the cooker, push and turn the gas valve counterclockwise to the OFF position. The

fryer is now completely shut down and can be cleaned and filtered.

ENGLISH

L20-394 rev 0 (04/12)

5

Page 8

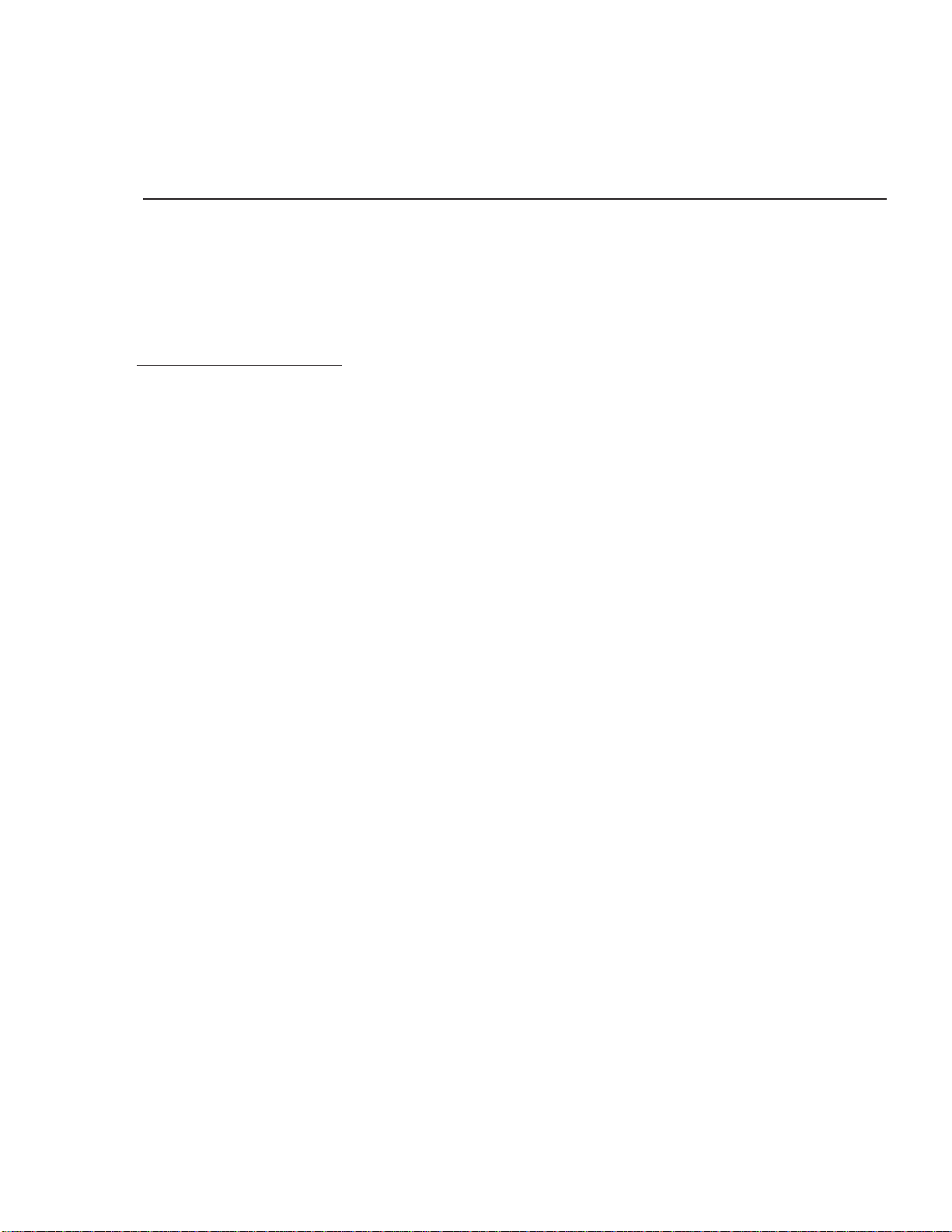

TOPIC UNDERWRITERS LABORA TORY NATIONAL FUEL GAS

DOCUMENT CODE DOCUMENT

EXHAUST HOODS ANSI/UL 710 ANSI/NFP A 96

POWER VENTILA TORS ANSI/UL 705 ANSI/NFP A 96

FIL TER UNIT ANSI/UL 586 ANSI/NFP A 96

ANSI/UL 900

TYPES OF FIRE EXTINGUISHERS

AND DETECTION EQUIPMENT

2

CO

ANSI/UL 154 ANSI/NFP A 12

DRY CHEMICAL ANSI/UL 299 ANSI/NFP A 17

W A TER ANSI/UL 626 ANSI/NFP A 13

FOAM ANSI/UL 8 ANSI/NFP A 11

SPRINKLERS ANSI/UL 199 ANSI/NFP A 13

SMOKE DETECTORS ANSI/UL 268 ANSI/NFP A 72

FIRE DETECTION THERMOST A TS ANSI/UL 521 ANSI/NFP A 72

IF MAINTENANCE IS REQUIRED, CONT ACT YOUR LOCAL FACT ORY SERVICER, LOCAL FACT ORY REPRESENTATIVE, OR THE F ACTOR Y TO OBT AIN SER VICE.

L20-394 rev 0 (04/12)

6

Page 9

ENGLISH

L20-394 rev 0 (04/12)

7

Page 10

INST ALLATION & OPERATION MANUAL

FOR GAS FR YERS NO OPTION/ST AND ALONE

COVERING MODELS SB14,SB14R,SB18

Southbend A Middleby Corporation Company

1100 Old Honeycutt Road, Fuquay-Varina, NC 27526

(919) 762-1000 phone (919) 552-9798 fax

L20-394 rev 0 (04/12)

8

Page 11

Manuel d’Installation et de Fonctionnement

Pour Friteuses à Gaz

Modèles

SB14,SB14R,SB18

FRANCAIS

Southbend A Middleby Corporation Company 1100 Old Honeycutt Road, Fuquay-Varina, NC 27526

(919) 762-1000 phone (919) 552-9798 fax

L20-394 R0 (04/12) www.southbend.com

Page 12

CONSERVEZ CETTE NOTICE AFIN DE POUVOIR LA CONSUL TER UL TÉRIEUREMENT

POUR VOTRE SÉCURITÉ

NE P AS stocker de l’essence ni d’autr es liquides ou vapeurs inflammables à proximité de cet

appareil ni de tout autre appareil.

AVERTISSEMENT

T oute mauvaise installation, altération, réparation et tout mauvais réglage ou entretien risque

de provoquer des dégâts matériels, des blessures graves, voir e la mort. Veuillez lire

attentivement les manuels d’installation, de fonctionnement et d’entretien avant d’installer ou

d’effectuer l’entretien de cet équipement.

A VIS À L ’ACHETEUR

Affichez en évidence les instructions à suivre si l’utilisateur sent une odeur de gaz. Cette information est disponible

auprès de votre fournisseur de gaz local.

A VER TISSEMENT

Il existe une veilleuse à flamme nue à l’intérieur de la friteuse. La machine peut chauffer à des températures très

élevées et risque d’enflammer des matériaux placés à proximité. Veillez à ce qu’il n’existe aucun élément combustible

autour de la friteuse.

A VER TISSEMENT

NE P AS alimenter en gaz la friteuse avec un gaz ne figurant pas sur la plaque signalétique. Si vous devez convertir la

machine afin de l’utiliser avec un gaz différent, contactez votr e revendeur .

A VER TISSEMENT

NE JAMAIS approcher de flamme nue afin de rechercher une fuite de gaz!

A VER TISSEMENT

Attendre 5 minutes avant de tenter de rallumer la veilleuse afin de permettre à tout gaz à l’intérieur de la friteuse de se

dissiper.

A VER TISSEMENT

Ne jamais faire fondre les barres de matièr e grasse sur les tubes du brûleur . Ceci risque de pr ovoquer un incendie et

annulera la garantie.

A VER TISSEMENT

NE P AS mélanger d’eau avec la matière grasse. Conserver tout liquide à l’écart de la matièr e grasse chaude. T out

aliment surgelé tombant dans la matière grasse chaude entraînera une ébullition intense.

A VER TISSEMENT

V eiller à ce que la friteuse soit suffisamment alimentée en air afin que la veilleuse brûle correctement. Si la flamme

n’est pas suffisamment alimentée en air , elle dégagera un gaz dangereux, à savoir de l’oxyde de carbone. L ’oxyde de

carbone est un gaz incolore et inodore qui peut provoquer l’asphyxie.

A VER TISSEMENT

T oute machine équipée de roulettes et d’un tuyau de gaz flexible doit être raccordée à une sour ce de gaz par

l’intermédiaire d’un dispositif de déconnexion rapide. Cette prise à déconnexion rapide doit être conforme à la norme

ANSI Z24.41. Pour limiter au maximum le déplacement de la friteuse sans dépendre du connecteur ou du dispositif de

déconnexion rapide, un câble de sécurité doit être installé.

L20-394 rev 0 (04/12)

10

Page 13

VÉRIFICATION DE LA NOUVELLE FRITEUSE

Votre nouvelle friteuse a été emballée avec précaution dans une caisse. Tout a été prévu afin que la friteuse vous soit livrée

en parfaite condition. Lorsque vous déballez votre nouvelle friteuse, vérifiez toutes les pièces afin de vous assurer qu’elles

ne sont pas endommagées. Si une des pièces a été endommagée, veuillez NE PAS signer le connaissement (lettre de transport).

Contactez immédiatement le transporteur car ce dernier ne peut être tenu responsable que pendant les 15 jours suivant la

livraison. Vérifiez le bordereau d’expédition fourni avec la friteuse afin de vous assurer que vous êtes en possession de toutes

les pièces. Si des pièces s’avèrent manquantes, contactez le revendeur auprès duquel vous avez acheté la friteuse.

ATTENTION

Afin d’éviter d’endommager l’appareil, ne pas pencher la friteuse sur deux de ces roues ni tirer sur le carneau ou

conduit de fumée.

Installation et Réglage des Pieds et des Roulettes

Montez les pieds et mettez la friteuse à niveau à l’aide d’une clé de 7/16 de po. et d’une pince multiprises. Les pieds et les roulettes

doivent être installées à une hauteur suffisante conforme aux codes sanitaires et afin de répondre aux besoins en air du brûleur.

Fixez les pieds comme suit:

a. Placez la friteuse sur sa partie latérale en veillant à ne pas tirer sur le conduit de fumée afin de ne pas l’endommager.

Lorsque vous placez la friteuse à terre, protégez l’extérieur de la machine avec du carton et une toile de protection.

b. Fixez chaque pied à roulettes avec des vis de fixation hexagonales fournies avec la friteuse. Chaque pied à roulettes

doit être fixé avec des vis de fixation de 1/4-20 x 5/8 de po.

c. Fixez les vis à partir de l’intérieur de la friteuse en plaçant l’écrou à l’extérieur. Les écrous comportent des rondelles

de sécurité, il n’est donc pas nécessaire d’utiliser de nouvelles rondelles de sécurité.

d. Après avoir monté les pieds à roulettes, redressez la machine afin de la placer debout en veillant à ne pas placer

trop de poids sur un des pieds à roulettes. Réglez la hauteur de la machine et mettez-la à niveau en réglant les

dispositifs de mise à niveau des pieds à l’aide des pinces multiprises.

e. Sur les machines comportant des roulettes, déplacez la friteuse jusqu’à l’emplacement choisi et bloquez les roues

à l’aide des dispositifs de blocage situés à l’avant des roulettes.

AVERTISSEMENT

La friteuse doit être fermement fixée. Pour éviter tout risque de blessures graves, fixez la friteuse afin qu’elle ne puisse

être déplacée ou penchée et risquer d’éclabousser le personnel avec de l’huile bouillante. Veillez à toujours porter des

gants étanches à l’huile lorsque vous transportez ou déplacez tout appareil ou liquide chaud.

Distances de Sécurité

Il doit y avoir un espace suffisant autour de la friteuse afin d’assurer son bon fonctionnement. Cet espace est nécessaire pour

accéder à cette dernière et effectuer toute réparation nécessaire et afin d’assurer le bon fonctionnement du brûleur. Les

dimensions indiquées ci-dessous sont pour l’installation de l’appareil dans un environnement combustible et non-combustible.

Construction Construction

Combustible Non-Combustible

Dos 6 po (15 cm) 0

Côtés 6 po (15 cm) 0

Sol - Combustible 9 po (23 cm) 9 po (23 cm) (Nécessaire à la Combustion)

Le comptoir doit être construit avec un matériau non-combustible pour les comptoirs destinés à accueillir des friteuses SG14C.

L’espace autour de la friteuse doit non seulement être suffisant afin que l’appareil fonctionne à plein rendement, mais il doit

également y avoir une distance de 50 cm devant la friteuse afin de pouvoir retirer ou installer le bac ou module de filtrage.

Raccordement du gaz

Votre friteuse offre un rendement optimal lorsque le tuyau d’alimentation en gaz est d’une taille suffisante afin de permettre

un débit de gaz adéquat. Le tuyau de gaz doit être installé conformément aux codes du bâtiment de votre localité et à la norme

ANSI Z223 de la dernière édition du Code national d’installation des appareils à gaz. Au Canada, installez la friteuse

conformément aux normes CAN/CGA-B149.1 ou 2 et à la réglementation locale. La taille du tuyau de gaz peut être déterminée

par la compagnie du gaz de votre localité en se référant au Code national d’installation des appareils à gaz, paragraphe C, tableau

C-4 (gaz naturel) et tableau C-16 (propane). Le tuyau de gaz doit être suffisamment large afin d’alimenter pleinement tous les

appareils sans qu’il ne se produise une perte de pression au niveau de ces derniers.

FRANCAIS

NE JAMAIS alimenter en gaz la friteuse avec un gaz ne figurant pas sur la plaque signalétique. L’emploi de tout autre

gaz entraînera un dysfonctionnement de la machine. Si vous devez convertir la machine afin de l’utiliser avec un gaz

L20-394 rev 0 (04/12)

AVERTISSEMENT

différent, contactez votre revendeur.

11

Page 14

Types de carburants: Chaque friteuse est équipée afin de fonctionner avec un seul type de carburant. Le type de carburant

destiné à cet appareil est indiqué sur la plaque signalétique fixée à l’intérieur de la porte.

AVIS

NE JAMAIS utiliser un adaptateur afin de raccorder un tuyau de gaz plus petit. Vous risquez de nuire au rendement

de la machine en au bon fonctionnement du brûleur en empêchant un débit de gaz optimal.

Raccord de gaz à déconnexion rapide

Les friteuses à gaz à roulettes doivent être installées avec des raccords conformes à la dernière édition de la norme ANSI Z223.1

et de l’addenda Z21.69A consacrée aux raccords pour appareils à gaz mobiles. Ce raccord doit comporter un dispositif à

déconnexion rapide conforme à la dernière édition de la norme ANSI Z223.1 pour les dispositifs à déconnexion rapide utilisés

avec des appareils à gaz. Lorsque vous installez un dispositif à raccord rapide, il vous faut également installer un dispositif

limitant le déplacement de la friteuse. Ce dispositif évitera que le tuyau ou le raccord à déconnexion rapide ne se tende

excessivement. Le dispositif de retenue doit être fixé à la friteuse, au dos du panneau arrière.

Fuite au niveau du tuyau d’alimentation en gaz et vérification de la pression

Le circuit d’alimentation doit être testé avant d’utiliser la friteuse. Si vous comptez tester le tuyau d’alimentation en gaz à une

pression supérieure à 1/2 PSIG (3.45 kPa), veillez à ce que ce dernier ait été débranché de la friteuse. Si vous comptez tester le

tuyau d’alimentation en gaz à une pression égale ou inférieure à 1/2 PSIG (3.45 kPa), la friteuse peut être raccordée mais la

commande de gaz de la friteuse doit être fermée. Une fois la pression rétablie, testez tous les tuyaux de gaz afin de vous assurer

qu’ils ne comportent aucune fuite avec le l’eau savonneuse.

RACCORDEMENT ÉLECTRIQUE

L’alimentation électrique de la friteuse doit être conforme aux codes de votre localité. En l’absence de réglementation locale,

reportez-vous au Code électrique national des États-Unis (NEC) et aux normes ANSI/NFPA pour l’installation électrique. Au

Canada, reportez-vous à la norme CSA C22.1 et à la réglementation de votre localité. Les diagrammes de câblages sont visibles

à l’intérieur de la boîte de commande de la friteuse.

Ventilation et Systèmes de Sécurité contre les Incendies

Votre nouvelle friteuse doit être correctement ventilée et fonctionner en toute sécurité. La température des gaz d’échappement

peut atteindre 1000°F (538°C). Par conséquent, il est indispensable d’installer un système de protection contre les incendies.

Votre système de ventilation doit être conçu afin de pouvoir être facilement nettoyé. Nettoyez fréquemment le système de

ventilation et la friteuse afin de réduire les risques d’incendie. Les tableaux 1 et 2 offrent une liste de documents de référence

sur la ventilation et les systèmes de protection contre les incendies. Cette liste n’est pas complète. Il vous est possible d’obtenir

des informations supplémentaires auprès de l’CSA-International, 8501 East Pleasant Valley Road, Cleveland, OH 44131.

Toute ventilation excessive entraînera des courants d’air. Ceci nuira au bon fonctionnement de la veilleuse et du brûleur. Laissez

un espace d’au moins 18 po. (45 cm) entre le carneau ou conduit de fumées de la friteuse et l’entrée de la hotte d’aspiration.

ATTENTION

Veiller à ce que le système de ventilation ne provoque pas de rupture de tirage au niveau de l’ouverture

du carneau de la friteuse. Toute rupture de tirage empêchera la friteuse d’évacuer correctement la

fumée et les gaz et entraînera une surchauffe risquant d’endommager la machine de façon irréversible.

Aucun dégât provoqué par une rupture de tirage ne sera couvert par la garantie de l’appareil. NE

JAMAIS laisser quoique ce soit pouvant gêner le débit des combustibles ou de la ventilation sortant

du conduit de fumée de la friteuse. NE RIEN placer sur le dessus du conduit de fumée.

AVIS

NE JAMAIS diriger le ventilateur directement sur les ouvertures du conduit de fumée. Toute

ventilation directe nuira à l’efficacité de la friteuse, gênera l’allumage et risquera d’éteindre la

veilleuse.

Critères d’Installation des Conduites de Gaz

Un circuit d’alimentation en gaz doit fournir de pression de 7.0 + 2.0 po. de colonne d’eau, avec gaz naturel (12.0 + 2.0 po. de

colonne d’eau pour le gaz de propane liquide) à tous les appareils raccordés à la conduite et fonctionnera à plein rendement.

NE PAS dépasser une pression de 13.5 po. de colonne d’eau car vous risquez d’endommager la commande de gaz.

L20-394 rev 0 (04/12)

AVIS

12

Page 15

INSTRUCTIONS D’ALLUMAGE

a. Remplissez la machine avant de l’allumer.

b. T ournez la commande de gaz jusqu’à “PILOT” (veilleuse).

c. Appuyez sur le bouton de la commande et allumez la veilleuse. Pendant que la veilleuse brûle, maintenez le

bouton appuyé pendant environ 60 secondes.

d. Relâchez le bouton, la veilleuse devrait demeurer allumée.

e. NE P AS RÉGLER LE BOUTON DE LA COMMANDE DE GAZ MIXTE

SUR «ON» (MARCHE) AVANT QUE LA FRITEUSE NE SOIT REMPLIE D’EAU OU DE MATIÈRE

GRASSE. LE FAIT DE PLACER LE BOUTON SUR «ON» (MARCHE) ALORS QUE LA FRITEUSE EST

VIDE, ENDOMMAGERA L’APPAREIL ET LES ÉLÉMENTS ASSOCIÉS ET ANNULERA LA GARANTIE.

f. Rallumage - attendre 5 minutes avant de tenter de rallumer la veilleuse afin de permettre à tout gaz à l’intérieur

de la friteuse de se dissiper.

Nettoyage Initial

Lorsque la friteuse est expédiée, elle comporte de nombreuses pièces recouvertes d’une fine pellicule d’huile afin d’assurer

leur protection. Avant que la friteuse ne soit prête à être utilisée, elle doit être nettoyée. Vous retirerez ainsi l’huile et tout résidu

s’étant accumulé lors de l’entreposage et l’expédition de la machine. Nettoyez la machine en suivant les indications suivantes:

a. Remplissez la friteuse avec de l’eau.

b. Réglez la commande de gaz de la friteuse sur “ON”.

Laissez la friteuse chauffer l’eau jusqu’à ébullition puis versez un sachet de nettoyant Pitco pour friteuse ou un

détergent peu moussant et laissez l’eau bouillir pendant encore une minute, en veillant que le mélange ne déborde pas.

c. Réglez la commande de gaz sur “PILOT” (veilleuse) et laissez la friteuse tremper dans l’eau chaude pendant

15 minutes.

AVIS

Ne pas laisser la friteuse sans surveillance lors du nettoyage. Ne jamais laisser le niveau d’eau

tomber en dessous de la mention “Min Level” (niveau minimum) au dos de la cuve.

d. Utilisez la brosse à nettoyer pour friteuse, frottez l’intérieur de la friteuse afin de retirer le revêtement protecteur.

e. Après avoir nettoyé la friteuse, réglez la commande de gaz sur “OFF” (arrêt) et purgez l’eau dans un récipient

pour eau chaude et jetez le contenu.

f. Après que la cuve ait refroidie, rincez-la complètement avec de l’eau froide. Continuez à rincer la cuve jusqu’à

ce que le nettoyant ait complètement disparu.

g. À l’aide d’un chiffon sec et propre, essuyez toute trace d’eau restante. Veillez à bien essuyer toute l’eau. En effet,

toute présence d’eau dans l’huile risque de provoquer une ébullition intense et des éclaboussures hors de la

friteuse. Fermez le robinet de purge et retirez le récipient.

ATTENTION

Toute cuve en acier normal doit être essuyée et protégée avec une fine pellicule d’huile afin

d’éviter qu’elle ne rouille.

h. À présent que la cuve est propre, la friteuse peut être remplie et utilisée. Reportez-vous aux instructions afin

d’ajouter la matière grasse à la friteuse.

NETTOYAGE QUOTIDIEN

Nettoyez votre friteuse tous les jours afin qu’elle fonctionne à son rendement optimal et conserve sa belle apparence.

a. Essuyez toute trace de matière grasse sur l’extérieur de la friteuse. Nettoyez à l’aide d’un chiffon pendant que

l’huile est encore chaude.

b. Utilisez de l’eau chaude et un nettoyant peu puissant pour nettoyez la surface. Veillez à ne pas laisser d’eau entrer

en contact avec l’huile et retirez toute trace de détergent à l’intérieur de la cuve.

c. Utilisez une poudre à récurer non-abrasive ou un tampon afin de nettoyer toute tâche rebelle.

d. Procédez au nettoyage par ébouillantage comme indiqué ci-dessous.

NETTOYAGE HEBDOMADAIRE DE LA FRITEUSE

La friteuse doit également être complètement vidangée et purgée puis chauffée jusqu’à ébullition.

a. Vous aurez besoin d’un récipient capable de contenir une fois et demi (1 1/2) la contenance en huile de la cuve.

Ce récipient doit également également être capable de supporter des températures d’huile de 400

b. Fermez complètement (OFF) le circuit de gaz de la friteuse avant de commencer afin d’éviter que la machine ne

se mette en marche pendant une phase quelconque du nettoyage.

0

F (2040C).

FRANCAIS

L20-394 rev 0 (04/12)

13

Page 16

c. Vidangez l’huile de la friteuse et jetez-la ou conservez-la afin de la réutiliser plus tard. Retirez les tamis des tubes

de filtrage ainsi que tout débris de grosse taille demeurant au fond de la cuve. Après avoir nettoyé les tamis des

tubes de filtrage, remettez-les en place. Fermez le robinet de purge et remplissez la cuve avec de l’eau et un

détergent non-corrosif.

d. Rallumez la veilleuse du circuit de gaz en suivant les instructions d’allumage.

e. Réglez la commande de gaz de la friteuse sur “ON”. Laissez la friteuse chauffer l’eau jusqu’à ébullition puis versez

un sachet de nettoyant Pitco pour friteuse ou un détergent peu moussant et laissez l’eau bouillir pendant encore

une minute, en veillant à ce que le mélange ne déborde pas.

f. Réglez la commande de gaz sur “PILOT” (veilleuse) et laissez la friteuse tremper dans l’eau chaude pendant 15

minutes.

g. Utilisez la brosse à nettoyer pour friteuse, frottez l’intérieur de la friteuse afin de retirer le revêtement protecteur.

h. Après avoir nettoyé la friteuse, réglez la commande de gaz sur “OFF” (arrêt) et purgez l’eau dans un récipient

pour eau chaude et jetez le contenu.

i . Après que la cuve ait refroidie, rincez-la complètement avec de l’eau froide. Continuez à rincer la cuve jusqu’à

ce que le nettoyant ait complètement disparu.

j . À l’aide d’un chiffon sec et propre, essuyez toute trace d’eau restante. Veillez à bien essuyer toute l’eau. En effet,

toute présence d’eau dans l’huile risque de provoquer une ébullition intense et des éclaboussures hors de la

friteuse. Fermez le robinet de purge et retirez le récipient.

k. À présent que la cuve est propre, la friteuse peut être remplie et utilisée. Reportez-vous aux instructions afin

d’ajouter la matière grasse à la friteuse.

A VER TISSEMENT

Toute friteuse à gaz à roulettes doit être équipée d’un dispositif de retenue. Ce dispositif de sécurité doit être raccordé à

tout moment lorsque la friteuse est raccordée à la conduite d’arrivée de gaz. Si pour une raison quelconque elle n’est

pas raccordée, raccordez-la.

Vérification de l’Étalonnage du Thermostat

L’étalonnage du thermostat nécessite que la température de la friteuse soit supérieure à la

température d’ébullition. Par conséquent, vous devrez purger l’eau de la friteuse et la remplacer

par de l’huile. Avant de remplacer l’eau, procédez au nettoyage initial de la friteuse. Le fait de

nettoyer la friteuse maintenant vous évitera de purger l’huile et de remplir d’huile à nouveau la

friteuse plus tard.

Pour effectuer l’étalonnage indiqué ci-dessous, munissez-vous d’un thermomètre numérique.

a. Placez la pointe du thermomètre dans la matière grasse environ 1 po. (2,5 cm) au-dessus des sondes de température.

b. Réglez le thermostat sur 325°F (163°C) et attendez que la température s’élève. Au fur et à mesure que la température

s’élève vers 325°F (163°C), surveillez attentivement le thermomètre.

c. Si la température de la matière grasse atteint 350°F (176°C) et que les brûleurs NE S’ÉTEIGNENT PAS, baissez

le thermostat. Continuez à baisser le thermostat jusqu’à ce que les brûleurs s’éteignent.

Si les brûleurs ne s’éteignent pas lorsque le thermostat se trouve sur son réglage le plus bas, le

thermostat est sans doute défectueux. Contactez votre distributeur immédiatement.

d. Laissez la friteuse effectuer 4 à 6 cycles avant de vérifier la température. Comparez la température du thermomètre

et le réglage du thermostat. Si les valeurs diffèrent de plus de 5°F (2°C), étalonnez le thermostat en suivant les

instructions d’étalonnage de ce manuel.

AVIS

ATTENTION

ÉTALONNAGE DU THERMOSTAT

Si le thermostat ne contrôle pas la température, vérifier les connexions entre le thermostat et la commande de gaz.

Thermostats millivolts

L20-394 rev 0 (04/12)

REMARQUE

a. Réglez le thermostat sur 325°F (163°C).

b. Retirez le cadran du thermostat en tirant tout droit sur le bouton. NE P AS tourner le cadran.

c. T enez l’extérieur de l’axe de façon à ce qu’il ne bouge pas. Utilisez la pointe d’un tournevis à lame plate

14

Page 17

pour retirer en grattant le mastic d’étanchéité de la vis de réglage.

d. Tournez la vis de réglage dans le sens de aiguilles d’une montre afin d’abaisser la température et dans le sens

inverse pour l’élever. Un quart de tour change la température d’environ 25°F (10°C).

e. T ournez la vis de réglage jusqu’à ce que les brûleurs atteignent 325°F (163°C). Replacez le bouton et laissez

la friteuse effectuer 4 à 6 cycles. Comparez la température du thermomètre et le réglage du thermostat. Si les

valeurs diffèrent de plus de 5°F (2°C), répétez la marche à suivre pour l’étalonnage de ce manuel.

f. Après avoir étalonné le thermostat, retirez le thermomètre et replacez le tamis du tube.

Remplir la Friteuse de Matière Grasse Liquide

a. Assurez-vous que le robinet de purge est complètement fermé.

b. Remplissez la friteuse d’huile jusqu’au repère du niveau d’huile (“Oil Level”) indiqué au dos de la cuve.

Remplir la Friteuse de Matière Grasse en Bloc

a. Assurez-vous que le robinet de purge est complètement fermé.

b. Retirez le tamis recouvrant les tubes.

c. Coupez la matière grasse en cubes ne dépassant pas 1 po (2,5 cm) de large. Veillez à TOUJOURS placer la matière

grasse sous, entre et sur le dessus des tubes des brûleurs. NE PAS laisser de gros espaces d’air. Faites attention

à NE PAS plier ni rompre les sondes de température. En effet, si ces dernières sont endommagées, la friteuse ne

pourra fonctionner correctement.

d. Après avoir rempli la friteuse de matière grasse, faites fondre la matière grasse.

e. Pour faire fondre la matière grasse, allumez (ON) et éteignez (OFF) les brûleurs à l’aide du thermostat jusqu’à ce

que la matière grasse se liquéfie suffisamment et recouvre les tubes. Ceci protégera la cuve et les éléments et

allongera la durée d’utilisation de l’huile.

Éteindre la Friteuse

Il existe deux modes d’arrêt de la friteuse, STANDBY (en attente) et COMPLETE (complet). Le mode d’arrêt en attente empêchera

aux brûleurs de s’allumer et de s’éteindre. Le mode d’arrêt complet coupe l’arrivée de gaz à la friteuse. Éteignez la friteuse en:

STANDBY (en attente)

Réglez le thermostat sur “OFF”(arrêt). Tournez la commande de gaz dans le sens des aiguilles d’une montre jusqu’à “PILOT”

(veilleuse). La machine est à présent en mode d’attente et ne pourra demeurer ainsi que pendant une brêve période. NE JAMAIS

laisser la machine demeurer en mode d’attente toute une nuit.

COMPLETE (complet)

Pour complètement éteindre la machine, appuyez et tournez la commande de gaz dans le sens contraire à celui des aiguilles d’une

montre jusqu’à “OFF” (arrêt). La friteuse est à présent complètement éteinte et peut être nettoyée et filtrée.

FRANCAIS

L20-394 rev 0 (04/12)

15

Page 18

ARTICLE DOCUMENT UNDERWRITERS DOCUMENT DU CODE

LABORA TORIES NATIONAL POUR

GAZ COMBUSTIBLE

HOTTE D’EXTRACTION ANSI/UL 710 ANSI/NFP A 96

VENTILA TEURS ANSI/UL 705 ANSI/NFP A 96

UNITÉ DE FIL TRAGE ANSI/UL 586 ANSI/NFP A 96

ANSI/UL 900

TYPES D’EXTINCTEURS

ET MA TÉRIEL DE DÉTECTION

2

CO

ANSI/UL 154 ANSI/NFP A 12

EXTINCTE UR À POUDRE ANSI/UL 299 ANSI/NFPA 17

EXTINCTEUR À EAU ANSI/UL 626 ANSI/NFP A 13

EXTINCTEUR À MOUSSE ANSI/UL 8 ANSI/NFPA 1 1

ARROSEURS AUTOMA TIQUES ANSI/UL 199 ANSI/NFP A 13

DÉTECTEURS DE FUMÉES ANSI/UL 268 ANSI/NFP A 72

THERMOST A T DE DÉTECTION ANSI/UL 521 ANSI/NFP A 72

INCENDIE

POUR TOUTE MAINTENANCE OU RÉPARATION, CONTACTEZ UN RÉPARATEUR AGRÉÉ DE L’USINE, UN REPRÉSENTANT DE L’USINE OU L’USINE ELLE-MÊME.

L20-394 rev 0 (04/12)

16

Page 19

FRANCAIS

L20-394 rev 0 (04/12)

17

Page 20

INST ALLA TION ET D’UTILISA TION Pour les friteuses

à gaz aucune OPTION / STAND ALONE Modèles

couvrant SB14,SB14R,SB18

Southbend A Middleby Corporation Company

1100 Old Honeycutt Road, Fuquay-Varina, NC 27526

(919) 762-1000 phone (919) 552-9798 fax

L20-394 rev 0 (04/12)

18

Page 21

Manual de Instalación y Operación

de Freidores de Gas

Cubre los Modelos

SB14,SB14R,SB18

Southbend A Middleby Corporation Company 1100 Old Honeycutt Road, Fuquay-Varina, NC 27526

(919) 762-1000 phone (919) 552-9798 fax

L20-394 R0 (04/12) www.southbend.com

ESPANOL

Page 22

ESTE MANUAL DEBE CONSER VARSE PARA REFERENCIA FUTURA

P ARA SU SEGURIDAD

NO ALMACENE o use gasolina u otras sustancias líquidas o de vapores inflamables en las

cercanías de este o de cualquier otro aparato similar.

ADVERTENCIA

Una instalación inadecuada, o la alteración del aparato, o servicio o mantenimiento inapropiados,

pueden causar daños, lesiones y, aún, la muerte. Lea cuidadosamente las instrucciones de

instalación, operación y mantenimiento antes de instalar o dar servicio a este equipo.

AL COMPRADOR

Coloque en una ubicación prominente las instrucciones que deban seguirse en caso de que un operador perciba el olor de

gas. Obtenga este tipo de información solicitándolo a su distribuidor local de gas.

ADVERTENCIA

Hay llama abierta en el interior de este freidor . La unidad puede calentarse hasta el punto de incendiar materiales en su

cercanía. Mantenga el área alrededor del freidor libre de materiales combustibles.

ADVERTENCIA

NO alimente el freidor con un gas que no sea el indicado en la placa de especificaciones. Si necesita convertir el freidor a

otro tipo de combustible, póngase en contacto con el distribuidor .

ADVERTENCIA

¡NO use una llama abierta para verificar la existencia de un escape de gas!

ADVERTENCIA

Espere 5 minutos antes de tratar de encender nuevamente el piloto para permitir que se disipe el gas que pueda haber

quedado en el freidor .

ADVERTENCIA

Nunca derrita bloques de grasa encima de los tubos del quemador . Esto puede causar un incendio e invalidar su garantía.

ADVERTENCIA

El agua y la grasa NO se mezclan. Mantenga los líquidos alejados de la grasa caliente. El poner un líquido congelado en

grasa caliente puede causar un hervor violento.

ADVERTENCIA

Asegúrese de que el freidor tiene suficiente aire para mantener la llama del quemador ardiendo en forma correcta. Si a la

llama le hace falta aire, se puede producir el peligroso gas de monóxido de carbono. El monóxido de carbono es un gas

incoloro e inodoro y puede causar asfixia.

ADVERTENCIA

Un aparato de cocción equipado con roldanas y línea de gas flexible debe estar conectado a la línea de suministro de gas por

medio de un artefacto de desconexión rápida. T al artefacto debe cumplir con la especificación ANSI Z24.41. Para limitar el

movimiento del aparato de cocción, sin depender del conector o del artefacto de desconexión rápida, debe instalarse un cable

que restrinja su movimiento.

L20-394 rev 4 (04/12)

Page 23

REVISION DE UN FREIDOR NUEVO

Su nuevo freidor ha sido cuidadosamente embalado en empaque de transporte. Se ha hecho todo esfuerzo para asegurar que

el freidor le llega en condiciones perfectas. A medida que usted lo desempaca, inspeccione cada una de sus partes para detectar

si han sufrido algún daño. Si algo llega dañado NO firme el comprobante de trasporte. Póngase en contacto con el transportista

inmediatamente. El transportista es responsable por un período de 15 días a partir de la fecha de entrega. Verifique la lista

de empaque que va junto con el freidor para asegurarse de que ha recibido todas las partes del aparato. Si hace falta alguna

parte, póngase en contacto con el distribuidor a quien compró el freidor.

PRECAUCION

Para evitar daños al equipo no incline o sostenga el freidor en sólo dos de sus roldanas o trate de mover la

unidad tirando de las aberturas de ventilacion del cañón de la chimenea.

Instalación y Ajuste de Patas y Roldanas

La instalación de las patas y la nivelación del freidor se hacen con una llave de copa de 7/16" y un par de alicates grandes

de bomba de agua. Las patas y las roldanas deben instalarse de manera que proporcionen la altura necesaria que permita la

limpieza de la máquina y asegure un suministro adecuado de aire al quemador. Fije las patas de acuerdo con el siguiente

procedimiento.

a. Ponga la máquina de manera que descanse sobre uno de sus costados, teniendo cuidado de no dañar el cañón

de chimenea tirando de él. Proteja el exterior del freidor con cartón o paños cuando va a colocarlo de costado.

b. Fije cada una de las patas/roldanas, si es el caso, con los pernos de cabeza hexagonal que se suministran con el

freidor. Cada pata/roldana requiere 4 pernos de 1/4 - 20 x 5/8".

c. Monte los pernos desde el interior del freidor, con la tuerca en el exterior. Las tuercas tienen arandelas de cierre

adosadas a la tuerca y, por lo tanto, no es necesario usar arandelas de cierre adicionales.

d. Una vez montadas las 4 patas/roldanas, pare la unidad teniendo cuidado de no poner mucho peso en ninguna

de las patas. Ajuste la altura y nivele el freidor por medio de los accesorios de nivelación que se encuentran en

la pata y utilizando los alicates de bomba de agua.

e. En unidades con roldanas mueva, el freidor a la ubicación deseada e inmovilice las roldanas usando los accesorios

de cierre, en el frente de cada roldana.

ADVERTENCIA

El freidor debe estar fijado adecuadamente para evitar que pueda moverse o ladearse. El sistema de fijación

debe poder evitar movimientos del freidor que puedan salpicar líquidos calientes sobre el personal, los que

pueden causar quemaduras o lesiones muy severas. Siempre use guantes a prueba de aceite cuando tenga

que mover o manejar equipo o líquidos calientes.

Distancias Libres para la Instalación

El freidor necesita distancias libres a su alrededor para poder operar apropiadamente. Las distancias libres adecuadas

posibilitan el dar servicio a la máquina y permiten la operación del quemador en forma correcta. Las distancias libres que

aquí se especifican son para la instalación del aparato en lugares de construcción tanto combustible como no combustible.

Construcción Construcción

Combustible Non-Combustible

Respaldo 6 po (15 cm) 0

Costados 6 po (15 cm) 0

Piso - Combustible 9 po (23 cm) 9 po (23 cm) (Distancia Necesaria para la

Combustión)

La superficie superior del mostrador debe fabricarse de material no combustible para instalación SG14C de

tablero de mostrador para freidora. Además de los espacios libres que requiere la operación correcta de la freidora, debe quedar un espacio de paso libre de por lo menos 50 cm en frente de la freidora que permita la instalación

o remoción del filtro del módulo de bandeja.

Conexión de Gas

Su freidor funcionará en condiciones óptimas siempre que la línea de suministro de gas sea de tamaño suficiente para

proporcionar el flujo apropiado de gas . La línea de gas debe instalarse cumpliendo los requisitos de los códigos locales de

construcción o los de la edición más reciente de National Fuel Gas Code ANSI Z223.1. En el Canadá, instale el freidor de

acuerdo con CAN/CGA-B149.1 o .2 y los códigos locales de construcción. Los requisitos de tamaño de la línea de gas pueden

ser determinados por la compañía local de gas consultando el National Fuel Gas Code, Appendix C, Table C-4 (natural gas)

y Table C-16 (propane). La línea de gas debe ser de suficiente tamaño para surtir la cantidad de combustible necesario a todos

los artefactos que usan gas, sin pérdida de presión en ninguno de los artefactos.

ESPANOL

L20-394 rev 0 (04/12)

21

Page 24

ADVERTENCIA

NUNCA utilice en el freidor un tipo de gas que no sea el indicado en la placa de

especificaciones. El uso de un tipo de gas que no sea el apropiado causará una operación

defectuosa. Si usted desea convertir su freidor a otro tipo de combustible, póngase en contacto

con el distribuidor.

Tipos de Combustible - Cada freidor está equipado para trabajar con un cierto tipo de combustible. El tipo de combustible

para el cual el aparato se ha diseñado está indicado en la placa de especificaciones que se encuentra en lado interior de

la puerta del freidor.

AVISO

NUNCA use un adaptador para hacer que una línea de suministro de gas de menor diámetro del

requerido se ajuste a la conexión del freidor. Esto puede no permitir un flujo de gas suficiente para la

operación óptima del quemador lo cual resultaría en un rendimiento bajo del freidor.

Conexión de Gas de Desconexión Rápida

Los freidores de gas equipados con roldanas deben instalarse con conectores que cumplan los requisitos de las ediciones

más recientes de Standard for Connectors for Movable Gas Appliances, ANSI Z223.1 y Addenda Z21.69A. Esta conexión

debe incluir un artefacto de desconexión rápida que cumpla los requisitos de la edición más reciente de Standard for Quick

Disconnect Devices for Use with Gas Fuel, ANSI Z223.1. Cuando se instale el artefacto para desconexión rápida también

deben instalarse un sistema para limitar el movimiento del freidor. Este sistema debe poder evitar que la línea de gas o el sistema

de desconexión rápida puedan estar sujetos a esfuerzos producidos por el movimiento del freidor. El sistema de restricción

de movimiento debe fijarse al panel de atrás del freidor.

Pruebas de Escapes y de Presión de la Línea de Suministro del Combustible

El sistema de suministro de combustible debe probarse antes de usar el freidor. En caso de que la línea de combustible se

vaya a probar a una presión mayor de (>)1/2 PSIG (3.45 kPa) asegúrese de que el freidor se ha desconectado de la línea de

suministro. En caso de que la línea de suministro se vaya a probar a una presión igual o menor de (=o>)1/2 PSIG (3.45 kPa),

el freidor puede estar conectado a la línea, pero la válvula de gas de la unidad debe estar cerrada. Pruebe todas las conexiones

de la línea de gas para detectar escapes usando una solución de agua y jabón cuando se aplica la presión.

CONEXION ELECTRICA

El servicio eléctrico que utilice el freidor debe cumplir todos los códigos locales. En caso de que no haya códigos locales

aplicables, consulte el National Electrical Code (NEC), ANSI/NFPA 70 para la instalación del servicio. En el Canadá consulte

los códigos locales y el CSA Standard C22.1. Los diagramas de alambrado se encuentran dentro de la caja de control del freidor.

Sistemas de Ventilación y Contra Incendios

El nuevo freidor debe tener ventilación apropiada para que pueda funcionar en forma adecuada y segura. Las temperaturas

de los gases de salida pueden llegar hasta los 1000°F (538°C). y, por lo tanto, es muy importante instalar un sistema contra

incendios. El sistema de ventilación debe diseñarse de manera que facilite su limpieza. La limpieza frecuente del sistema

de ventilación y del freidor reducirán la probabilidad de un incendio. El Cuadro 1-2 muestra una lista de documentos de

referencia que pueden servir como guías en el diseño de los sistemas de ventilación y contra incendio. El Cuadro no es

necesariamente completo. Se puede obtener información adicional de la CSA-International, 8501 E. Pleasant Valley Road,

Cleveland, Ohio 44131.

Una ventilación excesiva puede causar corrientes de aire que interfieren con la operación apropiada del piloto y del

quemador. Deje un espacio libre de 18 pulgadas (45 cm), por lo menos, entre la ventana de desahogo del cañón de

chimenea del freidor y el punto de entrada de la campana de extracción.

PRECAUCION

Asegúrese de que el sistema de ventilación no causa una corriente descendente de aire en la abertura

del cañón de chimenea del freidor. Las corrientes descendentes de aire no permiten que el freidor pueda

descargar en forma apropiada y causan recalentamiento que puede ocasionar daños permanentes. Los

daños causados por corrientes descendentes de aire no están cubiertos bajo la garantía del equipo.

NUNCA permita la obstrucción del flujo de combustible o el de la ventilación de salida del cañón de

chimenea del freidor. NUNCA coloque ningún objeto encima del área del cañón de chimenea.

AVISO

NUNCA conecte directamente el ventilador a las aberturas del cañón de chimenea. El flujo directo de

aire ocasiona recuperación térmica deficiente, ignición inadecuada, operación ineficiente del freidor

y puede extinguir el piloto.

Requerimientos de las Líneas de Gas

Un sistema de suministro de gas apropiadamente instalado debe poder surtir todos los aparatos conectados a la línea,

funcionando a plena carga, con una presión de 7.0" + 2.0" de agua, con gas natural (12.0" + 2.0" de agua, con propano

líquido).

L20-394 rev 0 (04/12)

22

Page 25

AVISO

NO exceda una presión de 13.5 pulgadas de agua, pues puede dañar la válvula de gas.

INSTRUCCIONES DE ENCENDIDO

a. Llene la marmita antes de encender el gas.

b. Gire la perilla de la válvula de combinación de gas a la posición “PILOT”.

c. Oprima la perilla de la válvula y encienda el piloto. Con el piloto encendido mantenga la perilla oprimida

por 60 segundos.

d. Deje salir la perilla y la llama del piloto deberá mantenerse encendida.

e. NO GIRE LA PERILLA DE LA V ALVULA DE COMBINACION DE GAS A LA POSICION “ON”

(ENCENDIDO), HAST A QUE EL RECIPIENTE NO ESTE COMPLET AMENTE LLENO DE AGUA O DE

GRASA. EL GIRAR LA PERILLA A LA POSICION “ON” CON EL RECIPIENTE V ACIO DAÑA EL

RECIPIENTE, O SUS COMPONENTES, E INV ALIDA LA GARANTIA.

f. Volver a encender - espere 5 minutos antes de tratar de encender nuevamente el piloto para permitir que se

disipe el gas que pueda haber quedado en el freidor.

Limpieza Inicial

Cuando el freidor se despacha de fábrica, muchas de sus partes están cubiertas por una capa delgada de aceite para su

protección. Antes de poner el freidor en operación debe limpiarse. Esta limpieza consiste en la remoción de la cubierta

de aceite y de cualquier material extraño que se haya acumulado durante el almacenamiento y transporte del equipo.

Lleve a cabo esta limpieza en la forma que aquí se describe.

a. Remplissez la friteuse avec de l’eau.

b. Gire la perilla de la válvula de combinación de gas a la posición “ON”, encendido.

Deje que el agua empiece a hervir y añádele un paquete de Limpiador Pitco para Freidor o un detergente suave que

no haga mucha espuma. Permita que siga hirviendo durante un minuto, asegurándose de que el agua no se derrame.

c. Gire la perilla de la válvula de combinación de gas a la posición “PILOT” y permita que el freidor se

caliente por 15 minutos.

AVISO

No deje el freidor desatendido durante la limpieza. Nunca deje que el nivel de agua descienda por

debajo de la marca “Min Level” en el respaldo del tanque.

LIMPIEZA DIARIA

Debe realizarse con esta frecuencia para mantener la apariencia de la máquina y obtener su operación óptima.

LIMPIEZA SEMANAL DEL FREIDOR

Esta limpieza debe incluir el drenaje completo de el freidor y su proceso de hervido.

L20-394 rev 0 (04/12)

d. Usando el cepillo de limpieza del freidor, friegue el interior del freidor para remover la capa de protección de

aceite.

e . Una vez terminada la limpieza, apague los quemadores principales del freidor y gire la perilla de la válvula de

gas a la posición “OFF” (apagado). Drene el agua en un recipiente adecuado para agua caliente y viértala al

desagüe.

f. Cuando el tanque se haya enfriado, enjuáguelo completamente con agua fría. Continúe enjuagando el tanque

hasta que el limpiador se haya removido completamente.

g. Usando un paño seco, seque el agua. Tenga cuidado de remover toda el agua, porque cualquier residuo de agua

hará que el aceite caliente salpique del freidor. Cierra la válvula de drenaje y quite el recipiente.

PRECAUCION

Los tanques hechos de acero dulce deben secarse completamente y cubrirse con

aceite para evitar que el tanque se oxide.

h . Ahora que el tanque ha quedado limpio, se puede proceder a llenarlo y operar el freidor. Consulte las

instrucciones sobre la forma de poner la grasa en el freidor.

a . Limpie cualquier cantidad de grasa que se derrame en el exterior del freidor. Esto debe hacerse con un paño

limpio y suave mientras el aceite está todavía tibio.

b. Use agua tibia con un detergente suave para limpiar las superficies. Tenga cuidado de no introducir agua

en la grasa y remueva cualquier cantidad de detergente que quede en el tanque de freír.

c. Use un polvo de limpieza no abrasivo o una almohadilla para limpiar manchas, si es necesario.

d. Realice semanalmente el hervido y limpieza del freidor, según se describe a continuación.

ESPANOL

a . Usted necesita un recipiente suficientemente grande para contener 1 1/2 veces el volumen de aceite del tanque.

Este recipiente debe ser de material adecuado para resistir aceite a temperatura de 4000F (2040C).

b. Antes de realizar este procedimiento, cierre completamente el sistema de gas poniendo la válvula en la posición

“OFF” (apagado), para asegurarse de que la unidad no se enciende durante ningún paso de la operación de

limpieza.

23

Page 26

c. Drene el aceite del freidor y disponga de él, o consérvelo para ser usado nuevamente. Remueva la reja tubular

y las mallas tubulares y saque los depósitos sólidos que encuentre en el fondo del tanque de freír. Una vez éste

limpio, vuelva a colocar la reja tubular y las mallas en el tanque de freír. Cierre la válvula de drenaje y llene

el tanque de freír con agua, a la que deberá agregar un detergente no cáustico.

d. Encienda el piloto del sistema de gas siguiendo las instrucciones de encendido.

e . Gire la perilla de la válvula de combinación de gas a la posición “ON”, encendido. Deje que el agua empiece

a hervir y añádele un paquete de Limpiador Pitco para Freidor o un detergente suave que no haga mucha espuma.

Permita que siga hirviendo durante un minuto, asegurándose de que el agua no se derrame.

f. Gire la perilla de la válvula de combinación de gas a la posición “PILOT” y permita que el freidor se caliente

por 15 minutos.

g. Usando el cepillo de limpieza del freidor, friegue el interior del freidor para remover la capa de protección de aceite.

h. Una vez terminada la limpieza, apague los quemadores principales del freidor y gire la perilla de la válvula a

la posición “OFF” (apagado). Drene el agua en un recipiente adecuado para agua caliente y viértala al desagüe.

i. Cuando el tanque se haya enfriado, enjuáguelo completamente con agua fría. Continúe enjuagando el tanque

hasta que el limpiador se haya removido completamente.

j. Usando un paño seco, seque el agua. Tenga cuidado de remover toda el agua, porque cualquier residuo de agua

hará que el aceite caliente salpique del freidor. Cierra la válvula de drenaje y quite el recipiente.

k. Ahora que el tanque ha quedado limpio, se puede proceder a llenarlo y operar el freidor.Consulte las

instrucciones sobre la forma de poner la grasa en el freidor.

ADVERTENCIA

Las unidades de gas instaladas sobre roldanas deben tener un sistema de sujeción. Este sistema debe estar

conectado en todo momento en que el freidor esté conectado al suministro de gas. Si por cualquier circunstancia se

desconecta, se debe volver a conectar.

Verificación de la Calibración del Termostato

AVISO

La calibración del termostato requiere que la temperatura del freidor suba por encima de los 212°F.

Por lo tanto, usted necesita drenar el agua del freidor y llenarlo con aceite. Antes de drenar el agua,

realice la limpieza inicial del freidor. El limpiar el freidor ahora le evitará tener que drenar el aceite

para llenar después la máquina con agua.

Para llevar a cabo la verificación de calibración que aquí se detalla, necesitará un termómetro digital.

a . Coloque la punta del termómetro en la grasa aproximadamente una pulgada por encima de los sensores de

temperatura.

b. Fije la temperatura del termostato en 325°F (163°C) y espere a que la temperatura en el termómetro principia

a subir. Cuando la temperatura esté llegando a los 325°F (163°C), observe cuidadosamente la lectura del

termómetro.

c. Si la temperatura de la grasa llega a los 350°F (176°C)y los quemadores no se apagan, reduzca la temperatura

en el termostato. Continúe bajando la temperatura en el termostato hasta que los quemadores se apaguen.

PRECAUCION

Si los quemadores no se apagan en la lectura más baja del termostato, el termostato puede estar dañado. Póngase

en contacto con el representante inmediatamente.

d. Permita que el freidor realice su ciclo de 4 a 6 veces antes de verificar la temperatura. Compare la temperatura

del termómetro con la temperatura del termostato. Si los valores tienen una diferencia de más de 5°F (2°C) ,

calibre el termostato usando el procedimiento apropiado de calibración que se describe en este manual.

CALIBRACION DEL TERMOSTATO

NOT A

Si el termostato no está controlando la temperatura, revise las conexiones de los cables entre el termostato y la

válvula de gas.

L20-394 rev 0 (04/12)

24

Page 27

CALIBRACION DEL TERMOSTATO

Termostato Millivolt

a. Fije el dial del termostato en 325°F (163°C).

b. Remueva el dial del termostato jalando de la perilla, derecho hacia afuera. NO haga girar el dial.

c. Sostenga el exterior del eje de manera que no se mueva. Use la punta de un destornillador pequeño de aleta

plana para raspar la sustancia de sellado del tornillo de ajuste.

d. Gire el tornillo de ajuste en la dirección de las manecillas del reloj para bajar la temperatura o en la

dirección opuesta a la de las manecillas del reloj para subir la temperatura. La cuarta parte de un giro del eje

cambia la temperatura aproximadamente en 25°F (10°C).

e. Continúe haciendo este ajuste hasta que los quemadores se prendan a una temperatura de 325°F (163°C).

Vuelva a colocar la perilla y permita que el freidor realice su ciclo de 4 a 6 veces. V erifique la temperatura

del termómetro contra la que muestra el dial del termostato. Si la diferencia entre ellas es de más de 5°F

(2°C), repita el proceso de calibración.

f. Una vez que el termostato está calibrado correctamente, saque el termómetro y vuelva a colocar la malla tubular .

Llenado del Freidor con Grasa Líquida

a . Asegúrese de que la válvula de drenaje está cerrada completamente.

b. Llene el freidor con aceite hasta el nivel indicado en la línea “Oil Level”, en el respaldo del tanque.

Llenado del Freidor con Grasa Sólida

a . Asegúrese de que la válvula de drenaje está completamente cerrada.

b. Remueva la malla que cubre los tubos.

c. Corte la grasa en cubos de dimensiones no mayores de una pulgada. Siempre empaque bien la grasa que queda

debajo, entre, y sobre los tubos del quemador. NO deje espacios abiertos grandes. Tenga cuidado al empacar

la grasa sólida en el tanque. NO tuerza o rompa las sondas de los sensores de temperatura. Si estas se dañan, el

freidor no podrá operar en forma adecuada.

d. Una vez que el freidor se ha empacado con grasa, la grasa debe licuarse.

e. Para licuar la grasa, manualmente, pulsando el termostato encienda y apague los quemadores, ON y OFF

(encendido y apagado), hasta que la grasa se haya licuado suficientemente para cubrir con líquido los tubos

del calor. Esto evitará causar daños al tanque y sus componentes, y prolongará la vida del aceite.

Apagado del Freidor

Hay dos formas de apagar la operación del freidor, STANDBY y COMPLETE. La modalidad de standby elimina la

capacidad de los quemadores principales del freidor para realizar sus ciclo. El apague completo cierra el suministro de

gas al freidor. Apague el freidor así:

STANDBY: Gire el termostato a la posición “OFF” (apagado). Gire la válvula de gas a la posición PILOT. El freidor está

ahora en Standby y puede mantenerse en estas condiciones por cortos períodos de tiempo. NUNCA deje el freidor en

Standby de un día para otro.

COMPLETE: Para apagar completamente el freidor, oprima y gire la válvula de gas en la dirección opuesta a las

manecillas del reloj para colocarla en la posición “OFF” (apagado). El freidor queda ahora apagado completamente y

puede dársele servicio al filtro o puede ser limpiado.

ESPANOL

L20-394 rev 0 (04/12)

25

Page 28

TEMA UNDERWRITERS’S LABORA TOR Y NACIONAL FUEL GAS

DOCUMENTO CODIGO DOCUMENTO

CAMP ANAS DE EXTRACCCION ANSI/UL 710 ANSI/NFP A 96

VENTILADORES DE POTENCIA ANSI/UL 705 ANSI/NFP A 96

UNIDAD DE FIL TRO ANSI/UL 586 ANSI/NFP A 96

ANSI/UL 900

TIPOS DE EXTINGUIDORES DE INCENDIO

Y EQUIPO DE DETECTCION DE INCENDIOS

2

CO

ANSI/UL 154 ANSI/NFP A 12

SUBST ANCIA QUIMICA ANSI/UL 299 ANSI/NFP A 17

AGUA ANSI/UL 626 ANSI/NFP A 13

ESPUMA ANSI/UL 8 ANSI/NFP A 11

ROCIADORES ANSI/UL 199 ANSI/NFP A 13

DETECTORES DE HUMO ANSI/UL 268 ANSI/NFP A 72

TERMOST A TOS DE DETECCION ANSI/UL 521 ANSI/NFPA 72

DE INCENDIOS

SI REQUIERE MANTENIMIENTO, PONGASE EN CONTACTO CON QUIEN DA SERVICIO A SU FABRICA, CON

NUESTRO REPRESENTANTE PARA SU FABRICA, O CON NUESTRA FABRICA PARA OBTENERLO.

L20-394 rev 0 (04/12)

26

Page 29

ESPANOL

L20-394 rev 0 (04/12)

27

Page 30

INSTALACIÓN Y OPERACIÓN FREIDORAS A GAS PARA

NINGUNA OPCIÓN / STAND ALONE Modelos que cubren

SB14,SB14R,SB18

Southbend A Middleby Corporation Company

1100 Old Honeycutt Road, Fuquay-Varina, NC 27526

(919) 762-1000 phone (919) 552-9798 fax

L20-394 rev 0 (04/12) 2 8

Loading...

Loading...